Abstract

This study investigates the mechanical, thermal, and liquid resistance properties of injection-molded composites made from recycled polypropylene (rPP) reinforced with jute fillers. Maleic anhydride-grafted polypropylene (MAPP) was used as a compatibilizer to enhance filler–matrix interfacial bonding. Tensile, flexural, and Charpy impact tests, along with density measurements, heat deflection temperature (HDT) tests, and resistance to short-duration liquid contact, were conducted to evaluate the composites. Results indicate that the addition of jute powder significantly improved stiffness (Young’s modulus increased up to 233%) and thermal stability (HDT increased to 147 °C for rPP/J40/MAPP) while reducing impact toughness due to the brittle nature of jute fillers. MAPP-modified composites demonstrated enhanced tensile and flexural strength compared to unmodified counterparts, with tensile strength improving by approximately 23% for rPP/J30/MAPP. The composites exhibited excellent liquid resistance, showing no visible changes after exposure to various automotive and household fluids.

1. Introduction

The modern automotive industry faces increasing demands for multifunctional materials tailored to diverse applications, ranging from structural components to interior systems. For off-road construction machinery, materials must combine impact resistance, load-bearing capacity, and thermal stability to withstand extreme conditions such as gravel and stone impacts. While metals like steel and cast iron dominate high-load and high-impact applications, the use of polymers and polymer composites is essential for specific parts due to their lightweight, inertness, and favorable thermo-electric properties [1,2,3]. This is especially evident in interior components where aesthetics, functionality, and sustainability drive material selection.

Polymeric materials are often reinforced with various fibers and fillers to enhance their mechanical properties and compensate for their inherent malleability [4,5]. In recent years, there has been a significant shift toward integrating natural fibers and bio-based fillers to reduce reliance on fossil-derived polymers, mineral fillers, and synthetic reinforcements like fiberglass [6,7]. This trend is driven by the dual goals of environmental sustainability and reduced carbon footprint, aligning with the global push for circular material solutions. Among the available natural fibers, jute stands out for its abundance, renewability, and socio-economic significance [8].

Jute is one of the most produced natural fibers, primarily grown in India and Bangladesh during the monsoon season. Known as the “Golden Fiber” [9], jute has a significant social and economic impact, particularly in Bangladesh [10], where approximately one-third of the population depends on its cultivation and processing [11].

Traditionally, jute fibers have been used in textiles, ropes, carpets, and packaging materials [12,13,14]. However, in recent years, innovative uses have emerged, including reinforcement in composite materials for structural and industrial applications. While jute fibers are widely used as yarn or fabric reinforcement, there has been increasing interest in utilizing the agricultural by-product, jute sticks. Often considered waste [15], jute sticks are either burned for fuel or discarded, yet they represent a promising resource for producing lightweight fillers or reinforcements.

Jute sticks, the woody core of the plant, are lightweight and contain significant quantities of α-cellulose [16,17], making them suitable for various applications, including pulp production, hardboards, and chemical derivatives like furfural and activated charcoal. Despite their potential, their use in advanced material systems remains underexplored. Juteborg Sweden AB, an innovation business specializing in high-tech natural fiber composites, has pioneered the transformation of jute sticks into fine powders for use as fillers in polymer composites. These powders offer a low-density alternative to conventional fillers while retaining the mechanical benefits of natural fibers.

Polypropylene (PP) is the one of the most widely used polymers in automotive interiors, owing to its favorable properties such as low density, chemical resistance, and ease of processing. However, the combination of recycled PP (rPP) with jute stick fillers represents a novel material solution, addressing the need for sustainability and waste reduction [18]. The integration of recycled polymers significantly reduces environmental impact, including lower energy consumption and greenhouse gas emissions during manufacturing [19]. Pairing rPP with bio-based jute fillers further amplifies these benefits by valorizing agricultural waste, contributing to circular economy objectives. While natural fiber composites have been widely investigated, the utilization of jute stick powders in combination with rPP remains largely unexplored, offering a unique opportunity to develop high-performance, sustainable materials for interior and structural applications.

This study introduced several novel contributions to the field of polymer composites. For one of the first times, jute powder was produced from the agricultural by-product of jute shives, offering a sustainable approach to valorizing what is often treated as waste. Additionally, this work marked the first combination of jute stick powders with recycled polypropylene (rPP), addressing both agricultural and industrial waste streams in a single composite system. A comprehensive set of mechanical tests, including tensile, flexural, and impact testing were performed providing a robust evaluation of the composites’ performance. A significant new aspect of this study involved testing aged specimens using an impact tester, offering insights into the long-term durability of the materials under extreme conditions. Furthermore, heat deflection temperature (HDT) measurements performed on these types of composites for the first time. Moreover, the investigation of resistance to various liquids, including automotive and household fluids, was another novel aspect of this work, providing practical insights into the composites’ applicability for real-world use cases. To the best of the authors’ knowledge, these contributions collectively represented a pioneering effort to explore and evaluate jute stick powders in recycled polymer systems.

This study aimed to investigate the potential of jute stick powder as a filler in recycled polypropylene (rPP) composites, with and without the addition of maleic anhydride-grafted polypropylene (MAPP) as a compatibilizer. The use of rPP aligned with sustainability objectives, while MAPP enhanced interfacial bonding between the hydrophilic jute fillers and the hydrophobic rPP matrix. The results are expected to provide insights into the suitability of jute-filled rPP composites for automotive and structural applications, contributing to the development of high-performance, sustainable materials.

2. Experimental

2.1. Materials

Recycled polypropylene (rPP) pellets, with an average density of 930 kg/m3 and a melt flow index (MFI) of 13 g/10 min (230 °C/2.16 kg), were supplied by Polykemi, Ystad, Sweden. Jute powder prepared from jute stick with an average length of 60 cm which was provided by Juteborg Sweden AB, Gothenburg, Sweden. Polypropylene-graft-maleic-anhydride (MAPP), containing 8–10 wt% maleic anhydride and having a melting point of 156 °C, was purchased from Sigma-Aldrich, Burlington, MA, USA. Recycled polypropylene (rPP) and jute powder were used as matrix and reinforcement, respectively, while MAPP was used as a bonding agent (compatibilizer) between rPP and jute powder.

2.2. Preparation of Jute Stick Powder

Jute sticks were initially cut manually into smaller pieces approximately 20 mm in length. The pieces were then ground using a RETSCH SM 100 grinder, Retsch GmbH, Haan, Germany, powdered in a KIKA-WERKE mechanical blender, IKA-Werke GmbH & Co. KG, Staufen, Germany, and subsequently sieved through a series of NYCANDER sieves with openings of 2 mm and 1 mm, respectively. The resulting jute powder was dried in an oven at 80 °C for 24 h.

2.3. Fabrication of the Composites

Composites were prepared using varying proportions of recycled polypropylene (rPP), jute powder (J), and maleic anhydride-grafted polypropylene (MAPP). The rPP/jute (rPP/J) and rPP/jute/MAPP (rPP/J/MAPP) composites were produced via melt mixing using an Xplore Micro 15cc Twin Screw Compounder at 200 °C, with a screw rotation speed of 50 rpm for 5 min. All materials were pre-dried in an oven at 80 °C for 24 h, and approximately 10 g of pre-mixed materials were used for each compounding process. The proportions of rPP, jute powder, and MAPP in each composite are detailed in Table 1. The weight fraction of MAPP is given as a percentage relative to the total mass of the polymer and jute powder combined.

Table 1.

Composition ratios of rPP, jute powder, and MAPP in the prepared composites.

The molten composite blends were directly transferred to the injection cylinder of the injection molding machine (Xplore Instruments B.V., Sittard, The Netherlands, set at 200 °C to produce specimens for mechanical property evaluation, including tensile, flexural, and Charpy impact tests, following the standard test methods ISO 527-2 [20], ISO 14125 [21] and ISO 179-1 [22], respectively. The mold temperature was maintained at 60 °C, and the material was injected into the mold under 16 bars of pressure in three stages, with holding times of 10, 15, and 15 s, respectively.

All mechanical tests, including tensile, flexural, and impact tests, were conducted at room temperature. Specimens were conditioned in a climate chamber for approximately 24 h at 23 °C and 50% relative humidity prior to testing. The properties of the resulting composites were compared with those of pure rPP.

2.4. Tensile Test

Tensile testing is crucial for assessing material behavior under stress, providing insights into their strength, stiffness, and resilience. Tensile test was performed on dog bone-shaped specimens, 75 mm in length, following the ISO 527-2:2012 standard [20], prepared by injection molding. The test was conducted using the Tinius Olsen H10KT tensile testing machine Tinius Olsen Ltd., Horsham, Pennsylvania, United States, and the results were proceeded on Horizon software (version 10.3.1.10). Specimens were tested using a 1 kN load cell. The loading rate during the tests was set at 2 mm/min. A gauge length of 20 mm was used, with an initial grip distance of 40 mm. A 100R mechanical extensometer was attached at the midpoint of the specimens’ gauge length. The average values for the strength, the modulus, and elongation to break point were calculated based on the results of five replicates.

2.5. Flexural Test

Flexural or bending tests were conducted to evaluate how composite materials respond to bending forces by measuring flexural strength and stiffness of the materials reflecting the maximum stress a material can withstand before failure and the material’s deformation under load. Rectangular specimens for the bending test were fabricated using injection molding with dimensions of 80 mm in length, 20 mm in width, and 4 mm in thickness [21]. The tests were performed using a Tinius Olsen H10KT tensile testing machine, Tinius Olsen Ltd., Horsham, Pennsylvania, United States, equipped with a three-point bending grip for at least five replicates of each composite. The span length between the grips was set to 64 mm. The testing setup operated at a crosshead speed of 5 mm/min.

2.6. Charpy Impact Test

The impact test was conducted in accordance with ISO 179-1 [22]. A 5 J pendulum with a mass of 1.377 kg and a center of mass distance of 0.202 m was used for the experiment. The samples were V-notched with a notch depth of approximately 2 mm, and their dimensions were 80 × 10 × 4 mm. The impact strength was then calculated for each specimen. Additionally, aging at 85 °C for 1000 h was performed to assess the long-term stability of the materials, with the impact energy measured before and after aging.

2.7. Density Measurements

The density of the specimens was measured in ethanol using the gravimetric buoyancy method based on Archimedes’ principle, as described in Equation (1). This process was carried out following the guidelines provided for the precise balance used (Kern ALS 220-4, KERN & SOHN GmbH, Balingen, Germany) [23], which has an accuracy of 0.1 mg.

where is the density of sample, A is the weight of the sample in air, B is the weight of the sample in ethanol, and is the density of ethanol.

2.8. Heat Deflection Temperature Test

The heat deflection temperature (HDT) of plastic material is a critical parameter in product design. It indicates the maximum temperature at which the material can maintain its structural integrity under load and heat without experiencing significant physical deformation, primarily deflection [24]. A heat deflection test (HDT) was carried out using a Ceast HV3 HDT Vicat/HDT tester from Instron, Turin, Italy, in accordance with the ISO 75-1 standard method B [25]. The sample dimensions were 80 mm × 20 mm × 4 mm, and a load of 0.45 MPa was applied at a heating rate of 120 °C/h. A medium to high-temperature silicone oil served as the heating medium to ensure consistent thermal conductivity and stability throughout the test. Three samples were tested for each material to ensure reliable results.

2.9. Determination of the Effects of Various Liquids

According to the technical requirement of interior application of automotives, the visible part material should fulfill grade 0 (no change in appearance) and result in no distinct changes in mechanical properties for the resistance to the short duration of contact during the fluid test. The test liquids were chosen according to ISO 1817:2024 [26]. The standard describes the test liquids that shall normally be used to determine the resistance to liquids of polymeric materials, e.g., rubber, plastics, paints, and enamels. This standard covers methods of testing the resistance of different test fluids that can cause swelling and/or discoloration of the test objects. The grade for change in appearance and distinct changes (swelling and/or discoloration) must be stated.

3. Results and Discussion

3.1. Tensile Test Results of Jute Composites

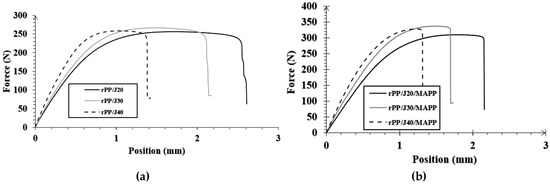

The tensile test results, presented as the average of five replicates for each composite, provide insights into the mechanical behavior of the materials. Key parameters, including Young’s modulus, tensile strength, and elongation at break point, are detailed in Table 2, and the force-displacements are provided in Figure 1 for the composites, with and without compatibilizer MAPP.

Table 2.

The influence of jute powder and anhydride-grafted polypropylene (MAPP) on the tensile properties of the recycled polypropylene (rPP).

Figure 1.

Tensile stress and strain curves of composites without MAPP (a) and with MAPP (b).

Young’s modulus is a highly practical and informative property, representing the stiffness of a material and the material’s resistance to elastic deformation. It reflects the degree of deformation a material undergoes under normal use while staying within its yield strength limits [27].

Table 2 highlights the reinforcing effect of natural fibers like jute in improving stiffness and strength. The Young’s modulus showed a notable increase with higher jute content, rising by 86% from 1.38 GPa (rPP) to 2.57 GPa (rPP/J20), and further increasing by 233% to 4.60 GPa (rPP/J50) due to the rigid nature of the jute. This trend suggests that the incorporation of jute powder contributed to enhanced interfacial bonding between the fibers and the matrix (which could be attributed to the rough surface of jute fibers which allows for better mechanical interlocking with the matrix), leading to better stress transfer. The increase in Young’s modulus by addition of greater jute content exhibited greater stiffness of composite, making it more suitable for applications where the higher modulus would be beneficial (e.g., automotive, construction) [28].

As jute content increased, the elongation at the break point decreases steadily. This is because the jute powder restricted the ability of the polymer matrix to deform, making the composite stiffer but less ductile. As shown in Table 2, there is a noticeable reduction in elongation with higher jute content, from 21.1% (rPP) to 4.43% (rPP/J50), showing the balance between stiffness and ductility. The reduction in elongation at the break point is typical for composites reinforced with rigid fibers, where the overall composite tends to be stiffer but less flexible.

As shown in Table 2, the maximum tensile strength observed is recorded at approximately 32 MPa for rPP/J20, rPP/J30 and rPP/J40. The tensile strength initially increased as jute content rose, reaching a peak at about 32.33 MPa. However, there was a noticeable drop in tensile strength at rPP/J50 (26.42 MPa). This decrease suggests that, beyond a certain concentration of jute, the interaction between the fibers and matrix may not be as effective, potentially due to weak adhesion between the fibers and the rPP matrix, resulting from the lack of a polymer acting as a binder. It could also be added that the higher jute content could lead to poor dispersion of the fibers in the matrix, resulting in localized stress concentrations and reduced strength. Additionally, this drop in tensile strength at higher jute content could also be related to the increased brittleness of the composite due to excess filler, which could disrupt the matrix’s ability to transfer the load efficiently.

The influence of maleic anhydride-grafted polypropylene (MAPP) as a compatibilizer on the stiffness of the composites is demonstrated in Table 2. The results indicated that the Young’s modulus did not exhibit further improvement compared to the unmodified composites, across the range from rPP/ J20 to rPP/J50. As displayed in Table 2, MAPP did not have any significant effect on the elongation at the break point of composites. While MAPP improves interfacial bonding, it may not significantly alter the ductility of the composite if the matrix itself remains relatively stiff. However, the introduction of MAPP significantly enhanced the tensile strength of the composites. The tensile strength increased across all jute contents compared to the unmodified composites. The tensile strength increased from approximately 32 MPa in RPP/J20, RPP/J30, and RPP/J40 to around 40 MPa in all the composites containing MAAP. This is because MAPP can enhance the compatibility between the hydrophilic jute fillers and the hydrophobic rPP matrix, which is crucial for enhancing mechanical properties. Studies [29,30] conducted by other researchers demonstrated that MAPP significantly enhanced the interfacial compatibility between natural fibers, such as mahogany wood flour or alfa fiber and both recycled PP and PP. This improvement led to increased mechanical properties, including tensile strength. However, the improvement in tensile strength was significantly lower in those studies compared to the enhancement observed in this study.

As a result, the use of MAPP transformed rPP/jute composites by enhancing tensile strength. These improved properties make the composites more suitable for applications requiring mechanical robustness, especially in structural and packaging materials.

3.2. Flexural Test of Jute Composites

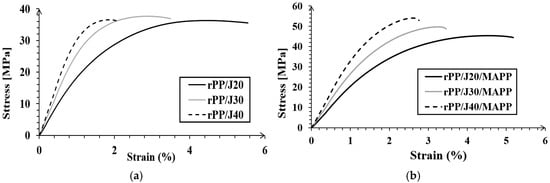

Table 3 demonstrates the flexural strength and flexural modulus of rPP and all composites, and Figure 2 displays the stress–strain curves of jute rPP composites, illustrating their bending behavior. The flexural modulus of the composites increased steadily with higher jute content, from 1.2 GPa for rPP to 3.7 GPa for rPP/J50. This trend reflected the stiffening effect of rigid jute fillers, which restricted the matrix’s flexibility and enhanced its rigidity. However, the incorporation of MAPP does not significantly alter the modulus, as seen in the similar values for rPP/J20 (2.0 GPa) vs. rPP/J20/MAPP (1.98 GPa). This observation suggests that, while MAPP enhanced interfacial bonding, it did not greatly influence the flexural stiffness due to the inherent rigidity of the jute fillers dominating the response.

Table 3.

The effect of jute powder and anhydride-grafted polypropylene (MAPP) on the bending properties of the recycled polypropylene (rPP).

Figure 2.

Flexural stress and strain curves of composites without MAPP (a) and with MAPP incorporation (b).

The flexural strength of the composites showed limited variation for rPP/J20 to rPP/J40, remaining in the range of 36–38 MPa. However, at 50% jute filler content, the flexural strength decreased for both unmodified and MAPP-modified composites, with rPP/J50 and rPP/J50/MAPP recording 29.7 MPa and 46.9 MPa, respectively. While MAPP enhanced the flexural strength at higher filler contents compared to the unmodified composites, this improvement was less pronounced at 50% filler content due to challenges like filler agglomeration and limited load transfer efficiency. Gholampour et al. [31] reported that, at very high fiber contents, issues such as filler agglomeration can lead to a decrease in flexural strength, which is consistent with the findings in this study at 50% jute filler content.

These findings suggest that MAPP plays a significant role in mitigating issues associated with poor filler–matrix adhesion, particularly at moderate filler contents. For the composites with MAPP, the flexural strength at higher jute contents (e.g., rPP/J50/MAPP, 46.9 MPa) remained significantly improved compared to unmodified composites (rPP/J50, 29.7 MPa). This indicates that MAPP mitigates some of the drawbacks associated with high jute content, such as poor dispersion, by ensuring better compatibility between the hydrophilic fibers and the hydrophobic rPP matrix [31].

Raghu et al. [32] studied rice husk reinforced polypropylene composites and demonstrated that the addition of MAPP improved the flexural properties of the composites. This aligns with the current observations of MAPP-enhanced interfacial bonding but did not significantly alter the flexural modulus.

3.3. Charpy Impact Energy Results of Jute Composites and Aging Effect on the Property of the Composites

The impact test results of the composites and rPP without aging are shown in Table 4.

Table 4.

The effect of jute powder and anhydride-grafted polypropylene (MAPP) on the impact energy of the recycled polypropylene (rPP).

The addition of jute powder consistently reduced the impact energy of the composites. For instance, the impact energy decreased from 8.8 kJ/m2 for pure rPP to 4.4 kJ/m2 for rPP/J20 and further declined to 2.6 kJ/m2 for rPP/J50. This trend reflects the inherent brittleness of jute powder, which limits the ability of the composite to absorb impact energy. The rigid jute particles create stress concentrations, reducing the material’s overall toughness.

The incorporation of MAPP had negligible influence on the impact energy of the composites. For instance, the impact energy for rPP/J20 (4.4 kJ/m2) was nearly identical to that of rPP/J20/MAPP (4.3 kJ/m2). Similar trends were observed for other formulations. While MAPP improves interfacial bonding and mechanical properties like tensile and flexural strength, and its effect on impact energy remains limited. This suggests that the matrix–filler/fiber bonding improvements do not significantly influence the ability of the composites to absorb impact energy during sudden loading.

The decline in impact energy with increasing jute content underscores a trade-off between stiffness/strength and toughness. Applications requiring high toughness may need additional modifications, such as the inclusion of elastomers or alternative filler/fiber treatments, to offset the brittleness introduced by jute powder.

After aging (Table 5), the composites showed a reduction in impact energy. The impact energy decreased by 20.5% for rPP/J20 (from 4.4 kJ/m2 to 3.5 kJ/m2) and by 13.3% for rPP/J20/MAPP (from 4.3 kJ/m2 to 3.73 kJ/m2). This reduction can be attributed to degradation processes like filler–matrix interface weakening, polymer chain scission, or moisture absorption, which collectively contribute to lower energy absorption capabilities.

Table 5.

Impact test results for the effect of aging for 1000 h at 85 °C (the values shown in parentheses represent the standard deviations).

Interestingly, the impact energy of the pure rPP increased after aging, from 8.8 kJ/m2 to 9.7 kJ/m2, showing a slight improvement. This might suggest that the polymer matrix underwent a crosslinking process or some other mechanism that increased its toughness after prolonged thermal exposure. Such behavior is uncommon but can occur under specific conditions, such as heat-induced polymer stabilization or the reduction of internal stresses in the material. The rPP’s tendency to improve upon aging could also be linked to changes in the molecular structure that increase its ability to withstand impact. Research [33] on the preparation of high-performance anti-aging polypropylene indicated that certain aging processes can lead to improvements in mechanical properties, such as increased impact strength, due to mechanisms like crosslinking or reduction of internal stresses.

3.4. Density Measurements of Virgin PP, Recycled PP, rPP/J10, rPP/J20, rPP/J30, and rPP/J40

The density values measured for the specimens are displayed in Table 6. The results showed a clear trend of increasing density with the incorporation of jute powder into the rPP matrix. Virgin polypropylene (non-recycled) had the lowest density at 0.90 g/cm3, while recycled polypropylene (rPP) had a slightly higher density of 0.96 g/cm3. As jute content increased, the density gradually rose, reaching 1.09 g/cm3 for rPP/J40. This increase in density can be attributed to the added mass of the natural fibers, which are denser than the rPP matrix, contributing to the overall increase in composite density.

Table 6.

Density measurements of all materials obtained at 23 °C.

3.5. Heat Deflection Temperature (HDT) Results of rPP and Composites with MAPP

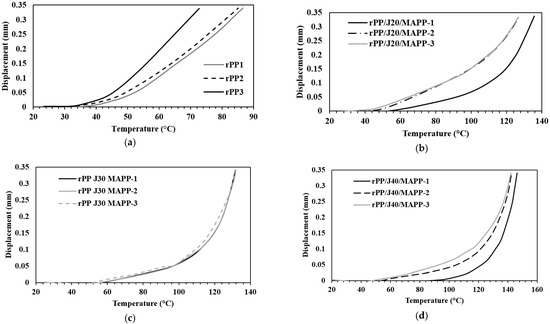

The tests were performed for rPP and composites with MAPP, because the mechanical performance of jute composites was significantly better with MAPP. MAPP improved the interfacial bonding between the hydrophilic jute fillers and the hydrophobic rPP matrix, as was also demonstrated in the investigation by Park et al. [34]. Therefore, HDT tests were performed on these materials, and the results are tabulated (Table 7). HDT curves of composites for rPP, rPP/J20/MAPP, rPP/J30/MAPP, and rPP/J40/MAPP are depicted in Figure 3. The individual measurements of HDT recorded from three replicate specimens tested under identical conditions, in accordance with ISO 75-2 Method B [25], are displayed in Table 7.

Table 7.

Heat deflection temperature (HDT) measurements of rPP, rPP/J20/MAPP, rPP/J30/MAPP, and rPP/J40/MAPP composites, obtained from three replicate specimens per material. (First, second, and third readings correspond to individual HDT values recorded for each replicate).

Figure 3.

HDT curves of composites for (a) rPP, (b) rPP/J20/MAPP, (c) rPP/J30/MAPP, and (d) rPP/J40/MAPP.

The HDT results showed a significant increase in heat deflection temperature (HDT) with the addition of jute powder and MAPP. For rPP, the HDT values range between 72.2 °C and 86.7 °C, indicating a relatively low HDT. However, as jute content increased in the composites, especially with the inclusion of MAPP, the HDT values increased significantly. The rPP/J20/MAPP showed an average HDT of around 130 °C, while rPP/J30/MAPP and rPP/J40/MAPP exhibited even higher values. This suggests that higher jute content improved the thermal stability of the composite, making it more suitable for high-temperature applications [35]. Similarly, it was shown [36] that the addition of jute fibers could significantly increase the heat deflection temperature (HDT) of polypropylene composites.

3.6. Liquid Resistance Test of the PP Polymers and Jute Composites

Resistance levels to short duration contact with liquid for rPP and jute composites are shown in Table 8. The results demonstrated that all tested rPP and jute composite materials, including those with MAPP, show no visible changes in appearance (grade 0) or distinct alterations in physical properties when exposed to various test fluids. These fluids include common automotive and household substances such as ethanol, diesel, engine coolant, and even coffee and soft drinks. The excellent resistance of these composites suggests they have robust durability and stability in environments where exposure to such liquids may occur, making them suitable for automotive interior applications where resistance to fluid contact is critical. The inclusion of jute and MAPP did not appear to affect the resistance to liquids, indicating the composites’ excellent overall performance in this regard.

Table 8.

Resistance levels of rPP and jute composites to various liquids.

4. Conclusions

This study demonstrates the feasibility and benefits of using recycled polypropylene reinforced with jute fillers for sustainable material applications. The addition of jute significantly increased stiffness, with Young’s modulus and HDT values showing marked improvements. The use of MAPP as a compatibilizer further enhanced tensile and flexural strength, highlighting its role in improving interfacial bonding between the hydrophilic jute fillers and the hydrophobic rPP matrix.

However, the inclusion of jute resulted in reduced impact energy due to the material’s increased brittleness, which may limit its application in environments requiring high toughness. Despite this, the excellent liquid resistance and thermal stability of these composites make them well-suited for applications in automotive interiors and structural components where stiffness and resistance to environmental conditions are critical.

Future work could explore strategies to improve the toughness of these composites, such as hybridization with elastomers or other natural fillers, while maintaining their sustainability and mechanical performance. This research underscores the potential of natural filler–recycled polymers as viable alternatives to conventional materials in the pursuit of circular and sustainable material solutions. This research was funded by VINNOVA, grant number.

Author Contributions

S.O.M.: methodology, visualization, investigation, writing—original. A.O.: methodology, visualization, investigation, writing—original. P.K.: conceptualization, methodology, validation, visualization, resources, investigation, supervision, funding acquisition and formal analysis. F.B.: supervision, writing-editing, methodology, visualization, writing—original. M.S.: Supervision, methodology, resources. E.-M.M.: Supervision, visualization, resources, funding acquisition. T.K.E.: Supervision, visualization, resources. N.F.: Conceptualization, validation, visualization, resources, formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This work was carried out within the Strategic Innovation Programme LIGHTer, a joint initiative of Vinnova, Formas, and the Swedish Energy Agency, with grant number 202303207.

Data Availability Statement

All data generated in this work are presented in this manuscript.

Acknowledgments

We thank our lab technician, Ville Skrifvars, for his unwavering assistance throughout the experimental phase of this work.

Conflicts of Interest

Author Else-Marie Malmek was employed by the company Juteborg AB. Author Thomas Koch Ecoist was employed by the company Ecoist AB. Author Nowshir Fatima was employed by the company Volvo Construction Equipment. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications–A review. J. Eng. Res.2024, in press.

- Mangino, E.; Carruthers, J.; Pitarresi, G. The future use of structural composite materials in the automotive industry. Int. J. Veh. Des. 2007, 44, 211–232. [Google Scholar] [CrossRef]

- Patel, M.; Pardhi, B.; Chopara, S.; Pal, M. Lightweight composite materials for automotive-a review. Carbon 2018, 1, 151. [Google Scholar]

- Huang, L.; Wu, Q.; Wang, Q.; Wolcott, M. Interfacial crystals morphology modification in cellulose fiber/polypropylene composite by mechanochemical method. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105765. [Google Scholar] [CrossRef]

- Casamento, F.; Padovano, E.; Pappalardo, S.; Frache, A.; Badini, C. Development of polypropylene-based composites through fused filament fabrication: The effect of carbon-based fillers. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107308. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Liu, X.; Deng, Y.; Sun, M.; Wang, J.; Cui, Y.; Pan, L.; Chen, Z. Hierarchical interface design of jute fibers/polypropylene composites for enhanced interfacial and mechanical properties. J. Clean. Prod. 2024, 450, 141966. [Google Scholar] [CrossRef]

- Gu, S.; Wang, C.; Smith, L.M.; Zheng, H.; Wang, G.; Cheng, H. Jute/PP composites for covering honeycomb panels: Designability and mechanical behaviors. Polym. Test. 2024, 133, 108413. [Google Scholar] [CrossRef]

- Rajlakshmi Dutta, S.; Saravanabhupathy, S.; Jayaseelan, P.; Anusha Kailasam, A.; Banerjee, R. Jute stick-based industrial artefact towards sustainable development goals. Ind. Crops Prod. 2024, 215, 118599. [Google Scholar] [CrossRef]

- Cionita, T.; Hamdan, M.H.M.; Siregar, J.P.; Fitriyana, D.F.; Junid, R.; Shing, W.L.; Jaafar, J.; Irawan, A.P.; Rihayat, T.; Ismail, R.; et al. Overview of Jute Fibre as Thermoplastic Matrix Polymer Reinforcement. J. Renew. Mater. 2024, 12, 457–483. [Google Scholar] [CrossRef]

- Islam, M.M.; Ali, M.S. Economic importance of jute in Bangladesh: Production, research achievements and diversification. Int. J. Econ. Theory Appl. 2017, 4, 45–57. [Google Scholar]

- Jahan, A. The Environmental and Economic Prospects of Jute with a Connection to Social Factors for Achieving Sustainable Development. Master’s Thesis, Uppsala Universitet, Uppsala, Sweden, 2019. [Google Scholar]

- Uddin, M.B.; Uddin, A.J. A sustainable approach to manufacture mélange yarn from waste jute fiber and pre-consumer cotton fabric waste using I-optimal mixture design. J. Clean. Prod. 2023, 421, 138376. [Google Scholar] [CrossRef]

- Hossain, M.S.; Ahmed, B.; Ahmed, R.; Ullah, M.W.; Kabir, S.M.T.; Bashar, K.K.; Emdad, E.M. The lignin riddle in jute: A comparative genomic investigation identifies targets for improving fiber quality. Gene Rep. 2024, 36, 101972. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Hasan, F.; Rahman, S.M.M.; Khan, S.; Saifullah, A.Z.A.; Chowdhury, M.A. Advances of natural fiber composites in diverse engineering applications—A review. Appl. Eng. Sci. 2024, 18, 100184. [Google Scholar] [CrossRef]

- Banerjee, S.K.; Mathew, M.D. Carbonisation of jute stick, an agricultural waste. Agric. Wastes 1985, 13, 217–227. [Google Scholar] [CrossRef]

- Farooq, A.; Islam, S.R.; Al-Amin, M.; Patoary, M.K.; Hossain, M.T.; Khawar, M.T.; Wang, Z.; Tian, M. From farm to function: Exploring new possibilities with jute nanocellulose applications. Carbohydr. Polym. 2024, 342, 122423. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, K.B.; Doraiswamy, I.; Chellamani, K.P. 2-Jute. In Bast and Other Plant Fibres; Franck, R.E., Ed.; Woodhead Publishing: Sawston, UK, 2005; pp. 24–93. [Google Scholar]

- Das, K.; Adhikary, K.; Ray, D.; Bandyopadhyay, N.R. Development of recycled polypropylene matrix composites reinforced with waste jute caddies. J. Reinf. Plast. Compos. 2010, 29, 201–208. [Google Scholar] [CrossRef]

- Rajendran, S.; Scelsi, L.; Hodzic, A.; Soutis, C.; Al-Maadeed, M.A. Environmental impact assessment of composites containing recycled plastics. Resour. Conserv. Recycl. 2012, 60, 131–139. [Google Scholar] [CrossRef]

- BS EN ISO 527-4:1997; Standardb Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. International Organization for Standardization: Geneve, Switzerland, 1997.

- BS EN ISO 14125:1998+A1:2011; Standardb Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. BSI: Bonn, Germany, 1998.

- ISO 179-1:2023; Plastics—Determination of Charpy Impact Properties: Part 1: Non-Instrumented Impact Test. International Standards Organization: Geneve, Switzerland, 2023.

- ISO 8655-6; Piston-Operated Volumetric Apparatus. International Standards Organization: Geneve, Switzerland, 2022.

- Wong, A.-Y. Heat deflection characteristics of polypropylene and polypropylene/polyethylene binary systems. Compos. Part B Eng. 2003, 34, 199–208. [Google Scholar] [CrossRef]

- ISO 75-1; Plastics—Determination of Temperature of Deflection Under Load. International Standards Organization: Geneve, Switzerland, 2020.

- ISO 1817; Rubber, Vulcanized or Thermoplastic—Determination of the Effect of Liquids. International Standards Organization: Geneve, Switzerland, 2024.

- Shackelford, J.F. Materials Science for Engineers; CRC Press: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, mechanical, and thermal properties of natural fiber-reinforced epoxy composites for construction and automotive applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Cavus, V. Selected properties of mahogany wood flour filled polypropylene composites: The effect of maleic anhydride-grafted polypropylene (MAPP). BioResources 2020, 15, 2227. [Google Scholar] [CrossRef]

- Messaoui, S.; Ghali, L.; Guermazi, N.; Fterich, M.; Haddar, N.; Msahli, S. Physico-Thermal and Mechanical Characterization of Alfa Fiber/Polypropylene Composites: Effects of Fiber Treatment and MAPP Compatibilization. J. Nat. Fibers 2024, 21, 2406457. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Raghu, N.; Kale, A.; Chauhan, S.; Aggarwal, P.K. Rice husk reinforced polypropylene composites: Mechanical, morphological and thermal properties. J. Indian Acad. Wood Sci. 2018, 15, 96–104. [Google Scholar] [CrossRef]

- Hosen, M.S.S.; Hoque, M.E.; Rahman, M.Z.; Sagadevan, S. Aging effects on mechanical properties of biocomposites with recycled polymers. In Aging Effects on Natural Fiber-Reinforced Polymer Composites: Durability and Life Prediction; Springer: Berlin/Heidelberg, Germany, 2022; pp. 317–333. [Google Scholar]

- Park, J.-M.; Quang, S.T.; Hwang, B.-S.; DeVries, K.L. Interfacial evaluation of modified Jute and Hemp fibers/polypropylene (PP)-maleic anhydride polypropylene copolymers (PP-MAPP) composites using micromechanical technique and nondestructive acoustic emission. Compos. Sci. Technol. 2006, 66, 2686–2699. [Google Scholar] [CrossRef]

- Kabir, M.M.; Islam, M.M.; Wang, H. Mechanical and thermal properties of jute fibre reinforced composites. J. Multifunct. Compos. 2013, 1, 71–77. [Google Scholar] [CrossRef]

- Somashekhar, S.; Shanthakumar, G.C.; Nagamadhu, M. Influence of fiber content and screw speed on the mechanical characterization of jute fiber reinforced polypropylene composite using Taguchi method. Mater. Today Proc. 2020, 24, 2366–2374. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).