Study of the Physico-Chemical Properties of Injection-Molded Polypropylene Reinforced with Spent Coffee Grounds

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Spent Coffee Grounds (SCGs)

2.3. Manufacturing of Composites

2.4. Physico-Chemical Characterizations

3. Results

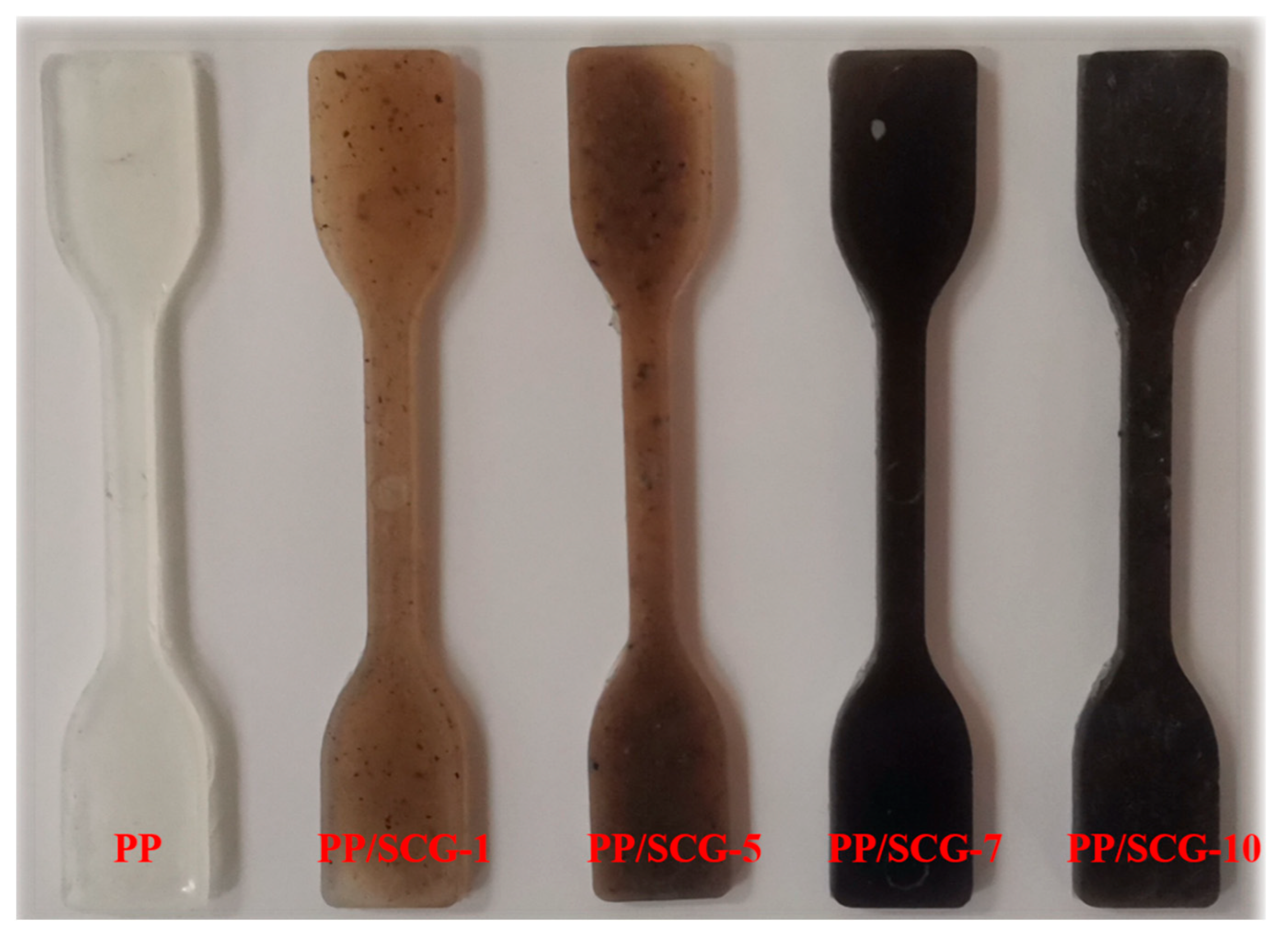

3.1. Visual Aspect

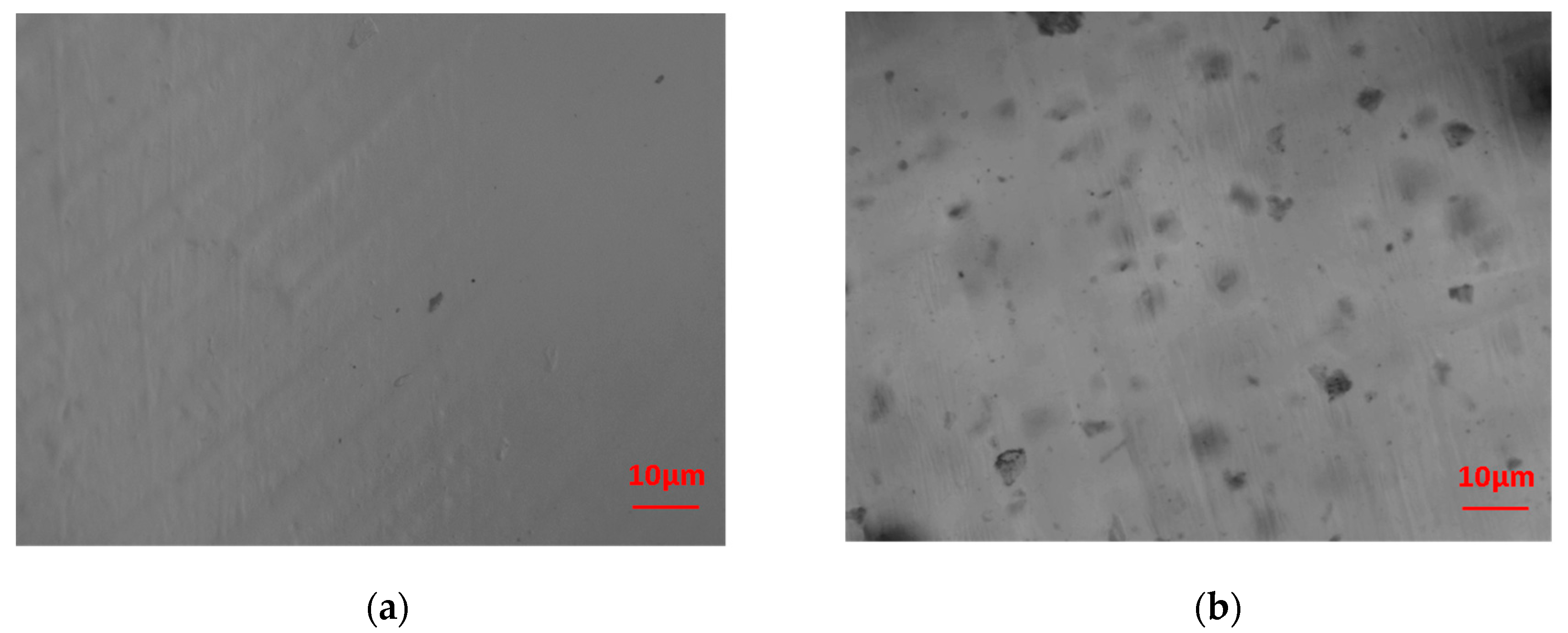

3.2. Optical Microscopy

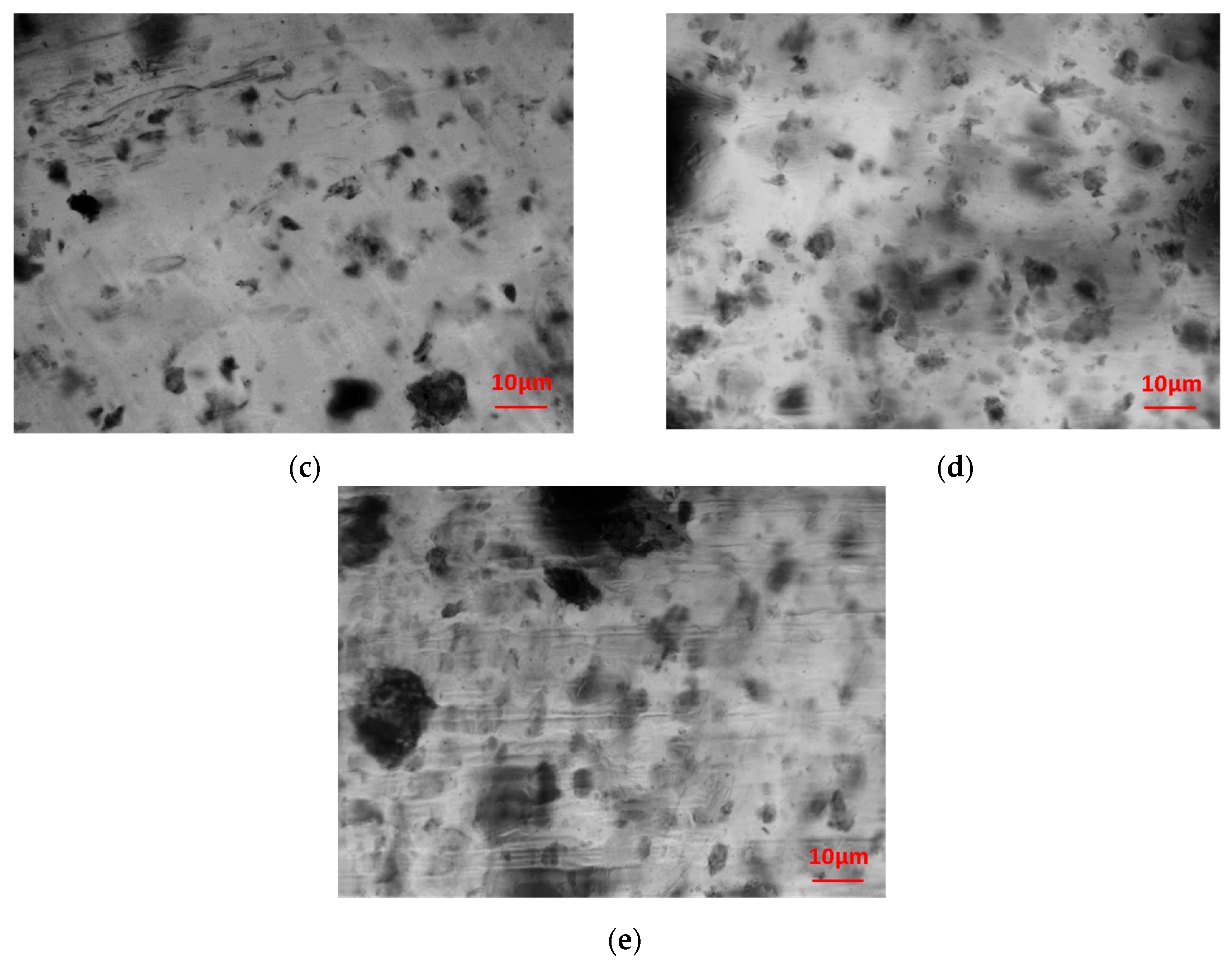

3.3. Differential Scanning Analysis

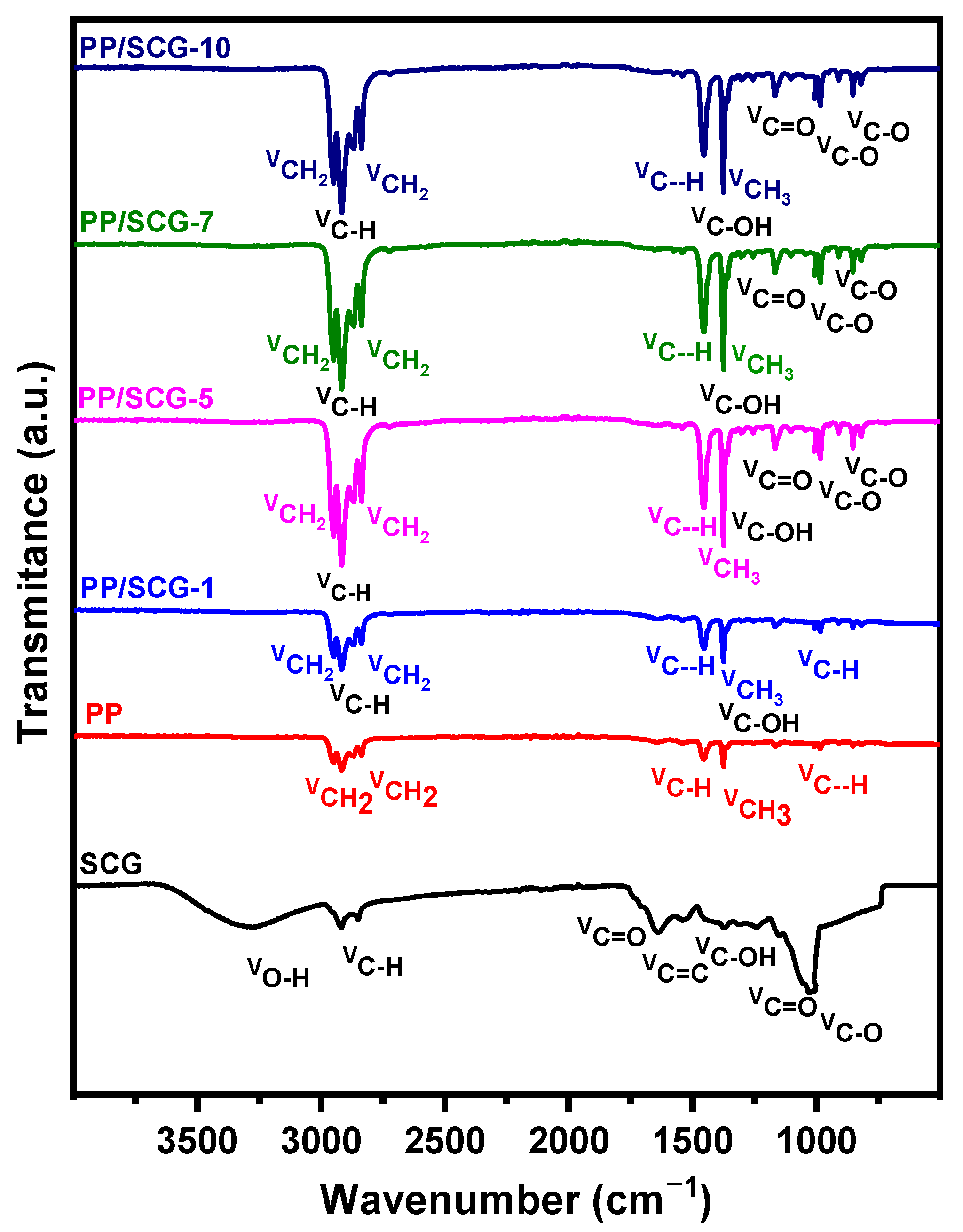

3.4. FT-IR

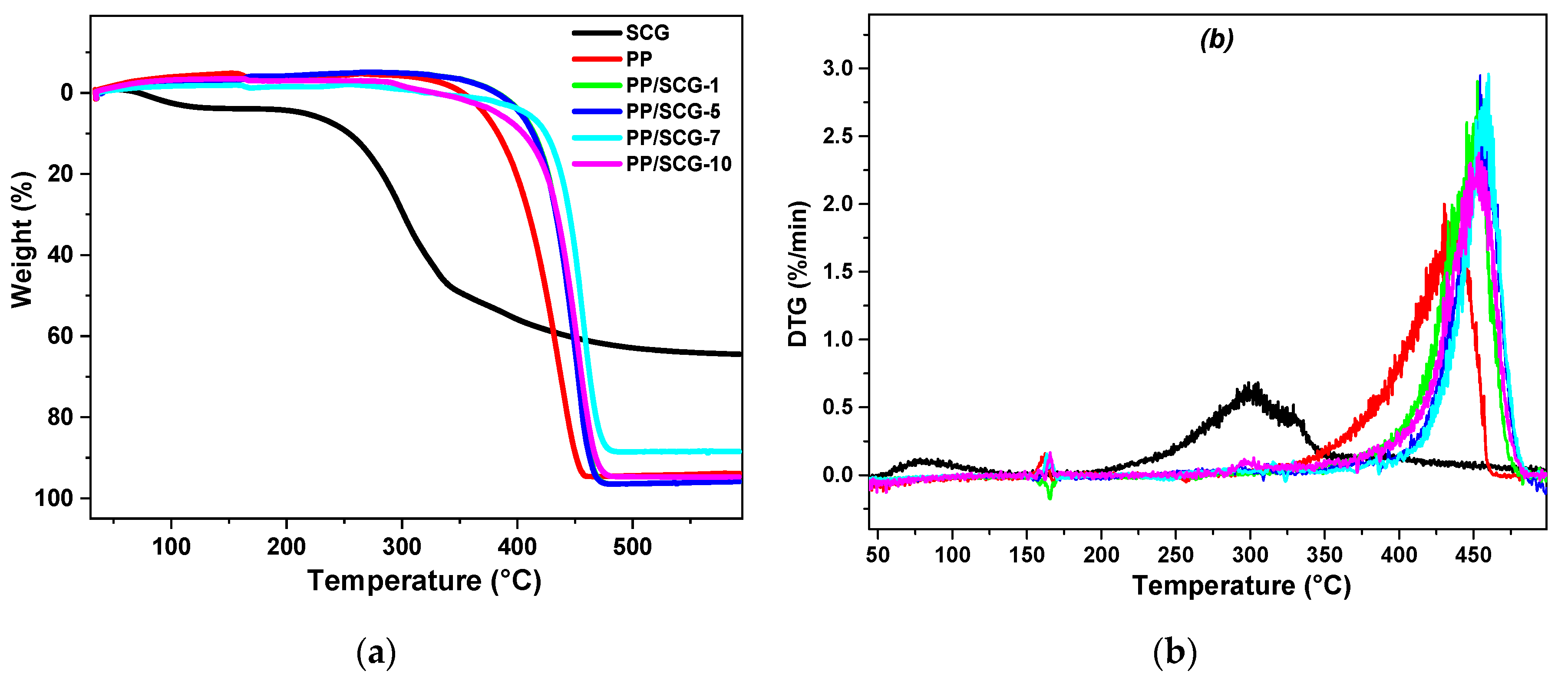

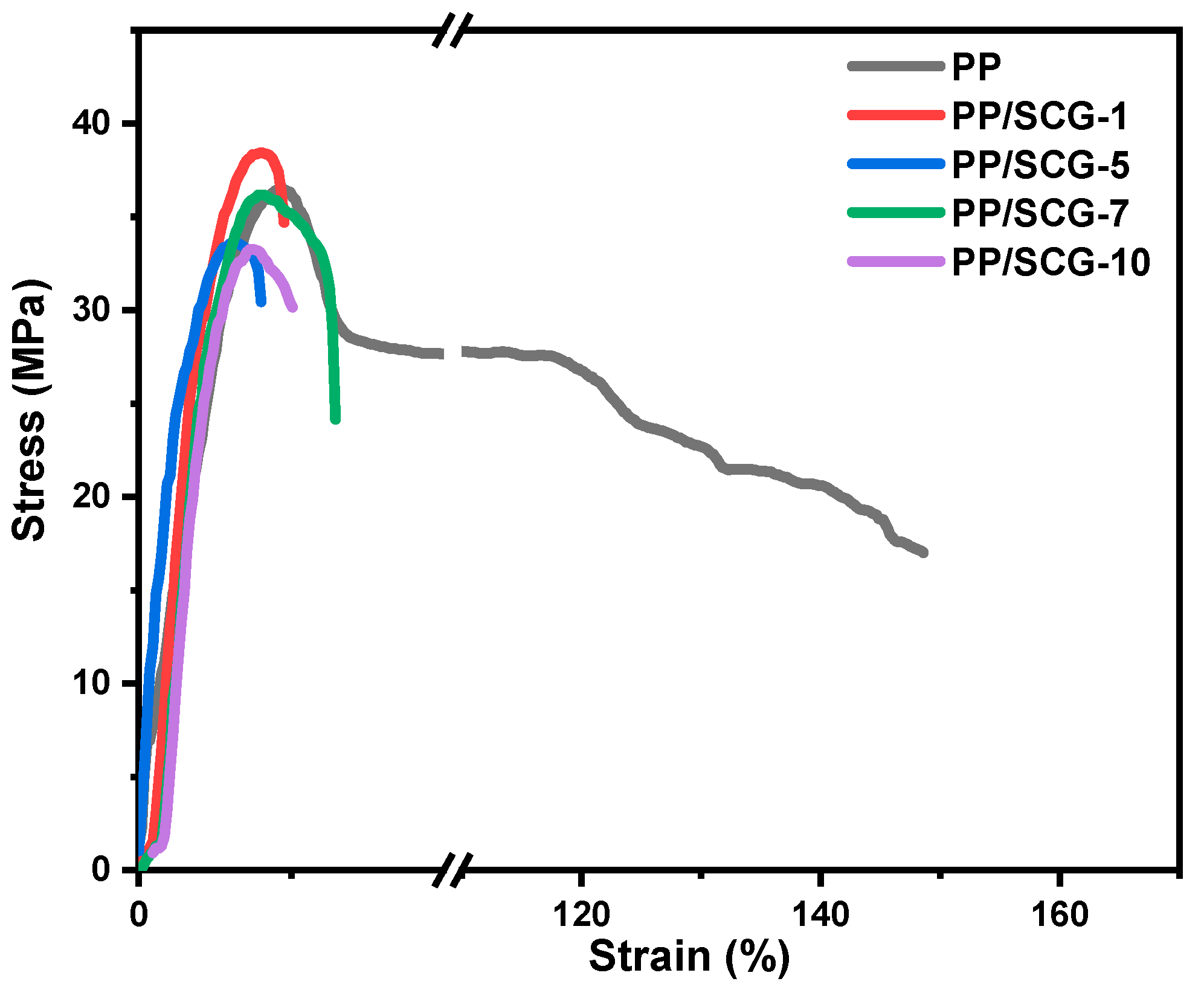

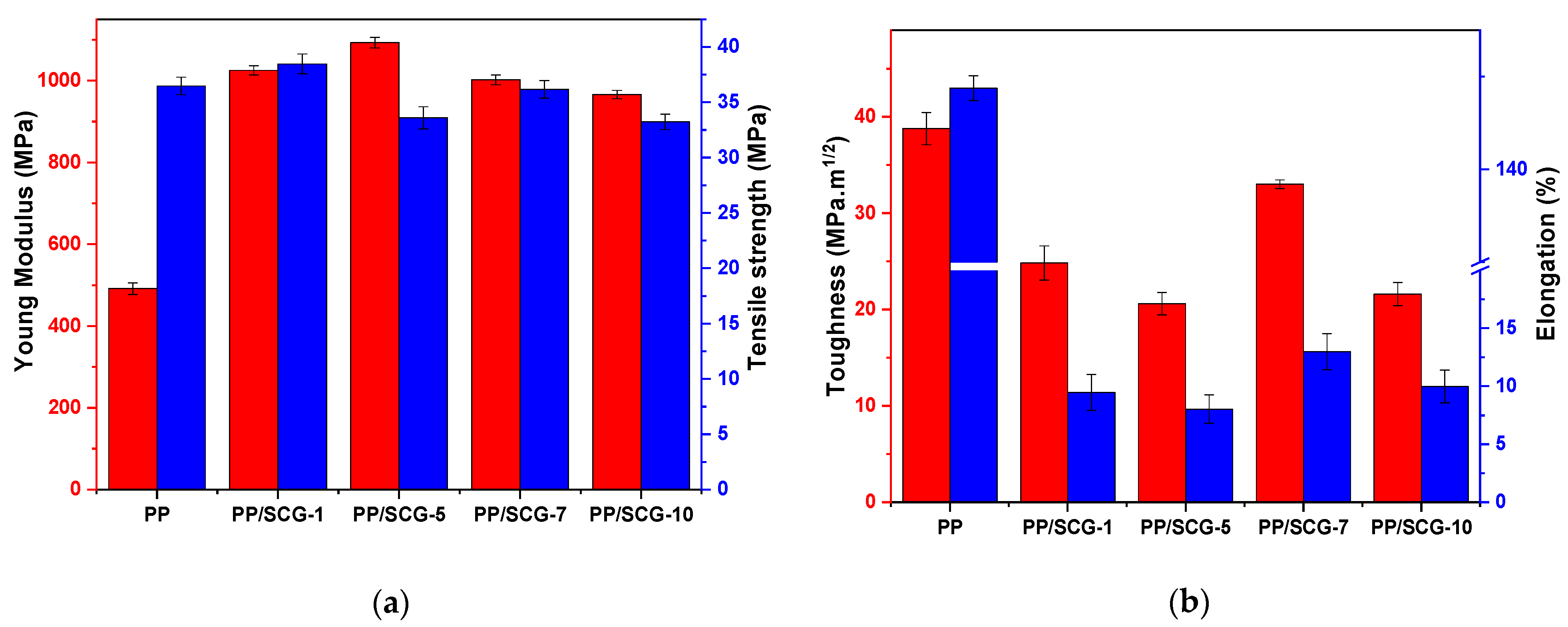

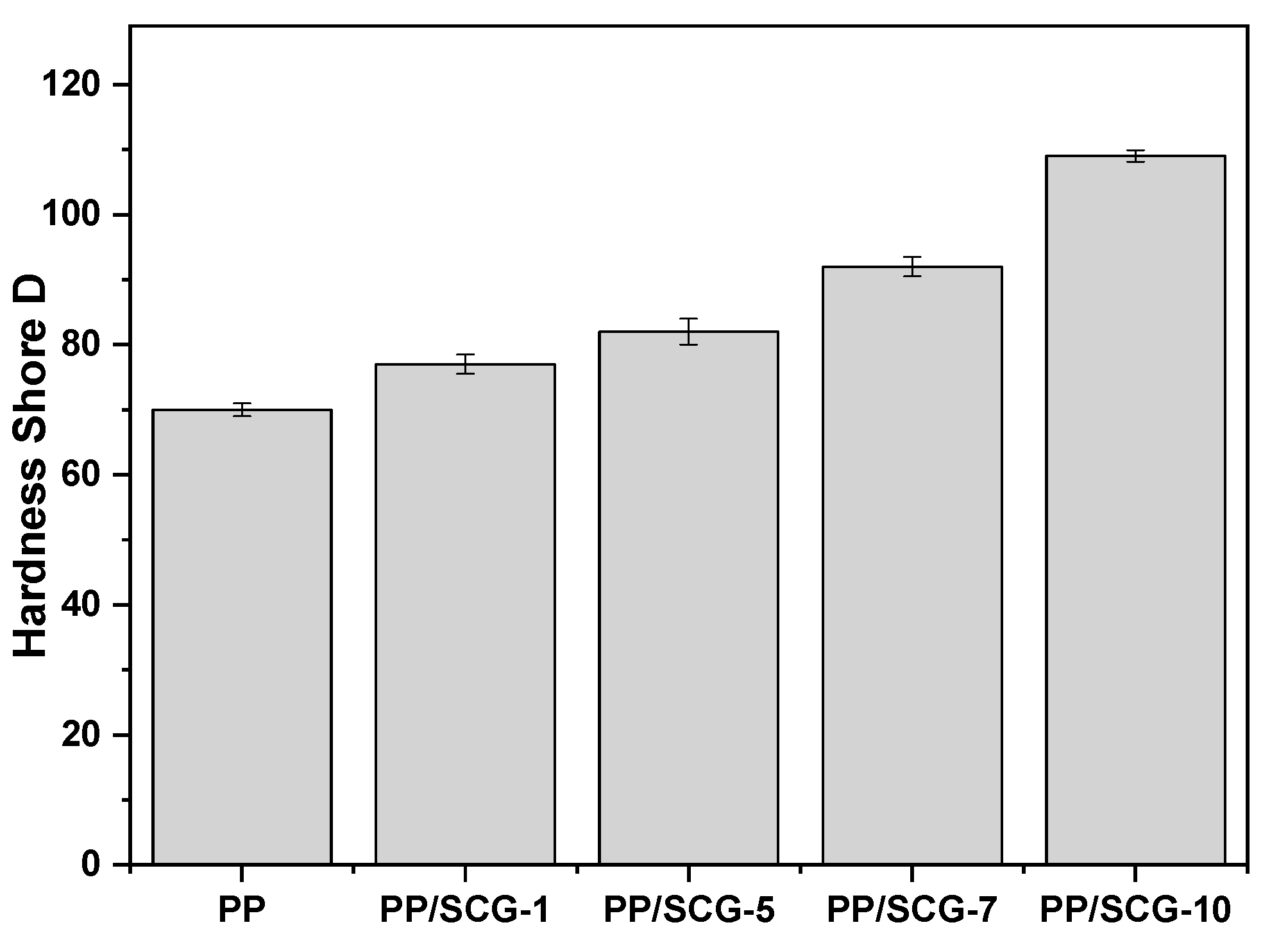

3.5. Mechanical Testing

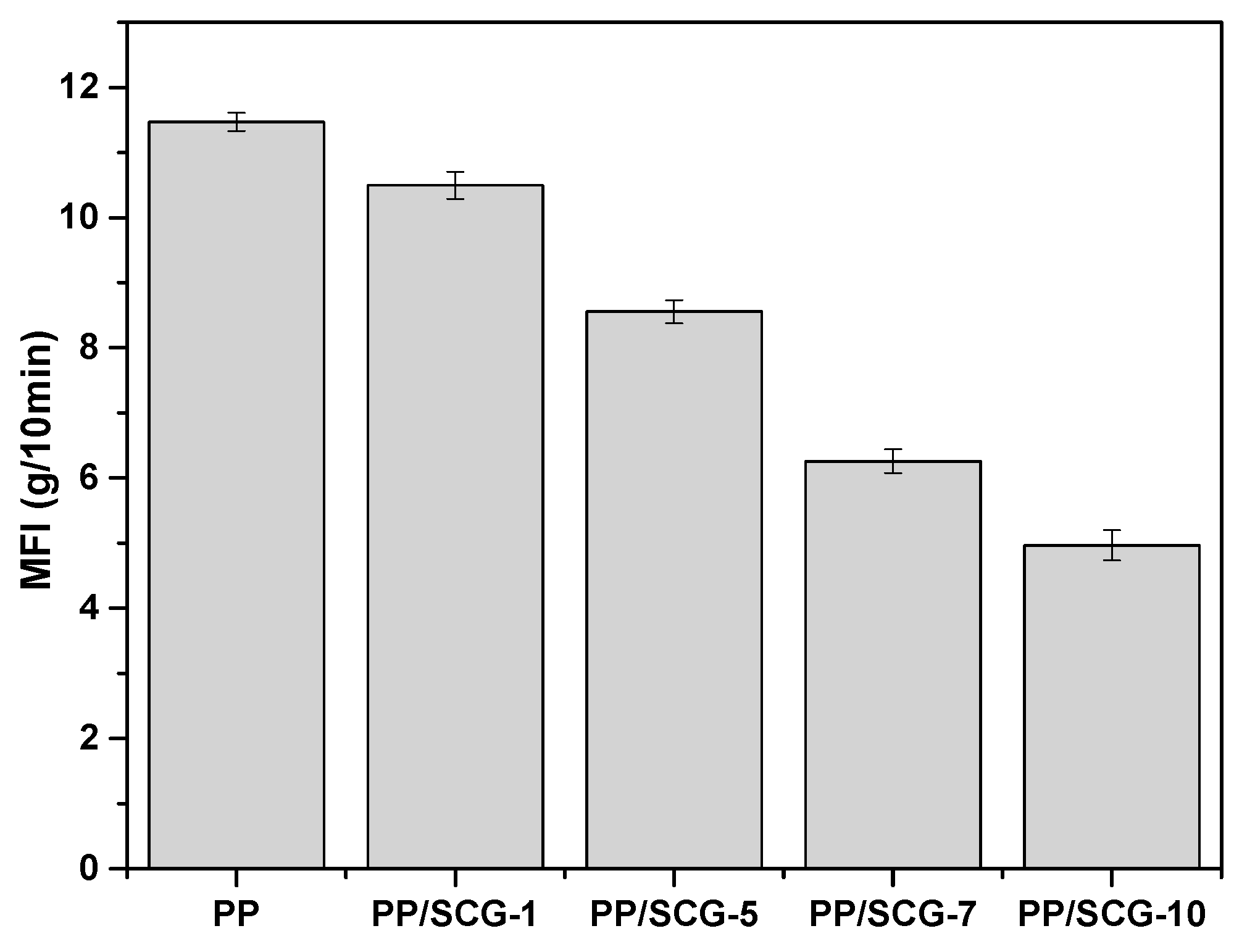

3.6. Flow Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nomura, M.; Shanmuga Ramanan, S.M.; Arun, S. 317 Automobile Bumpers. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 460–468. [Google Scholar]

- Koncar, V. Smart textiles for monitoring and measurement applications. In Smart Textiles for In Situ Monitoring of Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–151. [Google Scholar]

- Macedo, K.R.M.; Cestari, S.P.; Mendes, L.C.; Albitres, G.A.V.; Rodrigues, D.C. Sustainable hybrid composites of recycled polypropylene and construction debris. J. Compos. Mater. 2018, 52, 2949–2959. [Google Scholar] [CrossRef]

- Hu, X.; Wu, J.; Gao, Y. A Review of Structural Health Monitoring for Flexible Composite Materials. Appl. Compos. Mater. 2024, 32, 431–471. [Google Scholar] [CrossRef]

- Qaiss, A.; Bouhfid, R.; Essabir, H. Effect of Processing Conditions on the Mechanical and Morphological Properties of Composites Reinforced by Natural Fibres. In Manufacturing of Natural Fibre Reinforced Polymer Composites; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 177–197. [Google Scholar]

- Najafi, S.K.; Mostafazadeh-Marznaki, M.; Chaharmahali, M.; Tajvidi, M. Effect of Thermomechanical Degradation of Polypropylene on Mechanical Properties of Wood-Polypropylene Composites. J. Compos. Mater. 2009, 43, 2543–2554. [Google Scholar] [CrossRef]

- Ghazvini, A.K.A.; Ormondroyd, G.; Curling, S.; Saccani, A.; Sisti, L. An investigation on the possible use of coffee silverskin in PLA/PBS composites. J. Appl. Polym. Sci. 2022, 139, 52264. [Google Scholar] [CrossRef]

- Arya, S.S.; Venkatram, R.; More, P.R.; Vijayan, P. The wastes of coffee bean processing for utilization in food: A review. J. Food Sci. Technol. 2022, 59, 429–444. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioproc. Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent coffee grounds: A review on current research and future prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Hernández-Varela, J.D.; Medina, D.I. Revalorization of Coffee Residues: Advances in the Development of Eco-Friendly Biobased Potential Food Packaging. Polymers 2023, 15, 2823. [Google Scholar] [CrossRef]

- Kourmentza, C.; Economou, C.h.N.; Tsafrakidou, P.; Kornaros, M. Spent coffee grounds make much more than waste: Exploring recent advances and future exploitation strategies for the valorization of an emerging food waste stream. J. Clean. Prod. 2018, 172, 980–992. [Google Scholar] [CrossRef]

- Oliveira, G.; Passos, C.P.; Ferreira, P.; Coimbra, M.A.; Gonçalves, I. Coffee By-Products and Their Suitability for Developing Active Food Packaging Materials. Foods 2021, 10, 683. [Google Scholar] [CrossRef]

- Murthy, P.S.; Madhava Naidu, M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Thermal, mechanical, morphological, and structural properties of composites based on polyolefin and biofiller produced from snail shell (PP/SSP). Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part. B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Song, W.; Yang, Y.; Cheng, X.; Jiang, M.; Zhang, R.; Militky, J.; Cai, Y. Utilization of spent coffee grounds as fillers to prepare polypropylene composites for food packaging applications. Microsc. Res. Technol. 2023, 86, 1475–1483. [Google Scholar] [CrossRef]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R.; el kacem Qaiss, A. Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Compos. B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Suaduang, N.; Ross, S.; Ross, G.; Pratumshat, S.; Mahasaranon, S. Effect of spent coffee grounds filler on the physical and mechanical properties of poly(lactic acid) bio-composite films. Mater. Today Proc. 2019, 17, 2104–2110. [Google Scholar] [CrossRef]

- Schutz, G.F.; Alves, R.M.V.; Vieira, R.P. Development of Starch-Based Films Reinforced with Coffee Husks for Packaging Applications. J. Polym. Environ. 2023, 31, 1955–1966. [Google Scholar] [CrossRef]

- Marques, M.; Gonçalves, L.F.; Martins, C.I.; Vale, M.; Duarte, F.M. Effect of polymer type on the properties of polypropylene composites with high loads of spent coffee grounds. Waste Manag. 2022, 154, 232–244. [Google Scholar] [CrossRef]

- Wu, H.; Hu, W.; Zhang, Y.; Huang, L.; Zhang, J.; Tan, S.; Cai, X.; Liao, X. Effect of oil extraction on properties of spent coffee ground–plastic composites. J. Mater. Sci. 2016, 51, 10205–10214. [Google Scholar] [CrossRef]

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2 Test Conditions for Moulding and Extrusion Plastics. ISO: Genva, Switzerland, 2012.

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Thermal, flow, and mechanical properties of composites based on polystyrene (PS) and snail shell powder (SSP) biofiller (PS/SSP). Iran. Polym. J. 2023, 32, 621–631. [Google Scholar] [CrossRef]

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Physico-chemical characterization of snail shells powder prepared by mechanochemical processes and thermal treatment. J. Met. Mater. Miner. 2023, 33, 139–147. [Google Scholar] [CrossRef]

- ISO 868; Plastics and ebonite — Determination of indentation hardness by means of a durometer (Shore hardness). AFNOR: Paris, France, 2003.

- ASTM D1238; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM: West Conshohocken, PA, USA, 2021.

- ISO 1133-1; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. ISO: Genva, Switzerland, 2011.

- ISO 1133-2; Plastics—Determination of the melt mass-flow rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 2: Method for Materials with High Melt Flow Rates. ISO: Genva, Switzerland, 2011.

- Ortiz-Barajas, D.L.; Arévalo-Prada, J.A.; Fenollar, O.; Rueda-Ordóñez, Y.J.; Torres-Giner, S. Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability. Appl. Sci. 2020, 10, 6468. [Google Scholar] [CrossRef]

- de Brito, E.B.; Tienne, L.G.P.; Cordeiro, S.B.; Marques Mde, F.V. Development of Polypropylene Composites with Green Coffee Cake Fibers Subjected to Water Vapor Explosion. Waste Biomass Valorization 2020, 11, 6855–6867. [Google Scholar] [CrossRef]

- Domingues, M.L.B.; Bocca, J.R.; Fávaro, S.L.; Radovanovic, E. Disposable coffee capsules as a source of recycled polypropylene. Polim. E Tecnol. 2021, 30, 1–9. [Google Scholar] [CrossRef]

- Fanegas, N.; Gómez, M.A.; Marco, C.; Jiménez, I.; Ellis, G. Influence of a nucleating agent on the crystallization behaviour of isotactic polypropylene and elastomer blends. Polymer 2007, 48, 5324–5331. [Google Scholar] [CrossRef]

- Sellelo, M.G. Flow-induced crystallization effect on polypropylene with respect to nucleating agents. Heliyon 2022, 8, e12357. [Google Scholar] [CrossRef]

- Gaidukova, G.; Platnieks, O.; Aunins, A.; Barkane, A.; Ingrao, C.; Gaidukovs, S. Spent coffee waste as a renewable source for the production of sustainable poly(butylene succinate) biocomposites from a circular economy perspective. RSC Adv. 2021, 11, 18580–18589. [Google Scholar] [CrossRef]

- Guo, T.; Wang, L.; Zhang, A.; Cai, T. Effects of nano calcium carbonate modified by a lanthanum compound on the properties of polypropylene. J. Appl. Polym. Sci. 2005, 97, 1154–1160. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of Wastes and Coproducts from the Coffee Industry for Composite Material Production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Tangmankongworakoon, N. An approach to produce biochar from coffee residue for fuel and soil amendment purpose. Int. J. Recycl. Org. Waste Agric. 2019, 8, 37–44. [Google Scholar] [CrossRef]

- Jagdale, P.; Ziegler, D.; Rovere, M.; Tulliani, J.; Tagliaferro, A. Waste Coffee Ground Biochar: A Material for Humidity Sensors. Sensors 2019, 19, 801. [Google Scholar] [CrossRef] [PubMed]

- Foresta, T.; Piccarolo, S.; Goldbeck-Wood, G. Competition between α and γ phases in isotactic polypropylene: Effects of ethylene content and nucleating agents at different cooling rates. Polymer 2001, 42, 1167–1176. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Prabhakar, M.N.; Lee, D.-W.; Lee, I.C.; Song, J.-I. Films derived from thermoplastic starch/alginate/spent coffee grounds for food packaging applications. J. Polym. Res. 2023, 30, 1–9. [Google Scholar] [CrossRef]

- Gonçalves, B.M.M.; Camillo, M.d.O.; Oliveira, M.P.; Carreira, L.G.; Moulin, J.C.; Neto, H.F.; de Oliveira, B.F.; Pereira, A.C.; Monteiro, S.N. Surface Treatments of Coffee Husk Fiber Waste for Effective Incorporation into Polymer Biocomposites. Polymers 2021, 13, 3428. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Leys, C.; Gengembre, L.; Payen, E. Comparison between XPS- and FTIR-analysis of plasma-treated polypropylene film surfaces. Surf. Interface Anal. 2008, 40, 597–600. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless melt-electrospinning of polypropylene nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Barbes, L.; Radulescu, C.; Stihi, C.; Barbeş, L.; Rădulescu, C.; Stihi, C. ATR-FTIR spectrometry characterisation of polymeric materials. Rom. Rep. Phys. 2014, 66. [Google Scholar]

- Xu, J.-Z.; Xu, L.; Liang, Y.-Y.; Zhong, G.-J.; Lei, J.; Li, Z.-M. Temperature dependence of molecular conformation in uniaxially deformed isotactic polypropylene investigated by combination of polarized FTIR spectroscopy and 2D correlation analysis. J. Polym. Sci. B Polym. Phys. 2015, 53, 673–684. [Google Scholar] [CrossRef]

- Pan, L.; Guo, H.; Zhong, L.; Wang, M.; Xue, P.; Yuan, X. Influence of surface-modified glass fibers on interfacial properties of GF/PEEK composites using molecular dynamics. Comput. Mater. Sci. 2021, 188, 110216. [Google Scholar] [CrossRef]

- Chhatariya, H.F.; Srinivasan, S.; Choudhary, P.M.; Begum, S.S. Corn starch biofilm reinforced with orange peel powder: Characterization of physicochemical and mechanical properties. Mater. Today Proc. 2022, 59, 884–892. [Google Scholar] [CrossRef]

- Syamimi, N.F.; Islam, M.R.; Sumdani, M.G.; Rashidi, N.M. Mechanical and thermal properties of snail shell particles-reinforced bisphenol-A bio-composites. Polym. Bull. 2020, 77, 2573–2589. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Abdulkareem, S.A.; Ighalo, J.O.; Oladipo-Emmanuel, F.M.; Adeyanju, C.A. Microstructural and mechanical properties of the plantain fiber/local clay filled hybrid polystyrene composites. Mech. Adv. Mater. Struct. 2021, 29, 7104–7114. [Google Scholar] [CrossRef]

- Versino, F.; Garcia, M.A. Particle Size Distribution Effect on Cassava Starch and Cassava Bagasse Biocomposites. ACS Sustain. Chem. Eng. 2019, 7, 1052–1060. [Google Scholar] [CrossRef]

- Gallagher, L.W.; McDonald, A.G. The effect of micron sized wood fibers in wood plastic composites. Maderas Cienc. Y tecnología 2013, 15, 357–374. [Google Scholar] [CrossRef]

| Injection Pressure | Injection Velocity | Injection Temperature | Pressure Hold |

|---|---|---|---|

| 30 bar | 20 mm/s | 180–210 °C | 20 bar |

| Material Designation | Crystallization Temperature (°C) | Melting Temperature (°C) | ΔHm (J/g) | XC (%) |

|---|---|---|---|---|

| PP | 144.3 ± 0.60 | 165.7 ± 1.70 | 43.7 ± 1.20 | 20.90 ± 1.30 |

| PP/SCG-1 | 145.4 ± 0.30 | 168.8 ± 1.40 | 56.9 ± 1.20 | 27.22 ± 2.30 |

| PP/SCG-5 | 146.8 ± 0.30 | 167.8 ± 1.30 | 54.7 ± 1.80 | 5.23 ± 1.10 |

| PP/SCG-7 | 147.4 ± 0.60 | 168.0 ± 1.90 | 47.6 ± 1.40 | 4.55 ± 0.70 |

| PP/SCG-10 | 149.7 ± 0.20 | 169.4 ± 1.60 | 45.9 ± 1.70 | 4.38 ± 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaoui, M.; Fiore, V.; Elhamri, Z.; Kharchouf, S.; Alami, M.; Assouag, M. Study of the Physico-Chemical Properties of Injection-Molded Polypropylene Reinforced with Spent Coffee Grounds. J. Compos. Sci. 2025, 9, 257. https://doi.org/10.3390/jcs9060257

Karaoui M, Fiore V, Elhamri Z, Kharchouf S, Alami M, Assouag M. Study of the Physico-Chemical Properties of Injection-Molded Polypropylene Reinforced with Spent Coffee Grounds. Journal of Composites Science. 2025; 9(6):257. https://doi.org/10.3390/jcs9060257

Chicago/Turabian StyleKaraoui, Mostapha, Vincenzo Fiore, Zineb Elhamri, Samira Kharchouf, Mohammed Alami, and Mohammed Assouag. 2025. "Study of the Physico-Chemical Properties of Injection-Molded Polypropylene Reinforced with Spent Coffee Grounds" Journal of Composites Science 9, no. 6: 257. https://doi.org/10.3390/jcs9060257

APA StyleKaraoui, M., Fiore, V., Elhamri, Z., Kharchouf, S., Alami, M., & Assouag, M. (2025). Study of the Physico-Chemical Properties of Injection-Molded Polypropylene Reinforced with Spent Coffee Grounds. Journal of Composites Science, 9(6), 257. https://doi.org/10.3390/jcs9060257