Abstract

Recycled concrete aggregate (RCA) collected from the demolition of old reinforced concrete structures can be reused to prepare structural and non-structural concrete, thereby protecting the environment by preserving natural resources. This study explores RCA’s use, collected from the crushed concrete of different building projects in Riyadh, to manufacture fresh self-compacting concrete (SCC) and investigate its properties in the fresh and hardened state. Four SCC mixes were prepared by replacing natural aggregate (NA) with RCA at 0%, 25%, 50%, and 75% replacement levels. The water-cement (w/c) ratio was maintained constant at 0.38 for all the mixes. Slump Flow, J-ring, and V-funnel tests were performed on the SCC mixes in the fresh state, and the compressive strength of hardened concrete was determined after seven, 14, and 28 days. Water absorption and split tensile tests were also carried out for all the mixes. The findings revealed that it is possible to reach compressive strengths higher than 40 MPa at 28 days for RCA replacement level of 75% by using a superplasticizer and low w/c ratio. The decrease in compressive strength concerning the SCC-NA mix was 25% for 75% replacement level. The highest split tensile strength at 28 days was around 3.3 MPa for a 50% replacement level. The lowest water absorption was 3.2% for SCC-NA, which was gradually increased and was highest at 5.6% for 75% replacement level.

1. Introduction

Recently, the main objectives of most environmental policies regarding waste are to prevent waste and promote reuse, recycling, and recovery to decrease the negative environmental impact. However, when undertaking this issue, it is essential to consider that a key barrier for developing recyclable products is the lack of demand and clients’ readiness to pay more for these kinds of products, both in business to business and by consumers. Engineers have a significant role in environmentally friendly decision-making processes, as they should consider the lifelong influence and the impact on the environment [1]. Despite the mentioned barrier, RCA’s use can significantly decrease concrete cost and produce an appropriate mix (located in the cost-efficient zone). As the use of a high volume of RCA decreases the mechanical characteristics of concrete, those mixes are still considered suitable when superplasticizers are used [2], and this is the case of the produced concrete with a compressive strength of around 40 MPa, which is the range for mixes used in this research.

A further dimension of the environmental requirements and customer satisfaction deals with the green quality function deployment-II (GQFD-II), a recent methodology to improve and develop products, and was successfully used by many companies. GQFD-II integrated life cycle assessment (LCA) and life cycle costing (LCC) into QFD matrices and organized customer, environmental, and cost requirements through the complete product development process. This method integrates QFD (quality), LCA (environment), and LCC (cost) into one effective tool, which could be used to evaluate the diverse product concepts considering the quality, environment, and cost [3].

The previous recycling concepts, LCA and LCC, are followed in this research to be applied to the recycled concrete aggregate (RCA) and compare it with natural aggregate (NA). The deposition of construction and demolition waste (CDW) in landfills and the conforming costs are increasing. Consequently, concrete recycling and reuse as aggregates is very advantageous and allows the volume reduction of CDW, thus reducing environmental impacts formed by the construction sector [4]. Additionally, and based on the International Organization for Standardization (ISO) definition of LCA phases, a study of life cycle inventory (LCI) assessment in Serbia concluded specific transport distances and types of impacts on total environmental impacts. The effects investigated were global warming, energy use, acidification, photochemical oxidant creation, and eutrophication [5]. The study compared two scenarios: for the first one (RCA transport distances are smaller than those of NA), the RCA and NA production environmental impact in terms of studied categories was approximately the same, and the benefit from recycling in terms of waste and natural mineral resources depletion minimizing was clearly gained. For the second one (RCA transport distances are equal to those of NA), RCA’s total impacts were more significant, increasing, and ranging from 11.3% to 36.6%, depending on the impact category. Due to the study assumptions, the RCA case’s energy savings were possible only for specific ratios of NA to RCA transport distances. The results accordingly stressed the necessity of getting the RCA from very close distances than NA to achieve the targeted environmental gain. The existing crusher plants are located between 100 to 200 km from Riyadh city, so the crusher for RCA situated in the city vicinity can make such concretes cost-efficient and environmentally friendly.

One of the utmost substantial advances in concrete technology is self-compacting concrete (SCC), classified as high-performance concrete. This type of concrete is produced by including add-on materials like slag cement, viscosity modifying agents, and fly ash. The SCC is requested to possess three main elementary characteristics: high resistance to segregation, restrained flowability, and high deformability [6,7]. The RCA derived from concrete waste has recently been used to supplement (NA) to manufacture fresh concrete. The shortage of NA and the rising landfill charges have taken into account RCA usage in concrete. Given RCA’s underlying consistency, some researchers have shown that it may be used in the design, primarily for lower-level or non-structural applications, as an alternative to NA [8]. For the current concrete use, RCA was found to be theoretically acceptable. For barriers, shoulders, pavements, roads, embankments, bridge frames, and curbs, properly treated RCA may be included in the new concrete. It may also be found in bituminous concrete, gutters, surface bases for soil-cement, and structural grade concrete. However, the RCA obtained from demolished concrete should be seriously evaluated to pass the suitability requirements set out in the associated specifications for a particular application [9,10].

Many researchers investigated RCA beams’ flexural and shear properties, RCA columns’ compressive strength, and beam-column joints’ seismic performance [11,12,13]. The effect of concrete permeability on RCA’s durability in the marine environment and such aggressive environments was investigated. In these conditions, the RCA’s reliability was adversely impacted by concrete permeability in the event of its decrease. By utilizing a lower water-cement (w/c) ratio, the effect of RCA’s aggressive atmosphere may be minimized [14]. To guarantee fresh recycled concrete’s workability, it was suggested to retain a steady amount of efficient water over the initial moisture of precise control aggregates [15].

Using RCA replacement with higher percentages in concrete (reaching 100%) and its impact on various concrete properties was considered. Concrete mixes reaching 100% RCA replacement displayed up to 37% reduction in compressive strength than natural aggregate concrete (NAC) [16]. With quality-assured conditions, concrete with a high replacement percentage of RCA from real concrete waste and laboratory waste can achieve similar splitting tensile strength, compressive strength, abrasion resistance, modulus of elasticity, and water absorption as NAC [17,18]. Considering the bond between deformed bars and concrete, it was found that concrete with NA and concrete with different replacement levels of RCA have similar bond behavior [19]. Concrete exposure to high temperature (around 600 °C) resulted in a gradual increase in specimen cracks and increased weight loss. However, these problems can be overcome by increasing the fly ash content, which reduces the loss in compressive strength and enhances RCA’s ductility [20]. A similar reduction in RAC strength was experienced under intermittent and sustainable loadings [21]. The parent concrete has a considerable effect on the quality of RCA and its mechanical properties. RCA obtained from low-strength, and lightweight concrete has significantly lower ultimate bond strength and compressive strength than the one gained from a high-strength parent concrete [22].

SCC properties were studied using different replacement levels of 10%, 20%, 30%, and 40% of RCA. Flexural strength and SCC compressive strength decreased with the rise in RCA’s substitution ratio [23]. RCA’s mechanical properties can be improved by the appropriate use of nanomaterials, like Nanosilica and Nano-CaCO3. In some cases, higher compressive strength was obtained [24]. Combining slag, silica fume, and fly ash can gain more compressive strength to compensate for its reduction due to RCA in SCC. Using these materials in SCC with high replacement levels of RCA helps maintain resistance to segregation of this type of concrete and high filling and passing ability while reaching a comparable compressive strength that allows SCC’s structural use [25]. Relating to the fine aggregate in the RCA mixture, it was observed that compressive strength of 20 MPa could be obtained from SCC when using the manufactured sand and RCA as a 100% replacement of NA, which is almost 50% of original strength when using NA. The replacement of NA with manufactured sand and RCA resulted in a reduction in split tensile strength and SCC’s flexural strength [26]. Fly ash can be used with metakaolin and expanded glass aggregate for other applications that require good mechanical properties as well as thermal conductivities [27]. The use of a superplasticizer in SCC helps lower the water-cement ratio, which results in higher compressive strengths.

Based on this literature review, it is observed that RCA is already a topic of research interest, and this study aims to develop SCC mixes using RCA obtained from locally demolished structures. Managing demolition waste in Riyadh has become a critical problem in current years and is likely to escalate in the future. RCA’s use at different replacement levels with a constant fly ash content is considered in this study. Therefore, this study attempts to utilize local construction demolition waste produced in Riyadh to produce high-strength concrete that can be used to construct new structures. In this research, SCC with 100% NA and three replacement levels (25%, 50%, and 75%) of RCA were produced. The fresh and hardened properties of these mixes were studied. J-ring, v-funnel, and slump flow tests were performed, and a compressive strength test after seven, 14, and 28 days were conducted. Additionally, water absorption and split tensile tests were performed on samples of all the mixes.

2. Methods

This study was conducted in different phases. In phase one, the normal SCC mix was prepared using Ordinary Portland Cement (OPC), fine aggregate, NA, fly ash, and superplasticizer. Several trials were conducted to meet the performance requirements of SCC in the fresh state. Slump flow, V-funnel, and J-ring tests were conducted to analyze the fresh properties of SCC. In the subsequent phases, the NA was replaced by 25% RCA, followed by a 50% and 75% replacement.

2.1. Preparation of Raw Materials

NA and RCA of sizes 15, 10, and 5 mm were used. RCA was obtained from the demolished concrete waste from a construction site in Riyadh. The demolished concrete was collected from the project and dumped in a different location. It was crushed manually using a steel hammer to obtain smaller size particles. It took more than a week to crush the concrete and extract the RCA’s required amount and size. The RCA obtained was purely from concrete waste (concrete slab, columns, and beams), and it was ensured that it was free from other construction waste like blocks, bricks, and tiles. In the last phase, the crushed old concrete was sieved to segregate the required sizes. A sample is shown in Figure 1. RCA is inherently weaker than NA due to the presence of the old mortar layer on its surface. RCA has higher absorption because the mortar layer is porous and soft. The LA abrasion value of RCA is also higher than NA, while the specific gravity is lower. RCA’s quality can be improved by minimizing the amount of attached old mortar on the surface of RCA [28].

Figure 1.

Recycled coarse aggregate (RCA).

In Riyadh, OPC, fine aggregate, NA, and Type C Indian fly ash were obtained from local construction material suppliers. Class C fly ash has high cementing abilities, and these are formed from the burning of sub-bituminous coal. This type of fly ash does not need an activator (based on ASTM C 618 standards [29]) to form cementitious compounds. The specific properties of the Type C fly ash can be obtained from Mahakavi and Chithra [24].

Superplasticizer was used to get the desired properties of flowability and cohesion in the fresh state. It is a third-generation superplasticizer used to produce high-performance concrete. It allows the use of low water/binder ratios along with a high degree of compaction. It is an aqueous solution of modified polycarboxylates and co-polymers and is light brown. It may be used for all Portland cement forms, such as ground granulated blast slag, pulverized fly ash and micro-silica, and pozzolanic materials. The suggested dose is inside the binder’s weight range of 0.8–2.2%. Exact dosages, though, can only be calculated by conducting trial mixes to fulfill the precise criteria. It needs to be applied to the gauging water or pumped into the concrete mixer simultaneously. The dry mix cannot be applied to it. To give the required effects, the concrete should be mixed for at least 60 s with viscocrete [30]. For the preparation of all the concrete mixes used in this study, potable tap water was used.

2.2. Concrete Mix Proportions

The concrete proportions were calculated carefully following the European Federation of National Associations Representing for Concrete (EFNARC) for SCC [31]. Additionally, a detailed literature review [19,23,24] was also conducted to finalize the mixes’ proportions. Table 1 shows the SCC mix proportions.

Table 1.

SCC Mix Proportions.

The batching of the concrete mix materials was done carefully using automated controlled weighing machines in the lab, and the weighted materials were stored in different separate buckets. Water absorption tests were conducted for NA and RCA. The water absorption was found to be 5.5%, 1%, and 0.65% for 5, 10, and 15 mm size NA, respectively, and 3.4%, 3%, and 5.4% for 5, 10, and 15 mm size RCA, respectively. Based on the water absorption results, additional water was added to the concrete mix design.

For preparing concrete mixes, a tilting drum concrete mixer has been used. The mixer’s bottom was first lubricated with water to avoid sticking the material in the drum. Raw materials were then added in small quantities, along with water, while the mixer was rotated at a tilted position. Superplasticizer was dosed in small amounts to reach the required consistency. The mixer was stopped intermittently to check the concrete mix, and if found satisfactory, mixing was stopped to conduct tests on the mixes. During the initial trials, it was observed that even a slight overdose of the superplasticizer resulted in bleeding and segregation in the SCC mix. Unstable mixes were discarded, and retrials were done until all the SCC performance requirements were met as per EFNARC [31].

2.3. Testing of Fresh Properties

The slump flow and T50 measurements were used to estimate all concrete mixtures’ deformability intensity and flowability. The slump flow research was carried out, as per the American Society for Measuring Materials (ASTM) C 1611 [32]. The passing capability of concrete through rebar was tested by measuring the slump-flow and T50 values using the J-Ring test following ASTM C 1621 [32]. The concrete mix’s ability to resist segregation was determined by visually analyzing the concrete mix during the slump flow test and assigning a Visual Stability Index (VSI) value to each concrete mixture. Figure 2 displays the various studies performed on the most current SCC.

Figure 2.

Flowability, V-funnel, and J-ring Tests.

In the first stage, the flowability test was performed using the slump cone and steel base plate with a circle marked at the distance of 500 mm. The flowability time was recorded, and as per EFNARC standards, the SCC should touch the marked line in (2–5 s), and the slump flow diameter should range from 650 to 800 mm. During trial experiments, several attempts were made to satisfy the acceptance criteria of SCC. During the study’s final experiments, the concrete total spread area and timing were recorded (Table 2). After the flowability test, a V-funnel test was performed on SCC, and as per EFNARC standards, the concrete must flow from the funnel in 6 to 12 s. The complete readings of the V-Funnel test are shown in (Table 2). In the last stage of the fresh test on SCC, the J-ring test was performed. As per the EFNARC standard, the concrete should pass through the rings at around 0 to 10 s. The J-ring tests’ complete readings are shown in (Table 2).

Table 2.

Test Results.

After these three tests, the SCC was cast in 12-inch standard cylinders, and twelve cylinders were cast for each trial mix in this study. The cylinders were demolded the next day, and casting tags were marked on each cylinder. Tag information includes the date of the casting, mix number, and the days for curing. In the last phase, all cylinders were placed in a curing pond at room temperature in the lab, as shown in Figure 3.

Figure 3.

Concrete cylinder demolding and curing.

Potable water was used for the concrete cylinders curing in the laboratory. The curing water temperature was room temperature in the laboratory between 25–30 °C.

2.4. Testing of Hardened Properties

Nine 150 × 300 mm concrete cylinders were prepared and cured from each concrete mixture in the curing room at room temperature and at relative humidity greater than 95% before the day of testing for compressive strength testing of concrete mixtures on days 7, 14, and 28. The cylinders were inspected following ASTM C39 [32]. Two 150 × 300 mm cylinders prepared from each concrete mixture were used to perform the 28-day split tensile strength test. The splitting tensile strength of all concrete mixtures was performed by applying a diametric compressive force to a cylindrical concrete specimen placed with its horizontal axis between the plates of a measurement system in compliance with ASTM C 496-96 [32], (C496-96). One 150 × 300 mm cylinder prepared from each concrete mixture was used to test water absorption.

3. Results

Table 2 shows the complete results of a various test conducted on fresh concrete, which includes slump flow, T-50 test, V-funnel, and J-ring, and it also consists of the visual stability index results:

All the mixes satisfied the criteria to qualify as SCC. In the SCC-NCA case, the superplasticizer was dosed at 0.8% of cement and fly ash weight, whereas SCC-RCA25% was dosed at 1.0%. A sudden drop in the superplasticizer dosage (0.35%) was observed in the case of SCC-RCA50%. The curing pond temperature was room temperature, and ordinary drinkable water was used for curing, as shown in Figure 3. In the subsequent phases, the cylinders were tested in a comprehensive mechanical tester to observe concrete’s crushing strength, as shown in Figure 4.

Figure 4.

Concrete compression test.

The concrete split tensile strength was tested using the comprehensive concrete tester with split tensile test assemblies, as shown in Figure 5.

Figure 5.

Split tensile strength test.

The complete results of compressive strength and tensile strength tests and the water absorption test are shown in Table 3.

Table 3.

Compressive strength and water absorption results.

4. Discussions

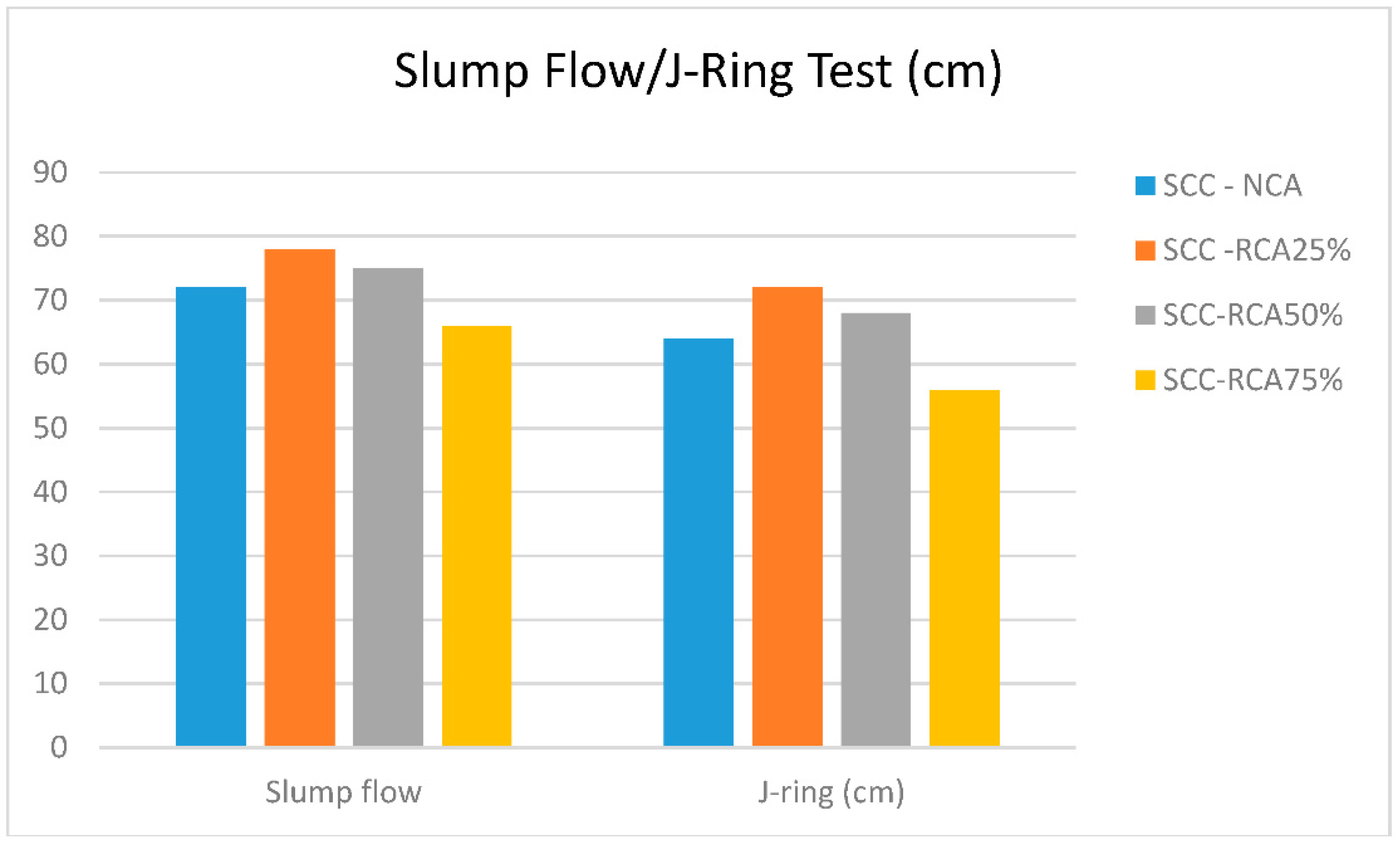

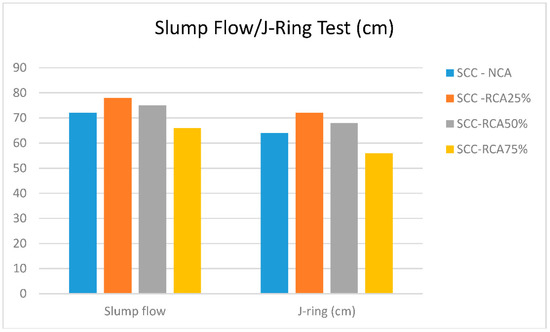

Workability tests on fresh concrete mixes compressive strength at seven, 14, and 28 days and split tensile strength results are discussed in this section. The slump flow, T-50 time, V-funnel, J-ring, and VSI results are summarized in Table 2, and Figure 6 shows the slump flow for all the mixes used in this study.

Figure 6.

Slump Flow and J-Ring Test.

The slump flow was found to be within the range of 660–780 mm, within the acceptable range for SCC. The difference between slump flow diameter and J-ring test was found to be 8, 6, 7, and 10 cm, respectively, which is also within the acceptable range of 0–100 mm. The higher slump value for SCC-RCA 25% can be correlated to a higher dosage of superplasticizer. Therefore, it is essential to use the superplasticizer very carefully, and the dosage should be increased in tiny amounts to avoid high flowability. Figure 7 shows the T50 time and V-funnel time.

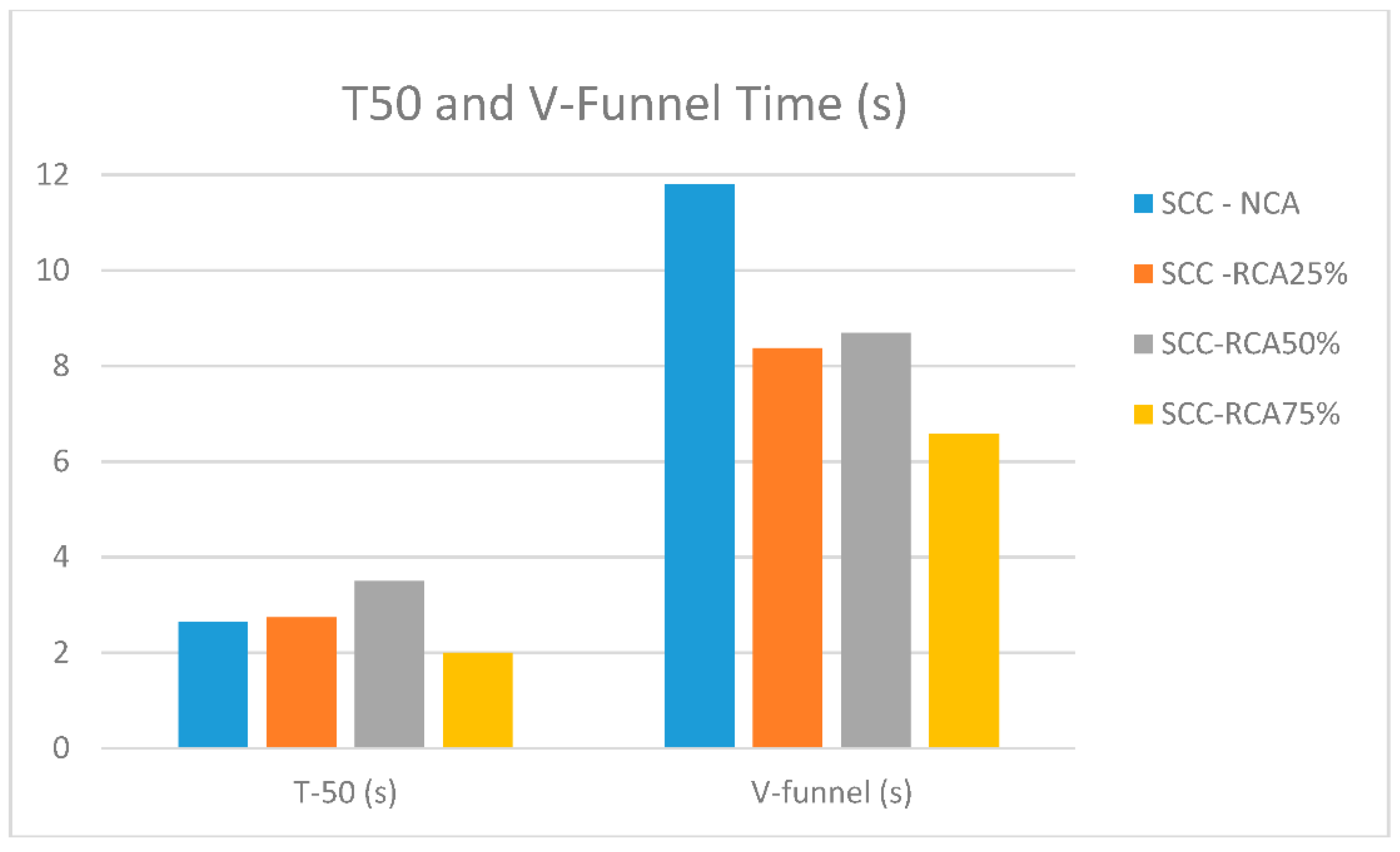

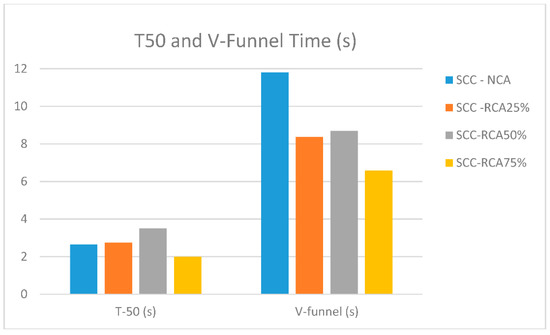

Figure 7.

T50 and V-funnel Test.

All the mixes satisfied the requirement of T-50 time (2–5 s) and V-funnel passing time (6–12 s), indicating good flowing and filling ability. Results from the J-ring test indicate good passing ability. The SCC mix must fulfill the fresh state criteria because it is necessary to maintain the right flowability, filling capability, and passing ability. If the SCC mix is too viscous, it can create a problem in pumping, or if it is less viscous, it might lead to segregation of the coarse aggregate and/or bleeding. This can be controlled by carefully administering the superplasticizer to the mix. Figure 8 compares the seven-, 14- and 28-days compressive strength for all the mixes designed for this study.

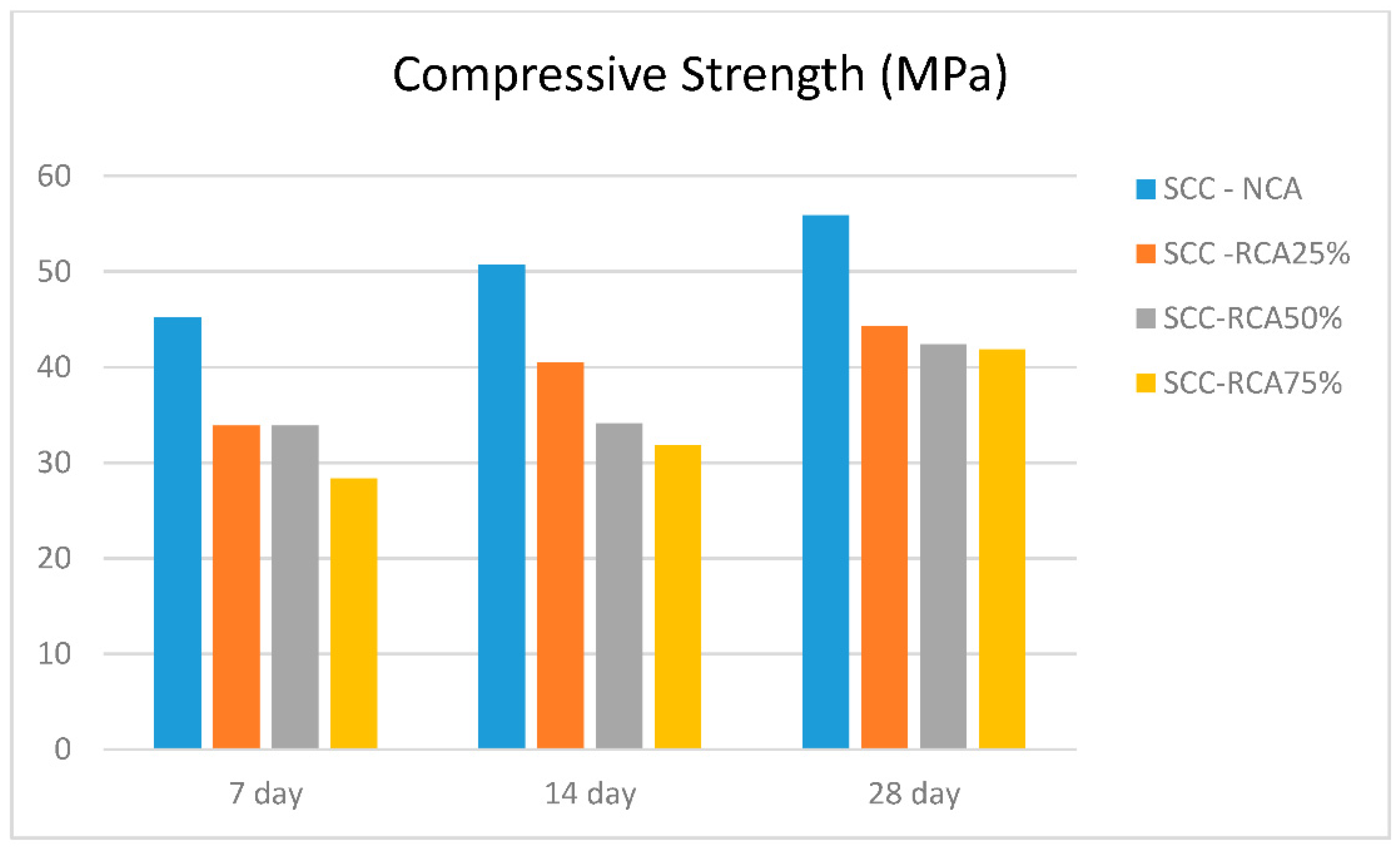

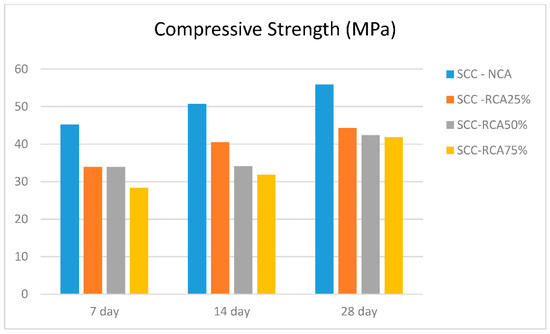

Figure 8.

Compressive strength at different curing cycles.

The highest 28-day compressive strength was reported for the control mix SCC-NCA, which was 55.9 MPa. SCC-NCA and SCC-RCA25% exhibited normal strength gain, while SCC-RCA50% and SCC-RCA75% did not show considerable strength gain from seven to 14 days but had a jump in strength from 14 to 28 days. There was a reduction of 21% in the 28-day compressive strength compared to SCC-NCA at the replacement ratio of 25%, a 24.1% reduction at the replacement ratio of 50%, and a 25% reduction at the replacement level of 75%. Similar studies [16,33] have reported a reduction of 37% and 43% in compressive strength at 28 days for 100% replacement level, which is relatively higher than the results achieved in this study. Other studies [34,35] have reported a decrease of 25% at a 100% replacement level, which is lower than the present study. Hence, these research results are pretty satisfactory compared with the previous research studies of similar nature and scenarios.

SCC-RCA75% achieved almost the same 28-day strength as SCC-RCA50%. It was observed that there was a decrease in the compressive strength with an increase in RCA content.

The possible error assessment is also done using the complete samples and mixes’ standard deviation test, as shown in Table 4.

Table 4.

Compressive strength deviation assessment.

It is observed that the maximum standard deviation reported was for SCC-NCA because of higher values of compressive strength (>35 MPa). Overall, the standard deviation values are in acceptable limits as per other studies [36]. Since the strength of the designed concrete in this study is greater than 40 MPa, it can satisfactorily be used as structural concrete [37].

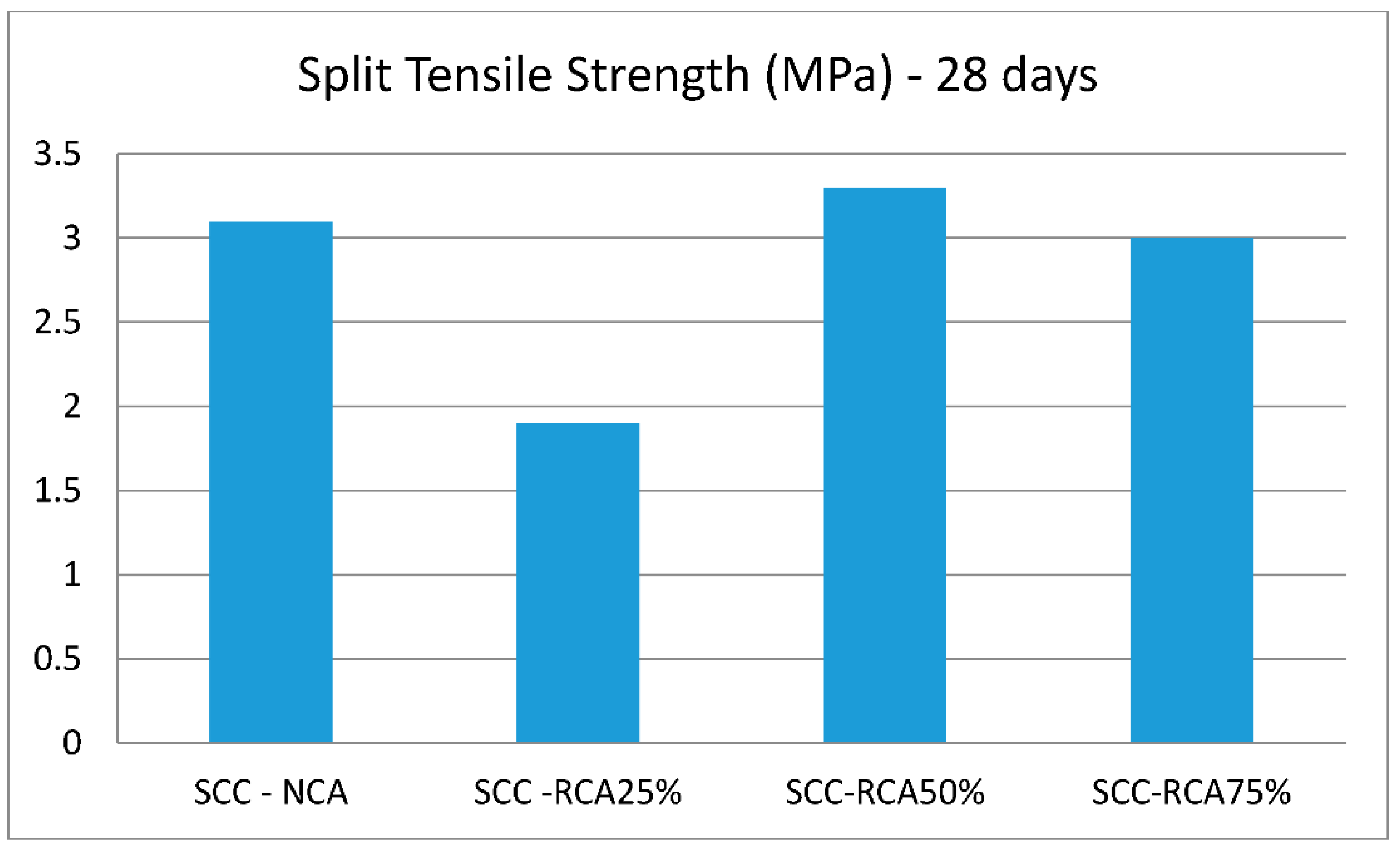

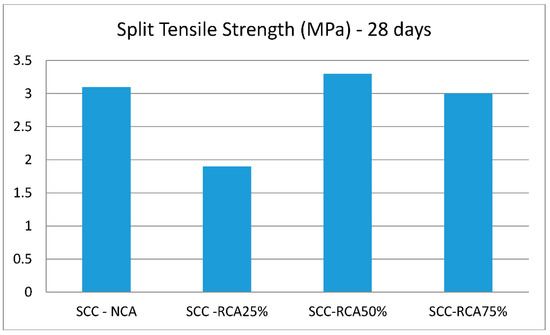

A Split Tensile Strength test was conducted after 28 days of curing. Results from the split tensile strength are shown in Figure 9.

Figure 9.

Split Tensile Strength of Concrete.

The values for split tensile strength were found to be in the range of 1.9–3.3 MPa, with SCC-RCA25% being the lowest at 1.9 MPa. This decrease in split tensile strength can be attributed to higher superplasticizer dosage for SCC-RCA25%, which resulted in a highly flowable mix. SCC-NCA, SCC-RCA50%, and SCC-RCA75% were 3.1, 3.3, and 3 MPa, respectively. The split tensile strength results are slightly on the lower side than concrete mixes with similar compressive strength.

5. Conclusions

The development of high-strength SCC mixes using RCA is genuinely challenging but needed. In this study, RCA obtained from the demolishing of old structures in Riyadh was used with replacement levels of 0%, 25%, 50%, and 75% forming four different SCC mixes. Fly ash and a superplasticizer were used to get the desired properties of flowability and cohesion in all mixes’ fresh states. The water/cement ratio was kept constant at 0.38. The samples of each mix were tested to check the properties of fresh concrete using the slump flow test, J-ring, and V-funnel. After appropriate curing in a water tank at room temperature, cylinders of different mixes were tested to get the compressive strength, split tensile strength, and water absorption after seven, 14, and 28 days. According to the study results, the following conclusions are obtained:

- Using RCA results in a reduction of the 7-, 14-, and 28-day compressive strength: As the replacement ratio is increased, more reduction in compressive strength is observed. The reduction of 28-day compressive strength was 21%, 24%, and 25%, for 25%, 50%, and 75% replacement levels, respectively. The minimum 28-day strength obtained was 41.8 MPa, for 75% RCA replacement, which is considered acceptable for structural applications.

- Water absorption of the SCC is increased with the increase of the replacement level of RCA. The absorption ratio was increased by 28%, 68%, and 72%, for 25%, 50%, and 75% replacement levels, respectively.

- There is no clear trend in the effect of the RCA replacement ratio on the split tensile strength.

RCA can enhance the environment, preserve the natural resources, and produce concrete with a reasonable compressive strength that can make the concrete eligible for use in structural applications. However, the cost reduction that resulted in using the RCA depends on crushing concrete plants within a reasonable distance to the site, which may encourage and promote more RCA usage that can improve the environment.

Author Contributions

Conceptualization: I.K., and Y.I.; methodology: M.A.M., and S.H.K.; formal analysis: M.A.M. and S.H.K.; investigation: I.K., and Y.I.; writing—original draft preparation: Y.I.; writing—review and editing: I.K., M.A.M., and S.H.K.; supervision: Y.I.; project administration: Y.I.; funding acquisition: Y.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Prince Sultan University, Seed Project of the 2020/2021 academic year.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank PSU for funding this project. The authors would also like to thank Engineer Omar Shabir for his efforts to conduct the tests and obtain the results. Finally, the authors thank the Structures and Materials Research Lab at the College of Engineering for its support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pajunen, N.; Rintala, L.; Aromaa, J.; Heiskanen, K. Recycling—The importance of understanding the complexity of the issue. Int. J. Sustain. Eng. 2016, 9, 93–106. [Google Scholar] [CrossRef]

- Rawaz, K.; Jorge, B.; José, D. Combined Economic and Mechanical Performance Optimization of Recycled Aggregate Concrete with High Volume of Fly Ash. Appl. Sci. 2018, 8, 1189. [Google Scholar] [CrossRef]

- Zhang, Y. Green QFD-II: A life cycle approach for environmentally conscious manufacturing by integrating LCA and LCC into QFD matrices. Int. J. Prod. Res. 1999, 37, 1075–1091. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Silvestre, J.D.; de Brito, J.; Pinheiro, M.D. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatovic, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Khatib, J.M. Performance of self-compacting concrete containing fly ash. Constr. Build. Mater. 2008, 229, 1963–1971. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Fresh, mechanical, and durability characteristics of self-consolidating concrete incorporating volcanic ash. J. Mater. Civ. Eng. 2010, 227, 651–657. [Google Scholar] [CrossRef]

- Hwang, S.D.; Khayat, K.H.; Bonneau, O. Performance-Based Specifications of Self-Consolidating Concrete Used in Structural Applications. ACI Mater. J. 2006, 103, 121. [Google Scholar]

- Grdic, Z.J.; Toplicic, C.G.A.; Despotovic, I.M.; Ristic, N.S. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- DG/TJ07-008. Technical Code of Application of Recycled Aggregate Concrete; Shanghai Construction Standard Society (SCSS): Shanghai, China, 2007. [Google Scholar]

- Thomas, C.; Setién, J.; Polanco, J.A.; Cimentada, A.I.; Medina, C. Influence of curing conditions on recycled aggregates concrete. Constr. Build. Mater. 2018, 72, 618–625. [Google Scholar] [CrossRef]

- Montero, J.; Laserna, S. Influence of effective mixing water in recycled concrete. Constr. Build. Mater. 2017, 132, 343–352. [Google Scholar] [CrossRef]

- Alexandridou, C.; Angelopoulos, G.N.; Coutelieris, F.A. Mechanical and durability performance of concrete produced with recycled aggregates from Greek construction and demolition waste plants. J. Clean. Prod. 2018, 176, 745–757. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Improvement of mechanical properties of recycled aggregate concrete basing on a new combination method between recycled aggregate and natural aggregate. Constr. Build. Mater. 2017, 148, 376–385. [Google Scholar] [CrossRef]

- Shi, Z.L. Experimental study on recycled aggregate concrete and its engineering application. China Fly Ash 2004, 4, 3–4. (In Chinese) [Google Scholar]

- Panda, K.C.; Bal, K.C. Properties of self-compacting concrete using recycled coarse aggregate. In Proceedings of the Chemical, Civil and Mechanical Engineering Tracks of 3rd Nirma University, International Conference on Engineering (NUiCONE), Ahmedabad, India, 6–8 December 2012. [Google Scholar]

- Omrane, M.; Kenai, S.; Kadri, E.-H.; Ait-Mokhtar, A.K. Performance and durability of self-compacting concrete using recycled concrete aggregate and natural pozzolan. J. Clean. Prod. 2017, 165, 415–430. [Google Scholar] [CrossRef]

- Govind, G.; Bhupinder, S. Analytical investigation in bond of deformed steel bars in recycled aggregate concrete. J. Sustain. Cem. Based Mater. 2020. [Google Scholar] [CrossRef]

- Qianqian, R.; Yaopeng, W.; Xu, Z.; Yonghui, W. Effects of fly ash on the mechanical and impact properties of recycled aggregate concrete after exposure to high temperature. Eur. J. Environ. Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Zhiyu, L.; Wengui, L.; Vivian, W.Y.T.; Jianzhuang, X.; Surendra, P.S. Current progress on nanotechnology application in recycled aggregate concrete. J. Sustain. Cem. Based Mater. 2019, 8, 79–96. [Google Scholar] [CrossRef]

- Zhanggen, G.; Jing, Z.; Tao, J.; Tianxun, J.; Chen, C.; Rui, B.; Yan, S. Development of sustainable self-compacting concrete using recycled concrete aggregate and fly ash, slag, silica fume. Eur. J. Environ. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Mahakavi, P.; Chithra, R. Effect of recycled coarse aggregate and manufactured sand in self-compacting concrete. Aust. J. Struct. Eng. 2020, 21, 33–43. [Google Scholar] [CrossRef]

- Bin, L.; Wengui, L.; Zhiyu, L.; Xitao, L.; Vivian, W.Y.T.; Zhuo, T. Performance deterioration of sustainable recycled aggregate concrete under combined cyclic loading and environmental actions. J. Sustain. Cem. Based Mater. 2020. [Google Scholar] [CrossRef]

- Assaad, J.J.; Matar, P.; Gergess, A. Effect of quality of recycled aggregates on bond strength between concrete and embedded steel reinforcement. J. Sustain. Cem. Based Mater. 2020, 9, 94–111. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A new Fabric Reinforced Geopolymer Mortar (FRGM) with mechanical and energy benefits. Fibers 2020, 8, 49. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resources. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Coal Fly Ash and Raw or calcined Natural Pozzolan for Use in Concrete; ASTM Standard C618; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Product Data Sheet. Sika Viscocrete—021301011000001467. 2020. Available online: https://gcc.sika.com/content/dam/dms/gcc/o/sika_viscocrete_ts-100.pdf (accessed on 22 March 2021).

- European Federation of National Associations Representing for Concrete (EFNARC). Specifications and Guidelines for Self-Compacting Concrete; EFNARC: Surrey, UK, 2002. [Google Scholar]

- ASTM C1611/C1611M-18. American Society for Testing and Materials, Standards and Publications. Available online: https://www.astm.org/Standard/standards-and-publications.html (accessed on 10 July 2018).

- Mohammed, D.; Tobeia, S.; Mohammed, F.; Hasan, S. Compressive Strength Improvement for Recycled Concrete Aggregate; Building and Construction Engineering Department, University of Technology: Baghdad, Iraq, 2018. [Google Scholar]

- Khan, A.R.; Fareed, S.; Khan, M.S. Use of Recycled Concrete Aggregates in Structural Concrete. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 14–17 July 2019. [Google Scholar]

- Qasrawi, H.; Marie, I. Towards Better Understanding of Concrete Containing Recycled Concrete Aggregate. Adv. Mater. Sci. Eng. 2013, 2013, 636034. [Google Scholar] [CrossRef]

- Zhang, X.B.; Fang, Z.; Deng, S.C. Study on the standard deviation for the compressive strength of recycled concrete. Adv. Mater. Res. 2013, 639–640, 313–318. [Google Scholar] [CrossRef]

- ACI 318. Building Code Requirements for Structural Concrete. Available online: https://engineervincentpardopilien.weebly.com/uploads/2/1/5/1/21511442/aci_318-2011.pdf (accessed on 22 March 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).