Wear and Abrasion Resistance of Nitride Coatings on Ceramic Substrates Processed with Fast Argon Atoms

Abstract

1. Introduction

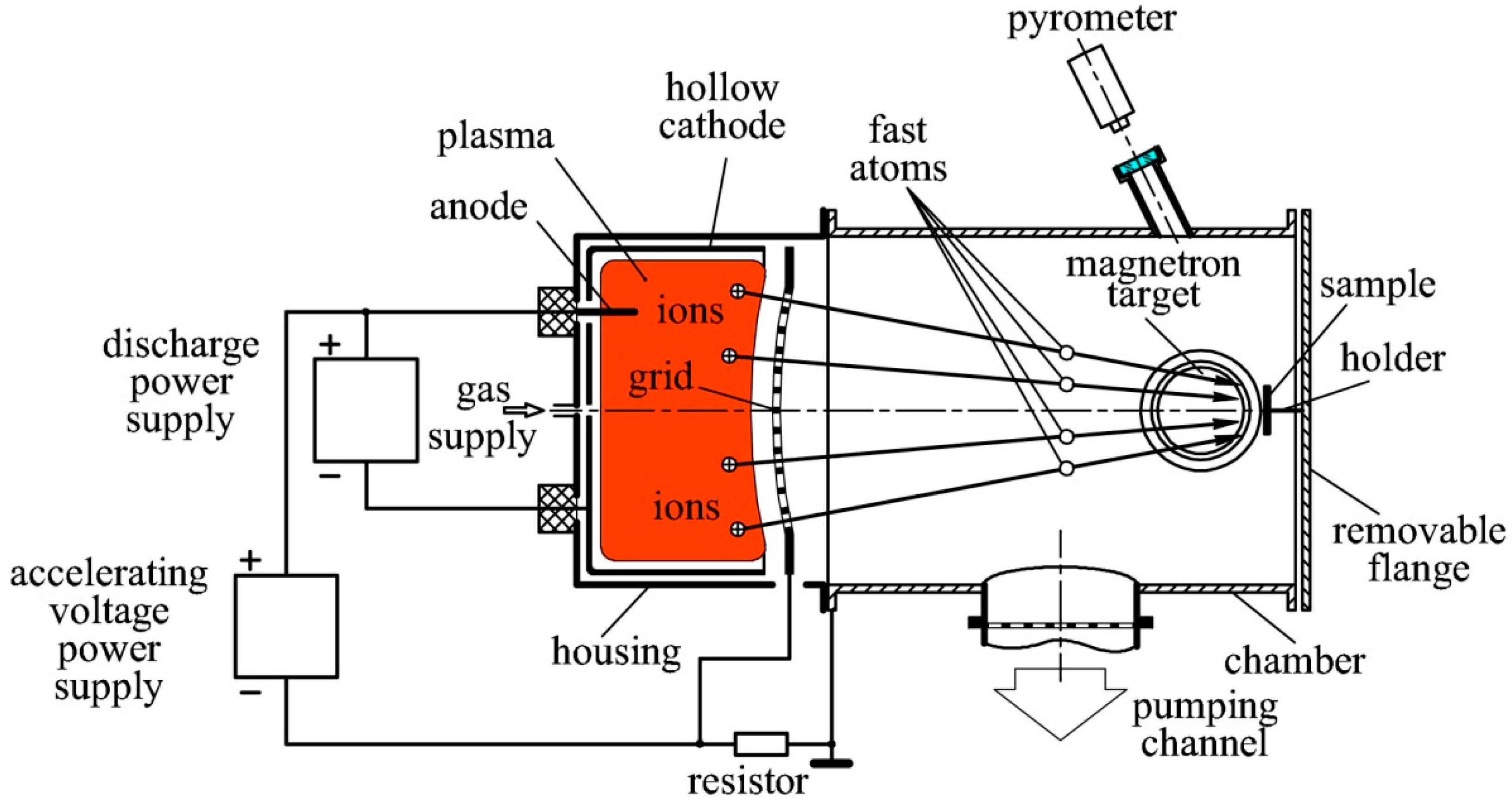

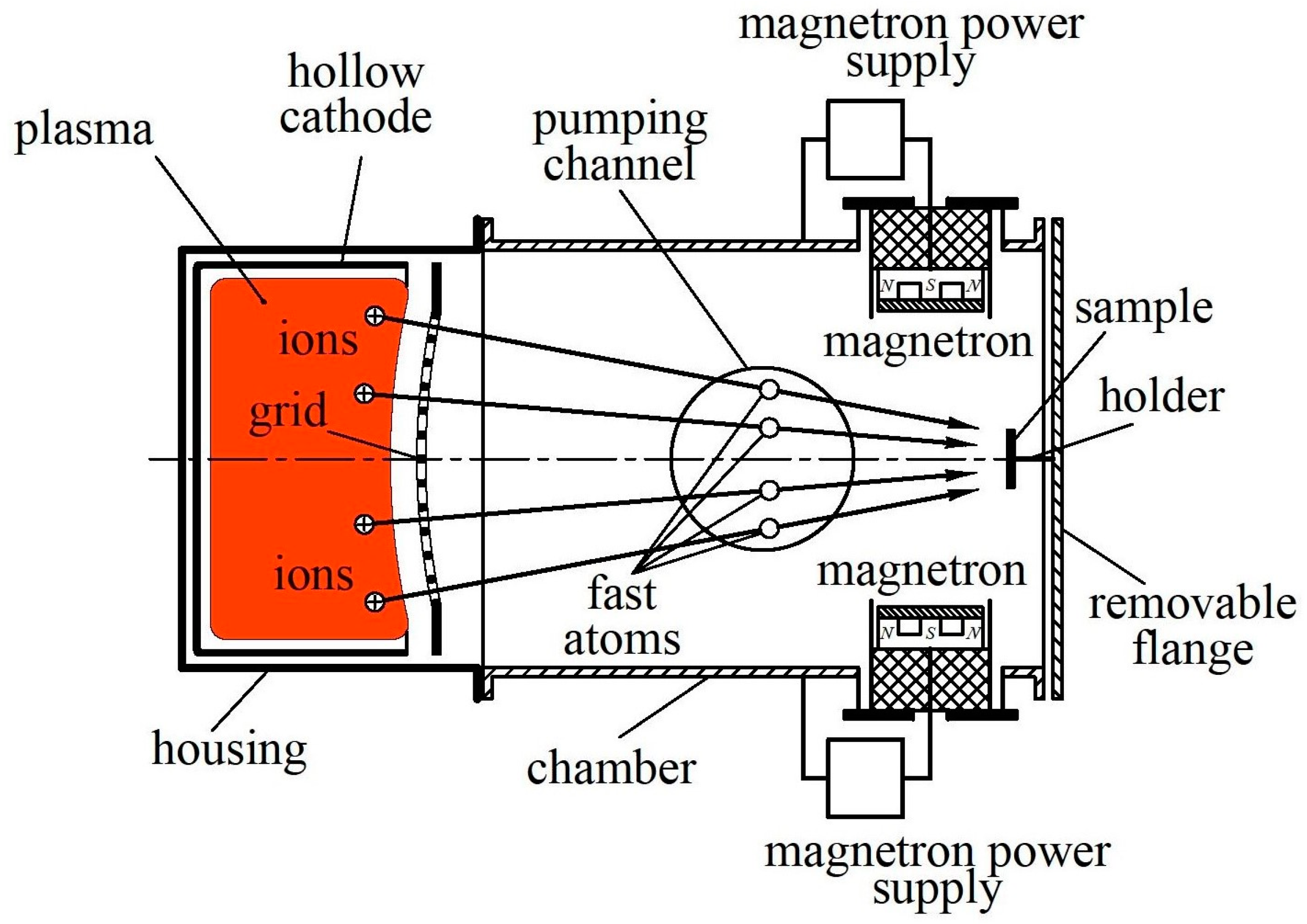

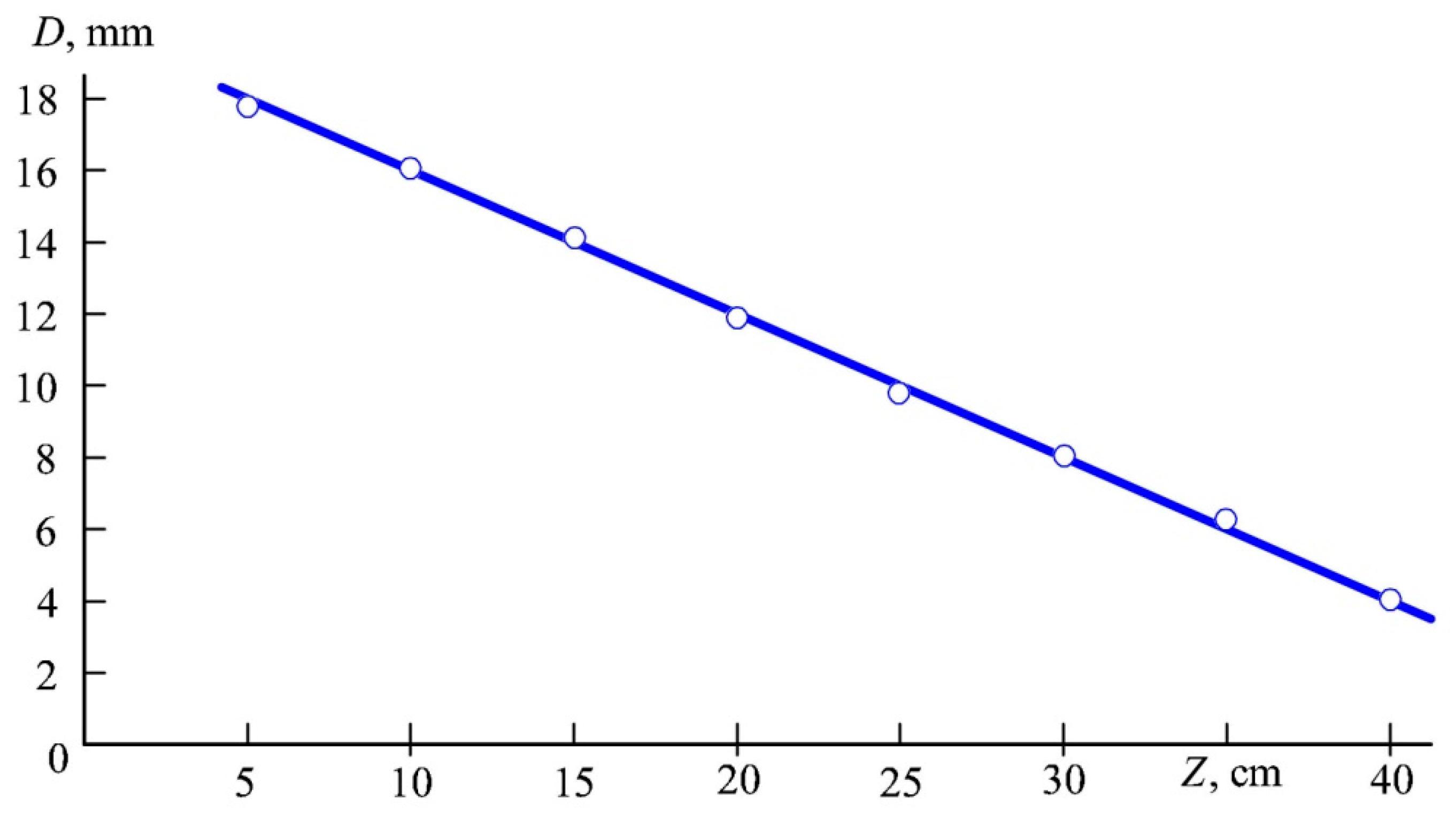

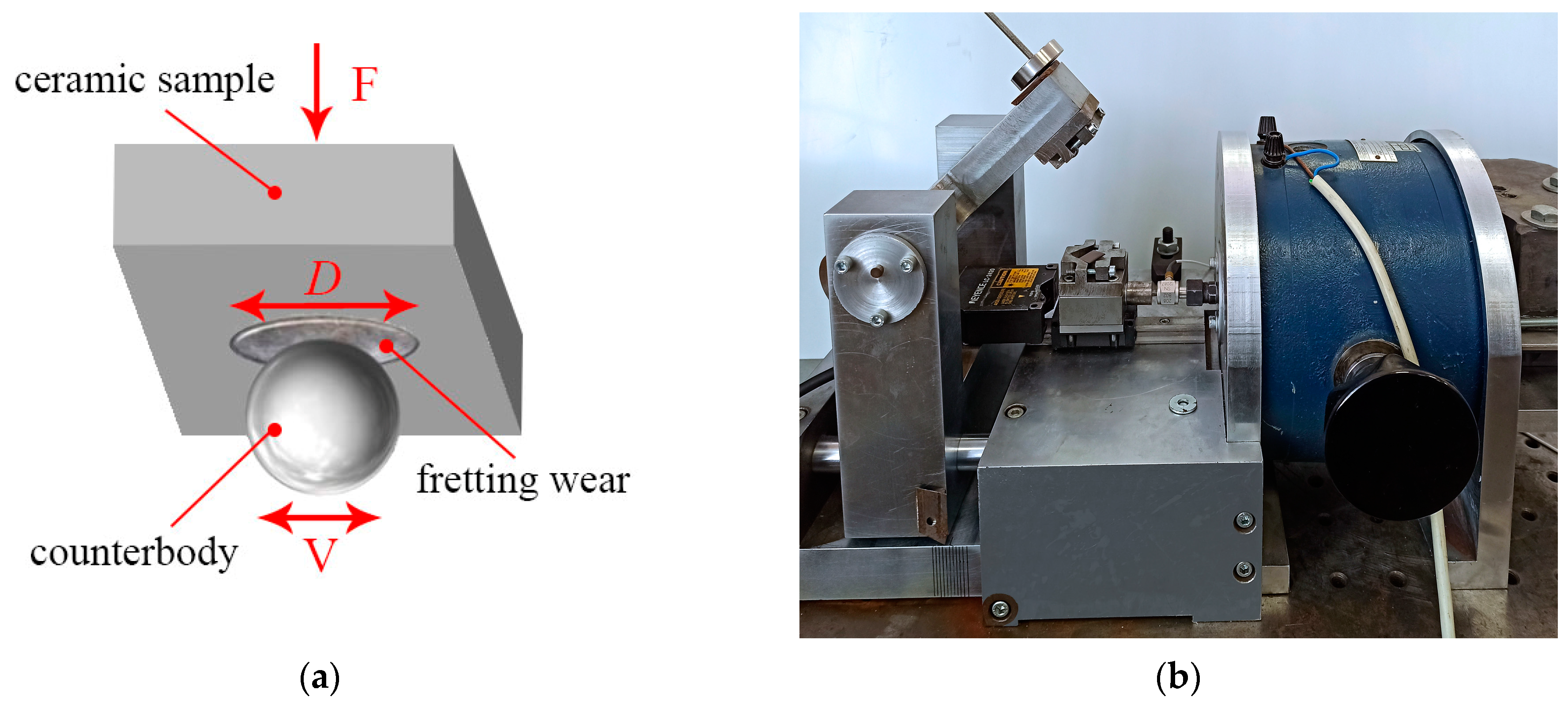

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zaki, E.G.; Selim, M.S.; Hao, Z.; ElSaeed, S.M.; EL-Saeed, A.M. Special Issue: Recent Trends in Wear and Erosion Resistance of Alloys. Coatings 2023, 13, 64. [Google Scholar] [CrossRef]

- Limpichaipanit, A.; Ngamjarurojana, A. Strain Characteristics of PLZT-Based Ceramics for Actuator Applications. Actuators 2023, 12, 74. [Google Scholar] [CrossRef]

- Wang, L.; Guo, X.; Zhang, H.; Liu, Y.; Wang, Y.; Liu, K.; Liang, H.; Ming, W. Recent Advances in Superhydrophobic and Antibacterial Coatings for Biomedical Materials. Coatings 2022, 12, 1469. [Google Scholar] [CrossRef]

- Xia, T.; Ma, Y.; Zhang, Y.; Li, J.; Xu, H. Effect of Mo and Cr on the Microstructure and Properties of Low-Alloy Wear-Resistant Steels. Materials 2024, 17, 2408. [Google Scholar] [CrossRef]

- Dang, M.N.; Singh, S.; Navarro-Devia, J.H.; King, H.J.; Hocking, R.K.; Wade, S.A.; Stephens, G.; Papageorgiou, A.; Wang, J. An Investigation into the Surface Integrity of Micro-Machined High-Speed Steel and Tungsten Carbide Cutting Tools. Micromachines 2023, 14, 1970. [Google Scholar] [CrossRef]

- Rizzo, A.; Goel, S.; Luisa Grilli, M.; Iglesias, R.; Jaworska, L.; Lapkovskis, V.; Novak, P.; Postolnyi, B.O.; Valerini, D. The Critical Raw Materials in Cutting Tools for Machining Applications: A Review. Materials 2020, 13, 1377. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Lyakhovetsky, M.A.; Mitrofanov, A.P.; Kolosova, N.V.; Okunkova, A.A. Technological Principles of Complex Plasma-Beam Surface Treatment of Al2O3/TiC and SiAlON Ceramics. J. Manuf. Mater. Process. 2023, 7, 205. [Google Scholar] [CrossRef]

- Li, L. Synergistic Effects of Stress-Rupture and Cyclic Loading on Strain Response of Fiber-Reinforced Ceramic-Matrix Composites at Elevated Temperature in Oxidizing Atmosphere. Materials 2017, 10, 182. [Google Scholar] [CrossRef]

- Li, L.; Reynaud, P.; Fantozzi, G. Cyclic-Dependent Damage Evolution in Self-Healing Woven SiC/[Si-B-C] Ceramic-Matrix Composites at Elevated Temperatures. Materials 2020, 13, 1478. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Okunkova, A.A.; Pivkin, P.M.; Peretyagin, P.Y.; Ershov, A. Development of DLC-Coated Solid SiAlON/TiN Ceramic End Mills for Nickel Alloy Machining: Problems and Prospects. Coatings 2021, 11, 532. [Google Scholar] [CrossRef]

- McDaniel, E.W. Collision Phenomena in Ionized Gases; John Willey: New York, NY, USA; London, UK, 1964; 775p, Available online: https://scholar.google.com/scholar_lookup?title=Collision+Phenomena+in+Ionized+Gases&author=McDaniel,+E.W.&publication_year=1964 (accessed on 1 September 2024).

- Phelps, A.V. Cross sections and swarm coefficients for nitrogen ions and neutrals in N2 and argon ions and neutrals in Ar for energies from 0.1 eV to 10 keV. J. Phys. Chem. Ref. 1991, 20, 557–573. [Google Scholar] [CrossRef]

- Phelps, A.V.; Greene, C.H.; Burke, J.P. Collision cross sections for argon atoms with argon atoms for energies from 0.01 eV to 10 keV. J. Phys. B At. Mol. Opt. Phys. 2000, 33, 2965–2981. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Prudnikov, V.V. Glow discharge with electrostatic confinement of electrons in a chamber bombarded by fast electrons. Plasma Phys. Rep. 2011, 37, 628–637. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Lu, P. Coatings and Surface Modification of Alloys for Tribo-Corrosion Applications. Coatings 2024, 14, 99. [Google Scholar] [CrossRef]

- Volosova, M.A.; Lyakhovetsky, M.A.; Mitrofanov, A.P.; Melnik, Y.A.; Okunkova, A.A.; Fedorov, S.V. Influence of Cr-Al-Si-N and DLC-Si Thin Coatings on Wear Resistance of Titanium Alloy Samples with Different Surface Conditions. Coatings 2023, 13, 1581. [Google Scholar] [CrossRef]

- Gazia, R.; Chiodoni, A.; Celasco, E.; Bianco, S.; Mandracci, P. X-ray Analysis on Ceramic Materials Deposited by Sputtering and Reactive Sputtering for Sensing Applications. In X-ray Spectroscopy; Sharma, S., Ed.; InTech: London, UK, 2012; pp. 219–241, ISBN 978-953-307-967-7; Available online: https://www.intechopen.com/chapters/27345 (accessed on 1 September 2024).

- Seah, M.; Spencer, S.; Shard, A. Depth Resolution, Angle Dependence, and the Sputtering Yield of Irganox 1010 by Coronene Primary Ions. J. Phys. Chem. B 2013, 117, 11885–11892. [Google Scholar] [CrossRef]

- Seah, M. Universal Equation for Argon Gas Cluster Sputtering Yields. J. Phys. Chem. C 2013, 117, 12622–12632. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V. Influence of Defects in Surface Layer of Al2O3/TiC and SiAlON Ceramics on Physical and Mechanical Characteristics. Ceramics 2023, 6, 818–836. [Google Scholar] [CrossRef]

- Seah, M.P.; Spencer, S.J.; Shard, A.G. Angle Dependence of Argon Gas Cluster Sputtering Yields for Organic Materials. J. Phys. Chem. B 2015, 119, 3297–3303. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Nikolaev, I.V.; Roenko, M.A.; Atuchin, V.V. Precise sputtering of silicon dioxide by argon cluster ion beams. Appl. Phys. A 2018, 124, 833. [Google Scholar] [CrossRef]

- Behrisch, R.; Wittmaack, K.; Hauffe, W.; Hofer, W.O.; Laegreid, N.; McClanahan, E.D.; Sundqvist, B.U.R.; Wittmaack, K.; Yu, M.L. Sputtering by Particle Bombardment III: Characteristics of Sputtered Particles, Technical Applications; Springer: Berlin/Heidelberg, Germany, 1991; Available online: https://scholar.google.com/scholar_lookup?title=Sputtering+by+Particle+Bombardment+III:+Characteristics+of+Sputtered+Particles,+Technical+Applications&author=Behrisch,+R.&author=Behrisch,+R.&author=Wittmaack,+K.&author=Hauffe,+W.&author=Hofer,+W.O.&author=Laegreid,+N.&author=McClanahan,+E.D.&author=Sundqvist,+B.U.R.&author=Wittmaack,+K.&author=Yu,+M.L.&publication_year=1991 (accessed on 1 September 2024).

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Mahne, N.; Čekada, M.; Panjan, M. Total and Differential Sputtering Yields Explored by SRIM Simulations. Coatings 2022, 12, 1541. [Google Scholar] [CrossRef]

- Cupak, C.; Szabo, P.S.; Biber, H.; Stadlmayr, R.; Grave, C.; Fellinger, M.; Brötzner, J.; Wilhelm, R.A.; Möller, W.; Mutzke, A.; et al. Sputter yields of rough surfaces: Importance of the mean surface inclination angle from nano- to microscopic rough regimes. Appl. Surf. Sci. 2021, 570, 151204. [Google Scholar] [CrossRef]

- Lindsey, S.J.; Hobler, G.; Maciążek, D.; Postawa, Z. Simple model of surface roughness for binary collision sputtering simulations. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 393, 17–21. [Google Scholar] [CrossRef]

- Kelemen, M.; Schwarz-Selinger, T.; Mutzke, A.; Balden, M.; Vassallo, E.; Pedroni, M.; Dellasega, D.; Passoni, M.; Romeo, F.; Hakola, A.; et al. Influence of surface roughness on the sputter yield of Mo under keV D ion irradiation. J. Nucl. Mater. 2021, 555, 153135. [Google Scholar] [CrossRef]

- Behrisch, R.; Eckstein, W. Sputtering by Particle Bombardment: Experiments and Computer Calculations from Threshold to MeV Energies; Springer: Berlin/Heidelberg, Germany, 2007; Available online: https://scholar.google.com/scholar_lookup?title=Sputtering+by+Particle+Bombardment:+Experiments+and+Computer+Calculations+from+Threshold+to+MeV+Energies&author=Behrisch,+R.&author=Eckstein,+W.&publication_year=2007 (accessed on 1 September 2024).

- Sigmund, P. Six decades of atomic collisions in solids. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 406, 391–412. [Google Scholar] [CrossRef]

- Wei, Q.; Li, K.-D.; Lian, J.; Wang, L. Angular dependence of sputtering yield of amorphous and polycrystalline materials. J. Phys. D Appl. Phys. 2008, 41, 172002. [Google Scholar] [CrossRef]

- Zheng, K.; Li, L.; Dong, Y.; Gao, J.; Hei, H.; Ma, Y.; Zhou, B.; He, Z.; Wang, Y.; Yu, S.; et al. Preparation, Microstructure, Mechanical Properties and Biocompatibility of Ta-Coated 3Y-TZP Ceramic Deposited by a Plasma Surface Alloying Technique. Materials 2020, 13, 1265. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Gselman, P.; Čekada, M.; Panjan, M.; Bončina, T.; Kek Merl, D. Influence of Growth Defects on the Corrosion Resistance of Sputter-Deposited TiAlN Hard Coatings. Coatings 2019, 9, 511. [Google Scholar] [CrossRef]

- Lewis, D.B.; Creasey, S.J.; Wüstefeld, C.; Ehiasarian, A.P.; Hovsepian, P.E. The role of the growth defects on the corrosion resistance of CrN/NbN superlattice coatings deposited at low temperatures. Thin Solid Films 2006, 503, 143–148. [Google Scholar] [CrossRef]

- Tan, H.; Sun, Q.; Chen, W.; Zhu, S.; Cheng, J.; Yang, J. Tribological performance and wear mechanisms of a high-temperature wear-resistant Al-Si/SiAlON composite. Tribol. Int. 2021, 164, 107227. [Google Scholar] [CrossRef]

- Sun, Q.; Yang, J.; Yin, B.; Tan, H.; Liu, Y.; Liu, J.; Cheng, J.; Qiao, Z.; Liu, W. Dry sliding wear behavior of β-Sialon ceramics at wide range temperature from 25 to 800 °C. J. Eur. Ceram. Soc. 2017, 37, 4505–4513. [Google Scholar] [CrossRef]

- Acikbas, N.C.; Kara, F. The effect of z value on intergranular phase crystallization of α1/β1-SiAlON-TiN composites. J. Eur. Ceram. Soc. 2017, 37, 923–930. [Google Scholar] [CrossRef]

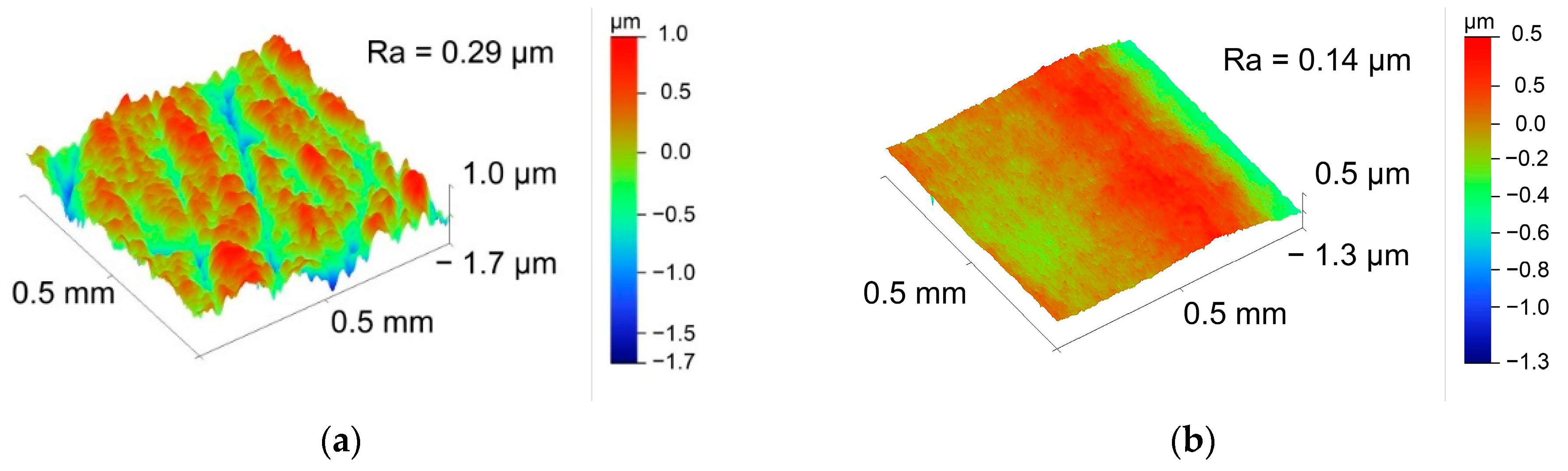

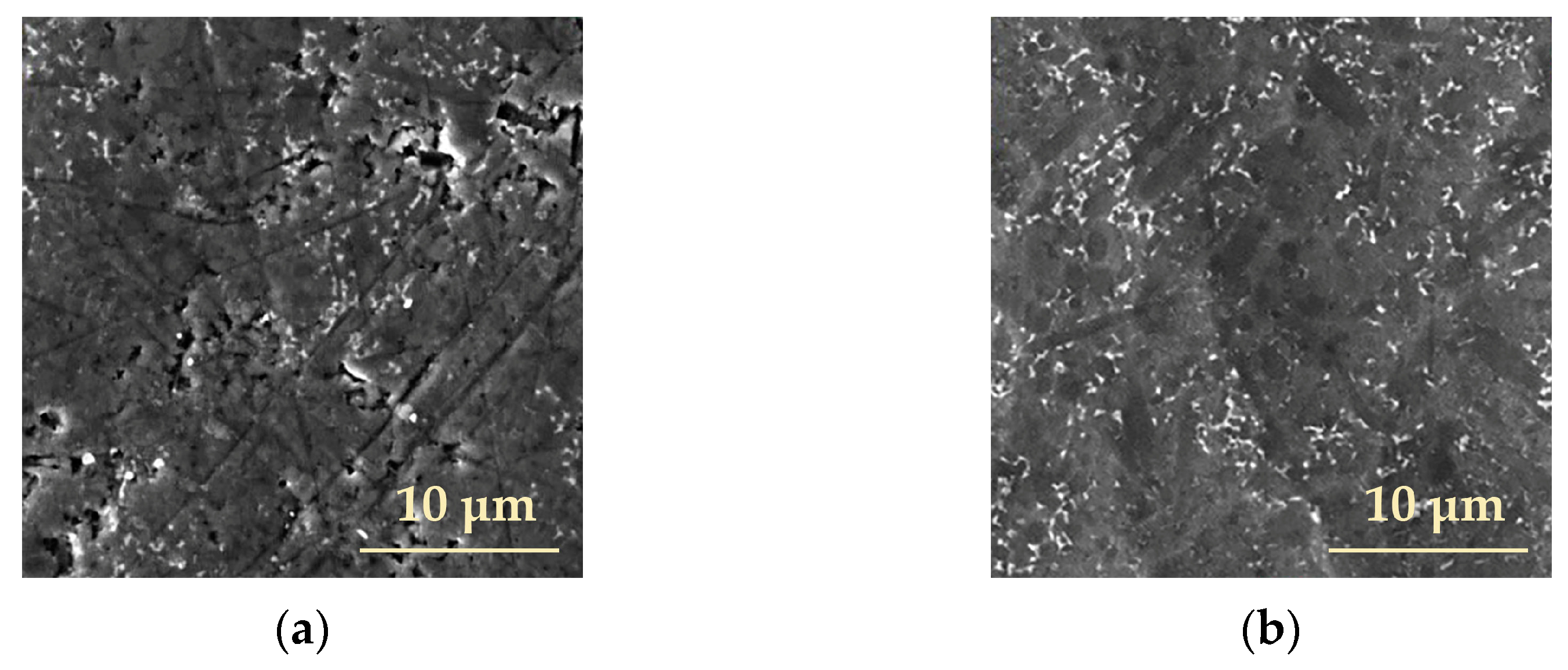

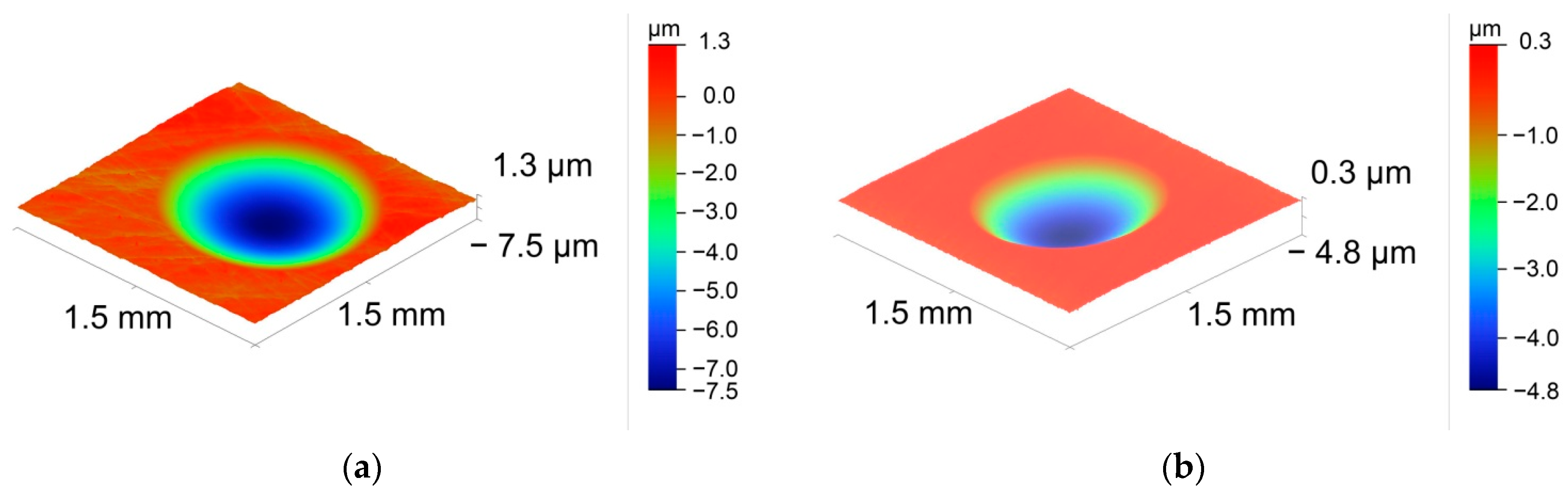

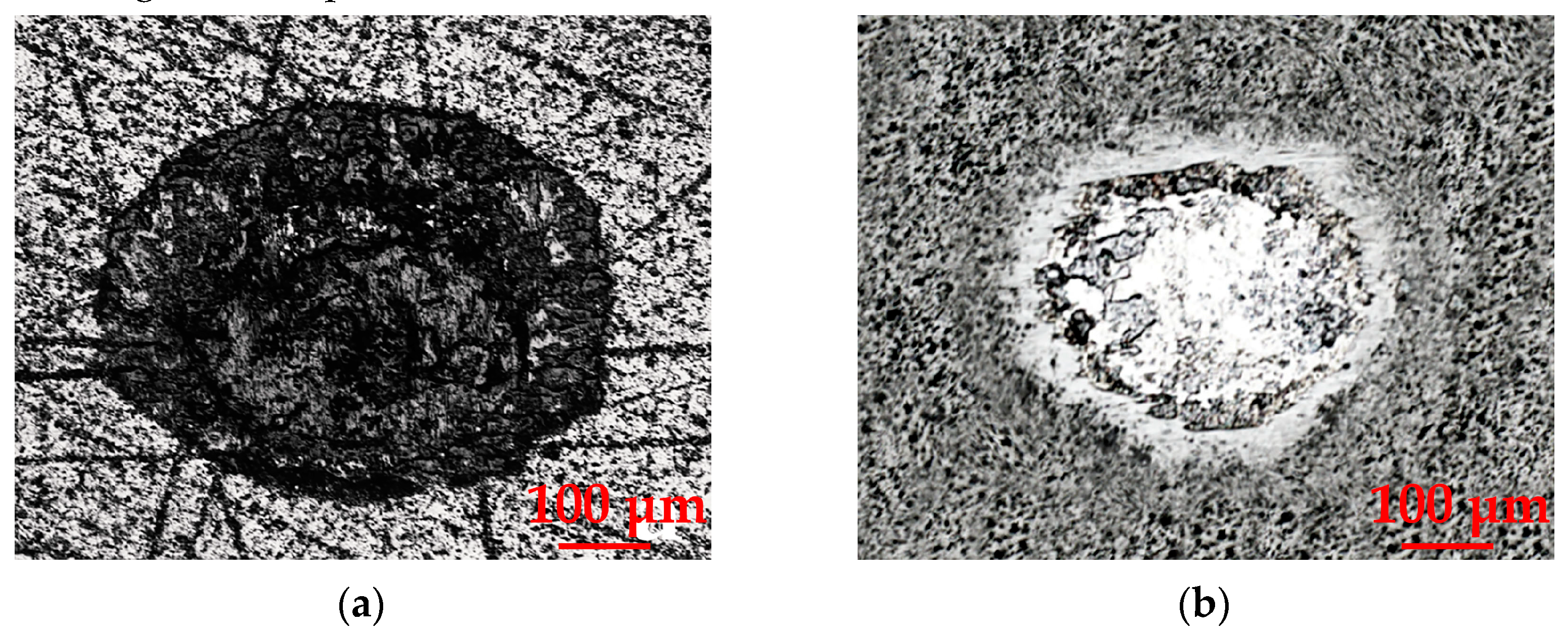

| Type of Processing | Parameter of the Surface | |||

|---|---|---|---|---|

| Density of Defects ρ | Maximum Depth of Defective Layer Rt, µm | Index of Defectiveness ρ∙Rt, µm | Roughness Parameter Ra, µm | |

| Diamond grinding | 0.33 | 3.27 | 1.08 | 0.29 |

| Treatment with 5 keV argon atoms for 1 h | 0.01 | 0.46 | 0.0046 | 0.14 |

| Diamond grinding, finishing and polishing | 0.004 | 0.38 | 0.0015 | 0.014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.N.; Metel, A.S.; Volosova, M.A.; Mustafaev, E.S.; Melnik, Y.A. Wear and Abrasion Resistance of Nitride Coatings on Ceramic Substrates Processed with Fast Argon Atoms. Surfaces 2024, 7, 714-724. https://doi.org/10.3390/surfaces7030046

Grigoriev SN, Metel AS, Volosova MA, Mustafaev ES, Melnik YA. Wear and Abrasion Resistance of Nitride Coatings on Ceramic Substrates Processed with Fast Argon Atoms. Surfaces. 2024; 7(3):714-724. https://doi.org/10.3390/surfaces7030046

Chicago/Turabian StyleGrigoriev, Sergey N., Alexander S. Metel, Marina A. Volosova, Enver S. Mustafaev, and Yury A. Melnik. 2024. "Wear and Abrasion Resistance of Nitride Coatings on Ceramic Substrates Processed with Fast Argon Atoms" Surfaces 7, no. 3: 714-724. https://doi.org/10.3390/surfaces7030046

APA StyleGrigoriev, S. N., Metel, A. S., Volosova, M. A., Mustafaev, E. S., & Melnik, Y. A. (2024). Wear and Abrasion Resistance of Nitride Coatings on Ceramic Substrates Processed with Fast Argon Atoms. Surfaces, 7(3), 714-724. https://doi.org/10.3390/surfaces7030046