Thermal Efficiency Analysis of a 1 kW ORC System with a Solar Collection Stage and R-245fa Working Fluid: A Case Study

Abstract

1. Introduction

- Analyzing mass and energy balance equations is crucial to optimizing a thermodynamic cycle.

- Implementing a regeneration stage with a solar collection system in an ORC plant enhances the thermal efficiency of the cycle system.

- The entry temperature of the organic working fluid in the primary exchanger from the regeneration stage is a critical factor.

2. Theoretical Considerations

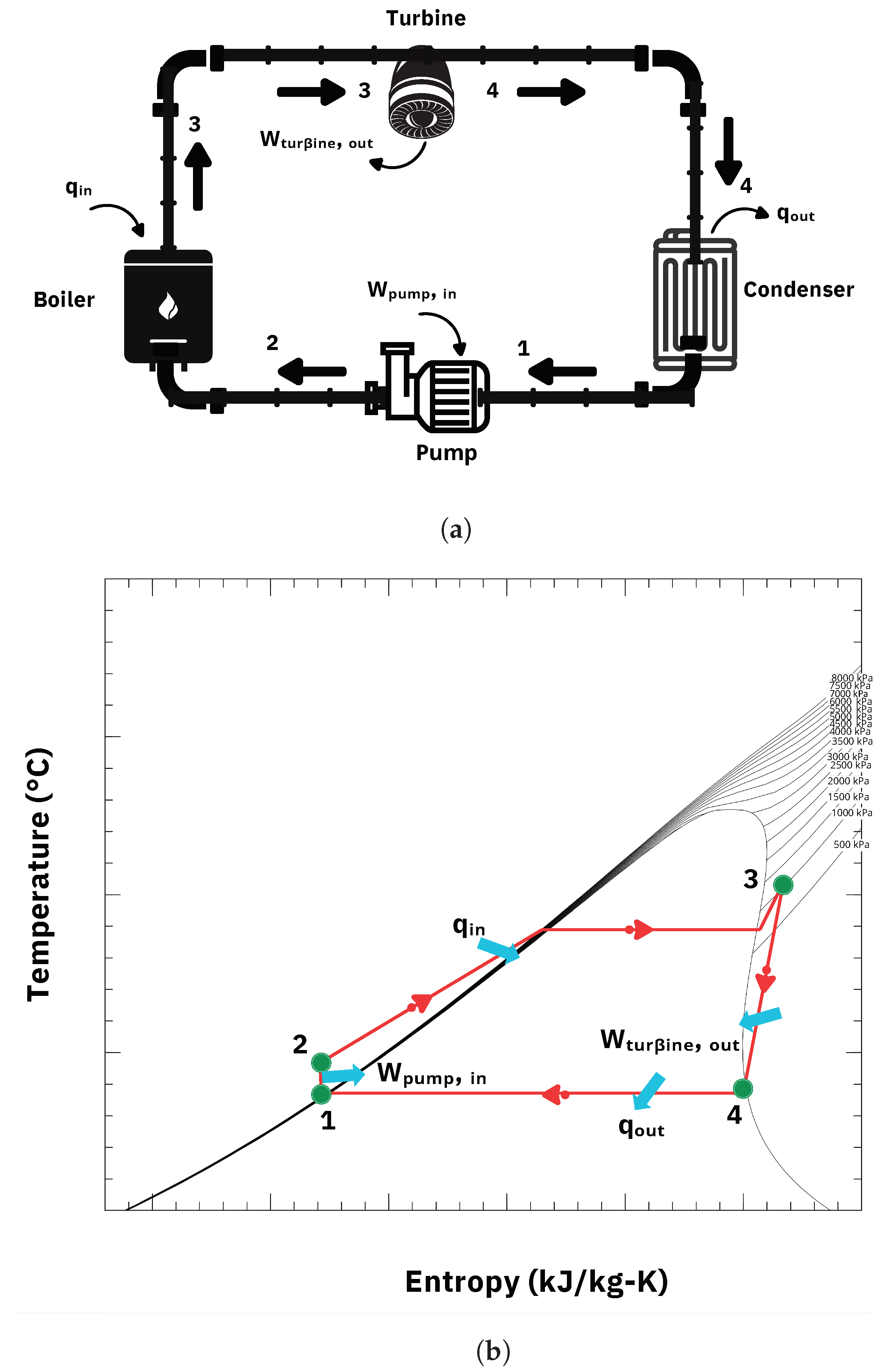

2.1. Rankine Cycle

- (1–2) Isentropic compression in the pump;

- (2–3) Isobaric evaporation in the boiler;

- (3–4) Isentropic expansion in the turbine;

- (4–1) Isobaric condensation in the condenser.

2.2. Rankine Cycle with a Regeneration Stage

2.3. Mass and Energy Balance

2.4. Solar Radiation Collection

2.5. R-245fa Working Fluid Properties

3. Methodology

3.1. Solar Collection Stage

3.2. Data Acquisition System

- TT-01: Temperature transmitter for the working fluid at the outlet of the high-pressure pump.

- TT-02: Temperature transmitter for the working fluid at the outlet of the primary heat exchanger.

- TT-03: Temperature transmitter for the working fluid at the inlet of the high-pressure pump.

- TT-04: Temperature transmitter for the working fluid at the turbine outlet.

- TT-05: Temperature transmitter for the working fluid at the outlet of the condensation heat exchanger.

- TT-06: Temperature transmitter for the working fluid at the outlet of the regeneration exchanger.

- TT-08: Temperature transmitter for the hot water circuit at the entrance of the regeneration exchanger.

- TT-09: Temperature transmitter for thermal oil at the steam generator outlet.

- TT-10: Temperature transmitter for thermal oil at the inlet of the steam generator.

- TT-11: Temperature transmitter for cold water at the entrance of the cooling tower.

- TT-12: Temperature transmitter for cold water at the cooling tower outlet.

- PIT-02: Pressure transmitter for the working fluid at the outlet of the primary heat exchanger.

- PIT-03: Pressure transmitter for the working fluid at the turbine inlet.

- PIT-01: Pressure transmitter for the working fluid at the inlet of the high-pressure pump.

3.3. Analysis of Data Obtained

Test Matrix

4. Results and Discussion

4.1. Analysis of Data Obtained with Instrumentation System

4.2. Result Validation

5. Conclusions

- The analysis of the mass and energy balance equations constitutes an essential tool to perform optimal analyses of a thermodynamic cycle.

- Implementing a regeneration stage with an energy supply from a solar collection system in an ORC plant allows the thermal efficiency of the cycle to be increased.

- To improve thermal efficiency, it is essential to implement a regeneration stage.

- The entry temperature of the organic working fluid flowing from the regeneration stage to the primary exchanger is a critical factor.

- The results support an economic analysis of the design and selection of ORC plant components when integrating a solar collection stage.

Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, S.; Zhang, K.; Deng, K. A review of waste heat recovery from the marine engine with highly efficient bottoming power cycles. Renew. Sustain. Energy Rev. 2020, 120, 109611. [Google Scholar] [CrossRef]

- Park, B.S.; Usman, M.; Imran, M.; Pesyridis, A. Review of Organic Rankine Cycle experimental data trends. Energy Convers. Manag. 2018, 173, 679–691. [Google Scholar] [CrossRef]

- Núñez Fernández, C. Diseño preliminar de un ciclo orgánico de Rankine solar para el suministro eléctrico a una PYME. Master’s Thesis, Mining Engineering-Universidad de Oviedo, Oviedo, Spain, 2017. [Google Scholar]

- Real Academia Española. Diccionario de la Lengua españOla, 23rd ed. 2021. Available online: https://dle.rae.es/energ%C3%ADa#FiynjK3 (accessed on 28 May 2024).

- Comisión Nacional para el Uso Eficiente de la EnergíaBeneficios por el uso de la Energía Solar. 2014. Available online: http://www.gob.mx/conuee/acciones-y-programas/beneficios-por-el-uso-de-la-energia-solar?state=published (accessed on 24 May 2024).

- Yilmaz, F. Thermodynamic performance evaluation of a novel solar energy based multigeneration system. Appl. Therm. Eng. 2018, 143, 429–437. [Google Scholar] [CrossRef]

- Loni, R.; Mahian, O.; Markides, C.; Bellos, E.; le Roux, W.; Kasaeian, A.; Najafi, G.; Rajaee, F. A review of solar-driven organic Rankine cycles: Recent challenges and future outlook. Renew. Sustain. Energy Rev. 2021, 150, 111410. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of a hybrid ORC driven by waste heat and solar energy. Energy Convers. Manag. 2018, 156, 427–439. [Google Scholar] [CrossRef]

- Yu, H.; Helland, H.; Yu, X.; Gundersen, T.; Sin, G. Optimal design and operation of an Organic Rankine Cycle (ORC) system driven by solar energy with sensible thermal energy storage. Energy Convers. Manag. 2021, 244, 114494. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Termodinámica, 7th ed.; Mc. Graw Hill: New York, NY, USA, 2003. [Google Scholar]

- Moran, M.J.; Shapiro, H.N. Fundamentos de termodinámica técnica, 2nd ed.; Reverté: Barcelona, Spain, 2018. [Google Scholar]

- Feng, Y.q.; Wang, X.; Niaz, H.; Hung, T.C.; He, Z.x.; Zeb, A.J.; Xi, H. Experimental comparison of the performance of basic and regenerative organic Rankine cycles. Energy Convers. Manag. 2020, 223, 113459. [Google Scholar] [CrossRef]

- Singh, J. Heat Transfer Fluids and Systems for Process and Energy Applications; CRC Press: Boca Raton, FL, USA, 1985. [Google Scholar]

- Cerrada Galán, A. Análisis de Ciclos de Rankine Orgánicos. Bachelor’s Thesis, Chemistry Engineering-Universidad de Sevilla, Sevilla, Spain, 2020. [Google Scholar]

- Carpio, R.S.B. Balance de Materia y Energía; UNSA: Arequipa, Peru, 2021. [Google Scholar]

- Severns, W.H.; Degler, H.E.; Miles, H. La Producción de Energía Mediante Vapor, Aire o Gas; Reverté: Ciudad de Mexico, Mexico, 2021. [Google Scholar]

- Cengel, Y.A.; Ghajar, A.J. Transferencia de Calor y Masa; McGraw-Hill Interamericana: New York, NY, USA, 2007; Volume 53. [Google Scholar]

- Godin, B. Models of Innovation: The History of an Idea; MIT Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Ike, G.N.; Usman, O.; Alola, A.A.; Sarkodie, S.A. Environmental quality effects of income, energy prices and trade: The role of renewable energy consumption in G-7 countries. Sci. Total Environ. 2020, 721, 137813. [Google Scholar] [CrossRef] [PubMed]

- Office of Energy Efficiency & Renewable Energy. Solar Radiation Basics. 2019. Available online: https://www.energy.gov/eere/solar/solar-radiation-basics (accessed on 24 May 2024).

- Yang, J.; Li, J.; Yang, Z.; Duan, Y. Thermodynamic analysis and optimization of a solar organic Rankine cycle operating with stable output. Energy Convers. Manag. 2019, 187, 459–471. [Google Scholar] [CrossRef]

- Cesca, T.; Scian, C.; Petronijevic, E.; Leahu, G.; Voti, R.L.; Cesarini, G.; Macaluso, R.; Mosca, M.; Sibilia, C.; Mattei, G. Correlation between in situ structural and optical characterization of the semiconductor-to-metal phase transition of VO2 thin films on sapphire. Nanoscale 2020, 12, 851–863. [Google Scholar] [CrossRef] [PubMed]

- ISO 50001:2018; Energy Management Systems—Requirements with Guidance for Use. ISO/IEC: Geneva, Switzerland, 2018.

- Extech Instruments. User Manual—Power and Harmonics Analyzer. Available online: https://www.instrumart.com/assets/Extech-PQ3350-3-Manual.pdf (accessed on 9 September 2024).

- Vásquez, S.A.; Barturén, A.P.; Carbajal, F.M. Application of the Aspen HYSYS simulator in solving problems of the regenerative Rankine cycle with intermediate superheat. Inf. Tecnológica 2020, 31, 199–208. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, J.; Luo, X.; Chen, J.; Yang, Z.; Chen, Y. Simultaneous optimization of combined supercritical CO2 Brayton cycle and organic Rankine cycle integrated with concentrated solar power system. J. Clean. Prod. 2020, 266, 121927. [Google Scholar] [CrossRef]

- Fernández Bermúdez, E.P. Análisis de factibilidad termotécnica de la incrementación del rendimiento de una planta termoeléctrica, empleando energía del proceso de condensación del ciclo Rankine como fuente térmica para la operación de motores Stirling. Bachelor’s Thesis, Civil Mechanical Engineer-Universidad de Talca, Talca, Chile, 2021. [Google Scholar]

- Scagnolatto, G.; Cabezas-Gómez, L.; Tibiriçá, C.B. Analytical model for thermal efficiency of organic Rankine cycles, considering superheating, heat recovery, pump and expander efficiencies. Energy Convers. Manag. 2021, 246, 114628. [Google Scholar] [CrossRef]

- Herrera, U.C.; García, J.; Sierra-Espinosa, F.; Rodríguez, J.; Jaramillo, O.; De Santiago, O.; Tilvaldiev, S. Enhanced thermal efficiency organic Rankine cycle for renewable power generation. Appl. Therm. Eng. 2021, 189, 116706. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, X.; Zhang, Y.; Liu, K.; Yang, H.; Li, J.; Akhlaghi, Y.G.; Liu, H.; Han, Z.; Liu, Z. Combined Rankine Cycle and dew point cooler for energy efficient power generation of the power plants-A review and perspective study. Energy 2022, 238, 121688. [Google Scholar] [CrossRef]

- Feng, H.; Chen, W.; Chen, L.; Tang, W. Power and efficiency optimizations of an irreversible regenerative organic Rankine cycle. Energy Convers. Manag. 2020, 220, 113079. [Google Scholar] [CrossRef]

- Qu, J.; Feng, Y.; Zhu, Y.; Zhou, S.; Zhang, W. Design and thermodynamic analysis of a combined system including steam Rankine cycle, organic Rankine cycle, and power turbine for marine low-speed diesel engine waste heat recovery. Energy Convers. Manag. 2021, 245, 114580. [Google Scholar] [CrossRef]

- Jiménez, A.G. La energía nuclear, esencial en la transición energética. Available online: https://www.industriaquimica.es/articulos/20220909/energia-nuclear-esencial-transicion-energetica (accessed on 14 April 2024).

| Variable | Value | Variable | Value |

|---|---|---|---|

| Physical state, color | Liquefied gas, colorless | Evaporation rate | >1 method: comparison with ether |

| Smell | Faint ethereal smell | Flammability (solid/gas) | - |

| Odor threshold | - | Upper/lower flammability or explosive limit | - |

| Hydrogen potential (pH) | Neutral | Vapor pressure | 11,227 hPa at 20 °C |

| Melting point/freezing point | −103 °C | Vapor density | 4.6 kg/m3 (air = 1.0) |

| Initial point and boiling range | 15.3 °C | Relative density | 1.32 g/cm3 at 20 °C |

| Flash point | - | Solubility | In methanol, partially soluble |

| Viscosity | - | N-Octanol/water partition coefficient | log POW: 1.35 |

| Molecular weight | 134.03 g/mol | Autoignition temperature | 412 °C |

| Tag | Technical Equipment | Parameter | Working Fluid |

|---|---|---|---|

| ESG-400 | Scroll expander (turbine) | Efficiency | 0.6 |

| Working fluid | R-245fa | ||

| Working fluid mass flow | 0.08 kg/s | ||

| Displacement | 14.5 cm3/rev | ||

| Speed. The maximum speed is 3600 rpm | 3500 rpm | ||

| Inlet pressure. The maximum operating pressure is 13.8 bar abs. | 11.8 bar man | ||

| Inlet temperature of 110 °C Overheating of 10 °C | 110 °C | ||

| Outlet pressure | 5.1 bar | ||

| Outlet temperature | 60 °C | ||

| EVA-300 | Heat exchanger | Evaporation temperature | 100 °C |

| Evaporation pressure | 11.66 bar man | ||

| Evaporator inlet temperature | 30 °C | ||

| Evaporator thermal power | 14 kW | ||

| Heat transfer area | 2.04 m2 | ||

| Evaporator side heat transfer fluid | MobilTherm 603 | ||

| Thermal oil flow | 1.27 kg/s | ||

| Thermal oil evaporator inlet temperature | 120 °C | ||

| Thermal oil evaporator outlet temperature | 100 °C | ||

| Electric power of circulation pump | 1.1 kW | ||

| COND-500 | Heat exchanger | Condensation temperature | 30 °C |

| Condensation pressure | 1.8 bar | ||

| Temperature of organic fluid at condenser inlet | 45 °C | ||

| Condenser thermal power | 17.5 kW | ||

| Heat transfer area | 3.06 m2 | ||

| Condenser side heat transfer fluid | Water | ||

| Cooling water flow | 0.94 kg/s | ||

| Cooling water condenser inlet temperature | 28 °C | ||

| Cooling water condenser outlet temperature | 23 °C | ||

| Electrical power of circulation pump | 0.745 kW | ||

| REG-200 | Heat exchanger | Regenerator thermal power | 1812 kW |

| Heat transfer area | 1.1 m2 | ||

| Hot fluid inlet temperature | 61 °C | ||

| Hot fluid outlet temperature | 45 °C | ||

| Cold fluid inlet temperature | 30 °C | ||

| Cold fluid outlet temperature | 60 °C | ||

| TLR-600 | Liquid-receiving tank | Amount of refrigerant in system | 8 kg |

| Volume | 80 lts | ||

| BAP-100 | High-pressure pump | Pallets | 12 |

| Discharge pressure | 11.56 bar | ||

| Pump flow | 0.1 L/s | ||

| Motor electrical power | 260 W | ||

| Suction pressure | 1.36 barg | ||

| Refrigerant | R-245fa 45 kg cylinder | R-245fa |

| Temp. TT-01 (°C) | Temp. TT-02 (°C) | Pit-01 (kPa) | Pit-02 (kPa) | (kJ/kg) | (kJ/kg) | (kg/s) | (kW) | (kW) | (kW) | (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 29.2 | 77.3 | 52.3 | 75.6 | 429.57 | 474.36 | 0.034 | 1.52 | 1.000 | 0.375 | 41.04 |

| 28.5 | 78.9 | 52.9 | 76.4 | 429.51 | 475.9 | 0.036 | 1.67 | 1.000 | 0.375 | 37.42 |

| 29.7 | 79.5 | 54.5 | 73.9 | 430.53 | 476.52 | 0.033 | 1.52 | 1.000 | 0.375 | 41.18 |

| 30.9 | 77.1 | 54.6 | 74.6 | 431.6 | 474.18 | 0.041 | 1.75 | 1.000 | 0.375 | 35.80 |

| 27.4 | 78.2 | 55.9 | 74.5 | 428.43 | 475.25 | 0.039 | 1.83 | 1.000 | 0.375 | 34.23 |

| 28.3 | 80.2 | 56.2 | 75.1 | 429.22 | 477.18 | 0.038 | 1.82 | 1.000 | 0.375 | 34.29 |

| 29.5 | 81.6 | 57.4 | 73.9 | 430.26 | 478.56 | 0.043 | 2.08 | 1.000 | 0.375 | 30.09 |

| 30.2 | 77.6 | 53.9 | 74.8 | 431 | 474.66 | 0.045 | 1.96 | 1.000 | 0.375 | 31.81 |

| 26.4 | 75.3 | 52.4 | 75.9 | 427.66 | 472.42 | 0.041 | 1.84 | 1.000 | 0.375 | 34.06 |

| 27.8 | 75.6 | 51.5 | 76.1 | 428.93 | 472.71 | 0.039 | 1.71 | 1.000 | 0.375 | 36.60 |

| 28.4 | 79.6 | 56.3 | 74.2 | 429.31 | 476.61 | 0.038 | 1.80 | 1.000 | 0.375 | 34.77 |

| 28.1 | 77.4 | 54.3 | 75.6 | 429.11 | 474.45 | 0.037 | 1.68 | 1.000 | 0.375 | 37.26 |

| 29 | 77.6 | 56.3 | 75.3 | 429.84 | 474.65 | 0.046 | 2.06 | 1.000 | 0.375 | 30.32 |

| 27.6 | 78.4 | 54.9 | 76.4 | 428.64 | 475.41 | 0.045 | 2.10 | 1.000 | 0.375 | 29.70 |

| 26.7 | 79.4 | 58.7 | 76.3 | 427.7 | 476.38 | 0.044 | 2.14 | 1.000 | 0.375 | 29.18 |

| 29.7 | 76.9 | 56.3 | 74.8 | 430.47 | 473.99 | 0.033 | 1.44 | 1.000 | 0.375 | 43.52 |

| 29.4 | 78.6 | 52.3 | 75.9 | 430.34 | 475.61 | 0.035 | 1.58 | 1.000 | 0.375 | 39.45 |

| 28.6 | 78.1 | 54.8 | 76.2 | 429.54 | 475.12 | 0.038 | 1.73 | 1.000 | 0.375 | 36.08 |

| 27.9 | 75.6 | 55.6 | 75.4 | 428.88 | 472.72 | 0.042 | 1.84 | 1.000 | 0.375 | 33.94 |

| 29.5 | 79.5 | 57.4 | 74.7 | 430.26 | 476.51 | 0.04 | 1.85 | 1.000 | 0.375 | 33.78 |

| 28.64 | 78.12 | 54.925 | 75.28 | 429.57 | 475.16 | 0.03935 | 1.79 | 1.000 | 0.375 | 34.84 |

| Temp. TT-06 (°C) | Temp. TT-02 (°C) | Pit-01 (kPa) | Pit-02 (kPa) | (kJ/kg) | (kJ/kg) | (kg/s) | (kW) | (kW) | (kW) | (kW) | (kW) | (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 36.6 | 78.8 | 51.5 | 75.8 | 436.83 | 475.81 | 0.035 | 1.36 | 0.896 | 0.59 | 0.52 | 0.78 | 41.49 |

| 37.8 | 78.9 | 52.5 | 76.4 | 437.88 | 475.9 | 0.036 | 1.30 | 0.997 | 0.56 | 0.57 | 0.8 | 51.20 |

| 38.5 | 79.5 | 54.5 | 73.9 | 438.46 | 476.52 | 0.033 | 1.18 | 0.885 | 0.52 | 0.56 | 0.78 | 49.76 |

| 38.3 | 79.5 | 53.9 | 75.6 | 438.3 | 476.49 | 0.039 | 1.42 | 1.090 | 0.49 | 0.53 | 0.69 | 53.54 |

| 39.4 | 78.2 | 55.9 | 74.5 | 439.24 | 475.25 | 0.039 | 1.39 | 1.081 | 0.48 | 0.58 | 0.65 | 48.30 |

| 37.6 | 80.2 | 52.4 | 75.1 | 437.71 | 477.18 | 0.038 | 1.43 | 1.028 | 0.56 | 0.56 | 0.62 | 36.77 |

| 38.6 | 80.4 | 57.4 | 74.6 | 438.47 | 477.38 | 0.041 | 1.56 | 1.162 | 0.59 | 0.63 | 0.76 | 45.03 |

| 39.5 | 77.6 | 53.9 | 74.8 | 439.39 | 474.66 | 0.045 | 1.57 | 1.222 | 0.51 | 0.48 | 0.67 | 57.40 |

| 37.9 | 75.3 | 52.9 | 75.9 | 437.96 | 472.42 | 0.041 | 1.33 | 1.131 | 0.48 | 0.69 | 0.78 | 55.51 |

| 36.5 | 75.6 | 54.9 | 75.4 | 436.64 | 472.72 | 0.033 | 1.12 | 0.960 | 0.49 | 0.56 | 0.75 | 58.98 |

| 40.1 | 79.2 | 56.3 | 74.2 | 439.86 | 476.22 | 0.038 | 1.46 | 1.134 | 0.49 | 0.64 | 0.81 | 55.68 |

| 39.4 | 77.4 | 54.3 | 75.6 | 439.28 | 474.45 | 0.037 | 1.27 | 1.063 | 0.48 | 0.57 | 0.77 | 61.64 |

| 38.6 | 77.6 | 55.7 | 76.5 | 438.52 | 474.63 | 0.042 | 1.44 | 1.063 | 0.52 | 0.48 | 0.68 | 51.47 |

| 37.8 | 77.9 | 54.9 | 76.4 | 437.81 | 474.93 | 0.039 | 1.39 | 1.026 | 0.56 | 0.47 | 0.69 | 49.43 |

| 38.6 | 79.4 | 58.7 | 76.3 | 438.43 | 476.38 | 0.044 | 1.63 | 1.292 | 0.55 | 0.49 | 0.68 | 57.04 |

| 37.5 | 76.9 | 54.6 | 74.6 | 437.55 | 473.99 | 0.033 | 1.17 | 0.914 | 0.52 | 0.63 | 0.84 | 51.79 |

| 39.3 | 76.5 | 52.3 | 75.9 | 439.25 | 473.58 | 0.033 | 1.18 | 0.817 | 0.47 | 0.57 | 0.89 | 56.33 |

| 37.6 | 78.1 | 54.8 | 78.5 | 437.64 | 475.08 | 0.032 | 1.15 | 0.921 | 0.46 | 0.62 | 0.72 | 48.56 |

| 38.9 | 75.6 | 53.6 | 75.4 | 438.85 | 472.72 | 0.039 | 1.32 | 1.089 | 0.49 | 0.64 | 0.63 | 44.61 |

| 37.4 | 78.9 | 55.4 | 72.6 | 437.44 | 475.96 | 0.04 | 1.45 | 1.106 | 0.46 | 0.59 | 0.78 | 57.68 |

| 38.4 | 78.08 | 54.52 | 75.4 | 438.37 | 475.11 | 0.0379 | 1.35 | 1.044 | 0.51 | 0.67 | 0.75 | 45.16 |

| Reference | Research Date | Thermal Efficiency | Research Study Title |

|---|---|---|---|

| [25] | 2022 | 37.12 | Application of the Aspen HYSYS simulator in solving problems of the regenerative Rankine cycle with intermediate superheat |

| [26] | 2020 | 7.24 | Simultaneous optimization of combined supercritical CO2 Brayton cycle and ORC integrated with concentrated solar power system |

| [27] | 2021 | 76.8 | Analysis of thermotechnical feasibility of increasing the performance of a thermoelectric plant, using energy from the production process condensation of the Rankine cycle as a thermal source for the operation of Stirling engines |

| [28] | 2023 | 13.9 | Analytical model for thermal efficiency of ORC, considering superheating, heat recovery, pump and expander efficiencies |

| [29] | 2021 | 10.54 | Enhanced thermal efficiency organic Rankine cycle for renewable power generation |

| [30] | 2022 | 49.4 | Combined Rankine Cycle and dew point cooler for energy efficient power generation of the power plants—A review and perspective study |

| [31] | 2020 | 25.22 | Power and efficiency optimizations of an irreversible regenerative ORC |

| [32] | 2021 | 28.48 | Design and thermodynamic analysis of a combined system including steam Rankine cycle, ORC, and power turbine for marine low-speed diesel engine waste heat recovery |

| This investigation | 2024 | 51.30 | Thermal efficiency analysis of 1 kW ORC system with solar collection stage and R-245fa working fluid: A Case Study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Sánchez, R.A.; Álvarez-Alvarado, J.M.; Pérez-Soto, G.I.; Macías-Socarrás, I.; Camarillo-Gómez, K.A.; Rodríguez-Reséndiz, J. Thermal Efficiency Analysis of a 1 kW ORC System with a Solar Collection Stage and R-245fa Working Fluid: A Case Study. Fluids 2024, 9, 217. https://doi.org/10.3390/fluids9090217

Martínez-Sánchez RA, Álvarez-Alvarado JM, Pérez-Soto GI, Macías-Socarrás I, Camarillo-Gómez KA, Rodríguez-Reséndiz J. Thermal Efficiency Analysis of a 1 kW ORC System with a Solar Collection Stage and R-245fa Working Fluid: A Case Study. Fluids. 2024; 9(9):217. https://doi.org/10.3390/fluids9090217

Chicago/Turabian StyleMartínez-Sánchez, Raúl Alejandro, José M. Álvarez-Alvarado, Gerardo I. Pérez-Soto, Idalberto Macías-Socarrás, Karla A. Camarillo-Gómez, and Juvenal Rodríguez-Reséndiz. 2024. "Thermal Efficiency Analysis of a 1 kW ORC System with a Solar Collection Stage and R-245fa Working Fluid: A Case Study" Fluids 9, no. 9: 217. https://doi.org/10.3390/fluids9090217

APA StyleMartínez-Sánchez, R. A., Álvarez-Alvarado, J. M., Pérez-Soto, G. I., Macías-Socarrás, I., Camarillo-Gómez, K. A., & Rodríguez-Reséndiz, J. (2024). Thermal Efficiency Analysis of a 1 kW ORC System with a Solar Collection Stage and R-245fa Working Fluid: A Case Study. Fluids, 9(9), 217. https://doi.org/10.3390/fluids9090217