Abstract

The expected rapid growth in electric vehicle deployment will inevitably be followed by a corresponding rise in the supply of end-of-life vehicles and their lithium-ion batteries (LIBs). The batteries may be reused, but will eventually be spent and provide a potential domestic resource that can help supply materials for future battery production. However, commercial recycling processes depend on profits from recovery of cobalt, use of which is being reduced in new cathode chemistries. The U.S. Department of Energy, therefore, established the ReCell Center in early 2019 to develop robust LIB recycling technology that would be economical even for batteries that contain no cobalt. The central feature of the technology is recovery of the cathode material with its unique crystalline cathode morphology intact in order to retain its value and functionality. Other materials are recovered as well in order to maximize revenues and minimize waste-handling costs. Analysis and modeling serve to evaluate and compare process options so that we can identify those that will be most economical while still minimizing energy use and environmental impacts. This paper provides background and describes highlights of the center’s first 2 years of operation.

1. Introduction

Because the volume of spent batteries from electric vehicles is expected to rise rapidly in the near future, the U.S. Department of Energy (DOE) recognized the need to forestall a potential waste issue and instead create the opportunity to use the material as a valuable domestic resource. In January 2019, the DOE announced the creation of the ReCell Center [1]. The center is a $15 million collaboration between three national laboratories and three universities, led by Argonne National Laboratory, advised by industry, and funded by the DOE Vehicle Technologies Office. Participants, in addition to Argonne, are Oak Ridge National Laboratory, National Renewable Energy Laboratory, University of California at San Diego, Michigan Technological University, and Worcester Polytechnic Institute.

The DOE tasked the ReCell Center to develop a cost-effective process for recycling lithium-ion batteries within 3 years. The center’s mission is to decrease the cost of recycling lithium-ion batteries in order to ensure that critical materials are available in the future, and to decrease energy use compared to the energy used to produce raw materials. The center is developing processes to begin with spent cells and use them to produce recycled cells that perform as well as new cells.

This paper highlights some of the initial progress achieved by the ReCell Center for Advanced Battery Recycling.

2. Material Available for Recycling

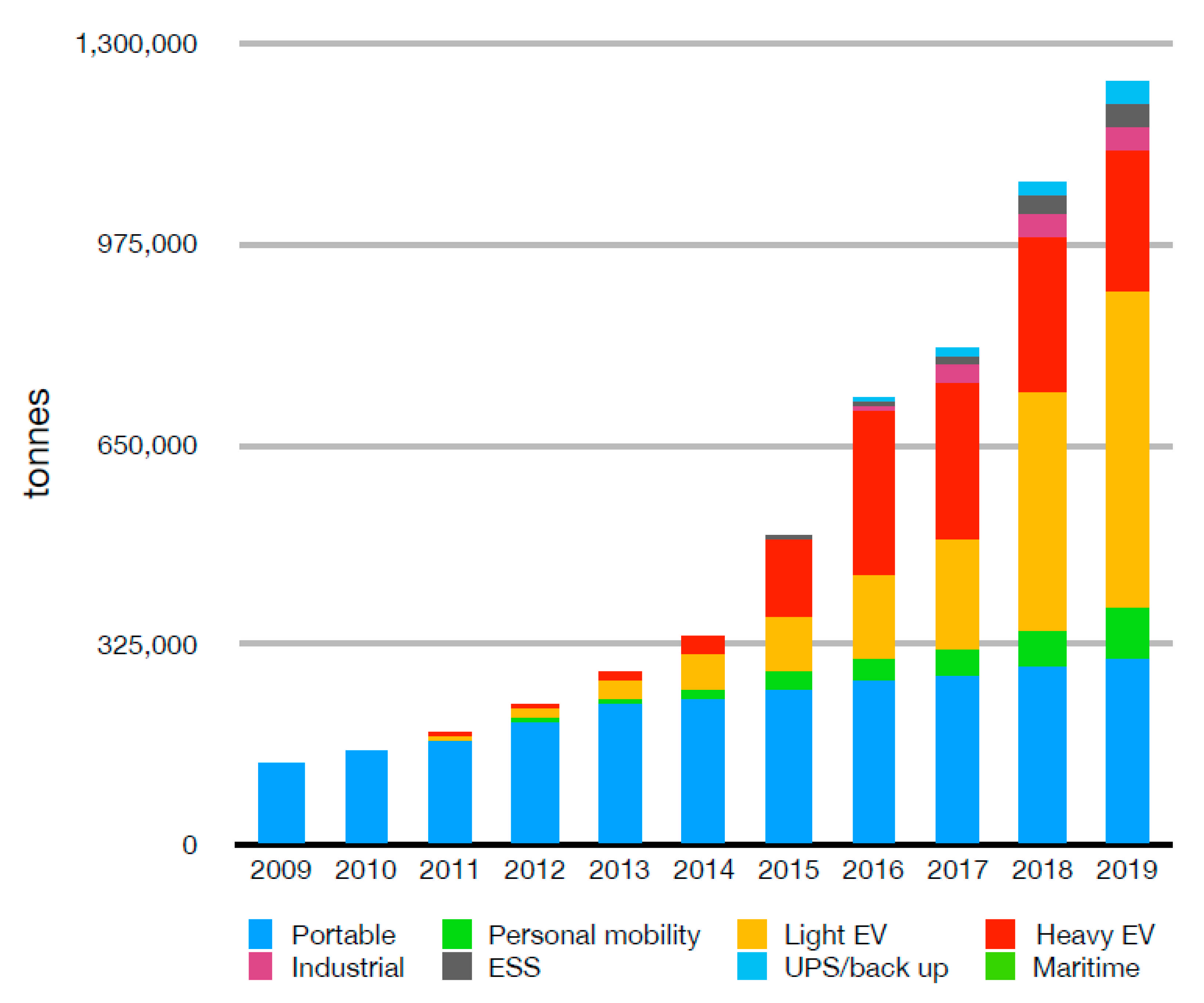

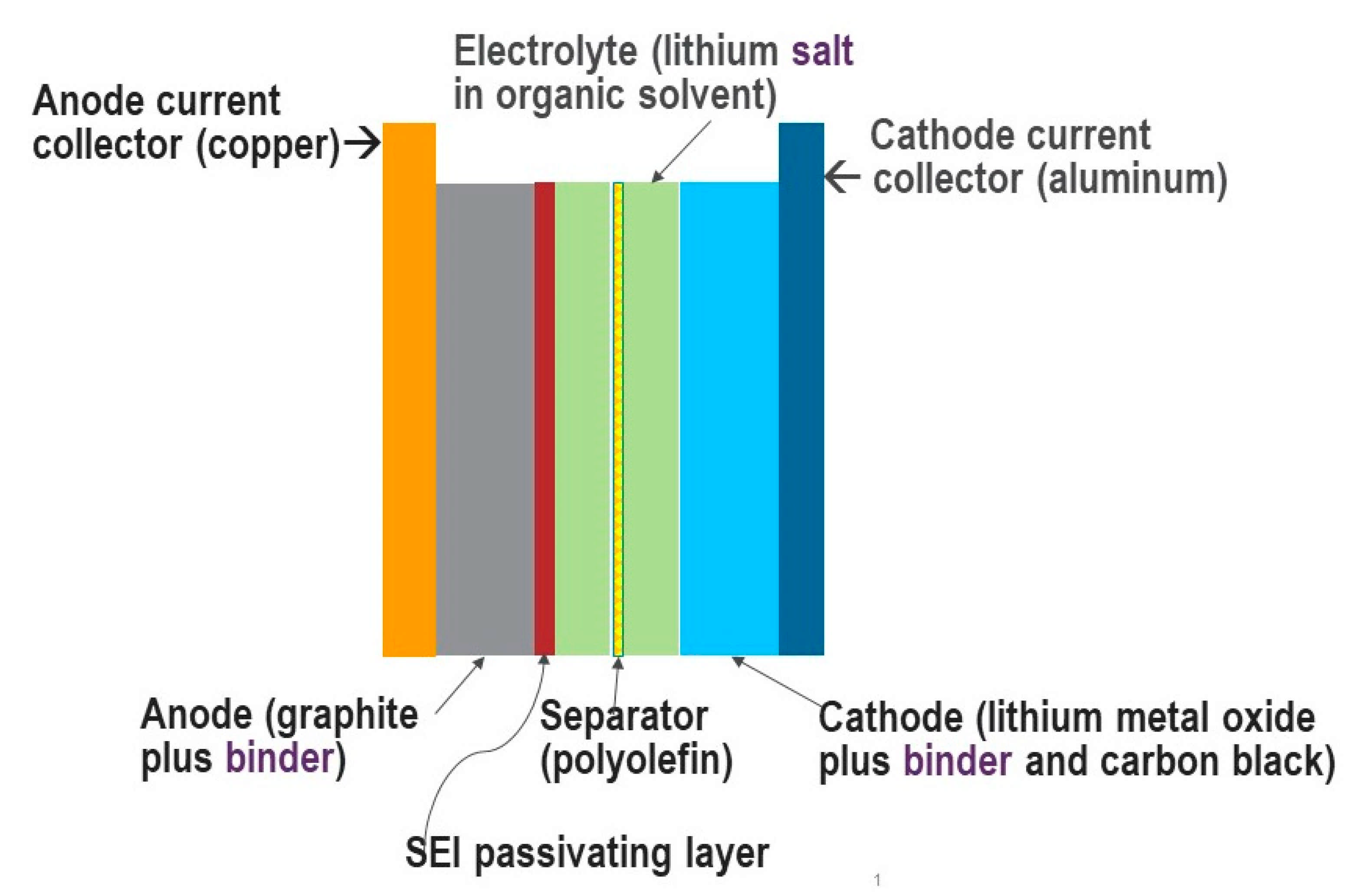

To date, almost all of the lithium-ion batteries available for recycling have come from portable electronic devices such as phones and laptop computers. However, the mass of batteries from electric vehicles is rapidly overtaking that from electronics (see Figure 1 [2]).

Figure 1.

Lithium-ion batteries placed on the global market, 2009–2019, in tonnes, at the cell level by application (courtesy of Circular Energy Storage).

2.1. End-of-Life Batteries

One analyst estimates that 29,000 tons of lithium-ion batteries (LIBs) was available for recycling in the United States in 2019. Of these, 59% were lithium cobalt oxide (LCO); 18% were lithium (nickel, manganese, cobalt) oxide (NMC111); 11% were lithium iron phosphate (LFP); 10% were lithium manganese oxide (LMO); and 2% were lithium (nickel, cobalt, aluminum) oxide (NCA) [2]. Call2Recycle, one of several firms that collects spent batteries in the United States and directs them to appropriate recyclers, collected approximately 1,300 tons of LIBs in 2019. These were discharged and shredded in Ohio, calcined in Pennsylvania, and smelted in Canada [3]. This represents approximately 4.5% of the available cells in the United States in 2019.

Three companies alone process 15% of the material that could be recycled in the United States: Call2Recycle, Battery Solutions (800 tons [4]) and Retriev (~2000 tons [5]). Therefore, the reported very low recycling rates are incorrect. However, all of this material was recycled elsewhere, and there is definitely room for improvement. Exact quantities of LIBs currently being recycled are difficult to determine. If economical recycling was available in the United States, this could reduce export of valuable material and increase the quantity actually recovered and available to be used again domestically.

2.2. Production Scrap

Production scrap is another important source of material for recycling. Scrap rates for lithium-ion battery production are rumored to be approximately 5% for the best producers, 10% for typical producers, and as high as 30% or more during start-up phases [6]. Whatever the actual rates are, this is a lot of material compared to the amount coming back at the end of life; it is based on the current production rate, which is much higher than the rate when the end-of-life material was produced, due to rapid growth. It is also available now and is much easier to process than spent cells.

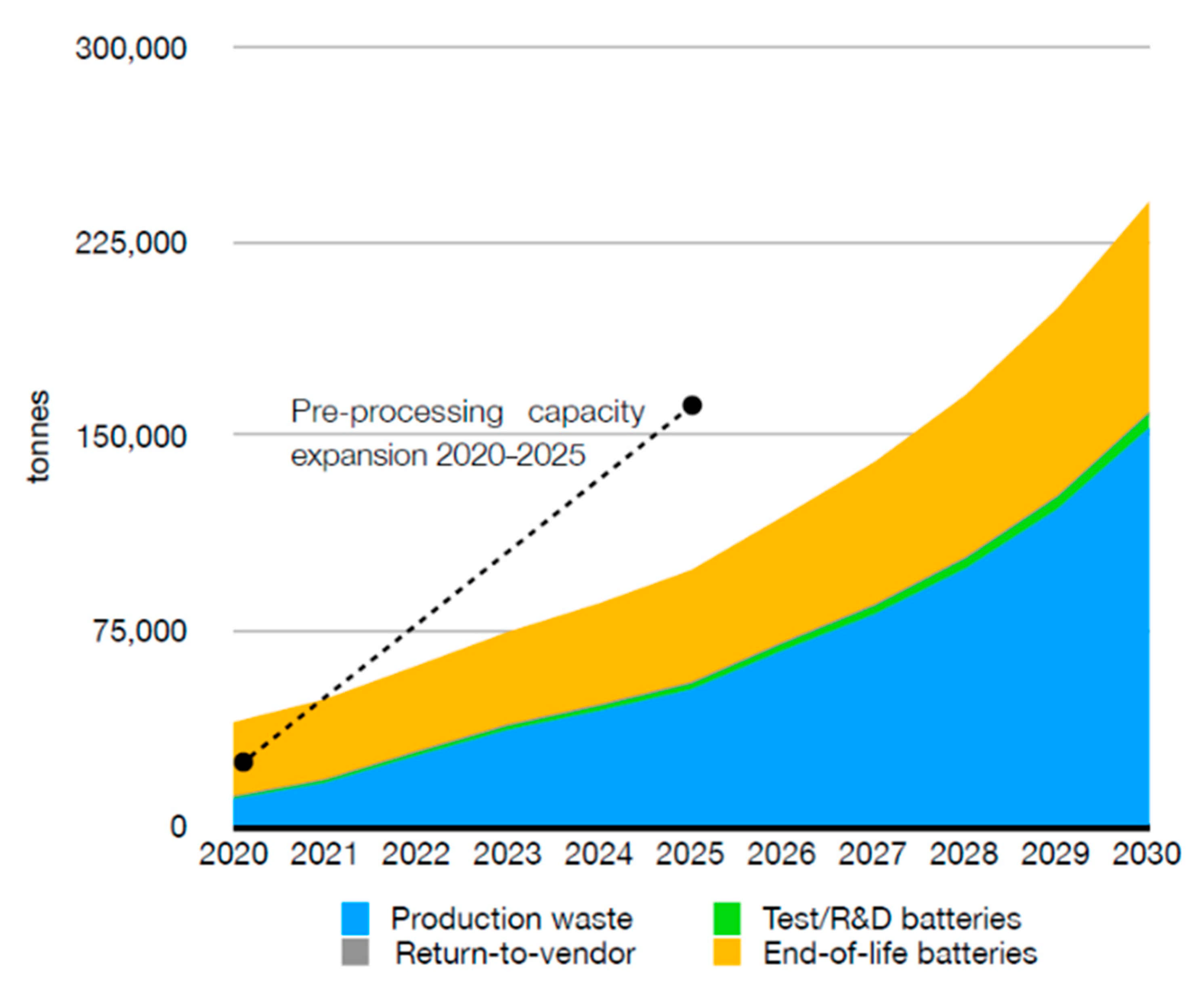

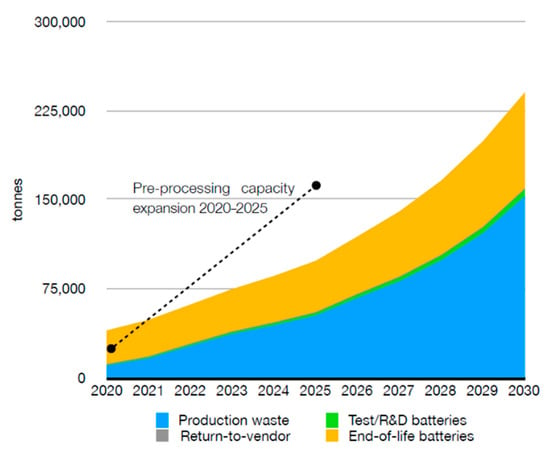

Scrap may be composed of trimmings or rejected product from several process steps, but it contains fewer components, is likely to be unpackaged, and is of known composition. ReCell scientists have already demonstrated that recovered cathode material from manufacturing scrap can be used in new cells directly, without any need to upgrade it. Scrap is an important feedstock for North American recyclers such as Li-Cycle and American Manganese. Redwood Materials gets scrap from Panasonic, which “alone provides approximately one gigawatt of material annually and (also) a dozen other partners contribute a similar amount, for a total equivalent of approximately 20,000 tons of material per year” [7]. In China, Hunan Brunp mainly produces ternary precursors for power batteries, using battery scraps from Contemporary Amperex Technology Co. (Fujian, China), Limited (CATL) as its main feedstock [8]. Figure 2 shows one analyst’s view that production scrap will become the dominant source of material for recycling plants.

Figure 2.

Total volume of LIBs available for recycling in the United States (courtesy of Circular Energy Storage).

2.3. Exports

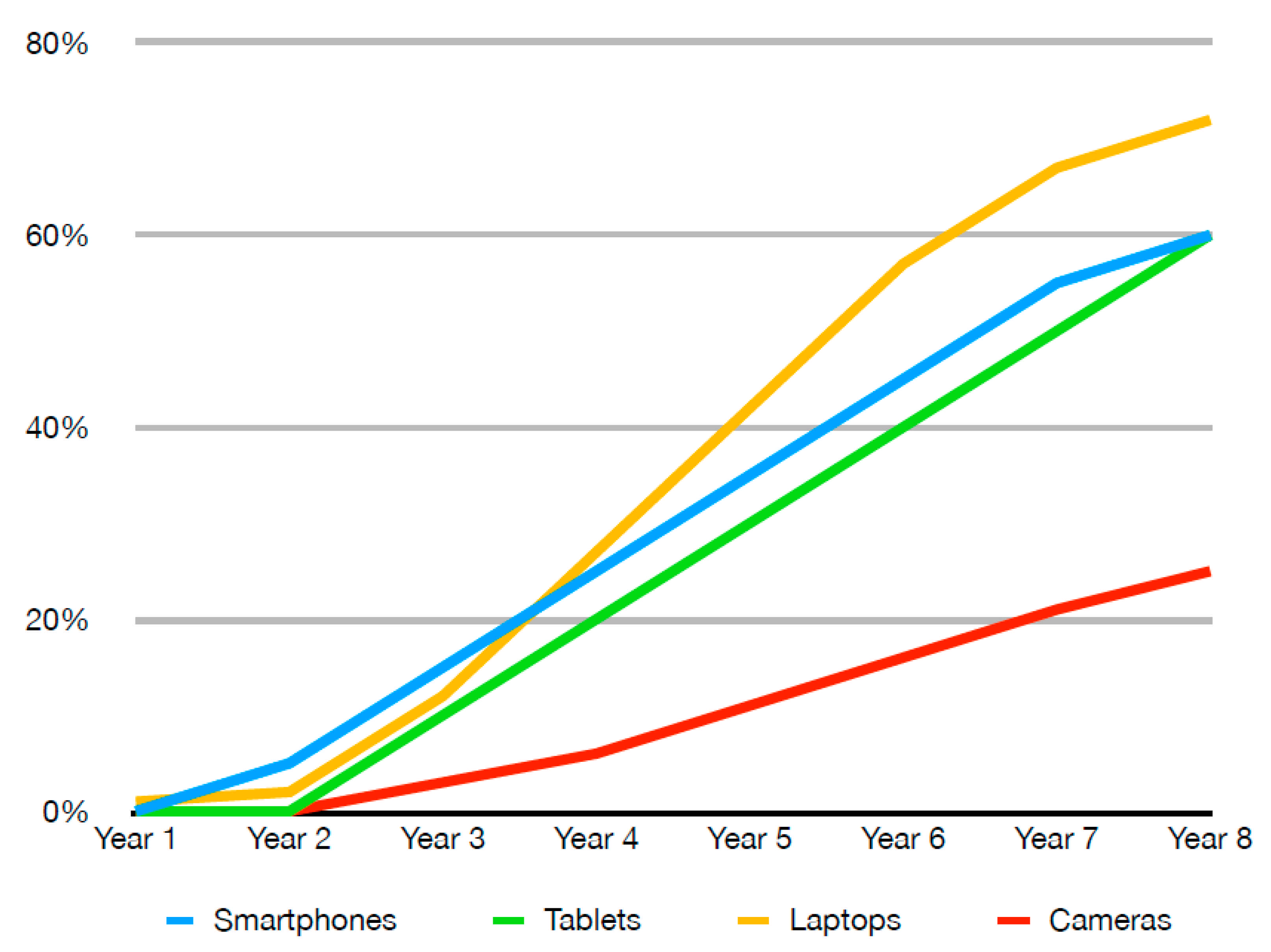

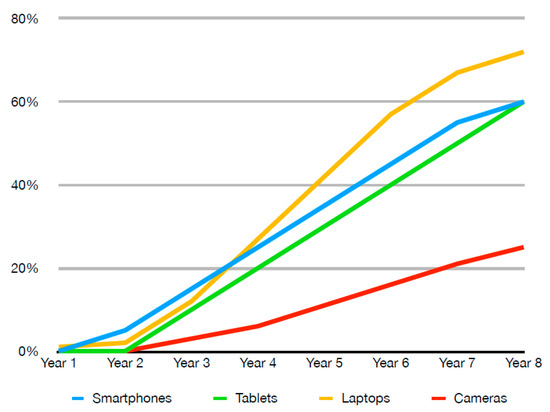

Exports reduce the quantity of material available for recycling in the United States. When still-functional portable electronic devices in the United States are replaced by newer models, sometimes the older devices end up stored away in drawers or trashed. More often, they are sold or given away to other consumers who do not demand or cannot afford the latest technology. Used devices are often sold overseas, still containing their batteries, which again leads to the export of valuable material resources (see Figure 3).

Figure 3.

Export ratio of portable electronics that contain LIBs in Europe and the United States (estimate courtesy of Circular Energy Storage).

This phenomenon is not limited to consumer electronics. Electric vehicles (EVs) and their batteries are also being exported. Of the approximately 500,000 Nissan Leafs produced as of 2019, approximately 94,000 were registered in the countries of Ukraine, Jordan, New Zealand, Sri Lanka, and Georgia [9]. EVs are more attractive imports than internal combustion engine vehicles in many nations, because they are subject to much lower import duties.

Tracing the flows of used batteries is difficult. There is commerce in used batteries, both through dedicated businesses and domestic and overseas sales on the open market on outlets such as e-Bay. In addition, some small batteries end up in landfills, where they have been blamed for causing fires. The DOE’s Battery Recycling Prize aims to avoid such problems by finding ways to capture 90% of used batteries for recycling [10].

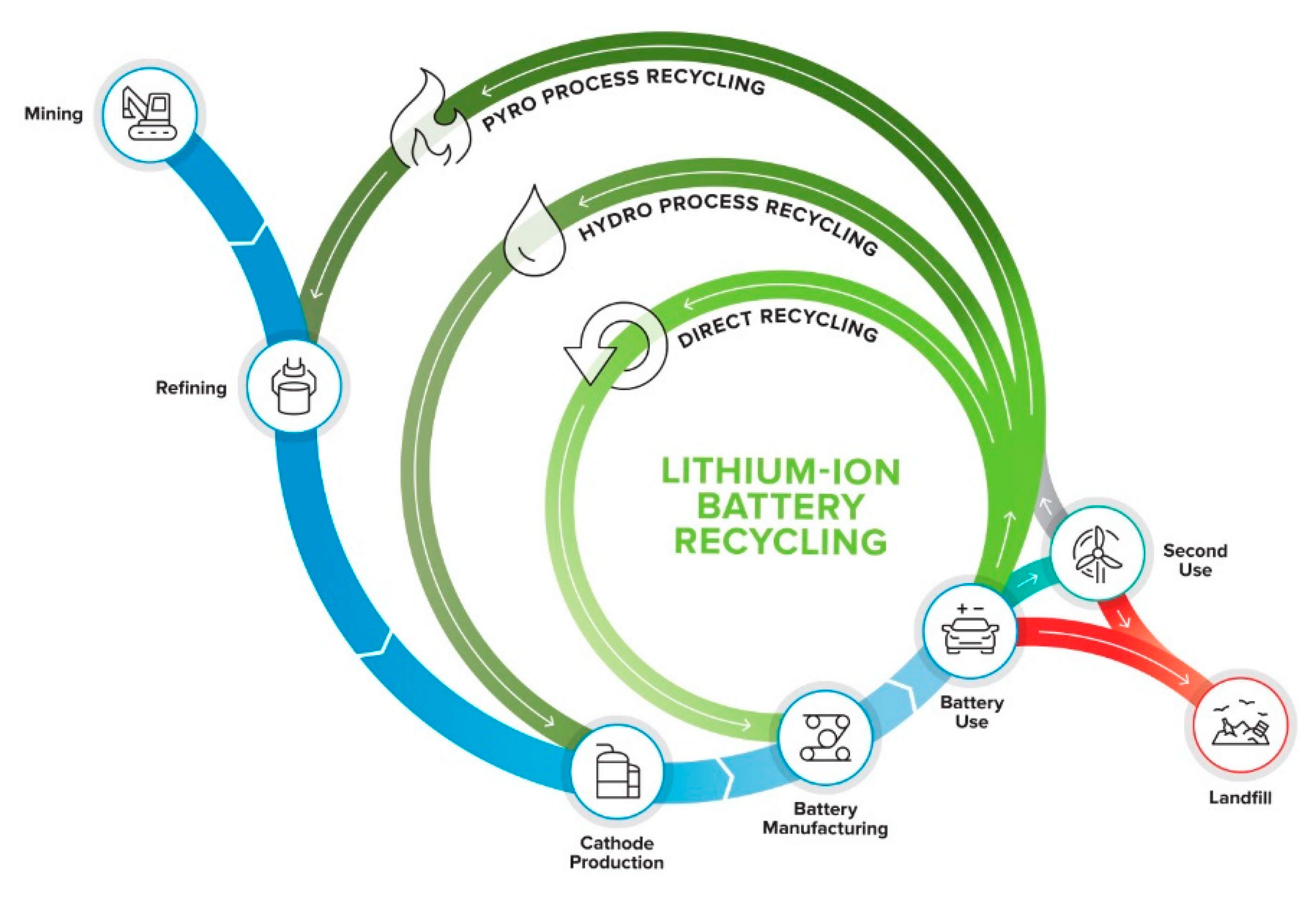

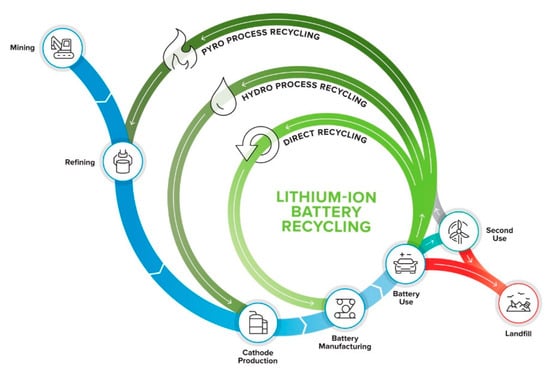

3. Recycling Processes and the Circular Economy

What is the best thing to do with recovered materials? In an ideal circular economy [11], we would extract materials from the earth, use them to make a product, and reuse the product repeatedly. Whatever refurbishment or repair is necessary would not require extracting additional materials. The options for used products form a hierarchy, with those requiring minimal new resources at the top. For Li-ion batteries, reuse in less-demanding applications such as low-speed vehicles or stationary storage is gaining some acceptance. However, eventually batteries can no longer hold sufficient charge for even those uses; at this point, they have reached their end of life. However, in keeping with circular economy thinking, we recognize that spent batteries are still a valuable resource that can be recycled. Several methods can be considered.

3.1. Recycling Process Comparison

Li-ion batteries are already recycled commercially using well-known processes, but these processes do not extract the maximum value from their feedstock. Pyrometallurgy, or smelting, treats the input as if it were an ore, exposing it to a high temperature (over 1100 °C) to volatilize, combust, or melt and reduce all of the components of the cell. The product is a mixed alloy of cobalt, nickel, and copper, which must then be treated hydrometallurgically to separate the component metallic elements. All of the organic (carbon-containing) materials—the carbon anode, plastic separator, and electrolyte solvents—are oxidized and lost. The lithium and aluminum are entrained as oxides in the process slag, and it is generally not economical to recover them. Both the electrolyte salt and the binder contain fluorine, so an expensive gas-treatment system is required.

Hydrometallurgy, or leaching, is used in several large new plants in China and Korea. Cells are shredded, with the product sieved to remove pieces of the copper and aluminum foil current collectors (which are then sent to a copper recycler). The remaining material is dissolved in strong acid to break up the crystal structure of the cathode material. The carbon anode does not dissolve and could be recovered if doing so were economical. A series of solvent extraction and precipitation processes separates the different metal ions, which can then be used to produce cathode precursors such as cobalt sulfate. As with pyrometallurgy, the value of the product lies in its cobalt content, and to a lesser extent its nickel content. For cathode materials such as LMO and LFP, little value can be extracted, although some recyclers in China do recover lithium [12].

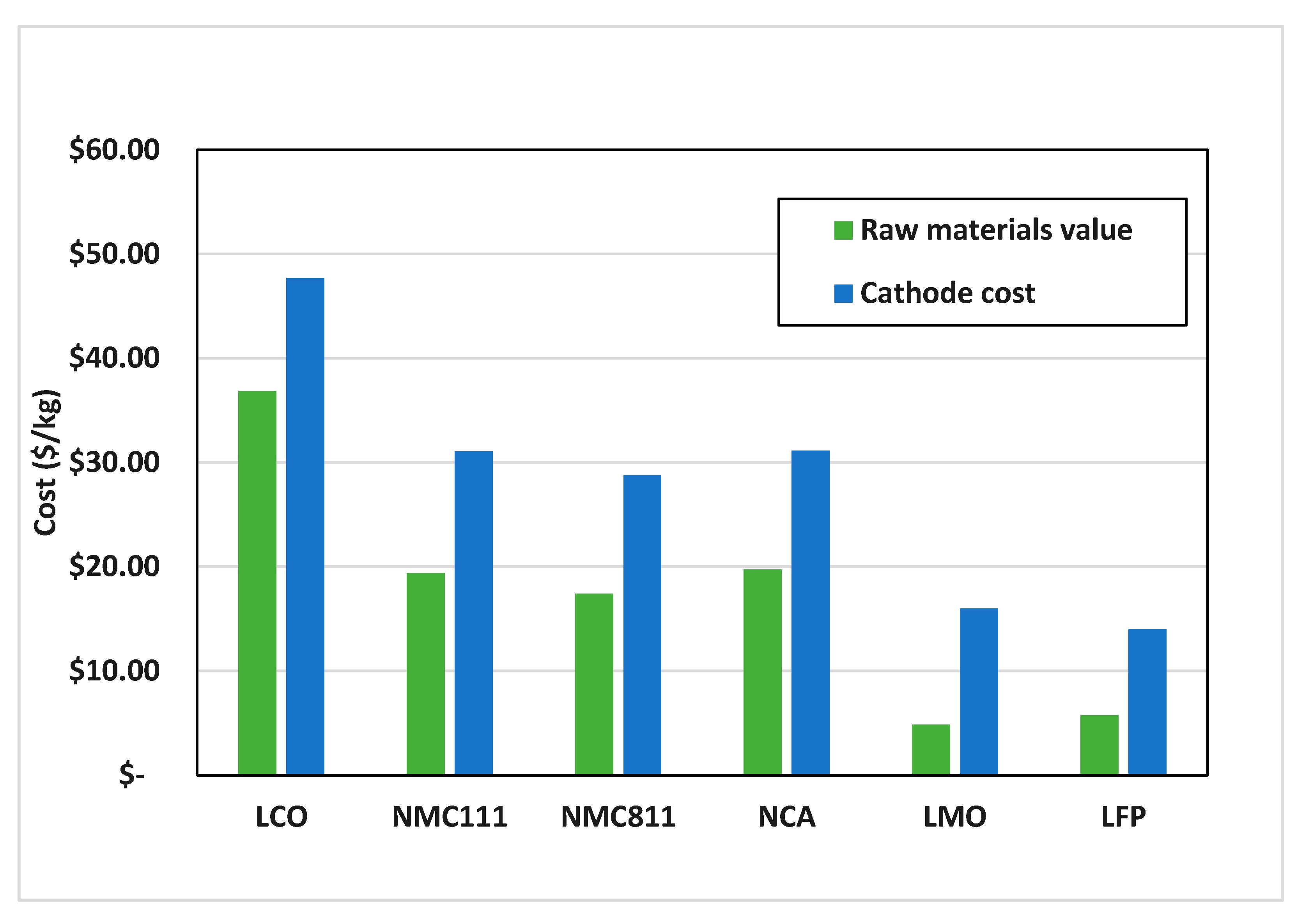

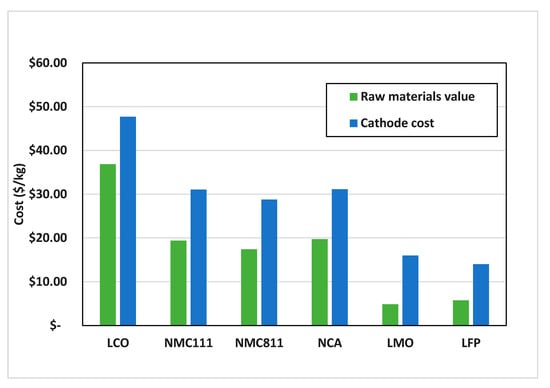

However, if the structure of the cathode material could be retained during recycling, a valuable material could be recovered from cathodes made from lower-valued elements. This is particularly important for automotive batteries, because there is a clear trend toward using cathode formulations with lower cobalt content, especially high-nickel NMCs. Figure 4 compares the value of battery-grade cathode material to that of its constituent elements. For high-cobalt cathodes (e.g., LCO), the elemental value approaches that of the intact cathode, but for low- or no-cobalt cathodes, the value that can be recovered from the elements is negligible and would not justify the cost of recycling.

Figure 4.

Estimated cathode cost vs. constituent cost.

The concept of direct recycling is simple: keep the cathode crystal structure intact. It was first patented in 2009 [13,14]. We define direct recycling as the recovery, regeneration, and reuse of battery components directly without breaking down the chemical structure. It has also been called direct cathode recycling and cathode-to-cathode recycling.

By recovering cathode material, several energy-intensive and costly processing steps can be avoided; this is shown schematically in Figure 5. The scope of ReCell R&D also includes the recovery of as many of the materials as possible, in keeping with circular economy principles. Not only does recovery of more materials offer potential additional revenues, but costs and other impacts from waste treatment can be avoided.

Figure 5.

Lithium-ion battery lifecycle.

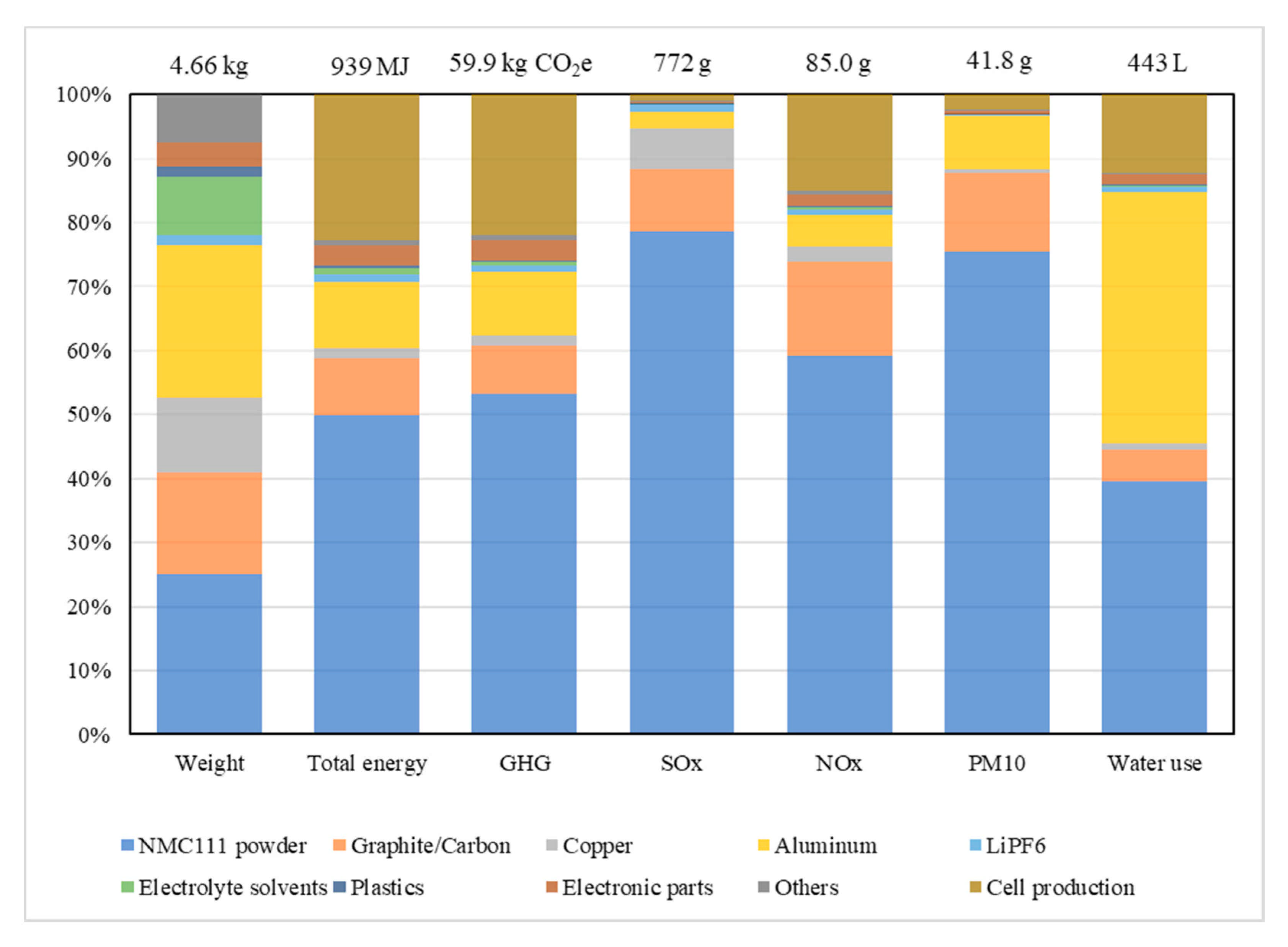

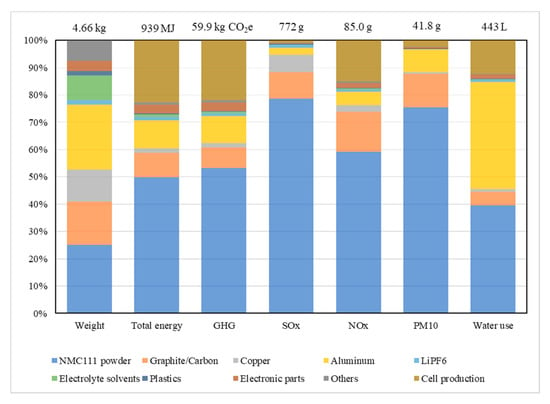

Direct recycling could be used now for manufacturing scrap. Advantages include low temperatures and low energy consumption, and the avoidance of most impacts from virgin material production. Lifecycle analysis of a lithium-ion battery (Figure 6) shows the contributions to various impact factors from the production of the various battery components. NMC powder makes a large contribution to all categories—particularly SOx and particulate matter (PM)—so its recovery in usable form minimizes impacts. We will discuss challenges in the context of more detailed process discussion in Section 4.2.

Figure 6.

Cradle-to-gate environmental impacts: 1 kWh NMC111 cells.

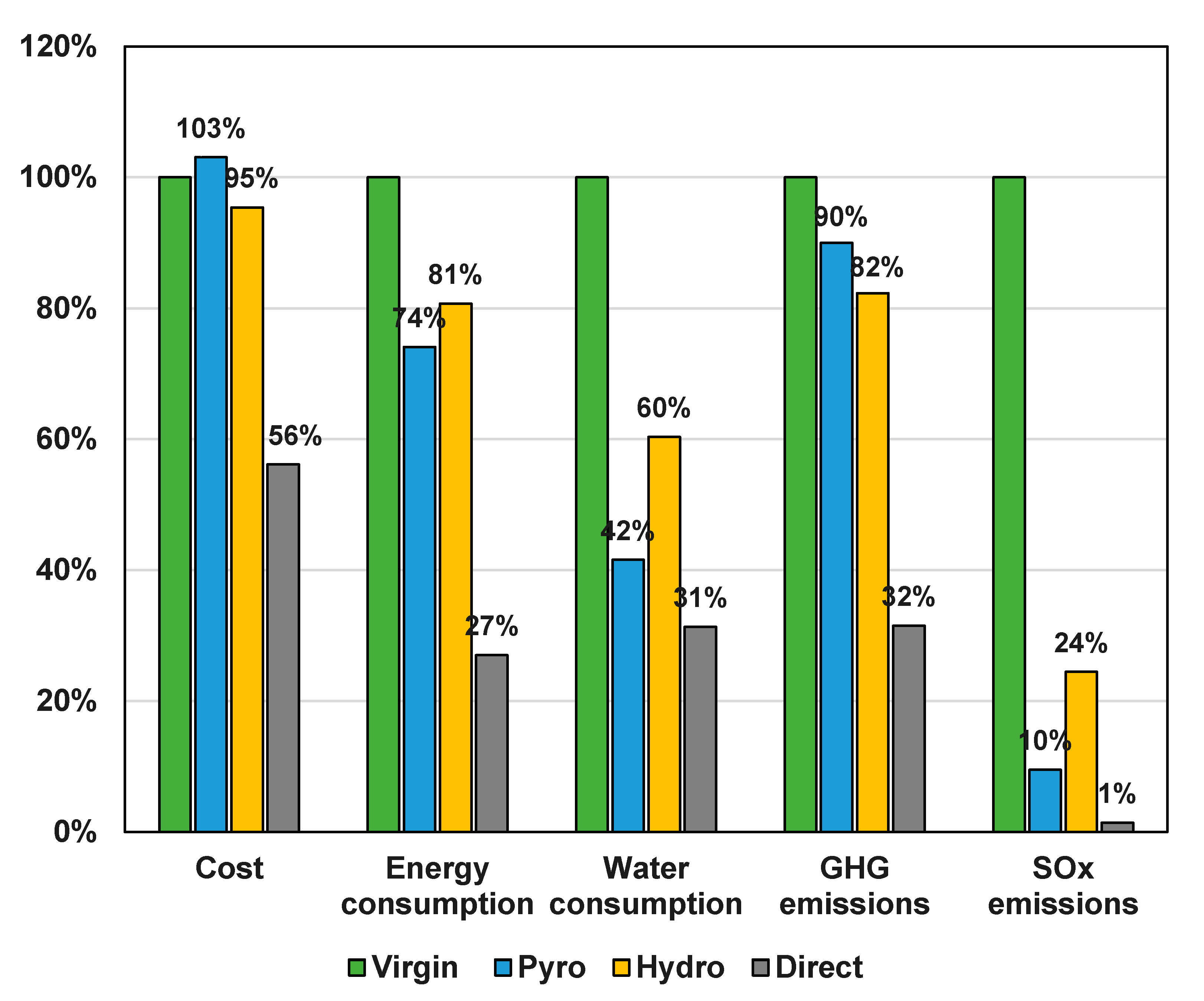

3.2. Recycling Process Comparison and the EverBatt Model

To develop the best process possible, it is necessary to have an appropriate set of tools and metrics with which to compare different process options. The EverBatt model is an Excel-based model that uses energy and environmental impact data from the Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies Model (GREETTM) model and cost and material quantity information from BatPac; both of these models were developed by Argonne and are publicly available. EverBatt is also available for free download, along with a user manual [15]. It provides technoeconomic analysis of different recycling pathways, adapts to differing battery chemistries and formats and cathode/cell production methods, and can be extended to future battery chemistries or different products. The model won an R&D100 award in 2019.

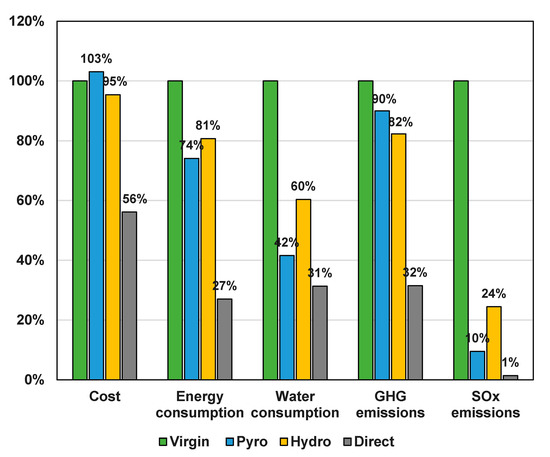

EverBatt models a closed loop of cell production from either virgin or recovered materials and back around through the end of life. It can be used to compare costs and impacts, such as energy and water use, greenhouse gas emissions, and emissions of criteria pollutants, for the production of materials or cells from virgin raw materials to impacts from different recycling processes. It can also be used to explore sensitivity of costs and impacts to different parameters. In addition, as we will show in Section 4.2.4, it can be used to compare different unit processes for a given process step, or similar process chains at different scales. Unit processes will also, of course, be compared on the basis of performance (see Section 4.2.4). Figure 7 compares the costs and selected environmental impacts to produce 1 kg of NMC111 from virgin raw materials and recycled pyrometallurgically, hydrometallurgically, and by direct recycling, all at large commercial scales (50,000 T/y). Direct recycling is shown to have the lowest impacts in all categories.

Figure 7.

Cost and environmental impacts to produce 1 kg NMC111.

4. Direct Recycling Process Development

A complete direct recycling process would be composed of a series of unit operations, such as those shown in Figure 8. This is just one possible chain of operations. The order could be varied to reduce cost or improve overall efficiency, and steps may be combined or omitted. As work continues, we will refine our evaluation of what is the optimum order. The best process chain could vary depending on the composition of the input material stream or the scale of operation. Determining optimum process chains will involve comparison of technoeconomic factors as well as performance, and key parameters (e.g., scale, transport distance, Co content).

Figure 8.

Possible direct recycling process order.

Unit operations of interest are discussed in Section 4.2.2, Preprocessing; Section 4.2.3, Separation Processes; and Section 4.2.4, Product Upgrading.

4.1. Preprocessing

Preprocessing consists of collecting material to be recycled, getting it to the recycling facility, and preparing it for processes to recover valuable components.

4.1.1. Collection, Transportation, and Sorting

Actually getting batteries to a recycling facility is not included in the scope of the ReCell Center; rather, our mission is to develop a system that will enable a spent battery cell to be processed economically into a new cell with equivalent—or even better—performance and make this technology available to American industry. However, since it is common knowledge that many batteries do not actually make it into the recycling system, the U.S. Department of Energy’s Vehicle Technologies Office also established the $5.5 million Battery Recycling Prize in early 2019, at the same time it established the center. The goal of this prize is to incentivize the development of innovative ideas that will enable collection of 90% of all end-of-life lithium-ion batteries in the United States for recycling. This will include not only automotive batteries, but also those from personal electronics and stationary storage. As of this writing, seven projects have received Phase II funding. Phase II winners receive $357,000 in cash, as well as $100,000 in vouchers to use at U.S. national laboratories and other approved organizations. Winners will advance to the third and final phase of the prize, pilot validation [16].

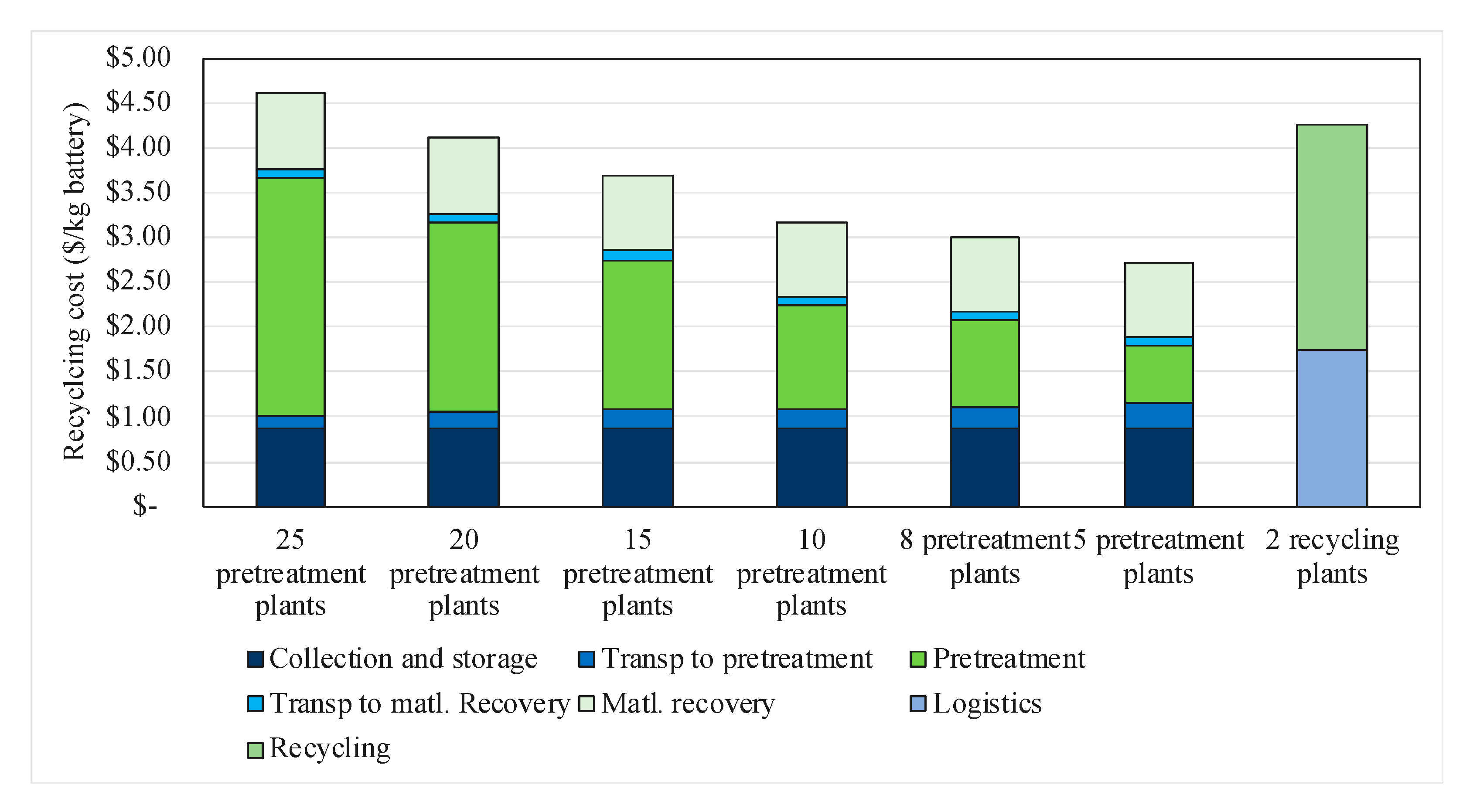

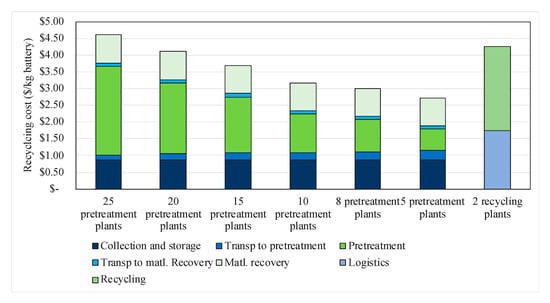

Transporting used batteries is expensive because they are classified as Class 9 hazardous substances. There is, therefore, an incentive to minimize transport distance. On the other hand, recycling plants exhibit significant economies of scale, which implies that it would be necessary to collect feedstock from a large area. One solution to this dilemma is to perform sufficient processing of the batteries near their source to make them non-hazardous for economical shipment to the main processing facility. Of course, preprocessing facilities would exhibit some economies of scale as well. Pretreatment plants need to be spread out in order to reduce transport costs, but they still need to be large enough to enjoy economies of scale. The EverBatt model captured these tradeoffs in Figure 9, which compares costs for a large hydrometallurgical recycling plant receiving material directly to those with different numbers and sizes of pretreatment plants feeding it. In this example, the optimum number of pretreatment plants is five, reducing the cost of recycling from over $4/kg to under $3/kg. Therefore, all the unit processes for recycling spent batteries may not take place in the same location. Li-Cycle, a new Canada-based recycler, has recognized this situation, and is siting 5000 ton/year “spoke” preprocessing plants to feed its proposed 25,000 ton/year hydrometallurgical “hub” [17].

Figure 9.

Total costs of deploying multiple distributed pretreatment facilities with a combined capacity of 50,000 tons/year, plus two hydrometallurgical facilities with a combined capacity of 30,000 tons/year, compared to that for two hydrometallurgical facilities with a combined capacity of 50,000 tons/year without pretreatment.

4.1.2. Disassembly

An automotive battery pack is both large and complex. Groups of individual cells are combined into modules, which are in turn packaged together into a specially designed housing with electrical connections and a battery management system. It may also have a cooling system. At the cell level, there is no standard cell chemistry or form factor, nor is there a standard module or pack design. This means that there can be a variety of products on the market at the same time, but it also complicates recycling. The ReCell Center is specifically concerned with recovering the valuable materials that are contained within the cells. Processes described here apply to cells from various consumer products as well as those from electric vehicles.

Disassembly is the process that takes apart a product at its end of life and yields components of a size and shape appropriate for further processing. All the recycling methods described above require some degree of disassembly. Pyrometallurgy can accept whole modules as feed, but both hydrometallurgy and direct recycling start with cells.

Disassembly would be the ideal way to separate spent cells into their uncontaminated components. However, manual disassembly is labor intensive, and advanced robotics would be required to handle a variety of cell designs that are not meant to come apart easily. Newer large cell designs such as the Build Your Dreams Auto Co., Ltd. (BYD) Blade may enable easier cell disassembly. In the meantime, researchers are working on robotic disassembly [18,19]. One company in Switzerland has a semiautomated process, but it is only designed to operate on the single cell design they use for their small mail delivery vehicles. The top of the cells are sliced off, and the cell contents pushed out. The electrodes are unfolded and separated using a manually assisted device [20]. In addition, of course, Apple has its Daisy robot that can disassemble a single product design (iPhones) [21].

4.1.3. Size Reduction

Size reduction is necessary if the cell cannot be disassembled. Because our focus is on what to do with the materials from spent cells, the ReCell team started by simply shredding cells. Other researchers are also considering shock wave technology [22] and methods of punching out most of a pouch cell. Toxco (now Retriev) used liquid nitrogen to inactivate the lithium in primary lithium cells and then put them in a hammermill, which shatters the material.

The output from different shredders is being compared to determine which produces material most amenable to further processing. Shredding causes some material loss via fine particles that are difficult to remove or subsequently process; this may lead to impurities in the process stream, which could negatively impact the performance of the resultant products. Hammermills were also tried, but the output contained as much as six times the quantity of fines. The impurities in the black mass are most likely to be fragments of the current collectors. Therefore, experiments were performed to assess the effects of small quantities of copper and aluminum in recovered cathode product. Although metal fragments could cause shorts, small quantities of copper ions were actually found to improve cathode performance; similarly, aluminum ions improved capacity at very low levels but reduced it at higher levels [23,24]. Cell components such as packaging and separator pieces would be separated downstream, using other methods such as magnetic separation and air classification.

4.2. Separation Processes

After shredding, a feedstock of anode and cathode on their current collectors is generated. This feedstock contains the most valuable components in a lithium-ion cell, including black mass (e.g., active cathode materials and graphite), electrolyte, Cu foils, and Al foils. This section describes some highlights of the separation processes that are being used as part of the direct recycling process chain. The tools we are using are expected to have applicability beyond battery recycling.

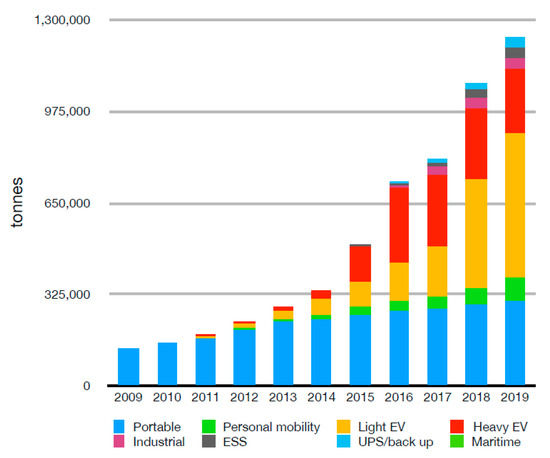

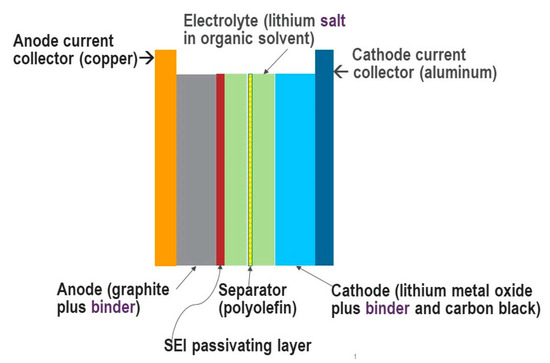

A lithium-ion cell is made up of many layers; the cross-section of one such layer is shown in Figure 10. Not only are there many components within each layer, but several of the components themselves are mixtures of material. In order to recover the highest-value products, these materials must all be separated from each other. Eventually, we need to separate electrolyte from shreds, electrolyte salt from solvents, active material from current collector foil, Al and Cu foils from each other, anode powder from cathode, different cathodes from each other, impurities from active material, binder from cathode and anode powders, and solid electrolyte interphase (SEI) from electrode powders. The initial emphasis is on recovering cathode material, since it is the most valuable product present in spent batteries.

Figure 10.

Cross-section of one layer of a lithium-ion cell.

Many of the potential separation processes are based on exploiting differing properties of the materials that are combined. Types of properties include density, magnetic susceptibility, electrical conductivity, hydrophobicity, solubility, volatility, and temperature or pressure dependence of mechanical properties (in other words, it shatters when frozen). The following are some types of processes that could be used to separate materials:

- Solvent extraction/dissolution;

- Precipitation;

- State or property change with temperature;

- Chemical replacement or addition;

- Gravity separation;

- Distillation;

- Froth flotation;

- Surface modification;

- Electrochemical processing;

- Microwave, ultrasonics, or other irradiation.

4.2.1. Electrolyte Recovery

Electrolytes must be removed from electrode materials to enable downstream processing. This can be done in one of several ways: supercritical CO2 extraction, thermal drying, water washing, or solvent extraction. Of these, only supercritical CO2 with added co-solvent or solvent extraction can recover the LiPF6, which is the most valuable component of the electrolyte and could prove problematic in a waste stream.

The electrolyte salt can be extracted by diethyl carbonate, and then reconstituted to obtain electrolyte with cycling performance exceeding that of 1.2 M LiPF6 in 3:7 EC:EMC electrolyte in full cells. Recycled electrolyte from a Nissan Leaf battery performed better that that from a Chevrolet Volt in initial tests. Current work at the center seeks to further purify the LiPF6 salt in a cost-effective manner. Initial testing indicates that 2000 psi supercritical CO2 extraction can remove approximately 90% of the propylene carbonate (PC) from LiPF6.

4.2.2. Delamination: Separation of Active Materials from Current Collectors

After battery shredding, electrolyte recovery, and separation of components such as plastics, cell casing, and magnetic ferrous-based metals, we are left with electrode fragments that include anode on copper foil and cathode on aluminum foil.

Staff at Oak Ridge National Laboratory developed an ethylene glycol-based separation process to efficiently delaminate electrode materials from current collectors. Both cathode and anode films can be completely peeled off from metal foils using a rapid and efficient process. The recovered battery materials, especially NMC cathodes, are damage-free in terms of crystal structure and microstructure and are equal to their pristine cathode counterparts in terms of electrochemical performance. The recovered metal foils show no sign of corrosion or residues, which makes it possible to reuse them in a new loop of battery manufacturing and thereby lessen the carbon footprint of mining and refining.

This robust separation process operates at a low temperature and is scalable. Ethylene glycol (EG) is a commodity and low-toxicity chemical. Every year, 20 million tons of EG are used as antifreeze and polymer precursor. The EG separation process can be deployed in battery manufacturing plants, ensuring that the generated electrode scraps can be treated onsite safely and reprocessed as new electrodes, with a potential saving of up to 10%. Moreover, ethylene glycol can be reused to close the recycling loop without generating secondary waste. Overall, EG-based separation is a sustainable electrode recovery process that greatly advances battery recycling [25].

A sequential process in which only one of either anode material or cathode material was released from its substrate would enable anode and cathode materials to be separated from each other before they are mixed together into a black mass. For instance, water could be used for anodes that have water-soluble binders. This would avoid the need for an anode–cathode separation step, considerably simplifying the direct recycling process.

4.2.3. Anode–Cathode and Cathode–Cathode Separation by Froth Flotation

Froth flotation is a well-established process on large scales in the mining industry. It has proven to be effective in separating anode and cathode active materials. However, the presence of poly(vinylidene difluoride) (PVDF) binder and carbon black in cathode composites results in a loss of cathode materials during the recycling process. In addition, the presence of a hydrophilic solid electrolyte interphase layer after cycling changes the surface properties of the anode material, causing a decrease in the purity of the recovered cathode material.

We used thermal pyrolysis to decompose adhering PVDF binder and carbon black as well as the solid electrolyte interphase layers. Our hypothesis is that anode materials become hydrophobic, while cathode active materials become hydrophilic during thermal pyrolysis, enabling good separation between anode and cathode materials [26].

Gravity separation of anode and cathode materials in various solvents is also under investigation.

Li-ion cells may use more than one type of cathode active material in a given design, and different manufacturers use different materials, so a stream for recycling could contain a mixture of cathode types. The highest-value product from direct recycling would be separated by chemistry; therefore, it is desirable to separate different cathode active materials prior to upgrading.

We successfully demonstrated that a number of binary cathode mixtures can be separated from each other by froth flotation. The separated products have a purity of more than 98% after multiple stages of froth flotation. Good separation between pristine NCA and LMO as well as between NMC111 and LMO has been achieved. The LMO is undamaged electrochemically during the water-based separation process, but both NMC and NCA are prone to capacity fade. However, separation in a high-solids slurry or in LiOH solution preserves the original capacity.

Pilot-scale separation of binary and ternary cathode mixtures has been demonstrated by exploiting their differing magnetic susceptibilities within a magnetic field [27].

4.2.4. Binder Removal and Recovery

Once cathode materials are separated, the PVDF binder needs to be removed to allow for further processing. This can be done by dissolving it in n-methyl-2-pyrrolidone (NMP), but doing so is not cost effective. As an alternative, thermal decomposition was demonstrated by ReCell staff. This has the advantage of producing no liquid waste and can be performed at temperatures as low as 500 °C. The key is slow ramping of the temperature plus the addition of a small amount of excess lithium to prevent lithium removal from the remaining materials.

Another project evaluates Soxhlet extraction to remove and recover the polymer binder. In this method, samples are repeatedly extracted with dimethylformamide solvent that is regenerated by distillation. Solvent use is minimized, and the process can be scaled up to the manufacturing scale.

A different novel process enables separation of spent cathode from binder using Cyrene as the solvent, with the aid of sonication. The PVDF can then be recovered from the solvent and both recycled [28].

4.3. Product Upgrading

4.3.1. Relithiation

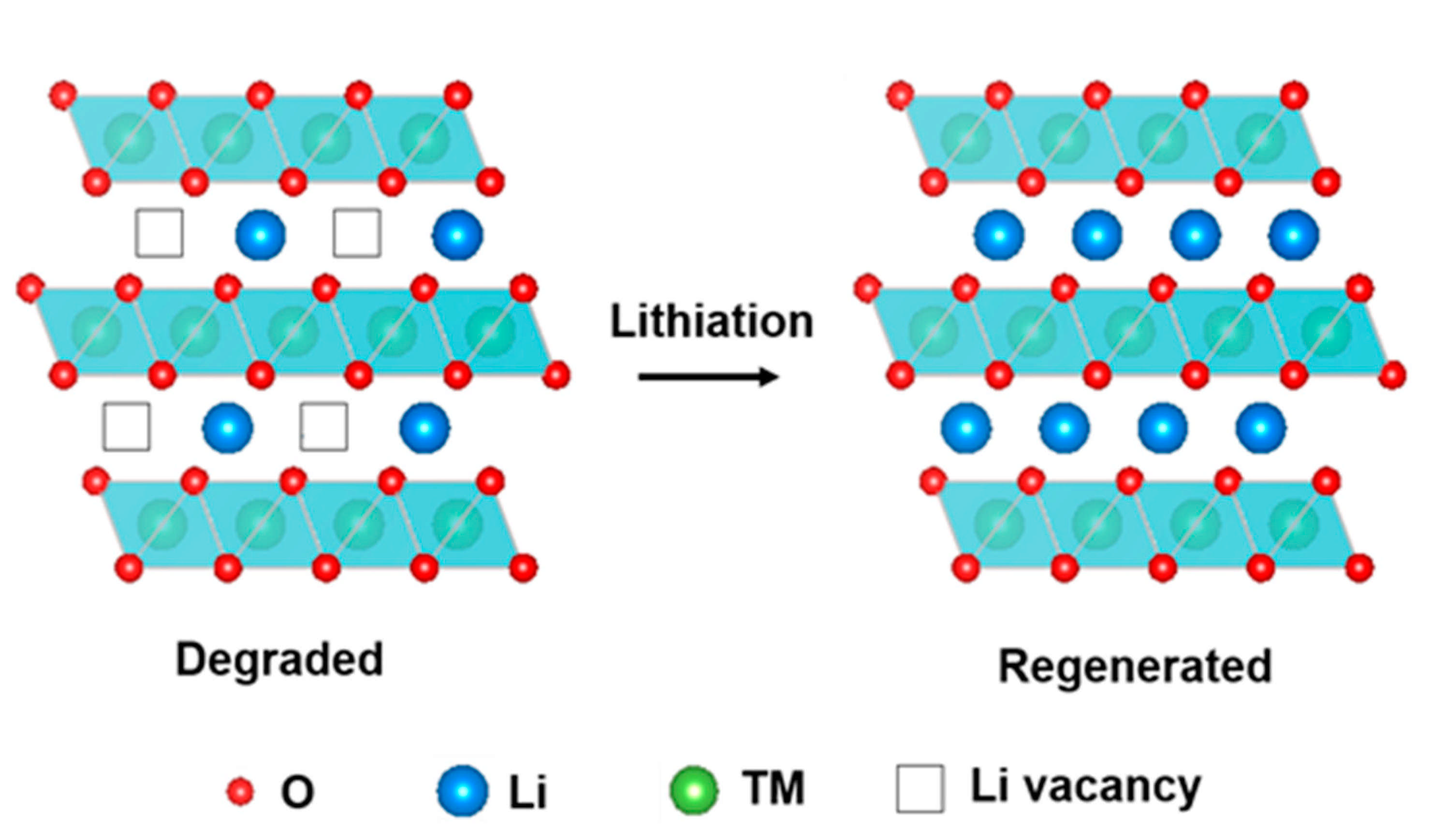

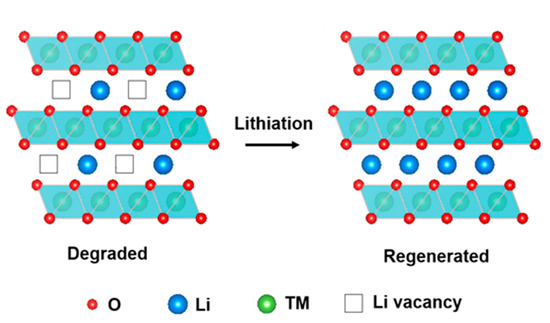

During repeated cycling, a fraction of the lithium is lost from the cathode material via reactions with the electrolyte, inclusion in the anode SEI, or electronic isolation at the graphitic anode. This causes a decrease in cell capacity and makes performance unacceptable. Therefore, cathode material recovered from spent batteries must be restored to original performance by relithiation, defined as adding back the lithium that was gradually lost during operation. This is shown schematically in Figure 11. It may be possible to recover the lost lithium. Analysis of one sample of anode material from a cycled cell revealed that it contained approximately 16% of the lithium that was originally in the cathode. Future study of the anode material will investigate ways to recover this lithium [29].

Figure 11.

Relithiation of degraded cathode material.

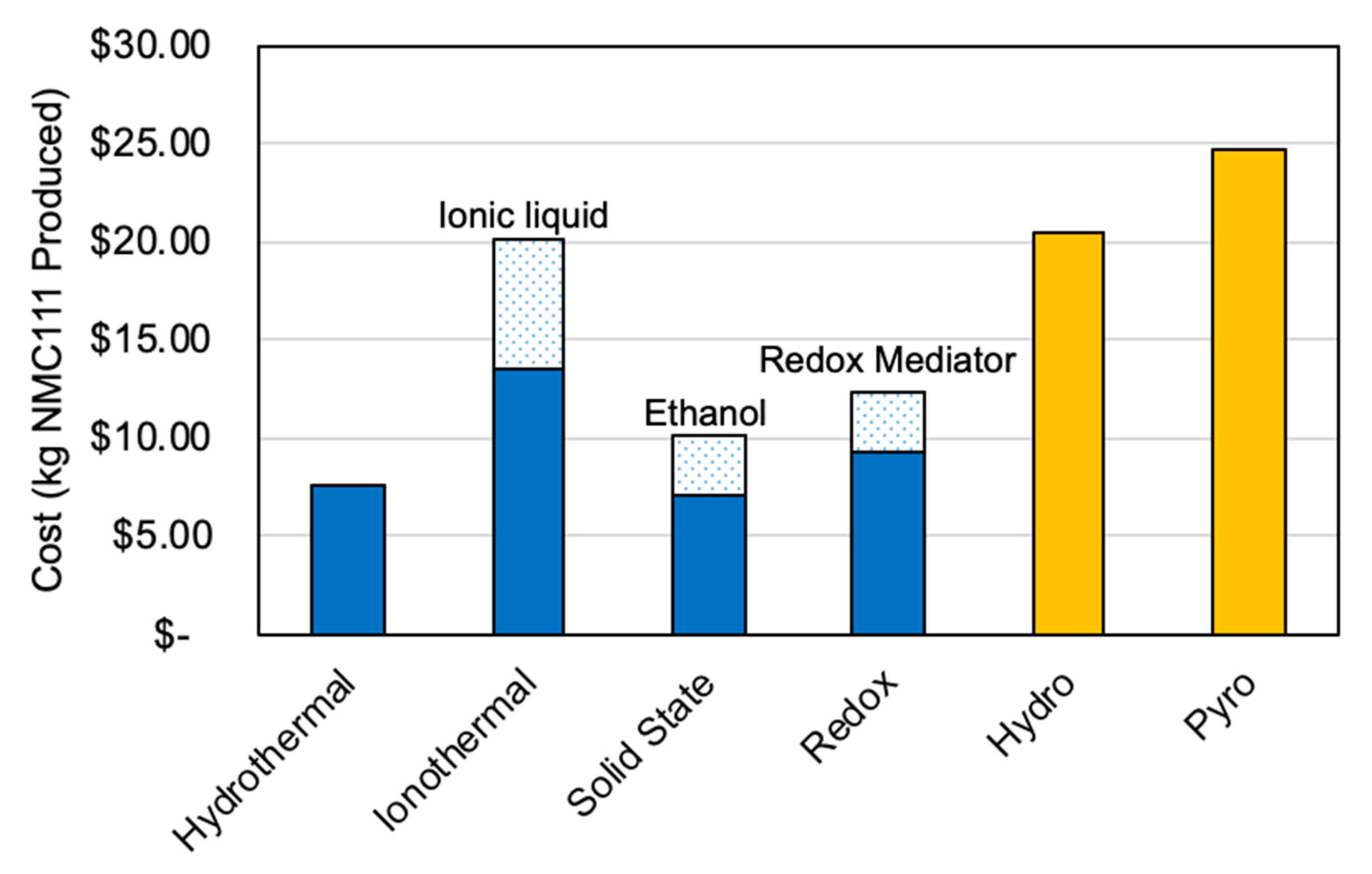

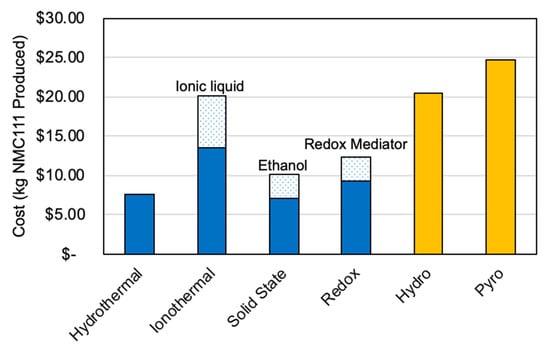

Several novel methods for relithiation have proven to be effective; the ReCell Center is currently comparing them using the same input material, and the most promising ones will be selected for scale-up. Key features of the different relithiation processes are summarized in Table 1. In addition to performance measures such as capacity and cycle life of the cells made from the product material, EverBatt is being used to evaluate the processes and help direct process development. Initial cost estimates for commercial-scale plants (Figure 12) reveal that all of the processes promise recycled cathode at costs below those of currently available processes, with the lowest being the hydrothermal process. In addition, analysis showed that material inputs represented a significant contributor to costs, and that costs could be reduced by replacing or reducing the use of the ionic liquid in the ionothermal process, redox mediator in the redox process, and ethanol in the solid-state process. These improvements are being realized.

Table 1.

Comparison of relithiation process characteristics.

Figure 12.

Cost comparison for cathode relithiated by different methods. Dotted bars represent potential cost reductions by closed-loop recycling of key materials; blue bars represent other costs for 10,000 ton/year direct recycling plants; yellow bars represent costs for 10,000 ton/year pyrometallurgical (pyro)/hydrometallurgical (hydro) recycling plants plus costs to convert recovered materials into cathode powder.

4.3.2. Upcycling

Cathode formulations for EVs are rapidly evolving toward higher-energy, high-nickel materials that are different from those used years ago. As a result, cathodes recovered by direct recycling relithiation processes could be 10 or more years out of date compositionally and may not be in demand in the current marketplace. In order to convert these materials to a formulation useful for current automotive batteries, ReCell scientists have developed the concept of “upcycling,” which we define as upgrading a cathode material by chemically changing its composition to reflect the stoichiometry of more desirable cathode formulations. An example would be conversion of NMC111 into NMC622.

The first candidate for upcycling was a lithium-rich NMC111 (used in General Motors Chevy Volt), which years later is being used in a diminishing percentage of commercial energy storage systems. Initial upcycling experiments targeted the transformation of NMC111 to NMC622. Using several different approaches, similar to the relithiation techniques, nickel was added to the surface cathode crystal structure. This process is more challenging than replacing lost lithium. For the lithium cation replacement, the vacancies already exist and a percolation network exists to equilibrate the sample, especially with the addition of heat to the system (see Table 1 and Figure 11).

For these NMC111 materials, the first step is lithium addition to fill surface vacancies to eliminate these sites as a place for the added Ni(II) to join the lattice. If nickel fills these former lithium sites, the favored surface structures, observationally, are spinels (M2O4) or rocksalt (NiO) compounds depending on temperature and time used. Initial studies focused on addition of Ni(OH)2 to the relithiated surface and annealing with a stoichiometric amount of LiOH, in a manner similar to the original synthesis method of these NMC materials. Followed by annealing in oxygen, the samples initially are physical mixtures of NMC111 and LiNiO2, which on annealing can be equilibrated to a more uniform NMC622.

Initial results are promising for controlling the final stoichiometry and the desired electrochemical performance. This method can be adapted to other cathodes including various LiMn2O4 spinels and Li(NiCoAl)O2 (NCA). Changing the overall stoichiometry while maintaining the structure means that many variables need to be understood and controlled. These include coating stoichiometric control, finding a precursor of the same structure type, and blocking nucleation at the interface of a phase that hinders cation diffusion. Synthetically, the two main variables to be optimized are time and temperature that control the homogeneity of the final product.

Because the exact materials needed in the future are unknown, the development of a general method of compositional upcycling is a key aspect of the process development. For instance, the use of some higher-nickel chemistries may rise rapidly, then fade as its market is displaced by a new formulation; this would make these chemistries candidates for upcycling. Any chemistry whose demand starts to fall may require upcycling as few as 10 years later. For instance, if Avicenne’s cathode demand projections [30] are correct, NMC532 could be ripe for upcycling around 2030.

If upcycling proves successful, it would be interesting to introduce a feedstock of mixed NMC materials requiring upgrades. This could enable omission of the cathode–cathode separation step.

4.4. Requirements for Industry Acceptance

There is little point to applied research if the technology is not accepted by industry. The first thing that is needed, before industry will consider adopting a new process, is assurance that the product performance matches or exceeds that of whatever they are currently using. Therefore, product validation is a key aspect of the ReCell program. Material produced during each unit operation is tested in cells and its chemical composition and crystal structure verified (by x-ray diffraction [XRD], inductively coupled plasma [ICP], or glow-discharge optical emission spectroscopy [GDOES]). Cell capacity and cycle life must match original performance. Of course, any new process must also be demonstrated beyond bench scale. Initial scale-up work is being carried out by ReCell, but pilot-scale work will require industry partners. The program objective is to provide material suitable for return to the automotive market, although product that does not meet that standard could be sold into other markets.

Industry must also be assured that product can be supplied reliably in sufficient volume and quality. That means that a supply chain for spent battery or scrap material supply must be developed. Battery manufacturers (such as Panasonic) can contract with local recyclers (such as Redwood Materials) and ensure both an outlet for their scrap and a source for material.

Industry is more likely to be comfortable adopting processes that closely resemble ones that they are already familiar with. Unfamiliar techniques may be regarded as risky. Industry is also more likely to adopt processes that use mild conditions and common reagents and do not require specialized equipment. Of course, these factors are connected with cost as well.

A barrier that must be overcome is that, historically, industry has been reluctant to purchase and use recycled material, especially for premium or high-performance applications. For instance, the tire industry does not generally purchase recycled rubber. However, if industry can be assured that strict performance specifications are consistently met, they may be willing to purchase recycled materials whose price is well below that of virgin material.

Another possible push (a stick rather than a carrot) would be regulatory requirements forcing either recycling, use of recycled material, or both. Europe is currently using that approach [31]. However, if recycling can be made attractive from an economic standpoint, regulations will not be needed.

5. Looking Forward

In the immediate future, work at the ReCell Center will continue to optimize and scale up unit operation, appropriately ordered for inclusion in a complete process to convert spent cells into good-as-new recycled cells. Our focus so far has been on cathode materials, but recovery of other materials, such as electrolyte solvents and salts, anode graphite, and even binder will be thoroughly investigated.

In the longer term, the focus could be broader. After the pandemic, the ReCell Center’s new labs will be open for collaborations with industry and universities, and the equipment and general techniques we develop could potentially be applied to recover other materials from other products besides batteries.

The initial lab call that led to the establishment of the ReCell Center was specifically for recycling of Li-ion batteries. However, the center was founded with a vision of the longer term in mind, hence the Advanced Battery Recycling in its logo. We are developing processes and laboratory facilities that will continue research to enable recycling of whatever advanced battery designs and chemistries the future holds.

Author Contributions

Conceptualization, L.G. and S.G.; methodology, software, and formal analysis Q.D.; investigation, J.T.V.; writing, L.G. All authors have read and agreed to the published version of the manuscript.

Funding

The submitted manuscript has been created by UChicago Argonne, LLC, Operator of Argonne National Laboratory (“Argonne”). Argonne, a U.S. Department of Energy Office of Science laboratory, is operated under Contract No. DE-AC02-06CH11357.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data about specific projects are available on request.

Acknowledgments

This work represents the work of over 50 staff members at 6 institutions that constitute the ReCell Center. The authors recognize their hard work and urge the reader to consult www.recellcenter.org (accessed on 12 May 2021) for updates and links to more detailed descriptions of the work summarized here. In particular, the facilities described in Appendix A provide crucial ongoing support.The U.S. Government retains for itself, and others acting on its behalf, a paid-up nonexclusive, irrevocable worldwide license in said article to reproduce, prepare derivative works, distribute copies to the public, and perform publicly and display publicly, by or on behalf of the Government. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan. http://energy.gov/downloads/doe-public-accessplan (accessed on 12 May 2021).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Supporting Facilities Are Crucial

CAMP: The Cell Analysis, Modeling, and Prototyping (CAMP) Facility at Argonne actively supports the efforts of the ReCell Center by providing baseline materials, fabricating trial electrodes and baseline electrodes, fabricating and testing numerous coin cells, and fabricating single-layer pouch cells. It has established a thorough test matrix and protocols that are used to conduct electrochemical evaluation of baseline active materials of interest. These protocols and the testing results are uploaded to the ReCell Center website (www.recellcenter.org) (access on 12 May 2021) as they become available.

POST-TEST: The Post-Test Facility at Argonne performs another key supporting role. Post-test diagnostics of aged batteries provide information on the causes of performance degradation, which previously could be only inferred. The facility combines microscopy, spectroscopy, and chromatography in a controlled-atmosphere glove box to characterize materials without air exposure. These results help identify issues in the recycled materials, such as how well a given recycling process separates an initial mixture of cathode, anode, supporting foils, and casing materials.

References

- Energy Department Announces Battery Recycling Prize and Battery Recycling R&D Center. Available online: https://www.energy.gov/articles/energy-department-announces-battery-recycling-prize-and-battery-recycling-rd-center (accessed on 7 January 2021).

- Circular Energy Storage Research and Consulting. The Lithium-ion Battery Life Cycle Report 2021; Circular Energy Storage Research and Consulting: London, UK, 2020. [Google Scholar]

- Smith, C. (Call2Recycle, Atlanta, GA, USA). Personal communication, 2020.

- New-Eichlin, D.; Spalding, D. (Battery Solutions, Wixom, MI, USA). Personal communication, 2020.

- Sanders, M. (Avicenne Energy, Landenberg, PA, USA). Personal communication, 2020.

- Tesla Battery Day Preview—Redwood Materials. Available online: https://www.youtube.com/watch?v=EWRvmFR8vKc (accessed on 1 January 2021).

- Wood, C. Amazon, Panasonic, And Recycling Start-Ups Prepare for Battery Wave tsunami. CNBC.com, 12 December 2020. (updated on 14 December 2020). Available online: https://www.cnbc.com/2020/12/12/amazon-panasonic-preparing-for-demand-of-battery-recycling.html (accessed on 1 January 2021).

- Argus. Explosion Hits CATL Battery Precursors Plant in China. Available online: https://www.argusmedia.com/en/news/2175179-explosion-hits-catl-battery-precursors-plant-in-china#:~:text=An%20explosion%20has%20hit%20a,Contemporary%20Amperex%20Technology%20(CATL).&text=The%20explosion%20was%20caused%20after,garbage%20dump%2C%20Hunan%20Brunp%20said (accessed on 8 January 2021).

- Melin, H.E. The Dynamics of the EV Battery End-Of-Life Market (Zoom Tutorial); Circular Energy Storage: London, UK, 22 October 2020. [Google Scholar]

- Herox. Lithium-Ion Battery Recycling Prize. Available online: https://www.herox.com/BatteryRecyclingPrize (accessed on 1 January 2021).

- World Economic Forum, prepared in collaboration with the Ellen MacArthur Foundation and McKinsey & Company. Towards the Circular Economy: Accelerating the Scale-Up across Global Supply Chains; World Economic Forum: Geneva, Switzerland, 2014. [Google Scholar]

- Avicenne Energy for NAATBatt International. Study of Large Format EV Lithium-Ion Battery Recycling in China; Unpublished work; 2018. [Google Scholar]

- Sloop, S.E. Recycling of Battery Electrode Materials. U.S. Patent 12/709,144, 15 March 2016. [Google Scholar]

- Sloop, S.E. Reintroduction of Lithium into Recycled Battery Materials. U.S. Patent 12/390,364, 15 March 2016. [Google Scholar]

- Argonne National Laboratory. EverBatt: Argonne’s Closed-Loop Battery Life-Cycle Model. Available online: https://www.anl.gov/egs/everbatt (accessed on 2 January 2021).

- U.S. Department of Energy. Battery Recycling Prize Announces Phase II Prize Winners. Available online: https://www.energy.gov/eere/articles/Battery-Recycling-Prize-Announces-Phase-Ii-Prize-Winners (accessed on 30 December 2020).

- Li-Cycle. A Unique and Dependable Approach to Solving the Global Battery Recycling Problem. Available online: https://li-cycle.com/technology/ (accessed on 5 January 2021).

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 79. [Google Scholar] [CrossRef] [PubMed]

- Thompson, D.; Hartley, J.; Lambert, S.; Shiref, M.; Harper, G.; Kendrick, E.; Anderson, P.; Ryder, K.; Gaines, L.; Abbott, A. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Groux, O. Kyburz Battery Recycling. In Proceedings of the International WEEE and Battery Recycling Conference, Virtual, 9 December 2020. [Google Scholar]

- Martin, J.; Sherr, I. How Apple’s Daisy iPhone Recycling Robot Works. Cnet.com. Available online: https://www.cnet.com/news/how-apples-daisy-iphone-recycling-robot-works/ (accessed on 3 January 2021).

- Eisert, S. Selective Decomposition of Composites: The Potential of Continuous Shockwave Technology. In Proceedings of the E-Waste World Conference and Expo, Virtual, 18–19 November 2020. [Google Scholar]

- Zhang, R.; Meng, Z.; Ma, X.; Chen, M.; Chen, B.; Zheng, Y.; Yao, Z.; Vanaphuti, P.; Bong, S.; Yang, Z.; et al. Understanding fundamental effects of Cu impurity in different forms for recovered LiNi0.6Co0.2Mn0.2O2 cathode materials. Nano Energy 2020, 78, 105214. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, Y.; Yao, Z.; Vanaphuti, P.; Ma, X.; Bong, S.; Chen, M.; Liu, Y.; Cheng, F.; Yang, Z.; et al. Systematic Study of Al Impurity for NCM622 Cathode Materials. ACS Sustain. Chem. Eng. 2020, 8, 9875–9884. [Google Scholar] [CrossRef]

- Bai, Y.; Muralidharan, N.; Li, J.; Essehli, R.; Belharouak, I. Sustainable direct recycling of lithium-ion batteries via solvent recovery of electrode materials. ChemSusChem 2020, 13, 5664–5670. [Google Scholar] [CrossRef]

- Zhan, R.; Yang, Z.; Bloom, I.; Pan, L. Significance of a Solid Electrolyte Interphase on Separation of Anode and Cathode Materials from Spent Li-Ion Batteries by Froth Flotation. ACS Sustain. Chem. Eng. 2021, 9, 531–540. [Google Scholar] [CrossRef]

- Ellis, T.W. Magnetic Separation of Electrochemical Cell Materials. U.S. Patent 2013/0256198A1, 3 October 2013. [Google Scholar]

- Bai, Y.; Hawley, W.B.; Jafta, C.J.; Muralidharan, N.; Polzin, B.J.; Belharouak, I. Sustainable recycling of cathode scraps via Cyrene-based separation. Sustain. Mater. Technol. 2020, 25, e00202. [Google Scholar] [CrossRef]

- Pupek, K. Other Materials Separation. Available online: https://www.energy.gov/sites/default/files/2019/06/f64/bat380_%20pupek_2019_o_5.14_3.27pm_jl.pdf (accessed on 6 May 2021).

- Sanders, M. The Rechargeable Battery Market and Main Trends 2019–2030. In Proceedings of the International Battery Seminar and Exhibition, Virtual, 30 July 2020. [Google Scholar]

- Implementation Appraisal: Batteries Directive. European Parliamentary Research Service. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2020/654184/EPRS_BRI(2020)654184_EN.pdf (accessed on 4 January 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).