Abstract

Considerable amounts of Reclaimed Asphalt Pavement (RAP) are produced every year, as the road network requires maintenance to ensure the safety and comfort of its users. RAP is a 100% recyclable material and a useful fit to be re-introduced into another cycle without downgrading its functionality. Despite the current knowledge about the benefits associated with RAP use, it is not yet largely applied in several countries. This paper aims to validate, on the basis of both short- and long-term mechanical behaviours, the application of a bituminous mixture with a high RAP incorporation rate (75%) in road pavement wearing courses. A crude tall oil rejuvenator was used. Both short- and long-term oven ageing procedures were employed to simulate the ageing that occurs during mixture production and in-service life, respectively. The tests for validating the RAP mixture as an alternative solution comprised stiffness, resistance to fatigue, permanent deformation, and determination of the water sensitivity. Furthermore, the RAP bitumen mobilisation degree was evaluated and a mixing protocol was established. In comparison with virgin bituminous mixtures, it was found that, in general, the high RAP mixtures presented similar or better behaviour. The ageing process had a hardening effect namely in terms of stiffness and resistance to permanent deformation, without significant effects on the resistance to fatigue and water damage.

1. Introduction

Reclaimed Asphalt Pavement (RAP) (nomenclature adopted in this study), or just Reclaimed Asphalt (RA), as referred to in EN 13108-8, corresponds to removed and/or reprocessed pavement material containing bitumen and aggregates or material deriving from surplus production [1]. When properly crushed and screened, RAP consists of high-quality and well-graded aggregates coated by bituminous mastic [2]. This material can be processed and used as secondary raw material to replace virgin aggregates and bitumen, and as such it is highly valuable for recycling purposes. RAP must be characterized by the following:

- Bitumen content and, in the case of high rates, bitumen properties.

- Grading, bulk density and other consensus properties of aggregates.

From the circular economy perspective, the material should be recycled and incorporated in similar applications without downgrading its utility [3,4]. Hence, the requirements established for some aggregate properties are met by considering that the RAP will replace, either totally or partially, both the virgin aggregates and the bitumen necessary to produce the mixture for that course.

The milled RAP from a single project usually has consistent characteristics in terms of gradation, bitumen content, aggregate and bitumen properties. However, some differences can be observed if the road section of the project has undergone several repaving interventions. RAP from a single project only needs separation and stockpiling of RAP particles by fraction and, if necessary, crushing of the larger particles followed by screening and separation. The control of gradation and reduction of larger particles enables efficient drying and heating when RAP is used in hot or warm recycled mixtures, hence leading to easier breaking down of RAP agglomerations during the mixing process [5,6].

Road authorities have been looking for different approaches to optimizing RAP use. Some guidelines were introduced in the specifications, which pointed to the need to optimize the management of these materials. Recycling solutions in pavement maintenance and rehabilitation (M&R) promote the extended use of materials, which leads to meeting sustainability policies. RAP recycling has been facing several obstacles. Indeed, the strict specifications and legislations enforced in some countries illustrate the poor confidence in RAP recycling in bituminous mixtures (RAP mixtures) [6,7,8]. With rare exceptions, the maximum RAP incorporation rates vary between 10% and 50%. The maximum rates are more restrictive for wearing courses. This value generally varies worldwide between 0% and 20% in some cases, and in some European countries, high RAP incorporation rates are allowed on the condition that the mixes fulfil the requirements for dense-graded surface mixtures [3,6,8,9].

The wearing courses of road pavements have limited service life periods since frequent M&R operations are necessary on the part of road authorities to guarantee adequate safety and comfort conditions for road users. These yearly operations carried out on the road networks result in the production of huge quantities of RAP and involve high costs. Hence, RAP should be more and more envisaged as a secondary raw material and the application of high RAP mixtures should be promoted.

The quality and the production process of materials strongly affect the performance of the bituminous mixture. Those factors acquire greater relevance in RAP mixtures, namely in the case of high rates, as RAP is a composite material containing aggregates, bitumen and, occasionally, additives. A correct design allows determining the type and proportion of those materials in the mixture.

The mixing procedure has impacts on the homogeneity of the mixture. The homogeneity is more relevant as the RAP content increases. RAP mixtures present issues regarding RAP sizes, mixing methods and diffusion mechanisms. The degree of RAP bitumen mobilization and blending with the new virgin bitumen is essential to guarantee the greatest homogeneity of the mixture [10,11,12].

In high RAP mixtures, it is fundamental to evaluate and define a laboratory mixing protocol capable of approximately simulating the in-plant mixing process, without requiring major changes in the current in-plant process. This will ultimately present benefits because it will reduce the investment in upgrading the plants for controlling RAP mixtures [13]. Due to the significant percentage of bitumen in the RAP composition, it can be mobilized to act as a binding element rather than as just a “black rock”. The mobilization degree of the RAP bitumen can result in economic gains, due to the reduced need for virgin bitumen, the most expensive component of bituminous mixtures [12,14].

In general, RAP recycling introduces some positive changes in the physical and mechanical behavior of bituminous mixtures. Some of them are related to the RAP bitumen resulting in an increased mixture stiffness, which eventually leads to the modification of resistances to fatigue, cracking (under low-temperature), and to permanent deformation [8,10,15,16,17,18,19,20,21,22]. Some important conclusions can be drawn from the literature:

- RAP should be heated to promote blending between the virgin bitumen and the RAP bitumen, otherwise, RAP tended to act like an aggregate (“black rock”); this allowed taking the greatest advantage of RAP [5,10].

- RAP particles had a coarser gradation than the aggregates present in these particles; in this way, RAP aggregates gradation needed to be determined [3,5,7].

- RAP particles failure to completely break down and blend in with the virgin materials may cause an overall coarser mixture and consequently lead to more voids in the mineral aggregate (VMA) than expected [10,23,24].

- RAP heating time allowed the breaking down of particles during the mixing process and, consequently, a highest rate of blending occurred between the RAP and the new materials [10,23,24].

- The increase in RAP content led to an increased variability of the results obtained in laboratory studies; this was mainly related to RAP variability and mixing procedures [5,10,25].

- RAP storage in fractions allowed a greater control over the mixture homogeneity, which led to less variability in laboratory results [5,10,25].

- RAP mixtures that reveal a higher stiffness were usually likely to present shorter fatigue life and higher susceptibility to thermal cracking [10,15,16,18,19].

- The in-service performance of recycled mixtures was in accordance with laboratory results. In terms of long-term performance, the RAP mixture presented less than or equal life to the virgin mixtures when compared against performance indicators [17,26,27,28].

- The recycling agent or rejuvenator allowed to partially regenerate RAP bitumen properties, which led to an easier blending between both the virgin and the RAP bitumen and the materials and, consequently, to lower stiffness and resistance to permanent deformation; as well as to higher fatigue and greater thermal cracking resistance [12,21,22,29,30,31,32,33,34,35].

RAP recycling in bituminous mixtures is not a novelty. However, this subject continues to generate renewed interest, due to the lack of confidence in this type of solution by the road authorities, namely in applications with high incorporation rates. Despite intensive investigation, the aspects that can contribute to obtaining homogeneous and good performance RAP bituminous mixtures have not been evaluated together. Hence, this paper aims to:

- Assess the RAP bitumen mobilization degree by a qualitative methodology.

- Evaluate the effect of RAP fractioning and mixing condition on mixture homogeneity.

- Determine the mechanical behavior of RAP mixtures with a high incorporation rate.

- Assess the long-term behavior of RAP mixtures by evaluating the impact of ageing on mechanical performance.

In sum, the main objective of this paper is to validate high RAP mixtures for wearing courses on basis of their long-term mechanical behavior. Hence, the previous aspects were evaluated together, with a view to contribute to a methodology that will lead to an increased confidence in RAP solutions. A comparison was established between high RAP mixtures (75% per total mass weight) and virgin bituminous mixtures. A dense-graded bituminous mixture for wearing courses with a maximum aggregate size of 14 mm was taken as a reference for all the mixtures.

2. Materials

2.1. RAP

The RAP was obtained from the rehabilitation of a motorway consisting of the replacement of the wearing course. The RAP was collected and its grading was characterized according to EN 933-1. RAP was fractionated in the laboratory and stocked in 3 fractions from the finest to the coarsest fraction: fine fraction 0/4.75 mm (RAP F), medium fraction 4.75/12.5 mm (RAP M) and coarse fraction 12.5/19 mm (RAP C).

2.2. Rejuvenator

The rejuvenator agent was a chemical by-product derived from Crude Tall Oil (CTO), a renewable raw material used in the paper production industry and consisting of a mixture of both fatty and rosin acids. This rejuvenator can act both as a softener and as a dispersant/compatibilizer/remobilizer of the RAP bitumen [36]. This is a rejuvenator that has already shown good results in previous studies [22,29,37].

2.3. Aggregates

This study involved fractions of basalt aggregates (0/4 mm, 4/12 mm, and 10/16 mm), limestone aggregates (0/4 mm) and commercial filler.

2.4. Bitumen

The bitumen used for producing the bituminous mixtures was a 35/50 nominal penetration neat bitumen, in accordance with EN 12591. It had a penetration of 44 × 10−1 mm, a softening point of 54.6 °C and a penetration index of −0.40.

3. Experimental Procedures

3.1. Bituminous Mixture Characterization

The studied dense graded bituminous mixture for wearing courses had a maximum aggregate size of 14 mm and was produced with a neat bitumen 35/50 (AC14 surf 35/50). Two compositions were studied: one without RAP (0RAP and 0RAPA); and another with a high incorporation RAP rate, 75% per total mass of mixture (75RAP0 and 75RAP0A). Both unaged (0RAP and 75RAP0) and aged conditions (0RAPA and 75RAP0A) were studied on the two compositions.

Bituminous mixture design was based on EN 12697-34, as a first approach to determine the optimum bitumen content. A set of cylindrical specimens were produced with different total bitumen contents (including RAP bitumen), 4.0%, 4.5%, 5.0% and 5.5%. The bituminous mixture composition was determined on basis of the volumetric and global performance behaviors.

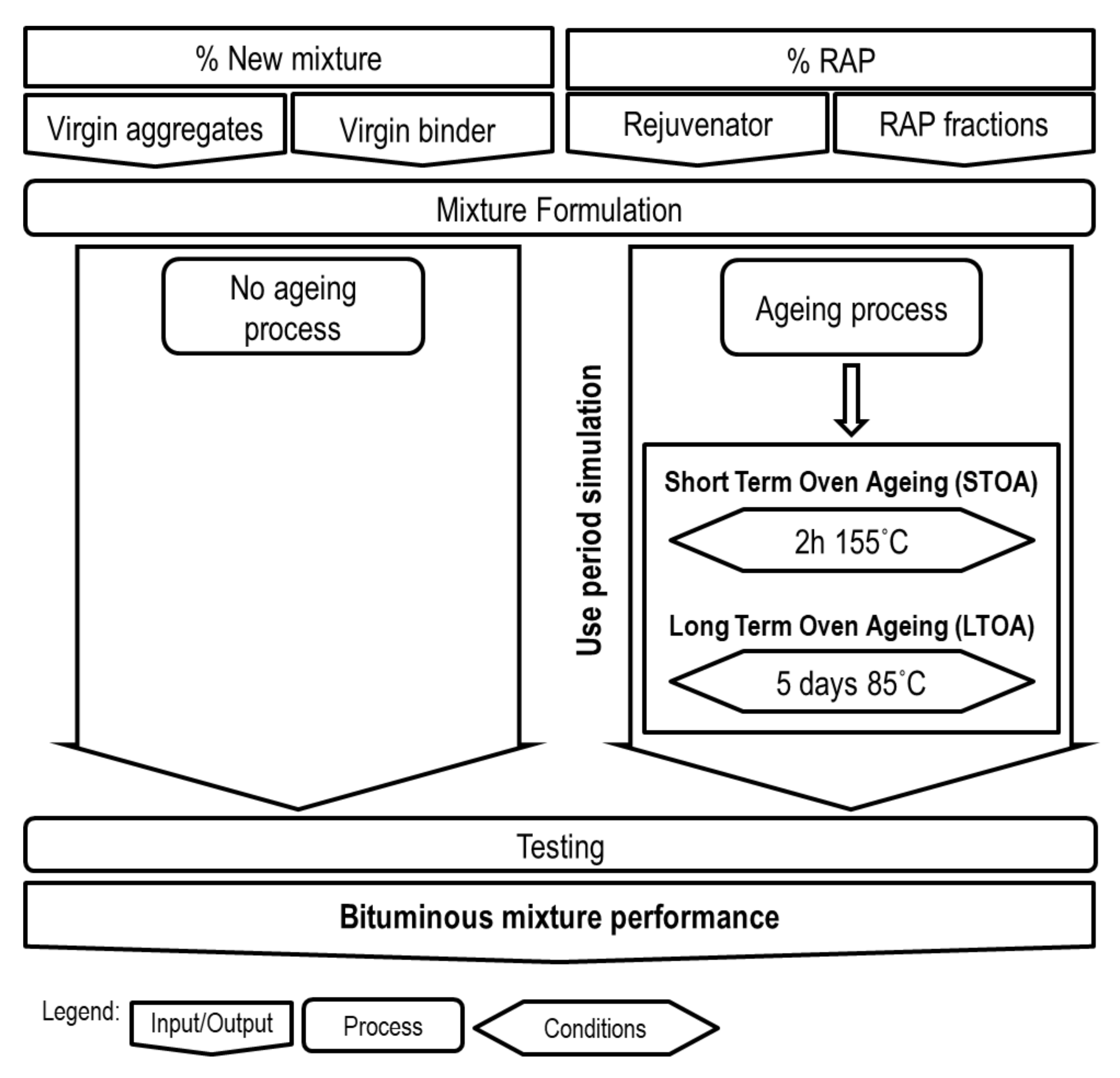

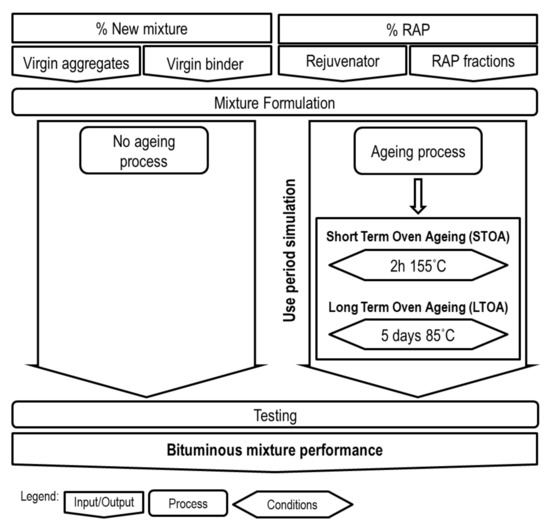

Figure 1 summarizes the bituminous mixture design, from the selection of materials until the performance assessment of the bituminous mixtures, as well as the formulation and ageing processes.

Figure 1.

Bituminous mixture testing protocol.

Prismatic specimens were produced and compacted using the roller compactor according to EN 12697-33. Their larger dimensions allowed a greater homogeneity of the mixture. As the RAP mixtures consist of different fractions of RAP and virgin aggregates, small amounts of each fraction are necessary for cylindrical specimens, namely for RAP C, which may imply a reduced number of particles. Taking into consideration the heterogeneity of RAP particles, different quantities of coarser aggregates and RAP bitumen could be introduced in each specimen. These differences were less significant in the case of larger specimens. Furthermore, the use of prismatic specimens allowed similar ageing, unlike what happens when different specimen sizes are used, which biased the conclusions in terms of the long-term behavior.

3.2. RAP Characterization

The characteristics of RAP fractions were determined by the following tests:

- Aggregate particle size distribution according to EN 933-1 and EN 12697-2.

- Bitumen content according to EN 12697-1.

- Bitumen needle penetration and softening point according to EN 1426 and EN 1427, respectively.

To evaluate the RAP bitumen characteristics, the bitumen of the medium and coarse RAP fractions were recovered using the rotary evaporator method according to EN 12697-3. The bitumen from RAP F was not evaluated due to the high content of fine material. However, as RAP had the same origin it was assumed that the bitumen present in all fractions had the same characteristics. The recovered RAP bitumen was characterized by the needle penetration and the softening point.

3.3. Rejuvenator Dosage

Three percentages of rejuvenator (3.0%, 4.5% and 7.0%) were used to determine the optimum rejuvenator dosage. The tests were performed on recovered RAP bitumen samples and they were treated with rejuvenator in accordance with the following blending protocol:

- The RAP bitumen was placed in an oven at 135 °C for 30 to 60 min, the time required for it to be fluid.

- Afterwards, the RAP bitumen was mixed for homogenization and removal of any bubble.

- The mass of RAP bitumen was determined and the container was placed on a hot plate at 100 to 135 °C.

- The dosage of rejuvenator was added to RAP bitumen and hand-blended using a glass rod for about 30 s.

- The container with the blend (RAP bitumen + rejuvenator) was placed in the oven at 135 °C for 10 min and the blend was mixed for 30 s at 5 min intervals.

After the treatment process, RAP bitumen samples were tested to penetration and softening point values. The literature indicates that the optimum percentage of rejuvenator by weight of RAP bitumen is the one that allows complying with the properties of the virgin bitumen percentage used in the RAP mixture [38]. In this study, the reference bituminous mixture is an AC14 surf 35/50, resulting in property limits for the treated bitumen similar to the 35/50 neat bitumen; the penetration varied between 35 and 50 mm at 25 °C and the softening point between 50 °C and 58 °C.

3.4. Mixing Conditions

To qualitatively assess how mixing conditions and the use of rejuvenator affect the mobilization of RAP bitumen and the homogeneity of the mixture, a set of 4 cylindrical specimens were produced using a blue pigmented bitumen. This option allows obtaining a visual contrast between the black from RAP bitumen and the blue from the virgin bitumen, which makes it possible to easily identify the RAP bitumen film coating the RAP aggregates. The pigment dosage was 2% per weight of the mixture, to obtain a strong color, and the virgin bitumen dosage was 4%, by assuming that no RAP bitumen would be mobilized. The addition was performed at room temperature because the bitumen and the pigment were provided in pellets. It was not necessary to perform to any corrections to the granulometric curve as the pigment was supplied in pellets and it melted down into the bitumen.

The specimens were produced considering the aspects as follows: the theoretical grading curve defined for the bituminous mixtures; the conditions in terms of temperature of materials; and the use of rejuvenator for the RAP mixtures. The following types of bituminous mixtures and specimens were produced:

- 0RAPH: produced with virgin aggregates heated in a ventilated oven at 165 °C for 4 h.

- 75RAPH: produced with 75% RAP and 25% virgin aggregates heated in a ventilated oven at 165 °C for 4 h together.

- 75RAPL: produced with 75% RAP and 25% virgin aggregates heated in a ventilated oven at 130 °C for 2.5 h and 205 °C for 4 h, respectively.

- 75RAPLR: produced with 75% RAP and 25% virgin aggregates heated in a ventilated oven at 130 °C for 2.5 h and 205 °C for 4 h, respectively, and using 4.5% of rejuvenator by mass of RAP bitumen.

The aggregates of the 0RAPH mixture were heated at 165 °C and mixed for 3 min with the virgin bitumen and the pigment pellets, added at room temperature. The same procedure was followed for 75RAPH, with the RAP being heated together with the virgin aggregates, which were both mixed with the virgin bitumen and the pigment pellets. The procedure presented a slight difference in the case of 75RAPL. The over-heated aggregate (205 °C) was mixed with the RAP for 30 s to allow the RAP to heat to the mixture temperature. Afterwards, the bitumen and the pigment pellets were added to the bowl and mixed for 150 s. Regarding the 75RAPLR, the process was more complex. In the case of rejuvenator addition combined with a low RAP temperature, the RAP was mixed with the rejuvenator for 30 s. Then, the over-heated aggregate was added and mixed for 60 s. Finally, the bitumen and the pigment pellets were added and mixed for 90 s. All the mixtures were compacted using the impact compactor.

3.5. Bituminous Mixture Production and Ageing

The bituminous mixture without RAP was produced according to EN 12697-35. For the RAP mixture, the standard protocol was modified to include a previous treatment of RAP with the rejuvenator. The protocol was intended to simulate the in-plant mixture production with pre-heating of RAP and the treatment with rejuvenator. The heating of RAP at lower temperatures avoids the hardening of the RAP bitumen and the consequent blue smokes [3,5,6,13]. In the case of high RAP mixtures, these changes in current methodology have substantial impacts. Thus, the RAP fractions were heated at 130 °C for 2.5 h. To achieve the mixture temperature for a 35/50 nominal penetration, the aggregate was superheated at 205 °C for 4 h, 40 °C more than the recommended mixing temperature. The virgin bitumen was heated at 165 °C for 3 h, as defined in the specification. The mixture procedure for the RAP mixture was the following:

- In the mixing bowl, the rejuvenator was spread over the heated RAP and mixed for 30 s.

- The over-heated aggregates were added to the mixing bowl and mixed for further 60 s.

- The virgin bitumen was added and mixed for 90 s.

- The mixture was poured into the mold and compacted.

To assess the performance of mixtures at a later stage of its service, the ageing process was simulated in the laboratory. The ageing methodology consisted of both short- (STOA) and long-term oven ageing (LTOA) according to AASHTO R30. Two sets of unaged and aged specimens were produced.

3.6. Mechanical Tests

The mixture performance was assessed in terms of mechanical properties: stiffness, resistance to fatigue, determination of the water sensitivity, and wheel-tracking (permanent deformation). Table 1 presents the test standards and conditions.

Table 1.

Mechanical tests.

The specimens were compacted in prismatic molds (roller compactor method) and, afterwards, they were either sawed, to obtain small prismatic specimens for stiffness and fatigue resistance tests, or cored to obtain cylindrical specimens for the water sensitivity test.

4. Results and Discussion

4.1. RAP Properties

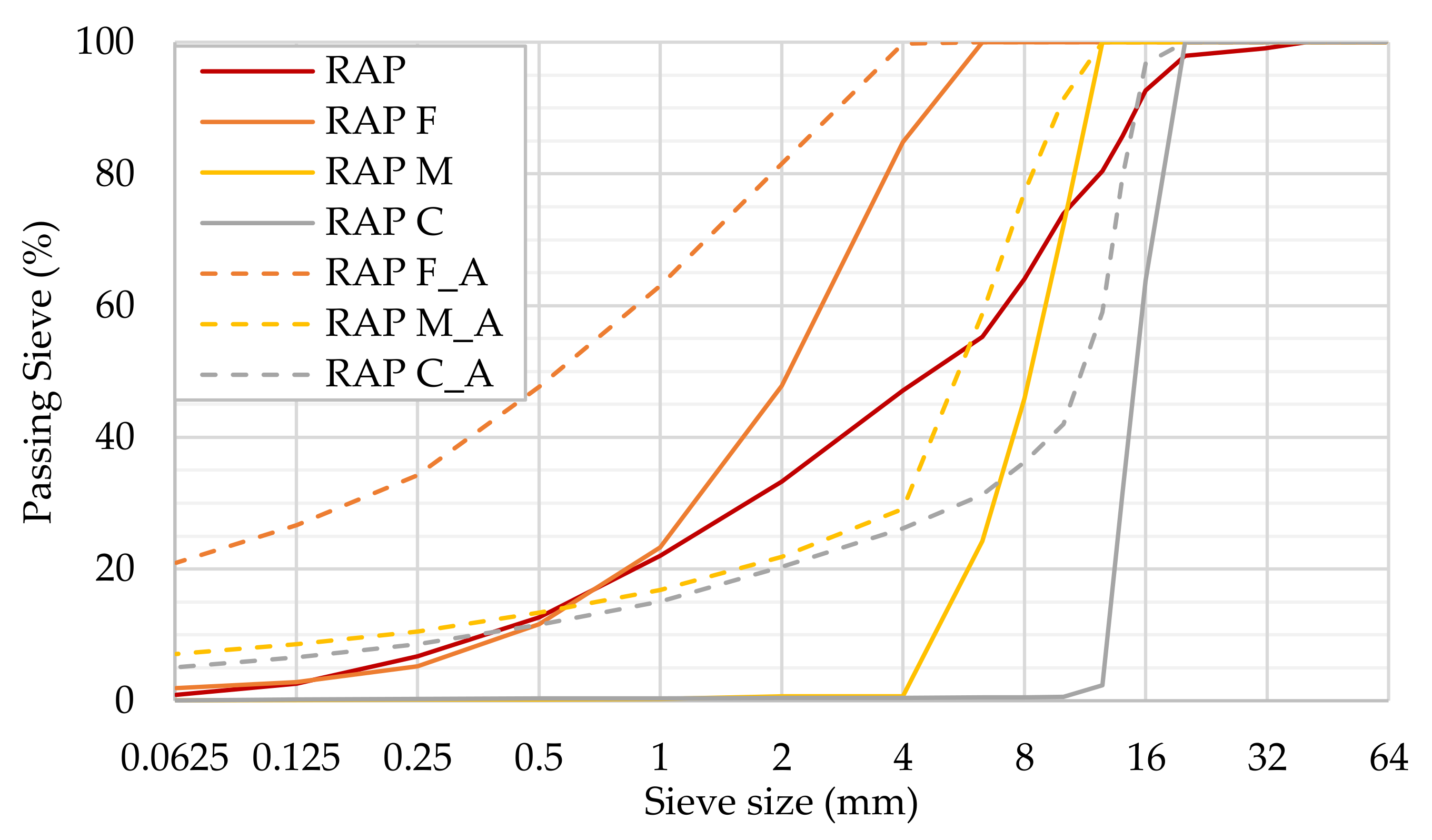

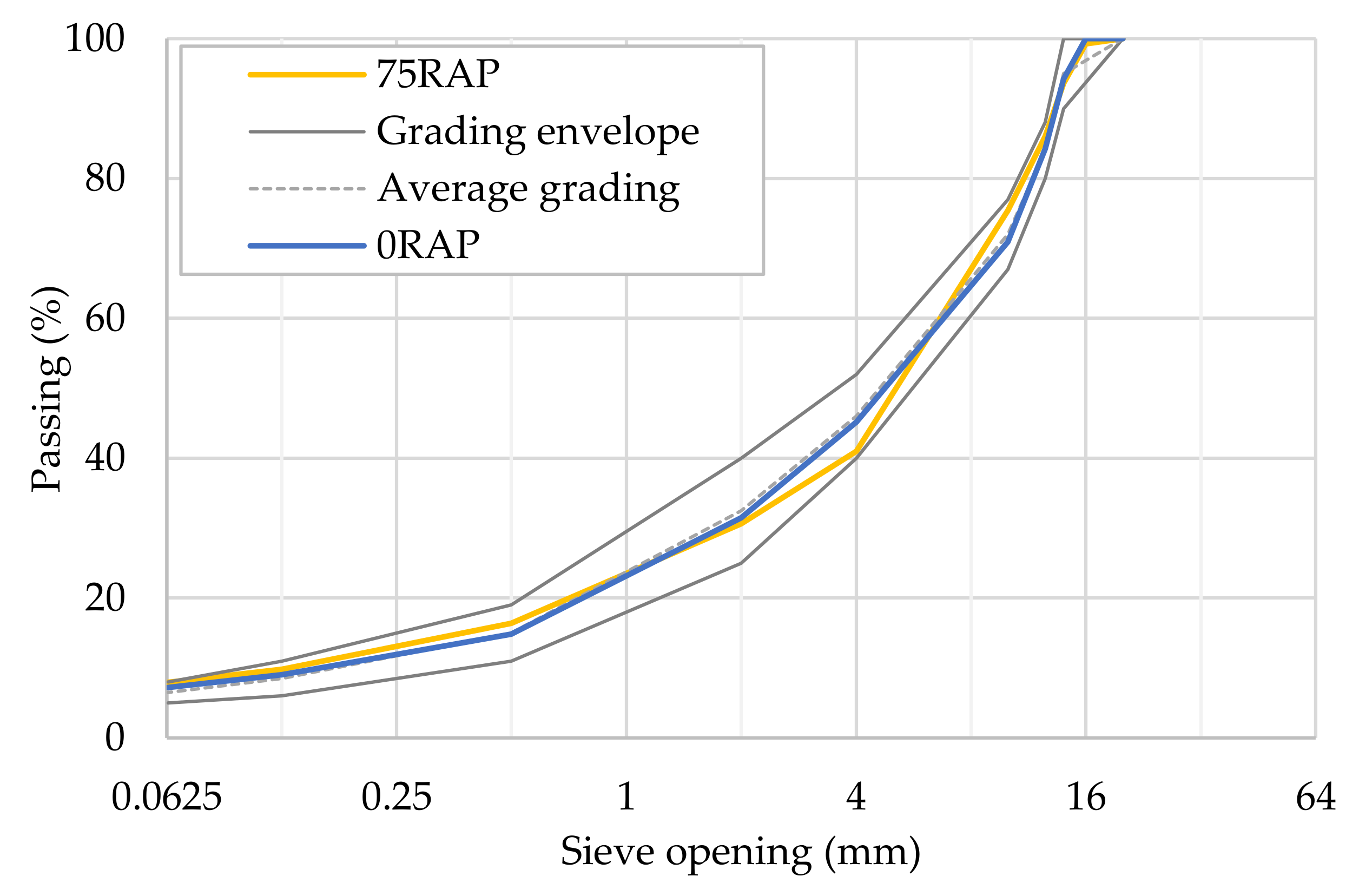

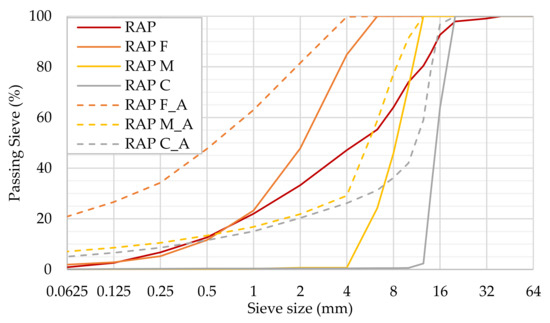

Figure 2 shows the grading curves of the RAP sample representative of both the stockpile and the 3 laboratory fractions. For the latter, both the bitumen content and the recovered RAP aggregate grading were determined. In terms of bitumen content, RAP F presented the highest value, 6.4%, followed by RAP C with 3.4% and RAP M with 3.3%.

Figure 2.

Grading curves of RAP.

After the determination of the bitumen content, the grading of RAP aggregates from each fraction was assessed. Figure 2 shows the grading curves of RAP, RAP fractions and RAP aggregates (designation followed by “A”). Despite fractioning, the RAP aggregates had a finer gradation than the fraction limits. This result was expected because the fraction was performed on RAP particles containing agglomerations of aggregates covered and bonded by mastic (RAP bitumen and fine material). Therefore, RAP M and RAP C showed a considerable amount of material passing the 0.063 mm sieve. Hence, the grading curves of the aggregates recovered from the RAP fractions were used for the RAP mixture formulation.

Table 2 presents the results of the penetration determined at 25 °C for RAP M and RAP C bitumen. RAP F presented a high fine material percentage during the bitumen content determination, which may influence the penetration of the bitumen recovered from this fraction; if the fraction was tested, it would be expected to lead to values similar to a bituminous mastic rather than to a recovered bitumen. For this reason, the results for this fraction will not be representative of the real ageing and the consequent hardening of the bitumen during the lifespan of the pavement course. The two coarsest fractions showed similar values of penetration, which demonstrates that the RAP ageing was homogeneous; the RAP bitumen presented an average penetration value of mm.

Table 2.

Penetration, softening point and penetration index of RAP bitumen and rejuvenated bitumen.

The softening point results are also shown in Table 2. The results of the aged bitumen recovered from RAP M and RAP C were evaluated. The results are similar for all samples (average value of 67.5 °C) which also confirms that the RAP ageing was homogenous.

As the RAP bitumen from laboratory fractions had the same origin, they presented similar softening point and penetration values. These results confirm the homogeneity of the ageing process. Thus, a single rejuvenator percentage was determined for all RAP fractions.

4.2. Optimum Rejuvenator Dosage

Three percentages of rejuvenator by weight of RAP bitumen were tested: 3.0%, 4.5% and 7.0%. The results are shown in Table 2. The 3.0% CTO did not fit with the values of a 35/50 nominal penetration bitumen. For the highest percentage, the penetration value obtained was 22% higher than the maximum limit. The 4.5% CTO allowed obtaining a penetration value that fits the limit. However, the softening point was 5% higher than the maximum limit. The difference in the softening point was not critical and 4.5% of rejuvenator was considered to be the optimum value that allows minimizing costs.

4.3. Mobilization of RAP Bitumen

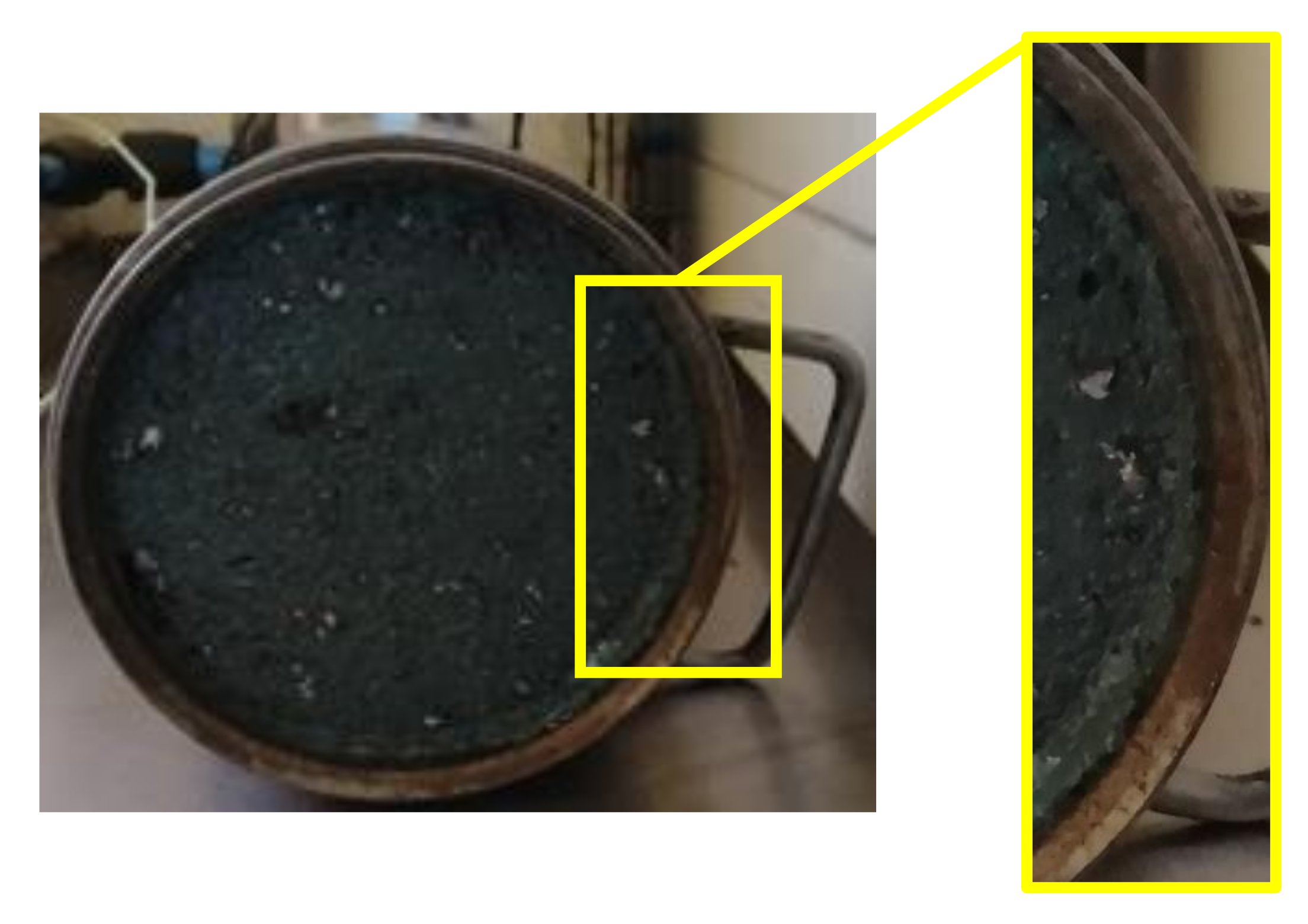

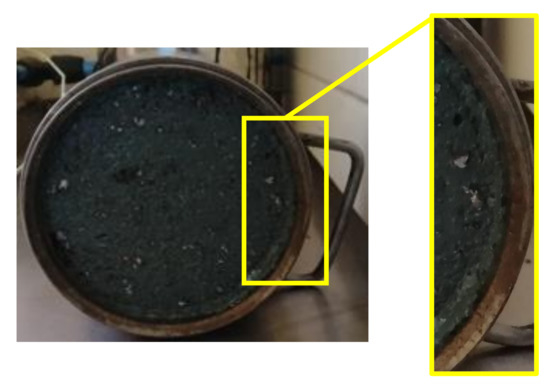

Figure 3 shows that the RAP specimens presented a smoother surface than the 0RAPH. The excess of bitumen detected in the rim of the mold is an indicator of excessive bitumen content, leading to conclude that more RAP bitumen might have been mobilized than expected.

Figure 3.

Blue specimen with an excess of bitumen.

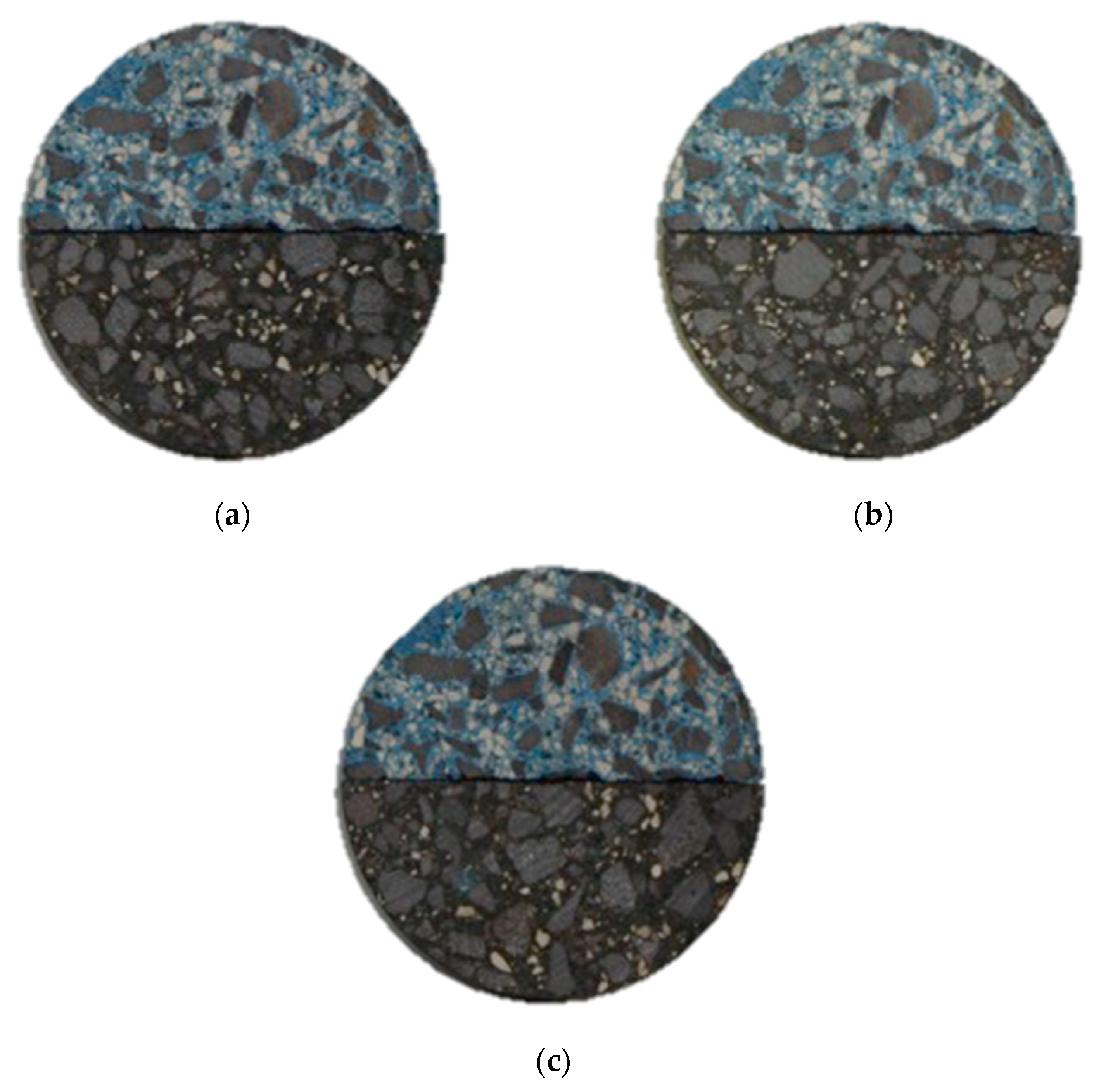

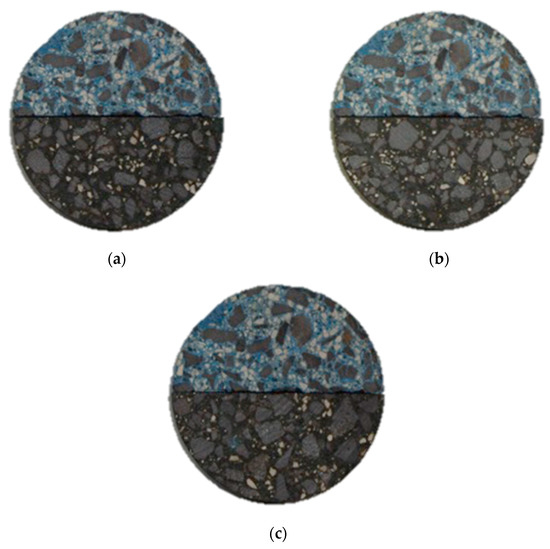

The tops of the specimens were trimmed and afterwards cut to obtain four semi-circular samples. The cut specimens’ surfaces were observed to evaluate the homogeneity of the mixtures. Figure 4 presents a comparison between mixtures with and without RAP for different mixing conditions. It was possible to observe that, at a macroscale, no RAP bitumen film surrounded the aggregates and that the RAP bitumen had darkened the mixture, which evidenced that most of the RAP bitumen was mobilized. Additionally, the mixture seemed to be homogeneous, presenting a small bluer area for the mixture 75RAPLR not darkened by the RAP bitumen. This area may result from a pellet of blue pigment that had not been totally blended into the mixture. This can be due to the shorter mixing time after the addition of the pigmented bitumen.

Figure 4.

Blue specimens half-cut view of bituminous mixtures without RAP and RAP mixtures: (a) 0RAPH-75RAPH; (b) 0RAPH-75RAPL; (c) 0RAPH-75RAPLR.

The use of low temperatures to heat the RAP was able to mobilize the RAP bitumen and hence avoid blue smoke emissions and additional ageing. Furthermore, the use of under-heated RAP combined with over-heated aggregates led to achieving the required mixing temperatures.

This qualitative analysis demonstrated that there was full or near to full mobilization of the RAP bitumen. Only a micro film of RAP bitumen surrounding RAP aggregates could probably be seen if observed in the microscope [11]. In this way, full mobilization of RAP bitumen was assumed in this study and the mixing protocol adopted made it possible to take the most advantage of the RAP bitumen.

4.4. Composition and Volumetric Properties

Table 3 shows the composition and properties of the mixtures. The same virgin aggregate fractions and virgin bitumen were used in the mixtures with and without RAP. In terms of total bitumen, both mixtures satisfied the minimum content (4%) specified for this type of mixture and application. Different total bitumen contents were defined for the mixtures, as the best behavior was verified with different bitumen contents. As RAP aggregates were coated by bitumen the adsorption and absorption phenomena had already occurred; the bituminous mixture presenting a lower total bitumen content due to a decreased need for bitumen. Moreover, as the finest part of the RAP mixture came from the RAP fractions, the filler was already coated by bitumen and this material, with a higher specific surface, did not mobilize as much bitumen as the virgin filler.

Table 3.

Composition and properties of the bituminous mixtures.

The grading curves of RAP fraction aggregates were used to establish the final grading curve of the RAP mixture. It was assumed that the RAP bitumen was fully mobilized and blended with the virgin bitumen. Thus, the full 2.8% of RAP bitumen percentage was considered in the mixture design. A percentage of 4.5% of rejuvenator was added to the mixture.

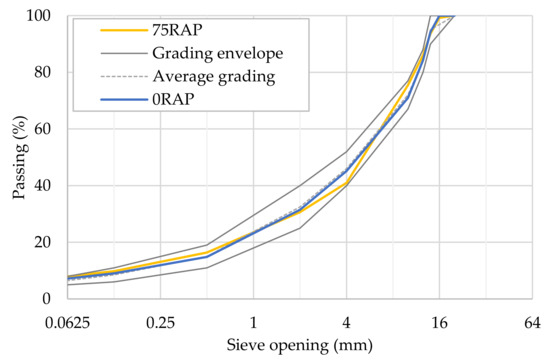

Figure 5 presents the aggregate grading curves of bituminous mixtures, within the required limits [39,40]. The RAP grading curve presents a higher content of fine material, which can be explained by the high RAP content.

Figure 5.

Aggregate grading curves.

Marshall tests according to EN 12697-34 were carried out to measure the stability and flow properties. The following volumetric properties of the test specimens were also evaluated: maximum specific density (), bulk specific density (), void content (V), voids in mineral aggregates (VMA), and voids filled with bitumen (VFB). Table 3 presents the average values obtained for those properties.

The total bitumen content of the RAP mixture was 0.7% lower than the one of virgin mixture (0RAP), which had a direct influence on V and VFB that were higher and lower, respectively. Despite the higher percentage of fine material of the RAP mixture when compared with the virgin mixture, the V of the mixture was not strongly affected. The fractioning and control of RAP allowed a greater control over the final RAP mixture characteristics.

The Marshall properties were only determined for the unaged bituminous mixtures. The unaged RAP mixture (75RAP0) presented higher stability, flow and coefficient when compared with 0RAP. In general, the values obtained complied with the required limits [39,40]. However, 75RAP0 presented a stability value equal to the maximum limit. Since the origin of the RAP aggregates is unknown, such a higher limit was assumed.

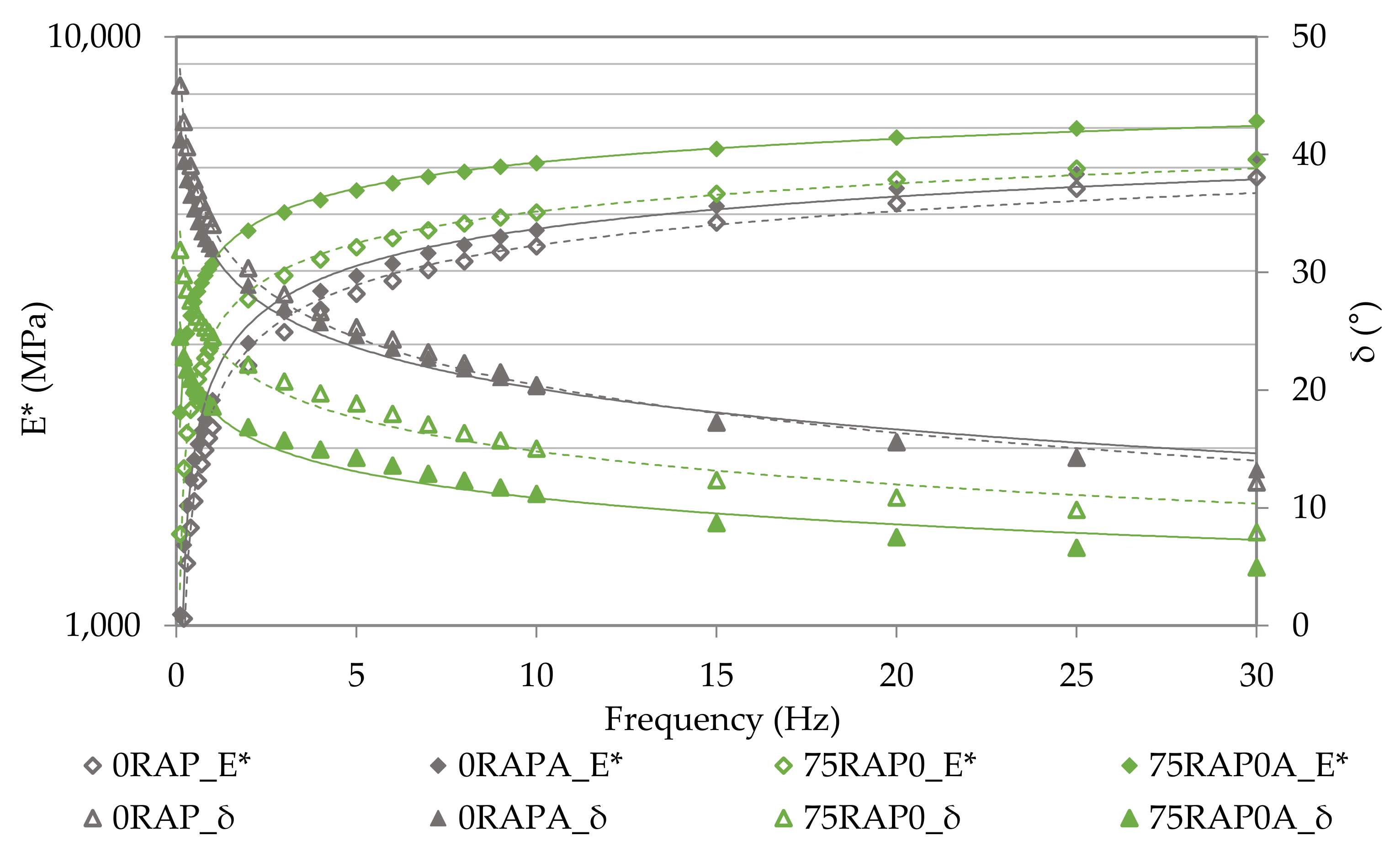

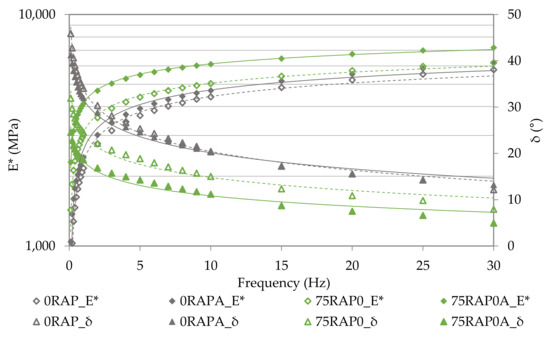

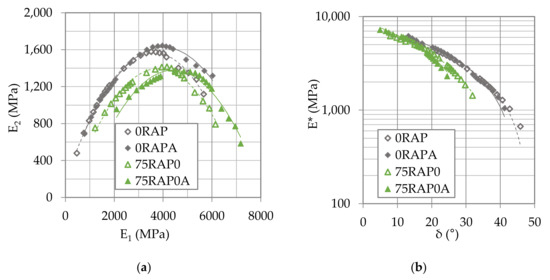

4.5. Stiffness Behaviour

Figure 6 shows the stiffness modulus (E*) and the phase angle of the bituminous mixtures. Unaged RAP mixture (75RAP0) presented an increase of 35% in the stiffness modulus for all tested frequencies and an increase of 18% for frequencies between 1 HZ to 30 Hz, when compared with the unaged virgin mixture (0RAP). These results are in accordance with the high values of Marshall stability. The increase in the test frequency led to a reduction in the stiffness difference due to the approximation of the glassy modulus verified at higher frequencies and lower temperatures.

Figure 6.

(left) Stiffness modulus; (right) Phase angle. E* is the stiffness modulus

The ageing procedure applied had a strong effect on the increase of the stiffness modulus. Similarly to the comparison between unaged virgin mixture (0RAP) and unaged RAP mixture (75RAP0), the difference verified for each frequency decreased with the increase in frequency. Average increases of 13% and 32% were observed when comparing the unaged virgin mixture with the aged one and the unaged RAP mixture with the aged one, respectively. The RAP mixture was more susceptible to ageing.

Regarding the phase angle, the introduction of RAP led to an average decrease of 13%. This effect is related to the RAP bitumen that contributes to the hardening of the bituminous mastic.

The ageing process contributes to the hardening of both bituminous mastics due to the alterations in the chemical and physical properties, which lead to losses of bitumen volatile parts and to alterations in the viscoelastic behavior. In consequence, a change occurred in the mechanical response of mixtures under load conditions, which corresponded to a decrease in the phase angle. The ageing contributed to average decreases of 4% for the virgin mixture and of 38% for the RAP mixture.

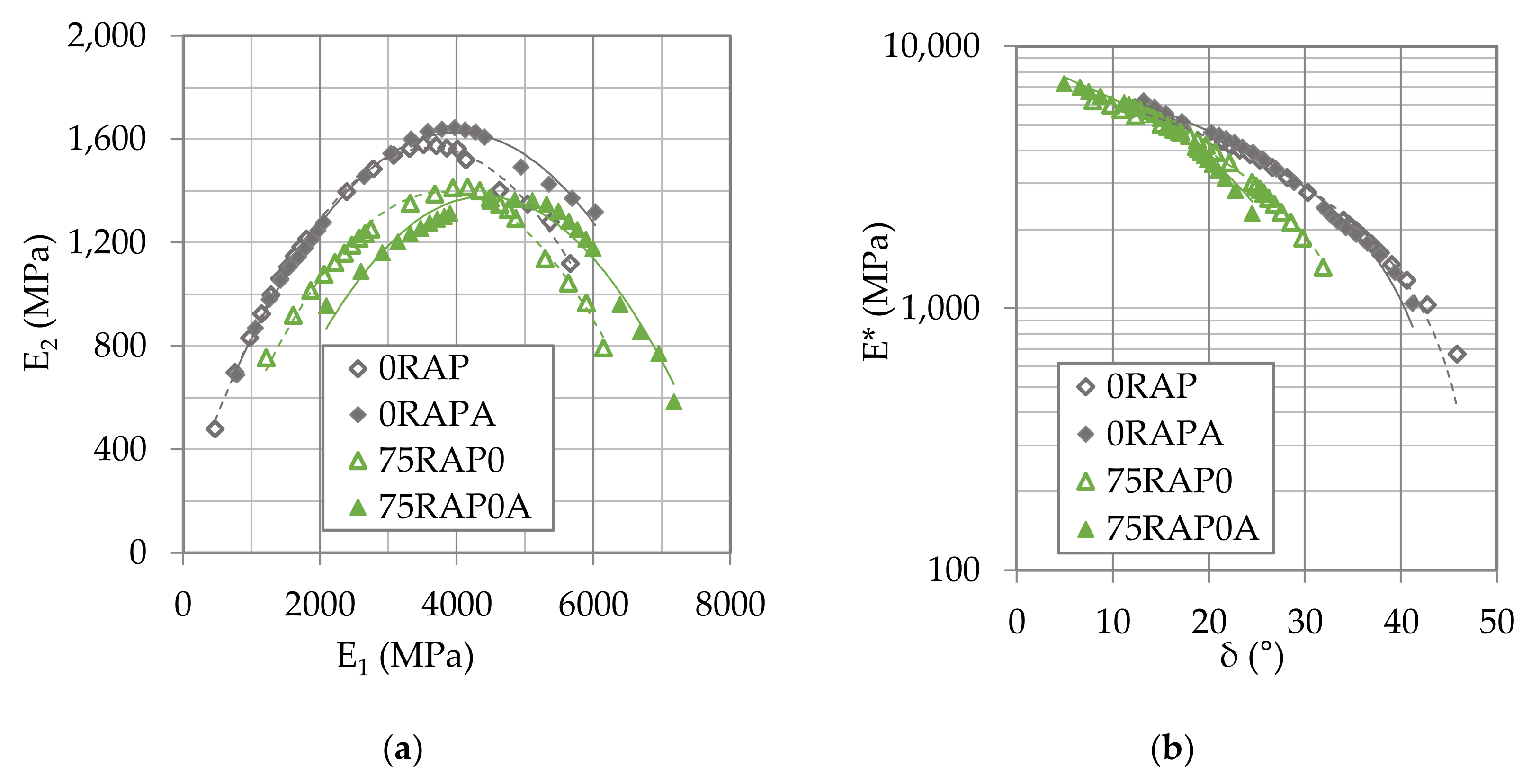

Figure 7 presents the Cole-Cole and the Black diagrams of the rheological properties of the bituminous mixtures. The Black diagram expresses the correlation between the stiffness modulus and the phase angle. Figure 7b shows a phase angle reduction from the unaged virgin mixture (0RAP) to the aged RAP mixture (75RAP0A), which is associated with the differences in bitumen type and ageing. The new bitumen and the rejuvenator of the RAP mixture contributed to reduce bitumen viscosity. Some differences observed in terms of stiffness modulus and phase angle may also be associated with the differences found in the mineral skeleton of bituminous mixtures. The RAP mixture presented a higher content of fine material, which led to a different aggregate configuration and to contacts between particles. Furthermore, the ageing process contributed to bitumen hardening and hence to a loss of viscosity of the bitumen mastic.

Figure 7.

(a) Cole-Cole diagram; (b) Black diagram. E* is the stiffness modulus.

The ageing led to a decrease in the phase angle and to an increase in stiffness, which was due to the contribution of the elastic part of the mixture.

Figure 7a confirmed the previous considerations. The 0RAP showed the highest values for both the elastic () and the viscous () components of the complex stiffness modulus (E*), for the same load and temperature conditions. RAP recycling led to the decrease of E1 and E2 when compared with the unaged virgin mixture (0RAP). The ageing protocol had a considerable effect on the rheological properties of mixtures, which is demonstrated by the increase in E1 of the aged mixtures with the reduction in E2, for the same load, temperature, and frequency conditions.

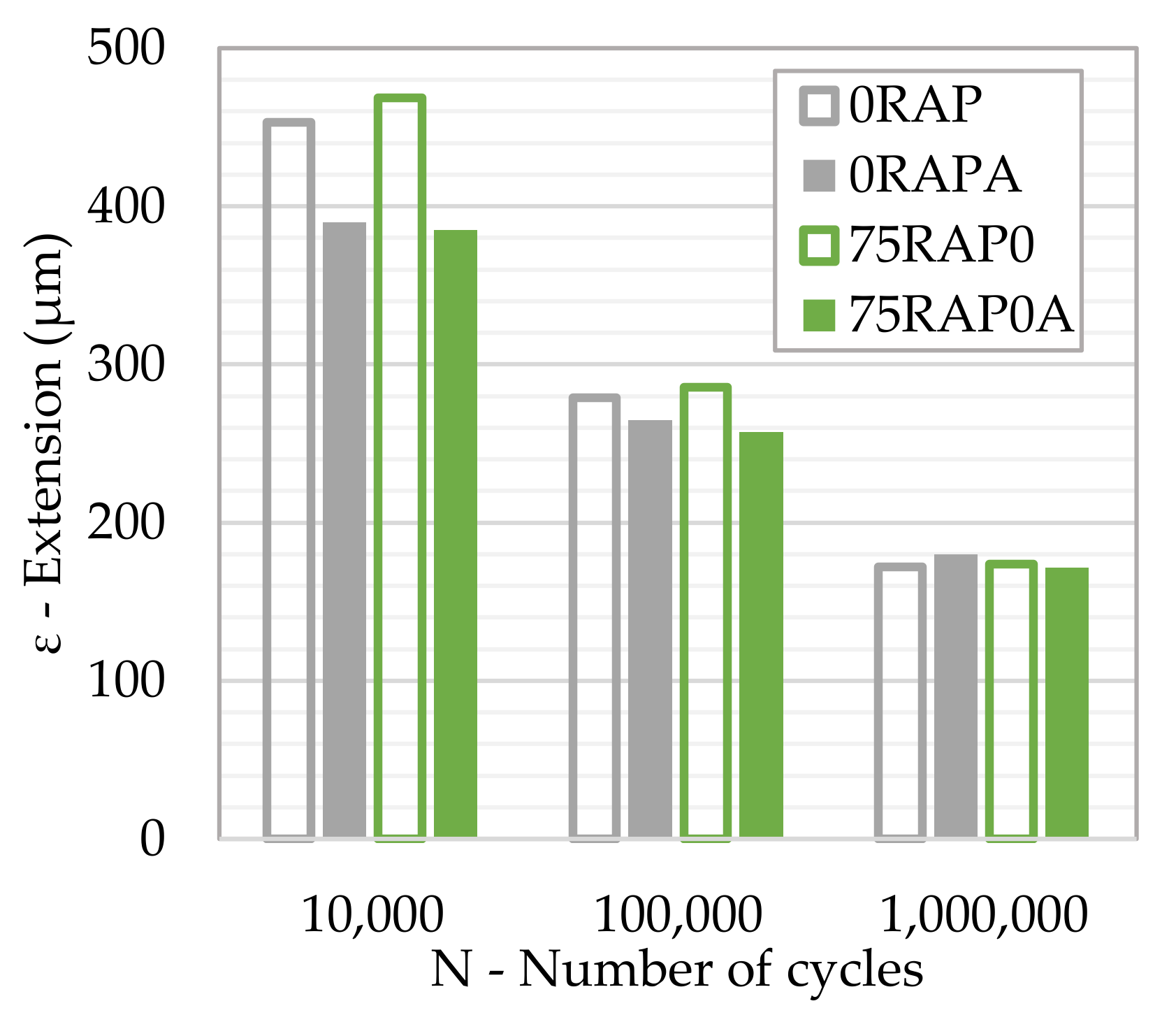

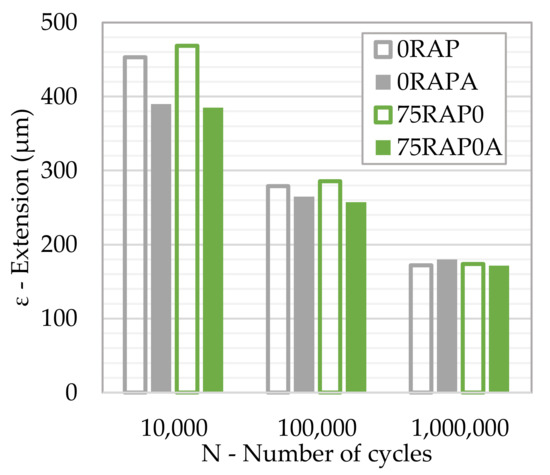

4.6. Resistance to Fatigue

Table 4 presents the coefficients and of the fatigue laws () obtained for three levels of strains. Figure 8 presents the extensions (, and ) to failure for each mixture as a function of three levels of applied loads: , and , respectively. The parameter is commonly used as a fatigue performance limit for the bituminous mixtures. The bituminous mixtures revealed similar behaviour based on this parameter. However, the unaged RAP mixture (75RAP0) revealed in general higher values for the three levels of failure strains.

Table 4.

Experimental coefficients of fatigue laws.

Figure 8.

Extension to failure as a function of the number of loads 104, 105 and 106.

Contrarily to the expectations, the increase in stiffness resulted from RAP having no influence on the fatigue performance. It can be concluded that RAP recycling, even with high rates, did not compromise fatigue resistance.

The ageing process led to a reduction in the fatigue resistance expressed by the average decreases of 5% for the virgin mixture and 10% for the RAP mixture. In the case of the aged virgin mixture (0RAPA) a slight increase was observed for 4.7%. The reductions in fatigue resistance were due to the hardening of bituminous mastics.

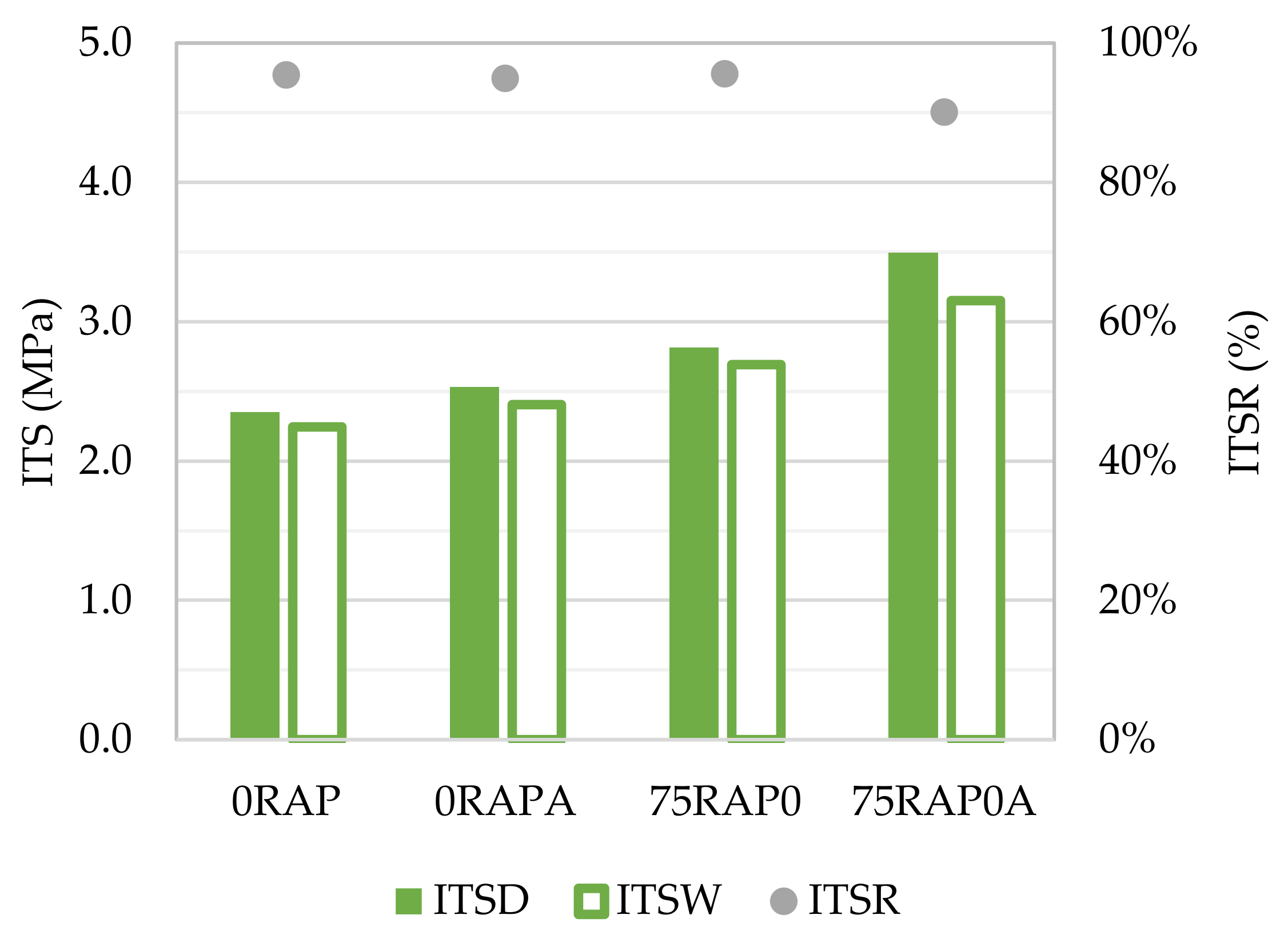

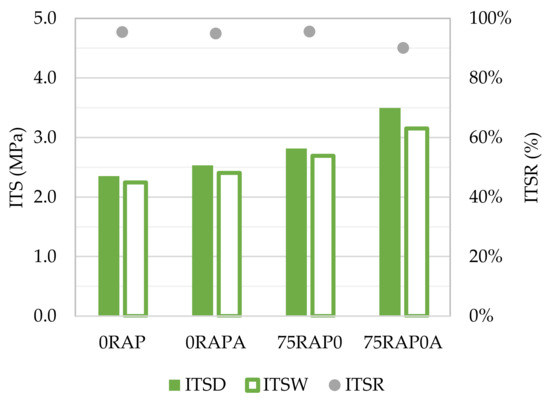

4.7. Resistance to Moisture Damage

Figure 9 shows the water sensitivity evaluated by the indirect tensile strength ratio (ITSR), as well as both dry (ITSd) and wet (ITSw) indirect resistances. All the bituminous mixtures revealed good performance, achieving an ITSR value higher than 80% (ITSR80), the minimum required limit [41]. The mixtures presented low sensitivity to moisture damage and they withstood the harmful action of water. The unaged RAP mixture (75RAP0) presented the best results (ITSR = 96%) followed by the unaged (0RAP) and aged (0RAPA) virgin mixtures. Additionally, the introduction of RAP increased by 20% both the ITSw and the ITSd. The unaged RAP mixture (75RAP0) showed good moisture resistance, associated with higher indirect resistances, in accordance with the higher values of stiffness and Marshall stability.

Figure 9.

Resistances to moisture damage.

The ageing did not affect the virgin mixture and decreased the ITSR of the RAP mixture (6%), reaching a value of 90%, and showing good resistance to moisture damage. Nonetheless, this lower value in terms of ITRS is correlated with higher values in terms of indirect tensile resistances due to ageing: aged virgin mixture (0RAPA) presented increases of 8% and 7% and aged RAP mixture (75RAP0A) showed increases of 24% and 17% for ITSd and ITSw, respectively.

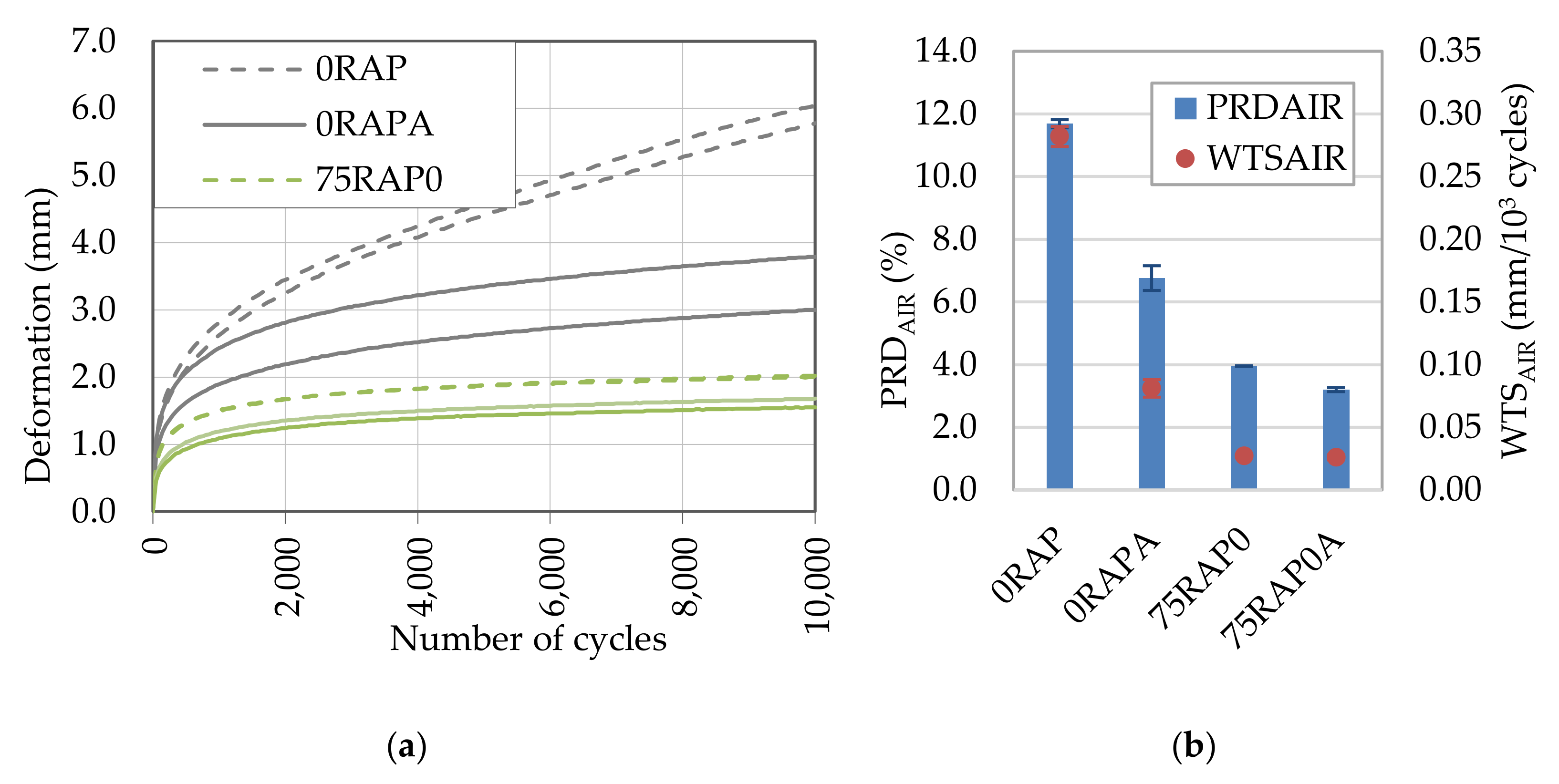

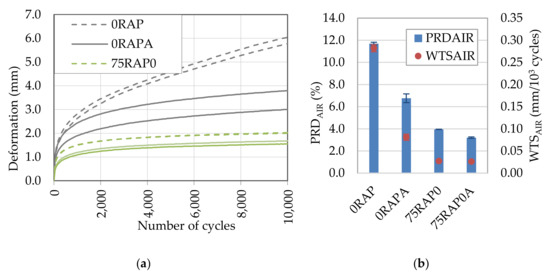

4.8. Resistance to Permanent Deformation

Figure 10a presents the deformation curves obtained from Wheel-tracking tests (WT). In terms of mean rut depth value (RDAIR). The mixtures can be ranked from the highest to the lowest value as unaged (0RAP) and aged (0RAPA) virgin mixtures followed by unaged (75RAP0) and aged (75RAP0A) RAP mixtures, with 5.9 mm, 3.4 mm, 2.0 mm and 1.6 mm, respectively. The parameters as follows were determined from the curves obtained: slope in air (WTSAIR) and mean proportional rut depth (PRDAIR) (Figure 10b). Unaged RAP mixture (75RAP0) presented 66%, 90% and 66% reductions for RDAIR, WTSAIR and PRDAIR, respectively, when compared with the unaged virgin mixture (0RAP). This behavior pointed out the clear contribution of RAP to the resistance to permanent deformation. This accrued resistance was due to the finer aggregate skeleton, which contributed to the increased number of contacts between particles, and to the presence of aged mastic from RAP.

Figure 10.

Permanent deformation performance: (a) wheel-tracking deformation curves; (b) WTSAIR and PRDAIR.

The ageing procedure adopted proved to have a discernible effect on the permanent deformation resistance when the aged and unaged mixtures were compared. The aged virgin mixture (0RAPA) presented a decrease of 43%, 71%, and 42% and the aged RAP mixture (75RAP0A) showed a decrease of 20%, 3.7% and 19% for RDAIR, WTSAIR and PRDAIR, respectively. These decreases for all variables are strongly related to the ageing of the bituminous mastic that occurred during the STOA and LTOA.

The chart in Figure 10a also shows that both RAP mixtures presented a tendency to a limit value, while the unaged virgin mixture (0RAP) tended to continue increasing the value of the maximum rut depth. Aged RAP mixture (75RAP0A) presents better results for the three parameters measured by the wheel tracking test.

5. Conclusions

The study presented in this paper investigated the possibility of incorporating high RAP rates in hot recycled bituminous mixtures for road wearing courses. The RAP was firstly fractionated into fine (RAP F—0/4.75 mm), medium (RAP M—4.75/12.5 mm) and coarse (RAP C—12.5/19 mm) fractions, according to the dimensions of the RAP particles. Two bituminous mixtures were studied: one virgin mixture (0RAP and 0RAPA) and one RAP mixture containing 75% RAP (75RAP0 and 75RAP0A) with rejuvenator, both unaged and aged to simulate the entire lifespan when in-service. All the bituminous mixtures fulfilled the properties required for a dense graded bituminous mixture with a maximum aggregate nominal size of 14 mm and a 35/50 nominal penetration bitumen, for road wearing courses.

The main findings of the study can be summarized as follows:

- Despite the unknown provenance and ageing of RAP, with just a mere fractioning and characterization of RAP bitumen and aggregate grading it was possible to formulate a high RAP mixture.

- The qualitative assessment of bitumen mobilization revealed that RAP bitumen can be fully or quasi fully mobilized when RAP is heated, allowing to take advantage of the RAP bitumen contribution as a binding element and not just as “black rock”.

- The use of a rejuvenator derived from Crude Tall Oil (CTO) allowed recovering the RAP bitumen viscosity properties.

- Generally, the unaged RAP mixture had a better or similar mechanical performance when compared with the virgin mixture.

- Unaged RAP mixture presented a higher stiffness modulus when compared with the virgin one. The ageing protocol further increased the stiffness modulus.

- Despite the increment in resistance observed in the Marshall stability and in the stiffness modulus, the unaged RAP mixture presented a better behavior in terms of fatigue resistance. This can be related to the presence of a rejuvenator and the finer gradation of the bituminous mixture.

- The ageing did not affect the fatigue resistance of the RAP mixture, which demonstrated good long-term behavior.

- The introduction of RAP strongly affected the rutting resistance of the mixtures. This can be related to the lower total bitumen content in the mixture and the presence of RAP bitumen. The ageing increased the rutting resistance of mixtures. This effect was due to the hardening of the bituminous mastic.

- The unaged RAP mixture revealed the highest moisture resistance, which demonstrates that the use of high RAP rates did not affect this property. Even after the ageing process, the mixture still presented good behavior.

The performance of RAP mixtures showed good results even after ageing, which made it possible to establish that high RAP mixtures can present good long-term performances. Hence, provided that a proper evaluation is carried out, high RAP mixtures combined with a rejuvenator to take advantage of the RAP bitumen, are suitable alternatives to conventional hot bituminous mixtures. The fractioning and stockpiling of RAP, combined with a relatively easy characterization, allow a greater control over the homogeneity of RAP mixtures and, hence, over their behavior.

Further investigations must be performed regarding the RAP multi-recycling capacity and the bitumen blend (RAP bitumen + rejuvenator + virgin bitumen) behavior to understand how this material can be recycled several times to fulfil the European goals to increase circular economy. Moreover, different RAP and bitumen sources must be considered.

Author Contributions

Conceptualization, V.A.; methodology, V.A.; validation, V.A., J.N. and A.C.F.; formal analysis, V.A., A.C.F. and J.N.; investigation, V.A.; resources, V.A., A.C.F. and J.N.; data curation, V.A.; writing—original draft preparation, V.A.; writing—review and editing, V.A., J.N. and A.C.F.; supervision, A.C.F. and J.N.; funding acquisition, V.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Portuguese agency that supports science and technology (“Fundação para a Ciência e Tecnologia”), grant number SFRH/BD/114715/2016.

Data Availability Statements

Not applicable.

Acknowledgments

The authors gratefully acknowledge the Portuguese agency that supports science and technology (“Fundação para a Ciência e a Tecnologia”) for the financial support provided through the grant SFRH/BD/114715/2016, and CERIS (Civil Engineering Research and Innovation for Sustainability).

Conflicts of Interest

The authors declare no conflict of interest.

References

- CEN, EN 13108-8. Bituminous Mixtures—Material Specifications—Part 8: Reclaimed Asphalt; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Chesner, W.; Collins, R.; MacKay, M.; Emer, J. FHWA-RD-97-148. In User Guidelines for Waste and Byproduct Materials in Pavement Construction; Federal Highway Administration: Washington, DC, USA, 1998. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/97148/index.cfm#content (accessed on 14 January 2021).

- EAPA. Asphalt the 100% Recyclable Construction Product EAPA Position Paper; European Asphalt Pavement Association: Brussels, Belgium, 2014. [Google Scholar]

- FIEC, EBC, EFBWW, UIPI, Eurima, BUILD EUROPE, RICS, CEMBUREAU, GCP EUROPE, EDA, ECCE, EAPA, EUROPEAN CONCRETE PLATFORM, EUPAVE, EFCA, CONSTRUCTION 2050—Building Tomorrow’s Europe Today. 2019. Available online: https://www.fiec.eu/download_file/force/539/510 (accessed on 15 March 2020).

- West, R.C. QIP 129—Best Practices for RAP and RAS Management; Lanham: Prince George’s County, MD, USA, 2015. [Google Scholar]

- Antunes, V.; Freire, A.; Neves, J. A review on the effect of RAP recycling on bituminous mixtures properties and the viability of multi-recycling. Constr. Build. Mater. 2019, 211, 453–469. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Zaumanis, M.; Arraigada, M.; Wyss, S.; Zeyer, K.; Cavalli, M.; Poulikakos, L. Performance-based design of 100% recycled hot-mix asphalt and validation using traffic load simulator. J. Clean. Prod. 2019, 237, 117679. [Google Scholar] [CrossRef]

- Petho, L.; Denneman, E. Maximising the Use of Reclaimed Asphalt Pavement in Asphalt Mix Design Field Validation; Austroads Research Report AP-R517-16; Austroads: Sydney, Australia, 2016. [Google Scholar]

- Nguyen, V.H. Effects of Laboratory Mixing Methods and RAP Materials on Performance of Hot Recycled Asphalt Mixtures. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2009. Available online: http://etheses.nottingham.ac.uk/863/ (accessed on 15 January 2021).

- Cavalli, M.; Griffa, M.; Bressi, S.; Partl, M.; Tebaldi, G.; Poulikakos, L. Multiscale imaging and characterization of the effect of mixing temperature on asphalt concrete containing recycled components. J. Microsc. 2016, 264, 22–33. [Google Scholar] [CrossRef] [PubMed]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% Hot Mix Asphalt Recycling: Challenges and Benefits. Transp. Res. Procedia 2016, 14, 3493–3502. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, C.; Li, P.; Jiang, H.; Liang, M.; Yao, Z.; Zhang, X.; Airey, G. Effect of different viscous rejuvenators on chemical and mechanical behavior of aged and recovered bitumen from RAP. Constr. Build. Mater. 2020, 239, 117755. [Google Scholar] [CrossRef]

- Daniel, J.; Lachance, A. Mechanistic and Volumetric Properties of Asphalt Mixtures with Recycled Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2005, 1929, 28–36. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Vukosavljevic, D. Laboratory evaluation of fatigue characteristics of recycled asphalt mixture. Constr. Build. Mater. 2008, 22, 1323–1330. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef]

- Huang, B.; Zhang, Z.; Kingery, W.; Zuo, G. Fatigue Crack Characteristics of HMA Mixtures Containing RAP. In Fifth International RILEM Conference on Reflective Cracking in Pavements; RILEM Publications SARL: Limoges, France, 2004; pp. 631–638. [Google Scholar]

- Izaks, R.; Haritonovs, V.; Klasa, I.; Zaumanis, M. Hot Mix Asphalt with High RAP Content. Procedia Eng. 2015, 114, 676–684. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of Rejuvenator’s Effectiveness with Conventional Mix Testing for 100% Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C. Improving fatigue and low temperature performance of 100% RAP mixtures using a soybean-derived rejuvenator. Constr. Build. Mater. 2017, 151, 345–352. [Google Scholar] [CrossRef]

- Bocci, E.; Grilli, A.; Bocci, M.; Gomes, V. Recycling of high percentages of reclaimed asphalt using a bio-rejuvenator—A case study. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef]

- Lee, T.-C.; Terrel, R.L.; Mahoney, J.P. Test for Efficiency of Mixing of Recycled Asphalt Paving Mixtures. Transp. Res. Rec. J. Transp. Res. Board. 1983, 51–60. [Google Scholar]

- Al-Qadi, I.L.; Carpenter, S.H.; Roberts, G.; Ozer, H.; Aurangzeb, Q.; Elseifi, M.; Trepanier, J. Determination of Usable Residual Asphalt Binder in RAP; Research Report ICT-09-031; Illinois Center for Transportation: Rantoul, IL, USA, 2009. [Google Scholar]

- Al-Qadi, I.L.; Aurangzeb, Q.; Carpenter, S.H.; Pine, W.J.; Trepanier, J. Impact of High RAP Content on Structural and Performance Properties of Asphalt Mixtures; Research Report ICT-R27-37; Illinois Center for Transportation: Rantoul, IL, USA, 2012. [Google Scholar]

- Wang, Y. The effects of using reclaimed asphalt pavements (RAP) on the long-term performance of asphalt concrete overlays. Constr. Build. Mater. 2016, 120, 335–348. [Google Scholar] [CrossRef]

- Stroup-Gardiner, M. Use of Reclaimed Asphalt Pavement and Recycled Asphalt Shingles in Asphalt Mixtures; The National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Gong, H.; Huang, B.; Shu, X. Field performance evaluation of asphalt mixtures containing high percentage of RAP using LTPP data. Constr. Build. Mater. 2018, 176, 118–128. [Google Scholar] [CrossRef]

- Gomes, V.; Di Nolfo, M.; Vlachos, P.; Bocci, M. Two case studies with high levels of RA enabled by a rejuvenating agent. In Proceedings of the 6th Eurasphalt Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Porot, L.; Di Nolfo, M.; Polastro, E.; Tulcinsky, S. Life cycle evaluation for reusing Reclaimed Asphalt with a bio-rejuvenating agent. In Proceedings of the 6th Eurasphalt Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Hagos, E.; Shirazi, M.; Van De Wall, A. The development of 100% RAP asphalt mixture with the use of innovative rejuvenator. In Proceedings of the 6th Eurasphalt Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, and RAP/RAS mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Radziszewski, P.; Piłat, J.; Sarnowski, M. New concept of sustainable road structure with RAP binder course using. In Proceedings of the 6th Eurasphalt Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef]

- Mangiafico, S.; Sauzéat, C.; Di Benedetto, H.; Pouget, S.; Olard, F.; Planque, L. Complex modulus and fatigue performances of bituminous mixtures with reclaimed asphalt pavement and a recycling agent of vegetable origin. Road Mater. Pavement Des. 2016, 18, 315–330. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the mechanical performance of recycled asphalt mixtures incorporated with high percentage of RAP and self-developed rejuvenators. Constr. Build. Mater. 2021, 269, 121337. [Google Scholar] [CrossRef]

- De Bock, L.; Piérard, N.; Vansteenkiste, S.; Vanelstraete, A. Categorisation and Analysis of Rejuvenators for Asphalt Recycling—Dossier 21; Belgian Road Research Centre: Brussels, Belgium, 2020. [Google Scholar]

- Tran, N.; Taylor, A.; Turner, P.; Holmes, C.; Porot, L. Effect of rejuvenator on performance characteristics of high RAP mixture. Road Mater. Pavement Des. 2016, 18, 183–208. [Google Scholar] [CrossRef]

- EAPA. Recommendations for the Use Rejuvenators in Hot and Warm Asphalt Production; European Asphalt Pavement Association: Brussels, Belgium, 2018. [Google Scholar]

- EP. 14.03—Materials. In Construction Specifications Book; Infraestruturas de Portugal: Almada, Portugal, 2012. (In Portuguese) [Google Scholar]

- EP. 15.03—Constructive Methods. In Construction Specifications Book; Infraestruturas de Portugal: Almada, Portugal, 2014. (In Portuguese) [Google Scholar]

- Nikolaides, A. Highway Engineering: Pavements, Materials and Control of Quality; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).