1. Introduction

High-performance Mo/Si multilayer mirrors for extreme ultraviolet (EUV) lithography with reflectivity (R) R ~ 70% @ 13.5 nm [

1] marked a significant milestone in modern optics and serve as a foundation for the development of high-performance multilayer optics for non-lithographic applications. Mo/Si mirrors can successfully operate in the spectral range of 12.4–35 nm, but their primary development has been driven by lithographic applications. For EUV multilayer mirrors designed at <12.4 nm, measured reflectivity of more than 60% @ 6.7 nm have also been reported [

2,

3], demonstrating the advancements in material engineering and coating precision required for shorter wavelengths.

For transmission microscopy of biological samples/objects, the spectral range between the absorption edges of oxygen (2.33 nm) and carbon (4.38 nm) is very important because a maximum contrast between organic materials and water can be achieved. Cr/Sc multilayer mirrors facilitate high-spatial-resolution imaging, widely applied in biomedical research [

4]. Recently, it was shown that R = 32% @ 3.15 nm is achievable by Cr/Sc multilayer mirrors with doping of Cr layers by nitrogen [

5]. There are also other multilayer systems available: Cr/V mirrors with R ~ 14.5% at a wavelength of ~2.4 nm [

6], and Cr/C with R ~ 15.6% mirrors at a wavelength of 4.42 nm [

7]. It is evident that optical performance strongly depends on the used wavelength, with efficiency significantly decreasing as the wavelength becomes shorter. This decline is primarily attributed to the interface imperfections of multilayer mirrors, which limit the broad application of multilayer optics for short wavelengths below 2.4 nm. The main challenge in the fabrication of highly reflective multilayer optics for <2.4 nm is the task of depositing a large number of bilayers (>300) with extremely small thickness and interface roughness [

8]. An efficient method to reduce the interface roughness in multilayer mirrors is the application of negative voltage (BIAS) on the samples during the thin film growth [

9]. The application of BIAS voltage results in increasing adatom energy by bombardment with ions that are accelerated by the potential difference between the plasma and the sample surface.

For wavelengths < 2.4 nm, the most promising material pairs are W/Si, W/B

4C, and W/C (for example, [

10,

11]). The aim of this study is to investigate the effect of BIAS voltage applied during Si-layer deposition on interface roughness and reflectivity of W/Si multilayers. Even though such W/Si mirrors have a wide range of potential applications, including X-ray microscopy, free electron lasers, plasma diagnostics, and X-ray instruments, only a few articles are currently available. For example, Zameshin et al. [

12] analyzed interface formation in W/Si multilayers but did not apply any ion assistance during growth. Similarly, IJpes et al. [

10] demonstrated the use of B

4C diffusion barriers to suppress interlayer mixing, while Pershyn et al. [

13] investigated the structure and phase composition of W/Si multilayers using GIXR and GIXRD. However, none of these studies addressed the direct influence of substrate biasing during the growth process.

In contrast, the present work systematically investigates the effect of BIAS voltage applied during the growth of Si layers, covering a range of values (0–200 V). To the best of our knowledge, this is the first report to demonstrate the direct effect of moderate BIAS voltage on interface roughness and optical performance in W/Si mirrors for the soft X-ray range.

2. Materials and Methods

2.1. Multilayer Deposition

The W/Si multilayers were deposited by DC magnetron sputtering using an industrial sputtering system Kenotec MRC 903 (Kenotec S.r.l., Binasco, Milan, Italy). This system is equipped with rectangular magnetrons with the size of 120 mm × 360 mm. The W and Si targets were operated at a power of 150 W. The system’s base pressure was 10-7 Torr, which is achieved by a cryopump, and the multilayer deposition was performed under Ar+ atmosphere of 2 × 10−3 Torr. During the deposition process, the samples are moved beyond the targets and the film thickness scales with the inverse velocity.

W/Si multilayers were deposited on super-polished silicon wafers with sizes of 25 mm × 25 mm (RMS roughness ~ 0.1 nm). All studied W/Si multilayers consisted of 100 bilayers (N) with a bilayer thickness (d) ~ 1.5 nm and thickness ratio (d(W)/d) of around 0.4. The deposition rate was approximately 0.35 nm/s for tungsten and 0.225 nm/s for silicon. W/Si mirrors were deposited with and without ion assistance, implemented by applying to the substrate holder (stage) BIAS voltages of 75 V, 100 V, and 200 V in continuous DC mode during the deposition of the Si layers. Special attention was given to investigating the effect of BIAS energy on the interface roughness (width) inside the studied W/Si multilayer structures.

2.2. Multilayer Characterization

The characterization of W/Si mirrors’ structure was performed using the θ–2θ grazing incidence X-ray reflectivity (GIXR) at the CuKα wavelength (λ = 0.154 nm) with a Bruker D8 diffractometer (Bruker AXS GmbH, Karlsruhe, Germany). [

14]. To study the surface morphology of W/Si mirrors, the atomic force microscope (AFM) Bruker Icon Pro (Bruker Nano Inc., Santa Barbara, CA, USA) was utilized [

15]. Surface roughness measurements were conducted over a 1 µm × 1 µm area with resolution of 512 × 512 pixels. Each mirror was measured at three different points to improve statistical accuracy.

Reflectivity measurements at a wavelength of about 1.5 nm and an incidence angle of approximately 60° were conducted at the BESSY II synchrotron at PTB in Berlin-Adlershof [

16]. The reflectivity of the samples was measured at the reflectometry beamline of the Physikalisch Technische Bundesanstalt (PTB) at the synchrotron storage ring BESSY II in Berlin. Technical details of this beamline can be found in [

17].

3. Results

3.1. Grazing Incidence X-Ray Reflectivity

Grazing incidence X-ray reflectivity at wavelength λ = 0.154 nm (CuKα) of W/Si multilayers without and with ion assistance is shown in

Figure 1.

For multilayer samples with the same d ~ 1.5 nm, the absolute value of the first Bragg peak intensity is a good measure for the interface quality of the W/Si multilayer structure. It is evident (

Figure 1) that ion assistance has a noticeable effect on the interface quality and the structure performance of W/Si multilayers. The application of BIAS ≤ 100 V significantly increased the height of the first Bragg peak, indicating an increase in the reflection coefficient at a wavelength of 0.154 nm. Specifically, the relative peak intensity (normalized to the total signal) increased by approximately 81% when applying 75 V compared to the unbiased sample, clearly demonstrating the beneficial effect of moderate ion assistance on interface quality. At the same time, the application of Ar⁺ ions with energy > 100 eV (BIAS = 200 V) resulted in a dramatic loss of reflectivity and a decrease in bilayer thickness from 1.5 nm to 1.29 nm. These structural changes suggest a degradation of the multilayer structure, most likely due to enhanced atomic intermixing at the W–Si interfaces. While no direct structural characterization such as TEM was performed in this study, similar effects have previously been attributed to the formation of amorphous silicide phases like WSi

2 at the interfaces [

13].

According to

Figure 1, a maximum reflectivity is reached close to BIAS = 75 V, and for higher BIAS voltage, a decrease is observed. This behavior may be explained by two different effects of ion assistance: In the initial stage of growth, the application of Ar

+ ions with energy < 100 eV has a positive impact on the nucleation of adatoms by providing them additional kinetic energy to move to energetic favorable nucleation sites. On the other hand, the application of high BIAS (>100 V) leads to a strong bombardment of the ultrathin W films with high-energy Ar

+ ions that may cause intensive diffusion intermixing between adjacent W and Si layers with possible incorporation of Ar

+ ions in the thin films.

An analysis of the GIXR results was performed to understand the overall pattern of changes. Simulations of GIXR curves were conducted by commercial software Leptos 7 using VerMetrix/ Simplex algorithm [

18]. The results of GIXR simulations are summarized in

Table 1.

For simplicity, the interface roughness (σ) of the studied W/Si mirrors was averaged as (σw + σSi)/2. In further discussions, the averaged interface roughness will be termed as the interface roughness.

According to GIXR simulations, the interface roughness are 0.45 nm, 0.42 nm, and 0.52 nm in W/Si multilayers coated without and with BIAS voltages of 75 V and 200 V, respectively.

It can be seen in

Table 1 that interface smoothing associated with reduced interface roughness is possible in W/Si mirrors. The starting interface roughness was 0.45 nm, but the application of Ar

+ ions with energies of 75 eV–100 eV reduced it to 0.42–0.43 nm. This change is likely what led to an overall improvement in the reflection coefficient in Cu Kα radiation (

Figure 1).

The crystalline structure of all W/Si multilayer mirrors was investigated using a Bruker D8 ADVANCE X-ray diffractometer (Bruker AXS GmbH, Karlsruhe, Germany) in θ–2θ geometry. The measurements were conducted at the Cu Kα wavelength (λ = 0.154 nm) with grazing incidence X-ray diffraction (GIXRD) mode to analyze the structural properties of the thin films. The results revealed that all layers in the W/Si multilayer mirror system are in an amorphous state, indicating no detectable crystalline phases within the investigated layers.

3.2. XUV-Reflectivity

For ideal W/Si mirrors (without any structural imperfections) with N = 100, the maximum calculated normal-incidence reflectivity at λ ~ 1.5 nm is 14.3%. Previously, it was reported that the W–Si material couple tend to form a silicide WSi

2 [

13], which leads to a reduction in bilayer thickness, causing certain changes in the period and thus in thickness ratio values during deposition.

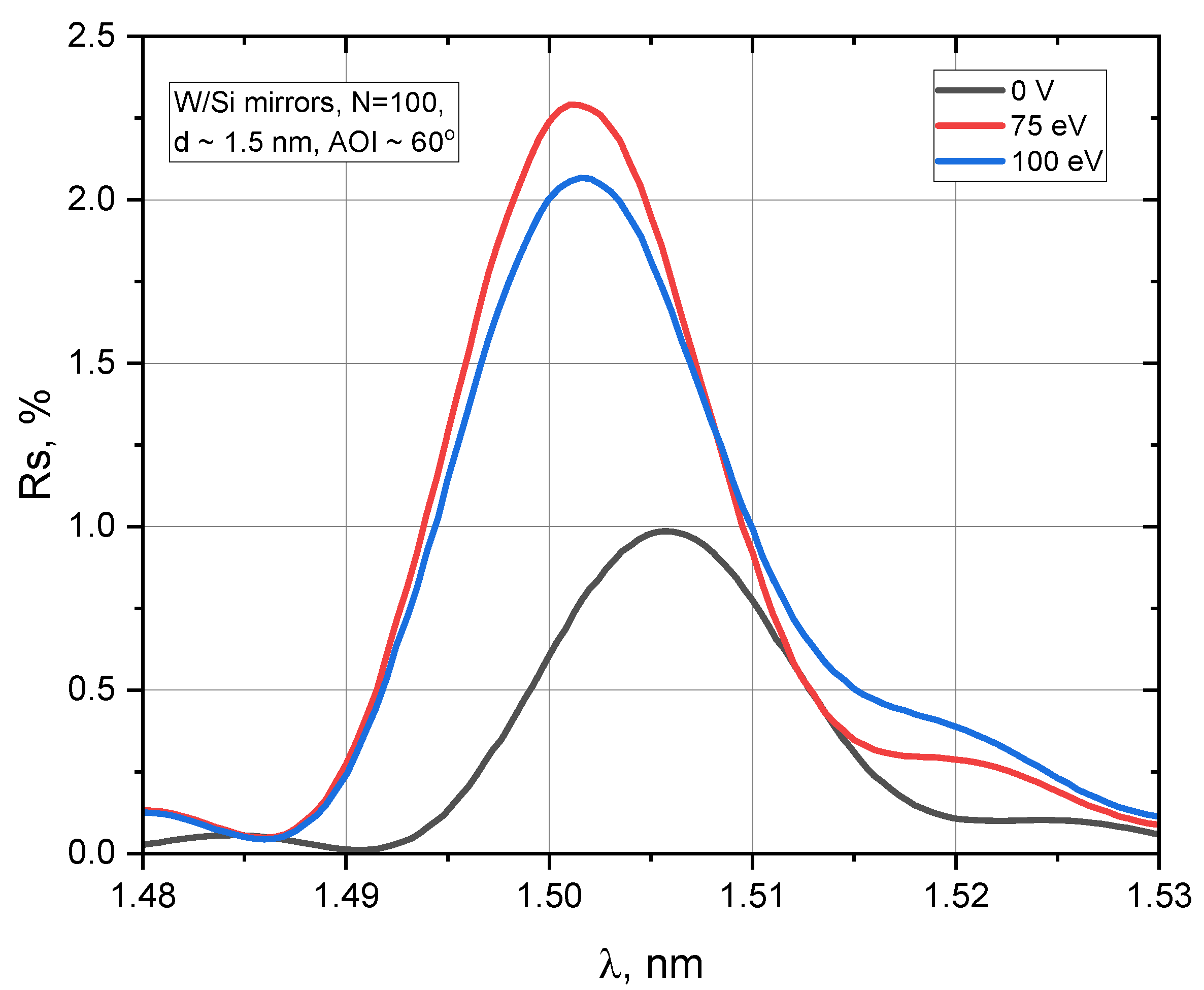

A series of three samples with d ~ 1.5 nm were prepared and measured with synchrotron radiation (

Figure 2). The period spacing (d) was optimized to achieve maximum peak reflectivity at a wavelength of 1.5 nm under/with AOI = 60°.

It is evident from

Figure 2 that the application of ion assistance significantly improved the optical properties of the W/Si mirrors. The mirror coated without BIAS showed a peak reflection coefficient of ~1%. At the same time, the application of BIAS on the silicon layers during the coating process doubled the reflection coefficient to ~2% for 100 V and 2.3% for 75 V.

The parameters of the W/Si multilayer mirror were determined through curve fitting simulations. Interface roughness data were extracted by IMD software, v. 5.0 [

19] using the Generic algorithm and are shown in

Table 2.

The presented data in

Table 2 show that the W/Si mirror sputtered without ion assistance on the silicon layer has an interface roughness of about 0.44 nm. At the same time, the application of BIAS = 75 V has reduced the interface roughness to 0.36 nm, resulting in an improvement of the internal structure of the multilayer mirror and a doubling of the reflectivity. The slight drop in the reflection coefficient of the W/Si mirror with BIAS 100 eV can be explained by enhanced intermixing of silicon and tungsten layers with possible formation of W

xSi

y at interfaces.

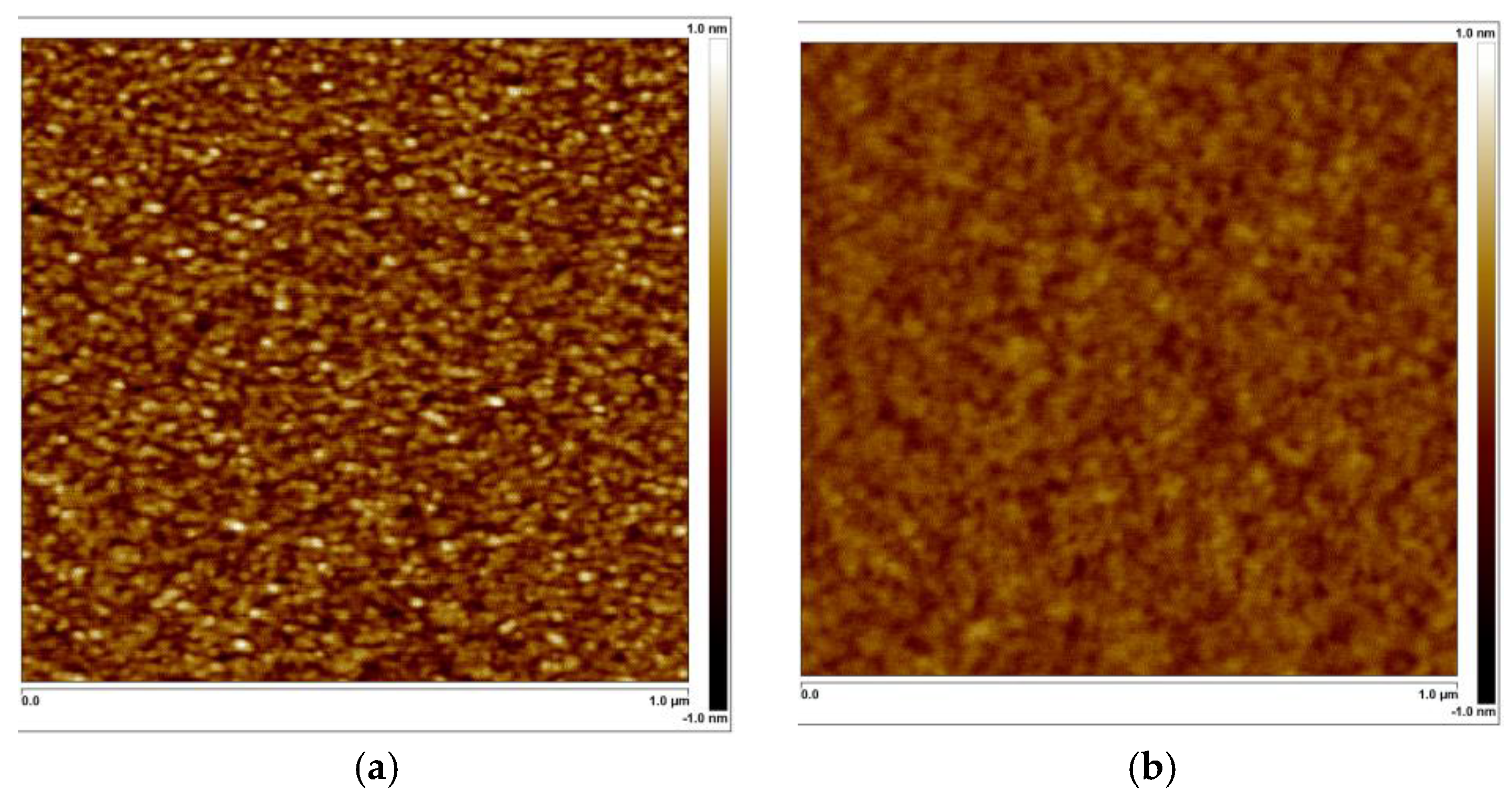

3.3. Atomic Force Microscopy

The quantitative analysis of the surface roughness in Si-capped W/Si mirrors was performed by AFM investigation over a scan area of 1 µm × 1 µm (

Figure 3) It has been found that the rms surface roughness are 0.22 nm and 0.11 nm for mirrors coated without and with BIAS = 100 V, respectively. It should be noted that the presented AFM results (

Figure 3) have a good agreement with GIXR and EUVR results (

Figure 1 and

Figure 2)

The results of the AFM study clearly confirm the surface smoothing effect in W/Si mirrors produced with additional ion assistance.

4. Discussion

Grazing incidence X-ray reflectivity (GIXR) measurements at Cu Kα (λ = 0.154 nm) showed that applying BIAS voltages of ≤100 V during silicon growth increased the first Bragg peak intensity, indicating improved interface quality and higher reflectivity. The highest reflectivity was observed for a BIAS = 75 V, while a BIAS = 200 V caused a drastic drop in reflectivity (~0.0003%) and a reduction in bilayer thickness from 1.5 nm to 1.29 nm, suggesting strong diffusion intermixing of W- and Si- layers with the accommodated formation of silicide.

Our GIXR simulation results (

Table 1) confirmed this trend by showing simulated interface roughness from 0.45 nm to 0.42 nm after BIAS application. The energy increase of Ar

+ ions up to 200 eV was accompanied by a noticeable development of interface roughness up to 0.52 nm due to intensive intermixing of W and Si layers with formation of amorphous silicide in the interface regions. XUV characterization at ~1.5 nm confirmed also that ion assistance improved optical performance of W/Si mirrors by increasing reflectivity from ~1% to ~2.3%. The 100 V W/Si sample coated under BIAS = 100 V showed slightly lower reflectivity (~2%), likely due to increased intermixing.

AFM analysis showed that surface roughness decreased from 0.22 nm (no BIAS) to 0.11 nm (75 V BIAS), correlating with the highest reflectivity. Excessive BIAS led to increased roughness and reduced reflectivity, confirming that high-energy ion bombardment disrupts layer integrity.

These results demonstrate that moderate ion assistance improves multilayer quality by reducing interface roughness, while excessive BIAS leads to intermixing and performance degradation. The optimal balance was achieved at 75 V, where the lowest roughness and highest reflectivity were observed.

This trend can be explained by the energy-dependent interaction of Ar⁺ ions with the growing film. At moderate BIAS voltages (75–100 V), the ions provide additional kinetic energy to surface adatoms, enhancing their mobility and promoting smoother interface formation. However, at higher BIAS voltages (200 V), ion penetration depth increases significantly, leading to atomic-scale intermixing at W–Si interfaces and the formation of amorphous silicide phases. These structural changes reduce the refractive index contrast and degrade the mirror reflectivity.

5. Conclusions

The study demonstrated that ion-assisted deposition significantly influences the structural and optical properties of W/Si multilayer mirrors. Applying a moderate BIAS voltage (75 V–100 V) during silicon layer deposition reduced interface roughness from 0.45 nm to 0.36 nm and improved reflectivity from 1.0% to 2.2% at the wavelength of 1.5 nm, with the highest optical performance observed at 75 V.

High-energy ion assistance (200 V) resulted in accelerated diffusion intermixing between W and Si layers in W/Si multilayers with d ~ 1.5 nm, leading to a reduction in bilayer thickness from 1.5 nm to 1.29 nm and a drastic decrease in reflectivity to ~0.0003% at Cu Kα-radiation. AFM analysis confirmed a significant reduction in surface roughness for samples deposited with moderate BIAS, while high-energy ion bombardment increased roughness and degraded multilayer structure. Although the absolute roughness values obtained from AFM and GIXR/EUVR differ due to the spatial frequency sensitivity of each method, all techniques showed a consistent trend in interface quality as a function of bias voltage.

To the best of our knowledge, this is the first study to investigate the effect of BIAS voltage during Si-layer deposition in ultrashort-period W/Si multilayers (d ~ 1.5 nm). These results indicate that optimizing ion assistance is crucial for achieving high reflectivity in short-period W/Si multilayer mirrors. A BIAS of 75 V provides the best balance between interface smoothness and minimal interlayer mixing, making it a promising technological approach for improving the optical performance of W/Si multilayer mirrors for soft X-ray applications.

Author Contributions

Conceptualization, D.S. and S.Y.; Methodology, D.S. and S.Y.; Software, D.S.; Investigation, D.S.; Data curation, D.S.; Writing–original draft, D.S.; Writing–review & editing, S.Y.; Supervision, S.Y., S.S. and A.T.; Project administration, S.Y., S.S. and A.T.; Funding acquisition, S.Y., S.S. and A.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chkhalo, N.I.; Gusev, S.A.; Nechay, A.N.; Pariev, D.E.; Polkovnikov, V.N.; Salashchenko, N.N.; Schäfers, F.; Sertsu, M.G.; Sokolov, A.; Svechnikov, M.V.; et al. High-reflection Mo/Be/Si multilayers for EUV lithography. Opt. Lett. 2017, 42, 5070–5073. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsov, D.S.; Yakshin, A.E.; Sturm, J.M.; van de Kruijs, R.W.; Louis, E.; Bijkerk, F. High-reflectance La/B-based multilayer mirror for 6.x nm wavelength. Opt. Lett. 2015, 40, 3778–3781. [Google Scholar] [CrossRef] [PubMed]

- Yulin, S.; Trost, M.; Schwinde, S.; Schröder, S. Coatings with barrier layers for extreme-short wavelengths: EUV lithography for the semiconductor industry and beyond. Vakuum Forsch. Prax. 2021, 33, 24–29. [Google Scholar] [CrossRef]

- Guggenmos, A.; Rothhardt, J.; Högner, M.; Venkatesan, S.; Wochnik, A.; Gullikson, E.M.; Fischer, S.; Nickel, B.; Scheu, C.; Kleineberg, U. Ion-polished Cr/Sc attosecond multilayer mirrors for high water window reflectivity. Opt. Express 2014, 22, 26526–26536. [Google Scholar] [CrossRef] [PubMed]

- Meltchakov, E.; Capitanio, B.; de Rossi, S.; Papagiannouli, I.; Mercère, P.; Delmotte, F. Optimization of Cr/Sc-based multilayer mirrors for water window soft x-rays. Opt. Lett. 2024, 49, 3420–3423. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Fei, J.; Liu, Y.; Li, P.; Wen, M.; Xie, C.; Jonnard, P.; Giglia, A.; Zhang, Z.; Wang, K.; et al. High reflectance Cr/V multilayer with B4C barrier layer for water window wavelength region. Opt. Lett. 2016, 41, 701–704. [Google Scholar] [CrossRef] [PubMed]

- Andreev, S.S.; Barysheva, M.M.; Vainer, Y.A.; Gaikovich, P.K.; Pariev, D.; Pestov, A.; Salashchenko, N.N.; Chkhalo, N. Multilayer X-ray mirrors for the (4.4–5)-nm carbon-window spectral region. Surf. Thin Film. 2013, 58, 505–508. [Google Scholar] [CrossRef]

- Windt, D.L.; Gullikson, E.M.; Walton, C.C. Normal-incidence reflectance of optimized W/B4C x-ray multilayers in the range 14 nm < λ < 24 nm. Opt. Lett. 2002, 27, 2212–2214. [Google Scholar] [CrossRef] [PubMed]

- Stollberg, H.; Yulin, S.; Takman, P.A.C.; Hertz, H.M. High-reflectivity Cr/Sc multilayer condenser for compact soft x-ray microscopy. Rev. Sci. Instrum. 2006, 77, 123101. [Google Scholar] [CrossRef]

- IJpes, D.; Yakshin, A.E.; Sturm, J.M.; Ackermann, M.D. Implementing 0.1 nm B4C barriers in ultrashort period 1.0 nm W/Si multilayers for increased soft x-ray reflectance. J. Appl. Phys. 2023, 133, 245301. [Google Scholar] [CrossRef]

- Medvedev, R.V.; Zameshin, A.A.; Sturm, J.M.; Yakshin, A.E.; Bijkerk, F. W/B short period multilayer structures for soft X-rays. AIP Adv. 2020, 10, 045305. [Google Scholar] [CrossRef]

- Zameshin, A.A.; Medvedev, R.V.; Sturm, J.M.; Yakshin, A.E.; Bijkerk, F. Interface formation in W/Si multilayers studied by Low Energy Ion Scattering. Thin Solid Film. 2021, 738, 138569. [Google Scholar] [CrossRef]

- Pershyn, Y.P.; Shipkova, I.G.; Devizenko, O.Y.; Mamon, V.V.; Chumak, V.S.; Kondratenko, V.V. Structure and phase composition of W-Si multilayer X-ray mirrors. East Eur. J. Phys. 2018, 5, 32–44. [Google Scholar]

- Bruker Corporation. D8 ADVANCE: X-Ray Diffraction Solutions. Available online: https://www.bruker.com/en/products-and-solutions/diffractometers-and-x-ray-microscopes/x-ray-diffractometers/d8-advance-family/d8-advance.html (accessed on 3 June 2025).

- Bruker Corporation. Dimension Icon AFM: World’s Highest Performance Large-Sample AFM. Available online: https://www.bruker.com/en/products-and-solutions/microscopes/materials-afm/dimension-icon-afm.html (accessed on 3 June 2025).

- Siewert, F.; Buchheim, J.; Eggenstein, F.; Gaupp, A.; Lammert, H.; Noll, T.; Schindler, A. The at-wavelength metrology facility for UV and XUV reflection and diffraction optics at BESSY-II. J. Synchrotron Radiat. 2016, 23, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Sokolov, A.; Bischoff, P.; Eggenstein, F.; Erko, A.; Gaupp, A.; Künstner, S.; Mast, M.; Schmidt, J.-S.; Senf, F.; Siewert, F.; et al. At-wavelength metrology facility for soft X-ray reflection optics. Rev. Sci. Instrum. 2016, 87, 052005. [Google Scholar] [CrossRef] [PubMed]

- Bruker Corporation. DIFFRAC.LEPTOS 7: X-Ray Reflectometry, HRXRD, GISAXS, and Residual Stress Analysis Software. Available online: https://www.bruker.com/en/products-and-solutions/diffractometers-and-x-ray-microscopes/x-ray-diffractometers/diffrac-suite-software/diffrac-leptos.html (accessed on 14 August 2025).

- Windt, D.L. IMD—Software for modeling the optical properties of multilayer films. Comput. Phys. 1998, 12, 360–370. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).