Overview of Spark Plasma Texturing of Functional Ceramics

Abstract

1. Introduction

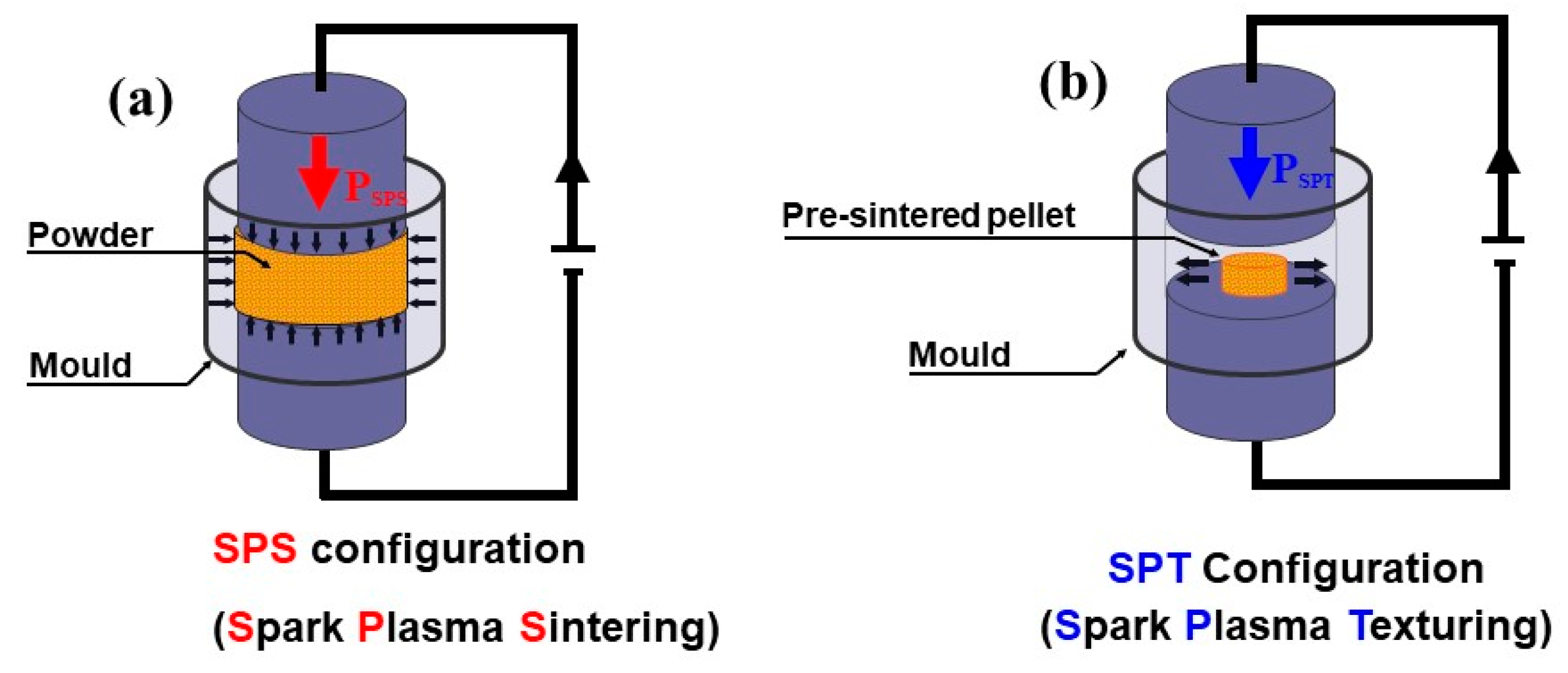

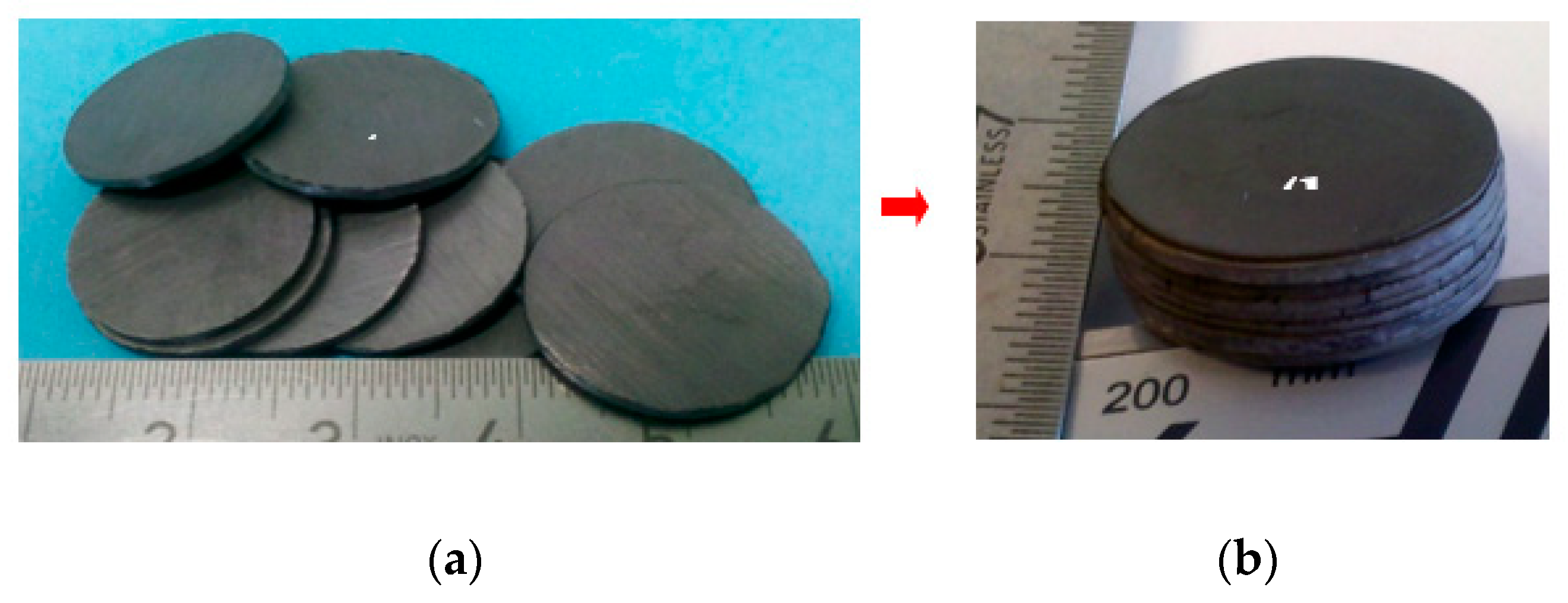

2. Experimental

2.1. Samples Preparation and Processing Conditions

2.2. Characterization

3. Results and Discussion

- (i)

- Superconducting Bi2Sr2Ca2Cu3O10 (Bi2223)

- (ii)

- Thermoelectric Ca3Co4O9 (Co349)

- (iii)

- Thermoelectric Ca3-xAgxCo4O9/Ag (Co349/Ag) composites

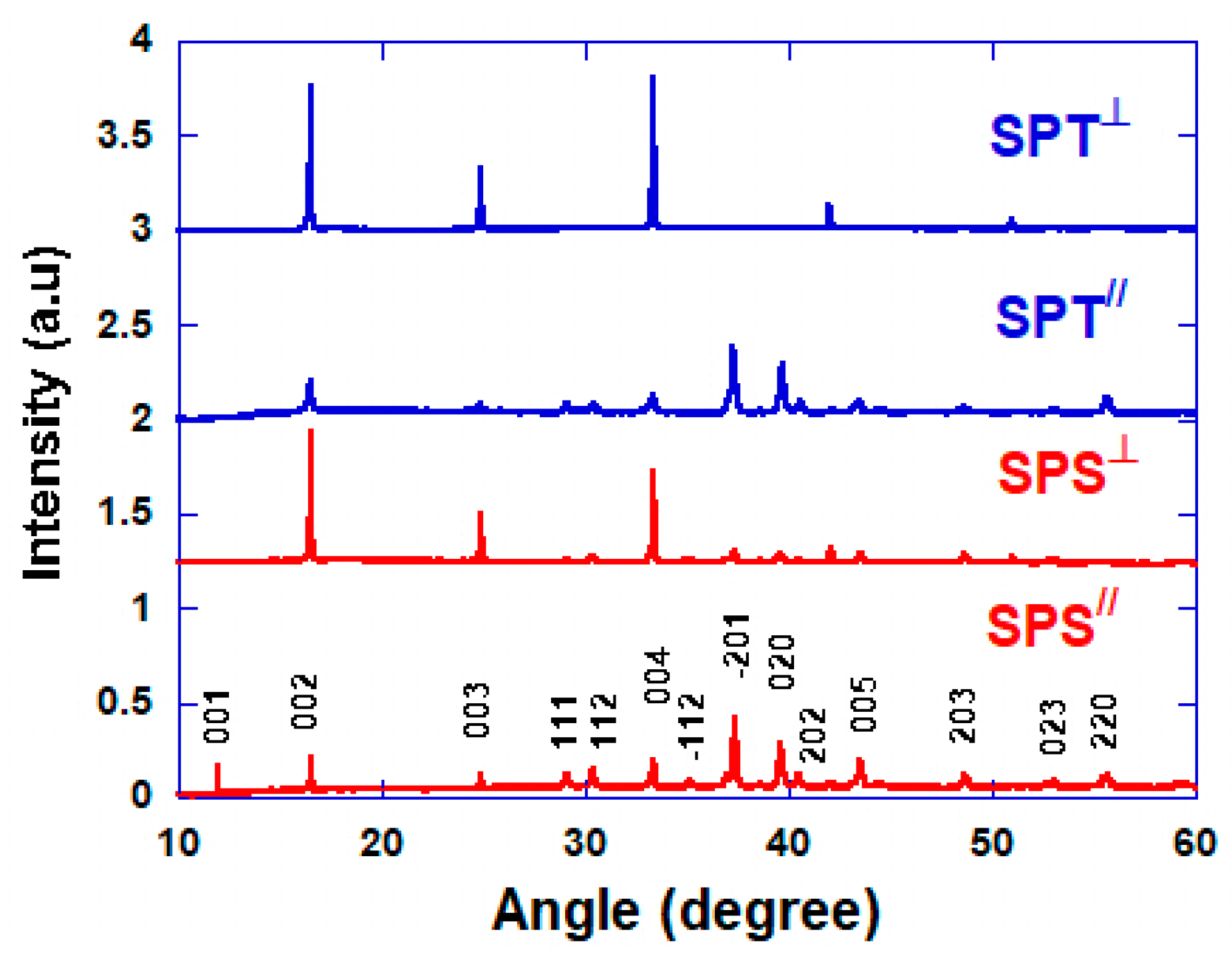

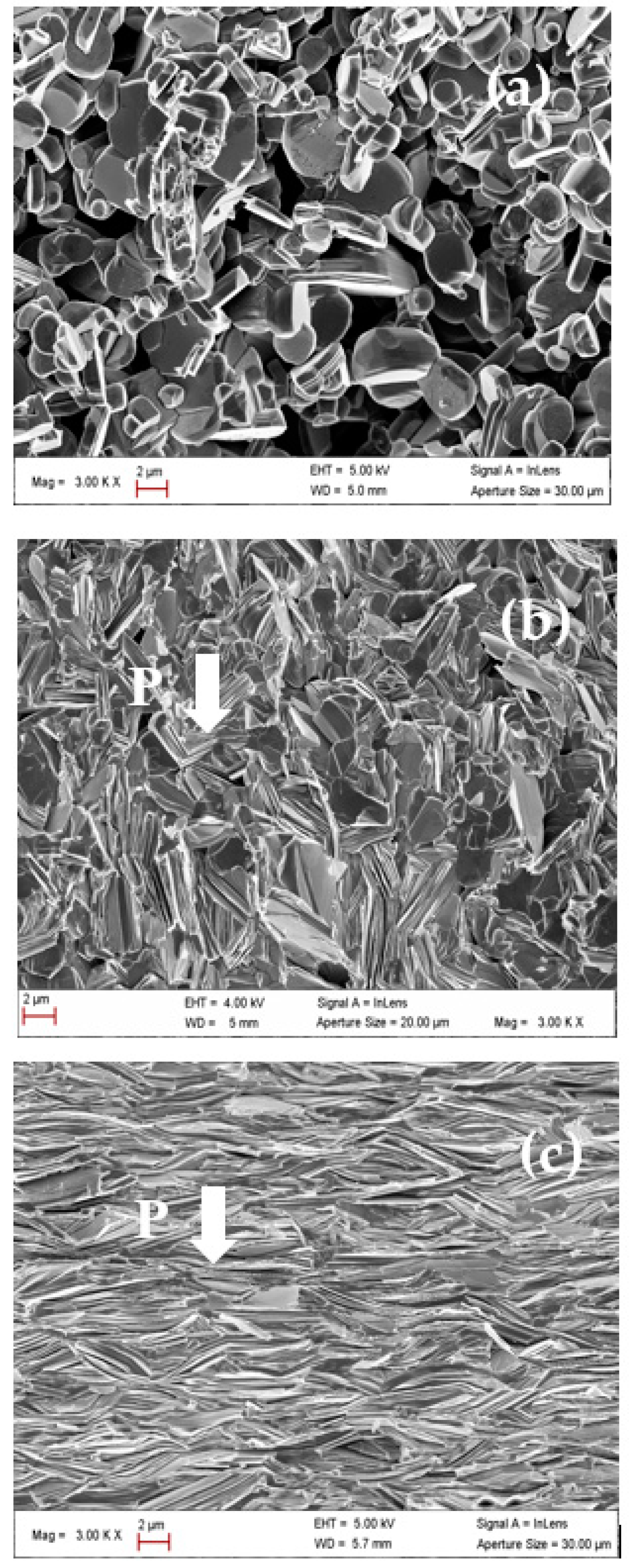

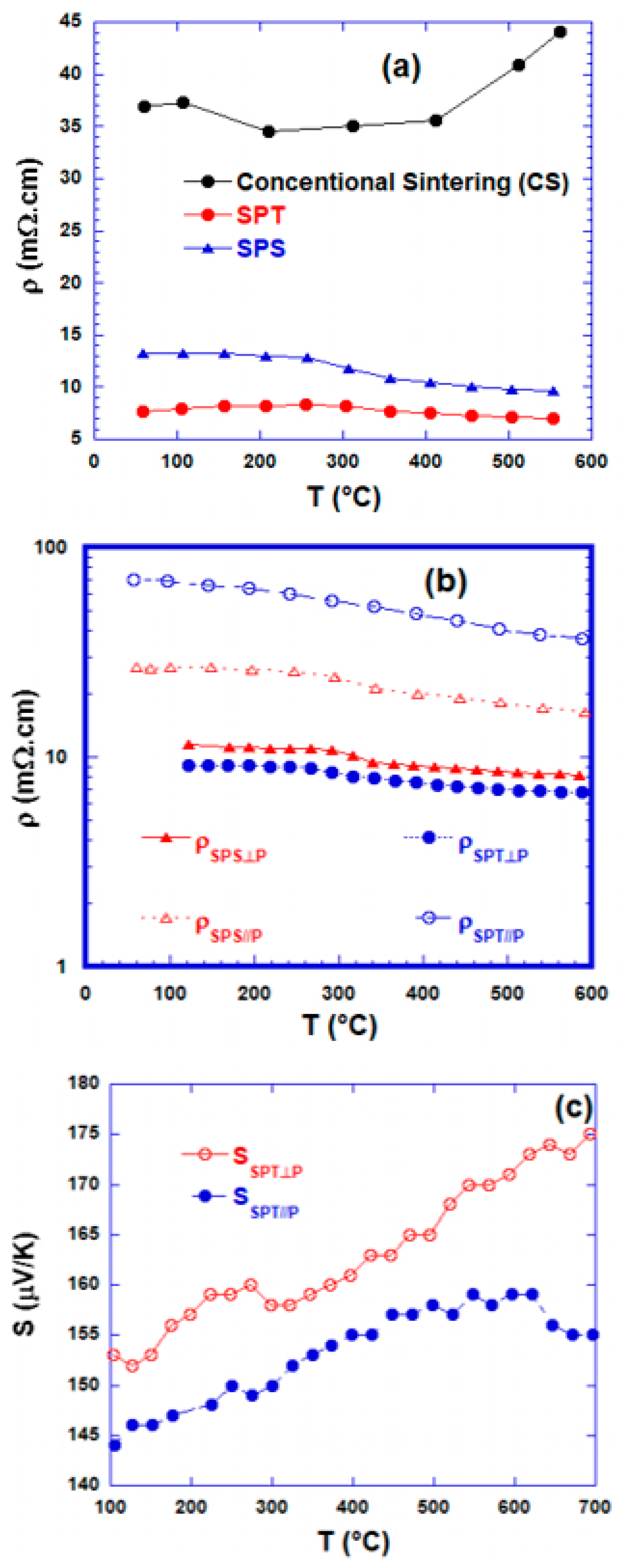

3.1. Thermoelectric Ca3Co4O9 (Co349)

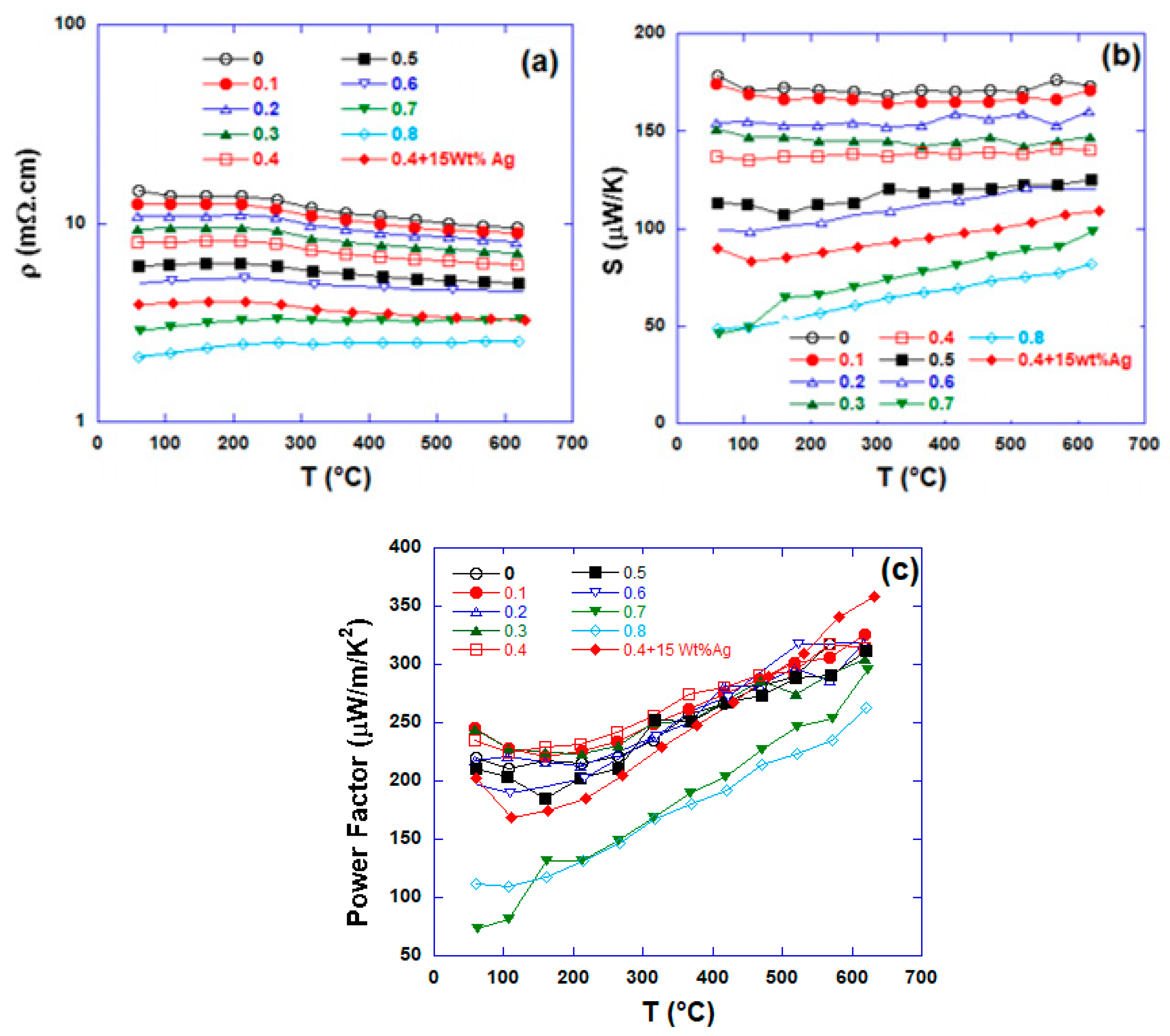

3.2. Thermoelectric Ca3-xAgxCo4O9/Ag (Co349/Ag) Composites

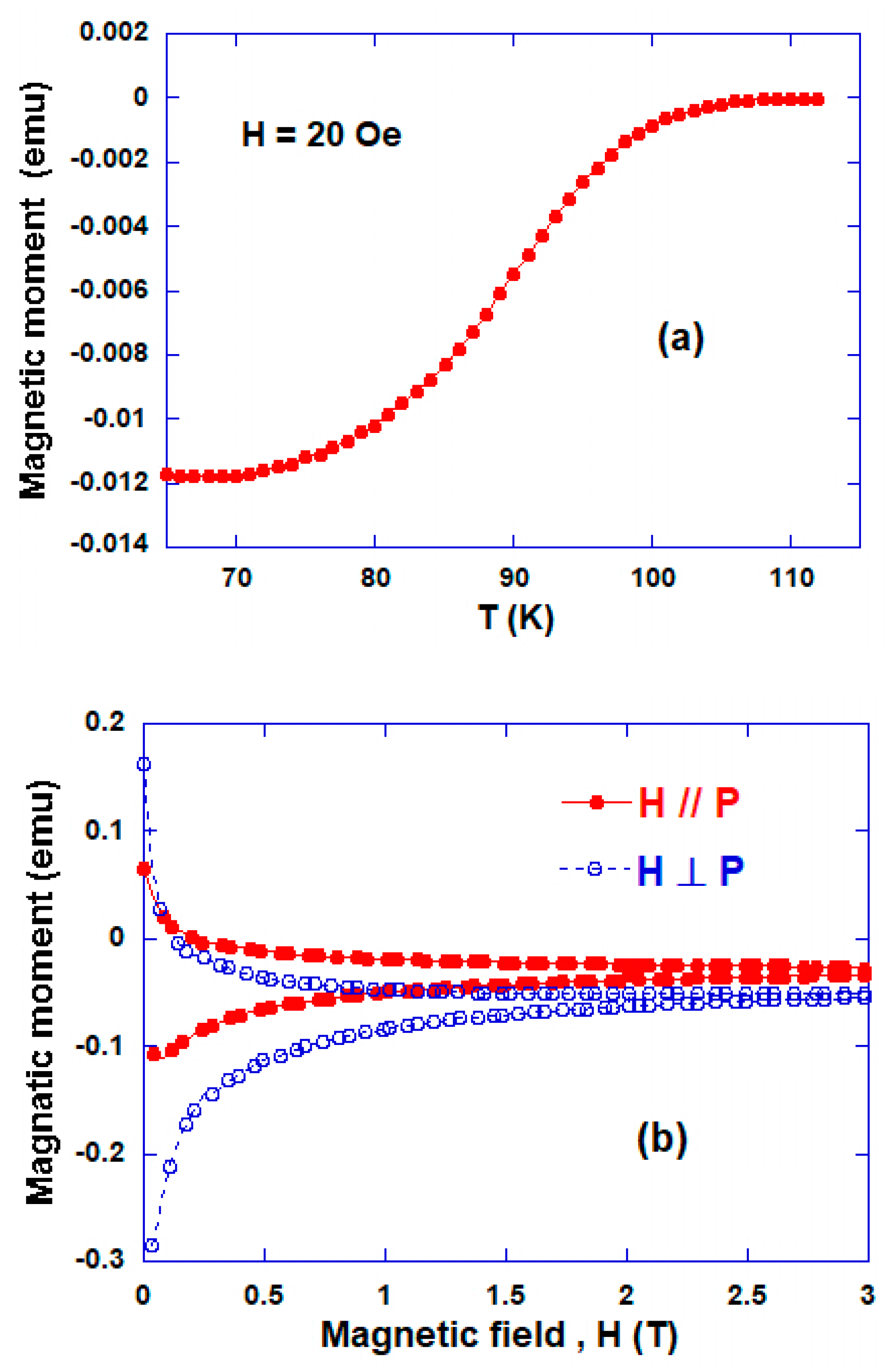

3.3. Bi2Sr2Ca2Cu3O10 Superconductor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bednorz, J.G.; Müller, K.A. Possible High T c Superconductivity in the Ba-La-Cu-0 System. Phys. B Condens. Matter. 1986, 64, 189. [Google Scholar] [CrossRef]

- Jin, S.; Tiefel, T.H.; Sherwood, R.C.; van Dover, R.B.; Davis, M.E.; Kammlott, G.W.; Fastnacht, R.A. Melt-textured growth of polycrystaIline YBa2Cu3O7-d with high transport J, at 77 K. Phys. Rev. B 1988, 37, 7850–7853. [Google Scholar] [CrossRef]

- de Rango, P.; Lees, M.R.; Lejay, P.; Sulpice, A.; Tournier, R.; Ingold, M.; Germi, M.; Pernet, M. Texturing of magnetic materials at high temperature by solidification in a magnetic field. Nature 1991, 349, 770–772. [Google Scholar] [CrossRef]

- Lees, M.R.; de Rango, P.; Bourgault, D.; Barbut, J.M.; Braithwite, D.; Lejay, P.; Sulpice, A.; Tournier, R. Bulk textured rare earth-Ba2Cu3O7-delta prepared by solidification in a magnetic field. Supercond. Sci. Technol. 1992, 5, 362–367. [Google Scholar] [CrossRef]

- Dou, S.X.; Liu, H.K.; Apperley, M.H.; Sing, K.H.; Sorrell, C.C.; Easterling, K.E.; Niska, J.; Guo, S.J. Improvement of critical current density in the Bi-Pb-Sr-Ca-Cu-O system through hot isostatic pressing. Phys. C 1990, 167, 525–528. [Google Scholar] [CrossRef]

- Seino, H.; Ishizaki, K.; Takata, M. HIPped high density Bi-(Pb)-Sr-Ca-Cu-O superconductors produced without any additional treatment. Jpn. J. Appl. Phys. 1989, 28, L78–L81. [Google Scholar] [CrossRef]

- Miller, D.J.; Sengupta, S.; Hettinger, J.D.; Shi, D.; Gray, K.E. Flux pinning in hot isostatically pressed Bi2Sr2CaCu2Ox. Appl. Phys. Lett. 1992, 61, 2823–2825. [Google Scholar] [CrossRef]

- Assano, T.; Tanaka, Y.; Fukutomi, M.; Jikihara, K.; Maeda, H. Properties of Pb-Doped Bi-Sr-Ca-Cu-O Superconductors Prepared by the Intermediate Pressing Process. Jpn. J. Appl. Phys. 1989, 28, L595–L597. [Google Scholar] [CrossRef]

- Gao, W.; Sande, J.B.V. Textured BSCCO/Ag superconducting microcomposites with improved critical current density through mechanical deformation. Supercond. Sci. Technol. 1992, 5, 318–326. [Google Scholar] [CrossRef]

- Ichinose, N.; Saito, K. Grain orientation of the Bi-Sr-Ca-Cu-O system ceramics by hotforging and their superconducting properties. Phys. C 1991, 190, 177–179. [Google Scholar] [CrossRef]

- Terasaki, I.; Sasago, Y.; Uchinokura, K. Large thermoelectric power in NaCo2O4 single crystals. Phys. Rev. B 1997, 56, R12685. [Google Scholar] [CrossRef]

- Masset, A.C.; Michel, C.; Maignan, A.; Hervieu, M.; Toulemonde, O.; Studer, F.; Raveau, B. Misfit-layered cobaltite with an anisotropic giant magnetoresistance: Ca3Co4O9. Phys. Rev. B 2000, 63, 166. [Google Scholar] [CrossRef]

- Zhou, Y.; Matsubara, I.; Horii, S.; Takeuchi, T.; Funahashi, R.; Shikano, M.; Shimoyama, J.; Kishio, K.; Shin, W.; Izu, N.; et al. Thermoelectric properties of highly grain-aligned and densified Co-based oxide ceramics. J. Appl. Phys. 2003, 93, 2653. [Google Scholar] [CrossRef]

- Scherrer, H.; Scherrer, S. Bismuth telluride, Antimony telluride and their solid solutions. In CRC Handbook of Thermoelectricity; Rowe, D.M., Ed.; CRC Press: London, UK, 1995; p. 211. [Google Scholar]

- Gonzalez, E.J.; Blendell, J.E.; Cline, J.P.; Ritter, J.J.; Maruthamuthu, P.; Nelson, E.H.; Horn, S.B. Texture development in Bi2Te3 during hot forging. J. Mater. Res. 1998, 13, 766. [Google Scholar] [CrossRef]

- Hervieu, M.; Boullay, P.; Michel, C.; Maignan, A.; Raveau, B. A New Family of Misfit Layered Oxides with Double Rock Salt Layers Biα(A0.75±εBi0.25±εO)(3+3x)/2MO2(A=Ca, Sr andM=Co, Cr). J. Solid State Chem. 1999, 142, 305. [Google Scholar] [CrossRef]

- Xu, G.; Funahashi, R.; Shikano, M.; Matsubara, I.; Zhou, Y. Thermoelectric properties of Bi2.2−xPbxSr2Co2Oy system. J. Appl. Phys. 2002, 91, 4344. [Google Scholar] [CrossRef]

- Yamamoto, T.; Tsukada, I.; Uchinokura, K.; Takagi, M.; Tsubone, T.; Ichihara, M.; Kobayashi, K. Structural Phase Transition and Metallic Behavior in Misfit Layered (Bi,Pb)-Sr-Co-O System. Jpn. J. Appl. Phys. 2000, 39, 747. [Google Scholar] [CrossRef]

- Fujii, T.; Terasaki, I.; Watanabe, T.; Matsuda, A. Large In-Plane Anisotropy on Resistivity and Thermopower in the Misfit Layered Oxide Bi2-xPbxSr2Co2O. Jpn. J. Appl. Phys. 2002, 41, 783. [Google Scholar] [CrossRef]

- Funahashi, R.; Urata, S.; Sano, T.; Kitawaki, M. Enhancement of thermoelectric figure of merit by incorporation of large single crystals in Ca3Co4O9 bulk materials. J. Mater. Res. 2003, 18, 1646. [Google Scholar] [CrossRef]

- Tani, T.; Itahara, H.; Xia, C.; Sugiyama, J. Topotactic synthesis of highly-textured thermoelectric cobaltites. J. Mater. Chem. 2003, 13, 1865. [Google Scholar] [CrossRef]

- Matsubara, I.; Funahashi, R.; Takeuchi, T.; Sodeoka, S. Thermoelectric properties of spark plasma sintered Ca2.75Gd0.25Co4O9 ceramics. J. Appl. Phys. 2001, 90, 462. [Google Scholar] [CrossRef]

- Noudem, J.G. A new process for lamellar texturing of thermoelectric Ca3Co4O9 oxides by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 2659–2663. [Google Scholar] [CrossRef]

- Noudem, J.G.; Kenfaui, D.; Chateigner, D.; Gomina, M. Toward the enhancement of thermoelectric properties of lamellar Ca3Co4O9 by edge-free spark plasma texturing. Scr. Mater. 2012, 66, 258–260. [Google Scholar] [CrossRef]

- Prevel, M.; Perez, O.; Noudem, J.G. Bulk textured Ca2.5(RE)0.5Co4O9 (RE: Pr, Nd, Eu, Dy and Yb) thermoelectric oxides by sinter-forging. Solid State Sci. 2007, 9, 231. [Google Scholar] [CrossRef]

- Oide, Y.; Miyazaki, Y.; Ono, Y.; Huang, X.Y.; Kajitani, T. Thermogravimetric Study and High-Temperature Thermoelectric Properties of [Ca2(Co1−xAx)O3]0.62CoO2. In Proceedings of the 2006 25th International Conference on Thermoelectrics, Vienna, Austria, 6–10 August 2006; pp. 402–405. [Google Scholar] [CrossRef]

- Miyazaki, Y.; Miura, T.; Onoda, M.; Uchida, M.; Ishii, Y.; Ono, Y.; Morii, Y.; Kajitani, T. Modulated Structure of Misfit-Layered Cobalt Oxide [Ca2(Co0:65Cu0:35)2O4]0:63CoO2. Jpn. J. Appl. Phys. 2003, 42, 7467–7473. [Google Scholar] [CrossRef]

- Liou, Y.C.; Tsai, W.C.; Lin, W.Y.; Lee, U.R. Synthesis of Ca3Co4O9 and CuAlO2 Ceramics of the Thermoelectric Application Using A Reaction- Sintering Proces. J. Aust. Ceram. Soc. 2008, 44, 17–22. [Google Scholar]

- Rouessac, V.; Wang, J.; Provost, J.; Desgardin, G. Processing and superconducting properties of highly textured Bi(Pb)-2223 ceramics by sinter-forging. Phys. C 1996, 268, 225. [Google Scholar] [CrossRef]

- Prevel, M.; Lemonnier, S.; Klein, Y.; Hébert, S.; Chateigner, D.; Ouladdiaf, B.; Noudem, J.G. Textured Ca3Co4O9 thermoelectric oxides by thermo-forging process. J. Appl. Phys. 2005, 98, 093706-9. [Google Scholar] [CrossRef]

- Kenfaui, D.; Lenoir, B.; Chateigner, D.; Ouladdiaf, B.; Gomina, M.; Noudem, J.G. Development of multilayer textured Ca3Co4O9 materials for thermoelectric generators: Influence of the anisotropy on the transport properties. J. Eur. Ceram. Soc. 2012, 32, 2405–2414. [Google Scholar] [CrossRef]

- Tang, G.D.; Guo, H.H.; Yang, T.; Zhang, D.W.; Xu, X.N.; Wang, L.Y.; Wang, Z.H.; Wen, H.H.; Zhang, Z.D.; Du, Y.W. Anisotropic thermopower and magnetothermopower in a misfit-layered calcium cobaltite. Appl. Phys. Lett. 2011, 98, 202109. [Google Scholar] [CrossRef]

- Soret, J.; Lepetit, M. Electronic structure of the Ca3Co4O9 compound from ab initio local interactions. Phys. Rev. B 2012, 85, 165145. [Google Scholar] [CrossRef]

- Ren, W.L.; Li, C.C.; Zhang, L.T.; Ito, K.; Wu, J.S. Effects of Ge and B substitution on thermoelectric properties of CoSi. J. Alloys Comp. 2005, 392, 50. [Google Scholar] [CrossRef]

- Asanabe, S.; Shinoda, D.; Saski, Y. Semimetallic Properties of Co1-xFexSi Solid Solutions. Phys. Rev. A 1964, 134, 774. [Google Scholar] [CrossRef]

- Koshibae, W.; Tsutui, K.; Maekawa, S. Thermopower in cobalt oxides. Phys. Rev. B 2000, 62, 6869. [Google Scholar] [CrossRef]

- Noudem, J.G.; Guilmeau, E.G.; Chateigner, D. Recent developments in processing and performance of hot stacked-sinter forged Bi2223 ceramics. Phys. C 2003, 391, 265. [Google Scholar] [CrossRef]

- Guilmeau, E.; Noudem, J.G. Influence of the sinter-forging temperature on the superconducting properties of Bi2223 textured discs. Supercond. Sci. Technol. 2002, 15, 1566–1570. [Google Scholar] [CrossRef]

- Wang, Y.; Sui, Y.; Cheng, J.; Wang, X.; Su, W. The thermal-transport properties of the Ca3−xAgxCo4O9 system (0 ≤ x ≤ 0.3). J. Phys. Condens. Matter. 2007, 19, 356216–356226. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

NOUDEM, J.G.; XING, Y. Overview of Spark Plasma Texturing of Functional Ceramics. Ceramics 2021, 4, 97-107. https://doi.org/10.3390/ceramics4010009

NOUDEM JG, XING Y. Overview of Spark Plasma Texturing of Functional Ceramics. Ceramics. 2021; 4(1):97-107. https://doi.org/10.3390/ceramics4010009

Chicago/Turabian StyleNOUDEM, Jacques G., and Yiteng XING. 2021. "Overview of Spark Plasma Texturing of Functional Ceramics" Ceramics 4, no. 1: 97-107. https://doi.org/10.3390/ceramics4010009

APA StyleNOUDEM, J. G., & XING, Y. (2021). Overview of Spark Plasma Texturing of Functional Ceramics. Ceramics, 4(1), 97-107. https://doi.org/10.3390/ceramics4010009