Conducting EVA/GNP Composite Films with Multifunctional Applications: Effect of the Phosphonium-Based Ionic Liquid

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Characterization

3. Results and Discussion

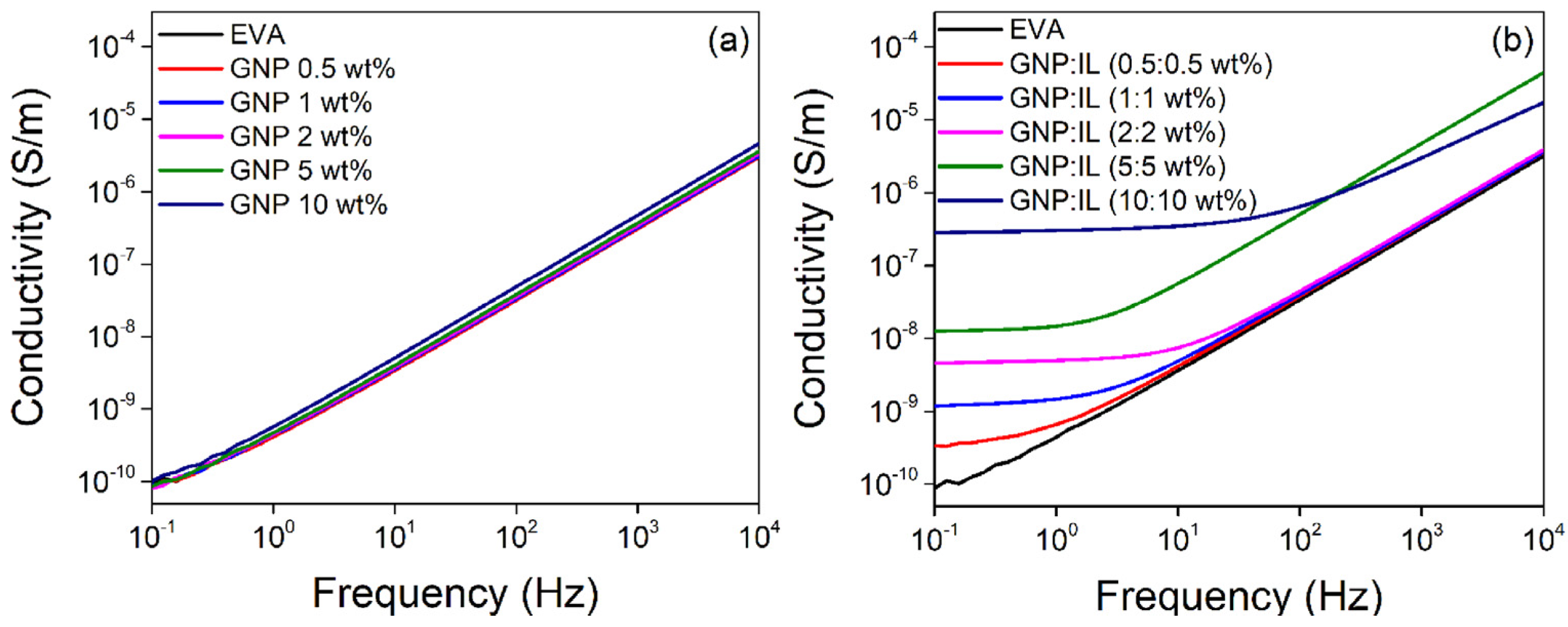

3.1. Electrical Conductivity

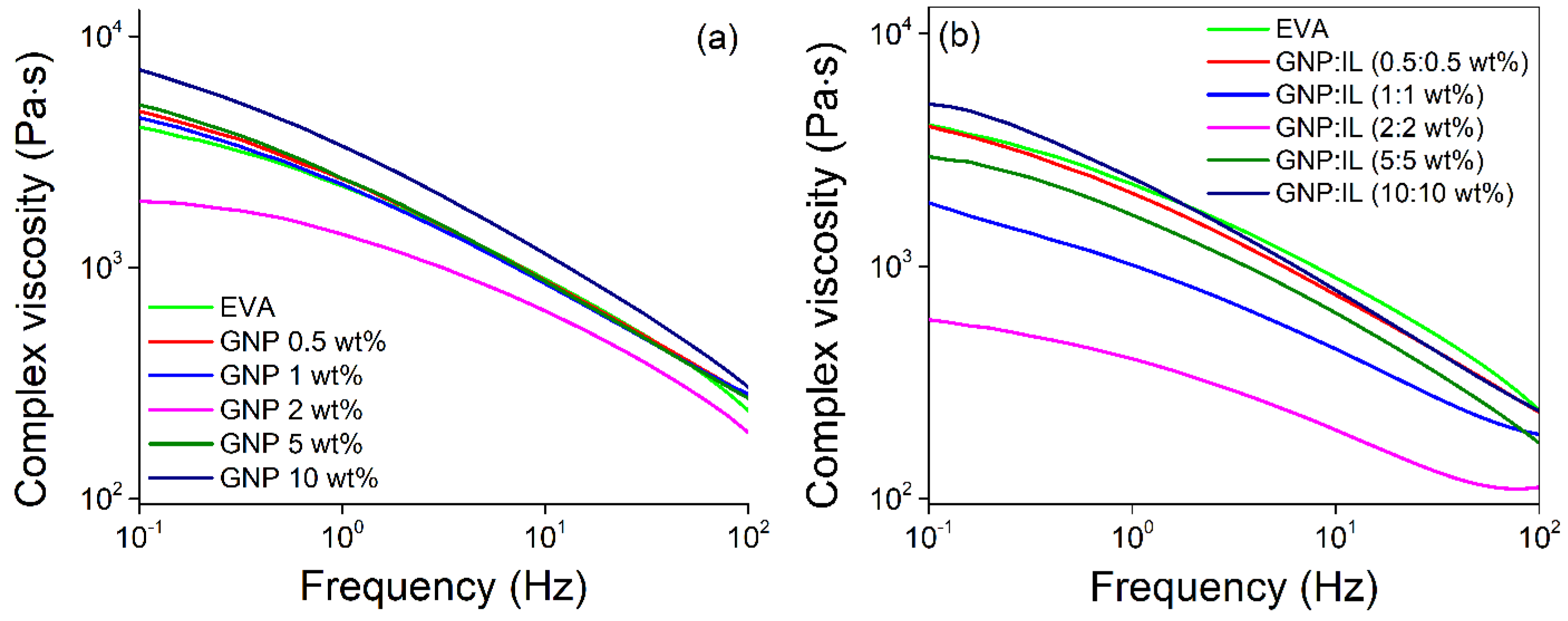

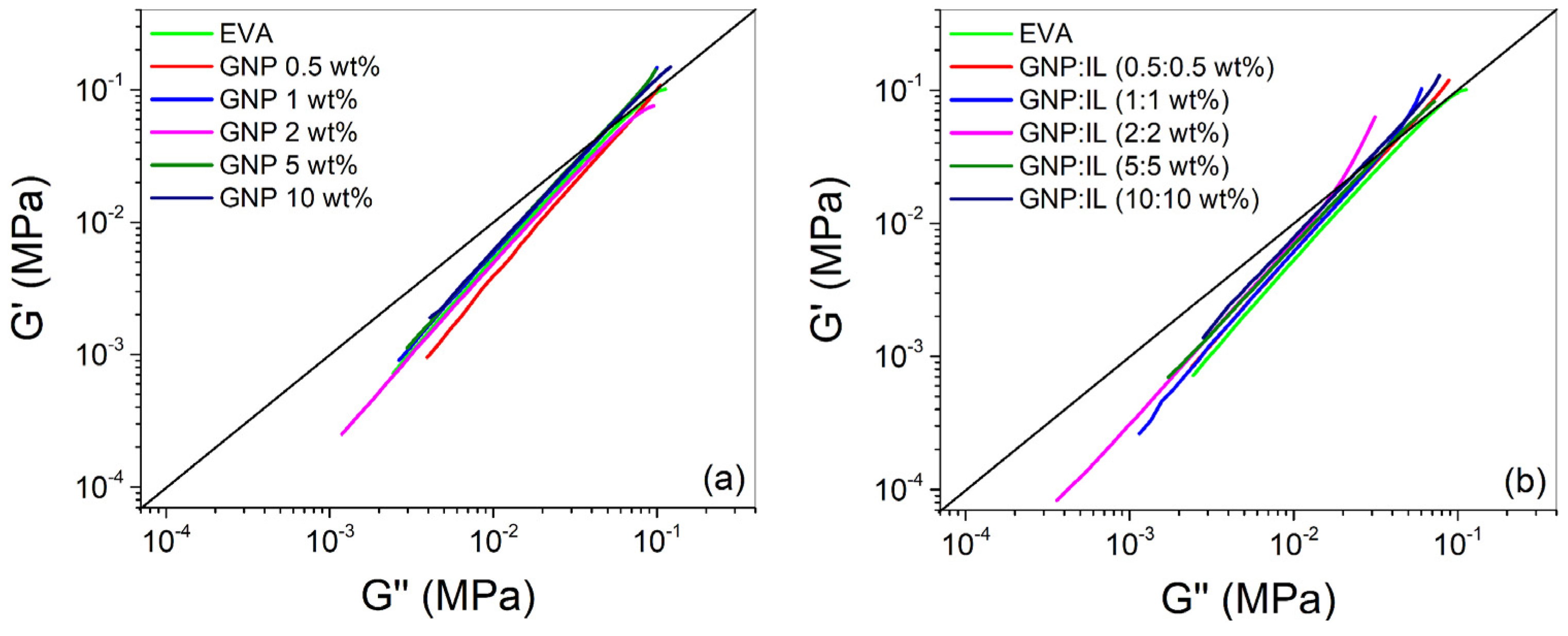

3.2. Rheological Properties

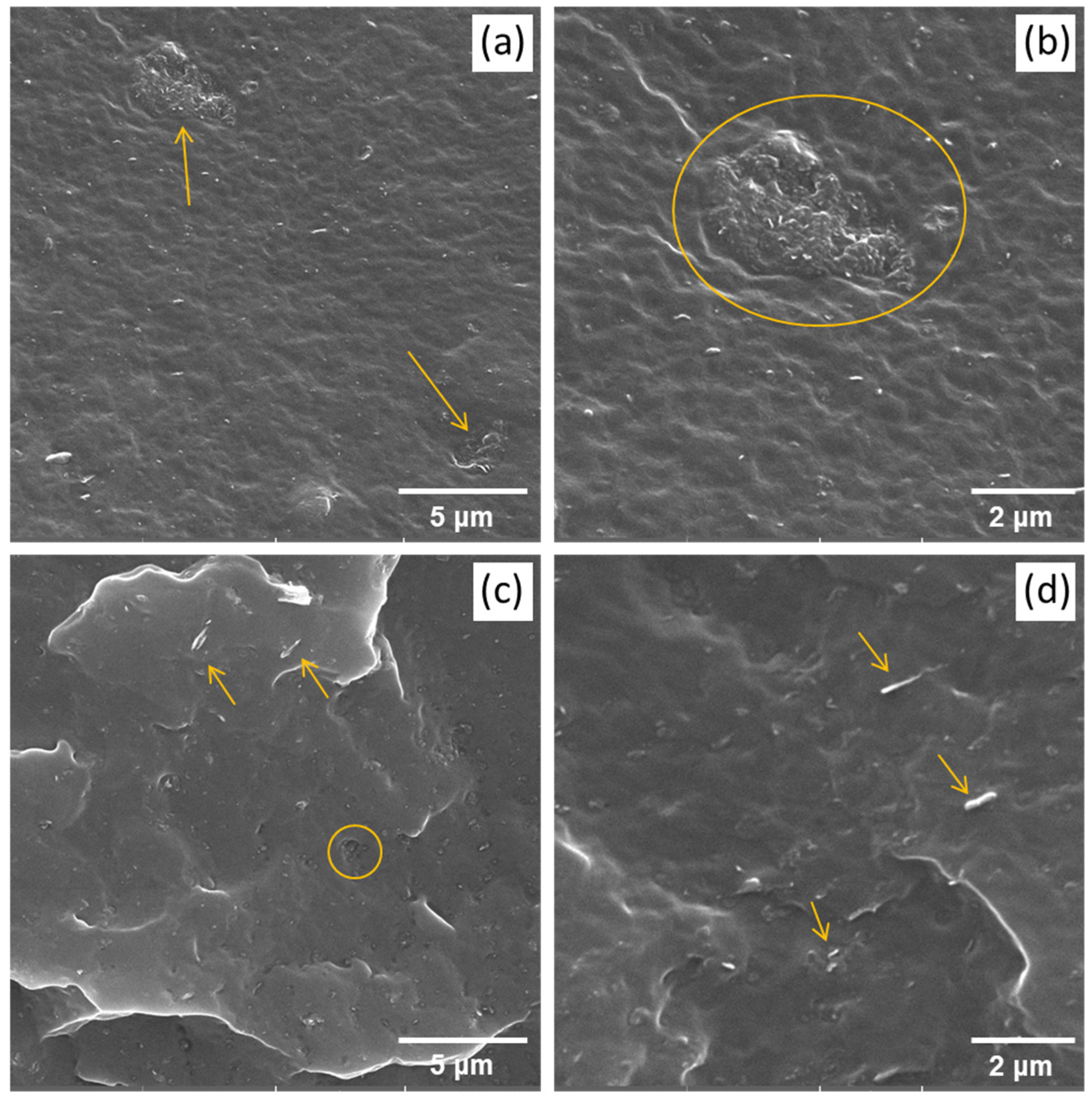

3.3. Morphology

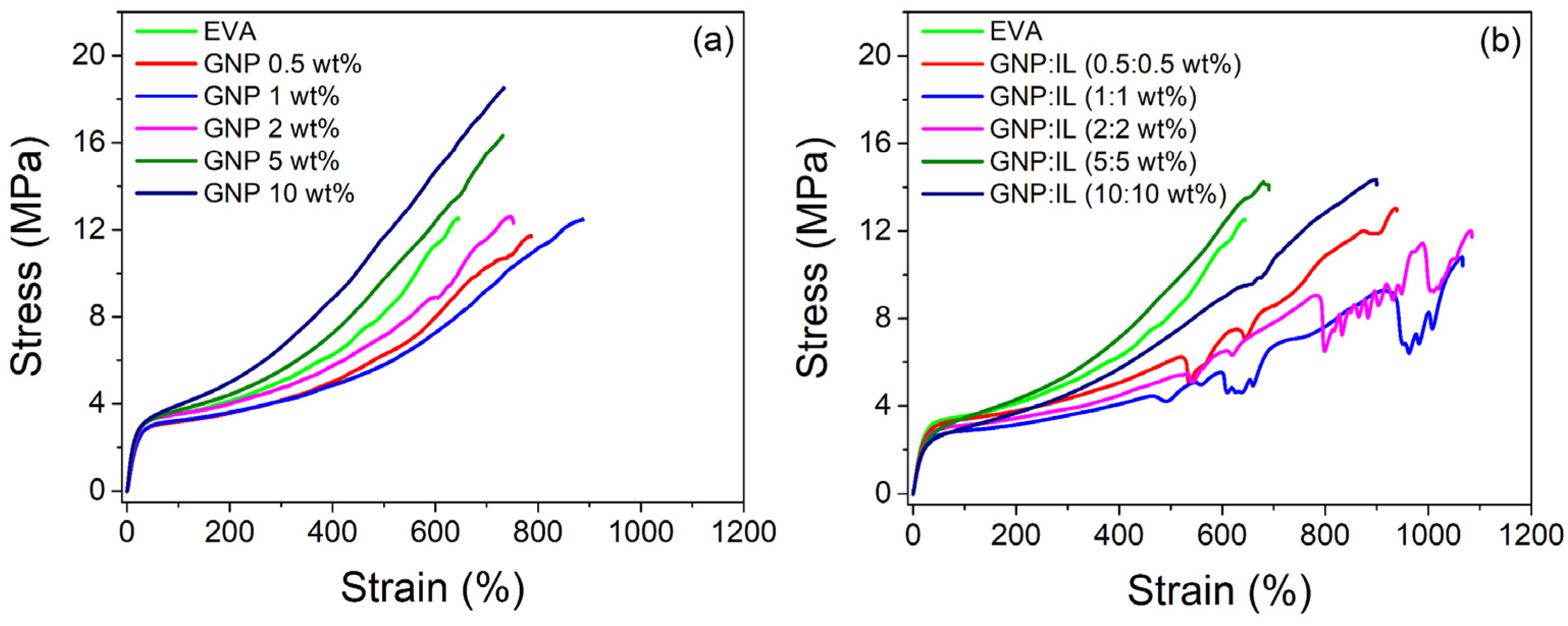

3.4. Mechanical Properties

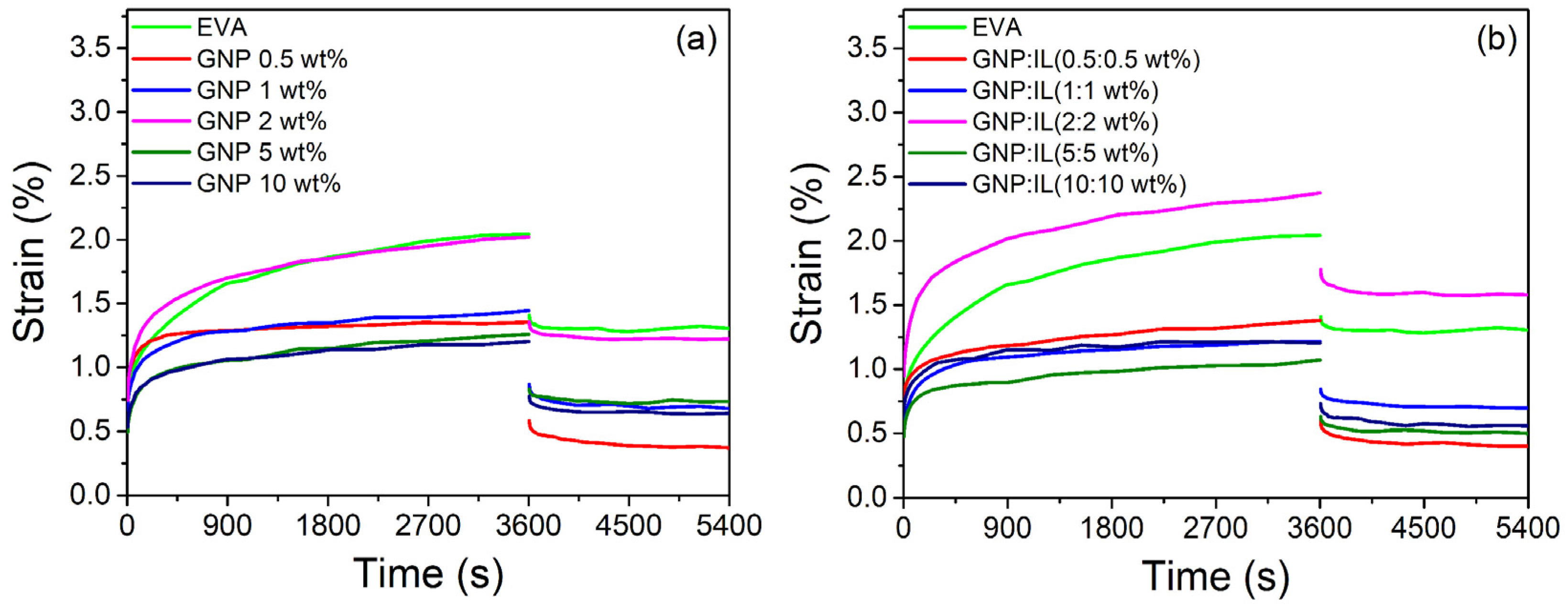

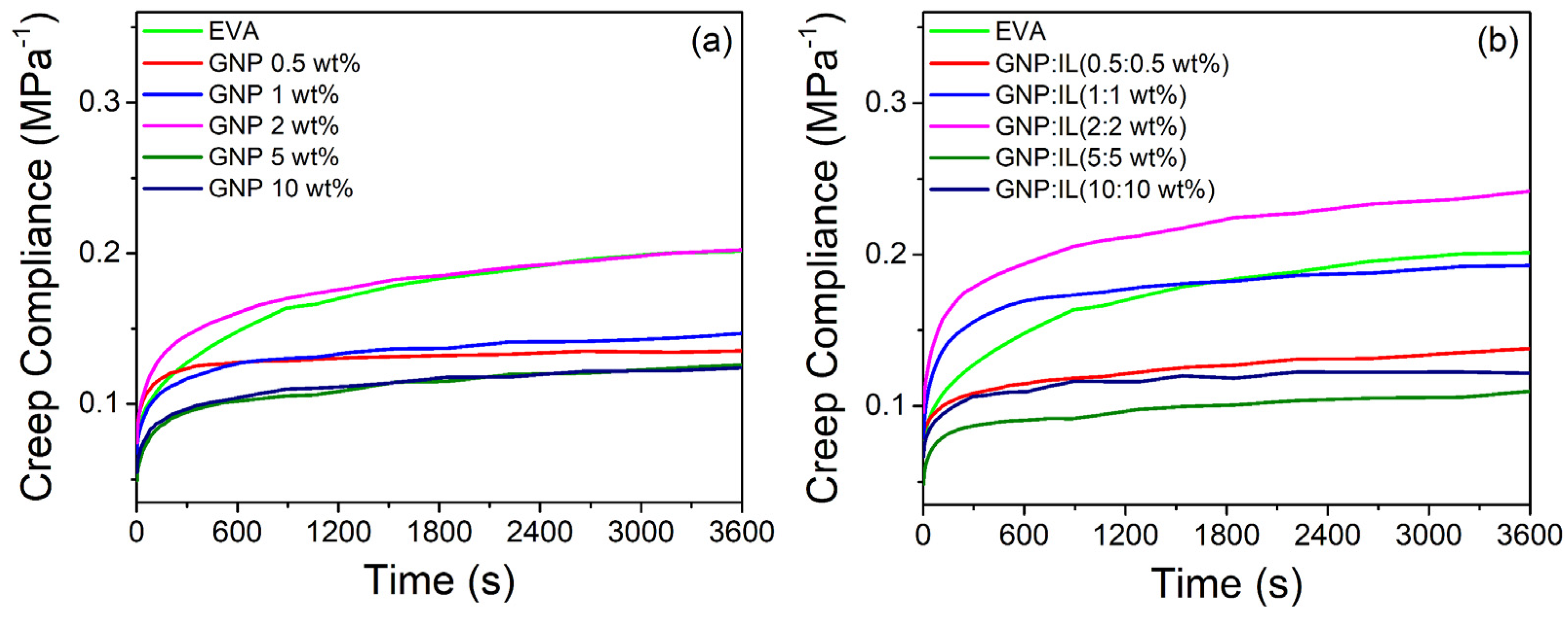

3.5. Creep Behavior

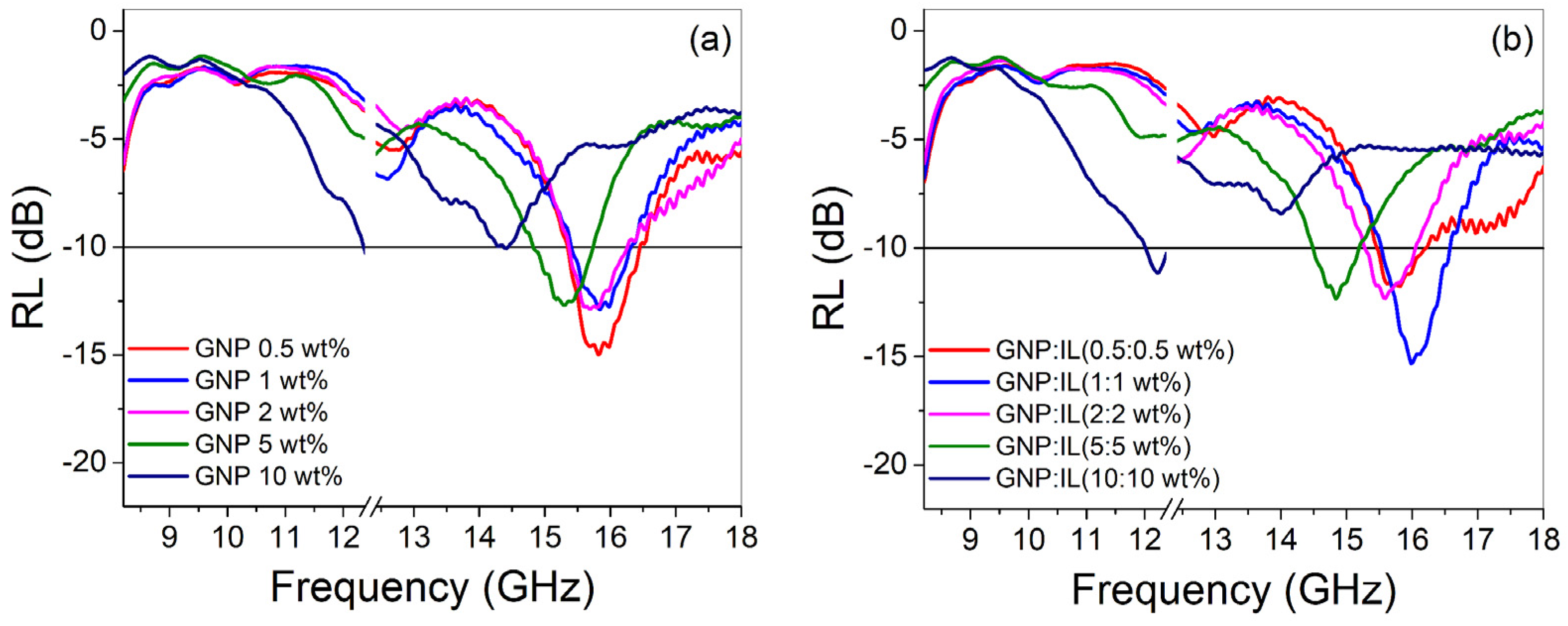

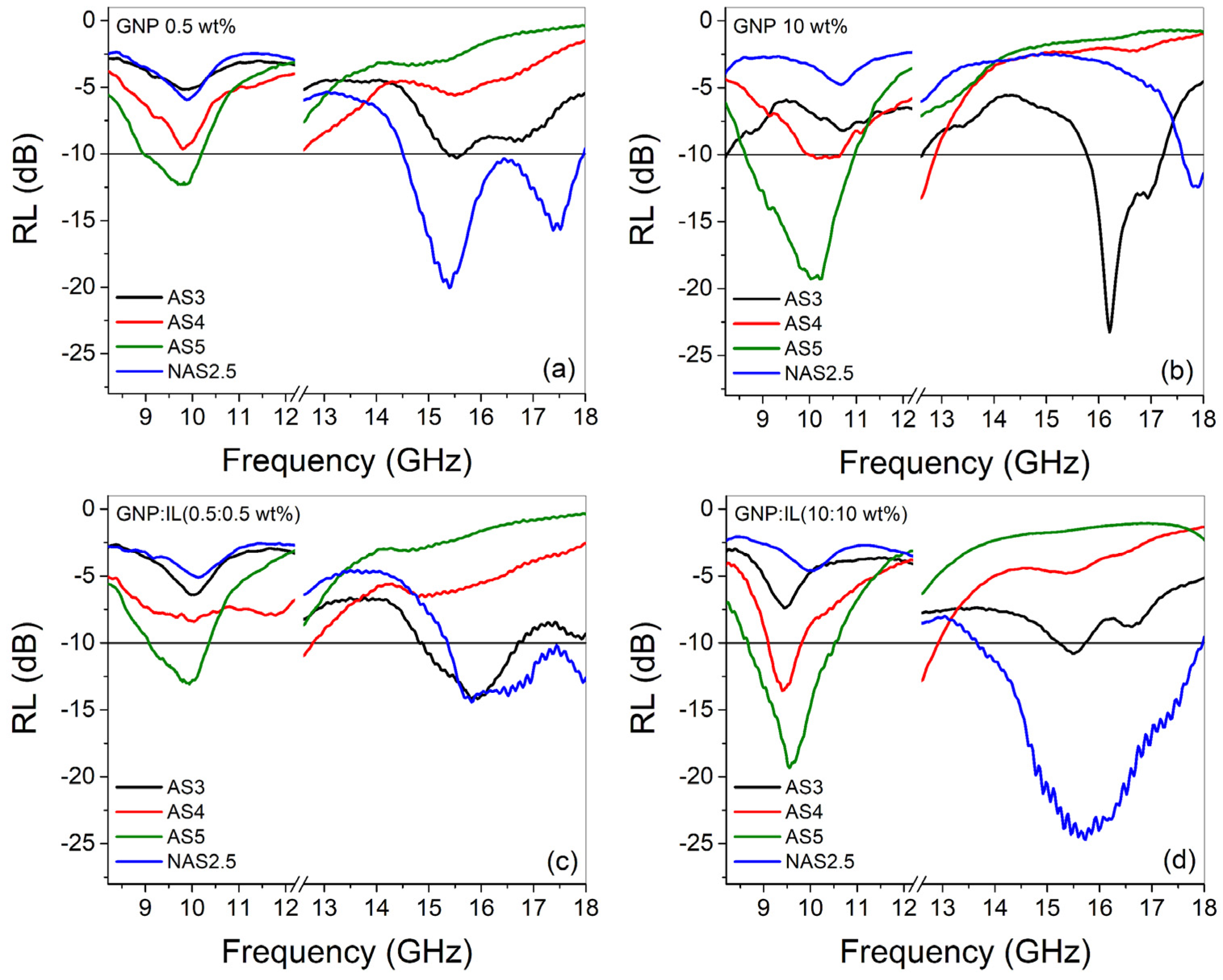

3.6. Electromagnetic Absorption Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GNP | Graphene nanoplatelet |

| EVA | Ethylene-vinyl acetate copolymer |

| RL | Reflection loss |

| IL | Ionic liquid |

| RGO | Reduced graphene oxide |

| PVDF | Poly(vinylidene fluoride) |

| DMA | Dynamic mechanical analysis |

| VNA | Vector network analyzer |

| CPC | Conducting polymer composites |

| EAB | Effective absorbing bandwidth |

| AS | Alternated structure of the films (with and without filler) |

| NAS | Non-alternated structure (layers with only filled films) |

References

- Shi, J.; Yang, J.; Zhou, J.; Ji, H.; Tang, X.; Gao, T. Effect of Graphene on Thermal Stability and Mechanical Properties of Ethylene-Vinyl Acetate: A Molecular Dynamics Simulation. Mater. Res. Express 2020, 7, 035304. [Google Scholar] [CrossRef]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-Polymer Nanocomposites for Structural and Functional Applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Sabet, M.; Soleimani, H.; Hosseini, S. Effect of Addition Graphene to Ethylene Vinyl Acetate and Low-Density Polyethylene. J. Vinyl Addit. Technol. 2018, 24, 177–185. [Google Scholar] [CrossRef]

- Ratzsch, K.-F.; Cecen, V.; Tölle, F.; Wartig, K.-A.; Thomann, R.; Müllhaupt, R.; Friedrich, C. Rheology, Electrical Properties, and Percolation of TRGO-Filled EVA-Copolymers. Macromol. Mater. Eng. 2014, 299, 1134–1144. [Google Scholar] [CrossRef]

- Cecen, V.; Thomann, R.; Mülhaupt, R.; Friedrich, C. Thermal Conductivity, Morphology, and Mechanical Properties of Thermally Reduced Graphite Oxide-Filled Ethylene Vinyl Acetate Copolymers. Polymer 2017, 132, 294–305. [Google Scholar] [CrossRef]

- Azizi, S.; David, E.; Fréchette, M.F.; Nguyen-Tri, P.; Ouellet-Plamondon, C.M. Electrical and Thermal Conductivity of Ethylene Vinyl Acetate Composite with Graphene and Carbon Black Filler. Polym. Test. 2018, 72, 24–31. [Google Scholar] [CrossRef]

- Soheilmoghaddam, M.; Adelnia, H.; Bidsorkhi, H.C.; Sharifzadeh, G.; Wahit, M.U.; Akos, N.I.; Yussuf, A.A. Development of Ethylene–Vinyl Acetate Composites Reinforced with Graphene Platelets. Macromol. Mater. Eng. 2017, 302, 1600260. [Google Scholar] [CrossRef]

- Anjos, E.G.R.; Brazil, T.R.; Morgado, G.F.M.; Antonelli, E.; Medeiros, N.C.F.L.; Santos, A.P.; Indrusiak, T.; Baldan, M.R.; Rezende, M.C.; Pessan, L.A.; et al. Graphene related materials as effective additives for electrical and electromagnetic performance of epoxy nanocomposites. FlatChem 2023, 41, 100542. [Google Scholar] [CrossRef]

- Anjos, E.G.R.; Moura, N.K.; Antonelli, E.; Baldan, M.R.; Gomes, N.A.S.; Braga, N.F.; Santos, A.P.; Rezende, M.C.; Pessan, L.A.; Passador, F.R. Role of adding carbon nanotubes in the electric and electromagnetic shielding behaviors of three different types of graphene in hybrid nanocomposites. J. Thermoplast. Compos. Mater. 2023, 36, 3209–3235. [Google Scholar] [CrossRef]

- Abdelal, N.; Dib, N.; Young, D.; Slanker, A. Electromagnetic interference shielding and dielectric properties of graphene nanoplatelets/epoxy composites in the x-band frequency range. J. Mater. Sci. 2022, 57, 13928–13944. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Zhang, P.; Song, L.; Yang, H.; Hu, Y. Covalent Functionalization of Graphene with Organosilane and its Use as a Reinforcement in Epoxy Composites. Compos. Sci. Technol. 2012, 72, 737–743. [Google Scholar] [CrossRef]

- Tkalya, E.E.; Ghislandi, M.; de With, G.; Koning, C.E. The Use of Surfactants for Dispersing Carbon Nanotubes and Graphene to Make Conductive Nanocomposites. Curr. Opin. Colloid Interface Sci. 2012, 17, 225–232. [Google Scholar] [CrossRef]

- Tunkol, M.; Durand, J.; Serp, P. Carbon Nanomaterial–Ionic Liquid Hybrids. Carbon 2012, 50, 4303–4334. [Google Scholar] [CrossRef]

- Ghatee, M.H.; Moosavi, F. Physisorption of Hydrophobic and Hydrophilic 1-Alkyl-3-methylimidazolium Ionic Liquids on the Graphenes. J. Phys. Chem. C 2011, 115, 5626–5636. [Google Scholar] [CrossRef]

- Wang, X.; Fulvio, P.F.; Baker, G.A.; Veith, G.M.; Unocic, R.R.; Mahurin, S.M.; Chi, M.; Dai, S. Direct Exfoliation of Natural Graphite into Micrometre Size Few Layers Graphene Sheets Using Ionic Liquids. Chem. Commun. 2010, 46, 4487. [Google Scholar] [CrossRef]

- Liu, Y.; He, C.E.; Peng, R.G.; Tang, W.; Yang, Y.K. Ionic Liquid Assisted Dispersion of Reduced Graphene Oxide in Epoxy Composites with Improved Mechanical Properties. Adv. Mater. Res. 2013, 738, 56–60. [Google Scholar] [CrossRef]

- Wang, J.; Wu, J.; Xu, W.; Zhang, Q.; Fu, Q. Preparation of Poly(vinylidene Fluoride) Films with Excellent Electric Property, Improved Dielectric Property and Dominant Polar Crystalline Forms by Adding a Quaternary Phosphorus Salt Functionalized Graphene. Compos. Sci. Technol. 2014, 91, 1–7. [Google Scholar] [CrossRef]

- Xu, P.; Gui, H.; Wang, X.; Hu, Y.; Ding, Y. Improved Dielectric Properties of Nanocomposites Based on Polyvinylidene Fluoride and Ionic Liquid-Functionalized Graphene. Compos. Sci. Technol. 2015, 117, 282–288. [Google Scholar] [CrossRef]

- Joseph, S.; Francis, B. Non-Covalent Interactions between Ionic Liquid and Graphene Nanoplatelets as a Tool to Fine Tune the Properties of Styrene Butadiene Rubber Nanocomposites. J. Appl. Polym. Sci. 2023, 140, 54573. [Google Scholar] [CrossRef]

- Yu, J.; Li, Y.; Qin, F.; Lu, S.; Yang, C.; Li, Y.; Zhou, W. Ultra-Lightweight and Multifunctional Ionic Liquid-Modified Graphene/Polyimide Aerogels for Efficient Electromagnetic Wave Absorption. J. Mater. Sci. 2023, 58, 9181–9195. [Google Scholar] [CrossRef]

- Kuila, T.; Khanra, P.; Mishra, A.K.; Kim, N.H.; Lee, J.H. Functionalized-Graphene/Ethylene Vinyl Acetate Co-Polymer Composites for Improved Mechanical and Thermal Properties. Polym. Test. 2012, 31, 282–289. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Z.; Kuma, D.J.P.; Qu, Y.; Long, Y.; Xie, P.; Liang, G.; Wang, J.; Yang, Q.; Qi, X.; et al. Flexible carbon nanotube/polystyrene membraneous composites towad ultraweakly and frquency-stable negative permittivity at kHz region. Eng. Sci. 2023, 24, 920. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Wang, Y.; Ren, J.; Alshammari, D.A.; Eabd lsalam, H.E.; El Azab, I.H.; Algadi, H.; Xie, P.; Liu, Y. Flexible cementite/ferroferric oxide/silicon dioxide/carbon nanofibers composite membrane with low-frequency dispersion weakly negative permittivity. Adv. Compos. Hybrid Mater. 2023, 6, 217. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, Z.; Wang, C.; Abualnaja, K.M.; Abo-Dief, H.M.; Hou, Q.; Algadi, H.; Yin, R.; Liu, X.; Xie, P.; et al. Radio-frequency broadband epsilon-near-zero response in biocompatible silver nanoparticles/polystyrene films with three-dimensional honeycomb-like superstructures. Adv. Compos. Hybrid Mater. 2023, 6, 206. [Google Scholar] [CrossRef]

- Peng, S.; Yu, Y.; Wu, S.; Wang, C.H. Conductive polymer nanocomposites for stretchable electronics: Material selection, design, and applications. ACS Appl. Mater. Interfaces 2021, 13, 43831–43854. [Google Scholar] [CrossRef]

- Shown, I.; Ganguly, A.; Chen, L.C.; Chen, K.H. Conducting polymer-based flexible capacitor. Energy Sci. Eng. 2015, 3, 2–26. [Google Scholar] [CrossRef]

- Zhao, D.; Jia, W.; Feng, X.; Yang, H.; Xie, Y.; Shang, J.; Wang, P.; Guo, Y.; Li, R.W. Flexible sensors based on conductive polymer composites. Sensors 2024, 24, 4664. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M.; Rahdar, A. Graphene-based polymer composites for flexible electronic applications. Micromachines 2022, 13, 1123. [Google Scholar] [CrossRef]

- Genoyer, J.; Helal, E.; Gutierrez, G.; Moghimian, N.; David, E.; Demarquette, N.R. Graphene and Nanoclay as Processing Aid Agents: A Study on Rheological Behavior in Polystyrene. C 2023, 9, 96. [Google Scholar] [CrossRef]

- de Lima, L.R.M.; da Silva, S.P.M.; Trindade, T.; Oliveira, J.M. Rheological Behavior of Poly(propylene) Reinforced with Graphene Nanoplatelets for Injection Molding. J. Appl. Polym. Sci. 2022, 139, 52492. [Google Scholar] [CrossRef]

- Han, C.D.; Jhon, M.S. Correlations of the First Normal Stress Difference with Shear Stress and of the Storage Modulus with Loss Modulus for Homopolymers. J. Appl. Polym. Sci. 1986, 32, 3809–3840. [Google Scholar] [CrossRef]

- Chakraborty, G.; Bhattacharjee, S.; Katiyar, V.; Pugazhenthi, G. Melt Rheology Analysis through Experimental and Constitutional Mechanical Models of Exfoliated Graphene-Based Polylactic Acid (PLA) Nanocomposites. J. Polym. Res. 2023, 30, 10. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Kurtz, S.M. Evaluation of Carbon Nanotubes and Graphene as Reinforcements for UHMWPE-Based Composites in Arthroplastic Applications: A Review. J. Mech. Behav. Biomed. Mater. 2014, 39, 129–145. [Google Scholar] [CrossRef]

- Goodarzi, V.; Kokabi, M.; Kashani, M.R.; Bahramian, A.R. Prediction of Long-Term Mechanical Properties of PVDF/BaTiO3 Nanocomposite. J. Appl. Polym. Sci. 2014, 131, 40596. [Google Scholar] [CrossRef]

- Maksimov, R.D.; Bitenieks, J.; Plume, E.; Zicans, J.; Meri, R.M. Properties of a Composite Prepared Using a Concentrate of Carbon Nanotube in Polyethylene. Mech. Compos. Mater. 2012, 48, 47–56. [Google Scholar] [CrossRef]

- Majda, P.; Skrodzewicz, J. A Modified Creep Model of Epoxy Adhesive at Ambient Temperature. Int. J. Adhes. Adhes. 2009, 29, 396–404. [Google Scholar] [CrossRef]

- Kumar, G.S.; Patro, T.U. Efficient Electromagnetic Interference Shielding and Radar Absorbing Properties of Ultrathin and Flexible Polymer-Carbon Nanotube Composite Films. Mater. Res. Express 2018, 5, 15304. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H.; Lam, T.D. Graphene Nanocomposites for Electromagnetic Interference Shielding—Trends and Advancements. J. Compos. Sci. 2023, 7, 384. [Google Scholar] [CrossRef]

- Cilento, F.; Curcio, C.; Martone, A.; Liseno, A.; Capozzoli, A.; Giordano, M. Effect of Graphite Nanoplatelets Content and Distribution on the Electromagnetic Shielding Attenuation Mechanisms in 2D Nanocomposites. J. Compos. Sci. 2022, 6, 257. [Google Scholar] [CrossRef]

- Soares, B.G.; Barra, G.M.O.; Indrusiak, T. Conducting Polymeric Composites Based on Intrinsically Conducting Polymers as Electromagnetic Interference Shielding/Microwave Absorbing Materials—A Review. J. Compos. Sci. 2021, 5, 173. [Google Scholar] [CrossRef]

- Choi, J.; Jung, H.T. A New Triple-Layered Composite for High-Performance Broadband Microwave Absorption. Compos. Struct. 2015, 122, 166–171. [Google Scholar] [CrossRef]

- Danlée, Y.; Bailly, C.; Huynen, I. Thin and Flexible Multilayer Polymer Composite Structures for Effective Control of Microwave Electromagnetic Absorption. Compos. Sci. Technol. 2014, 100, 182–188. [Google Scholar] [CrossRef]

- Folgueras, L.C.; Rezende, M.C. Multilayer Radar Absorbing Material Processing by Using Polymeric Nonwoven and Conducting Polymer. Mater. Res. 2008, 11, 245–249. [Google Scholar] [CrossRef]

- Wright, P.V.; Chambers, B.; Barnes, A.; Lees, K.; Despotakis, A. Progress in Smart Microwave Materials and Structures. Smart Mater. Struct. 2000, 9, 273–279. [Google Scholar] [CrossRef]

- Huynen, I. Investigation of Microwave Absorption Mechanisms in Microcellular Foamed Conductive Composites. Micro 2021, 1, 86–101. [Google Scholar] [CrossRef]

- Lou, L.; Al-Duhni, G.S.G.; Cruz, O.B.; Volakis, J.L.; Pulugurtha, M.; Agarwal, A. Iron Oxide Quantum Dots and Graphene Nanoplatelets Integrated in a Dual-Polymer Conductive Fiber for Electromagnetic Interference-Shielding Thin Films. ACS Appl. Nano Mater. 2025, 8, 3617–3630. [Google Scholar] [CrossRef]

- Yin, D.; Li, J.; Wang, S.; Xiu, H.; Liu, G.; Huang, S.; Fan, S.; Shen, M.; Pan, Y. Constructing Multi-Dimensional Alternating Layer Nested Structure for Enhancing Electromagnetic Shielding, Thermal Management and Strain Sensing. Chem. Eng. J. 2024, 497, 154954. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, Y.; Liu, S.; Chao, B.; Zhang, F.; Deng, S.; Wang, Q. Enhanced Microwave Absorption Through Fused Deposition Modeling of Cnt/Pla/Tpu Composites. J. Appl. Phys. 2025, 137, 155101. [Google Scholar] [CrossRef]

- Caldas, C.M.; Soares, B.G.; Indrusiak, T.; Barra, G.M.O. Ionic Liquids as Dispersing Agents of Graphene Nanoplatelets in Poly(Methyl Methacrylate) Composites with Microwave Absorbing Properties. J. Appl. Polym. Sci. 2021, 138, 49814. [Google Scholar] [CrossRef]

- Calheiros Souto, L.F.; Soares, B.G. EVA Copolymer Loaded with PAni/CNT/GNP Hybrids: A Flexible and Lightweight Material with High Microwave Absorption. J. Appl. Polym. Sci. 2024, 141, e55531. [Google Scholar] [CrossRef]

- Wang, S.; Yang, W.; Li, X.; Hu, Z.; Wang, B.; Gong, N. Volume Exclusion Effect and Ambient Temperature Induced Ultrahigh Electromagnetic Wave Absorption Properties of Polylactic Acid (PLA)/Graphene Nano-platelets (GNPs) Composites. J. Appl. Polym. Sci. 2024, 141, e55370. [Google Scholar] [CrossRef]

- Vovchenko, L.L.; Lozitsky, O.V.; Matzui, L.Y.; Zagorodnii, V.V. Optimization of Multilayered Electromagnetic Shielding Using Mesh Adaptive Direct Search. Appl. Nanosci. 2023, 13, 6761–6775. [Google Scholar] [CrossRef]

| EVA/GNP | Young’s Modulus (MPa) | Strain at Break (%) | Max Stress (MPa) | |||

|---|---|---|---|---|---|---|

| GNP (wt%) | Without IL | With IL | Without IL | With IL | Without IL | With IL |

| 0 | 19.0 ± 0.8 | - a | 671 ± 55 | - a | 12.2 ± 1.5 | - a |

| 0.5 | 17.9 ± 1.1 | 16.2 ± 0.8 | 793 ± 35 | 922 ± 96 | 12.1 ± 0.7 | 12.9 ± 0.8 |

| 1 | 17.1 ± 1.1 | 14.8 ± 0.9 | 858 ± 55 | 1139 ± 182 | 12.2 ± 1.9 | 11.5 ± 2.3 |

| 2 | 20.0 ± 0.6 | 15.9 ± 0.7 | 741 ± 33 | 1074 ± 126 | 12.5 ± 0.5 | 13.6 ± 1.1 |

| 5 | 21.3 ± 0.5 | 16.3 ± 1.2 | 825 ± 166 | 676 ± 70 | 17.2 ± 2.4 | 14.1 ± 2.6 |

| 10 | 22.7 ± 0.9 | 14.8 ± 1.4 | 832 ± 121 | 853 ± 111 | 19.3 ± 0.9 | 13.5 ± 1.3 |

| GNP (wt%) | Strain at 3600 s (%) | Instant Strain Recovery (%) | ||||

|---|---|---|---|---|---|---|

| Without IL | With IL | Without IL | With IL | |||

| Value | Variation (%) | Value | Variation (%) | |||

| EVA | 2.04 | - a | - a | - a | 31 | |

| 0.5 | 1.35 | 34 | 1.38 | 32 | 57 | 57 |

| 1 | 1.44 | 29 | 1.22 | 40 | 40 | 31 |

| 2 | 2.02 | 1 | 2.37 | −16 | 33 | 25 |

| 5 | 1.26 | 38 | 1.07 | 48 | 34 | 41 |

| 10 | 1.20 | 35 | 1.20 | 41 | 36 | 39 |

| GNP (wt%) | E1 (MPa) | E2 (MPa) | η1 (MPa∙s) | η2 (MPa∙s) | τ = η2/E2 (s) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | |

| EVA | 12.3 ± 0.2 | 13.6 ± 0.6 | (70 ± 7) × 103 | (45 ± 3) × 102 | 328.8 | |||||

| 0.5 | 11.9 ± 0.1 | 12.0 ± 0.1 | 24.9 ± 0.7 | 36.7 ± 1.2 | (276 ± 37) × 103 | (125 ± 7) × 103 | (19 ± 2) × 102 | (52 ± 4) × 102 | 212.5 | 141.5 |

| 1 | 13.5 ± 0.2 | 11.4 ± 0.2 | 20.9 ± 0.6 | 13.5 ± 0.4 | (132 ± 12) × 103 | (102 ± 10) × 103 | (25 ± 2) × 102 | (15 ± 1) × 102 | 121.7 | 110.9 |

| 2 | 12.0 ± 0.2 | 9.5 ± 0.1 | 14.3 ± 0.5 | 12.4 ± 0.4 | (65 ± 5) × 103 | (58 ± 4) × 103 | (19 ± 2) × 102 | (15 ± 1) × 102 | 134.1 | 124.4 |

| 5 | 18.7 ± 0.3 | 18.8 ± 0.3 | 23.3 ± 0.6 | 30.4 ± 0.9 | (110 ± 6) × 103 | (140 ± 9) × 103 | (25 ± 2) × 102 | (20 ± 2) × 102 | 105.4 | 67.4 |

| 10 | 16.5 ± 0.3 | 13.7 ± 0.2 | 25.0 ± 0.8 | 27.5 ± 1.0 | (134 ± 11) × 103 | (222 ± 31) × 103 | (29 ± 3) × 102 | (35 ± 3) × 102 | 117.7 | 129.0 |

| Amount of Filler | 0.5 GNP | 0.5 GNP IL | 10 GNP | 10 GNP IL | ||||

|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | RL (dB) | EAB (GHz) | RL (dB) | EAB (GHz) | RL (dB) | EAB (GHz) | RL (dB) | EAB (GHz) |

| AS3 | −10.3 | 0.28 | −14.2 | 1.9 | −23.3 | 1.5 | −10.8 | 0.5 |

| AS4 | −9.7 | − a | −10.9 | 0.4 | −13.2 | 1.2 | −13.6 | 1.2 |

| AS5 | −12.3 | 1.2 | −13.0 | 1.3 | −19.3 | 2.4 | −19.2 | 1.8 |

| NAS2.5 | −20.1 | 3.5 | −14.4 | 2.6 | −12.4 | 0.4 | −24.6 | 4.3 |

| Matrix | Filler | Concentration | Processing | RL | Ref |

|---|---|---|---|---|---|

| PET/PU | Pani-DBSA | 15 wt% | Nonwoven substrate impregnation | −23 dB | [43] |

| PLA/TPU | CNT | 4 wt% | Extrusion + 3D printing | −31 dB | [48] |

| PMMA | GNP + IL | Multilayer: 1.9 wt% | Solution mixture + compression molding | −13 dB | [49] |

| EVA | GNP | 0.8 wt% | Solution mixture + compression molding | ~−20 dB | [50] |

| PLA | GNP | 15 wt% | Solution mixture + compression molding | −19 dB * | [51] |

| EVA | GNP + IL | Multilayer: 10 wt% | Melt mixing + film extrusion | −24 dB | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schettini, A.A.; Schmitz, D.P.; Cunha, B.S.; Soares, B.G. Conducting EVA/GNP Composite Films with Multifunctional Applications: Effect of the Phosphonium-Based Ionic Liquid. J. Compos. Sci. 2025, 9, 256. https://doi.org/10.3390/jcs9060256

Schettini AA, Schmitz DP, Cunha BS, Soares BG. Conducting EVA/GNP Composite Films with Multifunctional Applications: Effect of the Phosphonium-Based Ionic Liquid. Journal of Composites Science. 2025; 9(6):256. https://doi.org/10.3390/jcs9060256

Chicago/Turabian StyleSchettini, André A., Debora P. Schmitz, Beatriz S. Cunha, and Bluma G. Soares. 2025. "Conducting EVA/GNP Composite Films with Multifunctional Applications: Effect of the Phosphonium-Based Ionic Liquid" Journal of Composites Science 9, no. 6: 256. https://doi.org/10.3390/jcs9060256

APA StyleSchettini, A. A., Schmitz, D. P., Cunha, B. S., & Soares, B. G. (2025). Conducting EVA/GNP Composite Films with Multifunctional Applications: Effect of the Phosphonium-Based Ionic Liquid. Journal of Composites Science, 9(6), 256. https://doi.org/10.3390/jcs9060256