Discrimination of Poor Electrode Junctions within Lithium-Ion Batteries by Ultrasonic Measurement and Deep Learning

Abstract

:1. Introduction

2. Ultrasonic Experiment

2.1. Specimens

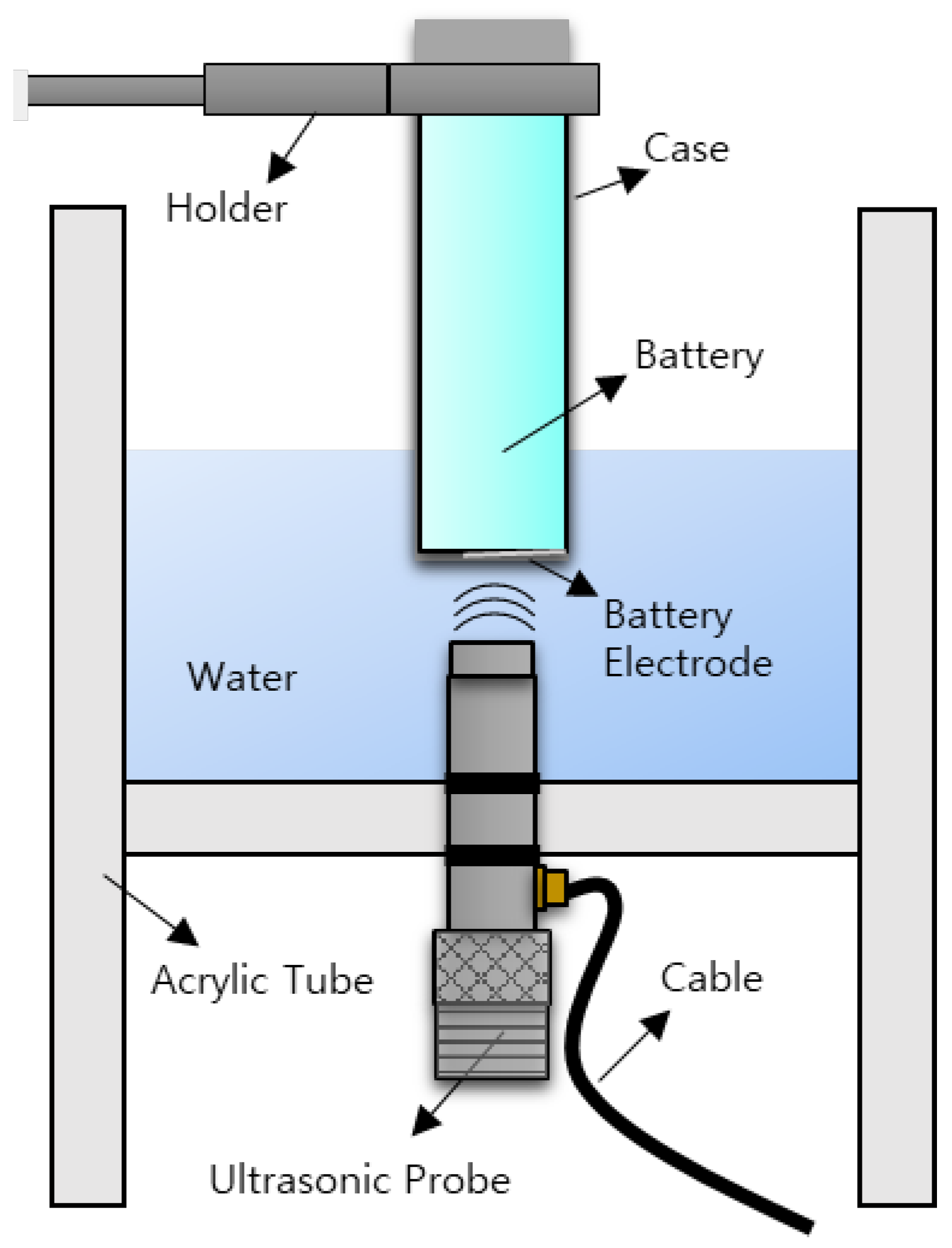

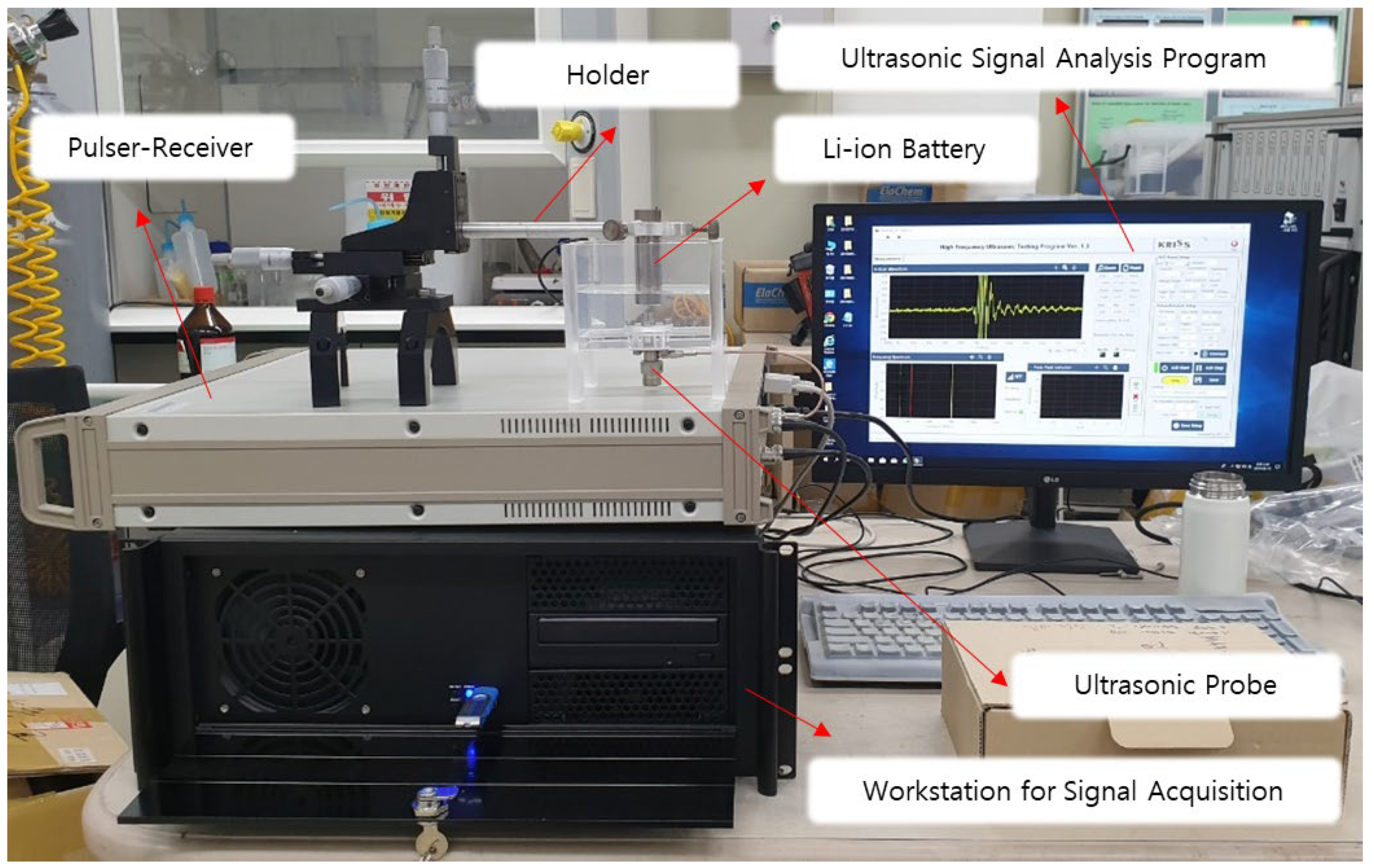

2.2. Experimental Set-Up

3. Ultrasonic Database

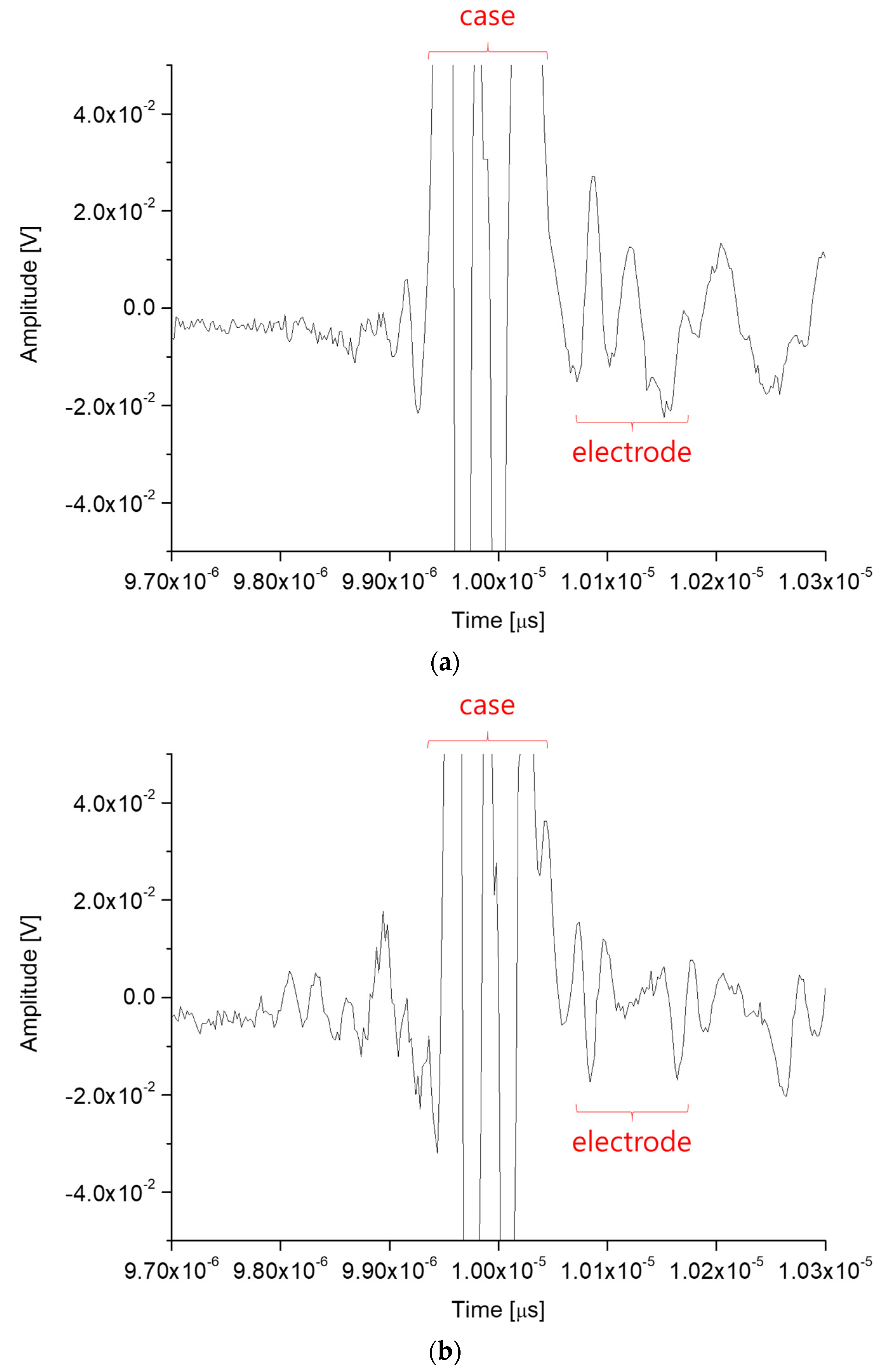

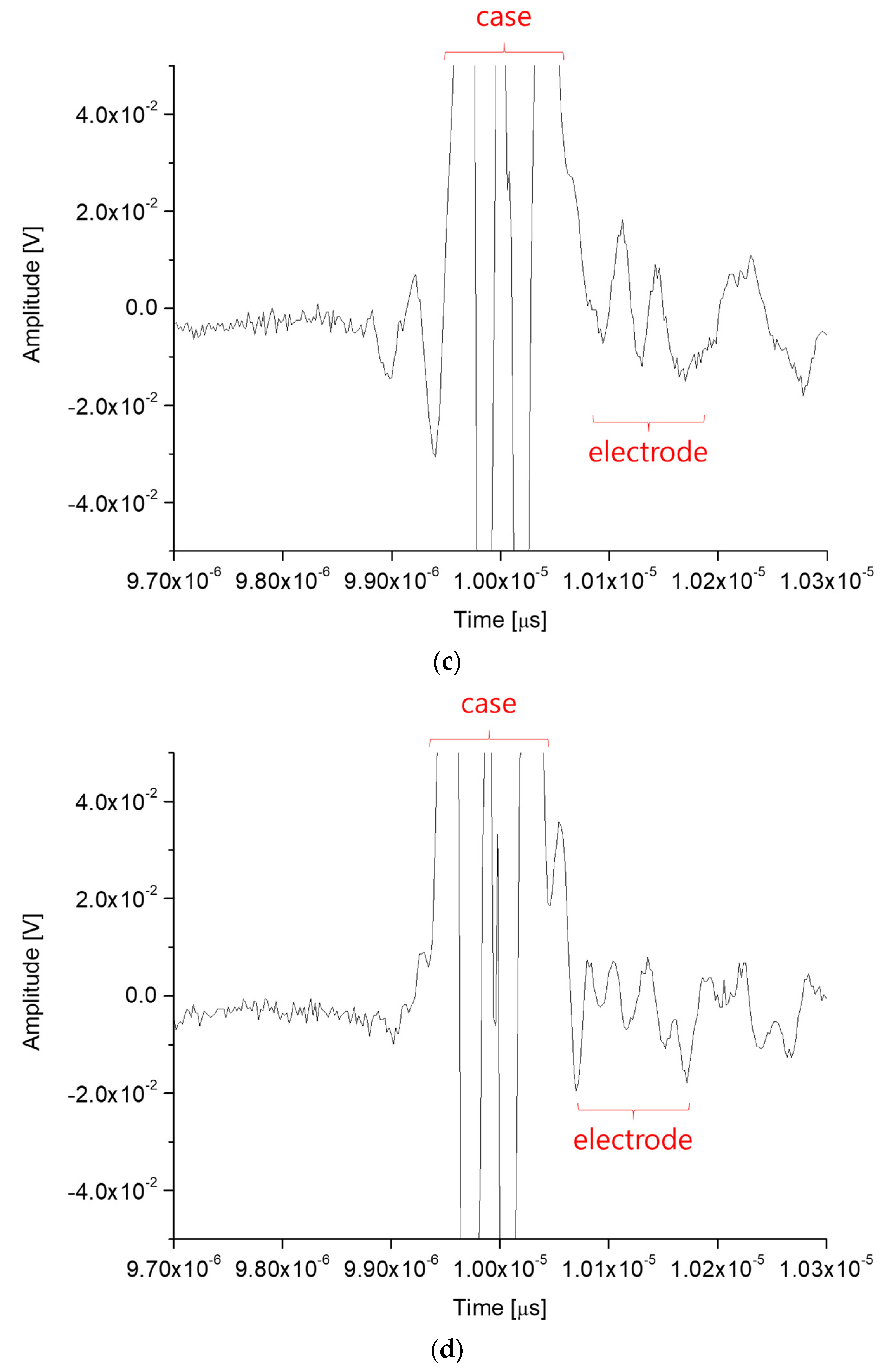

3.1. Analysis of Received RF Signals

3.2. Database Construction for Deep Learning

4. Deep Neural Network

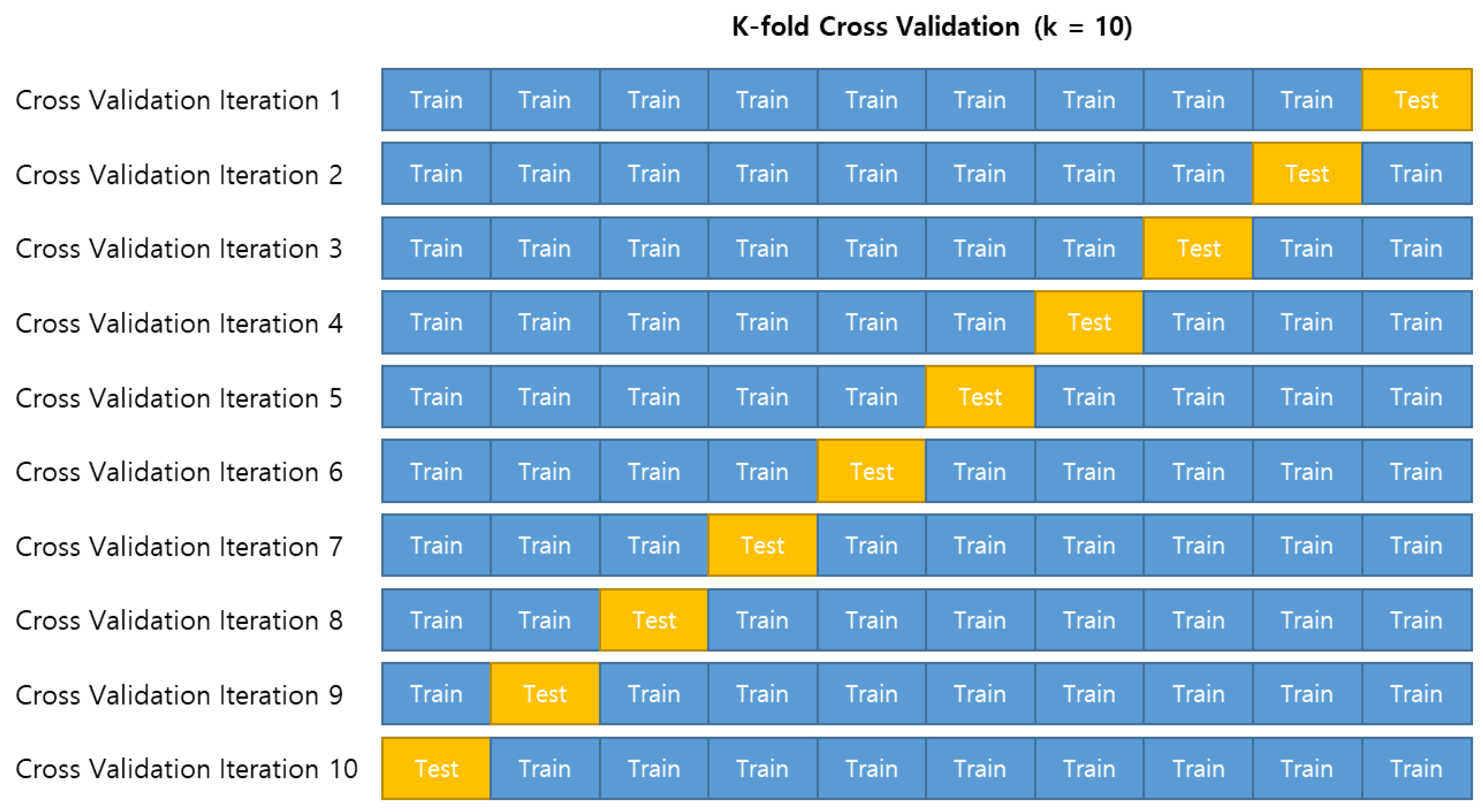

4.1. Regularization

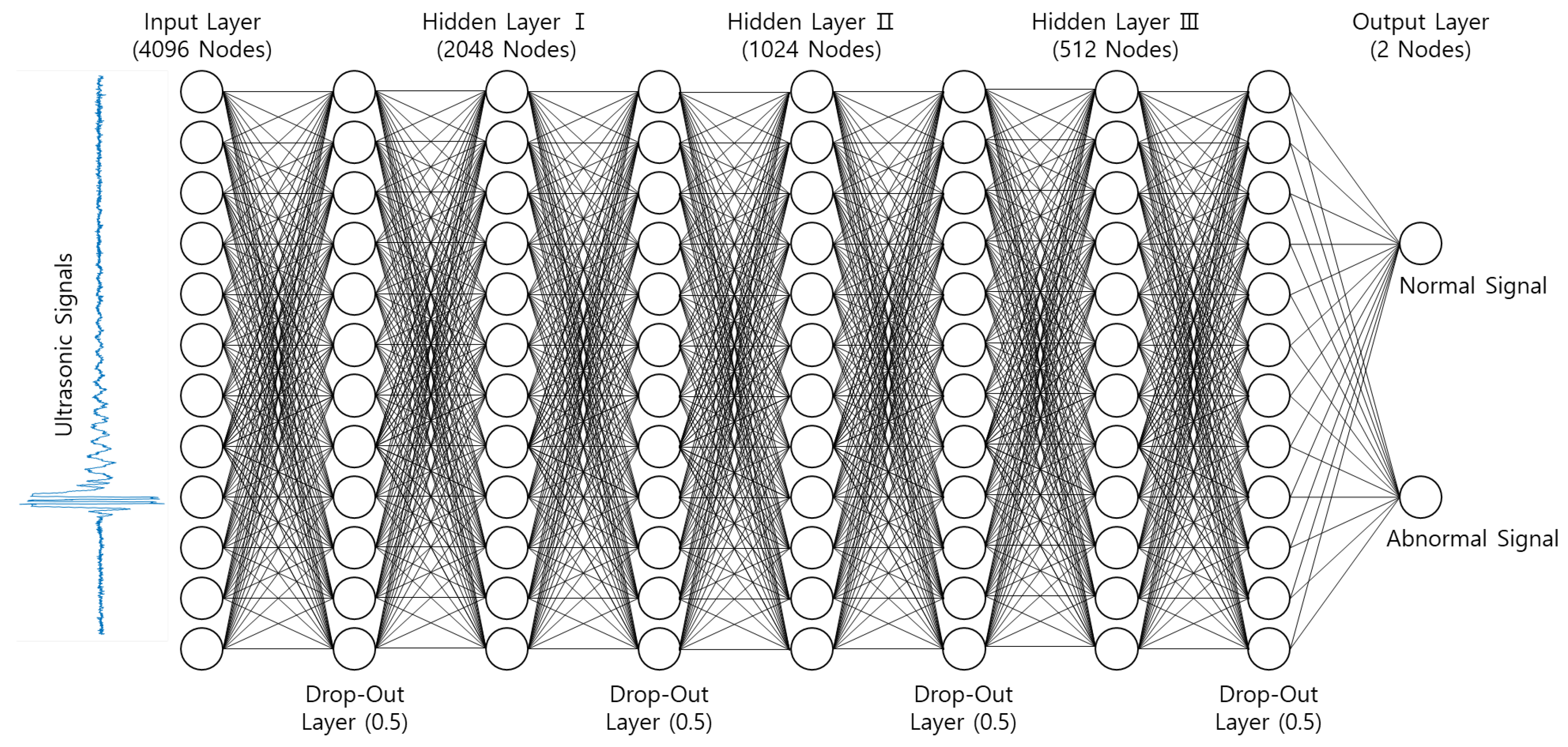

4.2. Fully Connected Deep Neural Network

4.3. Convolutional Neural Network

5. Results

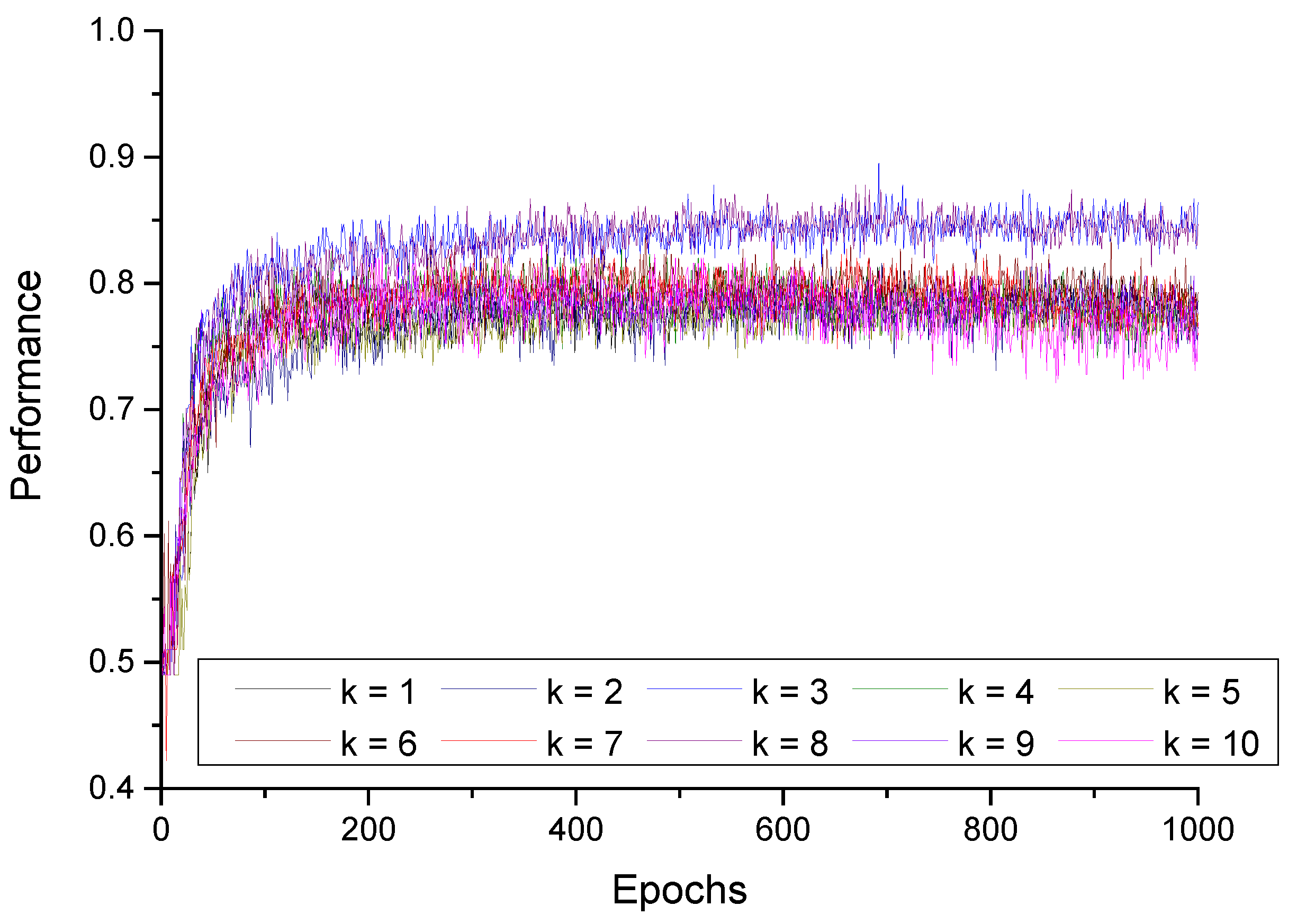

5.1. Results of the Fully Connected Deep Neural Network

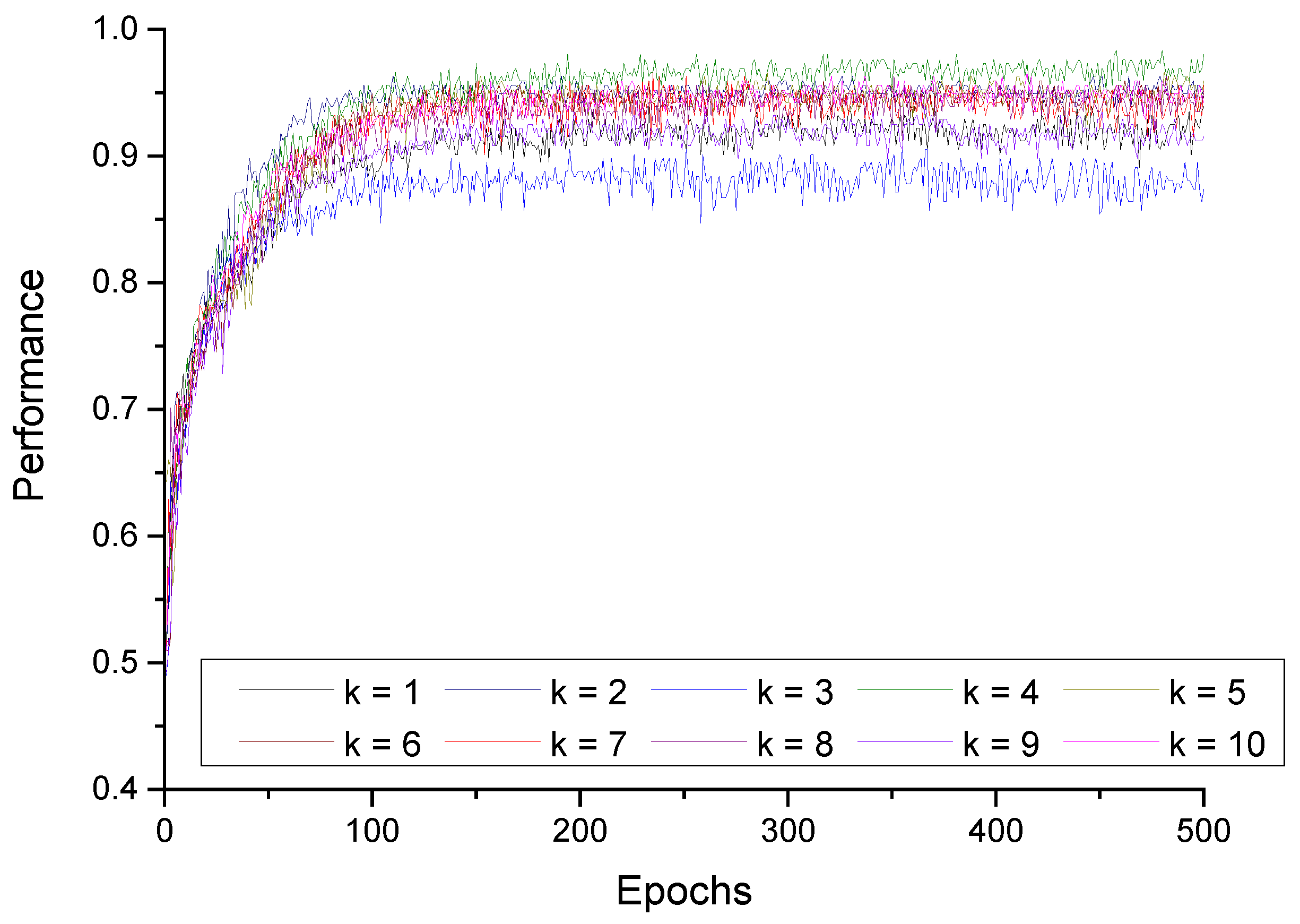

5.2. Results for the Convolutional Neural Network

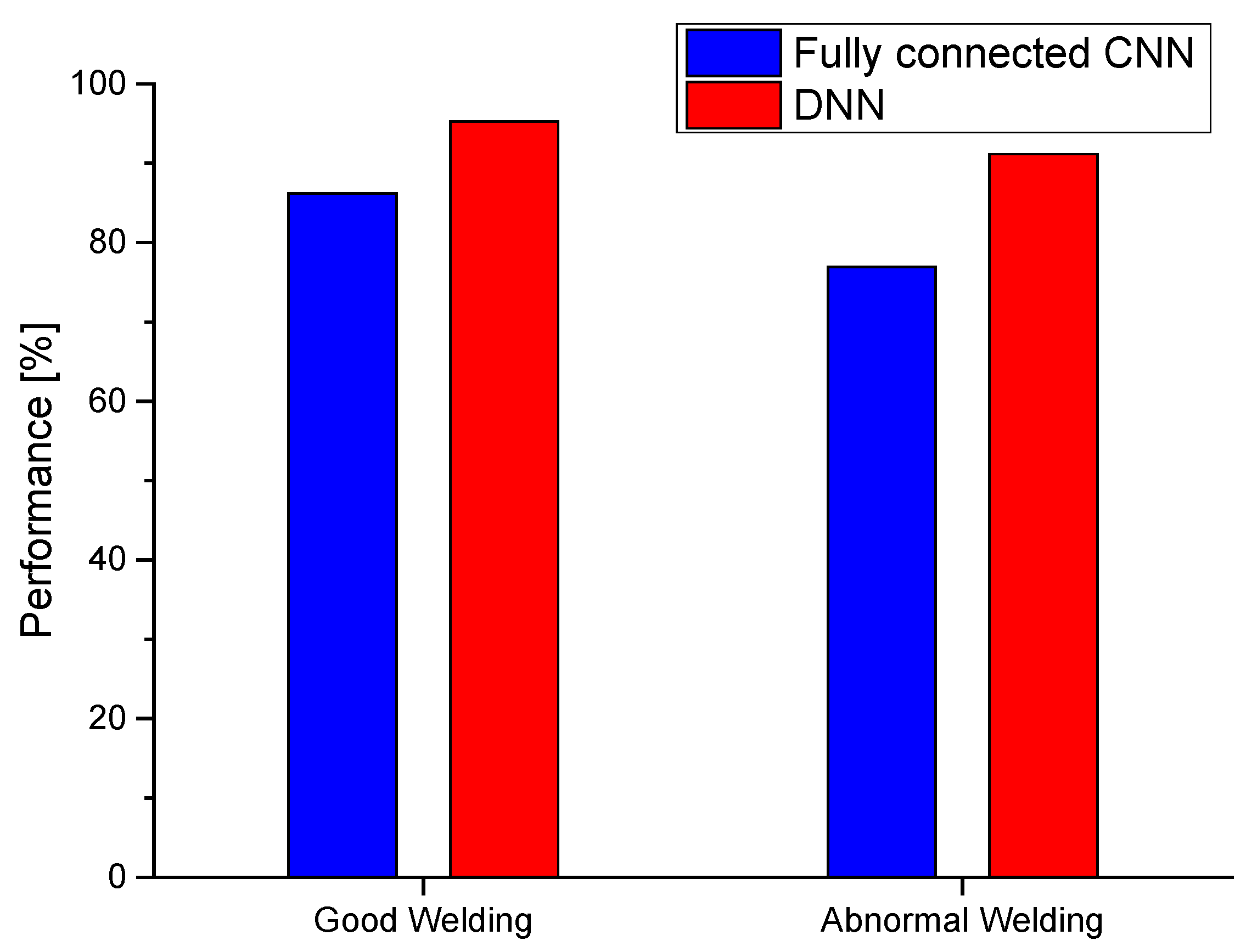

5.3. Performance Comparison

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Yoshino, A. The birth of the lithium-ion battery. Angew. Chem. Int. Ed. 2012, 51, 5798–5800. [Google Scholar] [CrossRef] [PubMed]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Kong, L.; Li, C.; Jiang, J.; Pecht, M.G. Li-Ion Battery Fire Hazards and Safety Strategies. Energies 2018, 11, 2191. [Google Scholar] [CrossRef] [Green Version]

- Yao, X.-Y.; Pecht, M.G. Tab Design and Failures in Cylindrical Li-ion Batteries. IEEE Access 2019, 7, 24082–24095. [Google Scholar] [CrossRef]

- Chung, J.S.; Park, S.S.; Kim, J.H.; Kwon, H.M.; Hong, S.H.; Lee, M.K. Process Optimization for Improving Resistance Welding Quality of Cylindrical Secondary Battery. J. Korean Soc. Qual. Manag. 2020, 48, 69–86. [Google Scholar]

- Lee, S.S.; Kim, T.H.; Hu, S.J.; Cai, W.W.; Abell, J.A. Joining Technologies for Automotive Lithium-Ion Battery Manufacturing: A Review. In Proceedings of the International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010; pp. 541–549. [Google Scholar] [CrossRef]

- Schwartz, S.; Soderstrom, R.; Bjareklint, A.U.S. Method of Joining Metal to Graphite by Spot Welding. U.S. Patent 4,343,982, 10 August 1982. [Google Scholar]

- Lambert, S.M.; Armstrong, M.; Attidekou, P.S.; Christensen, P.A.; Widmer, J.D.; Wang, C.; Scott, K. Rapid Nondestructive-Testing Technique for In-Line Quality Control of Li-Ion Batteries. IEEE Trans. Ind. Electron. 2016, 64, 4017–4026. [Google Scholar] [CrossRef]

- Sood, B.; Osterman, M.; Pecht, M. Health Monitoring of Lithium-Ion Batteries. In Proceedings of the 2013 IEEE Symposium on Product Compliance Engineering (ISPCE), Austin, TX, USA, 7–9 October 2013; pp. 1–6. [Google Scholar]

- Mohanty, D.; Li, J.; Born, R.; Maxey, L.C.; Dinwiddie, R.B.; Daniel, C.; Wood, D.L., III. Non-destructive evaluation of slot-die-coated lithium secondary battery electrodes by in-line laser caliper and IR thermography methods. Anal. Methods 2014, 6, 674–683. [Google Scholar] [CrossRef]

- Hou, W.; Wei, Y.; Guo, J.; Jin, Y.; Zhu, C. Automatic Detection of Welding Defects using Deep Neural Network. J. Phys. Conf. Ser. 2018, 933, 012006. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning Internal Representations by Error Propagation (No. ICS-8506); Institute for Cognitive Science, University of California: San Diego, CA, USA, 1985. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Schmidhuber, J. Deep Learning in Neural Networks: An Overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Munir, N.; Kim, H.-J.; Park, J.; Song, S.-J.; Kang, S.-S. Convolutional neural network for ultrasonic weldment flaw classification in noisy conditions. Ultrasonics 2018, 94, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.; Chen, Q.; Yan, S. Network in network. arXiv 2013, arXiv:1312.4400, preprint. [Google Scholar]

- Gan, Z.; Henao, R.; Carlson, D.; Carin, L. Learning Deep Sigmoid Belief Networks With Data Augmentation. In Proceedings of the International Conference on Artificial Intelligence and Statistics, San Diego, CA, USA, 9–12 May 2015; pp. 268–276. [Google Scholar]

- Cui, X.; Goel, V.; Kingsbury, B. Data augmentation for deep neural network acoustic modeling. IEEE/ACM Trans. Audio Speech Lang. Process. 2015, 23, 1469–1477. [Google Scholar] [CrossRef]

- Perez, L.; Wang, J. The effectiveness of data augmentation in image classification using deep learning. arXiv 2017, arXiv:1712.04621, preprint. [Google Scholar]

- Virkkunen, I.; Koskinen, T.; Jessen-Juhler, O.; Rinta-Aho, J. Augmented Ultrasonic Data for Machine Learning. J. Nondestruct. Eval. 2021, 40, 1–11. [Google Scholar] [CrossRef]

- Bengio, Y.; Grandvalet, Y. No unbiased estimator of the variance of k-fold cross-validation. J. Mach. Learn. Res. 2004, 5, 1089–1105. [Google Scholar]

- Rodríguez, J.D.; Pérez, A.; Lozano, J.A. Sensitivity Analysis of k-Fold Cross Validation in Prediction Error Estimation. IEEE Trans. Pattern Anal. Mach. Intell. 2009, 32, 569–575. [Google Scholar] [CrossRef]

- Géron, A. Hands-on Machine Learning with Scikit-Learn and Tensor Flow; O’Reilly Media, Inc.: Newton, MA, USA, 2018. [Google Scholar]

- Park, S.-H.; Choi, S.; Jhang, K.-Y. Porosity Evaluation of Additively Manufactured Components Using Deep Learning-based Ultrasonic Nondestructive Testing. Int. J. Precis. Eng. Manuf. Technol. 2021, 1–13. [Google Scholar] [CrossRef]

- Hinton, G.E.; Srivastava, N.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R.R. Improving neural networks by preventing co-adaptation of feature detectors. arXiv 2012, arXiv:1207.0580. [Google Scholar]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Nair, V.; Hinton, G.E. Rectified Linear Units Improve Restricted Boltzmann Machines. In Proceedings of the international Conference on Machine Learning, Haifa, Israel, 21–24 June 2010; pp. 807–814. [Google Scholar] [CrossRef]

- Maas, A.L.; Hannun, A.Y.; Ng, A.Y. Rectifier nonlinearities improve neural network acoustic models. Proc. Icml. 2013, 30, 3. [Google Scholar]

- Alex, K.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, D.; Gao, B.; Tian, G.Y.; Cai, Z.C. A Deep Learning-Based Ultrasonic Pattern Recognition Method for Inspecting Girth Weld Cracking of Gas Pipeline. IEEE Sens. J. 2020, 20, 7997–8006. [Google Scholar] [CrossRef]

- Ye, J.; Ito, S.; Toyama, N. Computerized Ultrasonic Imaging Inspection: From Shallow to Deep Learning. Sensors 2018, 18, 3820. [Google Scholar] [CrossRef] [Green Version]

- Park, S.-H.; Hong, J.-Y.; Ha, T.; Choi, S.; Jhang, K.-Y. Deep Learning-Based Ultrasonic Testing to Evaluate the Porosity of Additively Manufactured Parts with Rough Surfaces. Metals 2021, 11, 290. [Google Scholar] [CrossRef]

- Munir, N.; Park, J.; Kim, H.-J.; Song, S.-J.; Kang, S.-S. Performance enhancement of convolutional neural network for ultrasonic flaw classification by adopting autoencoder. NDT E Int. 2020, 111, 102218. [Google Scholar] [CrossRef]

- Clevert, D.A.; Unterthiner, T.; Hochreiter, S. Fast and accurate deep network learning by exponential linear units (elus). arXiv 2015, arXiv:1511.07289. [Google Scholar]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Miorelli, R.; Fisher, C.; Kulakovskyi, A.; Chapuis, B.; Mesnil, O.; D’Almeida, O. Defect sizing in guided wave imaging structural health monitoring using convolutional neural networks. NDT E Int. 2021, 122, 102480. [Google Scholar] [CrossRef]

- Cao, Y.; Dong, Y.; Cao, Y.; Yang, J.; Yang, M.Y. Two-stream convolutional neural network for non-destructive subsurface defect detection via similarity comparison of lock-in thermography signals. NDT E Int. 2020, 112, 102246. [Google Scholar] [CrossRef]

- Springenberg, J.T.; Dosovitskiy, A.; Brox, T.; Riedmiller, M. Striving for simplicity: The all convolutional net. arXiv 2014, arXiv:1412.6806. [Google Scholar]

| k | Good Welding | Abnormal Welding |

|---|---|---|

| 1 | 88.45 ± 5.58% | 76.85 ± 0.30% |

| 2 | 87.04 ± 1.21% | 75.07 ± 3.52% |

| 3 | 89.56 ± 14.86% | 77.29 ± 1.18% |

| 4 | 83.51 ± 7.53% | 78.32 ± 3.24% |

| 5 | 84.27 ± 2.02% | 73.24 ± 3.82% |

| 6 | 86.56 ± 9.09% | 75.82 ± 0.60% |

| 7 | 82.92 ± 2.49% | 78.18 ± 1.95% |

| 8 | 84.41 ± 3.73% | 82.59 ± 4.78% |

| 9 | 84.07 ± 6.29% | 77.04 ± 0.94% |

| 10 | 90.99 ± 6.01% | 75.21 ± 0.28% |

| k | Good Welding | Abnormal Welding |

|---|---|---|

| 1 | 95.67 ± 4.69% | 88.74 ± 0.64% |

| 2 | 94.95 ± 0.05% | 93.81 ± 3.78% |

| 3 | 90.91 ± 4.36% | 84.03 ± 2.24% |

| 4 | 98.26 ± 3.82% | 94.33 ± 0.33% |

| 5 | 95.97 ± 2.01% | 95.17 ± 0.05% |

| 6 | 94.72 ± 0.33% | 95.44 ± 1.40% |

| 7 | 93.38 ± 12.50% | 85.44 ± 3.16% |

| 8 | 99.26 ± 2.84% | 90.22 ± 0.63% |

| 9 | 92.20 ± 0.68% | 90.44 ± 4.44% |

| 10 | 97.23 ± 1.67% | 93.65 ± 0.67% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, Y.-I.; Park, J.; Munir, N.; Kim, H.-J.; Song, S.-J.; Kim, K.-B. Discrimination of Poor Electrode Junctions within Lithium-Ion Batteries by Ultrasonic Measurement and Deep Learning. Batteries 2022, 8, 21. https://doi.org/10.3390/batteries8030021

Hwang Y-I, Park J, Munir N, Kim H-J, Song S-J, Kim K-B. Discrimination of Poor Electrode Junctions within Lithium-Ion Batteries by Ultrasonic Measurement and Deep Learning. Batteries. 2022; 8(3):21. https://doi.org/10.3390/batteries8030021

Chicago/Turabian StyleHwang, Young-In, Jinhyun Park, Nauman Munir, Hak-Joon Kim, Sung-Jin Song, and Ki-Bok Kim. 2022. "Discrimination of Poor Electrode Junctions within Lithium-Ion Batteries by Ultrasonic Measurement and Deep Learning" Batteries 8, no. 3: 21. https://doi.org/10.3390/batteries8030021

APA StyleHwang, Y.-I., Park, J., Munir, N., Kim, H.-J., Song, S.-J., & Kim, K.-B. (2022). Discrimination of Poor Electrode Junctions within Lithium-Ion Batteries by Ultrasonic Measurement and Deep Learning. Batteries, 8(3), 21. https://doi.org/10.3390/batteries8030021