Abstract

This study shows an application of the Design for Six Sigma (DFSS) Methodology in the field of medical engineering. This research aims to demonstrate the application of a systematic design approach in the development of the “Ocane”, an innovative concept of smart cane for visually impaired patients which was thought of in answer to the end user’s needs, deploying an easy to transport, locate, and adjust element with ultrasonic sensors and tactile feedback. DFSS is an analytical design methodology meant to organize project workflow in a sequence of specific steps. Other standardized design procedures such as Quality Function Deployment (QFD) and Stylistic Design Engineering (SDE) have been used to support DFSS in terms of targeting customer requirements and focusing on aesthetics for ergonomics analysis, respectively. First, the QFD process is introduced and applied to gather the final customer needs, completing the analysis with benchmarking and similar-thought products on the market. Afterwards, a description of the DFSS methodology and application to the case study was deployed. Thereafter, the SDE procedure is exposed by identifying the “Ocane” concept and development, and moving towards the completion of an inventive product with a creative design and careful attention to visually impaired clients’ requirements.

Keywords:

DFSS; SDE; QFD; design; walking cane; blind people; assistive technology; visually impaired 1. Introduction

This research study is meant to address the power of the Design For Six Sigma (DFSS) through the application of this design methodology on an innovative product concept: a new navigation cane for blind people. In order to design a useful product that satisfies the blind populations’ requirements and supports visually impaired independency and safety in everyday life, careful effort was put into an extensive review of scientific literature and dedicated commercial products.

According to the World Health Organization (WHO), there are 2.2 billion visually impaired people in the world [1]. Among these people, 39 million suffer from complete blindness. The definition of visual impairment follows WHO categorization criteria [2]. Main causes of sight loss, along with congenital blindness, are uncorrected reflective errors and cataracts, diabetic retinopathy, and glaucoma, as well as others [3]. Recent study has shown that the number of the visually impaired population is expected to grow in the near future [4].

Blindness or partial loss of view is a profound disabling condition considering human environment perception is almost totally demanded to the sense of sight (83%). Information is collected also by hearing (11%), smell (3.5%), 1.5% by tactile sense, and 1% by taste [5].

Assistive technology is gradually improving daily routines of the visually impaired, moving from the traditional analogic blind stick to smart solutions and sensor integration [6], in which it is acknowledged that well-known techniques are being used in these systems, the basic features required to offer a fair performance (good user feedback), its advantages, and its disadvantages. In the beginning of the 20th century, the white cane was internationally recognized as the symbol of the blind community [7]. This is still used by most people with impairment, the best-known travel aid for the sightless. This rather simple device is used to detect obstacles at ground level, uneven surfaces, holes, steps, and other hazards; this inexpensive object is so lightweight and small that it can be found in the compact form that can be folded and slipped into a pocket. However, the study of Manduchi and Kurniawan [8] listed, among the multiple reasons why sightless people avoid the use of the traditional white cane, being fearful of striking people or undesired objects and of collisions with obstacles at a height higher than its contact reach distance among the most important reasons by sightless people avoid using it. In addition, the social stigma accompanied with the use of it, alongside a long training curve of about 100 h [9] required for its accurate use, were key problems found with many devices for the blind. The main drawback for the traditional white cane is that obstacles can only be detected by contact, which can be problematic to the user and the environment, for example, when traveling in a crowded street.

Nevertheless, in the last decades efforts have been invested in the development of assisted navigation canes, which may include state-of-the-art wireless communication technology and a number of sensors for avoiding objects and calculating its distance. Many of these were tested until a final product release. Others served as examples of a combination of existing technology for a specific purpose. Trials found in Literature include the GPS-included sensor-filled cane from Agrawal and Gupta [10]; circuitry-concentrated cane proposal from Damdhare and Sakhare [11]; proposal based on ultrasonic sensors by Dey et al. [12]; voice-command by Koley and Mishra [13]; haptic alerts for obstacles by Wang and Kuchenbecker [14]; low cost approach by Kumar et al. [15]; electronic sensors by Mahmud et al. [16]; overall improved smart-cane by Maidenbaum et al. [17] that would offer object type and detection with artificial intelligence (A.I.) by Mavarkar and Mundargi [18]; sound and touch input from Megalingam et al. [19], Infrared sensor-based by Nada et al. [20], Camera object detection with A.I. by Narayani et al. [21]; acoustic obstacle detection feedback by Rodríguez et al. [22]; Internet of Things approach by Sharmila [23] that, in a similar way to the Google Lens, requires wearing glasses and using the walking cane; a belt-like obstacle-avoidance system with A.I. technology by Shoval et al. [9] that showed the capacity to surpass all obstacles found by the white cane with state-of-the-art technology at the time; ultrasonic sensor-enabled shoes [24] that used ultrasonic sensors in shoes, sunglasses [25], and camera-integrated wearable devices including OrCam Read Smart which contains the text reading feature and a smart reading feature [26]; a very interesting four-stage double-diamond designed wearable orientation guidance device for modern travel aid systems by Zhang et al. [27]; and a cost-efficient object detection with deep learning algorithms achieved by applying the YOLO V3 dataset as the input to the model by Mekala et al. [28]. Other means of independent ambulation support found in literature include I Music, an audition image assessment by Abboud et al. [29]; a vibrotactile device that can translate facial expressions by Buimer et al. [30]; and a tactile-feedback safety device that helps blind people to avoid collisions at the head level by Jameson and Manduchi [31]. However, very few products have been released on the market and accurate efficiency in the real world calculation is still missing, meaning that there are still important investments to undergo in order to find the actual device that could deliver the best results to its customers.

Having seen the current development status of the industry, the aim of the present study is to apply the DFSS, i.e., an industrial procedure of product development in the design of an innovative smart cane for the visually impaired that uses the Deployment of Quality Functions gathered by a market analysis, a Top Flow, and benchmark analysis as well.

2. Materials and Methods

2.1. QFD—Quality Function Deployment

The Design For Six Sigma (DFSS) is a design methodology articulated in a sequence of steps that are meant to shape the phases of brainstorming, customer targeting, product development, benchmarking (BM), and aesthetic styling [32,33,34] in a standardized procedure. Procedure standardization is thought to upgrade product design by reducing time and energy dissipation, as well as by meeting client requirements meticulously. This research is based on products already available on the market, aiming to seek and correct main limitations, thus obtaining a more satisfying and innovative product.

The DFSS is also supported by Stylistic Design Engineering (SDE) and Quality Function Deployment (QFD) analysis which is articulated in different means of evaluation:

- the Six Questions;

- the Relationship Matrix of Relative Importance; and

- the Relationship Matrix of Dependence/Independence.

The Six Questions serve as mean of draft investigation on product characteristics. Answers will be further translated into project information through the Relationship Matrix of Relative Importance. This step has the objective to establish a utility hierarchy among selected features that determines which feature is the most important. Then, outcomes from the first matrix are examined through the Relationship Matrix of Dependence/Independence, with the purpose of evaluating the dependency and independency of product characteristics from one another.

The DFSS approach is built on a rigorous and farsighted strategy of specific work phases. At the industrial level, this systematic modus operandi is cost and time efficient as each step of the pattern is operated by dedicated offices, relying on specialized knowledge and skills. This research will further follow a work pattern in the form of the acronym DMADV, consisting of 5 distinct phases: define, measure, analyze, design, and validate.

- Define: The purpose of this step is to collect information of client needs, identifying product functions and its general context. The first phase is supported by QFD, a useful analysis for quality management, asking the Six Questions (namely who, where, when, how, what and why) that characterize the product placement.

- Measure: This phase is decisive in order to assess product features that guarantee customer satisfaction. Main characteristics are defined through QFD Interrelation Matrixes.

- Analyze: Benchmarking (BM) and Top/Flop (TF) analysis is performed, allowing for the examination of similar competitive products’ design.

- Design: Relying on data gathered from preceding steps, computer-aided design (CAD) concepts are made, aiming to fulfill both functional and aesthetical requirements. This phase is supported by the What/How Matrix following QFD guidelines.

- Validate: At last, it is verified if the product satisfies engineered characteristics. Eventually, prototypes are crafted and tested in order to assess the continuation of design features.

The DFSS steps’ purposes are summarized in Table 1.

Table 1.

DFSS structure and related methods employed.

A systematic methodology allows for the steady management of both technical phases and the industrial organization of personnel, striving to achieve efficiency and fluency of work. Relating to the DMADV design pattern:

- define and measure phases should be performed by the product marketing office;

- analyze phase by the purchasing office; and

- validate phase by the experimental technical office.

These considerations are summarized as follows in Table 2.

Table 2.

Symmetry of DFSS: industrial engineering vs. management engineering.

2.1.1. Define: The Six Questions

The first step of DFSS consists of giving open answers to the Six Questions (namely who, what, where, when, why and how); this phase supports product development by establishing guidelines that organize the process of brainstorming.

Who are the customers? What is the use of the developing product? Where, when, and how will they apply it to their daily routines? Why? These questions are functional to addressing major product characteristics by identifying the overall background and how the product is useful to the customer. Therefore, it is possible to detect those factors that have to be maintained and/or enhanced in the design of a competitive new product. Answers to the Six Questions applied to the case study are reviewed in Table 3.

Table 3.

QFD-Six Questions.

Moreover, according to current literature [34], main limitations concerning the ability to independently mobilize are found in the lacking of audio feedback from public transportation (82.4%) and traffic lights (81.4%); failing to find the entrance of a building (64.9%) and irregular sidewalks (58.7%); falling down because of unknown stairs (48.5%) and roadside holes (44.3%); hitting of obstacles on the waist level (47.4%); and getting lost (45.3%). Among the participants of the survey, 66% were blind and 34% had low vision. In total, 95.3% used white canes and 97.7% brought a mobile phone when travelling outdoors, showing a large acceptance of phone services such as the Short Message Service (70.1%), accessing the internet (45.4%), and GPS navigation (34%). Living in a world where society is increasingly connected, technological integrations such as GPS units for assisted navigation could enhance the safety of the customer. In fact, 84.5% of the participants pointed out the importance of GPS navigation tools while travelling outdoors. By having such a large number of white cane users, it is necessary to ask visually impaired citizens about the main impediments they face in their everyday independent navigation, with the purpose of designing the best product possible.

As the product is intended to actively assist people with profound disabilities in their daily tasks, characteristics of steadiness and reliability are mandatory.

Therefore, considering daily use in both indoor and outdoor environments, the product has to be ergonomic, lightweight, and easily transportable. The cane occupies the hand of the person and its use could also be protracted overtime, thus, it has to have an adequate battery life, must be comfortable, and should not overstrain the user. Cost is another important factor considering that the vast majority of visually impaired people live in poor countries and their disability strongly influences their ability to provide for themselves.

Traditional white cane is an affordable instrument but has no additional connection to the environment apart from tactile and acoustic feeling. The tip of the stick is usually made of a ceramic material that enhances a clear acoustic feedback by tapping it onto the surface [35]. Smart canes would integrate sensors and devices that connect with the surroundings in a deeper manner, resulting in an enhancement of safety and independence for the customer. However, additional technologies have to maintain the product’s simplicity of use, avoiding frustration and mistrust in users.

2.1.2. Measure: Relationship Matrices

A smart cane for the blind must be steady but also portable, must be ergonomic, easy to use, and should also be a reasonable investment that allows for safe navigation. How do these considerations become measurable information?

Found features are put in the Relationship Matrix of Relative Importance in rows and columns following the same order (Table 4).

Table 4.

Relationship Matrix: relative importance.

Relative importance is evaluated numerically, filling every cell with a value of 0, 1, or 2. If the requirement of the row is more important that the one of the column, 0 is given, while 1 is given if requirements are equally important and 2 if the requirement of the column is more important than the one from the row. Then, values are summed and features with the highest scores are highlighted.

Thus, the first matrix produces aspects that are essential for the purpose of the product. The innovative smart cane has to be steady, easy and comfortable to use, and must produce a reliable connection with the environment, enhancing safety of navigation.

The second matrix in Table 5 identifies their mutual dependence. Features still occupy rows and columns in the same order and a value of 0, 1, 3, or 9 is added in each cell. No dependence is represented by 0, while 1 represents mild dependence, 3 represents average dependence, and 9 represents strong dependence. The major sum of the rows indicates the aspect that is most affected by the others, while the major sum of the columns identifies the aspect that overall influences other features.

Table 5.

Relationship Matrix of Independence.

2.1.3. Analyze: Benchmarking and Top-Flop Analysis

The third step of the DFSS method consists of actively comparing available products in order to establish a hierarchy based on prominent parameters. The first phase of this stage is called Benchmarking (BM) and has the purpose of identifying similar products already available on the market. The second phase of this stage is called Top-Flop Analysis and consists of comparing chosen products, stating their winning features and limitations. The best values found are set to be the starting features for an innovative device. Canes were compared on the following parameters: safety, weight, ergonomic structure, price, battery life, charging time, water resistance, separate sale of the cane, period of warranty, obstacle detection range, and simplicity of use.

The selected canes are summarized in Table 5 and the best/worst features of each product are highlighted in green/red. For each top or flop characteristic, a value of +1 or −1 is considered for each item. Then, the total sum of each product is made, resulting in a DELTA (Δ) for each symbol. This value is meant to measure the innovation of a product on a certain number of features. In order to be competitive, the new product has to enter the market with a better Δ than its competitors.

Benchmarking

Although several research studies have been published aiming to design an innovative smart cane, some of them are still in development. Thus, very few products are already for sale [36]. Available canes are summarized in Table 6.

Table 6.

Smart canes benchmarking.

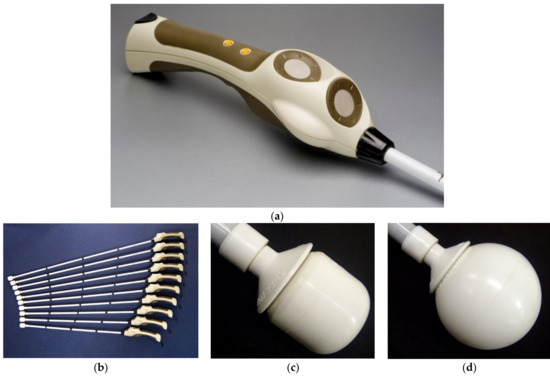

Figure 4.

UltraCane stock photos [40]: (a) UltraCane smart handle; (b) different white cane sizes that can be chosen at the time of purchase; (c) customizable rolling “marshmallow” tip; and (d) customizable rolling sphere tip.

Figure 3.

Stock photo of WeWalk Cane [39].

Figure 2.

Stock photo of SmartCane™ [38].

Figure 1.

Stock photo of BAWA Cane [37].

Top-Flop Analysis

This step has the purpose of highlighting the winning features for the end user and the limitations found in the identified competitors. Items are compared on a certain number of parameters and a Δ is evaluated for each product, expressing an “innovation” indicator.

Smart canes found on the market were confronted on the following parameters: price, safety, weight, ergonomic structure, and battery life.

Safety

A smart cane is designed with the purpose of protecting its user from obstacles that are not detectable with the traditional stick. It is documented that blind people very often experience head trauma [8] because the white analogic cane only gives feedback on knee-level objects. Therefore, safety is an indispensable aspect to consider when trying to improve daily routines of the visually impaired. Ultrasonic sensors are found to be a reliable and cost-effective mean of interaction with the environment. The device sends ultrasonic sound waves to the surroundings and processes a response of different electrical signals based on the time taken by the sound wave to travel back from the impacted surface.

The signal is generally transduced in an acoustic stimulus emitted from the cane (es. BAWA Cane emits feedbacks of 80 dB) or from a Bluetooth earpiece connected with the stick. However, an acoustic-driven navigation can be unhelpful in crowded places or in intense traffic. Furthermore, as blind people profoundly rely on the sense of sound [41], an earpiece or headset could be very distracting. In order to give customers the chance to receive feedback while having their ears free from obstruction, it was thought to equip the innovative cane with a bone conduction earpiece. Bone conduction hearing is an interesting technology that stimulates the skull, producing a vibration that transmits to the inner ear, bypassing outer and middle sections. It has been recently documented that a bone conduction navigation system for the blind gave optimistic results [42]. It is important that visually impaired people continue to rely on their senses rather than overstimulate them with artificial feedbacks [43].

The signal is also transduced very often in haptic stimuli, resulting in different vibrating patterns that shake the fingers of the user from the handle. UltraCane, SmartCane™, and WeWalk all give haptic feedbacks and differences in the intensity and frequency of the vibration are meant to give the visually impaired a sense of sight by trying to depict a mental map of the environment. However, long-lasting usage could damage the user’s health as it was found that vibrations of the hand and wrist produce pain and induce blind people to change their grip on the handle [44].

Weight and Ergonomic Factors

In order to design a useful and innovative product, it is important to use empathy to step into the shoes of the visually impaired and understand that a cane is their mean of independence and safety. Blind people make daily use of the white cane and their movements are greatly influenced by the need of a stick for assisted navigation. It has been seen that those repetitive movements [45] drastically change normal musculoskeletal walking patterns and the extended tapping of the tip onto the ground could potentially damage the user’s health [46]. Furthermore, it has been found that smart canes tend to be twice as heavy than traditional analogic canes [47]. Thus, a new smart cane must be lightweight and the handle must be ergonomic, preventing long-term repercussions on the muscular system.

Simplicity of Use

Every travel aid object, smart or traditional, needs several hours of training in order to be efficient and put in action. The learning curve of smart devices is inevitably longer, as the user needs to adapt to a certain number of extra features [48]. The blind community is still divided on addressing their utility, as a massive portion is gradually abandoning smart devices, aspiring to rely more on their own senses. It has been recently discovered that blindness “reorganizes” brain sections that are involved in information processing. Blind people use “echolocation” that gives them a feeling of sight by producing mouth-clicks or quick noises and allows them to produce a mental map of the ambience. This information acquisition process is similar to how bats communicate with the environment, as they often live in dark caves and have a very low level of sight [43]. It has been recently documented that echolocation is directly linked to the visual cortex rather than areas that are dedicated to process acoustic information [49]. Thus, it seems that the human brain naturally adapts to sight loss by trying to substitute viewing acquisition with other senses, producing a mental image of the environment [50]. In this direction, it is believed that overloading assistive devices with sensors and technology could potentially represent a disadvantage rather than an improvement.

Based on the previous considerations, simplicity of use was evaluated as follows:

- low: the device has a high level of assistance (smartphone connection with dedicated applications, a headset, a voice-assisted navigation, and multiple functions and controls);

- medium: the device has a medium level of assistance (smartphone connection, voice-assisted navigation, and acoustic feedbacks); and

- high: the device has a low level of assistance (the cane has no smartphone connection, no extra connections, and feedback comes from the handle only through haptic systems).

Ease of Transport

There is no substantial difference in the structure between the traditional white cane and a smart cane. The four abovementioned products are clip-on devices that support the traditional cane as an additional device (BAWA Cane), are smart handles that come with a stick and are easily disassembled (WeWalk, SmartCane™, and UltraCane), or are adapted to already existing sticks. Canes are usually rigid, telescopic, or made of foldable sections kept together by an inner elastic cable. The last configuration is really appreciated because it guarantees steadiness but is also easily transportable, as the cane can be discreetly carried in a bag. The material is usually an aluminum alloy, ensuring steadiness and ensuring a light weight.

Main characteristics were examined in detail as a smart cane for the visually impaired is not a common item but must accomplish very specific tasks for a particular customer need. Its requirements and limitations could be misunderstood by sightless citizens, especially if not familiar with sight loss and visual impairments. Based on the considerations examined, a top-flop table (Table 7) was constructed, comparing canes in terms of following the parameters demanded by unsighted customers: safety, weight, ergonomic structure, price, battery life, charging time, water resistance, separate sale of the cane, period of warranty, obstacle detection range, and simplicity of use. The best features are highlighted in green and worst features in red. Innovative features are summarized in Table 8.

Table 7.

Top-flop analysis.

Table 8.

Innovative features detected.

Hence, the new innovative cane should have at least a Δ > 2 in feature offering. It has to benefit from both an acoustic and tactile feedback system in order to avoid information dissipation in crowded places. A bone conduction system would be a very useful improvement, leaving user ears unimpeded. It must be light (around 100 g) and ergonomic to ensure the user does not feel overstrained by continuous use of the device and must have a long-lasting battery autonomy that could be quickly recharged. Water resistance could be a huge innovation. Considering ultrasonic sensors are able to detect raindrops, the feedback system would overload the user with information; thus, a sudden downpour could immediately stop the navigation of the visually impaired. The cane should be equipped with a variable range of obstacle detection including a short range for indoor navigation and a longer range for outdoor navigation. The cane should be included in the purchase; however, because the traditional white cane is still the main mean of navigation, it should be detachable and allow for the pairing with existing white canes through an adaptation system.

Overall, it should be an affordable investment with a low level of smart features and assistance.

2.2. SDE—Stylistic Design Engineering

Stylistic Design Engineering (SDE) is an industrial standardized procedure of product styling that was initially carried out by Eng. Lorenzo Ramacciotti, former CEO of Pininfarina Spa [51]. The purpose of this methodology is to organize the styling phase by dividing the workflow in six different steps:

- analysis of stylistic trends;

- sketches;

- 2D computer-aided design (CAD) drawings;

- 3D CAD models;

- rendering; and the

- solid stylistic model.

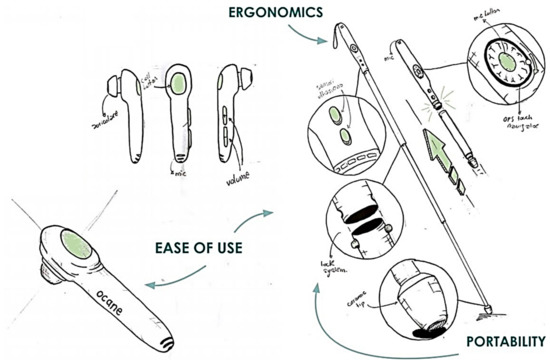

The case study was supported by a brief analysis of stylistic trends, assuming that a smart device which substitutes a traditional analogic cane should feel futuristic and advanced. Initial sketches were carried out considering technological solutions that were previously abandoned, such as the Bluetooth earpiece for acoustic feedbacks (Figure 5).

Figure 5.

Initial sketches.

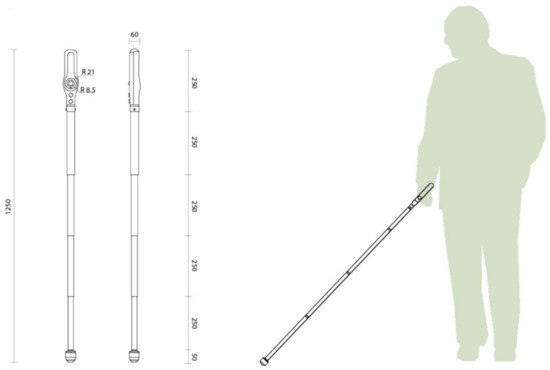

Then, 2D CAD drawings served as an indication of dimensions (Figure 6).

Figure 6.

2D computer-aided design (CAD) drawings.

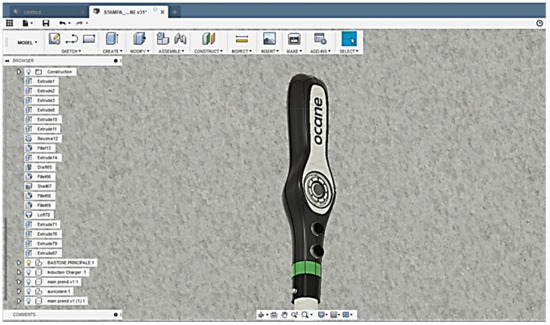

The resulting product was labelled “Ocane” and 2D drawings became 3D CAD models (Figure 7).

Figure 7.

CAD modelling on Fusion 360.

3. Results

Following DFSS guidelines, it was possible to achieve an excellent fluency of work. The aim of this research was to demonstrate an application of an industrial and rigorous methodology to conceptualize an innovative product. The QFD analysis produced good market and product characterization, and SDE organized artistic and crafty labor for the aesthetic design. The result of this research study is the developing of Ocane (Figure 8), a smart cane for the visually impaired. Proposed innovative aspects of this device are to be found in the:

Figure 8.

Ocane render.

- including of an innovative charging system that ensures a quick complete charge by means of a magnetic induction wall hanger, which was also a safety product design input;

- innovative user-feedback system that uses bone conduction hearing; and

- light and ergonomic structure.

Through a subsequent rendering process, product features and the aesthetic design were much clearer (Figure 9). The Bluetooth earpiece became a bone conduction device following previous considerations. A led for clearer identification was added in the handle, resulting in an enhancement of safety. The charging system became a magnetic induction wall hanger that ensures also to prevent the loss of the stick. Two ultrasonic sensors were positioned in the handle, adjustable for different heights.

Figure 9.

Rendering of earpiece, cane, and magnetic induction charging system.

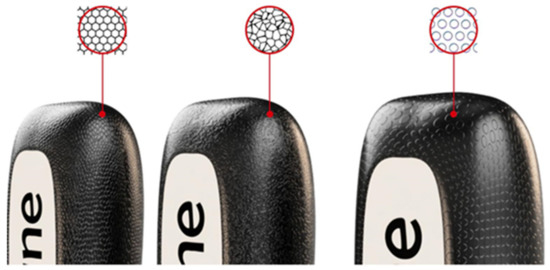

Another important aspect regarding the ergonomic structure is the tactile feeling of the handle. As the device is meant to be carried by hand for several hours, tactile comfort is not a secondary aspect; thus, handle customization was made possible in the shape of a honeycomb, a broken glass shape, and dots (Figure 10).

Figure 10.

Patterns of tactile customization of the handle: a honeycomb, a broken glass shape, and dots.

Additionally, the Ocane was developed following a methodology that focused entirely on the final customer’s needs to offer a device which is foldable for discrete transport, easily identifiable due to the handle led, includes ultrasonic sensors that are adjustable in angulation in order to cover the right range of detection, and most importantly, includes a handle that can be disassembled from the cane, thus the ordinary white canes can be installed in and benefit from smart functions. The tip is thought to be made of ceramic material that enhanced the environmental sound feedback and, finally, the handle is equipped with a haptic system that stimulates the thumb of the user with different frequencies and patterning in a similar way to devices designed for touch sense stimulus.

4. Conclusions

The scientific world is still putting in effort to reach the perfect blind cane. However, promising ideas have emerged in the last years and smart devices are slowly appearing on the market. This project pursued the idea of creating a device that could communicate with the end user more efficiently rather than overloading it with technology and sensors on a single device. This would leave more room for users to feel with their own senses, allowing them to acquire their known perception of the world rather than substituting natural information acquisition with artificial, which is not free from errors and approximations. As the development of assisted navigation technology is still in its early stages, the authors hope to push the design process of a smart white cane forward by applying the DFSS methodology that is shown to increase the accuracy of product placement and delivered higher technical improvement from those found in the product benchmark.

Furthermore, this device was designed following improved industrial product development and function deployment procedures, in which main functional and aesthetical characteristics were defined in order to guarantee market feasibility.

Lastly, it is very challenging to assist the visually impaired, as the lack of sight profoundly changes the perception of space. Even if engineering is far from emulating the nature of senses, empathetic efforts in designing such a delicate device that tries to use the same nature of perception as the final user has shortened the distance between the designer and its final user.

Future Work

Further research should investigate blind peoples’ clinimetrics of the pace and tensional state of the musculoskeletal system of users in order to design an accurate ergonomic element. In addition, extending the potential usage of the device by adding water resistant ultrasonic sensors that work in rainy and icy weather conditions should be considered.

Author Contributions

Conceptualization, L.F. and G.D.; methodology, L.F. and G.D.; software, A.L.; validation, L.F. and A.L.; formal analysis, L.F.; writing—original draft preparation, P.P. and C.L.-C.; writing—review and editing, C.L.-C.; visualization, P.P. and C.L.-C.; supervision, A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study, due to not consider this study as ethically intrusive.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- World Health Organization. World Report on Vision. Available online: https://www.iapb.org/learn/resources/the-world-report-on-vision/ (accessed on 17 February 2021).

- WHO International Statistical Classification of Diseases and Related Health Problems, 10th Revision ICD-10: Tabular List. World Heal. Organ. 2016, 1, 332–345.

- Pascolini, D.; Mariotti, S.P. Global estimates of visual impairment: 2010. Br. J. Ophthalmol. 2012, 96, 614–618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bourne, R.R.A.; Flaxman, S.R.; Braithwaite, T.; Cicinelli, M.V.; Das, A.; Jonas, J.B.; Keeffe, J.; Kempen, J.; Leasher, J.; Limburg, H.; et al. Magnitude, temporal trends, and projections of the global prevalence of blindness and distance and near vision impairment: a systematic review and meta-analysis. Lancet Glob. Heal. 2017, 5, e888–e897. [Google Scholar] [CrossRef] [Green Version]

- Mândru, D.; Lungu, I.; Mociran, A.; Tatar, O. Development of a Mechatronic Blind Stick. Ann. Oradea Univ. Fascicle Manag. Technol. Eng. 2007, VI, 797–802. [Google Scholar]

- Elmannai, W.; Elleithy, K. Sensor-based assistive devices for visually-impaired people: Current status, challenges, and future directions. Sensors 2017, 17, 565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Low Vision Technologies The History of the White Cane. Available online: http://www.lowvisiontechnologies.com/white-cane-history.html (accessed on 15 May 2020).

- Manduchi, R. Watch Your Head, Mind Your Step: Mobility-Related Accidents Experienced by People with Visual Impairment. Available online: http://www.soe.ucsc.edu/research/technical-reports/UCSC-SOE-10-24 (accessed on 10 April 2021).

- Shoval, S.; Ulrich, I.; Borenstein, J. NavBelt and the GuideCane. IEEE Robot. Autom. Mag. 2003, 10, 9–20. [Google Scholar] [CrossRef]

- Agrawal, M.P.; Gupta, A.R. Smart stick for the blind and visually impaired people. In Proceedings of the Second International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 20–21 April 2018; pp. 542–545. [Google Scholar] [CrossRef]

- Damdhare, S.; Sakhare, A. Smart stick for blind: Obstacle detection, artificial vision and real-time assistance via GPS. Int. J. Comput. Appl. 2011, 2, 31–33. [Google Scholar]

- Dey, N.; Paul, A.; Ghosh, P.; Mukherjee, C.; De, R.; Dey, S. Ultrasonic sensor based smart blind stick. In Proceedings of the 2018 International Conference on Current Trends towards Converging Technologies (ICCTCT), Coimbatore, India, 1–3 March 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Mishra, R. Voice Operated Outdoor Navigation System for on. Int. J. Eng. trends Technol. 2012, 3, 153–157. [Google Scholar]

- Wang, Y.; Kuchenbecker, K.J. HALO: Haptic alerts for low-hanging obstacles in white cane navigation. In Proceedings of the 2012 IEEE Haptics Symposium, Vancouver, BC, Canada, 4–7 March 2012; pp. 527–532. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Kabir, F.; Roy, S. Low Cost Smart Stick for Blind and Partially Sighted People. Int. J. Adv. Eng. Manag. 2017, 2, 65. [Google Scholar] [CrossRef]

- Mahmud, M.H.; Saha, R.; Islam, S. Smart walking stick-an electronic approach to assist visually disabled persons. Int. J. Sci. Eng. Res. 2013, 4, 111–114. [Google Scholar]

- Maidenbaum, S.; Hanassy, S.; Abboud, S.; Buchs, G.; Chebat, D.R.; Levy-Tzedek, S.; Amedi, A. The “EyeCane”, a new electronic travel aid for the blind: Technology, behavior & swift learning. Restor. Neurol. Neurosci. 2014, 32, 813–824. [Google Scholar] [CrossRef] [Green Version]

- Mavarkar, P.R.; Mundargi, Z.K. Real Time Smart Blind Stick using Artificial Intelligence. Indian J. Artif. Intell. Neural Netw. 2021, 1, 9–13. [Google Scholar]

- Megalingam, R.K.; Nambissan, A.; Thambi, A.; Gopinath, A.; Nandakumar, M. Sound and touch based smart cane: Better walking experience for visually challenged. In Proceedings of the 2014 IEEE Canada International Humanitarian Technology Conference (IHTC), Montreal, QC, Canada, 1–4 June 2014. [Google Scholar] [CrossRef]

- Nada, A.A.; Fakhr, M.A.; Seddik, A.F. Assistive infrared sensor based smart stick for blind people. In Proceedings of the Science and Information Conference (SAI), London, UK, 28–30 July 2015; pp. 1149–1154. [Google Scholar] [CrossRef]

- Lavanya Narayani, T.; Sivapalanirajan, M.; Keerthika, B.; Ananthi, M.; Arunarani, M. Design of Smart Cane with integrated camera module for visually impaired people. In Proceedings of the ICAIS 2021 International Conference on Artificial Intelligence and Smart Systems, Coimbatore, India, 25–27 March 2021; pp. 999–1004. [Google Scholar]

- Rodríguez, A.; Javier Yebes, J.; Alcantarilla, P.F.; Bergasa, L.M.; Almazán, J.; Cela, A. Assisting the visually impaired: Obstacle detection and warning system by acoustic feedback. Sensors 2012, 12, 17476–17496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharmila, K.; Boomika, D. Smart Walking Cane Using IOT. Available online: http://www.ijaesit.com/index.php/home/article/view/11 (accessed on 22 April 2021).

- Sethi, R.; Kumar, S.; Gupta, D.; Mangal, P.K.; Pujara, A. Blind Steppers Using Ultrasonic Sensors. Int. J. Adv. Res. Sci. Commun. Technol. 2021, 3, 331–337. [Google Scholar] [CrossRef]

- Son, H.; Krishnagiri, D.; Jeganathan, V.S.; Weiland, J. Crosswalk guidance system for the blind. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Montreal, QC, Canada, 20–24 July 2020; pp. 3327–3330. [Google Scholar] [CrossRef]

- OrCam. OrCam—MyEye. Available online: https://www.orcam.com/en/myeye2/ (accessed on 2 April 2020).

- Zhang, X.; Zhang, H.; Zhang, L.; Zhu, Y.; Hu, F. Double-Diamond Model-Based Orientation Guidance in Wearable Human–Machine Navigation Systems for Blind and Visually Impaired People. Sensors 2019, 19, 4670. [Google Scholar] [CrossRef] [Green Version]

- Mekala, V.K.; Gamidi, S.; Markapudi, B.R.; Chaduvula, K. Visual DUX: A low cost wearable device for guiding the blind. Turkish J. Comput. Math. Educ. 2021, 12, 2731–2738. [Google Scholar] [CrossRef]

- Abboud, S.; Hanassy, S.; Levy-Tzedek, S.; Maidenbaum, S.; Amedi, A. EyeMusic: Introducing a “visual” colorful experience for the blind using auditory sensory substitution. Restor. Neurol. Neurosci. 2014, 32, 247–257. [Google Scholar] [CrossRef] [Green Version]

- Buimer, H.P.; Bittner, M.; Kostelijk, T.; Van Der Geest, T.M.; Nemri, A.; Van Wezel, R.J.A.; Zhao, Y. Conveying facial expressions to blind and visually impaired persons through a wearable vibrotactile device. PLoS ONE 2018, 13, e0194737. [Google Scholar] [CrossRef] [Green Version]

- Jameson, B.; Manduchi, R. Watch your head: A wearable collision warning system for the blind. Proc. IEEE Sens. 2010, 1922–1927. [Google Scholar] [CrossRef]

- Frizziero, L.; Liverani, A.; Nannini, L. Design for six sigma (DFSS) applied to a new eco-motorbike. Machines 2019, 7, 52. [Google Scholar] [CrossRef] [Green Version]

- Francia, D.; Donnici, G.; Ricciardelli, G.M.; Santi, G.M. Design for six sigma (DFSS) applied to a new E-segment sedan. Sustainability 2020, 12, 787. [Google Scholar] [CrossRef] [Green Version]

- Zeng, L. A survey: Outdoor mobility experiences by the visually impaired. In Mensch und Computer 2015–Workshopband; De Gruyter: Berlin, Germany, 2015; pp. 391–398. [Google Scholar] [CrossRef]

- Schenkman, B.N. Identification of ground materials with the aid of tapping sounds and vibrations of long canes for the blind. Ergonomics 1986, 29, 985–998. [Google Scholar] [CrossRef]

- Husin, M.H.; Lim, Y.K. InWalker: smart white cane for the blind. Disabil. Rehabil. Assist. Technol. 2020, 15, 701–707. [Google Scholar] [CrossRef] [PubMed]

- WANGI LAI PLT BAWACANE (S) SDN BHD. Available online: https://www.bawa.tech/ (accessed on 4 February 2020).

- Saksham, I. Smart Cane Overview. Available online: http://smartcane.saksham.org/overview/ (accessed on 4 February 2020).

- UK, W.L. Product Details—WeWALK Smart Cane. Available online: https://wewalk.io/en/ (accessed on 4 February 2020).

- Technology, S.F. About the UltraCane. Available online: https://www.ultracane.com/about_the_ultracane (accessed on 4 February 2020).

- Nilsson, M.E.; Schenkman, B.N. Blind people are more sensitive than sighted people to binaural sound-location cues, particularly inter-aural level differences. Hear. Res. 2016, 332, 223–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asakura, T. Bone conduction auditory navigation device for blind people. Appl. Sci. 2021, 11, 3356. [Google Scholar] [CrossRef]

- Thaler, L.; De Vos, H.P.J.C.; Kish, D.; Antoniou, M.; Baker, C.J.; Hornikx, M.C.J. Human Click-Based Echolocation of Distance: Superfine Acuity and Dynamic Clicking Behaviour. J. Assoc. Res. Otolaryngol. 2019, 20, 499–510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pariti, J.; Oh, T. Understanding the hand and wrist strains caused by smart cane handles with haptic notification. In Proceedings of the 22nd International ACM SIGACCESS Conference on Computers and Accessibility, Online, 26–28 October 2020. [Google Scholar] [CrossRef]

- Mount, J.; Howard, P.D.; Dalla Palu, A.L.; Grafstrom, A.; Pinto, D.M.; Rudy, S.L. Postures and repetitive movements during use of a long cane by individuals with visual impairment. J. Orthop. Sports Phys. Ther. 2001, 31, 375–383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morioka, M.; Maeda, S. Measurement of hand-transmitted vibration of tapping the long cane for visually handicapped people in Japan. Ind. Health 1998, 36, 179–190. [Google Scholar] [CrossRef] [Green Version]

- Park, J.J.J.H.; Jin, Q.; Yeo, M.S.S.; Hu, B. (Eds.) Human Centric Technology and Service in Smart Space: HumanCom 2012; Springer: Berlin, Germany, 2012. [Google Scholar]

- Dos Santos, A.D.P.; Medola, F.O.; Cinelli, M.J.; Garcia Ramirez, A.R.; Sandnes, F.E. Are electronic white canes better than traditional canes? A comparative study with blind and blindfolded participants. Univers. Access Inf. Soc. 2021, 20, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Thaler, L.; Milne, J.L.; Arnott, S.R.; Kish, D.; Goodale, M.A. Neural correlates of motion processing through echolocation, source hearing, and vision in blind echolocation experts and sighted echolocation novices. J. Neurophysiol. 2014, 111, 112–127. [Google Scholar] [CrossRef] [Green Version]

- Arnott, S.R.; Thaler, L.; Milne, J.L.; Kish, D.; Goodale, M.A. Shape-specific activation of occipital cortex in an early blind echolocation expert. Neuropsychologia 2013, 51, 938–949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Donnici, G.; Frizziero, L.; Liverani, A.; Buscaroli, G.; Raimondo, L.; Saponaro, E.; Venditti, G. A new car concept developed with stylistic design engineering (SDE). Inventions 2020, 5, 30. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).