Influence of Jointing Methods on the Mechanical Properties of CFRTP Structure Under Bending Load

Abstract

1. Introduction

2. Materials and Methods

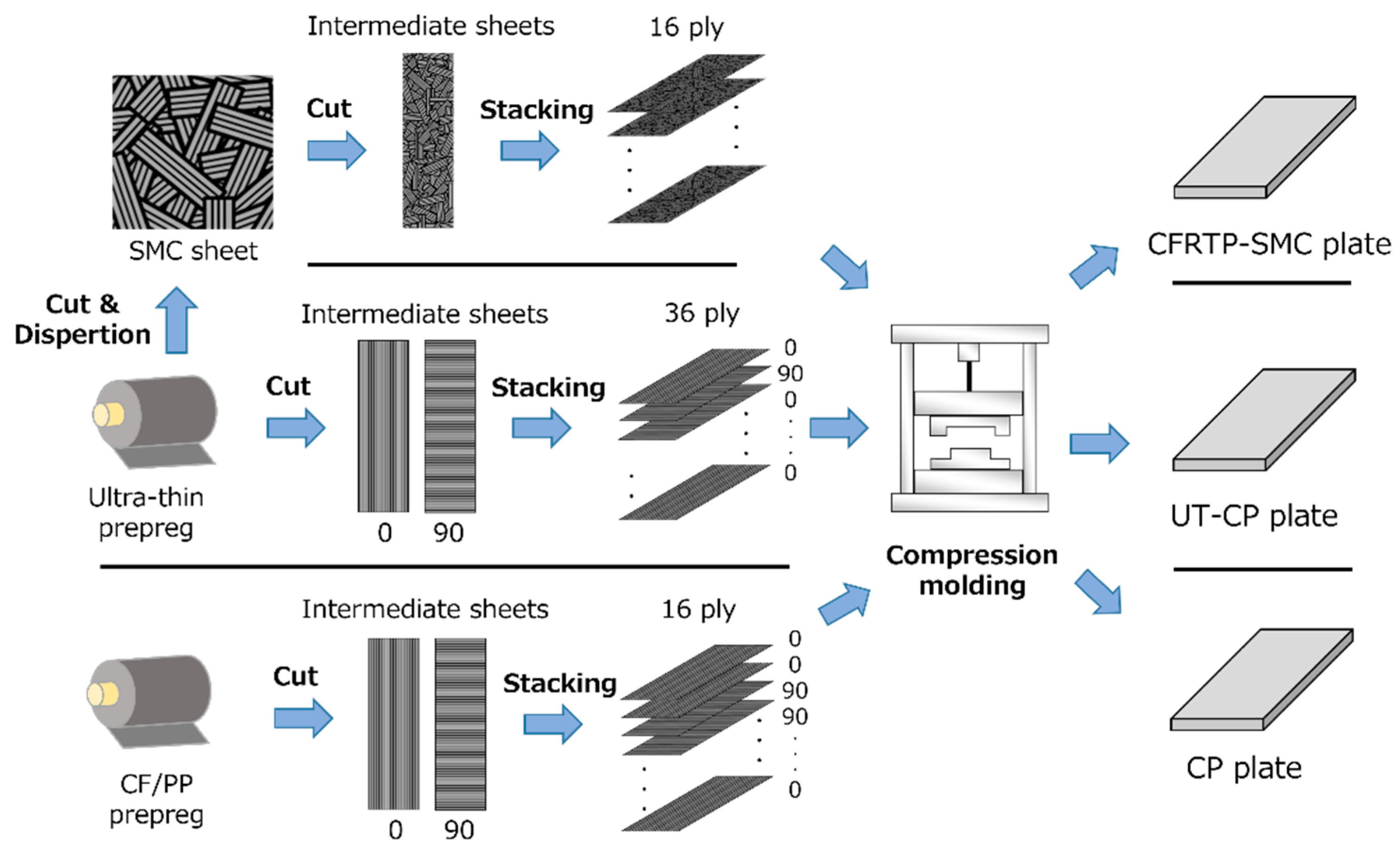

2.1. Materials

2.2. Jointing Methods and Specimens

2.2.1. Ultrasonic Welding

2.2.2. Bolted Joint

2.2.3. Adhesive Joining

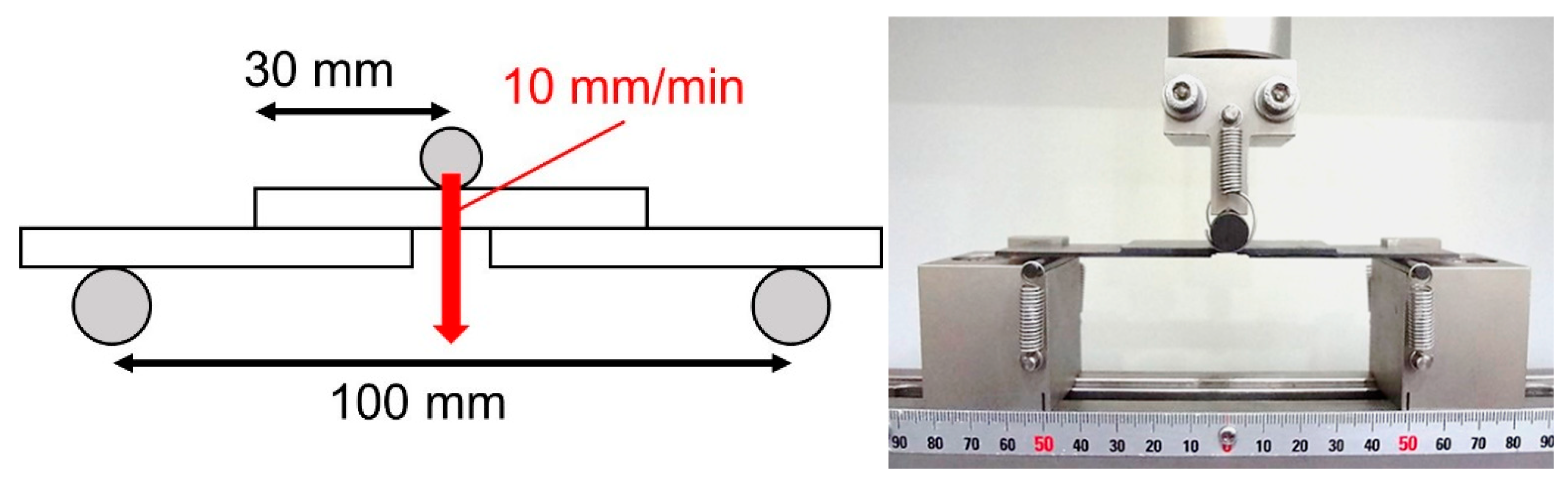

2.3. Experimental Procedure

2.4. FE Modeling

3. Results and Discussion

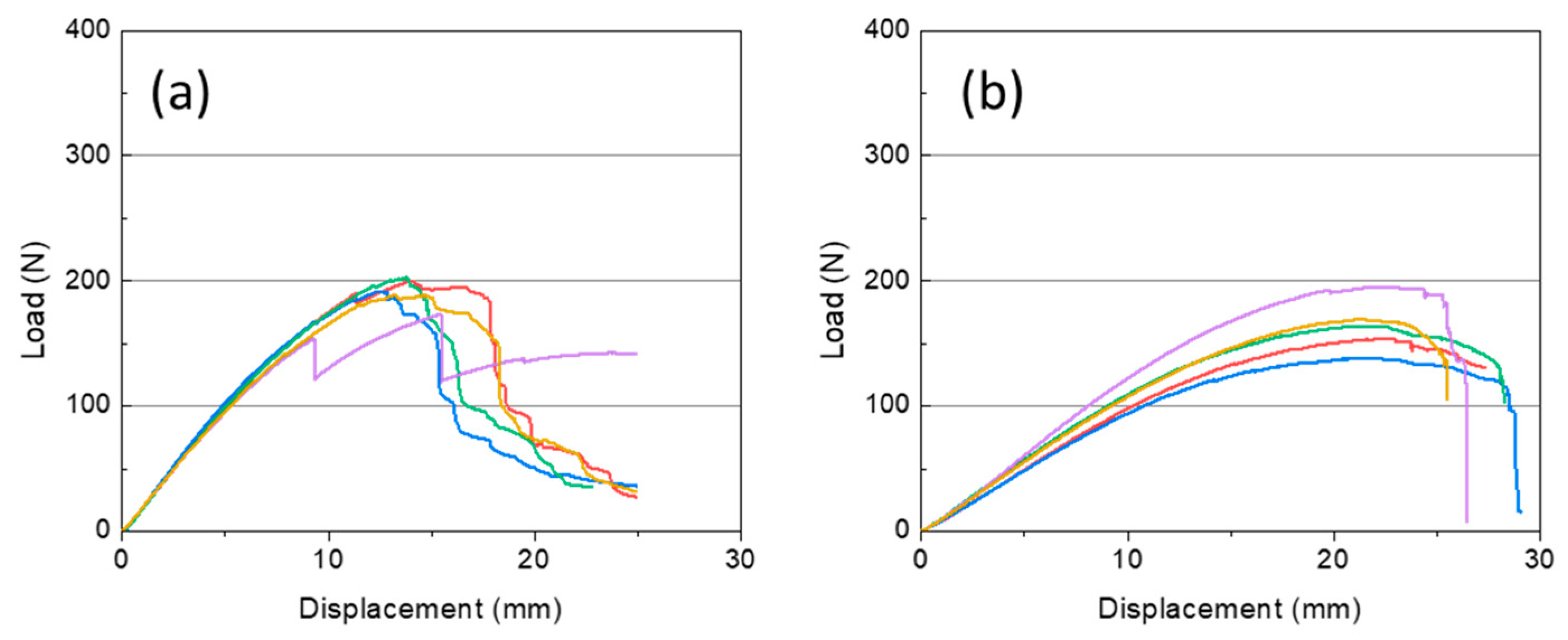

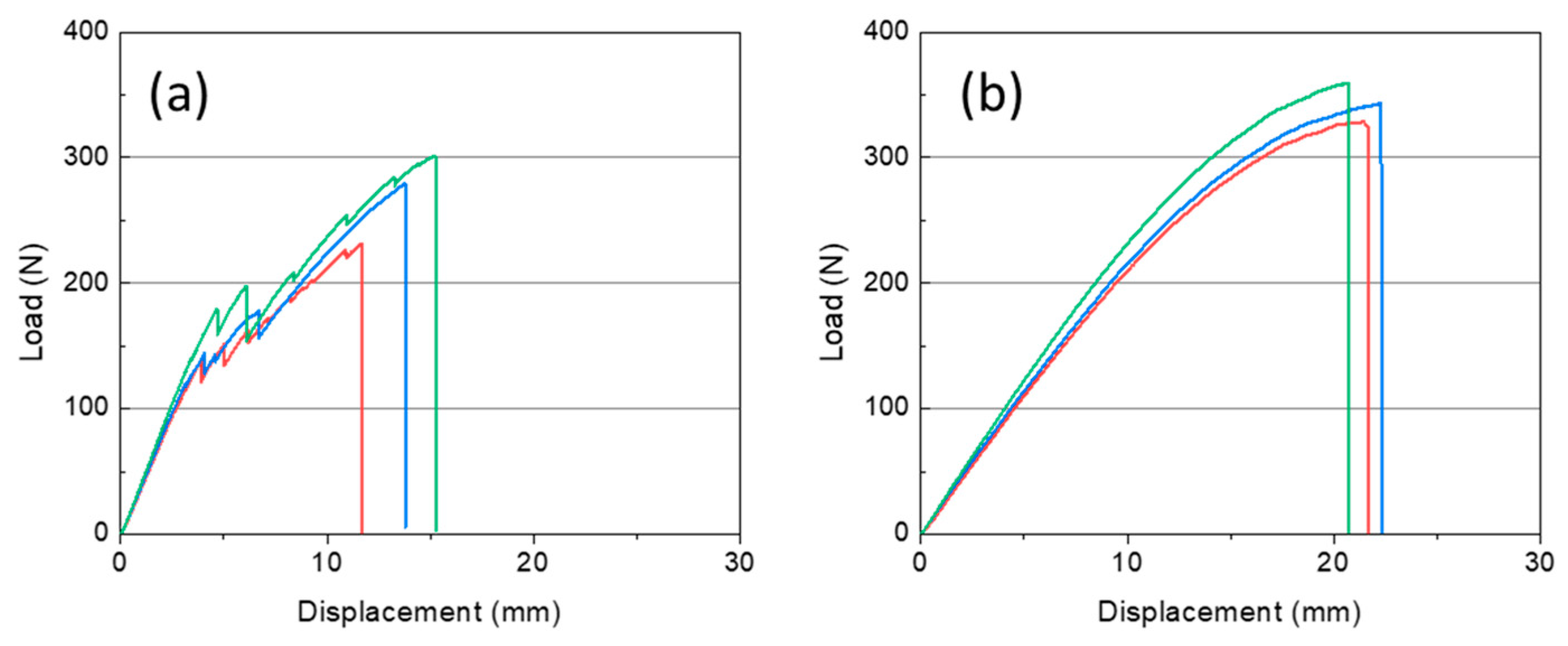

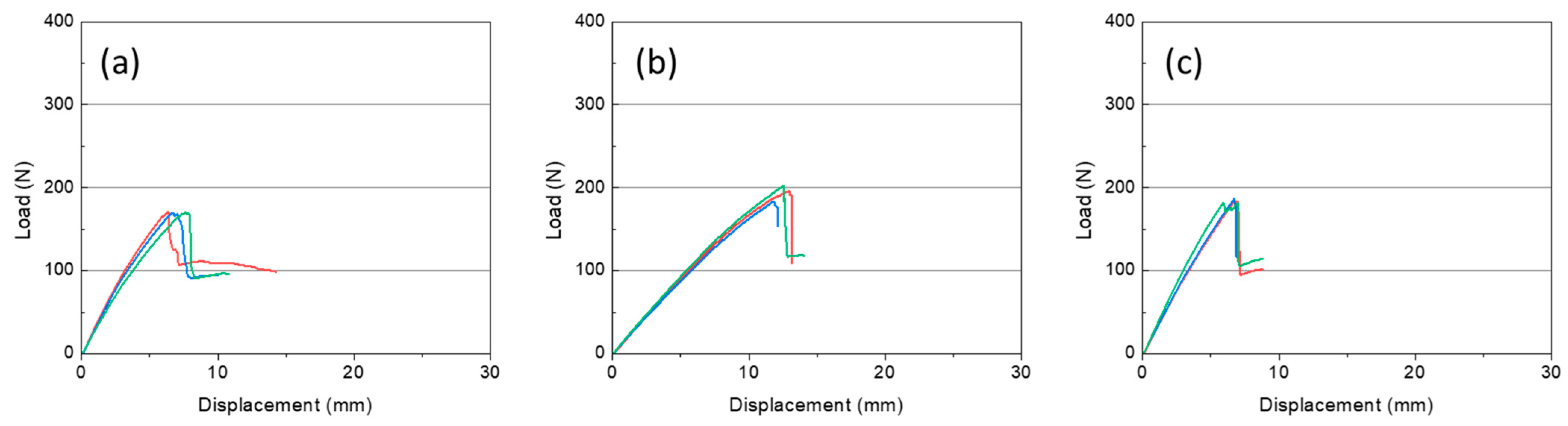

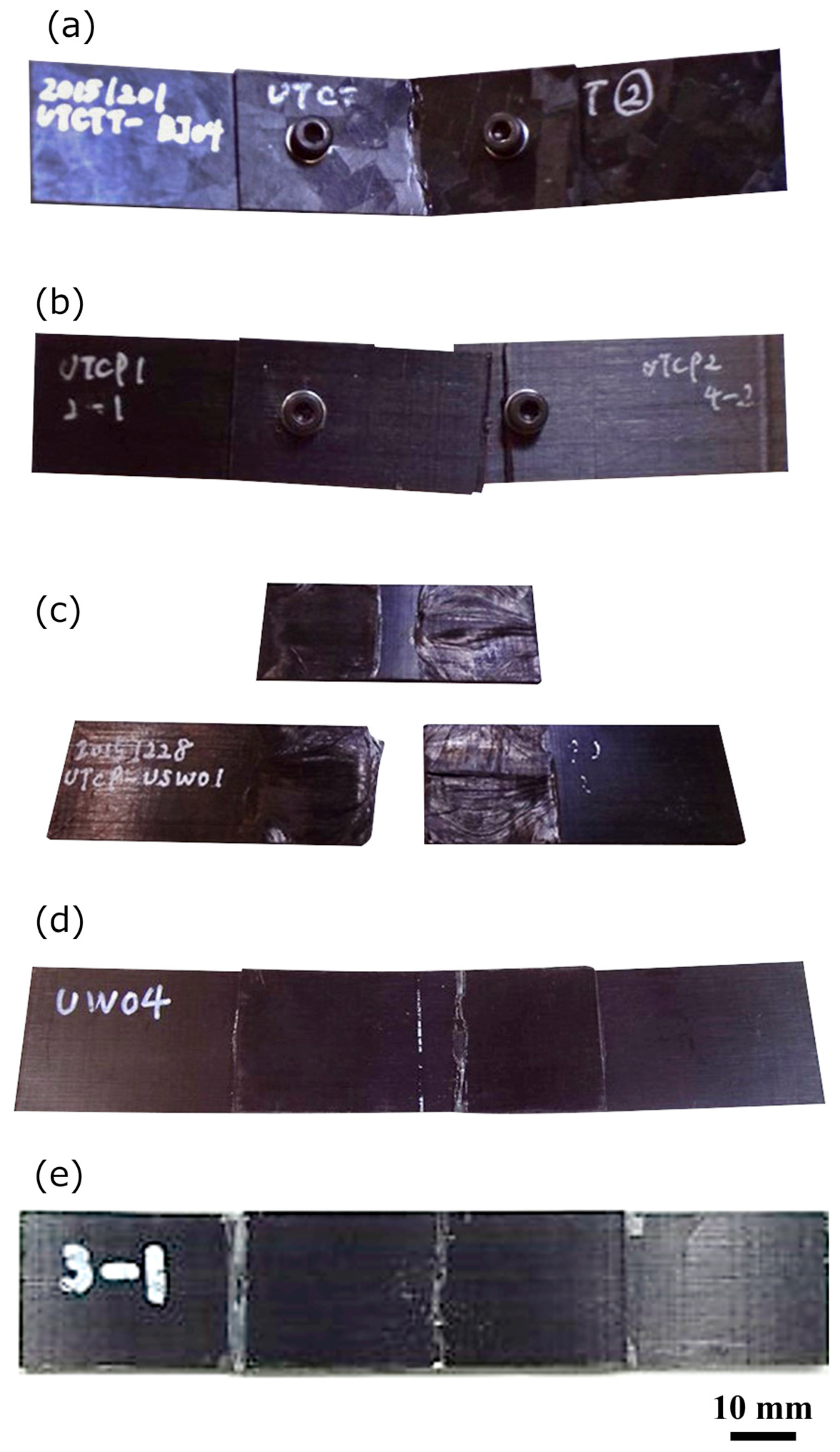

3.1. Three-Point Bending Test

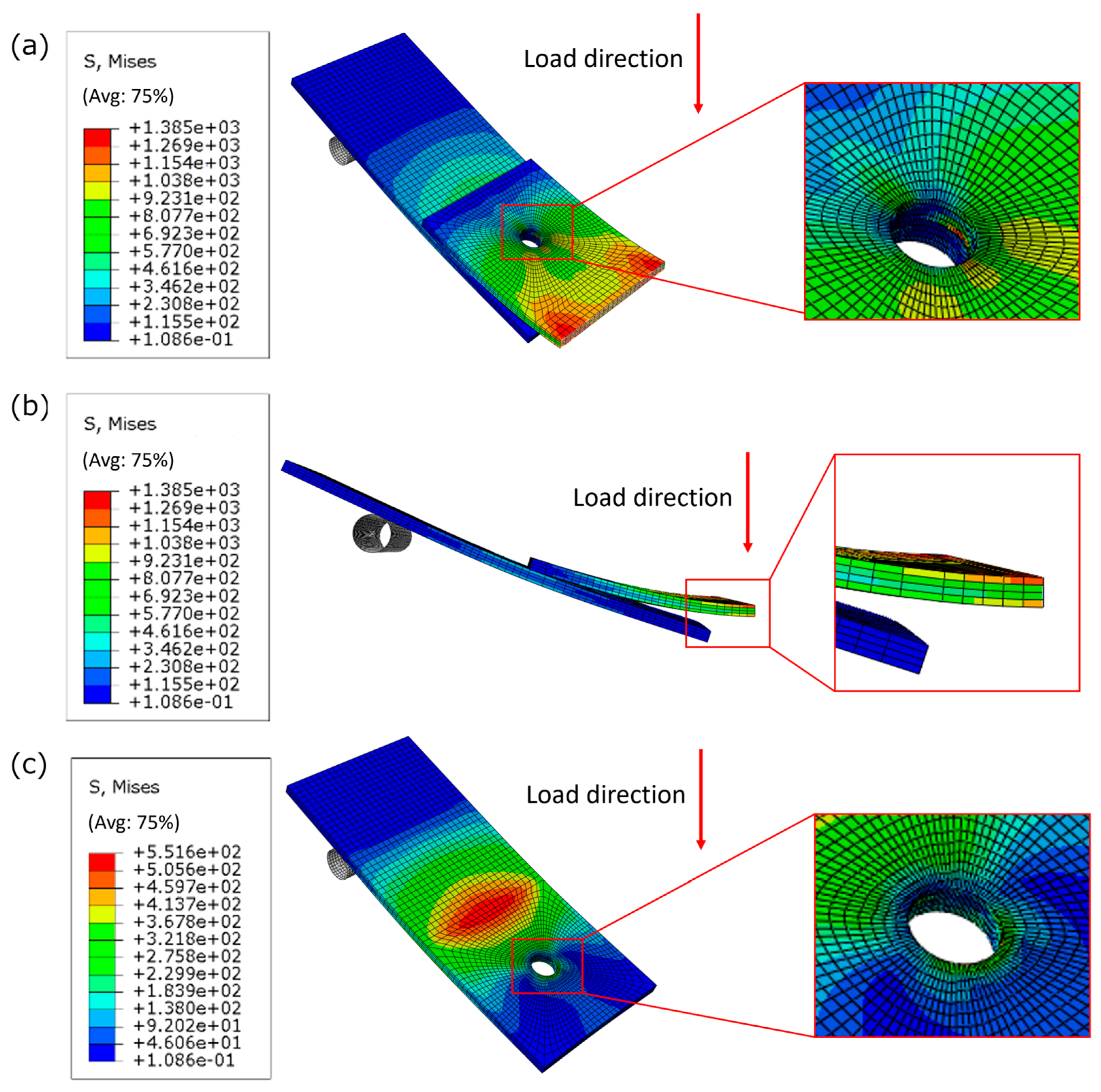

3.2. Finite Element Modeling

4. Conclusions

- Ultrasonic welding (USW) and adhesive joining (AJ) composite structures could reach similar rigidity under bending load in CP specimens; the small variance could be attributed to the thickness increment induced by the adhesive layer. Besides, the rigidity of the bolted joint (BJ) structure is much lower than USW and AJ, which is due to the separation of composite plates induced by bending deformation.

- The main damage patterns of jointed CFRTP structures under bending load include compressive failure under the indenter, detachment of the welding surface, failure at the washer edge, and compressive failure at the welding edge. Material failure or compressive failure under the indenter was the preferred failure mode since the material properties were not limited by the jointing properties; therefore, the failure of a jointing part should be avoided in structure design to achieve the best structural performance.

- The materials used in this study were aimed at being applied in the mass-production automotive industry. The hazardous area and bending rigidity could be precisely predicted by the FE model with regard to the CFRTP structures with different jointing methods. The FE method was demonstrated to be a useful tool to provide assistance for more complicated composite structure design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Crews, J.H., Jr.; Hong, C.S.; Raju, I.S. Stress-Concentration Factors for Finite Orthotropic Laminates with a Pin-Loaded Hole; NASA-TP-1862; National Aeronautics and Space Administration Hampton Va Langley Research: Hampton, VA, USA, 1981. [Google Scholar]

- Smith, P.A.; Pascoe, K.J.; Polak, C.; Stroud, D.O. The behaviour of single-lap bolted joints in CFRP laminates. Compos. Struct. 1986, 6, 41–55. [Google Scholar] [CrossRef]

- Hart-Smith, L.J. Bolted Joints in Graphite-Epoxy Composites; Douglas Aircraft Co., Inc.: Long Beach, CA, USA, 1976. [Google Scholar]

- Liu, F.; Zhao, L.; Mehmood, S.; Zhang, J.; Fei, B. A modified failure envelope method for failure prediction of multi-bolt composite joints. Compos. Sci. Technol. 2013, 83, 54–63. [Google Scholar] [CrossRef]

- Olmedo, Á.; Santiuste, C. On the prediction of bolted single-lap composite joints. Compos. Struct. 2012, 94, 2110–2117. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Ueda, M.; Miyake, S.; Hasegawa, H.; Hirano, Y. Instantaneous mechanical fastening of quasi-isotropic CFRP laminates by a self-piercing rivet. Compos. Struct. 2012, 94, 3388–3393. [Google Scholar] [CrossRef]

- Song, M.H.; Kweon, J.H.; Kim, S.K.; Kim, C.; Lee, T.J.; Choi, S.M.; Seong, M.S. An experimental study on the failure of carbon/epoxy single lap riveted joints after thermal exposure. Compos. Struct. 2008, 86, 125–134. [Google Scholar] [CrossRef]

- Lionetto, F.; Morillas, M.N.; Pappadà, S.; Buccoliero, G.; Villegas, I.F.; Maffezzoli, A. Hybrid welding of carbon-fiber reinforced epoxy based composites. Compos. Part. A Appl. Sci. Manuf. 2018, 104, 32–40. [Google Scholar] [CrossRef]

- Dell’Anna, R.; Lionetto, F.; Montagna, F.; Maffezzoli, A. Lay-up and consolidation of a composite pipe by in situ ultrasonic welding of a thermoplastic matrix composite tape. Materials 2018, 11, 786. [Google Scholar] [CrossRef]

- Levy, A.; Le Corre, S.; Villegas, I.F. Modeling of the heating phenomena in ultrasonic welding of thermoplastic composites with flat energy directors. J. Mater. Process Technol. 2014, 214, 1361–1371. [Google Scholar] [CrossRef]

- Levy, A.; Le Corre, S.; Poitou, A. Ultrasonic welding of thermoplastic composites: A numerical analysis at the mesoscopic scale relating processing parameters, flow of polymer and quality of adhesion. Int. J. Mater. Form. 2014, 7, 39–51. [Google Scholar] [CrossRef]

- Palardy, G.; Shi, H.; Levy, A.; Le Corre, S.; Villegas, I.F. A study on amplitude transmission in ultrasonic welding of thermoplastic composites. Compos. Part. A Appl. Sci. Manuf. 2018, 113, 339–349. [Google Scholar] [CrossRef]

- Krüger, S.; Wagner, G.; Eifler, D. Ultrasonic welding of metal/composite joints. Adv. Eng. Mater. 2004, 6, 157–159. [Google Scholar] [CrossRef]

- Kicukov, E.; Gursel, A. Ultrasonic welding of dissimilar materials: A review. Period Eng. Nat. Sci. 2015, 3. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Islam, A. Advances in Ultrasonic Welding of Thermoplastic Composites: A Review. Materials 2020, 13, 1284. [Google Scholar] [CrossRef]

- Balle, F.; Huxhold, S.; Wagner, G.; Eifler, D. Damage monitoring of ultrasonically welded aluminum/CFRP-joints by electrical resistance measurements. Procedia Eng. 2011, 10, 433–438. [Google Scholar] [CrossRef]

- Owens, J.F.P.; Lee-Sullivan, P. Stiffness behaviour due to fracture in adhesively bonded composite-to-aluminum joints I. Theoretical model. Int. J. Adhes. Adhes. 2000, 20, 39–45. [Google Scholar] [CrossRef]

- Owens, J.F.P.; Lee-Sullivan, P. Stiffness behaviour due to fracture in adhesively bonded composite-to-aluminum joints II. Experimental. Int. J. Adhes. Adhes. 2000, 20, 47–58. [Google Scholar] [CrossRef]

- Kelly, G. Load transfer in hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2005, 69, 35–43. [Google Scholar] [CrossRef]

- Camanho, P.P.; Tavares, C.M.L.; De Oliveira, R.; Marques, A.T.; Ferreira, A.J.M. Increasing the efficiency of composite single-shear lap joints using bonded inserts. Compos. Part B Eng. 2005, 36, 372–383. [Google Scholar] [CrossRef]

- Kweon, J.-H.; Jung, J.-W.; Kim, T.-H.; Choi, J.-H.; Kim, D.-H. Failure of carbon composite-to-aluminum joints with combined mechanical fastening and adhesive bonding. Compos. Struct. 2006, 75, 192–198. [Google Scholar] [CrossRef]

- Selezneva, M.; Lessard, L. Characterization of mechanical properties of randomly oriented strand thermoplastic composites. J. Compos. Mater. 2016, 50, 2833–2851. [Google Scholar] [CrossRef]

- Sihn, S.; Kim, R.Y.; Kawabe, K.; Tsai, S.W. Experimental studies of thin-ply laminated composites. Compos. Sci. Technol. 2007, 67, 996–1008. [Google Scholar] [CrossRef]

- Meng, L.; Wan, Y.; Ohsawa, I.; Takahashi, J. Effects of geometric parameters on the failure behavior of mechanically fastened chopped carbon fiber tape reinforced thermoplastics. Compos. Struct. 2019, 229, 111475. [Google Scholar] [CrossRef]

- Meng, L.; Wataki, H.; Ohsawa, I.; Takahashi, J. Failure analysis of ultra-thin chopped carbon fiber tape reinforced thermoplastic in mechanical joints. In Proceedings of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Wataki, H.; Hayashi, T.; Ohori, T.; Takahashi, J. Flexural property of jointed structure made by CFRTP. In Proceedings of the 14th JAPAN International SAMPE Symposium and Exhibition, Ishikawa, Japan, 6–9 December 2015. [Google Scholar]

| CFRTP-SMC | UT-CP | CP | |

|---|---|---|---|

| Prepreg thickness (μm) | 50 | 50 | 100 |

| Fiber/Matrix | TR 50S/PA6 | TR 50S/PA6 | TR 50S/PP |

| Stacking sequence | ROS sheets | [0/90]9s | [02/902]2s |

| Fiber volume fractions (%) | 55 | 55 | 45 |

| Joining Method | Length, L | Width, W | Thickness, T | Joint Cover Area | Number of Tests | |

|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm × mm) | |||

| CFRTP-SMC | USW | 59.83 | 24.95 | 1.40 | 25 × 25 | 5 |

| BJ | 59.87 | 24.84 | 1.42 | 6 | ||

| UT-CP | USW | 59.84 | 24.98 | 1.49 | 3 | |

| BJ | 59.88 | 24.98 | 1.49 | 3 | ||

| CP | USW | 59.88 | 24.77 | 1.50 | 3 | |

| BJ | 59.68 | 24.70 | 1.44 | 3 | ||

| AJ | 60.06 | 24.70 | 1.46 | 3 |

| Air Pressure | Amplitude | Vibration Time | Trigger Load | Holding Time | |

|---|---|---|---|---|---|

| (MPa) | (%) | (s) | (N) | (s) | |

| CFRTP-SMC | 0.2 | 100 | 2 | 500 | 5 |

| UT-CP | 0.2 | 100 | 2 | 500 | 5 |

| CP | 0.2 | 100 | 1 | 500 | 5 |

| Engineering Constant | Unit | CFRTP-SMC | UT-UP | CP |

|---|---|---|---|---|

| (0°) | (0°) | |||

| Young’s modulus (longitudinal direction) E1 | GPa | ** | ** | 101 * |

| Young’s modulus (thickness direction) E2 | 7.29 | 7.29 | 4.61 | |

| Young’s modulus (width direction) E3 | ** | ** | 4.61 * | |

| In-plane shear modulus G12 | 15.9 | 2.25 | 1.63 * | |

| In-plane shear modulus G13 | 15.9 | 2.25 ** | 1.63 | |

| Out-of-plane shear modulus G23 | 1.11 ** | 3.00 | 2.00 | |

| Poisson’s ratio ν13 | - | 0.28 ** | 0.33 ** | 0.34 * |

| Engineering Constant | Unit | Adhesive | Steel Bolt |

|---|---|---|---|

| Young’s modulus E | MPa | 959 | 2 × 105 |

| Poisson’s ratio ν | - | 0.47 | 0.3 |

| Specimen | Jointing Method | Failure Mode |

|---|---|---|

| CFRTP-SMC | USW | Compressive failure under the indenter |

| Detachment of the welding surface | ||

| BJ | Compressive failure the under indenter | |

| UT-CP | USW | Detachment of the welding surface |

| BJ | Failure at the washer edge | |

| CP | USW | Compressive failure at the welding edge |

| BJ | Compressive failure under the indenter | |

| AJ | Compressive failure under the indenter | |

| USW: ultrasonic welding, BJ: bolt joint, AJ: adhesive joining | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Y.; Meng, L.; Wataki, H.; Takahashi, J. Influence of Jointing Methods on the Mechanical Properties of CFRTP Structure Under Bending Load. J. Compos. Sci. 2025, 9, 291. https://doi.org/10.3390/jcs9060291

Wan Y, Meng L, Wataki H, Takahashi J. Influence of Jointing Methods on the Mechanical Properties of CFRTP Structure Under Bending Load. Journal of Composites Science. 2025; 9(6):291. https://doi.org/10.3390/jcs9060291

Chicago/Turabian StyleWan, Yi, Linshu Meng, Hirokuni Wataki, and Jun Takahashi. 2025. "Influence of Jointing Methods on the Mechanical Properties of CFRTP Structure Under Bending Load" Journal of Composites Science 9, no. 6: 291. https://doi.org/10.3390/jcs9060291

APA StyleWan, Y., Meng, L., Wataki, H., & Takahashi, J. (2025). Influence of Jointing Methods on the Mechanical Properties of CFRTP Structure Under Bending Load. Journal of Composites Science, 9(6), 291. https://doi.org/10.3390/jcs9060291