The Effect of the Addition of Maguey Bagasse in the Production of Bioplastics Based on Corn and Potato Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in the Bioplastics’ Development

2.2. Bioplastic Elaboration

2.3. Humidity Percentage

2.4. Water Absorption Percentage

2.5. Water Solubility

2.6. Mechanical Properties

2.7. Thermogravimetric Analysis (TGA)

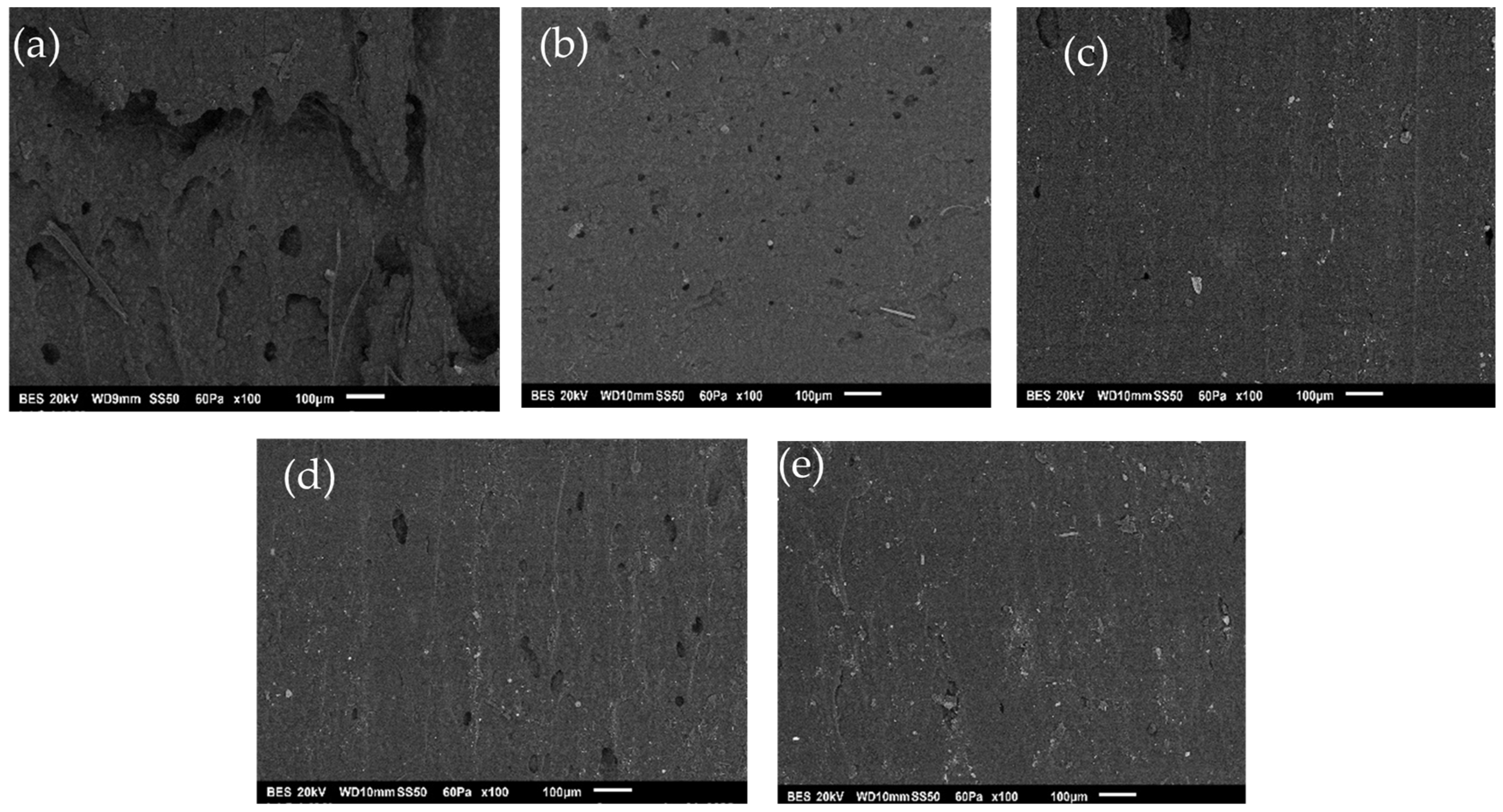

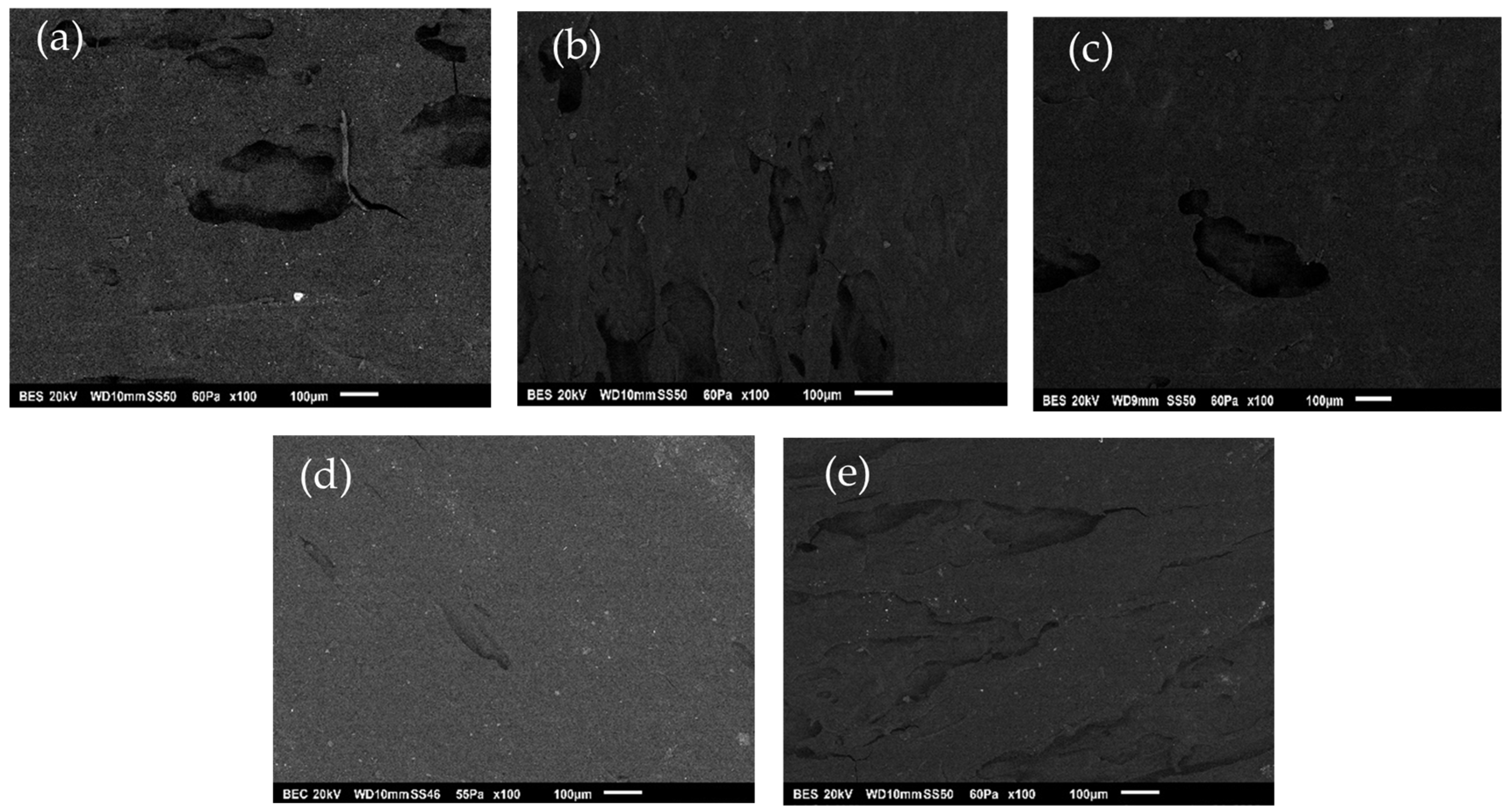

2.8. Scanning Electron Microscope (SEM)

2.9. Fourier Transform Infrared Spectroscopy (FTIR)

2.10. Statistical Analysis

3. Results

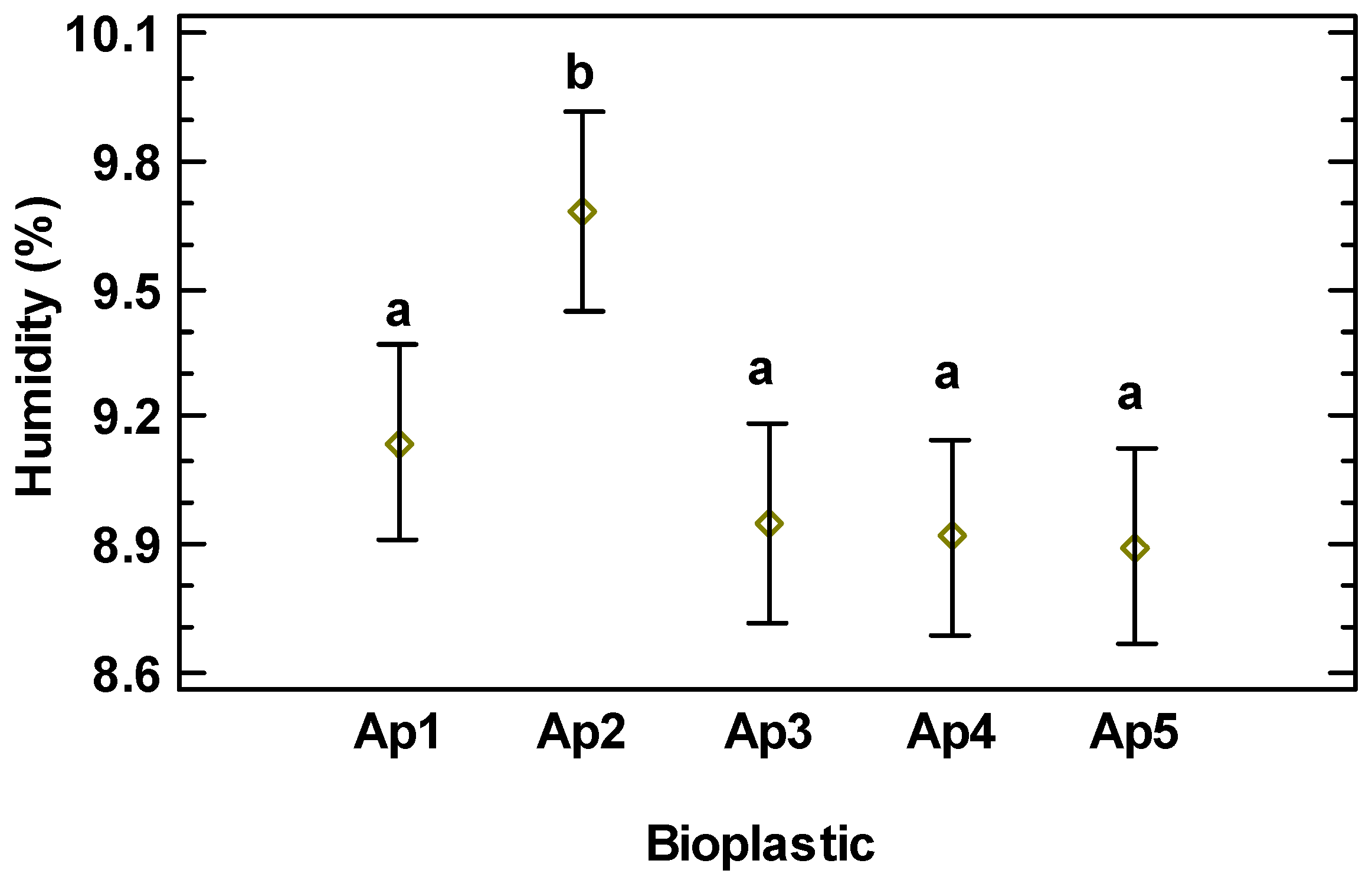

3.1. Bioplastic Humidity Percentage

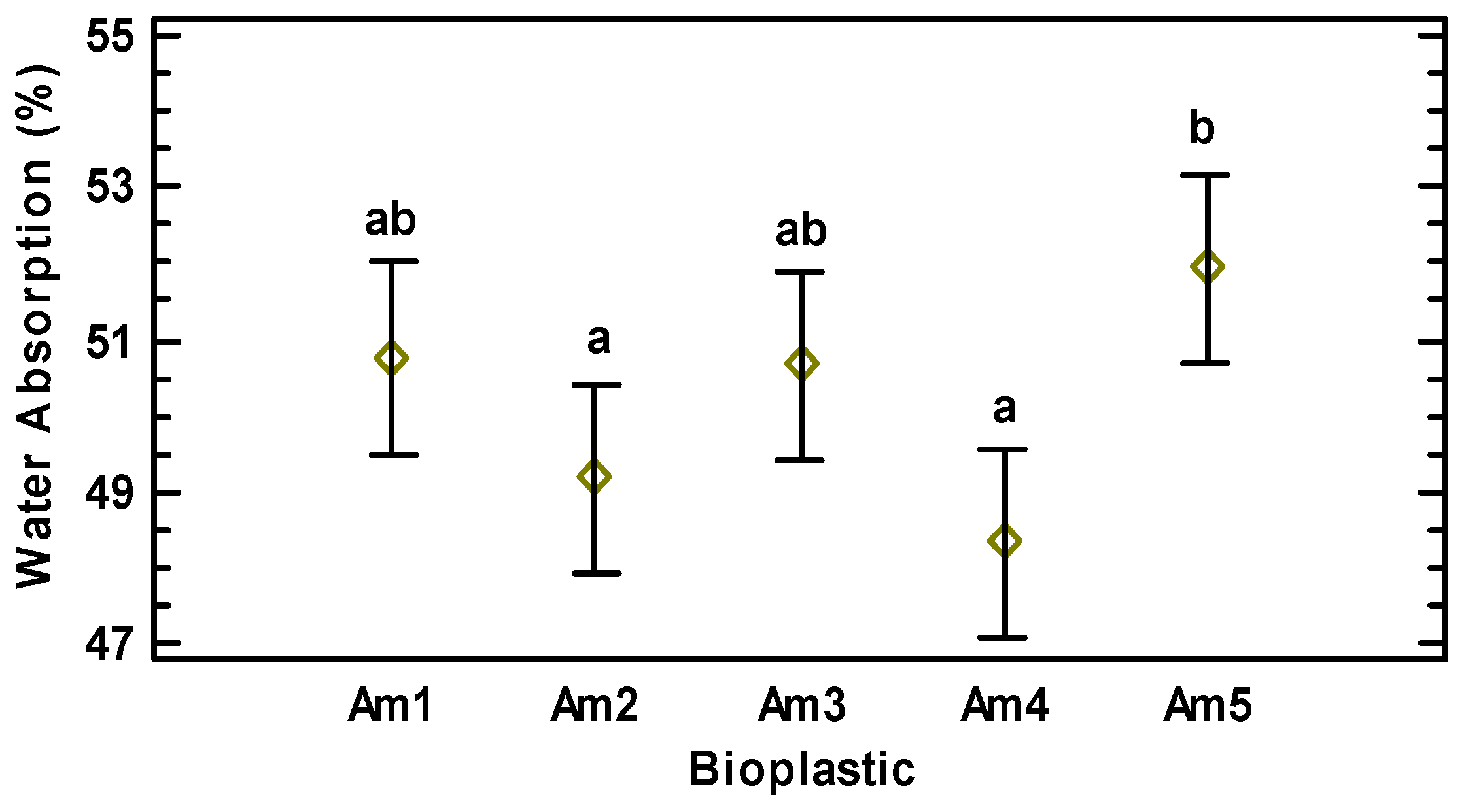

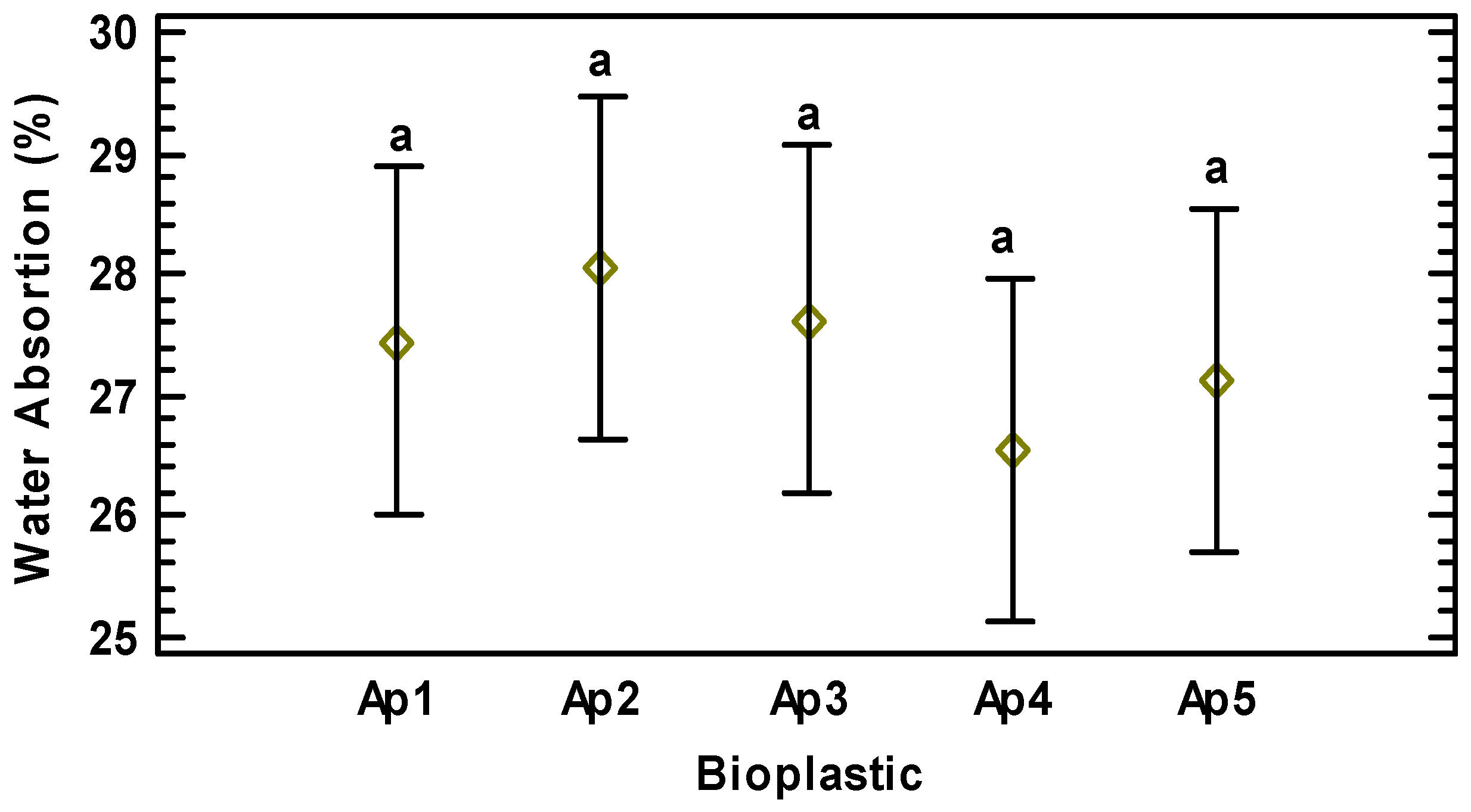

3.2. Bioplastics’ Water Absorption

3.3. Bioplastics’ Water Solubility

3.4. Bioplastics’ Mechanical Properties

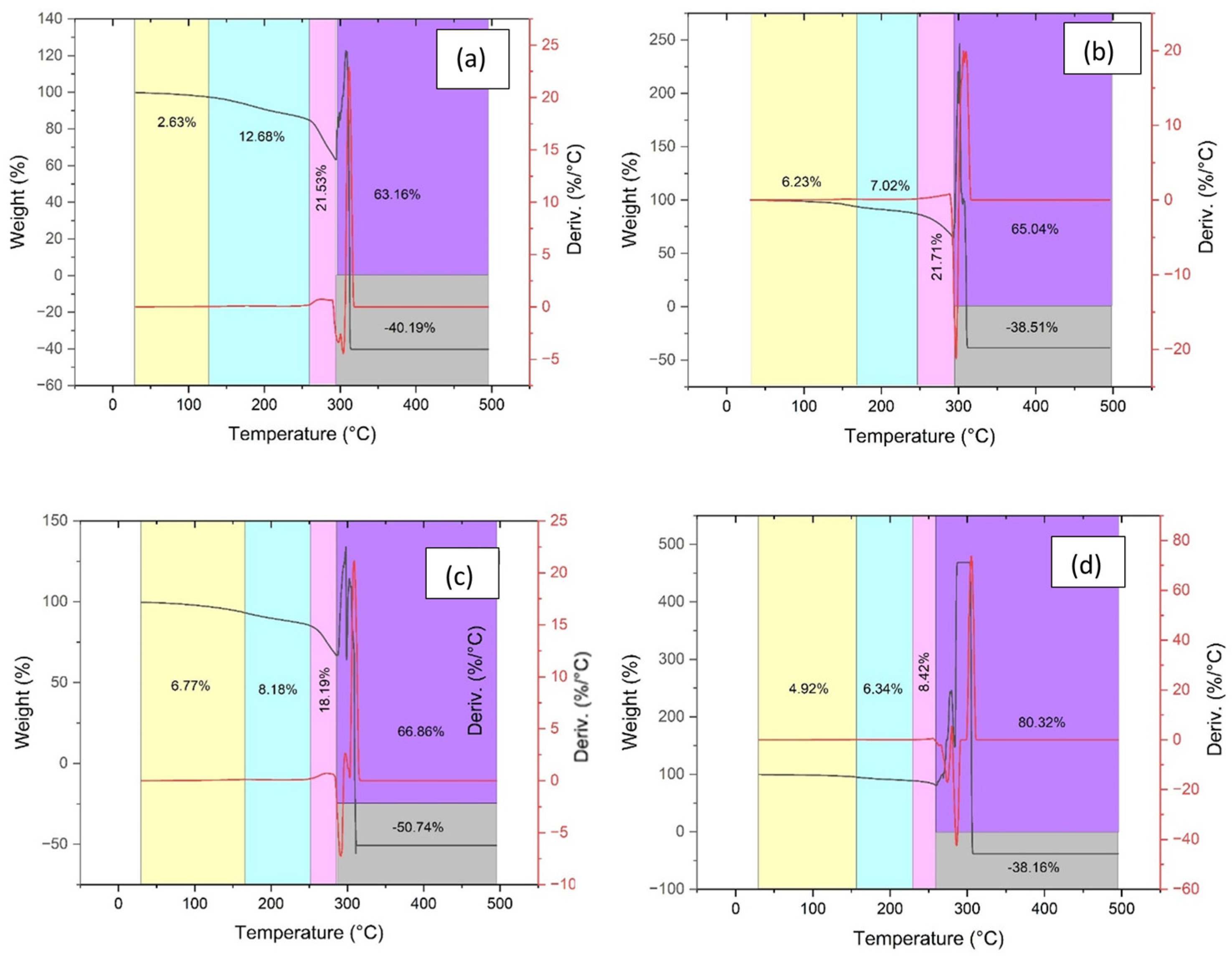

3.5. Thermal Properties

3.6. Scanning Electron Microscope of the Bioplastics

3.7. FTIR

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Costa, J.P.; Avellan, A.; Mouneyrac, C.; Duarte, A.; Rocha-Santos, T. Plastic additives and microplastics as emerging contaminants: Mechanisms and analytical assessment. Trends Anal. Chem. 2024, 158, 116898. [Google Scholar] [CrossRef]

- Nayanathara-Thathsarani-Pilapitiya, P.G.C.; Ratnayake, A.S. The world of plastic waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Pathak, G.; Nichter, M.; Hardon, A.; Moyer, E.; Latkar, A.; Simbaya, J.; Pakasi, D.; Taqueban, E.; Love, J. Plastic pollution and the open burning of plastic waste. Glob. Environ. Chang. 2023, 80, 102648. [Google Scholar] [CrossRef]

- Tasseron, P.F.; Van Emmerikk, T.H.M.; Vriend, P.; Hauk, R.; Alberti, F.; Mellink, Y.; Ploeg, M.V.D. Defining plastic pollution hotspots. Sci. Total Environ. 2024, 934, 173294. [Google Scholar] [CrossRef]

- Horton, A.A. Plastic pollution: When do we know enough? J. Hazard. Mater. 2022, 422, 126885. [Google Scholar] [CrossRef] [PubMed]

- Ihenetu, S.C.; Li, G.; Mo, Y.; Jacques, K.J. Impacts of microplastics and urbanization on soil health: An urgent concern for sustainable development. Green Anal. Chem. 2024, 8, 100095. [Google Scholar] [CrossRef]

- Cole, M.; Lindeque, P.; Halsband, C.; Galloway, T.S. Microplastics as contaminants in the marine environment: A review. Mar. Pollut. Bull. 2011, 62, 2588–2597. [Google Scholar] [CrossRef]

- Chen, K.; Tian, R.; Jiang, J.; Xiao, M.; Wu, K.; Kuang, Y.; Deng, P.; Zhao, X.; Jiang, F. Moisture loss inhibition with biopolymer films for preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2024, 263, 130337. [Google Scholar] [CrossRef]

- Ghannem, S.; Bacha, O.; Fkiri, S.; Kanzari, S.; Aydi, A.; Touaylia, S. Soil and sediment organisms as bioindicators of pollution. Ecologies 2024, 5, 679–696. [Google Scholar] [CrossRef]

- Olmo-Gilabert, R.; Fagiano, V.; Alomar, C.; Rios-Fuster, B.; Compa, M.; Deudero, S. Plastic webs, the new food: Dynamics of microplastic in a Mediterranean food web, key species as pollution sources and receptors. Sci. Total Environ. 2024, 918, 170719. [Google Scholar] [CrossRef]

- Mansfiel, I.; Reynolds, S.J.; Lynch, I.; Matthews, T.J.; Sadler, J.P. Birds as bioindicators of plastic pollution in terrestrial and freshwater environments: A 30-year review. Environ. Pollut. 2024, 348, 123790. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhang, T.; Zhong, Y.; Zhang, Y.; Wang, L.; Wang, X.W.; Zhou, L.; Zhou, X. Dynamic borate ester bond reinforced hydroxyethyl cellulose/corn starch crosslinked film for simple recycling and regeneration. Int. J. Biol. Macromol. 2024, 279, 135231. [Google Scholar] [CrossRef] [PubMed]

- Enwere, C.F.; Okafor, I.S.; Adeleke, A.A.; Petrus, N.; Jakada, K.; Olosho, A.O.; Ikubanni, P.P.; Paramasivam, P.; Ayuba, S. Production of bioplastic film from wildcocoyam (Caladium bicolor) starch. Results Eng. 2024, 24, 103132. [Google Scholar] [CrossRef]

- Alucho-Pasto, J.; Ramos-Naranjo, S.; Saltos-Segura, D. Tecnologías para el desarrollo de biopolímeros, como una alternativa en la sustitución del plástico. Alimentos. Aliment. Cienc. Ingeniería 2021, 28, 95–100. [Google Scholar] [CrossRef]

- Valero-Valdivieso, M.F.; Ortegón, Y.; Uscategui, Y. Biopolymers: Progress and prospects. Dyna 2013, 80, 171–180. [Google Scholar]

- Xu, J.; Sagnelli, D.; Faisal, M.; Perzon, A.; Taresco, V.; Mais, M.; Giosafatto, C.V.L.; Hebelstrup, K.H.; Ulvskov, P.; Jørgensen, B.; et al. Amilose/cellulose nanofiber composites for all-natural, fully biodegradable and flexible bioplastic. Carbohydr. Polym. 2021, 253, 117277. [Google Scholar] [CrossRef]

- Delgado-Villaseñor, A.K.; Maldonado-Santoyo, M. Circularidad para los plásticos: Reciclado post-uso vs fabricación de plásticos biodegradables. Rev. Electrónica Divulg. Investig. 2021, 21, 60–71. [Google Scholar]

- Tennakon, P.; Chandika, P.; Yi, M.; Jung, W.K. Marine-derived biopolymers as potential bioplastic, an eco-friendly alternative. IScience 2023, 26, 106404. [Google Scholar] [CrossRef]

- Villada, H.S.; Acosta, H.A.; Velazco, R.J. Biopolímeros naturales usados en empaques biodegradables. Temas Agrar. 2007, 12, 5–13. [Google Scholar] [CrossRef]

- Arias-Hernández, L.A.; Juaristi-Videgaray, E.; Mares-Martínez, H.E.; Solís-Silván, R.; Maldonado-Santoyo, M.; Calderón-Vega, F.; Valdés-Vázquez, J.F.; Delgadillo-Ruiz, E. Valoración de acolchados ecoplásticos utilizados para reducir la evaporación en suelos agrícolas. Cienc. Nicolaita 2024, 91, 1–9. [Google Scholar] [CrossRef]

- Delgadillo-Ruiz, E.; Vázquez Rodríguez, G.; Tirado Torres, D.; Robles Buenrostro, M.F.; Pérez Gallegos, D.O.; Hernández Moreno, J.D.; Arias Hernández, L.A. Efecto de la implementación de acolchados en los componentes del balance hídrico superficial. Jóvenes Cienc. 2022, 16, 1–9. Available online: https://www.jovenesenlaciencia.ugto.mx/index.php/jovenesenlaciencia/article/view/3837 (accessed on 28 December 2024).

- Delgadillo-Ruiz, E.; Castorena-Padilla, C.; Peña-Vázquez, F.; Exiga-Soria, A.R.; Ramírez-Siorda, G.Y.; Arias-Hernández, L.A.; Delgadillo-Ruiz, L. Clasificación de acolchados y su implementación en la retención de humedad del suelo. Jóvenes Cienc. 2022, 6, 1–9. Available online: https://www.jovenesenlaciencia.ugto.mx/index.php/jovenesenlaciencia/article/view/3838 (accessed on 28 December 2024).

- Chen, J.; Chen, X.; Guo, J.; Zhu, R.; Liu, M.; Kuang, X.; He, W.; Lu, Y. Agricultural, ecological, and social insights: Residual mulch film management capacity and policy recommendations based on evidence in Yunnan Province, China. Sustainability 2021, 13, 1603. [Google Scholar] [CrossRef]

- Rajeswari, A.; Christy, J.S.; Swathi, E.; Pius, A. Fabrication of improved cellulose acetate-based biodegradable films for food packaging applications. Environ. Chem. Ecotoxicol. 2020, 2, 107–114. [Google Scholar] [CrossRef]

- Khalid-Hossain, S.M.; Amin, M.R.; Kowser, M.A.; Chowdhury, M.A.C.; Hossain, N. Development and characterization of eco-friendly starch-based plastic reinforcing tea for packaging applications. Curr. Res. Green Sustain. Chem. 2023, 7, 100374. [Google Scholar] [CrossRef]

- Agunsoye, J.O.; Aigbodion, V.S. Baggasse filled recycled polyethylene bio-composites: Morphological and mechanical properties study. Results Phys. 2013, 3, 187–194. [Google Scholar] [CrossRef]

- Bardisso, M.L.; Salvatierra, L.M.; Giordano, R.M.; Pérez, L.M. Obtención y caracterización de biomateriales de interés tecnológico formulados a base de polímeros naturales y subproductos industriales. Energeia 2016, 14, 4–14. [Google Scholar]

- Józó, M.; Várdai, R.; Bartos, A.; Móczó, J.; Pukánszky, B. Preparation of biocomposites with natural reinforcements: The effect of native starch and sugarcane bagasse fiber. Molecules 2022, 27, 6423. [Google Scholar] [CrossRef]

- Fitch-Vargas, P.R.; Camacho-Hernández, I.L.; Rodriguez-González, F.J.; Martínez-Bustos, F.; Calderón-Castro, A.; Zazueta-Morales, J.J.; Aguilar-Palazuelos, E. Effect of compounding and plastic processing methods on the development of bioplastics based on acetylated starch reinforced with sugarcane bagasse cellulose fibers. Ind. Crops Prod. 2023, 192, 116084. [Google Scholar] [CrossRef]

- Schutz, F.G.; Goncalves, S.A.; Vercelino-Alves, R.M.; Vieira, R.P. A review of starch-based biocomposites reinforced with plant fiber. Int. J. Biol. Macromol. 2024, 261, 129916. [Google Scholar] [CrossRef]

- Delgadillo-Ruiz, L.; Bañuelos-Valenzuela, R.; Esparza-Ibarra, E.L.; Gutiérrez-Bañuelos, H.; Cabral-Arellano, F.J.; Muro-Reyes, A. Evaluación del perfil de nutrientes de bagazo de agave como alternativa de alimento para rumiantes. Rev. Mex. Cienc. Agrícolas 2015, 11, 2099–2103. [Google Scholar]

- Iñiguez-Covarrubias, G.; Díaz-Teres, R.; Sanjuan-Dueñas, R.; Anzaldo-Hernández, J.; Rowell, R.M. Utilization of by-products from the tequila industry. Part 2: Potential value of Agave tequilana weber azul leaves. Bioresour. Technol. 2001, 77, 101–108. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Jalalvandi, E.; Majid, R.A.; Ghanbari, T. Processing, morphological, thermal and absorption behavior of PLA/thermoplastic starch/montmorillonite nanocomposites. Int. J. Mater. Metall. Eng. 2012, 6, 1128–1132. [Google Scholar]

- Aguirre-Loredo, R.Y.; Velazquez, G.; Gutiérrez, M.C.; Castro-Rosas, J.; Ralgel-Vargas, E.; Gómez-Aldapa, C.A. Effect of airflow presence during the manufacturing of biodegradable films form polymers with different structural conformation. Food Packag. Shelf Life 2018, 17, 162–170. [Google Scholar] [CrossRef]

- Ashok, A.; Abhijith, R.; Rejeesh, C.J. Material characterization of starch derived bio degradable plastics and its mechanical property estimation. Mater. Today Proc. 2018, 5, 2163–2170. [Google Scholar] [CrossRef]

- Otolá-González, C.M.; Álvarez-Castillo, E.; Flores, S.; Gerschenson, N.; Bengoechea, C. Effect of plasticizer composition on the properties of injection molded cassava starch-based bioplastics. Food Packag. Shelf Life 2023, 40, 101218. [Google Scholar] [CrossRef]

- ASTM-D638; The Definitive Guide to Practice Plastic Tensile Testing. ASTM International: West Conshohocken, PA, USA, 1890.

- Sirivechphongkul, K.; Chiarasumran, N.; Saisriyoot, M.; Thanapimmetha, A.; Srinophakun, P.; Iamsaard, K.; Lin, Y.T. Agri-biodegradable mulch films derived from lignin in empty fruit bunches. Catalysts 2022, 12, 1150. [Google Scholar] [CrossRef]

- Cedeño-Sares, L.A.; Armijos-Cabrera, G.; Arias-Toro, D.; Bravo-Bravo, V.P. Efecto del glicerol como plastificante en películas de almidón de maíz modificado. J. Sci. Res. 2023, 8, 189–204. [Google Scholar] [CrossRef]

- Hernando, H.; Marpongahtun; Julianti, E.; Nuryawan, A.; Amaturrahim, S.A.; Rahman-Piliang, A.F.; Yanhar, M.R.; Goei, R.; Soykeabkaew, N.; Afdhal-Saputra, A.M.; et al. Impact of grycerol on oil palm trunk starch bioplastics enhanced with citric-acid epoxidized palm oil oligomers. Case Stud. Chem. Environ. Eng. 2024, 10, 100839. [Google Scholar] [CrossRef]

- Nasir, N.N.; Othman, S.A. The physical and mechanical properties of corn-based bioplastic films with different starch and glycerol content. J. Phys. Sci. 2021, 32, 89–101. [Google Scholar] [CrossRef]

- Cavalcanti-Azebedo, L.; Rovani, S.; Santos, J.J.; Batista-Dias, D.; Souza-Nascimiento, S.; Freire-Oliveira, F.; Silva, L.; Alves-Fungaro, D. Biodegradable films derived from corn and potato starch and study effect of silicate extracted from sugarcane waste ash. Appl. Polym. Mater. 2020, 2, 2160–2169. [Google Scholar] [CrossRef]

- Mohammed, A.A.B.A.; Hasan, Z.; Borhana-Omaran, A.A.; Elfaghi, A.M.; Khattak, M.A.; Ilyas, R.A.; Sapuan, S.M. Effect of various plasticizers in different concentrations on physical, thermal, mechanical and structural properties of wheat starch-based films. Polymers 2022, 15, 63. [Google Scholar] [CrossRef] [PubMed]

- Gamage, A.; Thiviya, P.; Liyanapathiranage, A.; Wasana, M.L.D.; Jayakodi, Y.; Bandara, A.; Manamperi, A.; Dassanayake, R.S.; Evon, P.; Merah, O. Polysaccharide-based bioplastics: Eco-friendly and sustainable solutions for packaging. J. Compos. Sci. 2024, 8, 413. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Riaz, S.; Maan, A.A.; Butt, M.S.; Iqbal-Khan, M.K. Valorization of agricultural residues in the development of biodegradable active packaging fims. Ind. Crops Prod. 2024, 215, 118587. [Google Scholar] [CrossRef]

- Hynes-Navasingh, R.; Gurunathan, M.K.; Nikolova, M.P.; Królczyk, B. Sustainable bioplastics for food packaging produced from renewable natural sources. Polymers 2023, 15, 3760. [Google Scholar] [CrossRef]

- Mohomane, S.M.; Motaung, T.E. Effect of sugarcane bagasse, softwood, and cellulose on the mechanical, thermal and morphological properties of PP/PE blend. Appl. Sci. 2024, 14, 2751. [Google Scholar] [CrossRef]

- Shaik, A.S.; Schuster, J.; Shaik, Y.P.; Kazmi, M. Manufacturing of biocomposites for domestic applications using bio-based filler materials. J. Compos. Sci. 2022, 6, 78. [Google Scholar] [CrossRef]

- Santos-Ventura, E.M.; Escalante-Alvarez, M.E.; González-Nuñez, R.G.; Esquivel-Alfaro, M.; Sulbarán-Rangel, B. Polypropilene composites reinforced with lignocellulose nanocrystals of corncob: Thermal and mechanical properties. J. Compos. Sci. 2024, 8, 125. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Jen, T.C. Synthesis and characterization of bioplastic films from potato peel starch; effect of glycerol as plasticizer. Mater. Today Proc. 2024, 105, 1–5. [Google Scholar] [CrossRef]

- Moaveni, R.; Ghane, M.; Soltani, P.; Zamani, A.; Ramamoorthy, S.K. Production of polymeric films from orange and ginger waste for packaging application and investigation of mechanical and thermal characteristics of biofilms. Appl. Sci. 2024, 14, 4670. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and rice starch-based bio-plastic as alternative packing materials. Fibers 2019, 7, 32. [Google Scholar] [CrossRef]

- Jayalath, U.T.; Samaraweera, H.; Samarasinghe, A. Development and characterization of gelatin-starch bioplastics: A comparative study of cassava, corn and rice-based alternatives. Sustain. Chem. Environ. 2025, 9, 100190. [Google Scholar] [CrossRef]

- Takkar, A.; Patel, B.; Sahu, S.K.; Yadav, V.K.; Patel, R.; Sahoo, D.K.; Joshi, M.; Patel, A. Potato starch bioplastic films reinforced with organic and inorganic fillers: A sustainable packaging alternative. Int. J. Biol. Macromol. 2025, 306, 141630. [Google Scholar] [CrossRef]

- Chowdhury, M.; Hossain, N.; Noman, T.I.; Hasan, A.; Shafiul, A.; Abul, K.M. Biodegradable, physical and microbial analysis of tamarind seed starch infused eco-friendly bioplastic by different percentage of Arjuna powder. Results Eng. 2022, 13, 100387. [Google Scholar] [CrossRef]

- Kowser, A.M.; Mahmud, H.; Chowdhury, M.A.; Hossain, N.; Mim, J.J.; Islam, S. Fabrication and characterization of corn starch-based bioplastic for packaging application. Results Mater. 2025, 25, 100662. [Google Scholar] [CrossRef]

- Fatima, S.; Khan, M.R.; Ahmand, I.; Sadiq, M.B. Recent advances in modified starch based biodegradable food packaging: A review. Helyon 2024, 10, e27453. [Google Scholar] [CrossRef]

- Reid, E.V.; Samuelson, M.B.; Blanco-Canqui, H.; Drijiber, R.; Kadoma, I.; Wortman, S.E. Biodegradable and biobased mulch residues had limited impacts on soil properties but reduced yield of the following crop in a low fertility soil. Renew. Agric. Food Syst. 2022, 37, 490–503. [Google Scholar] [CrossRef]

| Bioplastic | AM (g) | G (g) | AA (g) | ANM (g) | B (g) |

|---|---|---|---|---|---|

| Am1 | 650 | 300 | 50 | 20 | 0 |

| Am2 | 650 | 300 | 50 | 20 | 10 |

| Am3 | 650 | 300 | 50 | 20 | 30 |

| Am4 | 650 | 300 | 50 | 20 | 50 |

| Am5 | 650 | 300 | 50 | 20 | 70 |

| Bioplastic | AP (g) | G (g) | AA (g) | ANM (g) | B (g) |

|---|---|---|---|---|---|

| Ap1 | 650 | 300 | 50 | 20 | 0 |

| Ap2 | 650 | 300 | 50 | 20 | 10 |

| Ap3 | 650 | 300 | 50 | 20 | 30 |

| Ap4 | 650 | 300 | 50 | 20 | 50 |

| Ap5 | 650 | 300 | 50 | 20 | 70 |

| Bioplastic | Tension (MPa) | Deformation (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| Am1 | 2.30 ± 0.14 | 10.34 ± 0.63 | 38.60 ± 4.15 |

| Am2 | 2.11 ± 0.23 | 9.86 ± 0.26 | 31.34 ± 1.43 |

| Am3 | 3.15 ± 0.34 | 12.67 ± 1.47 | 40.53 ± 5.52 |

| Am4 | 4.20 ± 0.24 | 15.62 ± 1.60 | 50.47 ± 1.81 |

| Am5 | 4.59 ± 0.25 | 16.09 ± 1.33 | 57.46 ± 4.83 |

| Ap1 | 2.52 ± 0.16 | 12.40 ± 1.67 | 25.78 ± 2.15 |

| Ap2 | 2.09 ± 0.30 | 10.86 ± 1.35 | 22.49 ± 2.20 |

| Ap3 | 3.02 ± 0.21 | 14.22 ± 0.89 | 30.33 ± 3.89 |

| Ap4 | 3.37 ± 0.24 | 15.90 ± 0.95 | 34.77 ± 2.28 |

| Ap5 | 3.53± 0.38 | 16.17 ± 0.81 | 40.90 ± 4.63 |

| Observed Changes | Change Interval (°C) | Loss Weight (%) | |||||

|---|---|---|---|---|---|---|---|

| Ti | Tf | Am1 | Am2 | Am3 | Am4 | Am5 | |

| 1 | 30 | 160 | 2.63 | 3.84 | 6.85 | 5.51 | 6.23 |

| 2 | 160 | 250 | 12.68 | 9.59 | 6.01 | 5.61 | 7.02 |

| 3 | 250 | 290 | 21.53 | 28.45 | 21.92 | 22.57 | 21.71 |

| 4 | 290 | 500 | 63.16 | 58.12 | 65.22 | 66.31 | 65.04 |

| Observed Changes | Change Interval (°C) | Loss Weight (%) | |||||

|---|---|---|---|---|---|---|---|

| Ti | Tf | Ap1 | Ap2 | Ap3 | Ap4 | Ap5 | |

| 1 | 30 | 170 | 6.77 | 9.29 | 5.73 | 8.41 | 4.92 |

| 2 | 170 | 240 | 8.18 | 5.49 | 6.25 | 4.71 | 6.34 |

| 3 | 240 | 270 | 18.19 | 11.36 | 36.44 | 27.73 | 8.42 |

| 4 | 270 | 500 | 66.86 | 73.86 | 51.58 | 59.15 | 80.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arias Hernández, L.A.; Maldonado Santoyo, M.; Delgadillo Ruiz, L.; Solís Silván, R.; Calderón Vega, F.; Aguilera, G.C.; Reducindo Ruiz, S.M.; González Trinidad, J.; Berumen Cervantes, A.; Hernández, A.A.O.; et al. The Effect of the Addition of Maguey Bagasse in the Production of Bioplastics Based on Corn and Potato Starch. J. Compos. Sci. 2025, 9, 213. https://doi.org/10.3390/jcs9050213

Arias Hernández LA, Maldonado Santoyo M, Delgadillo Ruiz L, Solís Silván R, Calderón Vega F, Aguilera GC, Reducindo Ruiz SM, González Trinidad J, Berumen Cervantes A, Hernández AAO, et al. The Effect of the Addition of Maguey Bagasse in the Production of Bioplastics Based on Corn and Potato Starch. Journal of Composites Science. 2025; 9(5):213. https://doi.org/10.3390/jcs9050213

Chicago/Turabian StyleArias Hernández, Luz Adriana, María Maldonado Santoyo, Lucia Delgadillo Ruiz, Rudy Solís Silván, Felícitas Calderón Vega, Gilberto Carreño Aguilera, Shaula Melissa Reducindo Ruiz, Julián González Trinidad, Arturo Berumen Cervantes, Arturo Agustín Ortiz Hernández, and et al. 2025. "The Effect of the Addition of Maguey Bagasse in the Production of Bioplastics Based on Corn and Potato Starch" Journal of Composites Science 9, no. 5: 213. https://doi.org/10.3390/jcs9050213

APA StyleArias Hernández, L. A., Maldonado Santoyo, M., Delgadillo Ruiz, L., Solís Silván, R., Calderón Vega, F., Aguilera, G. C., Reducindo Ruiz, S. M., González Trinidad, J., Berumen Cervantes, A., Hernández, A. A. O., & Delgadillo Ruiz, E. (2025). The Effect of the Addition of Maguey Bagasse in the Production of Bioplastics Based on Corn and Potato Starch. Journal of Composites Science, 9(5), 213. https://doi.org/10.3390/jcs9050213