Effects of Hyperbaric Micro-Oxygenation on the Color, Volatile Composition, and Sensory Profile of Vitis vinifera L. cv. Monastrell Grape Must

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Experimental Treatments

2.3. Color Measurement

2.4. Volatile Organic Compounds (VOCs)

2.5. Descriptive Sensory Analysis

- Odor: alcohol, fruity, floral, herbal, spicy, woody, roasted, ripe fruit, tropical fruit, red fruit, citric, animal, balsamic, coffee, and nuts.

- Flavor: alcohol, fruity, floral, herbal, spicy, woody, roasted, sweet, sour, bitter, astringency, persistence, ripe fruit, tropical fruit, red fruit, citric, animal, balsamic, coffee, nuts, and defects.

2.6. Statistical Analysis

3. Results and Discussions

3.1. Color Measurements

3.1.1. CIELab

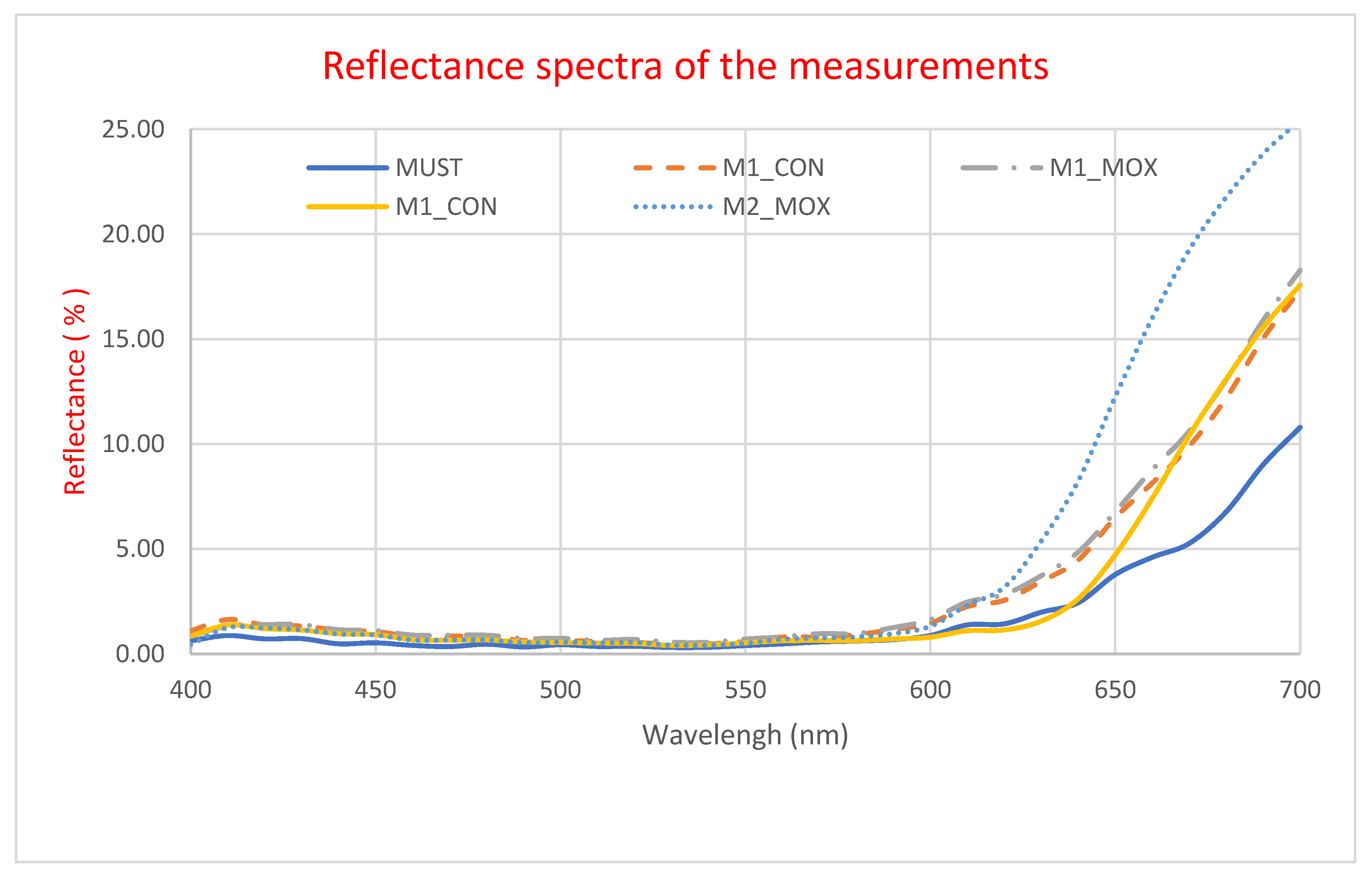

3.1.2. Reflectance Measurements in the Visible Spectrum

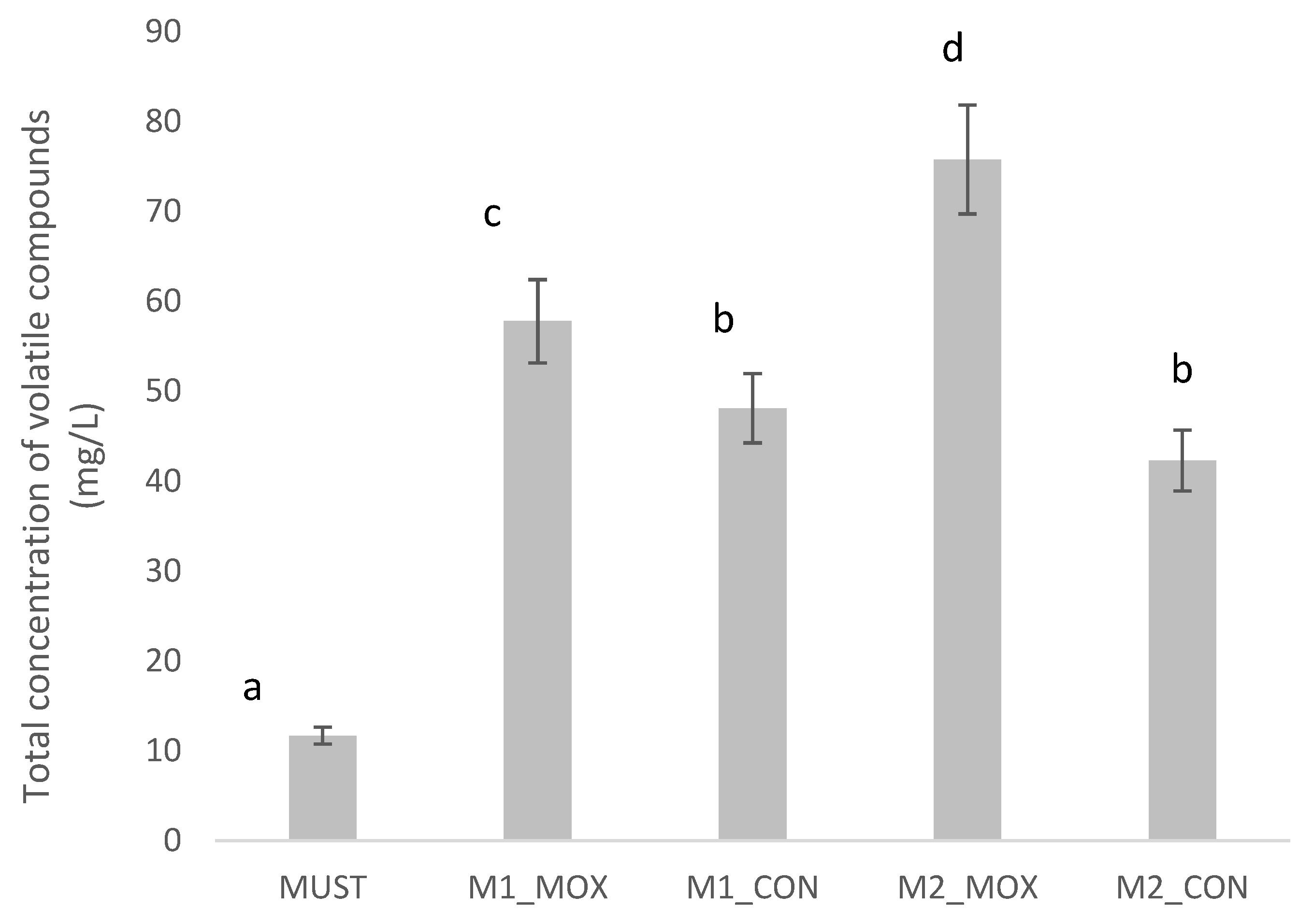

3.2. Volatile Compounds

3.3. Descriptive Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, Y.H.; Ye, Y.Q.; Hao, Z.P.; Tan, X.Y.; Ye, M.Q. Research on wine flavor: A bibliometric and visual analysis (2003–2022). Food Chem. Adv. 2024, 4, 100717. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Yang, H.; Sun, L.; Xia, H.; Sun, W.; Wang, Z.; Zhang, J. Bacterial communities related to aroma formation during spontaneous fermentation of ‘Cabernet Sauvignon’wine in Ningxia, China. Foods 2022, 11, 2775. [Google Scholar] [CrossRef]

- Tan, J.; Ji, M.; Gong, J.; Chitrakar, B. The formation of volatiles in fruit wine process and its impact on wine quality. Appl. Microbiol. Biotechnol. 2024, 108, 420. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Moreno, A.; Toledo-Gil, R.; Bautista-Ortín, A.B.; Gómez-Plaza, E.; Yuste, J.E.; Vallejo, F. Exploring the Impact of Extended Maceration on the Volatile Compounds and Sensory Profile of Monastrell Red Wine. Fermentation 2024, 10, 343. [Google Scholar] [CrossRef]

- González-Sanjosé, M.L.; Ortega-Heras, M.; Pérez-Magariño, S. Microoxygenation Treatment and Sensory Properties of Young Red Wines. Food Sci. Technol. Int. 2008, 14 (Suppl. S5), 123–130. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Pérez-Coello, M.S.; Hermosín-Gutiérrez, I. Effect of wine micro-oxygenation treatment and storage period on colour-related phenolics, volatile composition and sensory characteristics. LWT-Food Sci. Technol. 2011, 44, 866–874. [Google Scholar] [CrossRef]

- Sánchez-Gómez, R.; del Alamo-Sanza, M.; Martínez-Gil, A.M.; Nevares, I. Red Wine Aging by Different Micro-Oxygenation Systems and Oak Wood—Effects on Anthocyanins, Copigmentation and Color Evolution. Processes 2020, 8, 1250. [Google Scholar] [CrossRef]

- Gómez-Plaza, E.; Cano-López, M. A review on micro-oxygenation of red wines: Claims, benefits and the underlying chemistry. Food Chem. 2011, 125, 1131–1140. [Google Scholar] [CrossRef]

- Aceituno, F.F.; Orellana, M.; Torres, J.; Mendoza, S. Oxygen Response of the Wine Yeast Saccharomyces cerevisiae EC1118 Grown under Carbon-Sufficient, Nitrogen-Limited Enological Conditions. Appl. Environ. Microbiol. 2012, 78, 8340–8352. [Google Scholar] [CrossRef]

- Nevares, I.; Fernández-Díaz, A.; del Alamo-Sanza, M. Characterization and Control of Hidden Micro-Oxygenation in the Winery: Wine Racking. Foods 2021, 10, 386. [Google Scholar] [CrossRef] [PubMed]

- Guerrini, L.; Masella, P.; Angeloni, G.; Sacconi, A.; Calamai, L.; Parenti, A. Effects of a Small Increase in Carbon Dioxide Pressure during Fermentation on Wine Aroma. Foods 2020, 9, 1496. [Google Scholar] [CrossRef]

- Lukić, K.; Ćurko, N.; Tomasević, M.; Kovačević Ganić, K. Phenolic and Aroma Changes of Red and White Wines during Aging Induced by High Hydrostatic Pressure. Foods 2020, 9, 1034. [Google Scholar] [CrossRef]

- Kumar, Y.; Marangon, M.; Mayr Marangon, C. The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement. Beverages 2023, 9, 30. [Google Scholar] [CrossRef]

- Comuzzo, P.; Calligaris, S. Potential Applications of High Pressure Homogenization in Winemaking: A Review. Beverages 2019, 5, 56. [Google Scholar] [CrossRef]

- Cano-López, M.; Pardo-Mínguez, F.; Schmauch, G.; Saucier, C.; Teissedre, P.-L.; López-Roca, J.M.; Gómez-Plaza, E. Effect of micro-oxygenation on color and anthocyanin-related compounds of wines with different phenolic contents. J. Agric. Food Chem. 2008, 56, 5932–5941. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Álvarez, E.P.; Intrigliolo, D.S.; Almajano, M.P. Effects of water deficit irrigation on phenolic composition and antioxidant activity of Monastrell grapes under semiarid conditions. Antioxidants 2021, 10, 1301. [Google Scholar] [CrossRef]

- Schmidtke, L.M.; Clark, A.C.; Scollary, G.R. Micro-Oxygenation of Red Wine: Techniques, Applications, and Outcomes. Crit. Rev. Food Sci. Nutr. 2011, 51, 115–131. [Google Scholar] [CrossRef] [PubMed]

- Tarko, T.; Duda-Chodak, A.; Sroka, P.; Januszek, M. Effect of Musts Oxygenation at Various Stages of Cider Production on Oenological Parameters, Antioxidant Activity, and Profile of Volatile Cider Compounds. BioMolecules 2020, 10, 890. [Google Scholar] [CrossRef]

- Maza, M.; Álvarez, I.; Raso, J. Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages 2019, 5, 47. [Google Scholar] [CrossRef]

- Carrasco-Quiroz, M.; del Alamo-Sanza, M.; Martínez-Gil, A.M.; Nevares, I. Influence of Oxygen Management on Color and Phenolics of Red Wines. Molecules 2023, 28, 459. [Google Scholar] [CrossRef]

- International Commission on Illumination (CIE). Colorimetry, 4th ed.; CIE 15:2018; Technische Regel; International Commission on Illumination: Vienna, Austria, 2018. [Google Scholar]

- Pérez-López, A.J.; Beltran, F.; Serrano-Megías, M.; López, D.S.; Carbonell-Barrachina, A.A. Changes in orange juice color by addition of mandarin juice. Eur. Food Res. Technol. 2006, 222, 516–520. [Google Scholar] [CrossRef]

- Issa-Issa, H.; Hernández, F.; Lipan, L.; López-Lluch, D.; Carbonell-Barrachina, Á.A. Quality, Nutritional, Volatile and Sensory Profiles and Consumer Acceptance of Fondillón, a Sustainable European Protected Wine. Agronomy 2021, 11, 1701. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques, 4th ed.; Taylor Francis: Boca Raton, FL, USA; CRC Press: Boca Raton, FL, USA, 2006; p. 416. [Google Scholar]

- ISO 8586-1; Sensory Analysis—General Guidance for the Selection, Training and Monitoring of Assessors. International Organization for Standardization: Geneva, Switzerland, 1993.

- Issa-Issa, H.; Noguera-Artiaga, L.; Sendra, E.; Pérez-López, A.J.; Burló, F.; Carbonell-Barrachina, A.A.; López-Lluch, D. Volatile Composition, Sensory Profile, and Consumers’ Acceptance of Fondillón. J. Food Qual. 2019, 1, 5981762. [Google Scholar] [CrossRef]

- Sánchez-Gómez, R.; Cebrián-Tarancón, C.; Martínez-Gil, A.M.; Nevares, I.; Alonso, G.L.; Salinas, M.R.; Del Alamo-Sanza, M. Effect of micro-oxygenation on color of wines made with toasted vine-shoots. J. Sci. Food Agric. 2025, 105, 1569–1582. [Google Scholar] [CrossRef] [PubMed]

- Catania, A.; Lerno, L.; Sari, S.; Fanzone, M.; Casassa, L.F.; Oberholster, A. Impact of micro-oxygenation timing and rate of addition on color stabilization and chromatic characteristics of Cabernet Sauvignon wines. LWT-Food Sci. Technol. 2021, 149, 111776. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, T.; Gao, J.; Han, X.; Huang, W.; You, Y.; Zhan, J. Color myth: Anthocyanins reactions and enological approaches achieving their stabilization in the aging process of red wine. Food Innov. Adv. 2023, 2, 255–271. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, Y.; Li, Y. A New Approach for Quantitative Classification of Red Wine Color from the Perspective of Micro and Macro Levels. Fermentation 2023, 9, 519. [Google Scholar] [CrossRef]

- Uysal, R.S.; Issa-Issa, H.; Sendra, E.; Carbonell-Barrachina, Á.A. Changes in anthocyanin pigments, trans-resveratrol, and colorimetric characteristics of Fondillón wine and other “Monastrell” wines during the aging period. Eur. Food Res. Technol. 2023, 249, 1821–1831. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Lyu, X.; Fang, X.; Cao, X. Metabolomic analysis to unravel the composition and dynamic variations of anthocyanins in bayberry-soaked wine during the maceration process. Food Chem. 2024, 21, 101175. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Sun, Y.; Qian, M. Influence of Oxygen Management during the Post-Fermentation Stage on Acetaldehyde, Color, and Phenolics of Vitis vinifera L. Cv. Cabernet Sauvignon Wine. Molecules 2022, 27, 6692. [Google Scholar] [CrossRef]

- Yang, Y.; Deed, R.C.; Araujo, L.D.; Kilmartin, P.A. The Influence of Micro-oxygenation on the Long-term Ageing Ability of Pinot noir Wine. S. Afr. J. Enol. Vitic. 2022, 43, 1–9. [Google Scholar] [CrossRef]

- Baris, F.; Castro Marin, A.; Chinnici, F. Oxidative Evolution of Different Model Rosé Wines Affected by Distinct Anthocyanin and Tannin Contents. Beverages 2024, 10, 43. [Google Scholar] [CrossRef]

- Pelonnier-Magimel, E.; Chira, K.; Teissèdre, P.-L.; Jourdes, M.; Barbe, J.-C. Color Characterization of Bordeaux Red Wines Produced without Added Sulfites. Foods 2023, 12, 2358. [Google Scholar] [CrossRef]

- Oberholster, A.; Elmendorf, B.L.; Lerno, L.A.; King, E.S.; Heymann, H.; Brenneman, C.E.; Boulton, R.B. Barrel maturation, oak alternatives and micro-oxygenation: Influence on red wine aging and quality. Food Chem. 2015, 173, 1250–1258. [Google Scholar] [CrossRef]

- Sánchez-Iglesias, M.; González-Sanjosé, M.L.; Pérez-Magariño, S.; Ortega-Heras, M.; González-Huerta, C. Effect of micro-oxygenation and wood type on the phenolic composition and color of an aged red wine. J. Agric. Food Chem. 2009, 57, 11498–11509. [Google Scholar] [CrossRef]

- Durner, D.; Hensel, M. Is there a need to re-define the methods to evaluate wine color. In Proceedings of the 44th World Congress of Vine and Wine, Jerez de la Frontera, Spain, 5–9 June 2023. [Google Scholar]

- He, F.; Liang, N.-N.; Mu, L.; Pan, Q.-H.; Wang, J.; Reeves, M.J.; Duan, C.-Q. Anthocyanins and their variation in red wines II. Anthocyanin derived pigments and their color evolution. Molecules 2012, 17, 1483–1519. [Google Scholar] [CrossRef] [PubMed]

- Gambuti, A.; Rinaldi, A.; Ugliano, M.; Moio, L. Evolution of phenolic compounds and astringency during aging of red wine: Effect of oxygen exposure before and after bottling. J. Agric. Food Chem. 2013, 61, 1618–1627. [Google Scholar] [CrossRef]

- Pérez-Serradilla, J.A.; Luque de Castro, M.D. Role of lees in wine production: A review. Food Chem. 2008, 111, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Magariño, S.; Sánchez-Iglesias, M.; Ortega-Heras, M.; González-Huerta, C.; González-Sanjosé, M.L. Colour stabilization of red wines by microoxygenation treatment before malolactic fermentation. Food Chem. 2007, 101, 881–893. [Google Scholar] [CrossRef]

- Prusova, B.; Humaj, J.; Sochor, J.; Baron, M. Formation, Losses, Preservation and Recovery of Aroma Compounds in the Winemaking Process. Fermentation 2022, 8, 93. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, Z.; Han, Y.; Duan, Y.; Shi, B.; Ma, W. A Review on Wine Flavour Profiles Altered by Bottle Aging. Molecules 2023, 28, 6522. [Google Scholar] [CrossRef]

- Schmarr, H.G.; Bernhardt, J.; Fischer, U.; Stephan, A.; Müller, P.; Durner, D. Two-dimensional gas chromatographic profiling as a tool for a rapid screening of the chsanges in volatile composition occurring due to microoxygenation of red wines. Anal. Chim. Acta 2010, 672, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Orte, P.; Lapeña, A.C.; Escudero, A.; Astrain, J.; Baron, C.; Pardo, I.; Polo, L.; Ferrer, S.; Cacho, J.; Ferreira, V. Effect of micro-oxygenation on the evolution of aromatic compounds in wines: Malolactic fermentation and ageing in wood. LWT-Food Sci. Technol. 2009, 42, 391–401. [Google Scholar] [CrossRef]

- Drinkine, J.; Glories, Y.; Saucier, C. (+)-Catechin−Aldehyde Condensations: Competition between Acetaldehyde and Glyoxylic Acid. J. Agric. Food Chem. 2005, 53, 7552–7558. [Google Scholar] [CrossRef] [PubMed]

- Geldenhuys, L.; Oberholster, A.; du Toit, W.J. Monitoring the effect of micro-oxygenation before malolactic fermentation on South African pinotage red wine with different colour and phenolic analyses. S. Afr. J. Enol. Vitic. 2012, 33, 150–160. [Google Scholar] [CrossRef][Green Version]

- Heras, M.O.; Rivero-Pérez, M.D.; Pérez-Magariño, S.; González-Huerta, C.; González-Sanjosé, M.L. Changes in the volatile composition of red wines during aging in oak barrels due to microoxygenation treatment applied before malolactic fermentation. Eur. Food Res. Technol. 2008, 226, 1485–1493. [Google Scholar] [CrossRef]

| Samples | Fermentation Times | pH | Density (g/mL) | Total Acidity (g/L) | Potential Alcohol (% v/v) | Actual Alcohol (% v/v) | Residual Sugar (g/L) |

|---|---|---|---|---|---|---|---|

| Must (M) | Initial (Day 0) | 3.61 ± 0.10 ‡ a | 1.115 ± 0.022 a | 5.69 ± 0.04 a | 15.5 ± 0.1 c | 0 ± 0 d | 260 ± 0.52 d |

| M1_MOX | Mid (Day 3) | 3.64 ± 0.09 a | 1.088 ± 0.006 b | 5.70 ± 0.02 a | 12 ± 0.1 b | 3.5 ± 0.2 c | 203 ± 0.22 b |

| M2_MOX | Final (Day 13) | 3.58 ± 0.07 a | 0.993 ± 0.002 c | 5.77 ± 0.03 a | 0 ± 0 a | 15.4 ± 0.2 b | 2.3 ± 0.012 a |

| M1_CON | Mid (Day 3) | 3.63 ± 0.08 a | 1.090 ± 0.008 b | 5.73 ± 0.01 a | 12 ± 0.1 b | 3.2 ± 0.1 a | 207 ± 0.41 c |

| M2_CON | Final (Day 13) | 3.73 ± 0.07 a | 0.992 ± 0.004 c | 5.79 ± 0.03 a | 0 ± 0 a | 15.4 ± 0.2 b | 2.3 ± 0.035 a |

| Samples | Fermentation Times | L* | a* | b* | C* | hab | |

|---|---|---|---|---|---|---|---|

| Must (M) | Initial (Day 0) | 5.94 ± 0.02 a | 13.17 ± 0.10 a | 2.32 ± 0.02 a | 13.40 ± 0.11 a | 10.36 ± 0.16 a | - |

| M1_MOX | Mid (Day 3) | 10.59 ± 0.06 c | 18.12 ± 0.04 b | 1.86 ± 0.09 a | 18.23 ± 0.15 b | 5.82 ± 0.11 b | 6.81 ± 0.11 a |

| M2_MOX | Final (Day 13) | 10.76 ± 0.03 c | 24.54 ± 0.12 c | 5.25 ± 0.03 b | 25.10 ± 0.08 c | 12.05 ± 0.14 c | 12.69 ± 0.25 b |

| M1_CON | Mid (Day 3) | 6.98 ± 0.07 b | 13.90 ± 0.08 a | −1.44 ± 0.12 a | 13.97 ± 0.03 a | 4.20 ± 0.18 b | 3.97.20 ± 0.16 c |

| M2_CON | Final (Day 13) | 9.71 ± 0.11 c | 18.40 ± 0.03 b | 0.87 ± 0.15 a | 18.42 ± 0.09 b | 2.69 ± 0.21 b | 6.61 ± 0.19 a |

| Compound | RT (min) | ANOVA † | MUST | M1_MOX | M1_CON | M2_MOX | M2_CON |

|---|---|---|---|---|---|---|---|

| 1-Propanol | 2.417 | *** | 0.166 a ‡ | 0.837 a | 0.423 a | 5.898 b | 1.695 a |

| Ethyl acetate | 2.727 | *** | 3.399 a | 4.161 a | 4.232 a | 10.037 b | 5.391 a |

| 2-Methylpropan-1-ol | 2.837 | *** | 0.139 a | 0.312 a | 0.328 a | 1.162 c | 0.682 b |

| 3-Methylbutan-1-ol | 4.190 | *** | 0.915 a | 2.858 a | 3.161 a | 11.870 c | 6.602 b |

| Ethyl butyrate | 5.653 | *** | 0.003 a | 0.101 ab | 0.064 a | 0.216 b | 0.113 ab |

| 1-Hexanol | 8.063 | *** | 1.945 b | 0.333 a | 0.292 a | 0.663 a | 0.348 a |

| Isoamyl acetate | 8.347 | *** | 0.845 a | 2.955 b | 2.152 b | 5.134 c | 1.982 ab |

| Hexanoic acid | 13.497 | *** | 0.144 b | 0.124 a | 0.124 a | 0.125 a | 0.123 a |

| Ethyl hexanoate | 14.660 | *** | 0.129 a | 1.290 b | 0.973 b | 2.333 c | 0.866 b |

| Hexyl acetate | 15.490 | *** | 1.456 c | 0.786 b | 0.285 a | 0.411 a | 0.146 a |

| Linalool | 21.283 | *** | 0.142 a | 0.179 a | 0.176 a | 0.264 b | 0.160 a |

| 2-Phenylethanol | 22.027 | *** | 0.400 a | 1.368 b | 1.834 bc | 2.484 c | 1.703 b |

| Ethyl octanoate | 27.903 | *** | 0.304 a | 26.221 d | 20.085 c | 27.763 d | 16.276 b |

| Geraniol | 31.240 | *** | 0.135 a | 1.585 c | 1.724 c | 0.456 b | 0.077 a |

| Ethyl decanoate | 38.833 | *** | 1.003 a | 11.593 d | 9.439 c | 6.014 b | 5.256 b |

| β-Ionone | 42.460 | *** | 0.211 b | 0.023 a | 0.049 a | 0.101 a | 0.091 a |

| Ethyl dodecanoate | 47.403 | *** | 0.362 a | 3.051 b | 2.755 b | 0.835 a | 0.786 a |

| Alcohols | *** | 3.566 a | 5.707 b | 6.037 b | 22.077 d | 11.030 c | |

| Acids | NS | 0.144 | 0.124 | 0.124 | 0.125 | 0.123 | |

| Esters | *** | 7.502 a | 50.157 c | 39.985 b | 52.743 c | 30.816 b | |

| Terpenes | *** | 0.487 a | 1.787 c | 1.950 c | 0.820 b | 0.329 a |

| Descriptor | ANOVA † | MUST | M1_MOX | M1_CON | M2_MOX | M2_CON |

|---|---|---|---|---|---|---|

| Odor | ||||||

| Alcohol | ** | 0.0 a ‡ | 3.5 b | 3.5 b | 5.0 d | 4.5 c |

| Fruity | *** | 8.0 e | 6.5 d | 5.5 c | 4.5 b | 3.5 a |

| Floral | * | 5.5 c | 4.0 bc | 3.5 b | 3.5 b | 2.0 a |

| Herbal | ** | 4.5 c | 2.5 b | 2.5 b | 2.5 b | 1.5 a |

| Spicy | * | 0.0 a | 1.0 b | 1.0 b | 1.5 c | 1.0 b |

| Ripe fruit | * | 0.0 a | 1.0 b | 1.0 b | 1.5 c | 1.0 b |

| Tropical fruit | NS | 0.0 | 0.5 | 0.5 | 0.5 | 0.5 |

| Red fruit | ** | 4.5 c | 3.5 b | 3.0 b | 3.5 b | 2.0 a |

| Animal | NS | 0.0 | 0.5 | 0.5 | 0.5 | 1,0 |

| Balsamic | ** | 1.5 a | 2.5 b | 2.5 b | 2.5 b | 2.5 b |

| Flavor | ||||||

| Alcohol | *** | 0.0 a | 3.5 bc | 3.0 b | 5.0 c | 4.5 c |

| Fruity | ** | 8.5 e | 6.5 d | 5.5 c | 4.5 b | 2.5 a |

| Floral | * | 5.5 c | 3.5 b | 4.0 b | 3.5 b | 1.5 a |

| Herbal | ** | 2.5 b | 3.0 c | 3.0 c | 2.5 b | 1.0 a |

| Spicy | * | 0.0 a | 1.0 b | 1.0 b | 1.0 b | 1.0 b |

| Sweet | *** | 9.0 c | 5.5 b | 5.5 b | 4.0 b | 2.5 a |

| Sour | * | 5.0 c | 5.0 c | 4.5 bc | 3.5 b | 2.5 a |

| Bitter | ** | 0.5 a | 1.5 b | 1.5 b | 1.5 b | 2.5 c |

| Astringency | ** | 1.0 a | 2.5 b | 2.5 b | 2.5 b | 2.5 b |

| Persistence | * | 2.5 a | 3.5 b | 3.5 b | 3.5 b | 3.5 b |

| Ripe fruit | * | 0.0 a | 1.5 b | 1.5 b | 1.5 b | 1.5 b |

| Red fruit | * | 1.0 a | 2.5 b | 2.5 b | 2.5 b | 2.5 b |

| Animal | NS | 0.0 | 0.5 | 0.5 | 0.5 | 0.5 |

| Balsamic | NS | 1.0 | 1.5 | 1.5 | 1.5 | 1.5 |

| Defects | * | 0.0 a | 0.0 a | 0.0 a | 0.0 a | 1.5 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-López, A.J.; Noguera-Artiaga, L.; Navarro, P.; Mompean, P.; Van Lieshout, A.; Acosta-Motos, J.R. Effects of Hyperbaric Micro-Oxygenation on the Color, Volatile Composition, and Sensory Profile of Vitis vinifera L. cv. Monastrell Grape Must. Fermentation 2025, 11, 380. https://doi.org/10.3390/fermentation11070380

Pérez-López AJ, Noguera-Artiaga L, Navarro P, Mompean P, Van Lieshout A, Acosta-Motos JR. Effects of Hyperbaric Micro-Oxygenation on the Color, Volatile Composition, and Sensory Profile of Vitis vinifera L. cv. Monastrell Grape Must. Fermentation. 2025; 11(7):380. https://doi.org/10.3390/fermentation11070380

Chicago/Turabian StylePérez-López, Antonio José, Luis Noguera-Artiaga, Patricia Navarro, Pablo Mompean, Alejandro Van Lieshout, and José Ramón Acosta-Motos. 2025. "Effects of Hyperbaric Micro-Oxygenation on the Color, Volatile Composition, and Sensory Profile of Vitis vinifera L. cv. Monastrell Grape Must" Fermentation 11, no. 7: 380. https://doi.org/10.3390/fermentation11070380

APA StylePérez-López, A. J., Noguera-Artiaga, L., Navarro, P., Mompean, P., Van Lieshout, A., & Acosta-Motos, J. R. (2025). Effects of Hyperbaric Micro-Oxygenation on the Color, Volatile Composition, and Sensory Profile of Vitis vinifera L. cv. Monastrell Grape Must. Fermentation, 11(7), 380. https://doi.org/10.3390/fermentation11070380