Abstract

Aquaculture is a strategic sector that aims to meet the increased demands for healthy food for current and future populations. However, this progression needs to be sustainable, which can potentially be achieved by the implementation of circular practices. Integrated multi-trophic aquaculture (IMTA) systems promote the incorporation of circular principles. Nevertheless, the lack of harmonized definitions and standards impedes the quantification of these circular attributes. This study aims to explore the potential principles embedded in IMTA and the existing alternatives to quantify circularity. Two basic pillars (nutrient management and resource use efficiency) were identified as the most relevant circularity attributes for IMTA systems and were quantified through aquaculture-specific indicators. Bioremediation indicators, together with the efficiency indicators in terms of feed, water, energy, and infrastructure materials used, were selected to evaluate the circularity performance of four IMTA trials in three aquaculture facilities in Ireland, Brazil, and South Africa. Salmon, white shrimp, tilapia, abalone, and sea urchins were studied and cultivated together in various combinations with several low-trophic species in these IMTA trials to evaluate the improvement in circularity compared with corresponding monoculture conditions. The results showed an increase in circularity of up to 90% in terms of water recirculation, as well as bioremediation, which was improved by 80%–90%, providing evidence for the potential role of IMTA in the circularity transition.

Key Contribution:

Specific methodology is developed to evaluate multi-trophic aquaculture (IMTA) systems from a circularity perspective. The benefits of IMTA compared to monoculture are quantified in terms of the bioremediation of nutrients and the efficient use of resources.

1. Introduction

Population growth leads to an increased demand for food, while the pressure on the environment due to the intensification of food sector activities highlights the need for a more efficient use of natural resources. Aquaculture has a key role to play in feeding the growing population, but the sustainability of production systems must be ensured to meet the increasing demand for healthy aquatic food [1]. However, addressing sustainability in aquaculture is complex not only due to the existence of multiple frameworks for its evaluation but also the great variety of production systems to which sustainability approaches and tools can be applied [2].

To mitigate the negative effects on the environment, extensively studied ecological approaches promote aquaculture production designs that reduce nutrient discharges [3]. In addition to reducing environmental impacts, increasing production efficiency is the other main aspect by which the circular economy drives sustainable development, as recognized in policies put in place at the European level [4,5,6]. To improve environmental performance, as part of the strategy for the sustainable development of aquaculture, the European Commission recommends adopting the circular approach to waste management, including treating waste as a resource [7].

Although the principles of the “circular economy” have been expressed in many ways depending on the point of view [8], a definition based on examples would be a good approach to harmonize the concept. In this sense, the circular economy is a model of production and consumption where cleaner and more competitive practices focus on saving and recovering resources [4]. As part of the recommendations provided by Balsells et al. [9], a harmonized definition of the circular economy should address the importance of biological flows and the role of aquaculture in producing renewable biological resources.

In addition to the definition, the range of examples is also very extensive for aquaculture, and no previous studies are available that provide the state of the art of the real and current implementation of the circular economy in the sector [10]. The concept of circular aquaculture can be addressed in many ways [11], but generally, circularity in aquaculture includes the adoption of practices regarding waste management [12,13,14], the recycling of nutrients [15,16,17,18], or the incorporation of novel ingredients in feeds derived from the bio-economy [19,20].

Evidence for the alignment of aquaculture systems with the circular economy comes from the study of resource use efficiency and nutrient management, which are measured as the capacity to collect and use excess nutrients and uneaten feed fractions. In this regard, integrated multi-trophic aquaculture (IMTA) is a circular production system where different species such as fish, shellfish, and seaweed are strategically integrated/linked to create a symbiotic relationship that contributes to reducing the impacts on the environment [21,22]. Within IMTA systems, uneaten feed and nutrient losses can be recaptured by other organisms and converted into valuable nutrients for harvestable seafood and crops [23]. Fish excrete nitrogenous and phosphorus waste, the dissolved component of which can be utilized by cultivated seaweed species as a nutrient source for growth, thus reducing nutrient levels in the water and preventing eutrophication [13]. Additionally, filter-feeding organisms such as mussels and oysters can help in the removal of excess nutrients as particulate matter by efficiently filtering water [24]. Successful integrated systems require not only that the appropriate species are selected but also that waste from the fed species can be efficiently utilized by tolerant species [25]. For effective IMTA, bioremediation is interpreted as a circular attribute of the system, as it promotes the recycling of nutrients. Bioremediation capacity plays a crucial role in IMTA systems by utilizing the natural metabolic activities of various organisms to remediate and improve water quality [26,27,28,29]. This approach promotes a circular economy within aquaculture, where waste from one component becomes a valuable resource for another [30].

Following the premise that “what gets measured gets managed” [31], the evaluation of circularity performance at the farm level could provide useful information to manage and maximize the bioremediation capacity of IMTA systems. At the same time, the potential nutrient mitigation service achieved by IMTA may be of interest for possible economic benefits, but this is limited, among other reasons, by the lack of common standards to verify this mitigation. Standardized measurements of circularity could provide evidence for how well circular economy principles are applied to products [32].

A good approach for the evaluation of aquaculture products is provided by Valentí et al. [33], who defined quantitative indicators that address the three dimensions of sustainability (economic, environmental, and social) through 56 indicators. This framework aims to evaluate relevant aspects of sustainability by quantifying the efficiency of natural resource use, which would perfectly link to the evaluation of some circularity attributes. Complementary aspects such as natural resource depletion and the useful service lifetime should be considered essential indicators [34] at the product or material level. However, there is no agreement regarding the most appropriate framework for measuring circularity indicators [35,36].

Linder et al. compared different product-level circularity metrics, concluding that none of the existing initiatives scored highly across the criteria of validity, reliability, transparency, and generality [31]. As part of the metric studied by Linder et al. [31], the Material Circularity Indicator (MCI) was identified as an appropriate approach for the evaluation of product circularity. Although the revised version (2019) included biological cycles, the MCI was originally developed to measure the circularity of technical products [37]. Even so, it is relatively difficult to associate concepts such as utility (referring to durability or usage intensity) and lifespan to biological products. Moreover, the MCI refers to the use phase, which has a different interpretation depending on the focus and objective of the circularity analysis. Regarding aquaculture, feed is used (ingested) and assimilated by the fish, and then feed flow is transformed into nutrients that are released into the environment in the form of excretion and feces, in addition to the uneaten fraction. The concept of waste from the use phase within the MCI approach would refer not to feed but to the release of nutrients, although, if the focus is at the nutrient level, circularity can be addressed though the evaluation of nutrients entering and leaving the system during the aquaculture production period.

In addition to the fact that most circular economy (CE) metrics focus on the technical cycle and materials from non-renewable resources [35], none of the approaches reviewed at the farm level fulfill the particularities of aquaculture (even less of integrated multi-trophic production). The diversity of aquaculture systems makes it challenging to determine the circular profile of the sector using a single approach.

Life cycle assessment (LCA) is a very appropriate approach for measuring the environmental footprint for products, processes, or services. The International Organization for Standardization (ISO) provides the guidelines to evaluate environmental impacts through indicators such as carbon footprint, acidification, and land use, among others (ISO 14040 [38], 14044 [39]). When LCA is applied to aquaculture processes, the environmental impact assessment potentially reflects circularity in terms of nutrient management or resource use (through the study of the material resource depletion impact category). Furthermore, LCA studies with a broader approach (“from cradle to gate”) would potentially inform circularity beyond nutrients at the production level, encompassing the whole value chain. From a life cycle assessment perspective, the EU Environmental Footprint initiative [40] defines a circular footprint formula (CFF) to estimate emissions from processes involving recycling and energy recovery. However, as with the MCI, the CFF could be difficult to apply to measure the circularity of aquaculture production.

Given this context, the purpose of this work is to explore the potential principles embedded in IMTA through the definition of specific indicators that are adapted for and focused on IMTA production. This paper presents the specific case of three different IMTA production systems (known as IMTA laboratories) that were evaluated by applying sector-specific circularity indicators.

2. Materials and Methods

2.1. IMTA Laboratories

This study included four trials that were addressed through 3 IMTA laboratories. The term laboratory (lab) refers to large-scale demonstration sites in real environments, where new species and different combinations were investigated in the context of the EU ASTRAL project (GA 863034) (https://cordis.europa.eu/project/id/863034, accessed on 1 March 2024), which aims to develop new, sustainable, profitable, and resilient value chains for IMTA production within the framework of existing, emerging, and potential Atlantic markets.

Table 1 shows the IMTA systems that were evaluated following the methodology detailed in Section 2.2.

Table 1.

Study scenarios.

2.1.1. Irish IMTA Lab

The research at this IMTA lab, managed by the Marine Institute, was focused on multi-trophic production involving salmon (Salmo salar), seaweed (two kelp species, Alaria esculenta and Saccharina. latissima), urchin (Paracentrotus lividus), and oyster (Ostrea edulis). The primary objective of this lab was to investigate the capacity of these combined species to create a self-sustaining ecosystem that efficiently utilizes and recycles nutrients, thereby minimizing eutrophication and other negative effects on benthic zones. Bioremediation processes within this IMTA model were examined to understand the natural capabilities of the system to mitigate nutrient release. Salmon, known for producing nutrient-rich waste, served as the primary fed species in this IMTA setup. Salmon waste, which is particularly rich in nitrogen and phosphorus, becomes a valuable resource for secondary extractive species. Seaweeds were cultivated to absorb and utilize these excess soluble nutrients, contributing to the purification of the water and their own biomass production. Simultaneously, urchins and oysters were integrated into the system. Urchins were grown using the seaweed produced on-site, while oysters acted as filter feeders, removing particulate matter and enhancing water quality. The presence of the extractive species complements the nutrient cycling process and further contributes to maintaining a balanced ecosystem. Figure 1 shows the laboratory configuration located in Bertraghboy Bay (Connemara, Galway, Ireland).

Figure 1.

Irish IMTA lab design: the low-trophic grid with oysters, seaweeds, and urchins lies adjacent to the salmon pens within the licensed aquaculture site.

The circularity assessment of the Irish IMTA lab focused on the evaluation of the experimental trial, with a production of 50 t of salmon (FW/y), 2.1 t of seaweed (FW/y), 75.6 kg of oysters (FW/y), and 64 kg of urchins (FW/y).

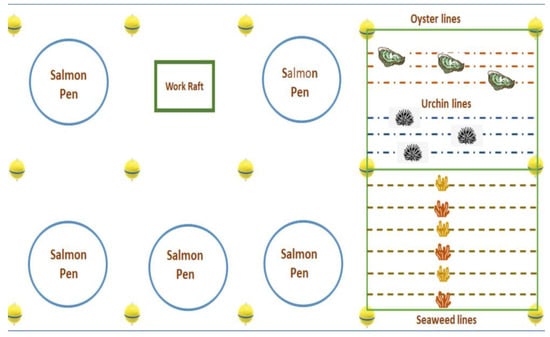

2.1.2. Brazilian IMTA Lab

The research at this IMTA lab, carried out by the Federal University of Rio Grande (FURG) located in the city of Rio Grande in Brazil, with Biofloc technology (BFT), focused on the optimization of white shrimp (Litopenaeus vannamei) production in a Recirculating Aquaculture System (RAS) (Figure 2).

Figure 2.

Brazilian IMTA lab design.

BFT entails the cultivation of dense populations of microorganisms in the water, creating a dynamic environment where the nitrogen excreted by fed species is converted into microorganism biomass (biofloc) under aeration and carbon fertilization. The biofloc growth is stimulated by the addition of active carbon (molasses) and constant aeration. The experiments carried out by this lab aimed at determining the most effective biomass ratios among marine white shrimp, tilapia, and algae, particularly evaluating the impacts of tilapia (Oreochromis niloticus) and sea lettuce (Ulva lactuca) in regulating organic material and nutrients. Moreover, the lab tested the performance of the system when fish meal was substituted by a fish meal analogue (FMA) in the shrimp diet formulation. The FMA used in this study was developed by Guabi Nutrition and Animal Health S.A. and consisted of a balanced blend of terrestrial animal by-products supplemented with amino acids, minerals, and commercial vitamins (Table 2). The animals were fed 2 times per day with the iso protein and isoenergetic diets (feed pellets with 38% crude protein and 7% lipids) and FMA at a 50/50 ratio.

Table 2.

Fish meal analog properties (used to prepare the shrimp diet).

This IMTA was designed to maximize the efficiency of nutrient utilization and circularity within the system [41,42]. White shrimp served as the primary species and produced organic waste and nutrients as by-products of their metabolic processes. These nutrients included nitrogen and phosphorus compounds. Nutrient-rich water was recirculated among the shrimp, tilapia, and seaweed tanks. Tilapia is a marketable species capable of consuming excess bioflocs, and Ulva absorbs excess dissolved nutrients, including nitrogen and phosphorus, from water [43], contributing to the overall nutrient balance [44]. This not only aids in water quality management but also provides an additional valuable product that can be harvested for various applications, such as biofuel, or as a nutrient-rich supplement for aquaculture feed [43].

The Brazilian IMTA lab circularity assessment was focused on the evaluation of the experimental trial, with a production of 4.3 kg/m3 of FW of shrimp, 13.4 kg/m3 of FW of tilapia, and 2 kg/m3 of FW of seaweed.

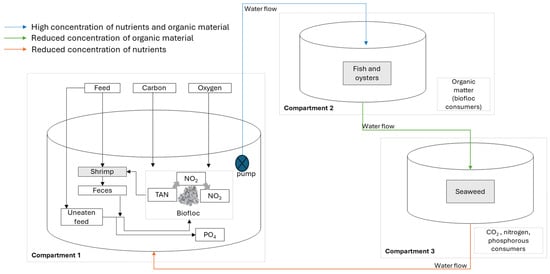

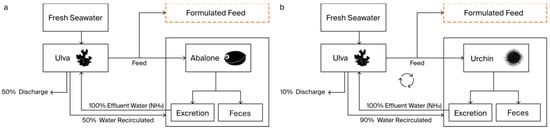

2.1.3. South African IMTA Lab

IMTA research at the lab in South Africa consisted of two experimental systems (Figure 3). The first system is a fully commercial integrated abalone–Ulva system at Buffeljags Abalone farm. The farm is managed by Viking Aquaculture and is located approximately 200 km east of Cape Town on a pristine stretch of coastal land near the remote settlement of Buffeljags on the Cape southwest coast. The second system is an urchin-Ulva pilot commercial-scale experimental system on the same farm. Data from the experimental trials conducted in the abalone and urchin systems were used to perform the circularity assessments.

Figure 3.

South African IMTA lab: (a) abalone/Ulva system; (b) urchin/Ulva system.

The abalone (Haliotis midae)-Ulva lacinulata IMTA system consists of seven modular platforms, each comprising four clusters. Each cluster is made up of a 150 m3 D-ended Ulva paddle raceway and multiple abalone raceway tanks (each 8.5 m3) arranged in six rows, with each row housing seven abalone raceway tanks. The effluent water from the abalone tanks in each cluster flows into the adjacent Ulva paddle raceway, where it is bioremediated (removal of N and P) by the Ulva [45] and mixed with 50% fresh seawater in the sump before being returned to the abalone raceway tanks. The continuous circulation of seawater through these tanks and Ulva paddle raceways ensures a steady supply of cool and aerated water for the growing abalone. Experiments in the SA IMTA lab were carried out to monitor the physical and chemical parameters of the abalone–Ulva IMTA system with increasing (50, 75, and 100%) recirculation rates [27].

Operating independently but at the same farm, the second system consisted of an integrated urchin (Tripneustes gratilla)-Ulva lacinulata system that consisted of five 58,000 L glass fiber tanks linked to a 14,000 L Ulva paddle raceway and a 14,000 L sump. Effluent water from each of the sea urchin tanks was directed into the Ulva paddle raceway (where nutrients were reduced by means of the bioremediation of the seaweed), having passed through the drum filter for the removal of larger particulates. The water replacement in this system, with fresh incoming seawater from the adjacent ocean, was 10% per day.

2.2. Circularity Assessment Methodology

As part of the present study, nutrient management and the use of resources were identified as the two principal attributes through which IMTA systems contribute most to circularity. In line with Chary et al. [10], nutrients and resource use are fundamental pillars embedded in the principles applicable to aquaculture (safeguard and regenerate, avoid, prioritize, reuse and recycle, and entropy). In this sense, a set of metrics was defined for the evaluation of nutrient recycling and resource use efficiency, with the aim of providing a comparison of circularity performance between the monoculture and IMTA scenario for each laboratory.

2.2.1. Nutrient Management Metrics

Nutrient management performance was quantified as part of the evaluation of the primary function of the IMTA system, which was bioremediation. Within the circularity assessment context, bioremediation is defined as a circularity indicator that provides information on the nutrient retention efficiencies (treating waste nutrients from fed species as by-products that can be recycled by extractive species). Seaweeds absorb dissolved inorganic nutrients (DINs), shellfish filter out suspended particulate organic matter (POM), and deposit feeders such as holothuroids and polychaetes consume settled particulate organic matter.

Various approaches exist to quantify bioremediation, including the measurement of nutrient removal rates, retention capacities, nutrient balances, the utilization of tracers (e.g., stable isotopes or fatty acid composition), and modeling techniques [16]. This section describes the methodology used to calculate the bioremediation indicator through the different trials in both scenarios, monoculture, and IMTA, with the objective of quantifying this circularity pillar.

- Bioremediation in the Irish IMTA lab

Salmon nutrient emissions were calculated in accordance with the methodology for mass balance calculation developed by Wang et al. [15], which enables the estimation of N, P, and C emissions to the surrounding water from the fed fish. N and P assimilated by seaweed were estimated from elementary analysis in the laboratory, while C was calculated considering the carbon fixation and storage potential of macroalgae [46]; N and P taken up by oysters were estimated based on laboratory nutritional analysis, while C was calculated from nutrient assimilation efficiencies in integrated multi-trophic aquaculture in accordance with the literature [47]. The same reference (Nederlof et al. [16]) was used to estimate N, P, and C absorption by urchins, which was based on the theoretical assimilation efficiency.

- Bioremediation in the Brazilian IMTA lab and SA IMTA lab (abalone)

For these 2 trials, bioremediation was calculated using monitored water flow data and information on nutrient concentrations across both closed and semi-closed experimental systems. Regarding the Brazil IMTA lab, one-year total solids and nutrient monitoring data were used as a basis for the evaluation of the nutrient management pillar (bioremediation indicator). Concentrations at the inlet and outlet of the shrimp, tilapia, and seaweed tanks were used to estimate the bioremediation potential for N and P.

Regarding abalone in the SA IMTA lab system, bioremediation was calculated directly from monitoring the water flows [48]. Information on total ammonia nitrogen (TAN), nitrate, nitrite, and phosphate concentrations in the inlet flow in Ulva raceways was compared to concentrations in the effluent water from abalone raceways to evaluate the bioremediation potential of Ulva [27].

- Bioremediation in the SA IMTA lab urchin trial

Urchin N emissions were calculated based on feed nutritional values; the nutrient balance was calculated based on the protein provided in feed to the N retained by urchins. The nitrogenous effluent from urchins, meaning the non-retained fraction, was used to calculate DINs in the effluent and the corresponding bio-available fraction for seaweed. Afterward, the DIN uptake efficiency of Ulva was estimated to finally determine the DIN balance between urchin and Ulva effluents.

2.2.2. Resource Use Efficiency

The use of resources was quantified through metrics that reflect the efficiency of IMTA with respect to the use of the most common resources in aquaculture, as reviewed in previous LCA studies [49]. Efficiency in the use of resources was studied under monoculture and IMTA conditions through the quantification and comparison of specific indicators related to feed, water, energy, and materials.

Regarding feed, the Feed Conversion Ratio (FCR) and the circularity of the formulations were defined as the most appropriate indicators (Equations (2) and (3) in Table 3). The former was interpreted as equivalent to the use of resources, in the sense that the higher the FCR, the more feed was required to produce one unit of fed-species and the less circular the culture. FCR considered the feed ingested when it was feasible to measure the uneaten fraction (in the case of the South African IMTA labs) and the feed delivered when ingestion was unknown (in the case of the Brazilian IMTA lab). The latter was measured based on the linearity concept adapted to aquaculture feeds [50], which reflects the percentage of ingredients that are sourced from the upcycling of products within the aquaculture systems. Whenever low-trophic species harvested from IMTA schemes were processed and incorporated as a feed ingredient in the trials under study, they were interpreted in the assessment as non-linear ingredients sourced from valorization routes. This was the case for the SA IMTA lab (urchin), where dried Ulva served as a feed ingredient in formulated feed for urchins.

Table 3.

Circularity indicators to measure IMTA performance.

Regarding water, the recirculation efficiency was quantified to reflect the dependency on external water sources, and it was thus an indicator applicable to semi-closed and closed systems (Equation (4) in Table 3). This indicator is particularly relevant for freshwater aquaculture systems and is therefore potentially of interest for the evaluation of RAS systems (90% of systems operating under freshwater conditions in Europe [51]). Although seawater is not considered a limited resource from a life cycle perspective [52], water recirculation in coastal areas was selected as a relevant indicator to measure not only the circularity but also the resilience capacity of farms, which is especially important when coastal sites are unable to pump seawater when toxic microalgal blooms occur.

Likewise, the energy indicator (Equation (5) in Table 3) was measured through the estimation of energy used by each experimental IMTA lab trial in relation to the biomass harvested. Maintenance during the production phase (cleaning pump and foam fractionator) was aggregated as part of the energy indicator and interpreted in terms of kWh. Both water and energy indicators were defined to reflect the intensity of resource use but not the associated potential environmental impacts, which would be the objective of an LCA study.

Finally, the infrastructure indicator (Equation (6) in Table 3) refers to materials needed for the IMTA set ups. The manufacturing of infrastructure components involves the extraction of resource materials, especially steel- and fossil-based plastics. This indicator was defined to obtain evidence on whether integrated systems promote synergies in the use of common elements (for example, floating infrastructure) that potentially reduce the use of materials relating to the biomass harvested. In fed-species systems with low-trophic species integration, the new materials required are less than those needed in a monoculture scenario due to the shared use of infrastructure to produce more than one species. Therefore, the increase in total biomass was interpreted as a major functionality. Functionality was defined as the practicality of the infrastructure for the purpose of enabling biomass growth. The infrastructure indicator was thus calculated as the total kg of materials within each infrastructure element in relation to the total biomass produced over its lifespan. Therefore, this indicator was represented as kg of infrastructure materials/kg of biomass harvested (Equation (6) in Table 3).

Table 3 shows the pillars, aspects, and indicators that were measured for the IMTA laboratories. These indicators were defined to quantify the circular attributes that reflect the alignment of the systems with the circular principles. The evaluation of circularity performance therefore consisted of assessing the variations in these indicators between the IMTA and monoculture scenarios.

3. Results

3.1. Irish IMTA Lab

3.1.1. Nutrient Management

The bioremediation indicator was calculated through the evaluation of nutrient emissions from salmon, which were differentiated between dissolved and particulate matter. Table 4 shows the nutrient balance obtained from this experimental laboratory, in which seaweed species mitigated the emissions of the dissolved nutrient fraction, oysters absorbed particulate nutrient fractions, and urchins utilized the seaweed grown on-site. Information on the excretion and respiration of the low-trophic animals was not available and therefore excluded from the analysis.

Table 4.

Nutrient balance in the Irish IMTA lab (all values refer to 1 kg of biomass—WWT).

3.1.2. Resource Use Efficiency

Fuel consumption refers to the petrol needed for maintenance and harvesting activities under both the monoculture and IMTA conditions. The energy within fuel consumed under the monoculture conditions was 2.53 × 10−1 kWh/kg of biomass harvested, whereas the energy within the fuel consumed under IMTA conditions was slightly lower (2.52 × 10−1 kWh/kg of biomass harvested), as derived from a previous LCA study [53].

Regarding the materials embedded in infrastructure elements, the same LCA [53] study identified the use of steel, concrete, and wood as the main materials used on the farm. The total amount of materials involved under the monoculture conditions was 0.04 kg of materials per kg of biomass harvested, while 0.05 kg of materials was used per kg of biomass harvested in IMTA.

3.2. Brazilian IMTA Lab

3.2.1. Nutrient Management

Bioremediation for this closed system was estimated through the monitoring of inlet and outlet nutrient concentrations. Nutrient monitoring for one year (Table 5) covered three production cycles for shrimp, two production cycles for tilapia, and four production cycles for seaweed. In the shrimp tank, the levels of ammonia, nitrate, nitrite, and phosphate increased due to the metabolic processes, while the total suspended solids (TSSs) increased due to the biofloc formation. The tilapia tank showed a similar pattern, where ammonia, nitrite, nitrate, and phosphate concentrations increased due to the biological outcomes of the nutrient assimilation of the fish, but TSSs decreased due to the capability of tilapia to eat the biofloc generated in the previous tank. Finally, the seaweed tank showed the process of bioremediation itself with nutrient retention and decreasing levels of dissolved ammonia, nitrite, nitrate, and phosphate; TSSs decreased due to the biological structure of Ulva, which retained part of the biofloc in the tank and was removed during the Ulva harvesting.

Table 5.

Nutrient balance in the Brazilian IMTA lab (average values from the monitoring period).

3.2.2. Resource Use Efficiency

For shrimp monoculture conditions, experiments carried out at the same research center indicated an FCR of 1.65 in ponds [54], which decreased to 1.34 in the BFT system integrated with tilapia [55]. Traditionally, for tilapia monoculture, the observed FCR ranged from 1.70 to 1.80 [5] and was reduced to practically half (0.85) in an integrated BFT system of marine shrimp and tilapia [55]. Therefore, the feed conversion of shrimp integrated with tilapia was improved in the BFT system compared to conventional farms [54,56], leading to increased resource use efficiency in terms of feed. Moreover, the substitution of fish meal in the conventional feed by by-products of the poultry industry in the shrimp diet implied that the linearity of the feed was reduced. Conventional fishmeal integrated 5% of fish (the source with no by-products), while FMA was totally based on by-products from the poultry industry. In particular, the system performance was not affected when 50% of the fish meal was replaced with FMA. The strategy of using poultry by-products had a positive effect on circularity performance, reducing the linearity within the fishmeal by 50%.

In terms of energy use, BFT systems imply the aeration of culture tanks to ensure the homogeneous distribution of nutrients and biofloc while avoiding biofloc deposition. BFT aeration equipment increases the energy demand compared to a pond system (the baseline of this study); therefore, energy consumption is a disadvantage of BFT [55].

To address the circularity of infrastructure materials, the kg of materials per kg of biomass harvested was compared between monoculture and IMTA conditions. To do so, components and elements identified in the LCA study [53] were taken as the basis for the indicator. For the monoculture conditions, 1.01 kg of materials per kg of biomass harvested was estimated, while the same indicator for BFT conditions resulted in 0.37 kg of materials per kg of biomass harvested.

3.3. South African IMTA Lab (Abalone System)

3.3.1. Nutrient Management

The bioremediation indicator was calculated based on the information sourced from Geldart, 2022 [48], who provided data on nutrient fluctuations in the system operating at 50%, 75%, and 100% recirculation (for the short term). The average concentration results from the 100% recirculation period are shown in Table 6.

Table 6.

Nutrient balance in the South African IMTA lab (abalone).

3.3.2. Resource Use Efficiency

When the abalone–Ulva IMTA system was implemented, the feed regime was similar to the abalone monoculture (with formulated feed for 4 days and wild harvested kelp (Ecklonia maxima) for 3 days per week), but the wild-harvested kelp was substituted whenever IMTA-grown Ulva lacinulata was available. This means that the formulated feed was provided for 4 days per week, while wild-harvested kelp was provided for 1 day, and IMTA-grown Ulva lacinulata was fed for 2 days per week. This feeding regime was assumed for the abalone–Ulva IMTA system for the purpose of this comparative analysis; however, it should be noted that in practice, the choice of seaweed depends on what is available at the time.

Combining the feeding regime with the specific FCR related to the different feed types (see Table 7), the FCR for the abalone monoculture system was 6.16, but when the abalone–Ulva IMTA system was implemented, the FCR was reduced to 4.01. Uneaten fractions also decreased from 1.14% to 0.71%, while the linearity of the feed decreased from 100% (no ingredient sourced from valorization routes) for the abalone monoculture system to a linearity of 71.42% for the abalone–Ulva IMTA system.

Table 7.

Use of resources: Feed indicator, SA IMTA lab (abalone).

In terms of water, 50% water recirculation at the Buffeljags abalone farm played a key role in enhancing the circularity of the abalone–Ulva IMTA system, as it allowed for a significant reduction in the reliance on fresh incoming seawater from the adjacent ocean. This promotes resource efficiency as the system recirculates a substantial portion of the water, minimizing the demand for external resources.

Moreover, the reduced dependence on the pumping of fresh seawater contributes to energy efficiency. By recirculating 50% of the water in the system, enabled by the bioremediation (ammonia removal) capacity of Ulva, the system minimizes the energy expenditure associated with bringing in new seawater. The energy consumed under abalone monoculture conditions was 10.35 kWh per ton of biomass harvested, but when IMTA conditions were implemented, the energy consumption was reduced to 6.80 kWh per ton of biomass harvested. The infrastructure indicator was not calculated for the abalone–Ulva trial since data were not available.

3.4. South African IMTA Lab (Urchin System)

3.4.1. Nutrient Management

To estimate bioremediation, urchin N emissions were calculated based on the feed characteristics. Total urchin biomass (9.5 t) was fed with a pelleted formulated feed at 1.5% BW per day for 4 days a week over the entire 7-month production cycle. During IMTA, urchins were fed fresh Ulva at 6% BW per day for 3 days a week for 4 months and with pellets at 1.5% BW per day for 4 days a week for the remaining 3 months of the production cycle; the latter enhanced the production of the final product (the gonad). Under monoculture conditions, 17.08 t of formulated feed per production cycle was provided, with a total of 257 g of protein per kg of feed, resulting in 0.70 t DINs per production cycle with the 0.16 protein-to-N conversion factor [56]. Considering the urchins’ potential N retention of 10.52%, approximately 0.63 t DINs remained in the system. The dissolved bio-available N in water was 60%, so the total N not retained by urchins was 0.38 t of N per production cycle.

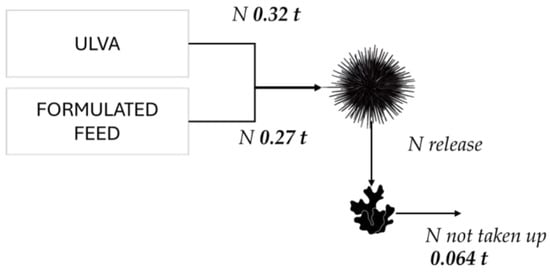

The Ulva supplied for urchin feeding over the production cycle was 68.31 t (WW) per IMTA production cycle. The total amount of formulated feed provided was 7.32 t per IMTA production cycle. The N supplied from feed was 0.59 t of N per IMTA production cycle. The DIN uptake efficiency of Ulva was 80%, so the N retained by Ulva was 0.25 t (Figure 4).

Figure 4.

N mass balance in the urchin-Ulva system.

3.4.2. Resource Use Efficiency

In terms of feed, the FCR for formulated feed in monoculture was 0.4 (formulated feed (pellets) containing 20% DW Ulva [57]), and the FCR related to the IMTA conditions was 0.91, in accordance with the feeding regime described in Table 8 (4 months with fresh Ulva and 3 months with formulated feed including 20% of dried Ulva). The amount of uneaten feed was 2% for monoculture and 1.14% for IMTA, and the linearity of the feed was reduced from 80% under the monoculture conditions to 34.3% when IMTA was implemented.

Table 8.

Use of resources: Feed indicator, SA IMTA lab (urchin).

Regarding water, implementing a high level of seawater recirculation (from 0 to 90%) in the urchin-Ulva IMTA system offered notable benefits in terms of the water conservation of pumped seawater resources, which is crucial for sustainable aquaculture. The provision and use of seawater are major cost components in running a land-based aquafarm. Seawater provision is a critical limiting factor in farm siting and sustainability.

With 90% seawater recirculation, the need to pump large volumes of seawater from external sources was minimized. This reduction in water exchange led to lower energy requirements for pumping, contributing to overall energy savings. The energy consumption under urchin monoculture conditions was 12.45 kWh/t of biomass harvested compared with 3.54 kWh in the urchin-Ulva IMTA system.

Additionally, regarding the resource use indicator, the infrastructure elements (Ulva D-shaped paddle raceway, pipes and fittings, pumps, and baskets, among others) were identified as part of the SA IMTA lab LCA study [53]. The monoculture and IMTA were compared considering the infrastructure material weight per kg of biomass harvested, resulting in 1.26 kg of material per kg of biomass harvested in monoculture and 0.42 kg of material per kg of biomass harvested in IMTA.

3.5. Circularity Performance of IMTA Labs

The difference between the indicators for monoculture and IMTA was calculated to evaluate the circularity performance of the experimental sites. Whenever the difference between indicators was positive, an improvement in circularity was interpreted (Table 9).

Table 9.

Circularity performance interpretation.

Regarding the IMTA lab in Ireland, the results (Table 10) revealed that the bioremediation of nutrients was the key pillar in this lab, while this system contributed comparatively less in terms of the use of resources (energy). The underlying reason was that the low increase in low-trophic biomass did not nearly offset the increase in energy demand due to the additional maintenance activities. FCR and linearity indicators were not calculated for the Irish IMTA, as no actions were taken to improve circularity in that sense. It was not applicable to calculate the water indicator in an open system.

Table 10.

Irish IMTA lab circularity performance.

The Brazilian IMTA lab demonstrated a better performance regarding the water indicator, as the system enabled a high recirculation rate compared to the baseline conditions (ponds). Secondly, the bioremediation of P in the system contributed notably to the improvement in the nutrient management pillar, followed by the improvement achieved in the circularity of shrimp feed formulation through the incorporation of by-products to replace the use of conventional (linear) ingredients (Table 11). The quantification of the improvement in FCR was calculated as the average of the two fed species, shrimp and tilapia. Nitrogen bioremediation was calculated as DINs (nitrite, nitrate, and ammonia), but only if ammonia was included in this assessment did this indicator increase (from 22.34% to 46.7%). The energy indicator is not represented, as no circularity improvement was shown, and C bioremediation was not calculated due to a lack of information.

Table 11.

Brazilian IMTA lab circularity performance.

Regarding the South African IMTA lab, results from the abalone system (Table 12) showed the potential increase in circularity due to water recirculation, thus reducing the dependency on the pumping of fresh seawater. The feasibility of operating at 75%, and at 100% recirculation for short periods, means that IMTA would increase resource efficiency not only in terms of water but also energy consumption. Under the same pillar, FCR was reduced in IMTA, and bioremediation also supported the alignment of the multi-trophic system with resource use efficiency and recycling principles. The infrastructure and C bioremediation indicators were not calculated due to a lack of information.

Table 12.

South African IMTA lab (abalone) circularity performance.

The urchin system results (Table 13) pointed to a higher circularity regarding water recirculation, followed by N bioremediation, which was boosted by the integrated cultivation of Ulva. IMTA demonstrated good circularity performance in infrastructure, which translated into equipment savings compared to monoculture conditions. The integration of fresh Ulva as feed was quantified as a circular benefit in this system. The FCR indicator is not represented in the table since no circularity improvement was found, and the P and C bioremediation indicators were not calculated due to a lack of information.

Table 13.

South African IMTA lab (urchin) circularity performance.

4. Discussion

Circular economy strategies offer a way to make better use of resources and produce less waste [2]. This study offers insights regarding the role of IMTA in the transition toward more circular aquaculture.

This work evaluates the performance of IMTA production systems, which have been shown to be suitable systems to increase circularity. In the Irish IMTA lab, Atlantic salmon release nutrients into the surrounding water, native oysters filter out particulate nutrients while the dissolved fraction is extracted by seaweeds that absorb dissolved minerals and carbon, and spiny sea urchins are fed with the seaweeds grown in this IMTA system. The Brazilian IMTA lab cultivates the most effective biomass ratios of white shrimp, tilapia, and sea lettuce in BFT systems, where organic material and nutrients are regulated. Finally, the South African IMTA lab demonstrates the feasibility of increasing recirculation in the commercial abalone–Ulva integrated systems. The pilot commercial-scale urchin-Ulva system is being run in the same way but at 90% recirculation, largely due to energy cost savings as the seawater needs to be heated to 25 °C for the warm water urchin to grow. This has been run successfully in a fully grown-out trial.

Multi-trophic aquaculture provides an opportunity to not only include nutrient recovery at the production level in aquaculture farms [12] but also increase the efficiency in terms of resource use. Based on the premise that IMTA performs as a circular system, the present work reveals the need for definitions of metrics. Methodology was developed to allow for the combined assessment of different indicators that can be pertinent to the evaluation of different IMTA systems at multiple scales. The metrics reflect the two principal pillars of aquaculture impacting circularity: nutrient management and the use of resources. The natural capacity of extractive species to assimilate nutrients from the water is evidenced through the quantification of the corresponding indicators. However, the benefits achieved due to the incorporation of macroalgae contribute not only to bioremediation but also to the increased resilience of systems to harmful algal blooms and other adverse events (e.g., chemical/oil spills) [48] (e.g., abalone in the South African IMTA lab with 100% recirculation that can isolate the system from the surrounding environment for short (3–4-day) periods [58]).

The review of nutrient-retention efficiency provided by Nederlof suggested that 40–75% of nutrient emissions could be mitigated by extractive species [16]. In the present study, the interpretation of results may consider suggest that the relevance of the bioremediation potential achieved by IMTA is determined by the scale of the production of low-trophic species. In this sense, the Irish IMTA lab did not reflect the total capacity in nutrient management that would be possible by increasing extractive species biomass. On the other hand, the bioremediation indicator was focused on P and N in Brazil and South Africa, as these were the main nutrients mitigated (especially toxic compounds such as ammonia) by the extractive species in the systems, but further evaluation of carbon balance would be relevant to obtain a fuller interpretation. In this context, the potential CO2 sequestration by mollusk shells was excluded from this study, as that is still controversial [59].

Given the relevance of bioremediation as a circular benefit of IMTA, more precise approaches are recommended to determine nutrient budgets. In mass balance approaches, there are many variations that can be incorporated for nutrient loading estimates, making them more appropriate than the use of static input values [60]. Moreover, the present assessment was not entirely performed with primary data, and secondary sources were needed (e.g., assimilation efficiency and the individual growth of urchins or the uneaten fraction of fish in Ireland). Additionally, the respiration and pseudofeces from low- trophic animals in open systems were not quantified and were thus excluded from the nutrient management indicator. Finally, the nutrient mitigation capacities of IMTA systems in open environments are strongly influenced by different factors that limit the nutrient retention capacity of low-trophic species [16], which should also be considered.

Data for bioremediation calculation were not derived from the application of advanced models, and limitations to accuracy are recognized in the calculation of this indicator. Modeling techniques provide precision and are key to optimization, but they require a lot of background and high-quality data that were not available for all the laboratories assessed in the present study. Nevertheless, a combination of experimental and modeling approaches is useful to provide further insight into refining the estimation of bioremediation efficiency. Similarly, stable isotope studies allow the differentiation of the origin of nutrients, and they help to trace fish farm waste and thus confirm the capacity of low-trophic species to contribute to bioremediation [61]. The circularity assessment in this study was applied to experimental laboratories that aimed to test and validate different species under IMTA schemes, in which the implementation of models or isotope studies was not targeted.

Regarding the use of resources, the Brazilian and South African IMTA (urchin system) labs notably improved feeding performance, as both systems incorporated circular ingredients. Brazil showed circularity attributes for the reduction in FCR, meaning a reduction in resource use. The linearity reduction due to the totally circular feed based on poultry industry by-products in the Brazilian IMTA lab is aligned with the global trend of reducing the demand for fishmeal in the aquaculture sector [62]. Further assessments would be needed to evaluate if the incorporation of circular ingredients could compensate for an increase in the use of resources due to lower nutritional functionalities of novel feeds based on non-processed ingredients (e.g., urchin fed with fresh Ulva). Strategies oriented to increase the digestibility [50] and palatability [57] of formulated feeds would lead to more efficient use of resources, and thus, the consideration of apparent digestibility coefficients (ADCs) of fed species within the circularity assessment would provide a more comprehensive overview of the pillar of resource use [60].

The water indicator is not interpreted as a water footprint indicator (as in the approach developed in AWARE (wulca-waterlca.org)) since the present study did not assess water use-related environmental impacts. In this regard, circular economy metrics cannot easily replace LCA approaches. Moreover, the potential for LCA to evaluate aquaculture performance is particularly recognized through indicators that reflect nutrient management performance. For example, implementing nutrient recirculation strategies in aquaculture with IMTA systems possibly contributes to reducing the impact of eutrophication, making it a complementary indicator of how well the systems work under a circular approach in the nutrient pillar.

The reduction in energy consumption enabled by water recirculation is particularly beneficial in the South African context. Electricity use for seawater pumping is a major cost of these operations. South Africa also currently has an intermittent electricity supply, and the recirculation reduces the demand for farm electricity generation (from diesel generators) for periods with daily outages. This means that the system can better deal with the frequent electricity outages if the recirculation rate is high, as less water needs to be heated to 25 °C. The Brazilian IMTA lab is an intensified system that is comparatively worse than pond systems in terms of energy consumption. The energy indicator reflects the entropy principle recognized by Chary et al. [10]. However, this study does not consider energy sources, as they would not necessarily reflect the performance of multi-trophic production.

Regarding infrastructure, the present study considered the lifespan as a fundamental parameter included in the indicator. Generally, better maintenance or the substitution of infrastructure elements with increased durability would increase the functionality and thus the circularity. The study of specific indicators, in particular the MCI indicator, would provide insight as part of studies of low- trophic aquaculture systems, in which infrastructure and equipment were identified as key elements within the environmental profile [53].

For all resource aspects, it may be relevant to highlight that the metrics suggested are oriented to evaluate the production itself (the gate-to-gate approach); thus, value chains of aquaculture products are out of the scope, except for the consideration of the origin of feed ingredients (the linearity aspect). Additionally, in the resource use pillar, the evaluation of other potential resource uses, such as fertilizer, antifouling agents, antibiotics, and other chemical agents or products, was excluded, as these were not reported during the operation of each lab.

Finally, this work demonstrates that circularity can be measured at the level of the fish farm, encouraging doing so in a simplified way while bringing the aquaculture sector closer to circular economy progress monitoring. A metrics-based circularity assessment is promoted using a broad approach that is applicable to all multi-trophic production systems. However, data availability is a major constraint, and there is still much room for improvement to increase the robustness of the results obtained, allowing comparisons between similar production systems.

5. Conclusions

The lack of specific definitions of circular aquaculture and standardized methodologies might discourage aquaculture producers from identifying and communicating strategies that contribute to increasing circular performance. The present study provided a definition of indicators that reflected in a simple but robust way the efficiency of aquaculture production from the perspective of circularity. The bioremediation, feed, water, energy, and infrastructure indicators would allow not-LCA practitioners to monitor cultivation performance without significantly increasing efforts in data collection and impact evaluation. The circularity indicators expressed here were not intended to be exclusive to LCA approaches, but rather, they complement and potentially encourage the sector to evaluate its contributions to the circular economy.

Our results confirmed that multi-trophic aquaculture systems perform in line with the circular attributes embedded in the essential definition of bioremediation. Metrics for bioremediation would promote the standardization of nutrient recycling rates, from which the effectiveness of the systems could be evaluated.

In addition to bioremediation, complementary indicators applied to IMTA provide evidence for the implementation of resource efficiency strategies, which further ensures the alignment of these systems with the circular economy.

Author Contributions

Conceptualization, D.C. and I.S.; methodology, D.C. and I.S.; validation, B.M.M., J.J.B., M.B.-H., P.O., A.C. and L.H.P.; formal analysis, I.S. and D.C.; investigation, B.M.M., J.J.B., M.B.-H., P.O., A.C. and L.H.P.; resources, B.M.M., J.J.B., M.B.-H., P.O. and L.H.P.; data curation, B.M.M., J.J.B., M.B.-H., P.O., A.C. and L.H.P.; writing—original draft preparation, D.C. and I.S.; writing—review and editing, B.M.M., J.J.B., M.B.-H., P.O. and L.P; visualization, I.S.; supervision, I.S.; project administration, I.S; funding acquisition, I.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the ASTRAL Project—H2020, grant agreement No. 863034.

Institutional Review Board Statement

Ethical review and approval were waived for this study, as the circularity assessment did not imply animal experimentation. The assessment was applied to studies involving animals in each laboratory that conducted the experiments according to the ethical requirements defined in the EU ASTRAL project ASTRAL, Grant Agreement Number: 863034 (Deliverable 9.3 A-Requirement No. 3). This protocol specifies that experiments in Ireland, Brazil and South Africa follow the national and international regulations and hold the necessary permits.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors are grateful to the ASTRAL project that has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 863034. Moreover, the authors are thankful to the reviewers for their constructive comments on this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- FAO. The State of World Fisheries and Aquaculture 2022. Towards Blue Transformation; FAO: Rome, Italy, 2022; ISBN 978-92-5-136364-5. [Google Scholar]

- Regueiro, L.; Newton, R.; Soula, M.; Méndez, D.; Kok, B.; Little, D.C.; Pastres, R.; Johansen, J.; Ferreira, M. Opportunities and Limitations for the Introduction of Circular Economy Principles in EU Aquaculture Based on the Regulatory Framework. J Ind. Ecol. 2022, 26, 2033–2044. [Google Scholar] [CrossRef]

- Costa-Pierce, B. The Principles and Practices of Ecological Aquaculture and the Ecosystem Approach to Aquaculture. World Aquac. 2021, 52, 25–31. [Google Scholar]

- European Commission. Directorate-General for Environment. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe COM/2020/98 Final; European Commission: Brussels, Belgium, 2020.

- European Commission. Secretariat-General: The European Green Deal COM/2019/640 Final; European Commission: Brussels, Belgium, 2019.

- European Commission. Directorate-General for Health and Food Safety: A Farm to Fork Strategy for a Fair, Healthy and Environmentally-Friendly Food System COM/2020/381 Final; European Commission: Brussels, Belgium, 2020.

- European Commission. Directorate-General for Maritime Affairs and Fisheries Strategic: Guidelines for a More Sustainable and Competitive EU Aquaculture for the Period 2021 to 2030 COM/2021/236 Final; European Commission: Brussels, Belgium, 2021.

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Balsells, S.; Chary, K.; Checa, D.; Enyedi, E. Policy Recommendations For a More Circular Aquaculture. iFishIENCi 2022. [Google Scholar] [CrossRef]

- Chary, K.; Van Riel, A.; Muscat, A.; Wilfart, A.; Harchaoui, S.; Verdegem, M.; Filgueira, R.; Troell, M.; Henriksson, P.J.G.; De Boer, I.J.M.; et al. Transforming Sustainable Aquaculture by Applying Circularity Principles. Rev. Aquac. 2023, 16, 656–673. [Google Scholar] [CrossRef]

- Campanati, C.; Willer, D.; Schubert, J.; Aldridge, D.C. Sustainable Intensification of Aquaculture through Nutrient Recycling and Circular Economies: More Fish, Less Waste, Blue Growth. Rev. Fish. Sci. Aquac. 2022, 30, 143–169. [Google Scholar] [CrossRef]

- Cooney, R.; De Sousa, D.B.; Fernández-Ríos, A.; Mellett, S.; Rowan, N.; Morse, A.P.; Hayes, M.; Laso, J.; Regueiro, L.; Wan, A.H.; et al. A Circular Economy Framework for Seafood Waste Valorisation to Meet Challenges and Opportunities for Intensive Production and Sustainability. J. Clean. Prod. 2023, 392, 136283. [Google Scholar] [CrossRef]

- Luo, G. Review of Waste Phosphorus from Aquaculture: Source, Removal and Recovery. Rev. Aquac. 2023, 15, 1058–1082. [Google Scholar] [CrossRef]

- Fraga-Corral, M.; Ronza, P.; Garcia-Oliveira, P.; Pereira, A.G.; Losada, A.P.; Prieto, M.A.; Quiroga, M.I.; Simal-Gandara, J. Aquaculture as a Circular Bio-Economy Model with Galicia as a Study Case: How to Transform Waste into Revalorized by-Products. Trends Food Sci. Technol. 2022, 119, 23–35. [Google Scholar] [CrossRef]

- Wang, X.; Olsen, L.; Reitan, K.; Olsen, Y. Discharge of Nutrient Wastes from Salmon Farms: Environmental Effects, and Potential for Integrated Multi-Trophic Aquaculture. Aquacult. Environ. Interact. 2012, 2, 267–283. [Google Scholar] [CrossRef]

- Nederlof, M.A.J.; Verdegem, M.C.J.; Smaal, A.C.; Jansen, H.M. Nutrient Retention Efficiencies in Integrated Multi-trophic Aquaculture. Rev. Aquac. 2022, 14, 1194–1212. [Google Scholar] [CrossRef]

- Carvalho Pereira, J.; Lemoine, A.; Neubauer, P.; Junne, S. Perspectives for Improving Circular Economy in Brackish Shrimp Aquaculture. Aquac. Res. 2022, 53, 1169–1180. [Google Scholar] [CrossRef]

- Villar-Navarro, E.; Garrido-Pérez, C.; Perales, J.A. Recycling “Waste” Nutrients Back into RAS and FTS Marine Aquaculture Facilities from the Perspective of the Circular Economy. Sci. Total Environ. 2021, 762, 143057. [Google Scholar] [CrossRef] [PubMed]

- Colombo, S.M.; Roy, K.; Mraz, J.; Wan, A.H.L.; Davies, S.J.; Tibbetts, S.M.; Øverland, M.; Francis, D.S.; Rocker, M.M.; Gasco, L.; et al. Towards Achieving Circularity and Sustainability in Feeds for Farmed Blue Foods. Rev. Aquac. 2023, 15, 1115–1141. [Google Scholar] [CrossRef]

- Ahmad, A.; Hassan, S.W.; Banat, F. An Overview of Microalgae Biomass as a Sustainable Aquaculture Feed Ingredient: Food Security and Circular Economy. Bioengineered 2022, 13, 9521–9547. [Google Scholar] [CrossRef] [PubMed]

- Sanz-Lazaro, C.; Sanchez-Jerez, P. Regional Integrated Multi-Trophic Aquaculture (RIMTA): Spatially Separated, Ecologically Linked. J. Environ. Manag. 2020, 271, 110921. [Google Scholar] [CrossRef] [PubMed]

- Granada, L.; Sousa, N.; Lopes, S.; Lemos, M.F.L. Is Integrated Multitrophic Aquaculture the Solution to the Sectors’ Major Challenges? – A Review. Rev. Aquac. 2016, 8, 283–300. [Google Scholar] [CrossRef]

- Chopin, T. Aquaculture, Integrated Multi-Trophic (IMTA). In Encyclopedia of Sustainability Science and Technology; Springer: New York, NY, USA, 2013; Volume 12, pp. 542–564. ISBN 978-1-4614-5796-1. [Google Scholar]

- The Aquaculture Advisory Council (AAC). 8.-AAC-Recommendation-Shellfish-Farming-as-a-Nitrogen-Sink_2023_8; The Aquaculture Advisory Council (AAC): Brussels, Belgium, 2023; 11p. [Google Scholar]

- Costa, L.C.D.O.; Carvalho, A.; Holanda, M.; Santos, J.; Borges, L.; Guterres, B.; Nam Junior, J.; Fonseca, V.; Muller, L.; Romano, L.; et al. Biological Responses of Oyster Crassostrea Gasar Exposed to Different Concentrations of Biofloc. Fishes 2023, 8, 586. [Google Scholar] [CrossRef]

- Kang, Y.H.; Shin, J.A.; Kim, M.S.; Chung, I.K. A Preliminary Study of the Bioremediation Potential of Codium Fragile Applied to Seaweed Integrated Multi-Trophic Aquaculture (IMTA) during the Summer. J. Appl. Phycol. 2008, 20, 183–190. [Google Scholar] [CrossRef]

- De Prisco, J.A. An Investigation of Some Key Physico-Chemical Water Quality Parameters of an Integrated Multi-Trophic Aquaculture (IMTA) System Operating Recirculation Methodology in the Western Cape of South Africa. Master’s Thesis, University of Cape Town, Cape Town, South Africa, 2020. [Google Scholar]

- Chopin, T.; Cooper, J.A.; Reid, G.; Cross, S.; Moore, C. Open-water Integrated Multi-trophic Aquaculture: Environmental Biomitigation and Economic Diversification of Fed Aquaculture by Extractive Aquaculture. Rev. Aquac. 2012, 4, 209–220. [Google Scholar] [CrossRef]

- Neveux, N.; Bolton, J.J.; Bruhn, A.; Roberts, D.A.; Ras, M. The Bioremediation Potential of Seaweeds: Recycling Nitrogen, Phosphorus, and Other Waste Products. In Blue Biotechnology; Wiley: Weinheim, Germany, 2018; pp. 217–239. ISBN 978-3-527-80171-8. [Google Scholar]

- Stabili, L.; Giangrande, A.; Arduini, D.; Borghese, J.; Petrocelli, A.; Alabiso, G.; Ricci, P.; Cavallo, R.A.; Acquaviva, M.I.; Narracci, M.; et al. Environmental Quality Improvement of a Mariculture Plant after Its Conversion into a Multi-Trophic System. Sci. Total Environ. 2023, 884, 163846. [Google Scholar] [CrossRef] [PubMed]

- Linder, M.; Sarasini, S.; Van Loon, P. A Metric for Quantifying Product-Level Circularity. J Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards Sustainable Development through the Circular Economy—A Review and Critical Assessment on Current Circularity Metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Valenti, W.C.; Kimpara, J.M.; Preto, B.D.L.; Moraes-Valenti, P. Indicators of Sustainability to Assess Aquaculture Systems. Ecol. Indic. 2018, 88, 402–413. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical Appraisal of the Circular Economy Standard BS 8001:2017 and a Dashboard of Quantitative System Indicators for Its Implementation in Organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H. Monitoring Circular Biobased Economy – Systematic Review of Circularity Indicators at the Micro Level. Resour. Conserv. Recycl. 2023, 197, 107104. [Google Scholar] [CrossRef]

- Niero, M.; Kalbar, P.P. Coupling Material Circularity Indicators and Life Cycle Based Indicators: A Proposal to Advance the Assessment of Circular Economy Strategies at the Product Level. Resour. Conserv. Recycl. 2019, 140, 305–312. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation Circularity Indicators: An Approach to Measuring Circularity. Methodology; Ellen MacArthur Foundation: Isle of Wight, UK, 2019.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneve, Switzerland, 2006; 20p.

- ISO 14044:2006; Environmental Management—Life cycle Assessment—Requirements and Guidelines. ISO: Geneve, Switzerland, 2006; 45p.

- European Commission. Understanding Product Environmental Footprint and Organisation Environmental Footprint Methods; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Badiola, M.; Mendiola, D.; Bostock, J. Recirculating Aquaculture Systems (RAS) Analysis: Main Issues on Management and Future Challenges. Aquac. Eng. 2012, 51, 26–35. [Google Scholar] [CrossRef]

- Garo, Q.; Tanrattana, N.; Vincent, L. Integrated Multi-Trophic Aquaculture: Integrated Marine Recirculated Aquaculture Analysis. Available online: https://keep.eu/api/project-attachment/3928/get_file/ (accessed on 1 March 2024).

- Leandro, A.; Pereira, L.; Gonçalves, A.M.M. Diverse Applications of Marine Macroalgae. Mar. Drugs 2019, 18, 17. [Google Scholar] [CrossRef]

- Carvalho, A.; Costa, L.C.D.O.; Holanda, M.; Gonçalves, M.; Santos, J.; Costa, C.S.B.; Turan, G.; Poersch, L.H. Growth of the Macroalgae Ulva Lactuca Cultivated at Different Depths in a Biofloc Integrated System with Shrimp and Fish. Phycology 2023, 3, 280–293. [Google Scholar] [CrossRef]

- Uttia Alstad, S. Bioremediation Potential of the Green Algae Ulva Sp. Cultivated in Wastewater from Marine Recirculating Aquaculture Systems (RAS). Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2022. [Google Scholar]

- Marine Algae as Carbon Sinks and Allies to Combat Global Warming. In Marine Algae; Vaz-Pinto, F., Arenas, F., Eds.; CRC Press: Boca Raton, FL, USA, 2014; pp. 148–185. ISBN 978-0-429-16637-2. [Google Scholar]

- Sjøtun, K.; Fredriksen, S.; Rueness, J. Seasonal Growth and Carbon and Nitrogen Content in Canopy and First-Year Plants of Laminaria Hyperborea (Laminariales, Phaeophyceae). Phycologia 1996, 35, 1–8. [Google Scholar] [CrossRef]

- Geldart, M. The Potential for Increasing the Recirculation Rate in a Commercial Integrated Abalone/Ulva Aquaculture System; Marine Biology Honours Degree project GLDMIC023; University of Cape Town: Cape Town, South Africa, 2023. [Google Scholar]

- Bohnes, F.A.; Hauschild, M.Z.; Schlundt, J.; Laurent, A. Life Cycle Assessments of Aquaculture Systems: A Critical Review of Reported Findings with Recommendations for Policy and System Development. Rev. Aquac. 2019, 11, 1061–1079. [Google Scholar] [CrossRef]

- Sánchez, I.; Checa, D. Report on Circularity of the iFishIECNCi Approach; iFishIENCi Project GA No: 818036; 2023.

- European Commission. Directorate General for Maritime Affairs and Fisheries. y EUMOFA—2020—Recirculation Aquaculture Systems; European Commission: Brussels, Belgium, 2020.

- Vasquez-Mejia, C.M.; Shrivastava, S.; Gudjónsdóttir, M.; Manzardo, A.; Ögmundarson, Ó. Current Status and Future Research Needs on the Quantitative Water Use of Finfish Aquaculture Using Life Cycle Assessment: A Systematic Literature Review. J. Clean. Prod. 2023, 425, 139009. [Google Scholar] [CrossRef]

- Surendran, P.; Sanchez, I.; Checa, D.; Poersch, L.; Macleod, A.; Michalek, K.; O’Donohoe, P.; Casserly, J.; Waters, C.; Macey, M.; et al. Life Cycle Assessment—ASTRAL Project (GA 863034); ASTRAL Project GA no 863034; 2023; 63p. Available online: https://www.astral-project.eu/ (accessed on 1 March 2024).

- Poli, M.A.; Legarda, E.C.; De Lorenzo, M.A.; Martins, M.A.; Do Nascimento Vieira, F. Pacific White Shrimp and Nile Tilapia Integrated in a Biofloc System under Different Fish-Stocking Densities. Aquaculture 2019, 498, 83–89. [Google Scholar] [CrossRef]

- Minaz, M.; Yazıcı, İ.S.; Sevgili, H.; Aydın, İ. Biofloc Technology in Aquaculture: Advantages and Disadvantages from Social and Applicability Perspectives. Ann. Anim. Sci. 2023. [Google Scholar] [CrossRef]

- FAO. Nitrogen and Protein Content Measurement and Nitrogen to Protein Conversion Factors for Dairy and Soy Protein-Based Foods: A Systematic Review and Modelling Analysis; FAO: Rome, Italy, 2019. [Google Scholar]

- Cyrus, M.; Bolton, J.; Scholtz, R.; Macey, B. The Advantages of Ulva (Chlorophyta) as an Additive in Sea Urchin Formulated Feeds: Effects on Palatability, Consumption and Digestibility. Aquac. Nutr. 2014, 21, 578–591. [Google Scholar] [CrossRef]

- Bolton, J.J.; Robertson-Andersson, D.V.; Shuuluka, D.; Kandjengo, L. Growing Ulva (Chlorophyta) in Integrated Systems as a Commercial Crop for Abalone Feed in South Africa: A SWOT Analysis. J. Appl. Phycol. 2009, 21, 575–583. [Google Scholar] [CrossRef]

- Alonso, A.A.; Álvarez-Salgado, X.A.; Antelo, L.T. Assessing the Impact of Bivalve Aquaculture on the Carbon Circular Economy. J. Clean. Prod. 2021, 279, 123873. [Google Scholar] [CrossRef]

- Reid, G.K.; Chopin, T.; Robinson, S.M.C.; Azevedo, P.; Quinton, M.; Belyea, E. Weight Ratios of the Kelps, Alaria Esculenta and Saccharina Latissima, Required to Sequester Dissolved Inorganic Nutrients and Supply Oxygen Atlantic Salmon, Salmo Salar, in Integrated Multi-Trophic Aquaculture Systems. Aquaculture 2013, 408–409, 34–46. [Google Scholar] [CrossRef]

- Sanz-Lazaro, C.; Sanchez-Jerez, P. Mussels Do Not Directly Assimilate Fish Farm Wastes: Shifting the Rationale of Integrated Multi-Trophic Aquaculture to a Broader Scale. J. Environ. Manag. 2017, 201, 82–88. [Google Scholar] [CrossRef]

- Luthada-Raswiswi, R.; Mukaratirwa, S.; O’Brien, G. Animal Protein Sources as a Substitute for Fishmeal in Aquaculture Diets: A Systematic Review and Meta-Analysis. Appl. Sci. 2021, 11, 3854. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).