Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations

Abstract

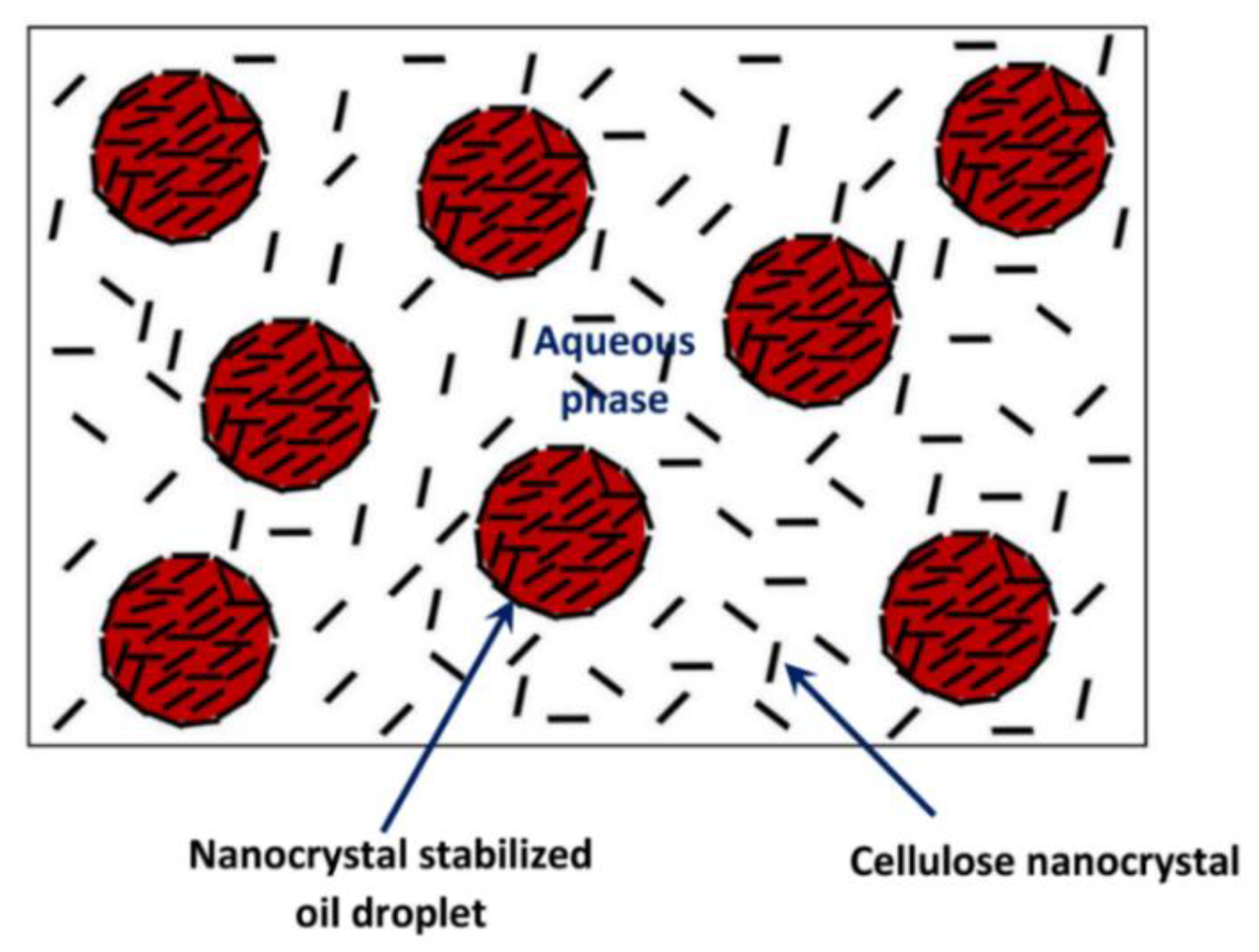

1. Introduction

2. Materials and Methods

2.1. Preparation of Nanocrystalline Cellulose Dispersions

2.2. Preparation of O/W Emulsions

2.3. Measurements

3. Results and Discussion

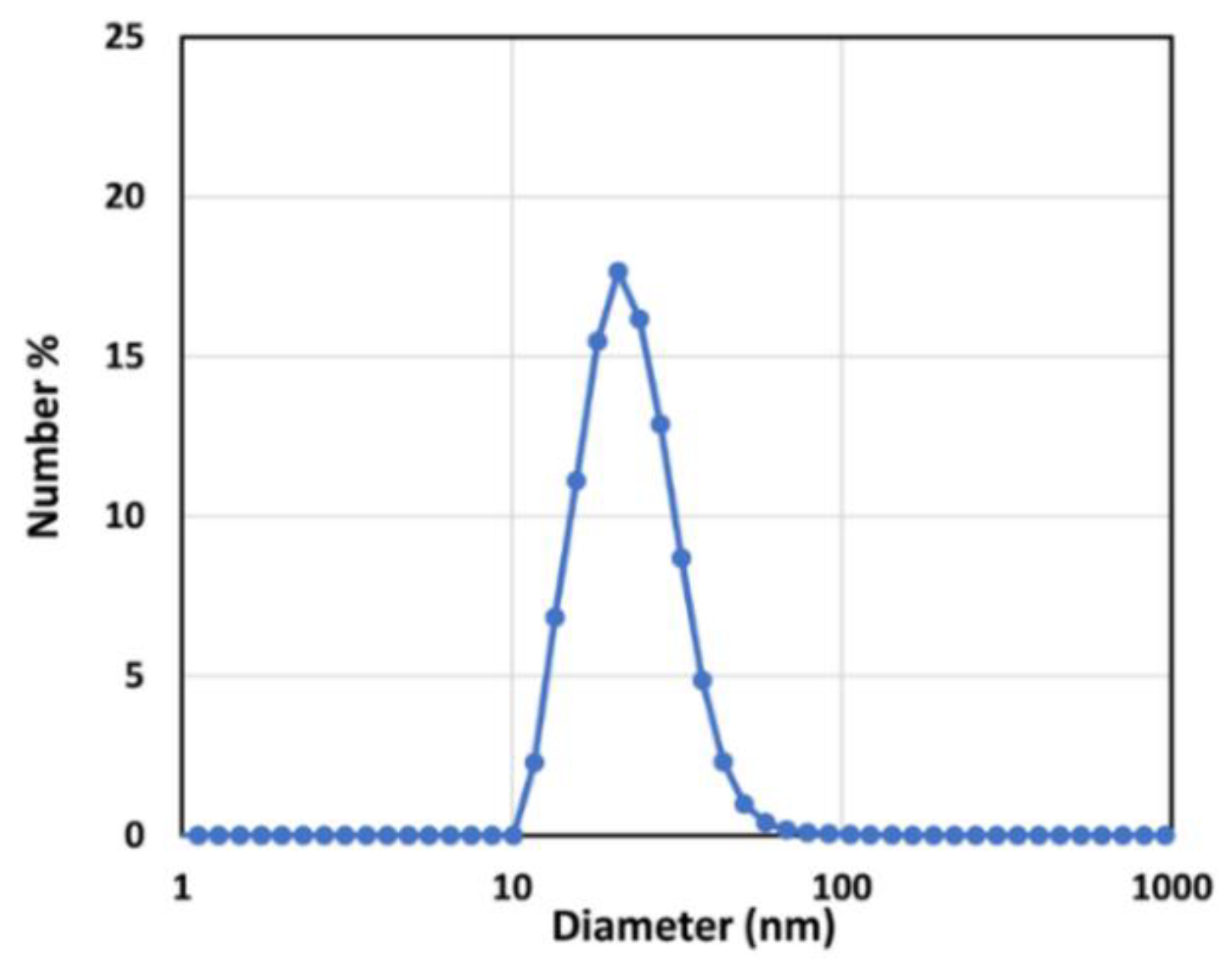

3.1. Rheology of Nanocrystalline Cellulose Dispersions

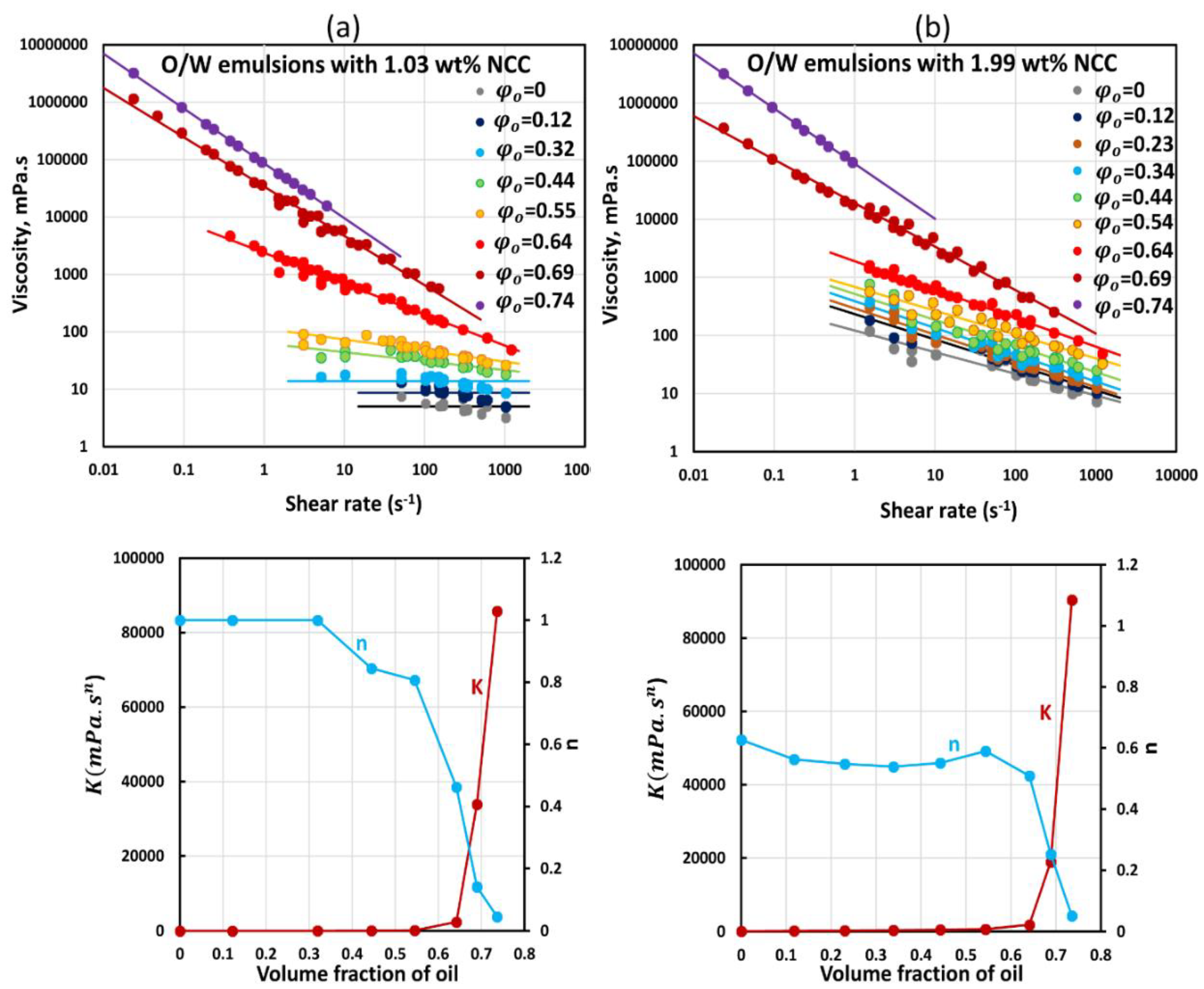

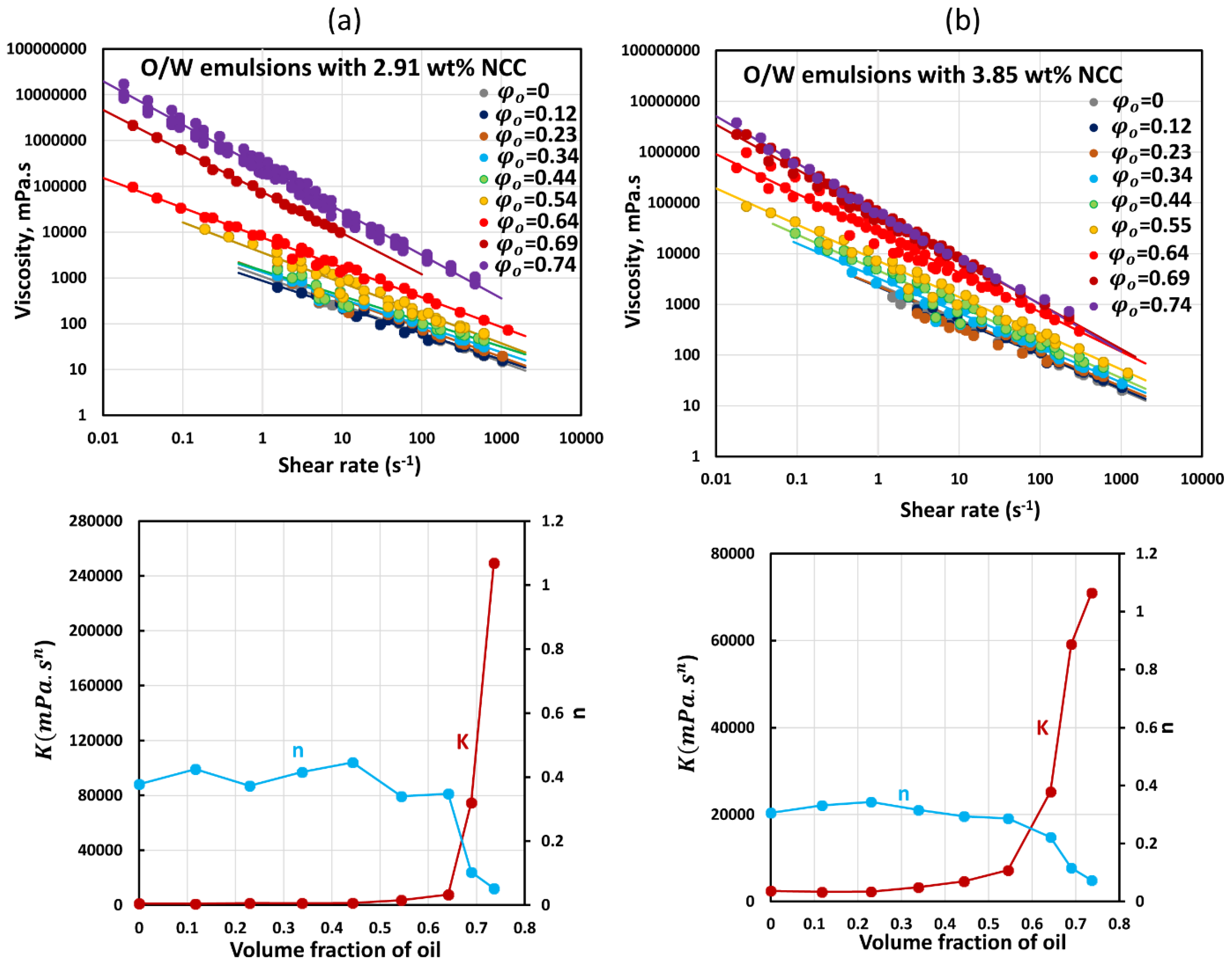

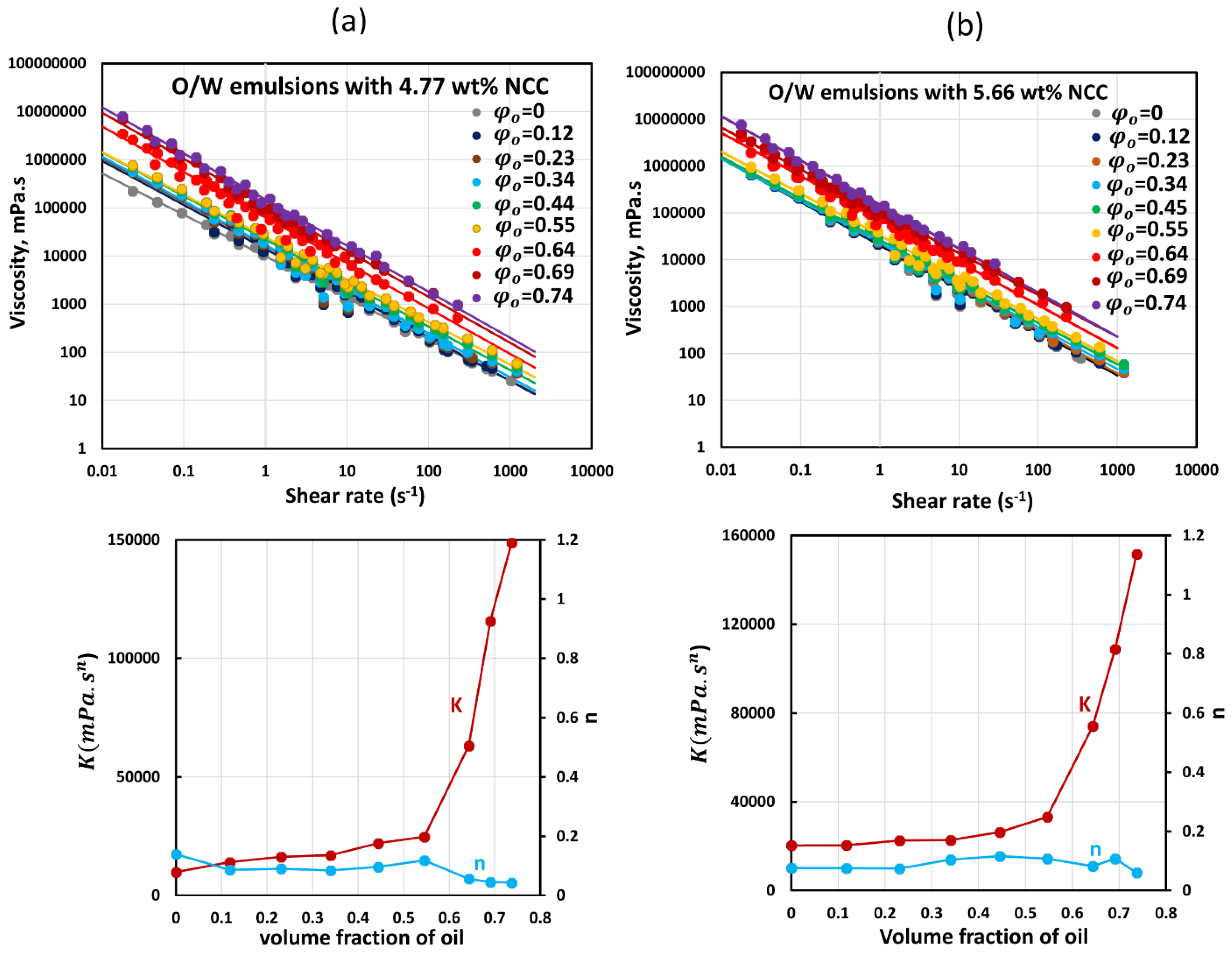

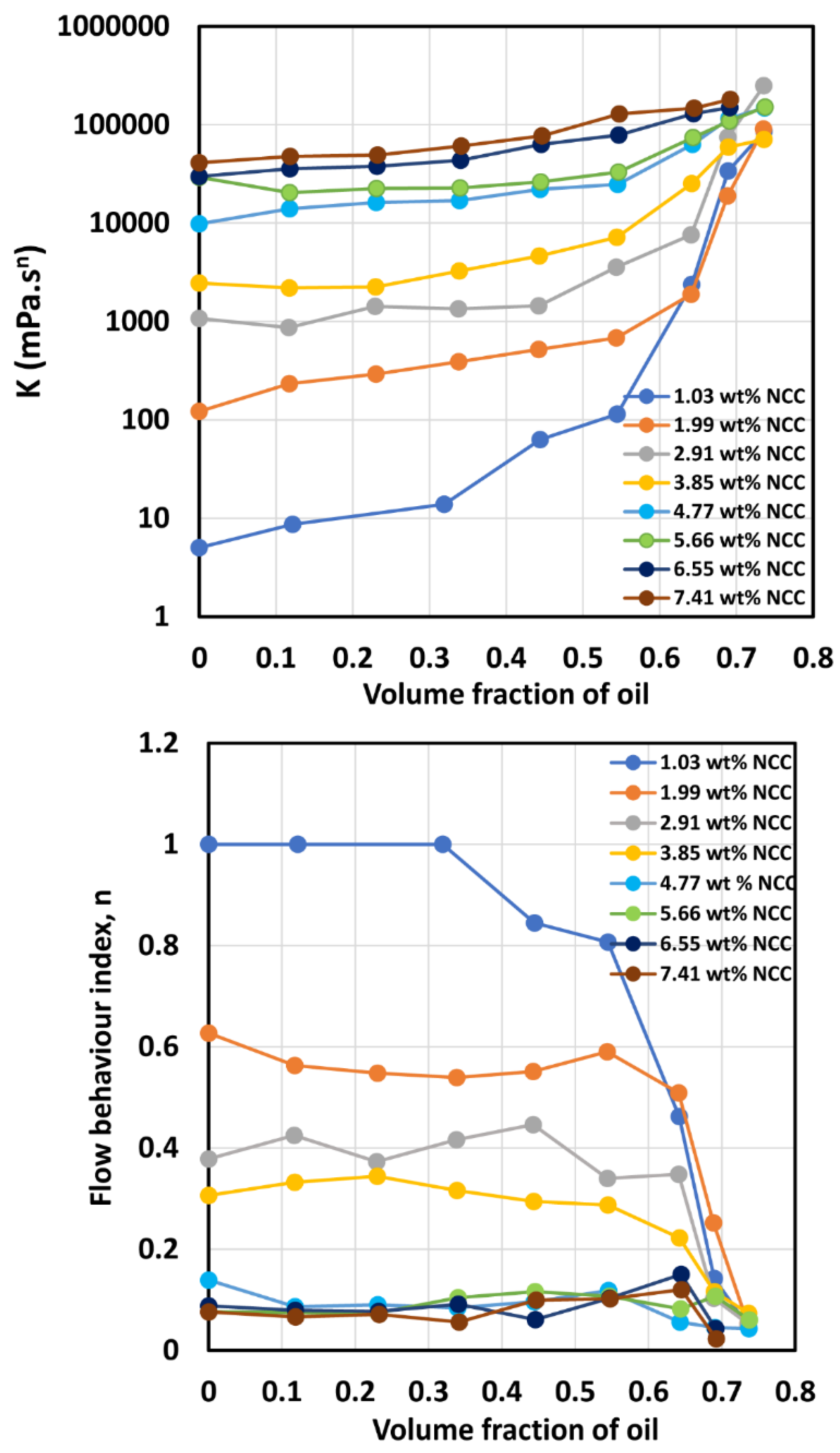

3.2. Rheology of O/W Emulsions Stabilized and Thickened by Nanocrystalline Cellulose

- Emulsions are Newtonian at low oil concentrations () and low NCC concentration (1.03 wt%).

- Emulsions are shear-thinning non-Newtonian; that is, viscosity decreases with the increase in shear rate, when the NCC concentration is 1.99 wt%, regardless of the oil concentration.

- The viscous flow behavior of emulsions can be described very well using the power law model (see Equations (1) and (2)); that is, the decrease in viscosity with the increase in shear rate exhibits a linear relationship on a log–log plot.

- The consistency index increases with the increase in oil concentration at any given NCC concentration.

- The flow behavior index of non-Newtonian emulsions is generally well below a value of unity indicating a severe shear-thinning nature of emulsions.

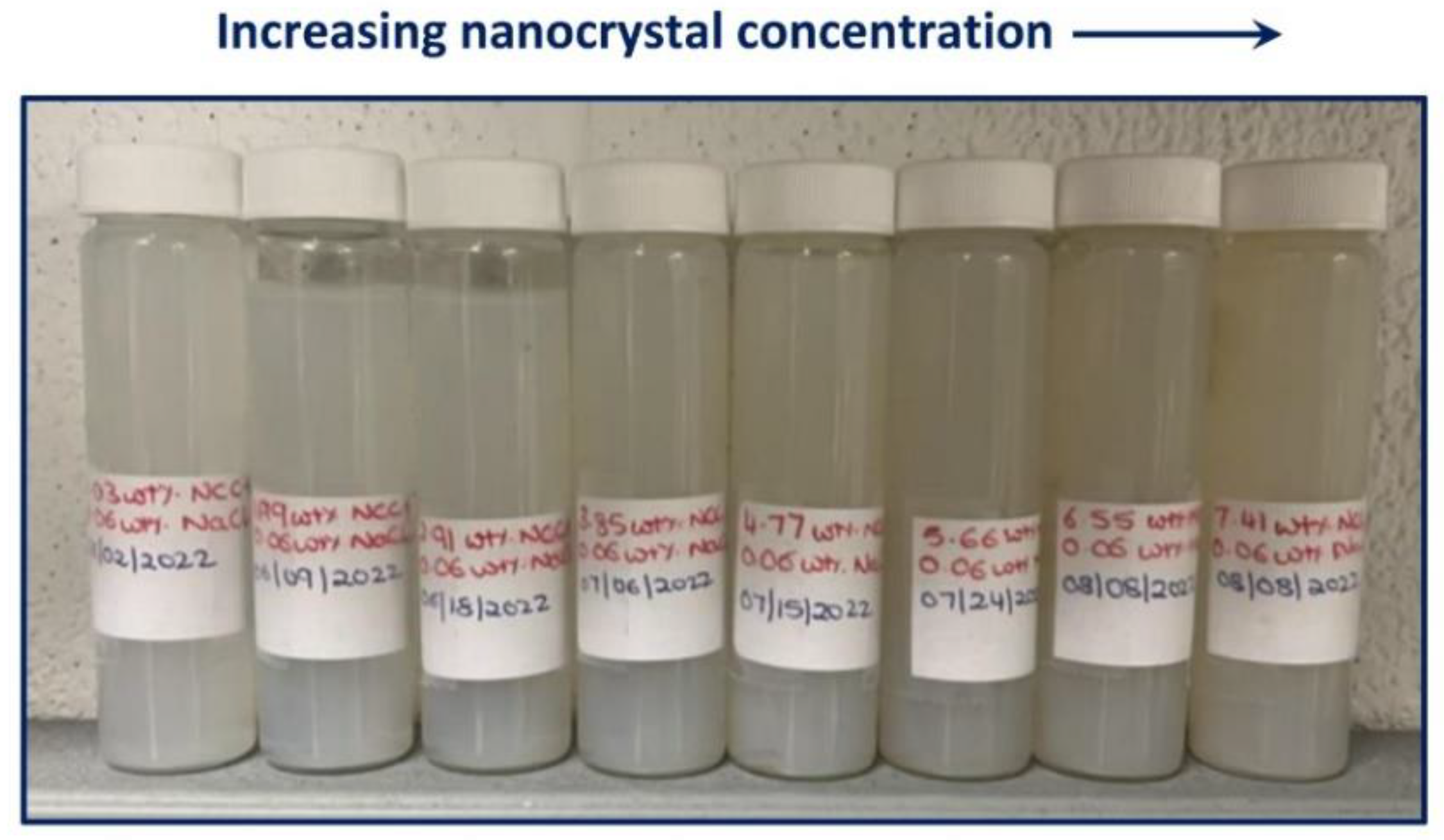

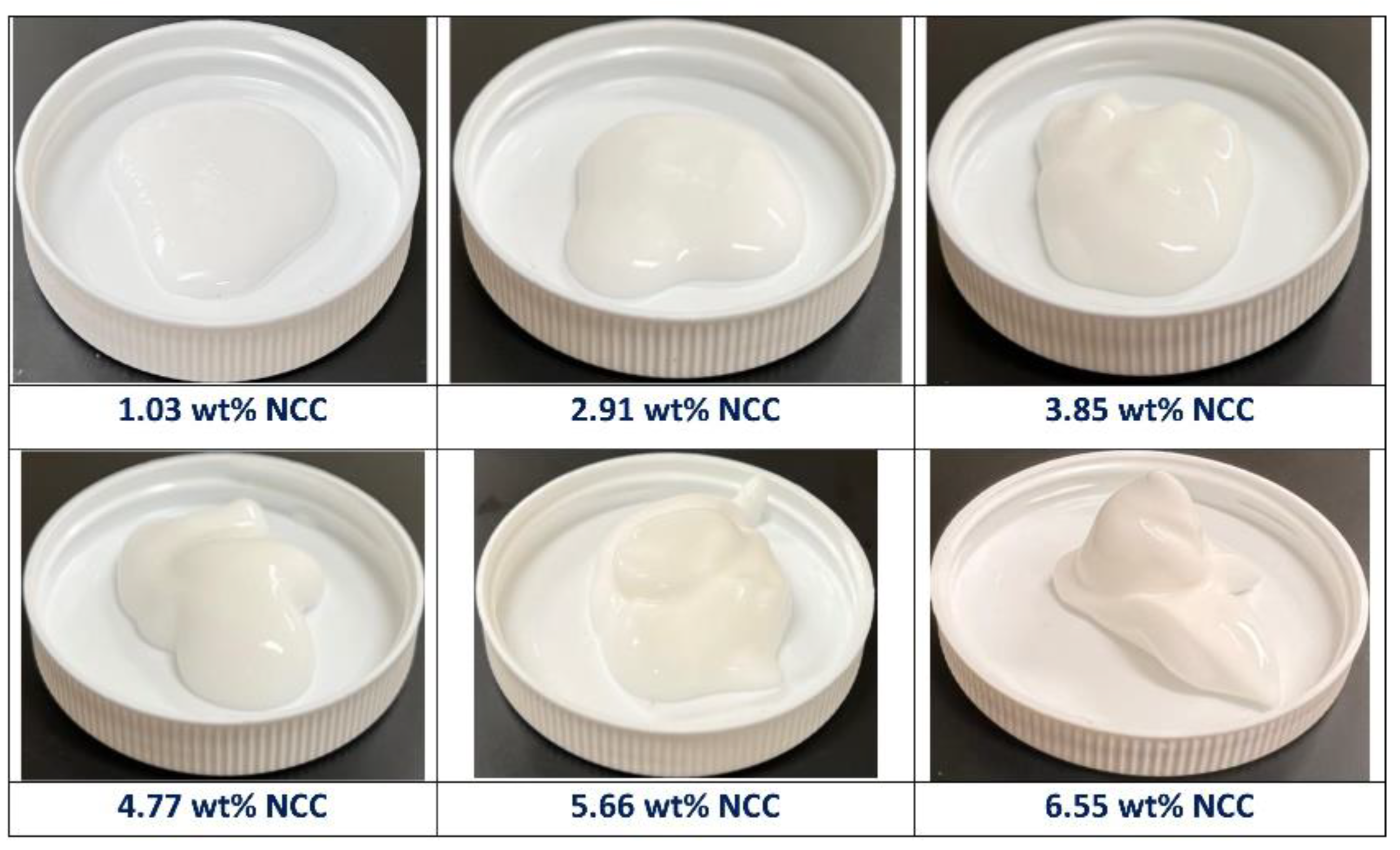

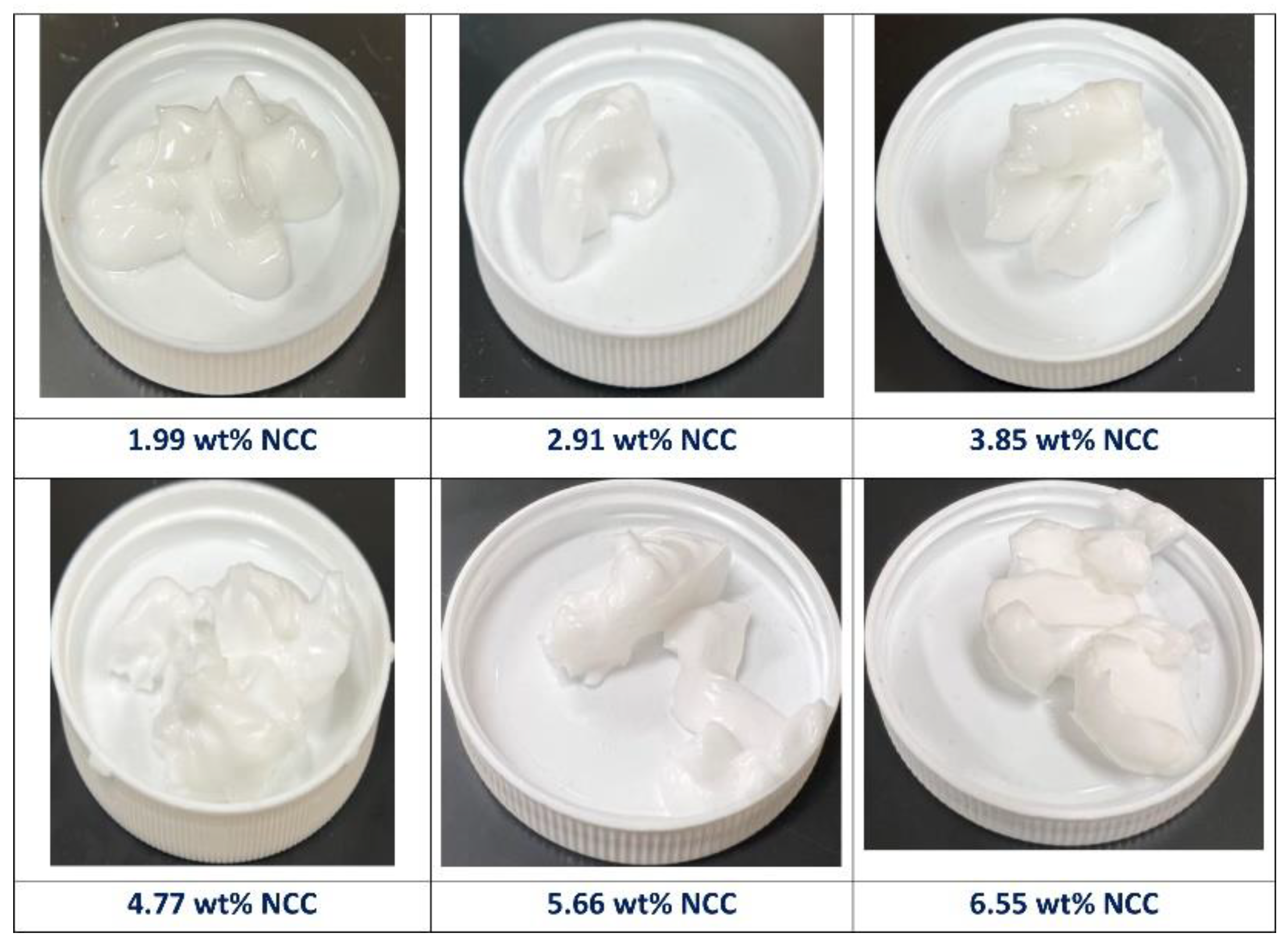

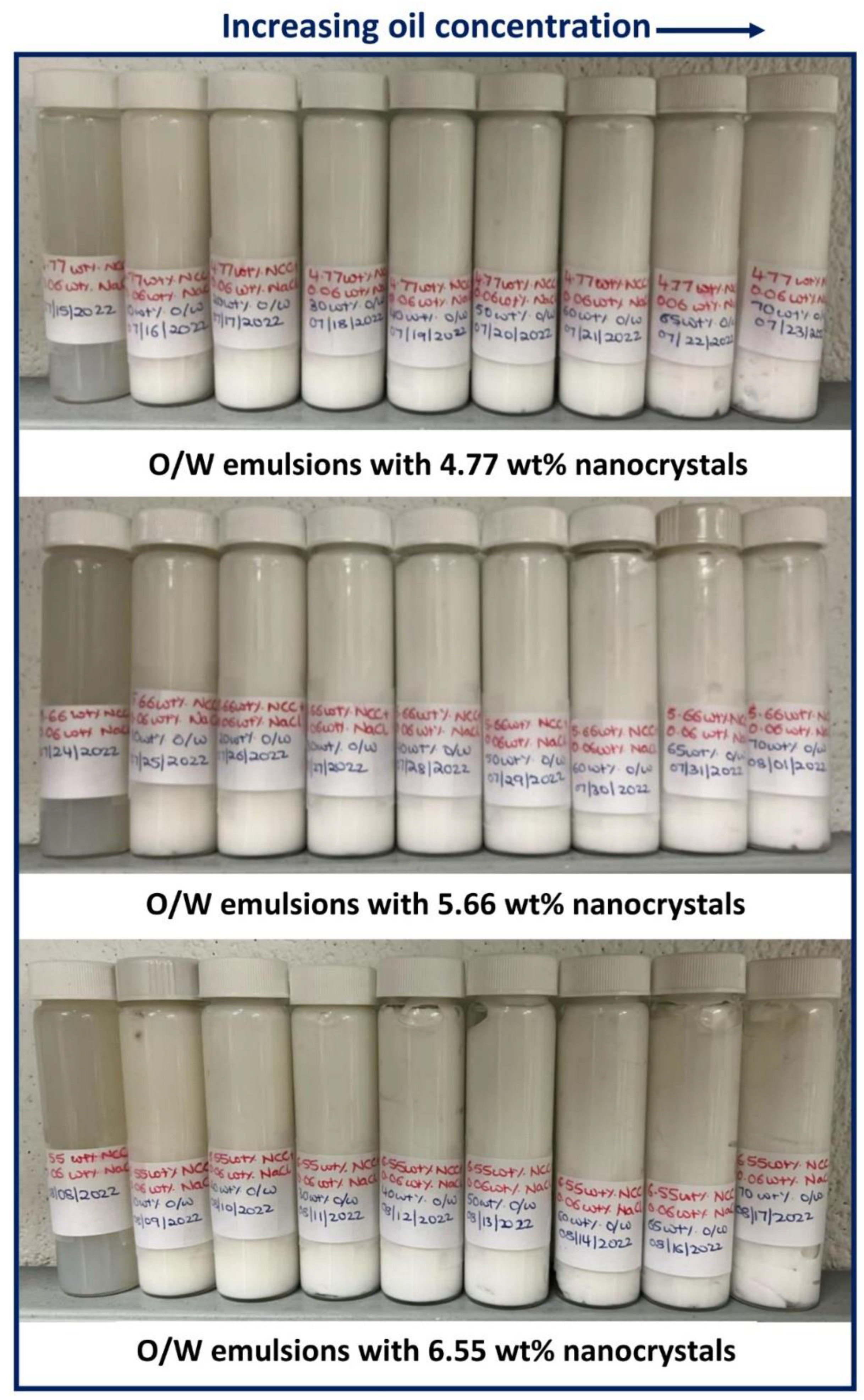

3.3. Physical Appearance and Stability of Emulsions

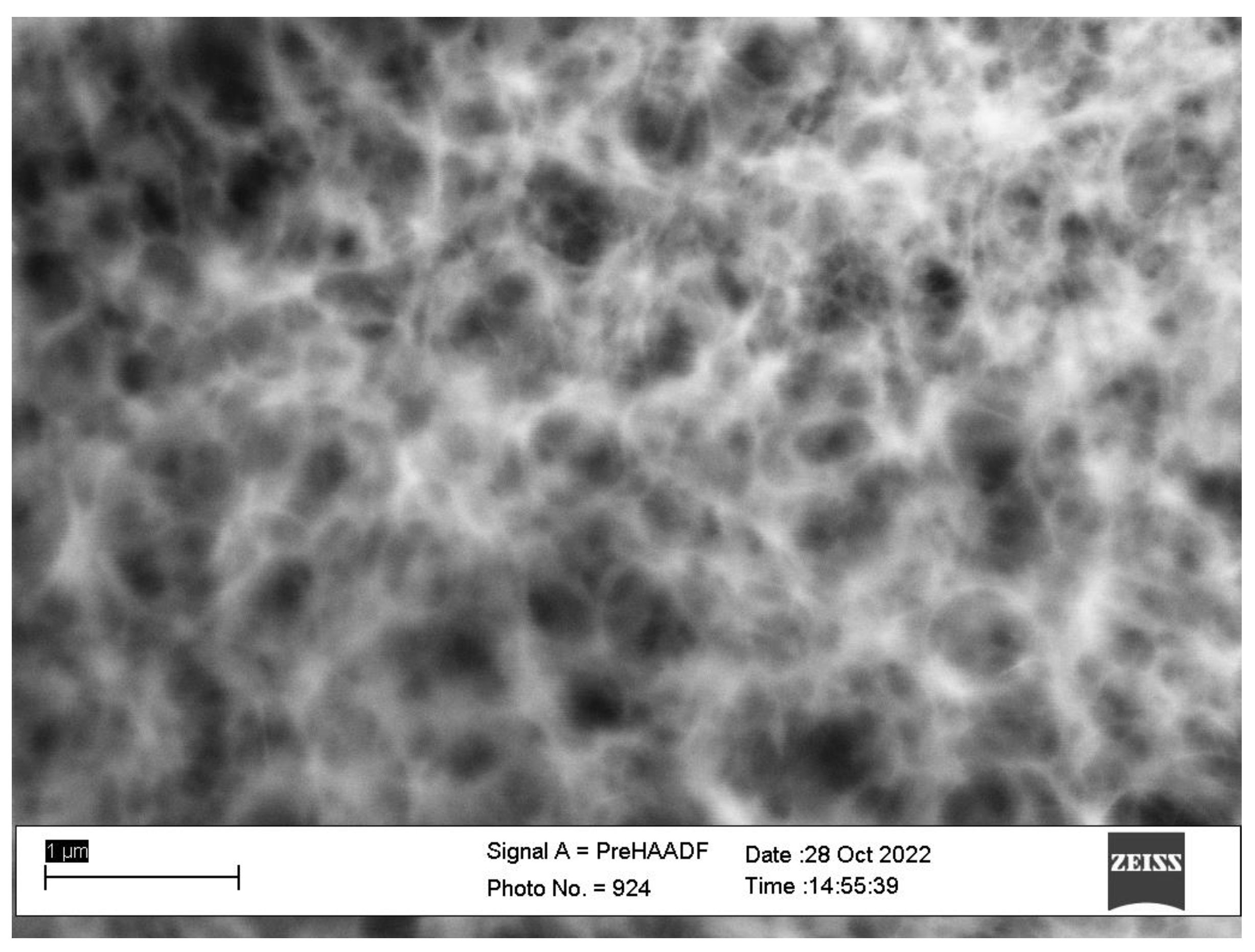

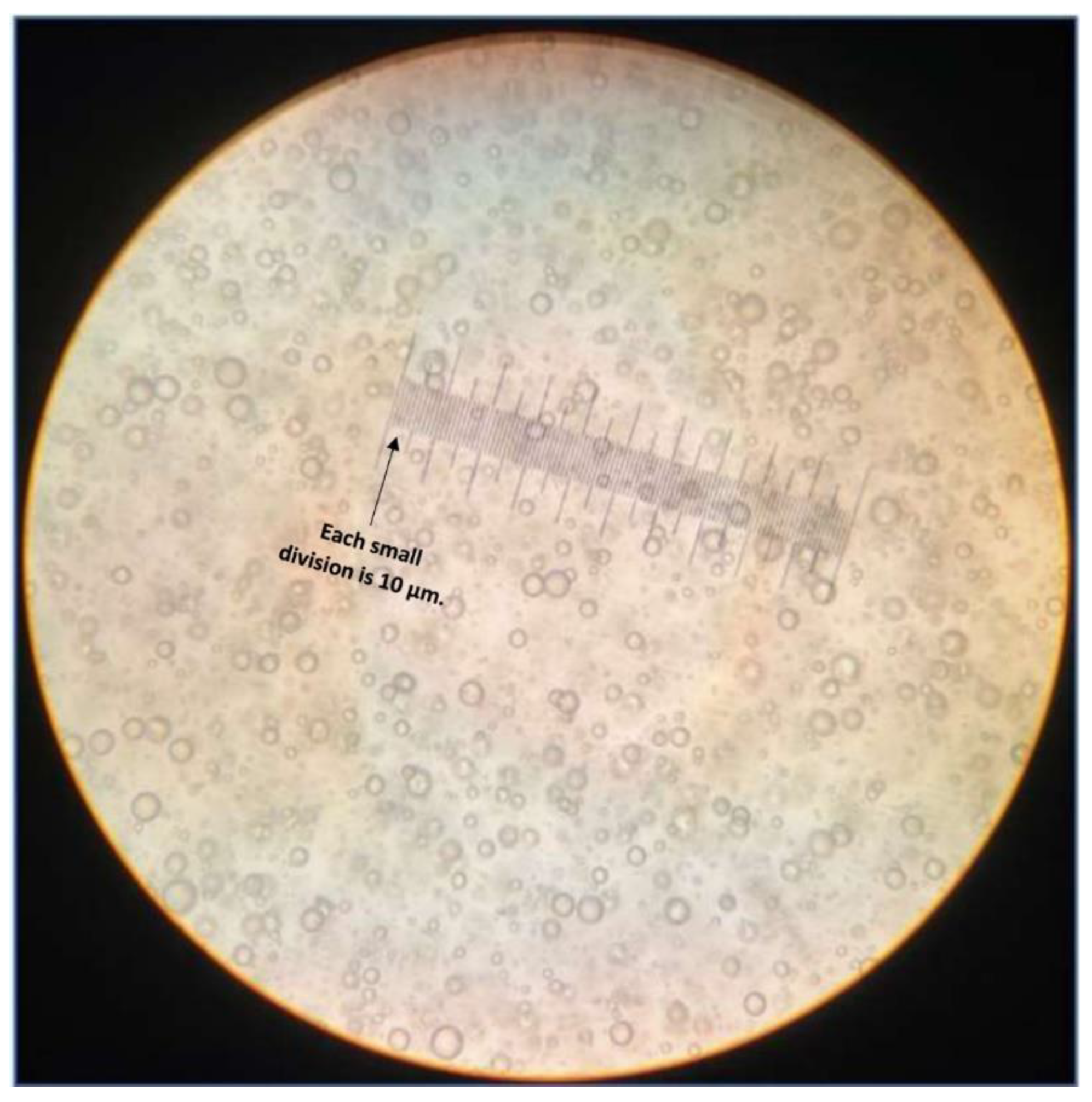

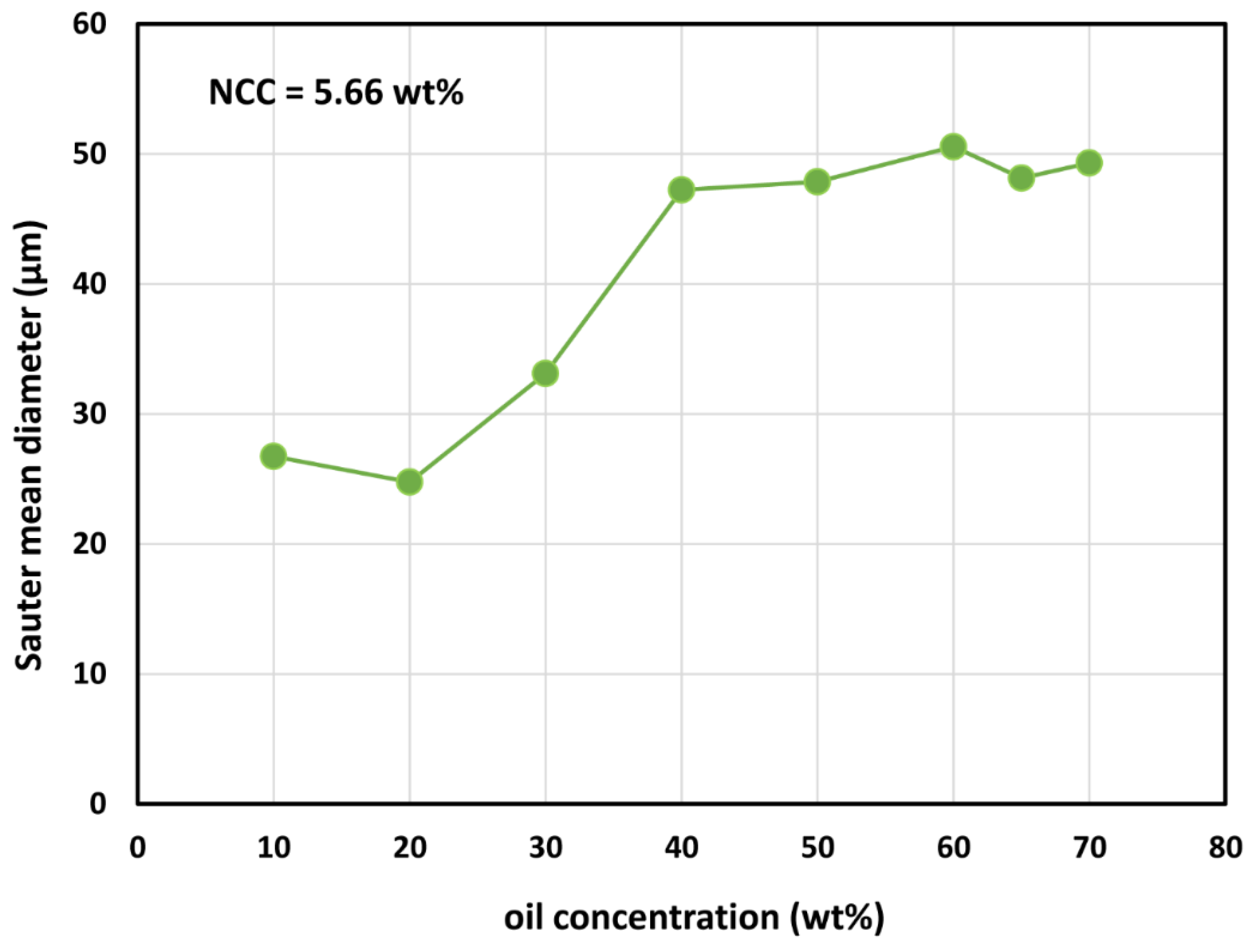

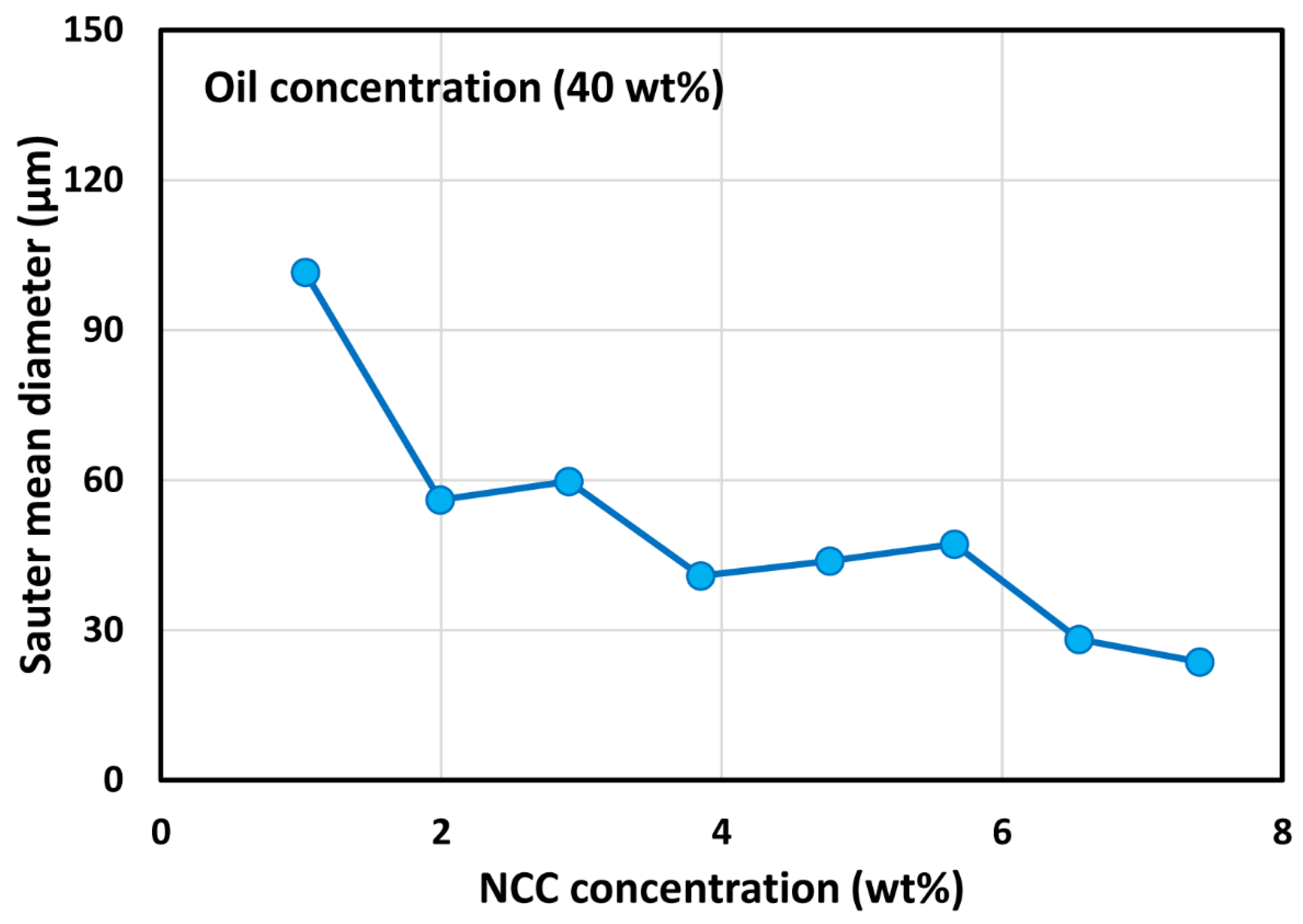

3.4. Droplet Size of Emulsions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prathapan, R.; Thapa, R.; Garnier, G.; Tabor, R.F. Modulating the zeta potential of cellulose nanocrystals using salts and surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2016, 509, 11–18. [Google Scholar] [CrossRef]

- Lu, P.; Hsieh, Y. Preparation and properties of cellulose nanocrystals: Rods, spheres, and network. Carbohydr. Polym. 2010, 82, 329–336. [Google Scholar] [CrossRef]

- Girard, M.; Vidal, D.; Bertrand, F.; Tavares, J.R.; Heuzey, M. Evidence-based guidelines for the ultrasonic dispersion of cellulose nanocrystals. Ultrason. Sonochem. 2021, 71, 105378. [Google Scholar] [CrossRef] [PubMed]

- Shojaeiarani, J.; Bajwa, D.S.; Chanda, S. Cellulose nanocrystal-based composites: A review. Compos. Part C Open Access 2021, 5, 100164. [Google Scholar] [CrossRef]

- Yang, X.; Biswas, S.K.; Han, J.; Tanpichai, S.; Li, M.; Chen, C.; Zhu, S.; Das, A.K.; Yano, H. Surface and interface engineering for nanocellulosic advanced materials. Adv. Mater. 2021, 33, 2002264. [Google Scholar] [CrossRef] [PubMed]

- Trache, D.; Hussin, M.H.; Haafiz, M.K.M.; Thakur, V.K. Recent progress in cellulose nanocrystals: Sources and production. Nanoscale 2017, 9, 1763–1786. [Google Scholar] [CrossRef]

- Aziz, T.; Fan, H.; Zhang, X.; Haq, A.; Ullah, R.; Khan, F.U.; Iqbal, M. Advance study of cellulose nanocrystals properties and applications. J. Polym. Environ. 2020, 28, 1117–1128. [Google Scholar] [CrossRef]

- Aziz, T.; Ullah, A.; Fan, H.; Ullah, R.; Haq, F.; Khan, F.U.; Iqbal, M.; Wei, J. Cellulose nanocrystals applications in health, medicine, and catalysis. J. Polym. Environ. 2021, 29, 2062–2071. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose processing properties and potential applications. Curr. For. Rep. 2019, 5, 76–89. [Google Scholar] [CrossRef]

- Vanderfleet, O.M.; Cranston, E.D. Production routes to tailor the performance of cellulose nanocrystals. Nat. Rev. Mater. 2021, 6, 124–144. [Google Scholar] [CrossRef]

- Panchal, P.; Ogunsona, E.; Mekonnen, T. Trends in advanced functional material applications of nanocellulose. Processes 2019, 7, 10. [Google Scholar] [CrossRef]

- Zhang, H.; Dou, C.; Pal, L.; Hubbe, M.A. Review of electrically conductive composites and films containing cellulosic fibers or nanocellulose. BioResources 2019, 14, 7494–7542. [Google Scholar] [CrossRef]

- Gupta, A.; Mekonnen, T.H. Cellulose nanocrystals enabled sustainable polycaprolactone based shape memory polyurethane bionanocomposites. J. Colloid Interface Sci. 2022, 611, 726–738. [Google Scholar] [CrossRef]

- Cellulose Nanocrystals (CNC). Available online: https://celluforce.com/cellulose-nanocrystals-cnc/ (accessed on 26 February 2023).

- Zhu, S.; Lu, Y.; Wang, S.; Sun, H.; Yue, Y.; Xu, X.; Mei, C.; Xiao, H.; Fu, Q.; Han, J. Interface design of stretchable and environment-tolerant strain tensors with hierarchical nanocellulose-supported graphene nanocomplexes. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107313. [Google Scholar] [CrossRef]

- Lu, Y.; Yue, Y.; Ding, Q.; Mei, C.; Xu, X.; Wu, Q.; Xiao, H.; Han, J. Self-recovery, fatigue-resistant, and multifunctional sensor assembled by a nanocellulose/carbon nanotube nanocomplex-mediated hydrogel. Appl. Mater. Interfaces 2021, 13, 50281–50297. [Google Scholar] [CrossRef]

- Zhu, S.; Sun, H.; Lu, Y.; Wang, S.; Yue, Y.; Xu, X.; Mei, C.; Xiao, H.; Fu, Q.; Han, J. Inherently conductive poly(dimethylsiloxane) elastomers synergistically mediated by nanocellulose/carbon nanotube nanohybrids toward highly sensitive, stretchable, and durable strain sensors. Appl. Mater. Interfaces 2021, 13, 59142–59153. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, H.; Xu, X.; Han, F.; Lubineau, G. Ultrasensitive, stretchable strain sensors based on fragmented carbon nanotube papers. Appl. Mater. Interfaces 2017, 9, 4835–4842. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Lu, Y.; Chen, Y.; Yue, Y.; Jiang, S.; Xu, X.; Mei, C.; Xiao, H.; Han, J. Flexible environment-tolerant electroluminescent devices based on nanocellulose-mediated transparent electrodes. Carbohydr. Polym. 2022, 296, 119891. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Cheng, W.; Cao, M.; Wang, D.; Wang, Q.; Han, J.; Long, Y.; Han, G. Recent advances in cellulose-based flexible triboelectric nanogenerators. Nano Energy 2021, 87, 106175. [Google Scholar] [CrossRef]

- Wang, J.; Euring, M.; Ostendorf, K.; Zhang, K. Biobased materials for food packaging. J. Bioresour. Bioprod. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Li, Y.; Chen, Y. Stabilization of oil-in-water emulsions by nanocellulose: A review. J. Colloid Interface Sci. 2018, 518, 12–22. [Google Scholar]

- Le, H.D.; Loveday, S.M.; Singh, H.; Sarkar, A. Pickering emulsion stabilized by hydrophobically modified cellulose nanocrystals: Responsiveness to pH and ionic strength. Food Hydrocoll. 2020, 99, 105344. [Google Scholar]

- Dong, H.; Ding, Q.; Jiang, Y.; Han, W. Pickering emulsions stabilized by spherical cellulose nanocrystals. Carbohydr. Polym. 2021, 265, 118101. [Google Scholar] [CrossRef] [PubMed]

- Varanasi, S.; Henzel, L.; Mendoza, L.; Prathapan, R.; Batchelor, W.; Tabor, R.; Garnier, G. Pickering emulsion electrostatically stabilized by cellulose nanocrystals. Front. Chem. 2018, 6, 409. [Google Scholar] [CrossRef]

- Ma, T.; Cui, R.; Lu, S.; Hu, X.; Xu, B.; Song, Y.; Hu, X. High internal phase Pickering emulsion stabilized by cellulose nanocrystals for 3D printing. Food Hydrocoll. 2022, 125, 107418. [Google Scholar] [CrossRef]

- Saidane, D.; Perrin, E.; Cherhal, F.; Guellec, F.; Capron, I. Some modification of cellulose nanocrystals for functional Pickering emulsions. Philos. Trans. R. Soc. A 2016, 374, 20150139. [Google Scholar] [CrossRef]

- Wu, B.; Yang, C.; Xin, Q.; Kong, L.; Eggersdorfer, M.; Ruan, J.; Zhao, P.; Shan, J.; Liu, K.; Chen, D.; et al. Attractive Pickering emulsion gels. Adv. Mater. 2021, 33, 2102362. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Yang, C.; Wang, F.; Wu, B.; Shao, B.; Li, Z.; Chen, D.; Yang, Z.; Liu, K. Biocompatible and pH-responsive colloidal surfactants with tunable shape for controlled interfacial curvature. Angew. Chem. 2020, 59, 9365–9369. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Yan, X.; Xiao, Y.; Hu, L.; Eggersdorfer, M.; Chen, D.; Yang, Z.; Weitz, D.A. Pickering emulsions stabilized by colloidal surfactants: Role of solid particles. Particuology 2022, 64, 153–163. [Google Scholar] [CrossRef]

- Ataeian, P.; Shi, Q.; Ioannidis, M.; Tam, K.C. Effect of hydrophobic modification of cellulose nanocrystal (CNC) and salt addition on Pickering emulsions undergoing phase-transition. Carbohydr. Polym. Technol. Appl. 2022, 3, 100201. [Google Scholar]

- Ni, Y.; Fan, L.; Sun, Y. Interfacial properties of cellulose nanoparticles with different lengths from ginkgo seed shells. Food Hydrocoll. 2020, 109, 106121. [Google Scholar] [CrossRef]

- Saffarionpour, S. Nanocellulose for stabilization of Pickering emulsions and delivery of nutraceuticals and its interfacial adsorption mechanism. Food Bioprocess Technol. 2020, 13, 1292–1328. [Google Scholar] [CrossRef]

- Capron, I.; Rojas, O.J.; Bordes, R. Behavior of nanocellulose at interfaces. Curr. Opin. Colloid Interface Sci. 2017, 29, 83–95. [Google Scholar] [CrossRef]

- Gong, X.; Wang, Y.; Chen, L. Enhanced emulsifying properties of wood-based nanocrystals as Pickering emulsion stabilizer. Carbohydr. Polym. 2017, 169, 295–303. [Google Scholar] [CrossRef] [PubMed]

- Kalashnikova, I.; Bizot, H.; Cathal, B.; Capron, I. New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir 2011, 27, 7421–7479. [Google Scholar] [CrossRef]

- Aw, Y.Z.; Lim, H.P.; Low, L.E.; Singh, S.K.S.; Chan, E.S.; Tey, B.T. Cellulose nanocrystal (CNC)-stabilized Pickering emulsion for improved curcumin storage stability. LWT 2022, 159, 113249. [Google Scholar] [CrossRef]

- Pal, R. Rheology of Particulate Dispersions and Composites; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Pal, R. Rheology of polymer-thickened emulsions. J. Rheol. 1992, 36, 1245–1259. [Google Scholar] [CrossRef]

- Pal, R. Effect of droplet size on the rheology of emulsions. AICHE J. 1996, 42, 3181–3190. [Google Scholar] [CrossRef]

- Pal, R. Rheology of high internal phase ratio emulsions. Food Hydrocoll. 2006, 20, 997–1005. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, H.; Liu, W.; Zou, L.; McClements, D.J. A review of the rheological properties of dilute and concentrated food emulsions. J. Texture Stud. 2020, 51, 45–55. [Google Scholar] [CrossRef]

- Morfo, Z.; Murray, B.S.; Sarkar, A. Water-in-oil emulsions stabilized by surfactants, biopolymers and/or particles: A review. Trends Food Sci. Technol. 2020, 104, 49–59. [Google Scholar]

- Sarkar, A.; Dickinson, E. Sustainable food-grade Pickering emulsions stabilized by plant-based particles. Curr. Opin. Colloid Interface Sci. 2020, 49, 69–81. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, Z.; Chen, X.; Zhang, W.; Xie, Y.; Chen, Y.; Liu, Z.; Yuan, W. An overview of Pickering emulsions: Solid-particle materials, classification, morphology, and applications. Front. Pharmacol. 2017, 8, 287. [Google Scholar] [CrossRef]

- Angkuratipakorn, T.; Sriprai, A.; Tantrawong, S.; Chaiyasit, W.; Singkhoonrat, J. Fabrication and characterization of rice bran oil-in-water Pickering emulsion stabilized by cellulose nanocrystals. Colloids Surf. A Physicochem. Eng. Asp. 2017, 522, 310–319. [Google Scholar] [CrossRef]

- Pal, R. A simple model for the viscosity of Pickering emulsions. Fluids 2017, 3, 2. [Google Scholar] [CrossRef]

- Binks, B.P.; Clint, J.H.; Whitby, C.P. Rheological behavior of water-in-oil emulsions stabilized by hydrophobic bentonite particles. Langmuir 2005, 21, 5307–5316. [Google Scholar] [CrossRef]

- Wolf, B.; Lam, S.; Kirkland, M.; Frith, W.J. Shear-thickening of an emulsion stabilized with hydrophilic silica particles. J. Rheol. 2007, 51, 465–478. [Google Scholar] [CrossRef]

- Katepalli, H.; John, V.T.; Tripathi, A.; Bose, A. Microstructure and rheology of particle stabilized emulsions: Effects of particle shape and inter-particle interactions. J. Colloid Interface Sci. 2017, 485, 11–17. [Google Scholar] [CrossRef]

- Braisch, B.; Kohler, K.; Schuchmann, H.P.; Wolf, B. Preparation and flow behavior of oil-in-water emulsions stabilized by hydrophilic silica particles. Chem. Eng. Technol. 2009, 32, 1107–1112. [Google Scholar] [CrossRef]

- Ganley, W.J.; Van Duijneveldt, J.S. Controlling the rheology of montmorillonite stabilized oil-in-water emulsions. Langmuir 2017, 33, 1679–1686. [Google Scholar] [CrossRef] [PubMed]

- Hermes, M.; Clegg, P.S. Yielding and flow of concentrated Pickering emulsions. Soft Matter 2013, 9, 7568–7575. [Google Scholar] [CrossRef]

- Lee, E.; Kim, D.; Kim, K. Distinctive rheological properties of Pickering emulsions: From their origin to the applications. Korea-Aust. Rheol. J. 2022, 34, 91–103. [Google Scholar] [CrossRef]

- Miao, C.; Mirvakili, M.; Hamad, W.Y. A rheological investigation of oil-in-water Pickering emulsions stabilized by cellulose nanocrystals. J. Colloid Interface Sci. 2022, 608, 2820–2829. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.; Derakhshandeh, M.; Kedzior, S.A.; Pilapil, B.; Shomrat, N.; Segal-Peretz, T.; Bryant, S.L.; Trifkovic, M. Role of interparticle interactions on microstructural and rheological properties of cellulose nanocrystal stabilized emulsions. J. Colloid Interface Sci. 2018, 532, 808–818. [Google Scholar] [CrossRef]

- Bai, L.; Lv, S.; Xiang, W.; Huan, S.; McClements, D.J. Oil-in-water Pickering emulsions via microfluidization with cellulose nanocrystals: 1. Formation and stability. Food Hydrocoll. 2019, 96, 699–708. [Google Scholar] [CrossRef]

- Velandia, S.F.; Marchal, P.; Lemaitre, C.; Sadtler, V.; Roques-Carmes, T. Evaluation of the repartition of the particles in Pickering emulsions in relation with their rheological properties. J. Colloid Interface Sci. 2021, 589, 286–297. [Google Scholar] [CrossRef]

- Shafiei-Sabet, S.; Hamad, W.Y.; Hatzikiriakos, S.G. Rheology of nanocrystalline cellulose aqueous suspensions. Langmuir 2012, 28, 17124–17133. [Google Scholar] [CrossRef]

- Kadar, R.; Fazilati, M.; Nypelo, T. Unexpected microphase transitions in flow towards nematic order of cellulose nanocrystals. Cellulose 2020, 27, 2003–2014. [Google Scholar] [CrossRef]

- Pignon, F.; Challamel, M.; De Geyer, A.; Elchamaa, M.; Semeraro, E.F.; Hengl, N.; Jean, B.; Putaux, J.; Gicquel, E.; Bras, J.; et al. Breakdown and buildup mechanisms of cellulose nanocrystal suspensions under shear and upon relaxation probed by SAXS and SALS. Carbohydr. Polym. 2021, 260, 117751. [Google Scholar] [CrossRef]

- Wu, Q.; Meng, Y.; Wang, S.; Li, Y.; Fu, S.; Ma, L.; Harper, D. Rheological behavior of cellulose nanocrystal suspension: Influence of concentration and aspect ratio. J. Appl. Polym. Sci. 2014, 131, 40525. [Google Scholar] [CrossRef]

| Nanocrystal Concentration of Matrix Phase (wt%) | Oil Concentration of Emulsion (wt%) | Oil Concentration of Emulsion (vol%) |

|---|---|---|

| 1.03 | Seven concentrations: 10.49, 28.42, 40.38, 50.32, 60.28, 65.27, 70.26 | Seven concentrations: 12.17, 31.93, 44.45, 54.47, 64.20, 68.95, 73.62 |

| 1.99 | Eight concentrations: 10.10, 20.16, 30.15, 40.13, 50.12, 60.10, 65.10, 70.12 | Eight concentrations: 11.75, 23.03, 33.84, 44.27, 54.35, 64.10, 68.85, 73.55 |

| 2.91 | Eight concentrations: 10.01, 20.01, 30.03, 40.05, 50.06, 60.05, 65.07, 70.09 | Eight concentrations: 11.68, 22.92, 33.79, 44.26, 54.37, 64.12, 68.89, 73.59 |

| 3.85 | Eight concentrations: 10.03, 20.04, 30.06, 40.05, 50.06, 60.06, 65.07, 70.07 | Eight concentrations: 11.73, 23.01, 33.89, 44.34, 54.45, 64.20, 68.96, 73.73 |

| 4.77 | Eight concentrations: 10.05, 20.04, 30.04, 40.05, 50.06, 60.07, 65.07, 70.07 | Eight concentrations: 11.79, 23.07, 33.94, 44.42, 54.53, 64.28, 69.03, 73.69 |

| 5.66 | Eight concentrations: 10.02, 20.03, 30.04, 40.07, 50.09, 60.08, 65.08, 70.08 | Eight concentrations: 11.78, 23.11, 34.01, 44.52, 54.64, 64.36, 69.10, 73.75 |

| 6.55 | Eight concentrations: 10.01, 20.04, 30.04, 40.05, 50.06, 60.08, 65.08, 70.08 | Eight concentrations: 11.81, 23.17, 34.07, 44.58, 54.68, 64.43, 69.16, 73.81 |

| 7.41 | Seven concentrations: 10.03, 20.06, 30.05, 40.07, 50.06, 60.07, 65.07 | Seven concentrations: 11.86, 23.25, 34.15, 44.67, 54.76, 64.49, 69.22 |

| Device | Inner Cylinder Radius, (cm) | Outer Cylinder Radius, (cm) | Length of Inner Cylinder (cm) | Gap-Width (cm) |

|---|---|---|---|---|

| Fann 35A/SR-12 | 1.72 | 1.84 | 3.8 | 0.12 |

| Haake Roto- visco RV 12 with MV I | 2.00 | 2.1 | 6.0 | 0.10 |

| Haake Roto- visco RV 12 with MV III | 1.52 | 2.1 | 6.0 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kinra, S.; Pal, R. Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations. Colloids Interfaces 2023, 7, 36. https://doi.org/10.3390/colloids7020036

Kinra S, Pal R. Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations. Colloids and Interfaces. 2023; 7(2):36. https://doi.org/10.3390/colloids7020036

Chicago/Turabian StyleKinra, Saumay, and Rajinder Pal. 2023. "Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations" Colloids and Interfaces 7, no. 2: 36. https://doi.org/10.3390/colloids7020036

APA StyleKinra, S., & Pal, R. (2023). Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations. Colloids and Interfaces, 7(2), 36. https://doi.org/10.3390/colloids7020036