Effect of the Heating Rate on the Spark-Plasma-Sintering (SPS) of Transparent Y2O3 Ceramics: Microstructural Evolution, Mechanical and Optical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation and Processing of Y2O3 Powders

2.2. Characterization Techniques

3. Results and Discussion

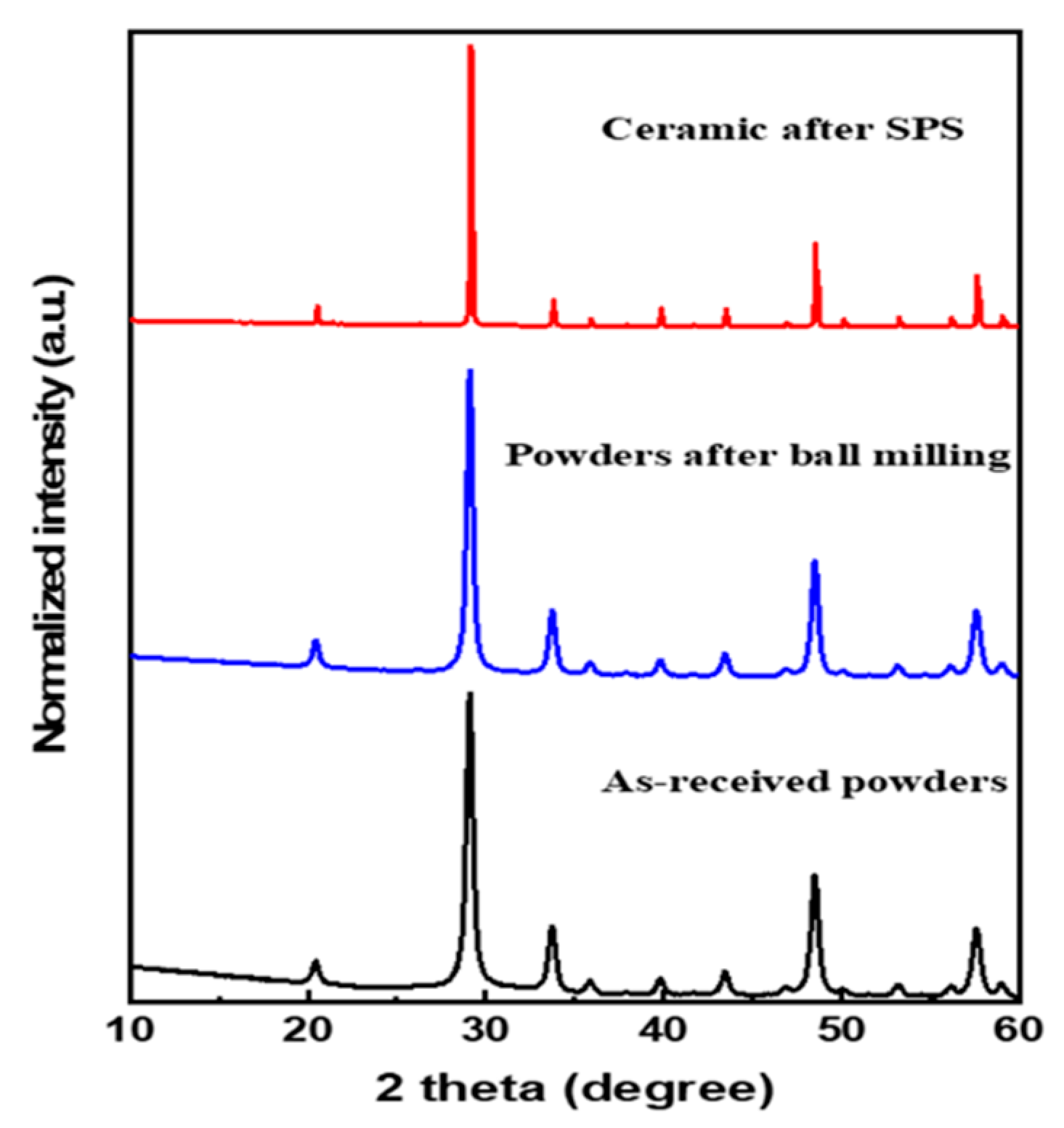

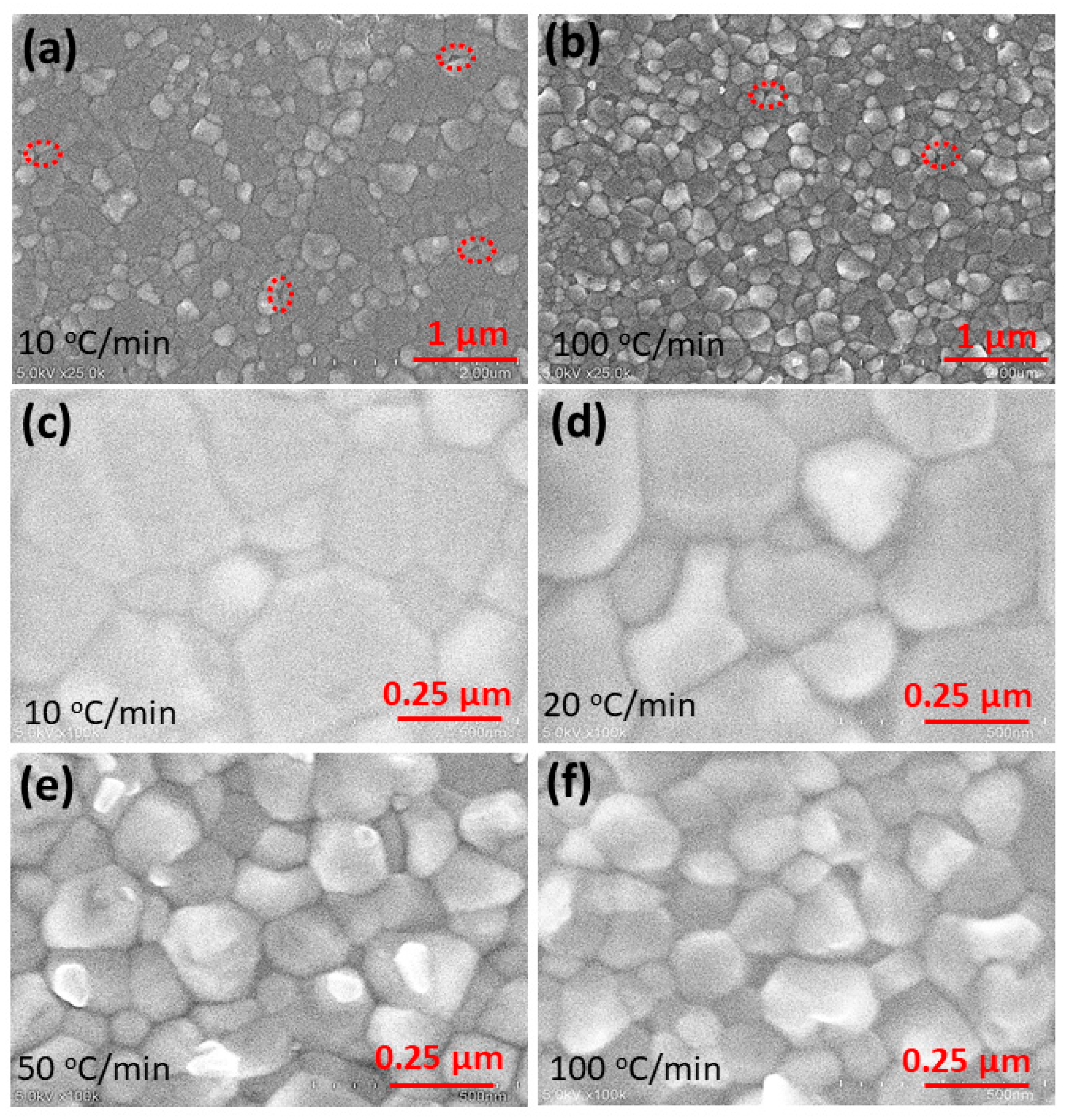

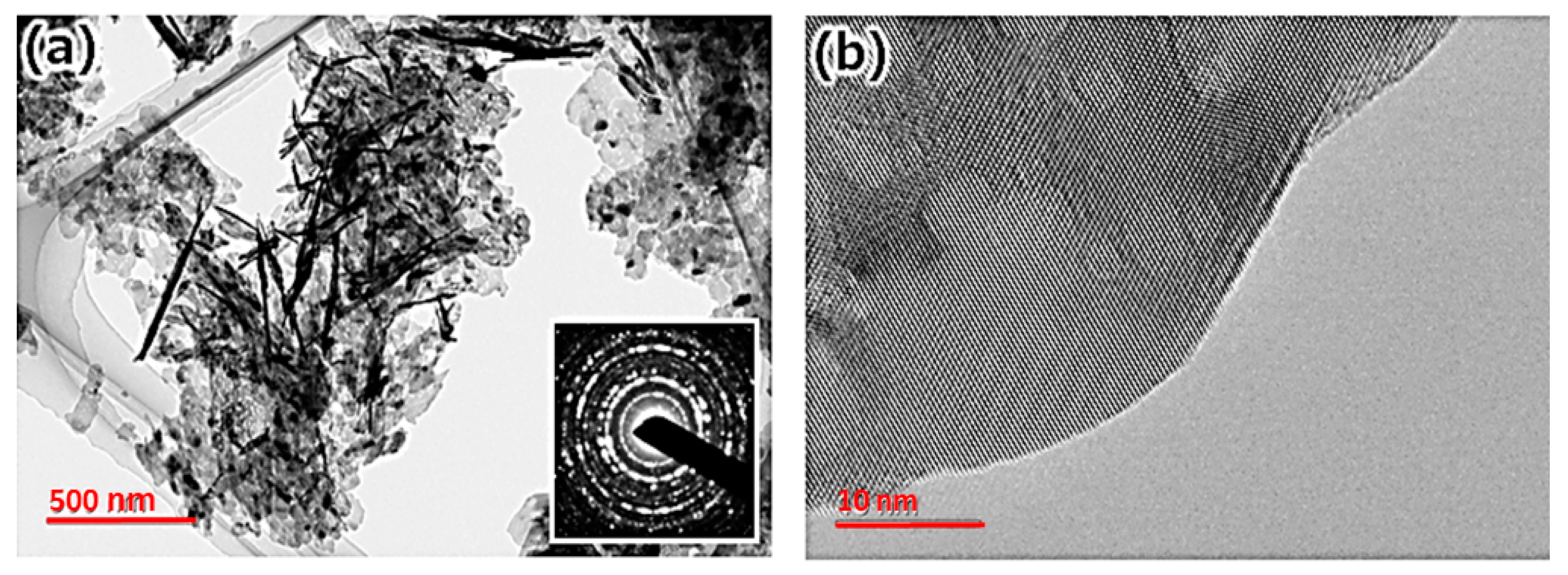

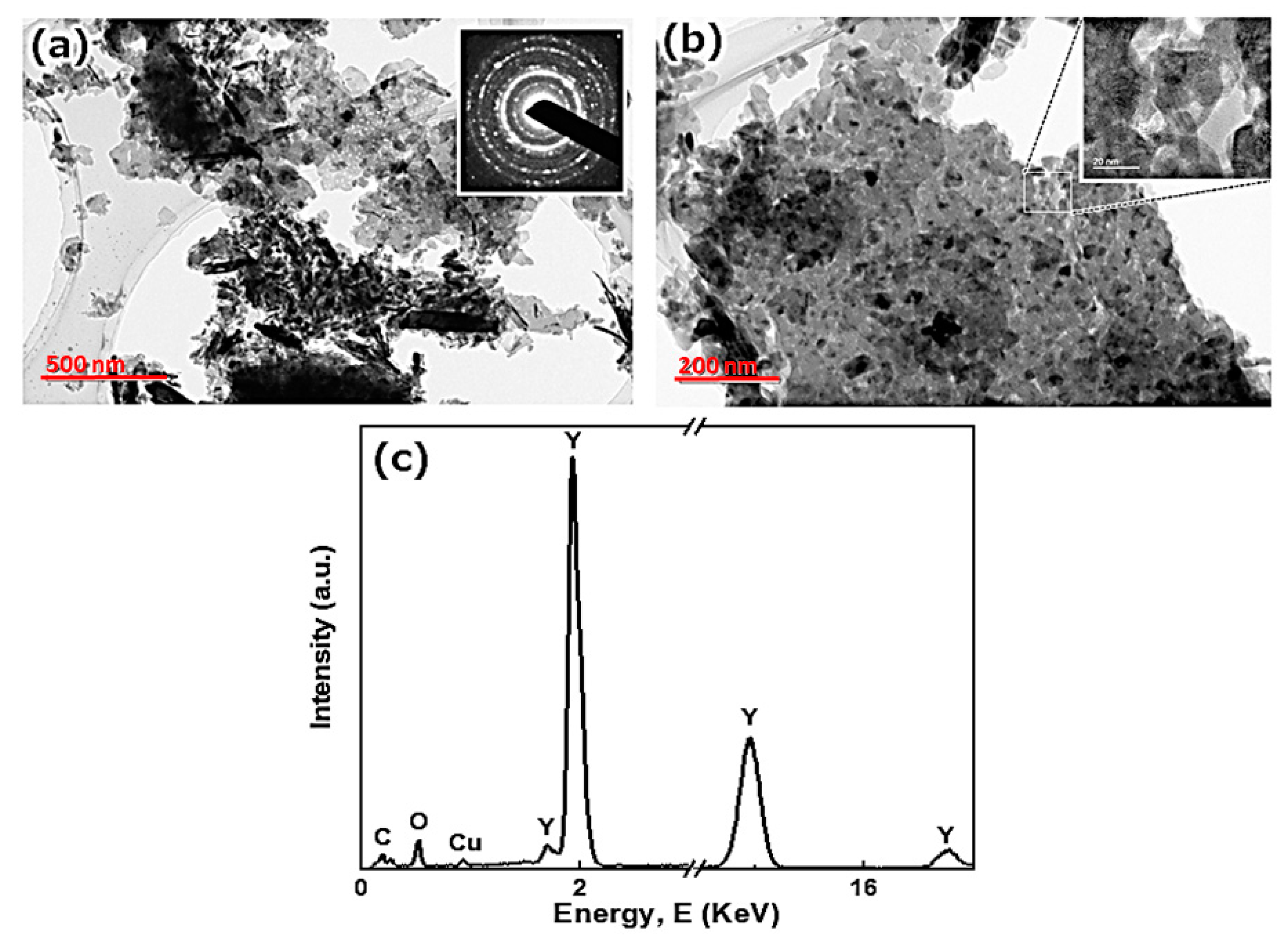

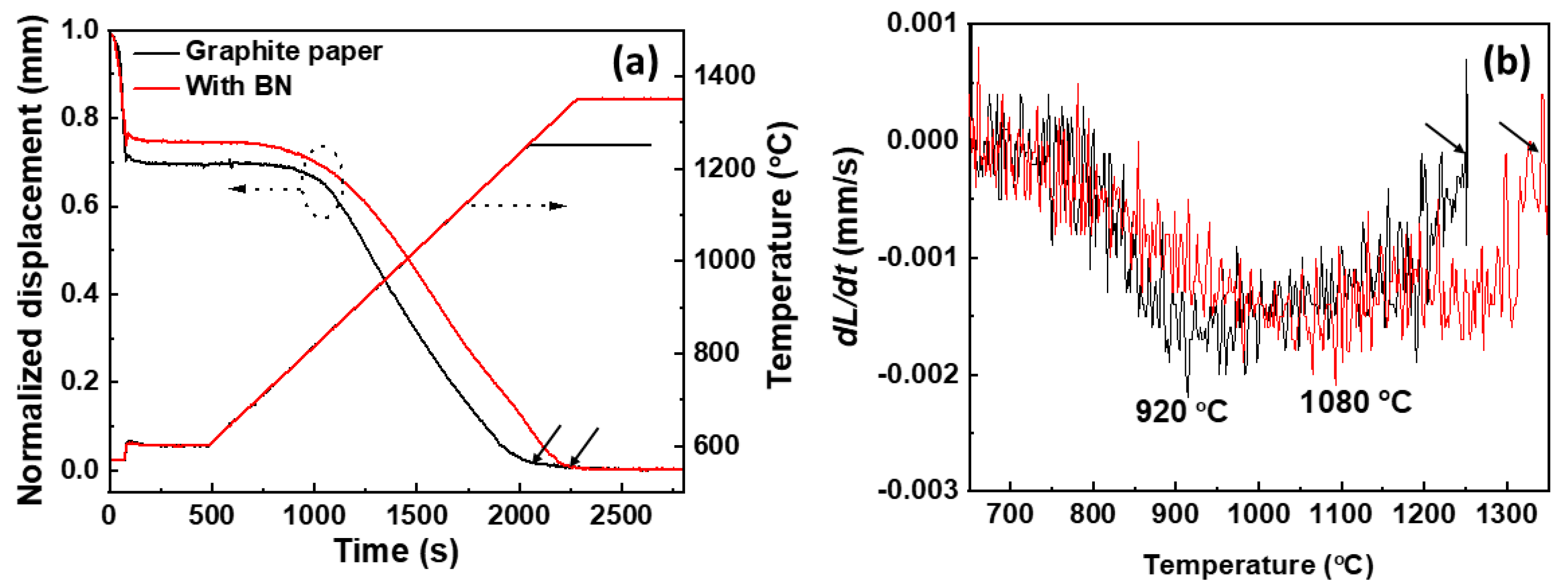

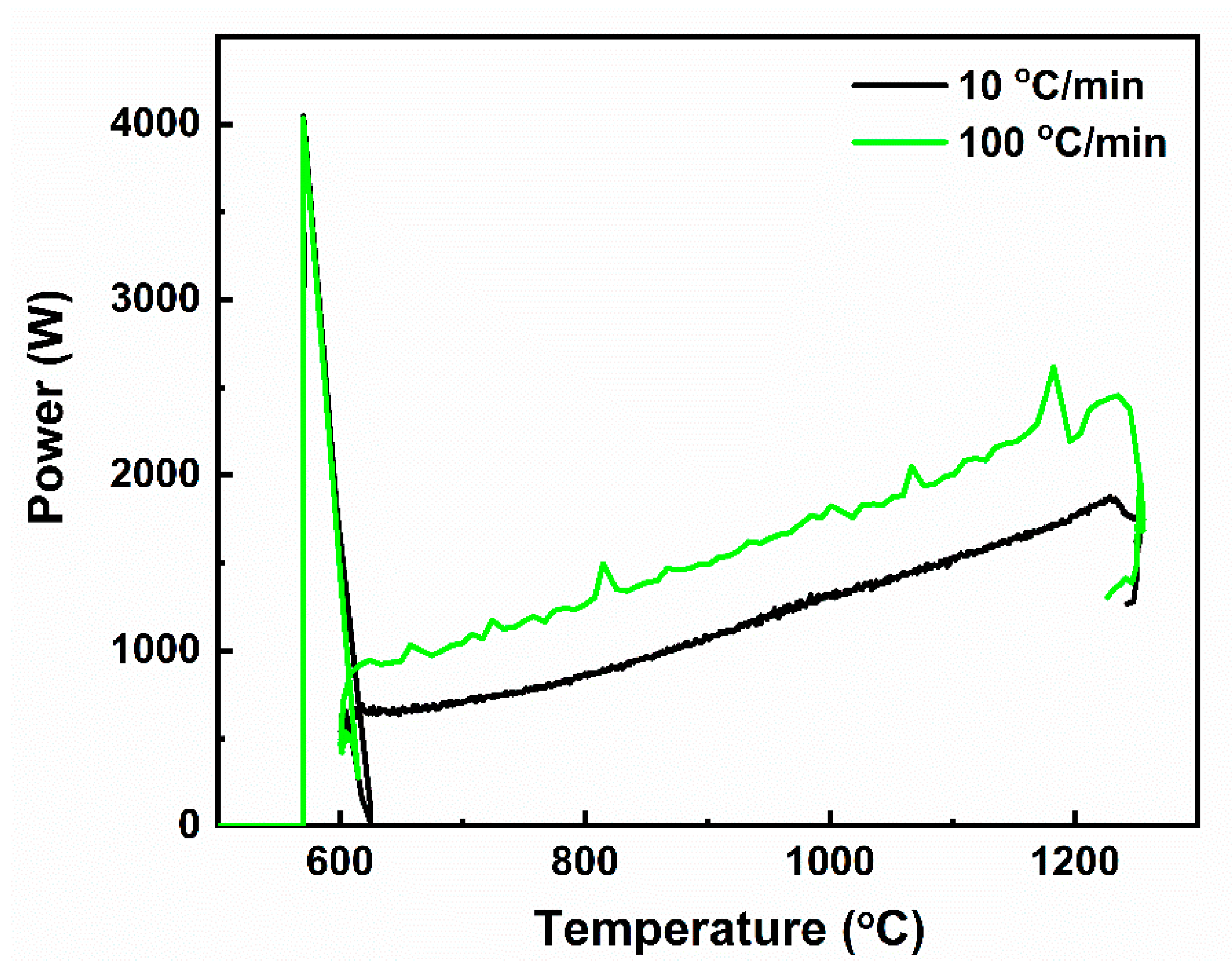

3.1. Microstructure Evaluation

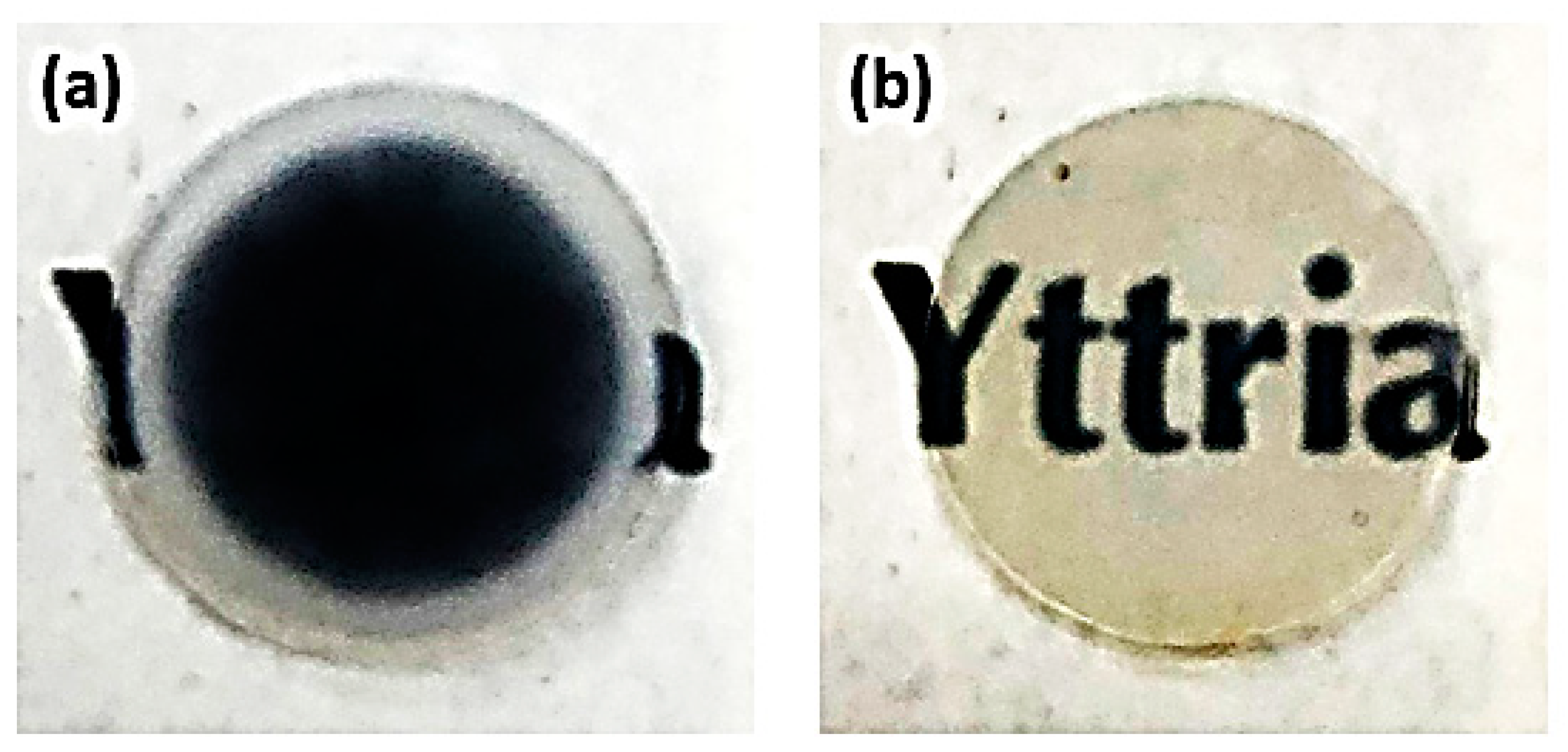

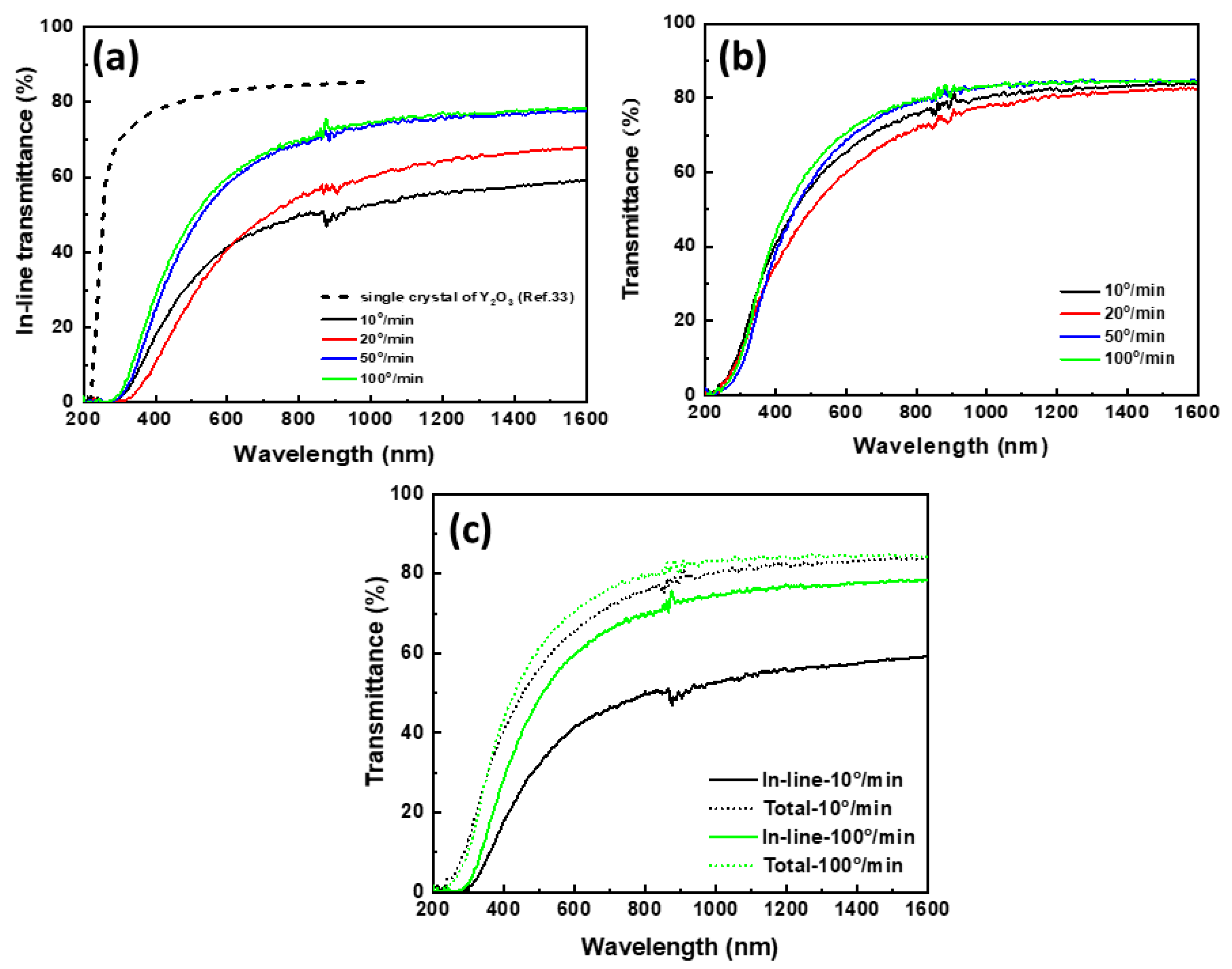

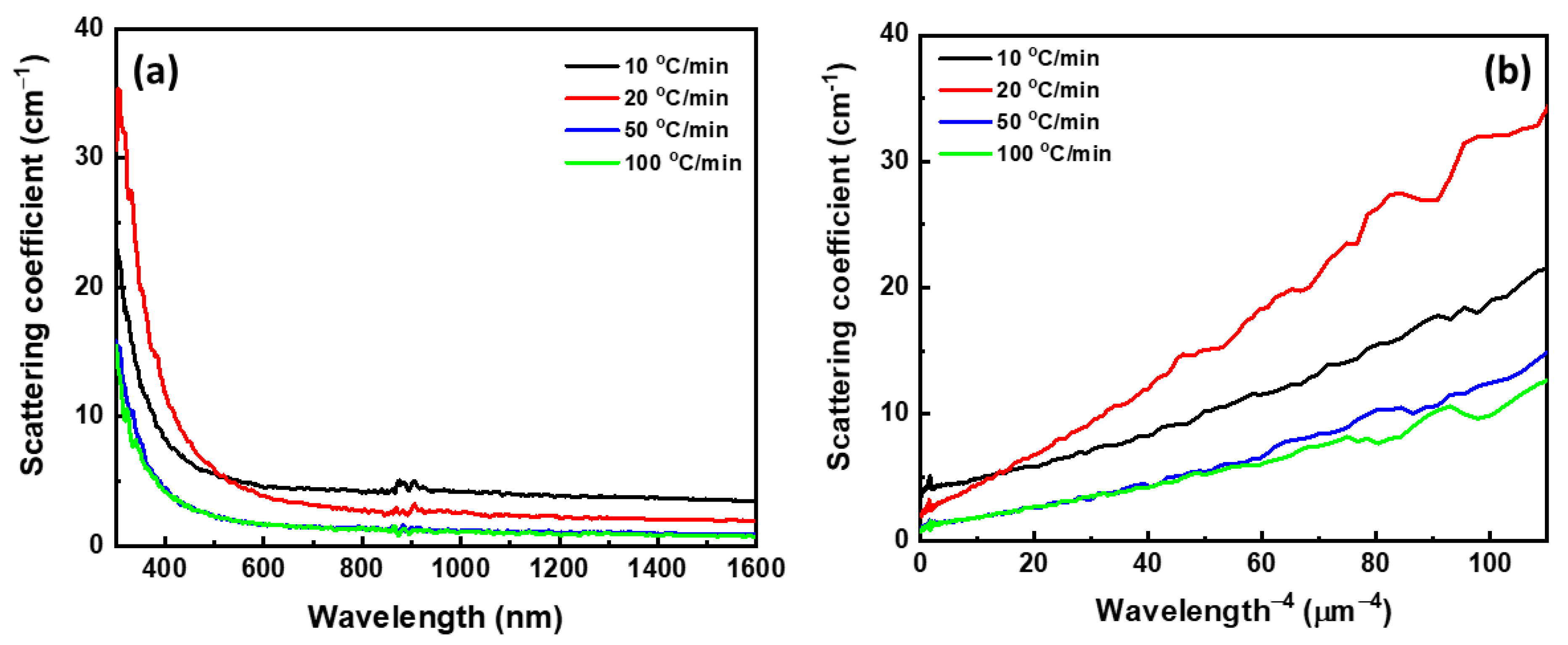

3.2. Optical Properties

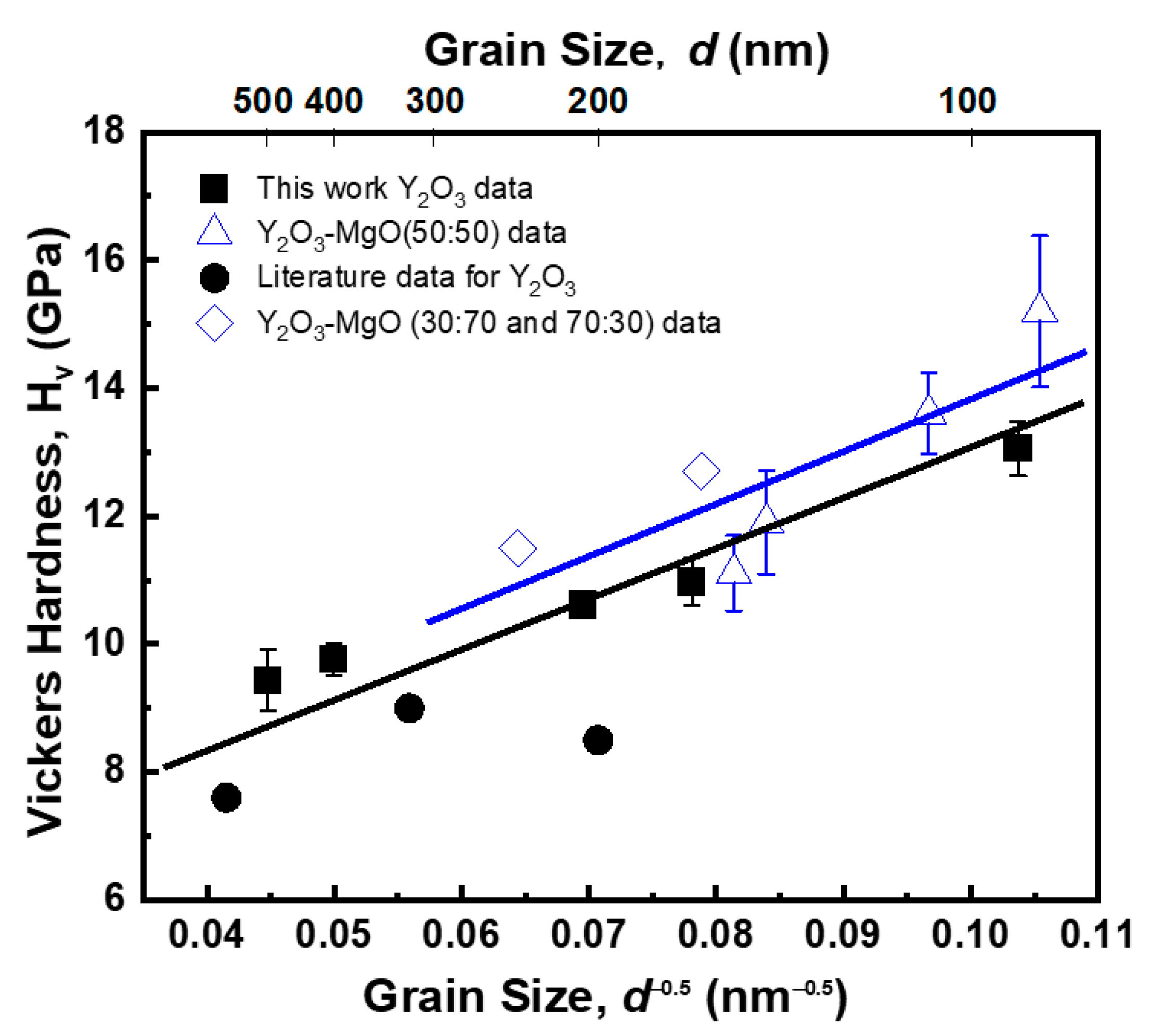

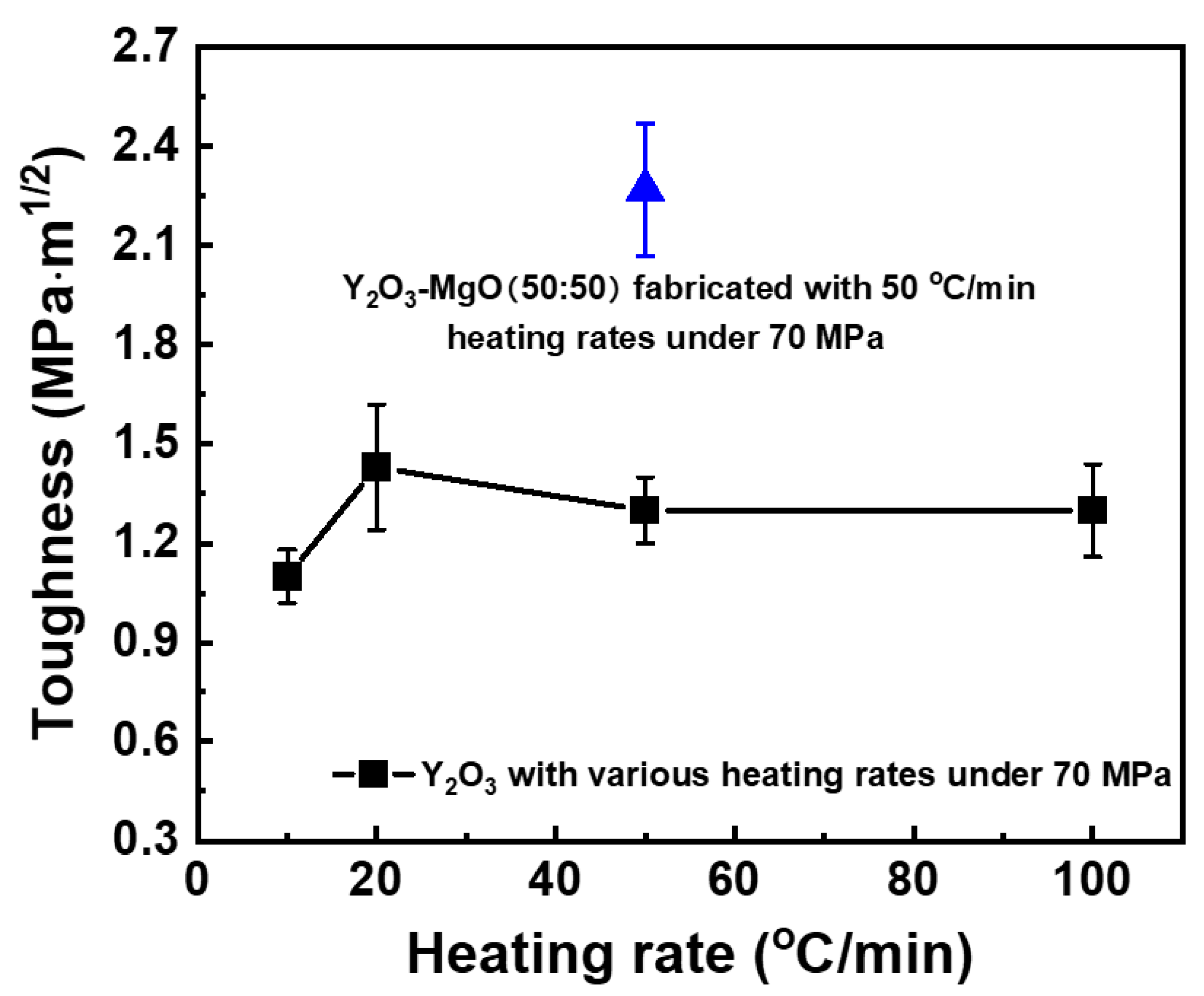

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, D.; Xu, X.; Lu, H.; Wang, Y.; Liu, P.; Zhang, J. Fabrication and properties of Y2O3 transparent ceramic by sintering aid combinations. Ceram. Int. 2016, 42, 16640–16643. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Yang, H.; Zhang, J.; Wang, L.; Zhang, Q. High optical quality Y2O3 transparent ceramics with fine grain size fabricated by low temperature air pre-sintering and post-HIP treatment. Ceram. Int. 2016, 42, 4238–4245. [Google Scholar] [CrossRef]

- Gan, L.; Park, Y.-J.; Kim, H.; Kim, J.-M.; Ko, J.-W.; Lee, J.-W. Effects of pre-sintering and annealing on the optical transmittance of Zr-doped Y2O3 transparent ceramics fabricated by vacuum sintering conjugated with post-hot-isostatic pressing. Ceram. Int. 2015, 41, 9622–9627. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, X.; Hu, Z.; Feng, Y.; Wei, J.; Liu, X.; Li, X.; Chen, H.; Wu, L.; Pan, H.; et al. Fabrication of Y2O3 transparent ceramics by hot isostatic pressing from precipitated nanopowders. Opt. Mater. 2019, 92, 359–365. [Google Scholar] [CrossRef]

- Chaim, R.; Shlayer, A.; Estournes, C. Densification of nanocrystalline Y2O3 ceramic powder by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 91–98. [Google Scholar] [CrossRef]

- Brown, E.E.; Hömmerich, U.; Bluiett, A.; Kucera, C.; Ballato, J.; Trivedi, S. Near-Infrared and Upconversion Luminescence in Er:Y2O3 Ceramics under 1.5 μm Excitation. J. Am. Ceram. Soc. 2014, 97, 2105–2110. [Google Scholar] [CrossRef]

- Dutta, S.; Gazza, G. Transparent Y2O3 by hot-pressing. Mater. Res. Bull. 1969, 4, 791–796. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Zhang, J.; Liu, P.; Luo, D.; Yin, D.; Tang, D.; Kong, L.B. Yb:Y2O3 transparent ceramics processed with hot isostatic pressing. Opt. Mater. 2017, 71, 117–120. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, W. Structural and Thermo-Mechanical Properties of Nd: Y2O3 Transparent Ceramics. J. Am. Ceram. Soc. 2015, 98, 3326–3331. [Google Scholar] [CrossRef]

- Chaim, R. Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng. A 2007, 443, 25–32. [Google Scholar] [CrossRef]

- Morita, K.; Kim, B.-N.; Yoshida, H.; Hiraga, K. Densification behavior of a fine-grained MgAl2O4 spinel during spark plasma sintering (SPS). Scr. Mater. 2010, 63, 565–568. [Google Scholar] [CrossRef]

- Jiang, N.; Xie, R.-J.; Liu, Q.; Li, J. Fabrication of sub-micrometer MgO transparent ceramics by spark plasma sintering. J. Eur. Ceram. Soc. 2017, 37, 4947–4953. [Google Scholar] [CrossRef]

- Chaim, R.; Chevallier, G.; Weibel, A.; Estournès, C. Grain growth during spark plasma and flash sintering of ceramic nanoparticles: A review. J. Mater. Sci. 2018, 53, 3087–3105. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Basu, B. Consolidation–microstructure–property relationships in bulk nanoceramics and ceramic nanocomposites: A review. Int. Mater. Rev. 2007, 52, 257–288. [Google Scholar] [CrossRef]

- Jiang, D.T.; Hulbert, D.M.; Anselmi-Tamburini, U.; Land, T.; Ng, D.; Mukherjee, A.K. Optically transparent polycrystalline Al2O3 produced by spark plasma sintering. J. Am. Ceram. Soc. 2008, 91, 151–154. [Google Scholar] [CrossRef]

- Kosyanov, D.Y.; Yavetskiy, R.P.; Vorona, I.O.; Shichalin, O.O.; Papynov, E.K.; Vornovskikh, A.A.; Kuryavyi, V.G.; Vovna, V.I.; Golokhvast, K.S.; Tolmachev, A.V. Transparent 4 at% Nd3+: Y3Al5O12 ceramic by reactive spark plasma sintering. In AIP Conference Proceedings; AIP Publishing LLC: New York, NY, USA, 2017; Volume 1874, p. 040020. [Google Scholar]

- Chaim, R.; Margulis, M. Densification maps for spark plasma sintering of nanocrystalline MgO ceramics. Mater. Sci. Eng. A 2005, 407, 180–187. [Google Scholar] [CrossRef]

- Morita, K.J.; Kim, B.-N.; Yoshida, H.; Hiraga, K.; Sakka, Y. Influence of spark plasma sintering (SPS) conditions on transmission of MgAl2O4 spinel. J. Am. Ceram. Soc. 2015, 98, 378–385. [Google Scholar] [CrossRef]

- Morita, K.; Hiraga, K.; Kim, B.N.; Yoshida, H.; Sakka, Y. Fabrication of Nanocrystalline Superplastic ZrO2 Ceramics. Mater. Sci. Forum 2007, 551, 491–496. [Google Scholar] [CrossRef]

- Hiroaki, F.; Nakasawa, S.; Yoshida, H.; Morita, K.J.; Suzuki, T.S.; Kim, B.-N.; Sakka, Y.; Hiraga, K. Transparent ultrafine Yb3+: Y2O3 laser ceramics fabricated by spark plasma sintering. J. Am. Ceram. Soc. 2018, 101, 694–702. [Google Scholar]

- Marder, R.; Chaim, R.; Estournès, C. Grain growth stagnation in fully dense nanocrystalline Y2O3 by spark plasma sintering. Mater. Sci. Eng. A 2010, 527, 1577–1585. [Google Scholar] [CrossRef]

- Korkmaz, E.; Sahin, F. Fabrication of Transparent Yttria Ceramics by Spark Plasma Sintering. Acta Phys. Pol. A 2017, 131, 460–462. [Google Scholar] [CrossRef]

- Park, C.W.; Lee, J.H.; Kang, S.H.; Park, J.H.; Kim, H.M.; Kang, H.S.; Lee, H.; Lee, J.H.; Shim, K.B. Characteristics of Y2O3 transparent ceramics rapidly processed using spark plasma sintering. J. Ceram. Process. Res. 2017, 18, 183–187. [Google Scholar]

- Zhang, H.; Kim, B.-N.; Morita, K.J.; Yoshida, H.; Hiraga, K.; Sakka, Y. Fabrication of transparent yttria by high-pressure spark plasma sintering. J. Am. Ceram. Soc. 2011, 94, 3206–3210. [Google Scholar] [CrossRef]

- Yoshida, H.; Morita, K.J.; Kim, B.-N.; Hiraga, K.; Yamanaka, K.; Soga, K.; Yamamoto, T. Low-temperature spark plasma sintering of yttria ceramics with ultrafine grain size. J. Am. Ceram. Soc. 2011, 94, 3301–3307. [Google Scholar] [CrossRef]

- Ahmadi, B.; Reza, S.R.; Ahsanzadeh-Vadeqani, M.; Barekat, M. Mechanical and optical properties of spark plasma sintered transparent Y2O3 ceramics. Ceram. Int. 2016, 42, 17081–17088. [Google Scholar] [CrossRef]

- Yeung, J.; Keong, L.C. Hardness Measurement of Copper Bonding Wire. Procedia Eng. 2014, 75, 134–139. [Google Scholar] [CrossRef][Green Version]

- Evans, A.G.; Charles, E.A. Fracture Toughness Determinations by Indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Tallan, N.M.; Vest, R.W. Electrical Properties and Defect Structure of Y2O3. J. Am. Ceram. Soc. 1966, 49, 401–404. [Google Scholar] [CrossRef]

- Norby, T.; Kofstad, P. Electrical Conductivity and Defect Structure of Y2O3as a Function of Water Vapor Pressure. J. Am. Ceram. Soc. 1984, 67, 786–792. [Google Scholar] [CrossRef]

- Zhang, H.B.; Kim, B.N.; Morita, K.; Hiraga, K.; Sakka, Y. Effect of sintering temperature on optical properties and microstructure of translucent zirconia prepared by high-pressure spark plasma sintering. Sci. Tech. Adv. Mater. 2011, 12, 055003. [Google Scholar] [CrossRef]

- Jiang, D.; Mukherjee, A.K. Spark Plasma Sintering of an Infrared-Transparent Y2O3-MgO Nanocomposite. J. Am. Ceram. Soc. 2009, 93, 769–773. [Google Scholar] [CrossRef]

- Mouzon, J.; Maître, A.; Frisk, L.; Lehto, N.; Odén, M. Fabrication of transparent yttria by HIP and the glass-encapsulation method. J. Eur. Ceram. Soc. 2009, 29, 311–316. [Google Scholar] [CrossRef]

- Liu, L.; Morita, K.; Suzuki, T.S.; Kim, B.-N. Evolution of microstructure, mechanical, and optical properties of Y2O3-MgO nanocomposites fabricated by high pressure spark plasma sintering. J. Eur. Ceram. Soc. 2020, 40, 4547–4555. [Google Scholar] [CrossRef]

- Sokol, M.; Halabi, M.; Kalabukhov, S.; Frage, N. Nano-structured MgAl2O4 spinel consolidated by high pressure spark plasma sintering (HPSPS). J. Eur. Ceram. Soc. 2017, 37, 755–762. [Google Scholar] [CrossRef]

- Vasylkiv, O.; Sakka, Y.; Skorokhod, V.V. Low-Temperature Processing and Mechanical Properties of Zirconia and Zirconia-Alumina Nanoceramics. J. Am. Ceram. Soc. 2003, 86, 299–304. [Google Scholar] [CrossRef]

- Krell, A.; Blank, P. Grain Size Dependence of Hardness in Dense Submicrometer Alumina. J. Am. Ceram. Soc. 1995, 78, 1118–1120. [Google Scholar] [CrossRef]

- Liu, W.; Wu, Y.; He, J.; Nieh, T.; Lu, Z. Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Carsley, J.E.; Fisher, A.; Milligan, W.W.; Aifantis, E.C. Mechanical behavior of a bulk nanostructured iron alloy. Met. Mater. Trans. A 1998, 29, 2261–2271. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Diego, G.-G.; Arturo, D.-R.; Richard, I.T. Grain size dependence of hardness and fracture toughness in pure near fully-dense boron carbide ceramics. J. Eur. Ceram. Soc. 2016, 36, 1829–1834. [Google Scholar] [CrossRef]

- Rice, R.W.; Wu, C.C.; Boichelt, F. Hardness-Grain-Size Relations in Ceramics. J. Am. Ceram. Soc. 1994, 77, 2539–2553. [Google Scholar] [CrossRef]

- Wollmershauser, J.A.; Feigelson, B.N.; Gorzkowski, E.P.; Ellis, C.T.; Goswami, R.; Qadri, S.B.; Tischler, J.G.; Kub, F.J.; Everett, R.K. An extended hardness limit in bulk nanoceramics. Acta Mater. 2014, 69, 9–16. [Google Scholar] [CrossRef]

- Liu, L.; Morita, K.; Suzuki, T.S.; Kim, B.-N. Effect of volume ratio on optical and mechanical properties of Y2O3-MgO composites fabricated by spark-plasma-sintering process. J. Eur. Ceram. Soc. 2021, 41, 2096–2105. [Google Scholar] [CrossRef]

- Tani, T.; Miyamoto, Y.; Koizumi, M.; Shimada, M. Grain size dependences of vickers microhardness and fracture toughness in Al2O3 and Y2O3 ceramics. Ceram. Int. 1986, 12, 33–37. [Google Scholar] [CrossRef]

- An, L.; Ito, A.; Goto, T. Transparent yttria produced by spark plasma sintering at moderate temperature and pressure profiles. J. Eur. Ceram. Soc. 2012, 32, 1035–1040. [Google Scholar] [CrossRef]

- Ma, H.J.; Jung, W.K.; Baek, C.; Kim, D.K. Influence of microstructure control on optical and mechanical properties of infrared transparent Y2O3-MgO nanocomposite. J. Eur. Ceram. Soc. 2017, 37, 4902–4911. [Google Scholar] [CrossRef]

- Yao, W.; Liu, J.; Holland, T.B.; Huang, L.; Xiong, Y.; Schoenung, J.M.; Mukherjee, A.K. Grain size dependence of fracture toughness for fine grained alumina. Scr. Mater. 2011, 65, 143–146. [Google Scholar] [CrossRef]

- Huang, L.; Yao, W.; Liu, J.; Mukherjee, A.K.; Schoenung, J.M. Spark plasma sintering and mechanical behavior of magnesia–yttria (50:50vol.%) nanocomposites. Scr. Mater. 2014, 75, 18–21. [Google Scholar] [CrossRef]

- AZO Materials. Magnesia-magnesium Oxide (MgO) Properties & Applications. Available online: https://www.azom.com/properties.aspx?ArticleID=54 (accessed on 10 November 2020).

- Zhu, L.-L.; Park, Y.-J.; Gan, L.; Kim, H.-N.; Ko, J.-W.; Kim, H.-D. Fabrication of transparent Y2O3 ceramics with record-high thermal shock resistance. J. Eur. Ceram. Soc. 2018, 38, 4050–4056. [Google Scholar] [CrossRef]

- Conner, C.L.; Faber, K.T. Segregant-enhanced fracture in magnesium oxide. J. Mater. Sci. 1990, 25, 2737–2742. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Morita, K.; Suzuki, T.S.; Kim, B.-N. Effect of the Heating Rate on the Spark-Plasma-Sintering (SPS) of Transparent Y2O3 Ceramics: Microstructural Evolution, Mechanical and Optical Properties. Ceramics 2021, 4, 56-69. https://doi.org/10.3390/ceramics4010006

Liu L, Morita K, Suzuki TS, Kim B-N. Effect of the Heating Rate on the Spark-Plasma-Sintering (SPS) of Transparent Y2O3 Ceramics: Microstructural Evolution, Mechanical and Optical Properties. Ceramics. 2021; 4(1):56-69. https://doi.org/10.3390/ceramics4010006

Chicago/Turabian StyleLiu, Lihong, Koji Morita, Tohru S. Suzuki, and Byung-Nam Kim. 2021. "Effect of the Heating Rate on the Spark-Plasma-Sintering (SPS) of Transparent Y2O3 Ceramics: Microstructural Evolution, Mechanical and Optical Properties" Ceramics 4, no. 1: 56-69. https://doi.org/10.3390/ceramics4010006

APA StyleLiu, L., Morita, K., Suzuki, T. S., & Kim, B.-N. (2021). Effect of the Heating Rate on the Spark-Plasma-Sintering (SPS) of Transparent Y2O3 Ceramics: Microstructural Evolution, Mechanical and Optical Properties. Ceramics, 4(1), 56-69. https://doi.org/10.3390/ceramics4010006