Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics

Abstract

:1. Introduction

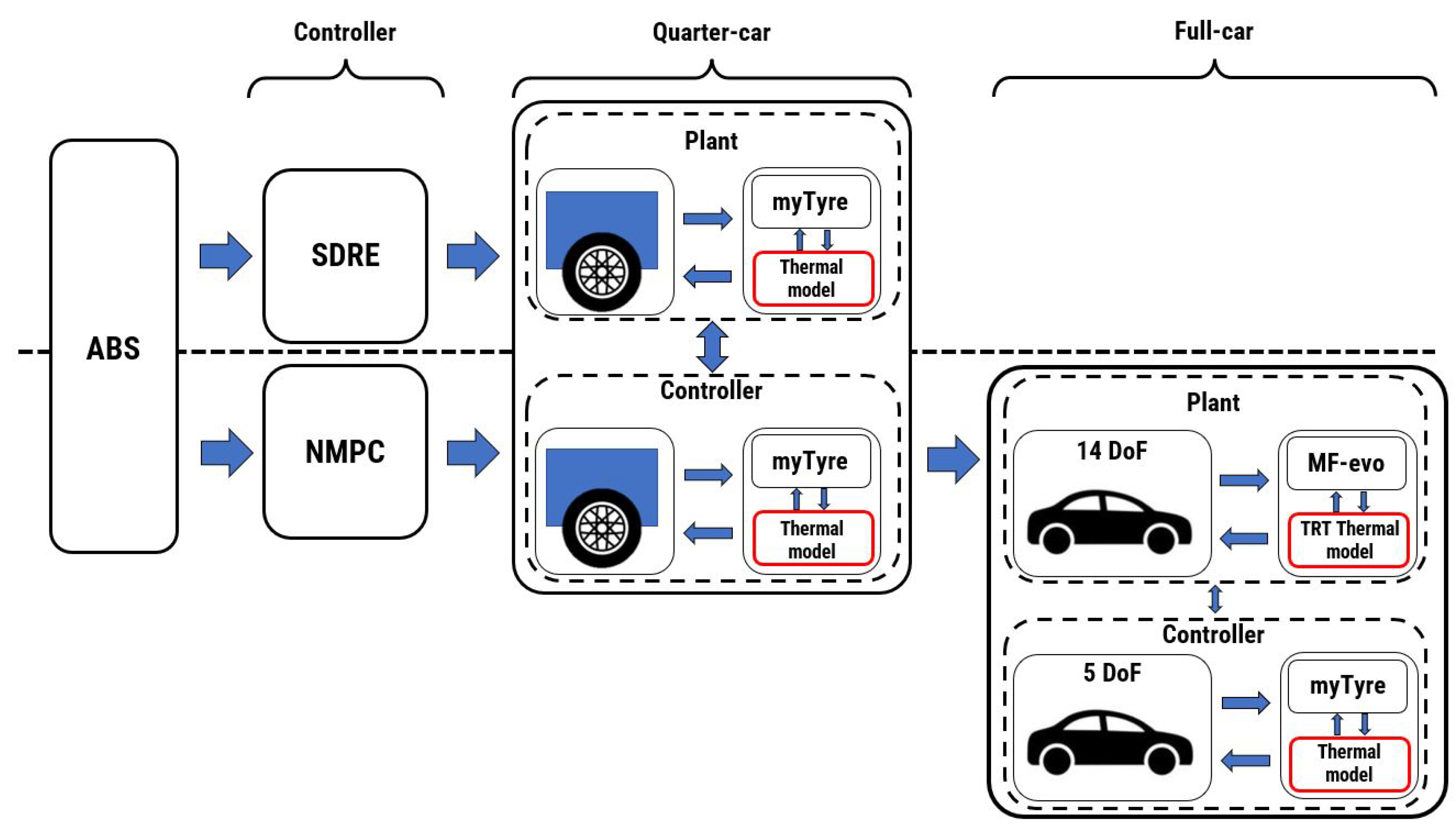

2. Methodology and Co-Simulation Platform

- Six DoF to reproduce longitudinal, lateral, vertical, pitch, roll, and yaw motion of the vehicle body;

- Four DoF concerning the wheel rotation and four DoF for the wheel normal displacement, with the hypothesis that the degrees of freedom relative to the motion between the wheel and the vehicle body can be neglected along the longitudinal and lateral directions, allowing only the independent rotational and vertical displacements.

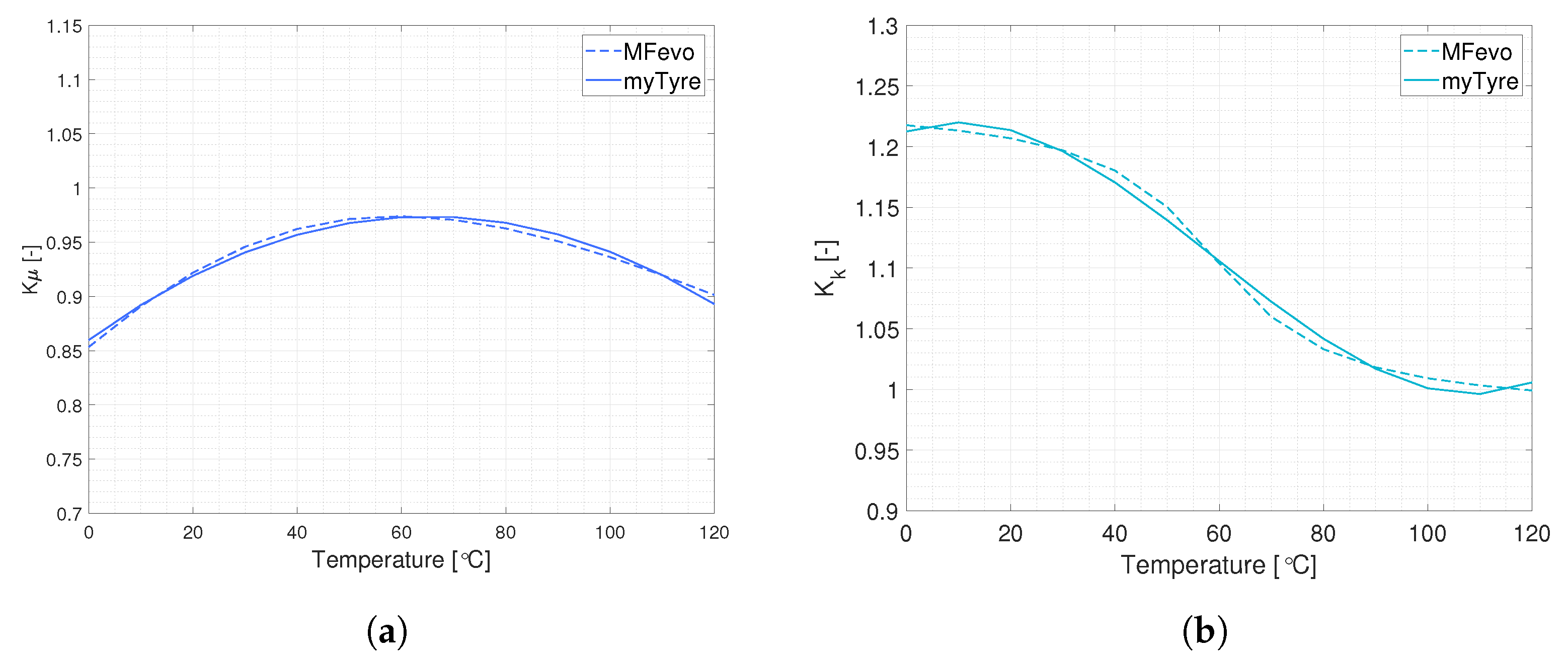

2.1. Tyre Model

Tyre Force Model—Pacejka Model Based

2.2. Tyre Thermal Modelling

2.2.1. Thermal Model

- : Heat generated due to the friction power in the sliding region of the contact patch;

- : Heat generated due to the strain energy within the mass;

- : Heat exchange due to the forced convection with ambient air;

- : Heat exchange due to the conductive cooling in the non-sliding region of the contact patch.

2.2.2. Connection and

2.3. Vehicle Model

2.3.1. Quarter-Car

- It moves in a straight line, and thus, longitudinal dynamics of tyre must suffice;

- No camber () effects;

- No suspension/load transfer effects considered;

- Purely rigid longitudinal connections;

- No coupling effects due to a chassis connecting the four wheels;

- No variations in wheel radius.

2.3.2. Full-Car

- Six DoF to reproduce longitudinal, lateral, vertical, pitch, roll, and yaw motion of the vehicle body;

- Four DoF concerning the wheel rotation and four DoF for the wheel normal displacement, with the hypothesis that the degrees of freedom relative to the motion between the wheel and the vehicle body can be neglected along the longitudinal and lateral directions, allowing only the independent rotational and vertical displacements.

2.3.3. 5-DOF Vehicle Prediction Model

3. Validation

3.1. myTyre Validation

3.2. myVeh Validation

3.3. Plant Validation

- S-Motion: for longitudinal and lateral velocity and sideslip angle measurement.

- IMU: provides measurement of pitch, roll, and yaw rate using three rate gyros, and x, y, z acceleration.

- encoders: to detect the four wheels’ angular speeds.

- An infrared sensor for measuring the tread surface temperature.

- Internal powered pressure and IR temperature array sensor with transmitter fitted to a wheel rim, sending pressure and temperature data samples.

4. Controller and Simulation

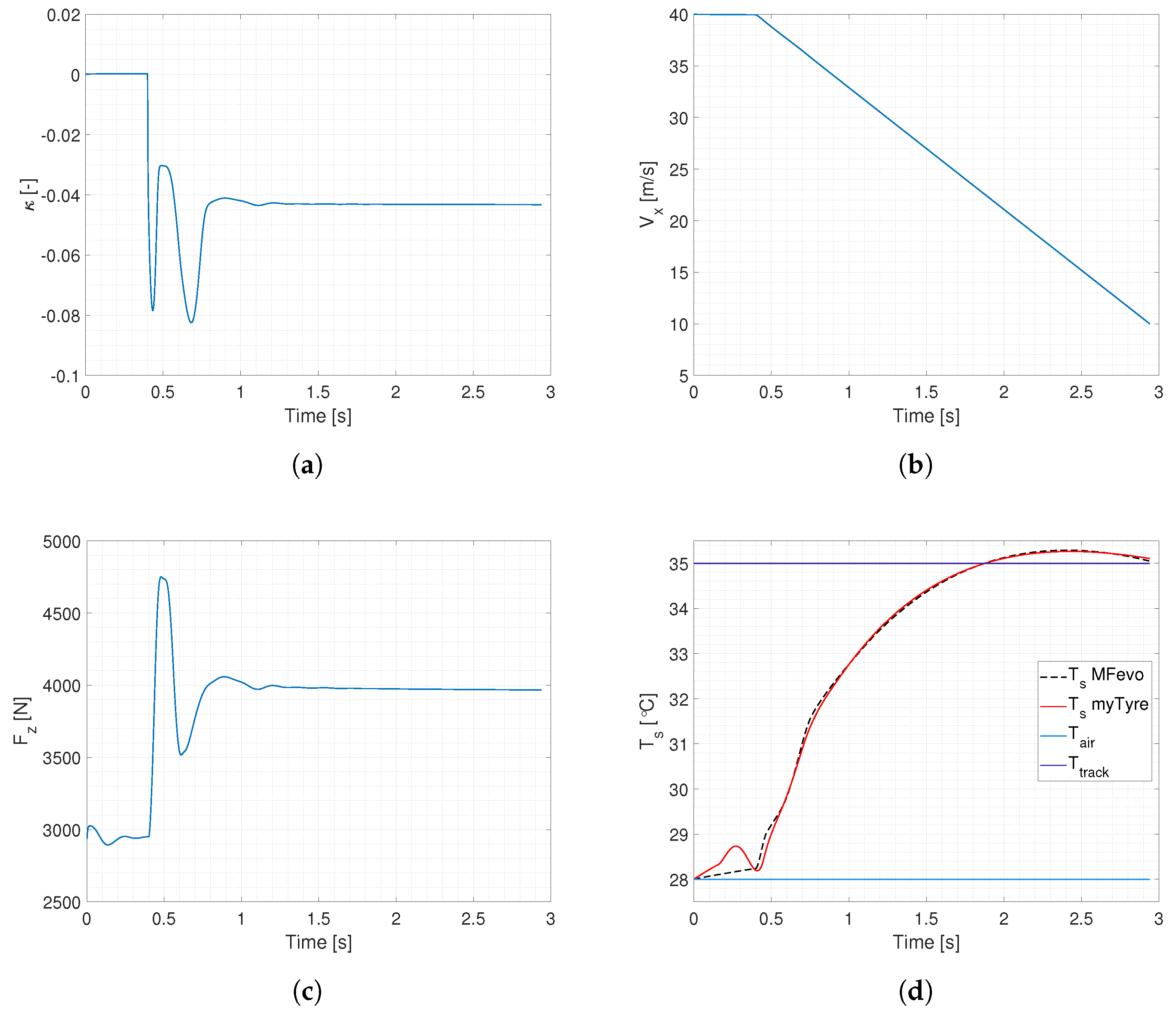

4.1. Quarter-Car Simulation

4.2. Quarter-Car SDRE Controller

4.2.1. Reference Generation

4.2.2. Tuning

4.3. Quarter-Car NMPC Controller

4.3.1. Reference Generation

4.3.2. Tuning

4.4. Full-Car Simulation and NMPC Controller

4.4.1. Reference Generation

4.4.2. Tuning

5. Tests and Metrics

5.1. Controller Setups

- Setup A [Pacejka:(-contr)]: This controller setup’s prediction model consists of an ’myVeh’ model with the reference Pacejka model (as used in ’myTyre’) without any tread surface temperature dynamics (so states are not available). Hence, the prediction model only consists of six states . The parameterisation of this tyre model is taken as that of the tyre operating at (40 °C). Such a setup, to a good extent, replicates the controller shown by Pretagostini et al. [5], which he showed performs much better than the state-of-the-art rule-based controllers. The only difference here is that the first-order torque rate dynamics are not considered inside the prediction model, and the tyre force equations are included inside the controller instead of feeding them as inputs from wheel load sensors. Hence, this setup can be considered a benchmark for this work and results of the proposed controller setups (Setup B and C) can be compared relative to this setup. As regards the selection of tyre force model’s parameterisation at 40 °C, it is like representing the tyre behaviour that acts like an average amongst the whole range of shown in Figure 20. Even when a parameterisation at some other temperature is selected, the controller’s performance is expected to degrade at temperatures far above or below that. The reference generation being another important factor, Pretagostini et al. [5] used the slip reference input as a function of tyre load for the the parameterisation used in their work. In this work, the reference was taken as the value that could perform well across the whole temperature range and maintain stable behaviour (not go beyond the peak of characteristic). Thus, here, the reference generation was only a function of the tyre normal load (). Such a setup of parameterisation and the reference slip values helps a controller with no knowledge of temperature to perform good enough across all the tests. The controller weights on the longitudinal slips () were set as shown in Section 4.4.2. For ease of readability, it is named ’Pacejka:(-contr)’, meaning that its tyre model is only based on the Pacejka tyre force equation and has no temperature effects, and only tries to control the longitudinal slips, i.e., .

- Setup B [TempKnwl:(-contr)]: This controller setup’s prediction model consists of the full ’myVeh’ (Section 2.3.3) model combined with the ’myTyre’, i.e., with the tread surface temperature dynamics. Hence, this controller is able to also predict the change in tyre grip and stiffness with the changing temperature conditions throughout and between each test. This helps it control the tyre slip more precisely as compared to Setup A Pacejka:(-contr). Here, the controller weights are non-zero only for the longitudinal slips () and equal to the values used for Setup A (as defined for the case of -control in Table 5). For convenience, it is named ’TempKnwl:(-contr)’, meaning that it has the temperature knowledge (TempKnwl) and just controls the .

- Setup C [TempKnwl:( & -contr)]: This controller setup is the same as that described in Setup B, with the slight difference being that, here the controller weights on tyre tread temperature states () are non-zero (as defined for the case of and -control in Table 5). Especially, the weighting on is kept non-zero to check how heating the tyre more towards the optimal temperature could help in terms of braking distance. For convenience, it is named ’TempKnwl:( & -contr)’, meaning that it has the same temperature knowledge as Setup B, and it tries to control the and the . Hence, Setup B and Setup C only differ in terms of the weights (Figure 21).

5.2. Tests

- Braking distance (): This is defined as the distance the vehicle covers from the time the brake input is given to the time it reaches the set cut-off velocity () of 10 m/s, as defined above. As the main objective of ABS is to ensure the tyre delivers the maximum possible force, braking distance is the perfect metric for that. To assess the performance of this high-level controller, this metric is sufficient.

- Maximum tread temperature (): This is the maximum value of the tread surface temperature reached in each test. The subscript i refers to the wheel identity on the car (1, 2, 3, 4)≡(, , , ). The higher its value, the more the carcass of the tyre heats up using the heat coming from the tread, of course depending on the initial temperature of the carcass. In such a short braking manoeuvre, an increase in the maximum temperature value can easily depict that there is faster and overall more heating of the tread.

6. Results

6.1. Full-Car Results

6.2. Braking Distance

6.3. Temperature Behaviour

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farroni, F.; Sakhnevych, A.; Timpone, F. An evolved version of thermo racing tyre for real time applications. Lect. Notes Eng. Comput. Sci. 2015, 2218, 1159–1164. [Google Scholar]

- Moore, D.F. Friction and wear in rubbers and tyres. Wear 1980, 61, 273–282. [Google Scholar] [CrossRef]

- Liefferink, R.W.; Hsia, F.C.; Weber, B.; Bonn, D. Friction on ice: How temperature, pressure, and speed control the slipperiness of ice. Phys. Rev. X 2021, 11, 011025. [Google Scholar] [CrossRef]

- Février, P.; Fandard, G. Thermal and mechanical tyre modelling for handling simulation. ATZ Worldw. 2008, 110, 26–31. [Google Scholar] [CrossRef]

- Pretagostini, F.; Ferranti, L.; Berardo, G.; Ivanov, V.; Shyrokau, B. Survey on Wheel Slip Control Design Strategies, Evaluation and Application to Antilock Braking Systems. IEEE Access 2020, 8, 10951–10970. [Google Scholar] [CrossRef]

- Kelly, D.P.; Sharp, R.S. Time-optimal control of the race car: Influence of a thermodynamic tyre model. Veh. Syst. Dyn. 2012, 50, 641–662. [Google Scholar] [CrossRef]

- Perantoni, G.; Limebeer, D.J. Optimal control for a formula one car with variable parameters. Veh. Syst. Dyn. 2014, 52, 653–678. [Google Scholar] [CrossRef] [Green Version]

- Berntorp, K.; Quirynen, R.; Di Cairano, S. Steering of autonomous vehicles based on friction-adaptive nonlinear model-predictive control. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; pp. 965–970. [Google Scholar]

- Romano, L.; Johannesson, P.; Bruzelius, F.; Jacobson, B. An enhanced stochastic operating cycle description including weather and traffic models. Transp. Res. Part D Transp. Environ. 2021, 97, 102878. [Google Scholar] [CrossRef]

- Xiong, L.; Yu, Z.; Wang, Y.; Yang, C.; Meng, Y. Vehicle dynamics control of four in-wheel motor drive electric vehicle using gain scheduling based on tyre cornering stiffness estimation. Veh. Syst. Dyn. 2012, 50, 831–846. [Google Scholar] [CrossRef]

- Guo, N.; Lenzo, B.; Zhang, X.; Zou, Y.; Zhai, R.; Zhang, T. A real-time nonlinear model predictive controller for yaw motion optimization of distributed drive electric vehicles. IEEE Trans. Veh. Technol. 2020, 69, 4935–4946. [Google Scholar] [CrossRef] [Green Version]

- Romano, L.; Bruzelius, F.; Hjort, M.; Jacobson, B. Development and analysis of the two-regime transient tyre model for combined slip. Veh. Syst. Dyn. 2022, 8, 1–35. [Google Scholar] [CrossRef]

- Sakhnevych, A. Multiphysical MF-based tyre modelling and parametrisation for vehicle setup and control strategies optimisation. Veh. Syst. Dyn. 2021, 1–22. [Google Scholar] [CrossRef]

- Shim, T.; Ghike, C. Understanding the limitations of different vehicle models for roll dynamics studies. Veh. Syst. Dyn. 2007, 45, 191–216. [Google Scholar] [CrossRef]

- Farroni, F.; Russo, M.; Sakhnevych, A.; Timpone, F. TRT EVO: Advances in real-time thermodynamic tire modeling for vehicle dynamics simulations. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 121–135. [Google Scholar] [CrossRef] [Green Version]

- Pacejka, H. Tire and Vehicle Dynamics; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar] [CrossRef]

- Harsh, D.; Shyrokau, B. Tire model with temperature effects for formula SAE vehicle. Appl. Sci. 2019, 9, 5328. [Google Scholar] [CrossRef] [Green Version]

- Février, P.; Blanco Hague, O.; Schick, B.; Miquet, C. Advantages of a thermomechanical tire model for vehicle dynamics. ATZ Worldw. 2010, 112, 33–37. [Google Scholar] [CrossRef]

- Hackl, A. Enhanced Tyre Modelling for Vehicle Dynamics Control Systems; Verlag der Technischen Universität Graz: Graz, Austria, 2020; Volume 4, p. 182. [Google Scholar]

- Maniowski, M. Optimisation of driver actions in RWD race car including tyre thermodynamics. Veh. Syst. Dyn. 2016, 54, 526–544. [Google Scholar] [CrossRef] [Green Version]

- Tremlett, A.J.; Limebeer, D.J. Optimal tyre usage for a Formula One car. Veh. Syst. Dyn. 2016, 54, 1448–1473. [Google Scholar] [CrossRef]

- West, W.; Limebeer, D. Optimal tyre management for a high-performance race car. Veh. Syst. Dyn. 2020, 60, 1–19. [Google Scholar] [CrossRef]

- Calabrese, F.; Baecker, M.; Galbally, C.; Gallrein, A. A Detailed Thermo-Mechanical Tire Model for Advanced Handling Applications. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 501–511. [Google Scholar] [CrossRef]

- De Rosa, R.; Di Stazio, F.; Giordano, D.; Russo, M.; Terzo, M. ThermoTyre: Tyre temperature distribution during handling manoeuvres. Veh. Syst. Dyn. 2008, 46, 831–844. [Google Scholar] [CrossRef]

- Farroni, F.; Giordano, D.; Russo, M.; Timpone, F. TRT: Thermo racing tyre a physical model to predict the tyre temperature distribution. Meccanica 2014, 49, 707–723. [Google Scholar] [CrossRef] [Green Version]

- Capra, D.; Farroni, F.; Sakhnevych, A.; Salvato, G.; Sorrentino, A.; Timpone, F. On the Implementation of an Innovative Temperature-Sensitive Version of Pacejka’s MF in Vehicle Dynamics Simulations. In Proceedings of the XXIV AIMETA Conference, Rome, Italy, 15–19 September 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1084–1092. [Google Scholar]

- Frasch, J.V.; Gray, A.; Zanon, M.; Ferreau, H.J.; Sager, S.; Borrelli, F.; Diehl, M. An auto-generated nonlinear MPC algorithm for real-time obstacle avoidance of ground vehicles. In Proceedings of the 2013 European Control Conference, ECC 2013, Zurich, Switzerland, 17–19 July 2013; pp. 4136–4141. [Google Scholar] [CrossRef]

- Ayub, A.; Wahab, H.A.; Balubaid, M.; Mahmoud, S.; Ali, M.R.; Sadat, R. Analysis of the nanoscale heat transport and Lorentz force based on the time-dependent Cross nanofluid. Eng. Comput. 2022, 1–20. [Google Scholar] [CrossRef]

- Farroni, F.; Sakhnevych, A. Tire multiphysical modeling for the analysis of thermal and wear sensitivity on vehicle objective dynamics and racing performances. Simul. Model. Pract. Theory 2022, 117, 102517. [Google Scholar] [CrossRef]

- Farroni, F. TRICK-Tire/Road Interaction Characterization & Knowledge-A tool for the evaluation of tire and vehicle performances in outdoor test sessions. Mech. Syst. Signal Process. 2016, 72, 808–831. [Google Scholar]

- Petersen, I.; Johansen, T.A.; Kalkkuhl, J.; Ludemann, J. Gain-scheduled wheel slip reset control in automotive brake systems. In Proceedings of the 2001 European Control Conference, ECC 2001, Porto, Portugal, 4–7 September 2001; pp. 606–611. [Google Scholar] [CrossRef]

- Alirezaei, M.; Kanarachos, S.; Scheepers, B.; Maurice, J.P. Experimental evaluation of optimal Vehicle Dynamic Control based on the State Dependent Riccati Equation technique. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 408–412. [Google Scholar] [CrossRef]

- Wachter, E.; Alirezaei, M.; Bruzelius, F.; Schmeitz, A. Path control in limit handling and drifting conditions using State Dependent Riccati Equation technique. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 783–791. [Google Scholar] [CrossRef]

- Menon, P.; Lam, T.; Crawford, L.; Cheng, V. Real-time computational methods for SDRE nonlinear control of missiles. In Proceedings of the 2002 American Control Conference (IEEE Cat. No. CH37301), Anchorage, AK, USA, 8–10 May 2002; Volume 1, pp. 232–237. [Google Scholar]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes with Source Code CD-ROM, 3rd Edition: The Art of Scientific Computing; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Kunnappillil Madhusudhanan, A.; Corno, M.; Bonsen, B.; Holweg, E. Solving algebraic riccati equation real time for integrated vehicle dynamics control. In Proceedings of the American Control Conference, Montreal, QC, Canada, 27–29 June 2012; pp. 3593–3598. [Google Scholar] [CrossRef]

- Bryson, A.; Ho, Y. Applied Optimal Control: Optimization, Estimation, and Control; Blaisdell Pub. Co.: Waltham, MA, USA, 1969. [Google Scholar]

- Itik, M.; Salamci, M.U.; Banks, S.P. SDRE optimal control of drug administration in cancer treatment. Turk. J. Electr. Eng. Comput. Sci. 2010, 18, 715–729. [Google Scholar] [CrossRef]

- Available online: https://www.vi-grade.com/en/products/vi-carrealtime (accessed on 5 May 2022).

- Available online: https://www.megaride.eu/ (accessed on 5 May 2022).

- Available online: https://www.mathworks.com/ (accessed on 5 May 2022).

- Available online: https://www.speedgoat.com/ (accessed on 5 May 2022).

| Coefficient Description | Symbol | Value | Unit |

|---|---|---|---|

| Tread mass | 2.54 | kg | |

| Tread specific heat capacity | 1.6 × 103 | ||

| Tread-road heat transfer coefficient | 4.5 × 102 | ||

| Contact patch width | 2.9 × 10−1 | m | |

| Contact patch length function coefficient | 2.9 × 10−3 | m | |

| Contact patch length function power | 4.9 × 10−1 | − | |

| Fraction of contact patch in sliding at zero slip | 3 × 10−1 | − | |

| Fraction of contact patch in sliding at slip | 8 × 10−1 | − | |

| slip value (assumed fixed) | 1 × 10−1 | − |

| Initial Conditions | Boundary Conditions |

|---|---|

| = 40 m/s | = 28 °C |

| = 28 °C | = 35 °C |

| QC-SDRE | QC-NMPC | ||||

|---|---|---|---|---|---|

| State | Weight Variable | Value: κ-Control | Value: κ and -Control | Value: κ-Control | Value: κ and -Control |

| κ | 1 × 1010 | 1 × 1010 | 1 × 104 | 1 × 104 | |

| 1 × 10−1 | 1 × 10−1 | 0 | 0 | ||

| 0 | 1 ×106 | 0 | 5 | ||

| Setting Parameter | Value |

|---|---|

| Hessian approximation | Gauss–Newton |

| Integrator-type | Implicit Runge–Kutta 3rd order |

| QP condensing | full |

| QP solver | qpOASES (full-condensed QP) |

| hotstart | no |

| RTI scheme | no |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arricale, V.M.; Genovese, A.; Tomar, A.S.; Kural, K.; Sakhnevych, A. Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics. Appl. Mech. 2022, 3, 855-888. https://doi.org/10.3390/applmech3030050

Arricale VM, Genovese A, Tomar AS, Kural K, Sakhnevych A. Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics. Applied Mechanics. 2022; 3(3):855-888. https://doi.org/10.3390/applmech3030050

Chicago/Turabian StyleArricale, Vincenzo Maria, Andrea Genovese, Abhishek Singh Tomar, Karel Kural, and Aleksandr Sakhnevych. 2022. "Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics" Applied Mechanics 3, no. 3: 855-888. https://doi.org/10.3390/applmech3030050

APA StyleArricale, V. M., Genovese, A., Tomar, A. S., Kural, K., & Sakhnevych, A. (2022). Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics. Applied Mechanics, 3(3), 855-888. https://doi.org/10.3390/applmech3030050