Business Models Definition for Next-Generation Vision Inspection Systems †

Abstract

1. Introduction

- -

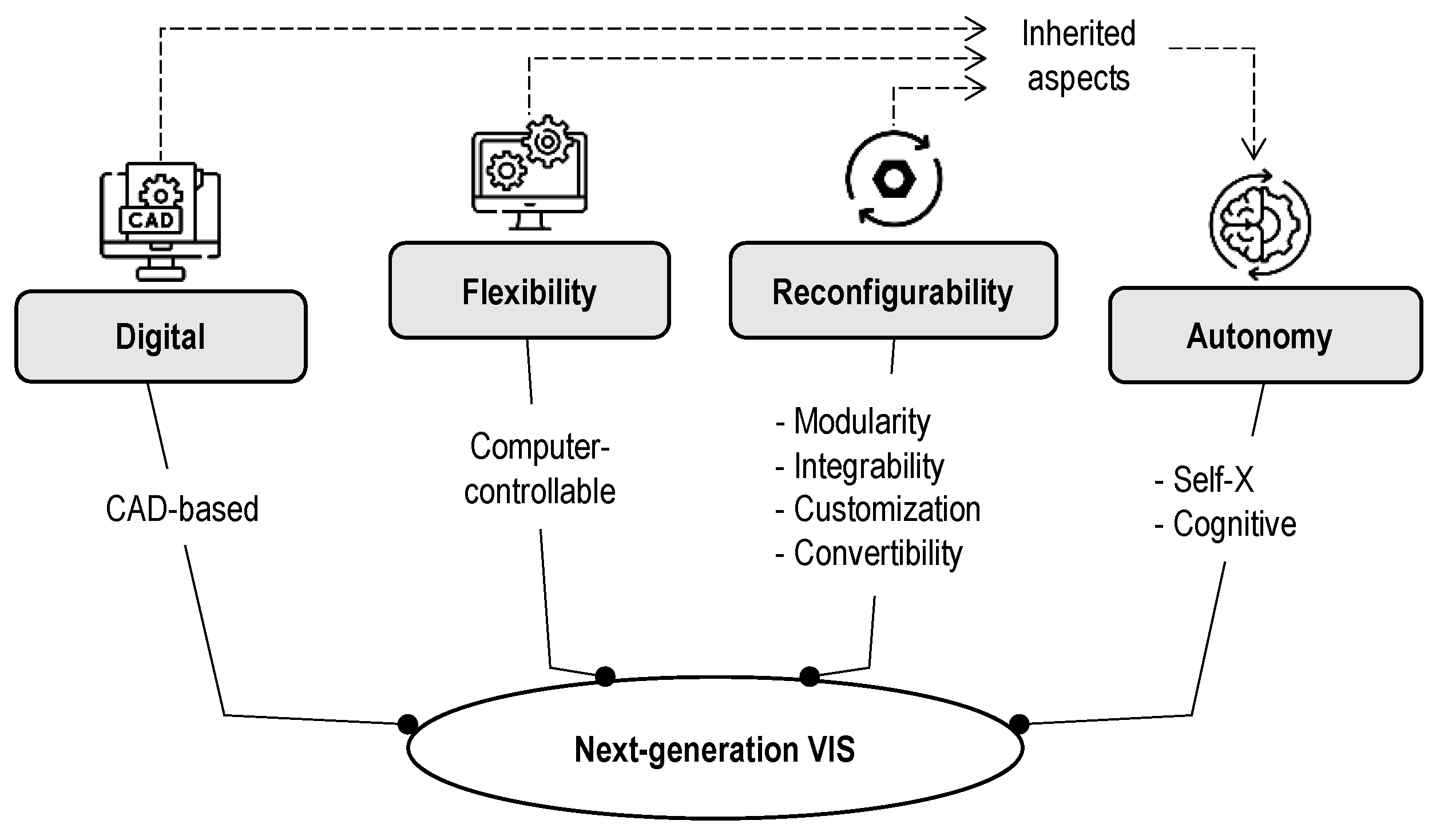

- Hardware: the development of flexible (i.e., computer-controllable) physical architectures integrating general purpose Numerically Controlled (NC) axes, six-Degree-of-Freedom (6DoF) industrial robots/cobots, drones or Automated Guided Vehicles (AGV) capable of positioning and orienting cameras and lighting systems with nearly unlimited flexibility within the working volume and according to constructive constraints. The physical components of these systems are designed to include reconfigurability features such as modularity (i.e., modular components), integrability (i.e., modules designed with interfaces for integration), convertibility and scalability (i.e., fast ramp-up), and customized flexibility (around a specific parts family).

- -

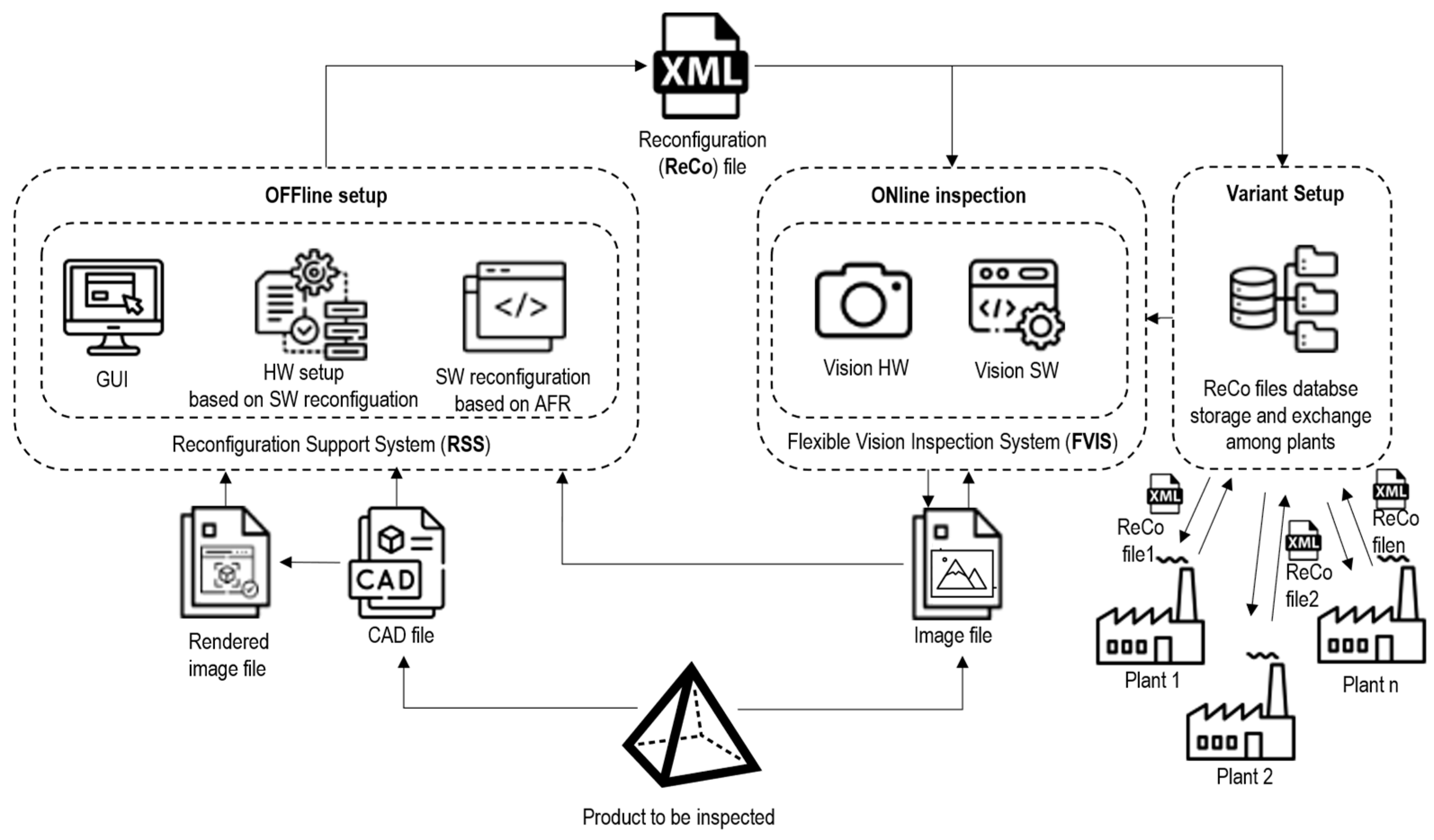

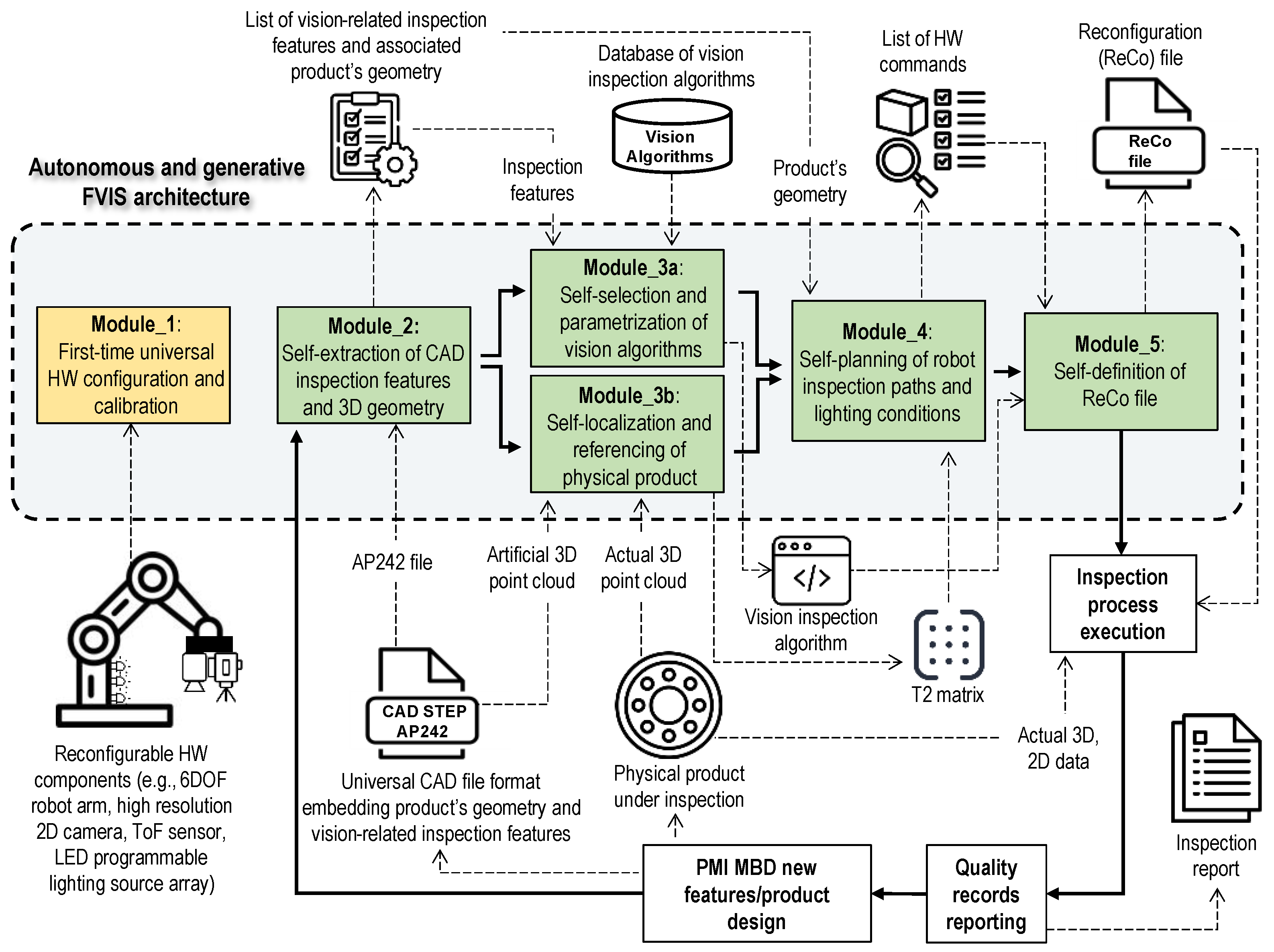

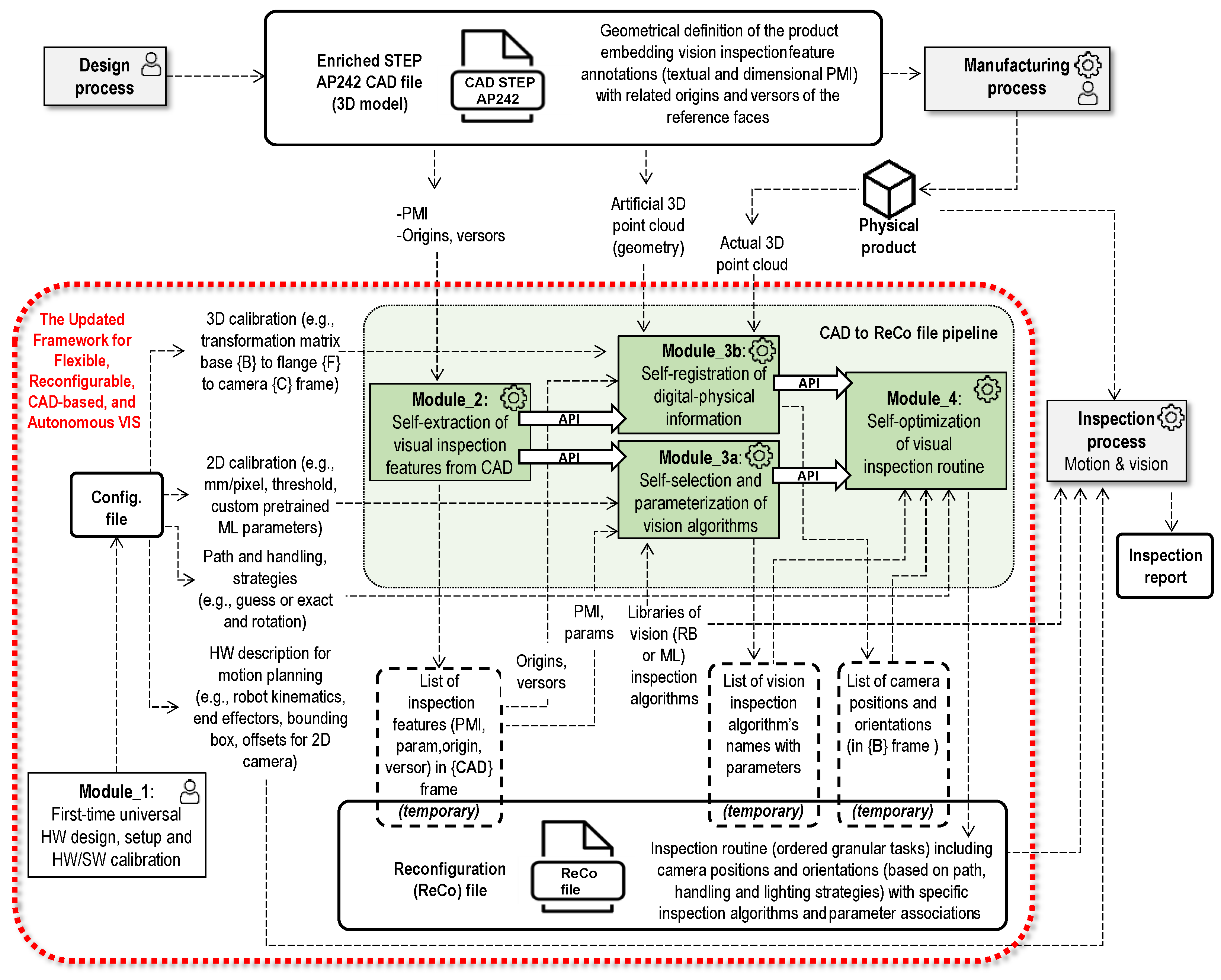

- Software: To achieve the previously described aims of reconfigurability and flexibility, software components need to exhibit the same aspects of modularity, integration, and easy setup and reconfiguration via user-friendly forms of Graphical User Interface (GUI) or Human Machine Interface (HMI), reducing the need for high-skilled personnel in low-coding tasks and complex automation integration. In this context, the potential of fully exploiting Computer Aided Design (CAD) three-dimensional (3D) models as a single point of truth (e.g., adopting a universal CAD file such as Standard for the Exchange of Product Data (STEP) and using Product Manufacturing Information (PMI)) has been recently included in these VIS new frameworks. These approaches each present a different Level of Automation (LoA) according to their degree of human interaction.

2. Background

2.1. Next-Generation VIS

2.2. Requirements, Peculiarities, and Trends of BMs

- Value-generating activities refer to the core actions or processes that a business undertakes to produce goods or services that are valuable to customers. These activities are crucial, as they directly contribute to the primary value proposition of a business, enhancing customer satisfaction, driving sales, and improving market positioning. Examples include product design, production, marketing, and customer service. Each of these activities adds value to the firm’s offerings and helps to attract and retain customers by meeting their needs and expectations effectively.

- Value-capturing mechanisms, on the other hand, are the strategies or methods a company uses to retain some portion of the value its activities create. This is essential for generating revenue and ensuring the company’s long-term viability and profitability. Value capturing can occur through various means, such as pricing strategies, cost control, intellectual property management, and innovative revenue models. For instance, a company might implement a premium pricing strategy to capture more value from high-quality products or adopt a subscription model to ensure steady revenue flow over time.

- Maximize material and energy efficiency: This archetype focuses on optimizing the use of resources to reduce waste and increase efficiency. Businesses adopt practices that streamline operations and minimize energy consumption, such as implementing more efficient production technologies or redesigning products to use less material [22].

- Create value from waste: Turning waste into a resource is a key strategy in this archetype. Companies develop processes to reuse, refurbish, and recycle materials that would otherwise be discarded. This can involve innovative ways to repurpose by-products or the production of waste materials valuable to other industries [23].

- Substitute with renewables and natural processes: Here, the focus is on replacing non-renewable resources with renewable ones, such as using bio-based materials or incorporating the use of wind, solar, and other sustainable energy sources into operations. This also includes adopting natural processes that are less resource-intensive and more benign with respect to the environment [24].

- Deliver functionality rather than ownership: This model shifts the focus from selling products to providing services that fulfill customer needs. For instance, instead of selling cars, a company might offer a car-sharing service. This helps reduce material use and can lead to innovations in how products are designed and used [25,26].

- Adopt a stewardship role: Companies adopting this archetype take responsibility for the impacts their operations have on the environment and society. They engage in practices that protect natural resources, support community development, and ensure that their operations are sustainable in the long term [27].

- Encourage sufficiency: Reducing consumption is at the heart of this archetype. Companies employing this strategy focus on promoting products that are more durable and able to be repaired, as well as encouraging consumers to buy less, but also to purchase products of a higher quality. This could also involve promoting sharing platforms or redesigning products for longer lifecycles [28].

- Develop scale-up solutions: The focus here is on expanding the reach of sustainable practices in order to have a broader impact. This might involve scaling-up successful pilot projects, franchising, or forming alliances to spread sustainable innovations more widely.

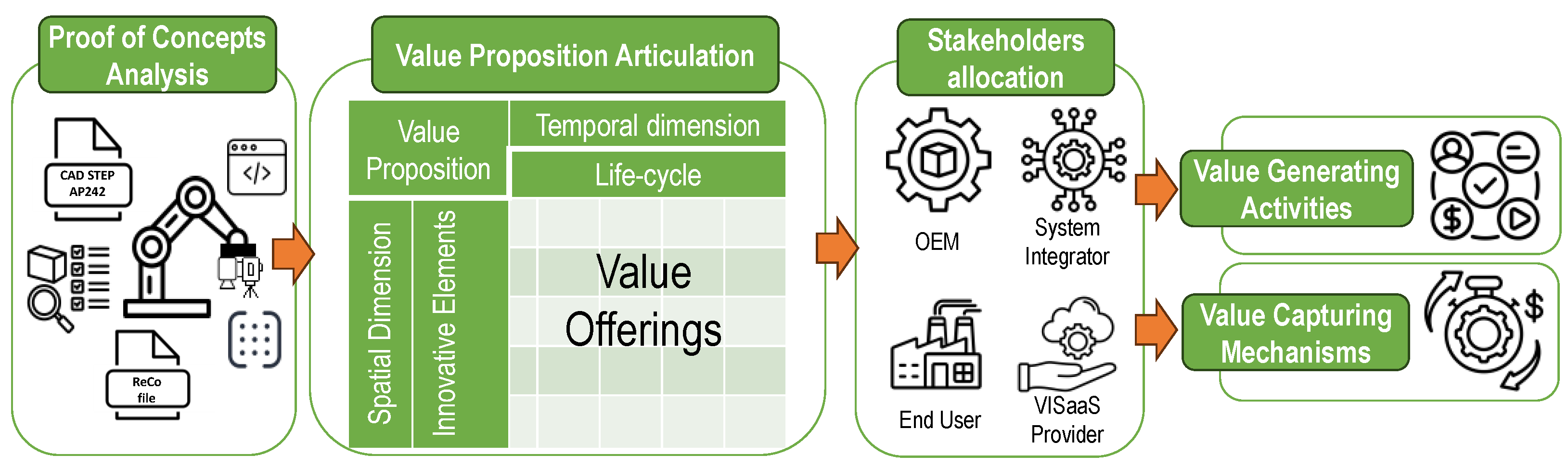

2.3. BM for Next-Generation VIS

- Define the value proposition along the whole lifecycle: This objective seeks to articulate the value proposition of the next-generation VIS by identifying and detailing specific value offerings at each stage of the system’s lifecycle. This also includes the identification of target stakeholders for each value offering. The goal is to establish a clear and continuous narrative of value creation, emphasizing how each phase contributes to the overarching benefits derived from the next-generation VIS.

- Discuss the value-generating activities and value-capturing mechanisms for each value offering: For each identified value offering, the paper will explore the associated value-generating activities—those actions or processes that directly enhance the utility, efficiency, or desirability of the next-generation VIS. Simultaneously, the study will examine the value-capturing mechanisms employed to secure economic benefits, ensuring the financial sustainability of the system throughout its lifecycle. This dual analysis will provide insights into how value is both created and retained.

- Determine the manner in which the resulting BM maps onto the sustainable BM archetypes: Finally, the research will investigate how the focal concept aligns the identified business models with respect to the sustainable BM archetypes presented above.

3. Methodology

4. Business Model of Next-Generation VIS

- OEMs: OEMs are pivotal in the lifecycle of next-generation VIS. These stakeholders are responsible for the creation and renewal of value by supplying the essential hardware components and the engineering expertise required to construct and continuously improve the system. OEMs benefit from both the initial sale of equipment and the ongoing revenue generated through maintenance, upgrades, and the provision of replacement parts necessary to keep the systems operational and up-to-date with respect to technological advancements.

- System integrators: System integrators play a critical role in aligning the various technological components from different manufacturers into a cohesive, functioning system. They specialize in integrating hardware and software to create a tailored solution that meets specific operational needs of the end users. Like OEMs, system integrators also benefit from the creation and ongoing renewal of value, particularly through engineering services, system upgrades, follow-up, and maintenance. Their expertise ensures that the next-generation VIS operate efficiently within the existing manufacturing infrastructure.

- VISaaS Providers: VISaaS providers are a newly defined category of stakeholders in the next-generation VIS ecosystem. They own the inspection systems and offer them to manufacturing companies under a pay-per-use scheme. This model allows end users to leverage advanced inspection technologies without the upfront capital investment typically associated with purchasing and installing such systems. VISaaS providers manage the deployment, maintenance, and upgrading of the systems, ensuring they deliver consistent performance and technological relevancy. This category of stakeholders may also include those software developers in the industrial marketplace hub who propose developing VIS algorithms for vision inspection library creation, as well as services for custom ReCo file development.

- End users: End users are the manufacturers who employ the next-generation VIS to enhance the quality and efficiency of their production processes. They benefit from the advanced capabilities of the VIS, such as increased accuracy, faster processing times, and reduced manual labor and low-coding skills, without having to invest in and manage the complex technology directly. By utilizing VISaaS, they can adapt to varying production demands and technological changes more flexibly and cost-effectively.

- Deliver functionality rather than ownership: The next-generation VIS support a service-oriented BM, particularly through the VISaaS model. This approach reduces the need for individual companies to own and maintain specialized inspection equipment, instead providing access to high-quality inspection capabilities as a service, which reduces overall material consumption and focuses on functionality.

- Develop scale-up solutions: The technology behind the next-generation VIS can be easily scaled and adapted to various industrial contexts, allowing for broad implementation across different sectors and geographies. This scalability enables widespread adoption of advanced inspection techniques, spreading the benefits of sustainable manufacturing practices more widely and contributing to global sustainability goals.

- 3.

- Maximize material and energy efficiency: The next-generation VIS enhance efficiency in manufacturing processes by optimizing inspection routines and reducing the need for repeated processes through its inspections. This leads to less material waste and lower energy consumption, as defects are identified more accurately and earlier in the manufacturing process, minimizing rework and scrap.

- 4.

- Create value from waste: While the primary function of the next-generation VIS is not directly related to waste management, quality control can help identify parts that can be reworked instead of discarded, indirectly contributing to waste reduction. Moreover, by ensuring higher quality control, materials that would otherwise be discarded due to defects can be saved and utilized effectively.

- 5.

- Encourage sufficiency: The next-generation VIS contribute to this archetype by ensuring the system extends its lifespan through reconfigurability and by reducing the need for component customization or recommissioning, thanks to their high flexibility and modularity.

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Koren, Y.; Heisel, U.; Jovane, F.; Moriwaki, T.; Pritschow, G.; Ulsoy, G.; Van Brussel, H. Reconfigurable Manufacturing Systems. CIRP Ann. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- ElMaraghy, H.A. Flexible and reconfigurable manufacturing systems paradigms. Int. J. Flex. Manuf. Syst. 2006, 17, 261–276. [Google Scholar] [CrossRef]

- Lupi, F.; Rocha, A.D.; Maffei, A.; Ferreira, P.; Barata, J.; Lanzetta, M. A Survey on Trends in Visual Inspection Systems Toward Industry 5.0. In Proceedings of the A Systematic Mapping Study, IEEE 30th International Conference on Engineering, Technology and Innovation (ICE 2024), Funchal, Portugal, 24–28 June 2024. [Google Scholar]

- Lupi, F.; Freitas, N.; Arvana, M.; Rocha, A.D.; Maffei, A.; Barata, J.; Lanzetta, M. Next-generation Vision Inspection Systems: A Pipeline from 3D Model to ReCo File. J. Intell. Manuf. 2024; in press. [Google Scholar] [CrossRef]

- Lupi, F.; Maffei, A.; Lanzetta, M. CAD-based Autonomous Vision Inspection Systems. Procedia Comput. Sci. 2024, 232, 2127–2136. [Google Scholar] [CrossRef]

- Lupi, F.; Biancalana, M.; Rossi, A.; Lanzetta, M. A framework for flexible and reconfigurable vision inspection systems. Int. J. Adv. Manuf. Technol. 2023, 129, 871–897. [Google Scholar] [CrossRef]

- Lupi, F.; Pacini, A.; Lanzetta, M. Laser powder bed additive manufacturing: A review on the four drivers for an online control. J. Manuf. Process. 2023, 103, 413–429. [Google Scholar] [CrossRef]

- Quintanilla, F.G.; Cardin, O.; L’anton, A.; Castagna, P. A modeling framework for manufacturing services in Service-oriented Holonic Manufacturing Systems. Eng. Appl. Artif. Intell. 2016, 55, 26–36. [Google Scholar] [CrossRef]

- Kusiak, A. Service manufacturing: Basic concepts and technologies. J. Manuf. Syst. 2019, 52, 198–204. [Google Scholar] [CrossRef]

- Chiera, M.; Lupi, F.; Rossi, A.; Lanzetta, M. Lean Maturity Assessment in ETO Scenario. Appl. Sci. 2021, 11, 3833. [Google Scholar] [CrossRef]

- Maffei, A. Characterisation of the Business Models for Innovative, Non-Mature Production Automation Technology. Doctoral Dissertation, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Buerkle, A.; Eaton, W.; Al-Yacoub, A.; Zimmer, M.; Kinnell, P.; Henshaw, M.; Coombes, M.; Chen, W.-H.; Lohse, N. Towards industrial robots as a service (IRaaS): Flexibility, usability, safety and business models. Robot. Comput. Manuf. 2023, 81, 102484. [Google Scholar] [CrossRef]

- Breschi, S.; Malerba, F.; Orsenigo, L. Technological Regimes and Schumpeterian Patterns of Innovation. Econ. J. 2000, 110, 388–410. [Google Scholar] [CrossRef]

- Teece, D.J. Business Models, Business Strategy and Innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Chesbrough, H.; Rosenbloom, R.S. The role of the business model in capturing value from innovation: Evidence from Xerox Corporation’s technology spin-off companies. Ind. Corp. Change 2002, 11, 529–555. [Google Scholar] [CrossRef]

- DaSilva, C.M.; Trkman, P. Business Model: What It Is and What It Is Not. Long Range Plan. 2014, 47, 379–389. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y.; Bernarda, G.; Smith, A. Value Proposition Design: How to Create Products and Services Customers Want; John Wiley & Sons: Hoboken, NJ, USA, 2014; ISBN 978-1-118-96805-5. [Google Scholar]

- Industry 5.0—Towards a Sustainable, Human-Centric and Resilient European Industry—European Commission. Available online: https://research-and-innovation.ec.europa.eu/knowledge-publications-tools-and-data/publications/all-publications/industry-50-towards-sustainable-human-centric-and-resilient-european-industry_en (accessed on 22 April 2024).

- Porter, M.E. Competitive strategy. Meas. Bus. Excell. 1997, 1, 12–17. [Google Scholar] [CrossRef]

- Osterwalder, A. The Business Model Ontology a Proposition in a Design Science Approach. 2004. Available online: https://www.academia.edu/download/30373644/thebusinessmodelontology.pdf (accessed on 17 April 2024).

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Brändström, J.; Eriksson, O. How circular is a value chain? Proposing a Material Efficiency Metric to evaluate business models. J. Clean. Prod. 2022, 342, 130973. [Google Scholar] [CrossRef]

- Pacini, A.; Lupi, F.; Rossi, A.; Seggiani, M.; Lanzetta, M. Direct Recycling of WC-Co Grinding Chip. Materials 2023, 16, 1347. [Google Scholar] [CrossRef] [PubMed]

- Chaubey, R.; Sahu, S.; James, O.O.; Maity, S. A review on development of industrial processes and emerging techniques for production of hydrogen from renewable and sustainable sources. Renew. Sustain. Energy Rev. 2013, 23, 443–462. [Google Scholar] [CrossRef]

- Lupi, F.; Cimino, M.G.C.A.; Berlec, T.; Galatolo, F.A.; Corn, M.; Rožman, N.; Rossi, A.; Lanzetta, M. Blockchain-based shared additive manufacturing. Comput. Ind. Eng. 2023, 183, 109497. [Google Scholar] [CrossRef]

- Huang, Y.; Qian, L.; Soopramanien, D.; Tyfield, D. Buy, lease, or share? Consumer preferences for innovative business models in the market for electric vehicles. Technol. Forecast. Soc. Change 2021, 166, 120639. [Google Scholar] [CrossRef]

- Nijhof, A.; Schaveling, J.; Zalesky, N. Business, society, and the need for stewardship orientation. J. Organ. Change Manag. 2019, 32, 145–163. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S. Towards a sufficiency-driven business model: Experiences and opportunities. Environ. Innov. Soc. Transit. 2016, 18, 41–61. [Google Scholar] [CrossRef]

- Koren, Y. General RMS characteristics. comparison with dedicated and flexible systems. In Reconfigurable Manufacturing Systems and Transformable Factories; Springer: Berlin/Heidelberg, Germany, 2006; pp. 27–45. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 smart reconfigurable manufacturing machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Boffa, E.; Maffei, A. Development and application of an Integrated Business Model framework to describe the digital transformation of manufacturing—A bibliometric analysis. Prod. Manuf. Res. 2023, 11, 2164952. [Google Scholar] [CrossRef]

- Amit, R.; Zott, C. Value creation in E-business. Strat. Manag. J. 2001, 22, 493–520. [Google Scholar] [CrossRef]

| Phase Type | Phase Description |

|---|---|

| Creation | Involves designing and customizing the product to enhance its value. |

| Purchase | Focuses on the transaction phase, in which ease of purchase, fast delivery, and reliability are key value enhancers. |

| Use | The traditional phase in which the product is utilized; the value is maximized when it meets current customer needs. |

| Renewal | Entails updating or upgrading the product to prolong its use, which is more valuable when it fits the customer’s increasing requirements, occurs non-invasively, and restores the product to a like-new condition. |

| Transfer | Deals with the end of the product’s lifecycle, focusing on the disposal or repurposing of the product to maximize end-of-life value and ease of disposal. |

| Category | Requirement |

|---|---|

| Hardware | Built using commercial 6DoF industrial robots/cobots, NC rotative/linear axes, drones, AGVs as well as cameras, lights, and others. Few customized components. Integrated within a compact and transportable solution. |

| Software | Commercial and integrated within an autonomous pipeline supporting the whole process. Customized modules for intra-communication between different platforms and for handling the self-X algorithms. Customary interface for the end user. Utilization of semantically enriched CAD data as a single point of truth. |

| Process | Autonomous self-X behavior: extraction of features, selection and parametrization of algorithms, product registration (including sensors calibration), and planning and execution of the inspection. Input: enriched CAD file with the geometry of the component and semantic annotations regarding the desired performed task (key information for each inspection feature: point, versor, and text/dimensions). Config file for hardware and software setup. Output: ReCo file. |

| Lifecycle Phase | Requirement | Stakeholders |

|---|---|---|

| Creation | The compact and transferable next-generation VIS are built, integrating different commercial and customized hardware components and developing the necessary hardware for interfacing with the customer and handling the self-X behaviors by integrating different commercial software with ad hoc intra-communication functionalities, delivering an autonomous pipeline from the annotated CAD input to the final ReCo file. | █ █ |

| Purchase | This phase includes the transaction within which the next-generation VIS unit reaches the final user. | █ |

| Use | This is the phase in which the system is deployed and used to perform the task for the current end-user. | █ |

| Renewal | This phase includes necessary upgrades and maintenance of the next-generation VIS system. | █ █ |

| Transfer | This phase is here similar to the “Purchase” phase, as it involves the transfer of the next-generation VIS to the subsequent end-user. | █ |

| Stakeholder | Value-Generating Activities | Value-Capturing Mechanisms |

|---|---|---|

| OEM | Producing and selling high-quality, reliable equipment that forms an integral part of the next-generation VIS. | Selling ownership. |

| System integrator | Integrating hardware (HW) and software (SW) to build tailored next-generation VIS solutions for generic industrial applications. | Charging for integration services, ongoing technical support, follow-up and system optimization to ensure seamless operation. |

| End user | Using the next-generation VIS to perform precise and efficient inspections of products to ensure quality compliance and reduce waste. | Cost savings and enhanced productivity: realizing increased operational efficiency and lower defect rates, which translate to higher product quality and reduced costs. |

| VISaaS provider | Renting or leasing the next-generation VIS to different end users, allowing for flexible, usage-based access over multiple lifecycles. Offering vision algorithms or ReCo file development as services. | Subscription-based and usage-based pricing: generating recurring revenue through subscription models or pay-per-use agreements which provide continuous income while offering scalability to customers. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lupi, F.; Maffei, A.; Lanzetta, M. Business Models Definition for Next-Generation Vision Inspection Systems. J. Manuf. Mater. Process. 2024, 8, 161. https://doi.org/10.3390/jmmp8040161

Lupi F, Maffei A, Lanzetta M. Business Models Definition for Next-Generation Vision Inspection Systems. Journal of Manufacturing and Materials Processing. 2024; 8(4):161. https://doi.org/10.3390/jmmp8040161

Chicago/Turabian StyleLupi, Francesco, Antonio Maffei, and Michele Lanzetta. 2024. "Business Models Definition for Next-Generation Vision Inspection Systems" Journal of Manufacturing and Materials Processing 8, no. 4: 161. https://doi.org/10.3390/jmmp8040161

APA StyleLupi, F., Maffei, A., & Lanzetta, M. (2024). Business Models Definition for Next-Generation Vision Inspection Systems. Journal of Manufacturing and Materials Processing, 8(4), 161. https://doi.org/10.3390/jmmp8040161