Numerical Investigation of Flow and Heat Transfer over a Shallow Cavity: Effect of Cavity Height Ratio

Abstract

1. Introduction

2. Mathematical Formulations

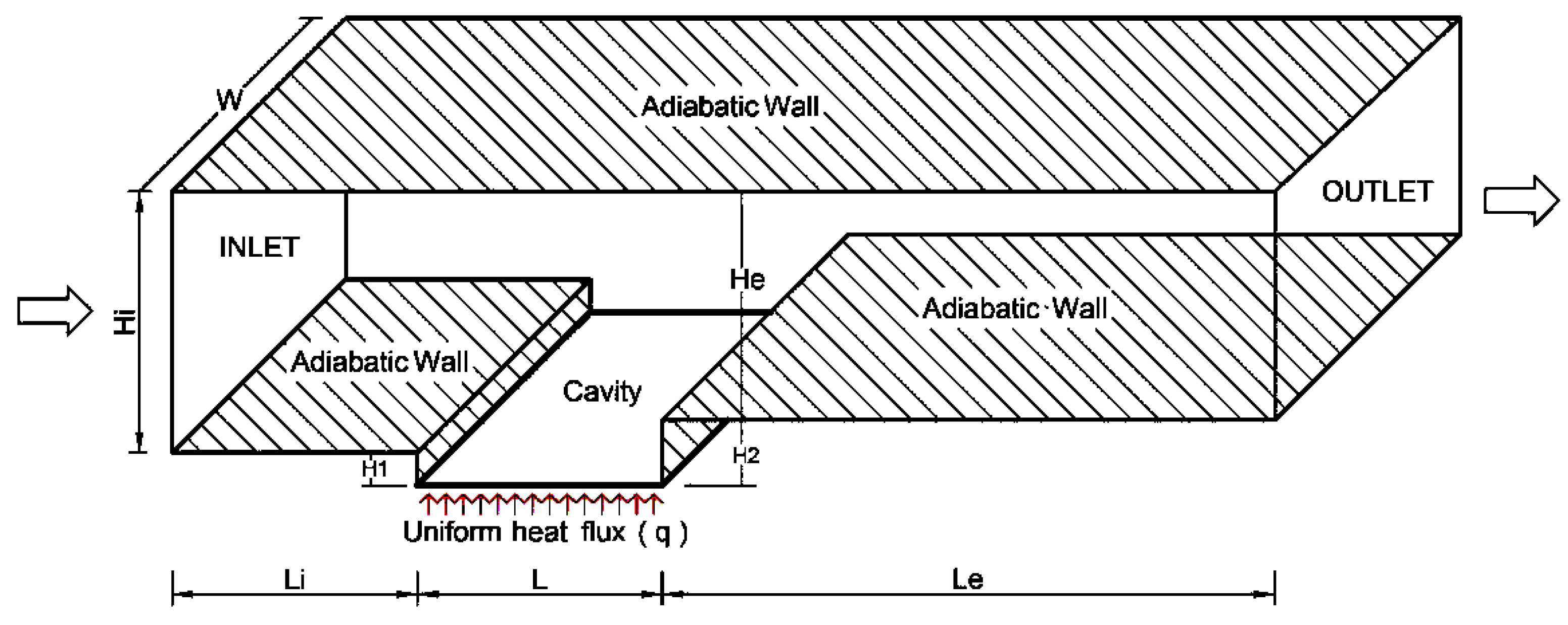

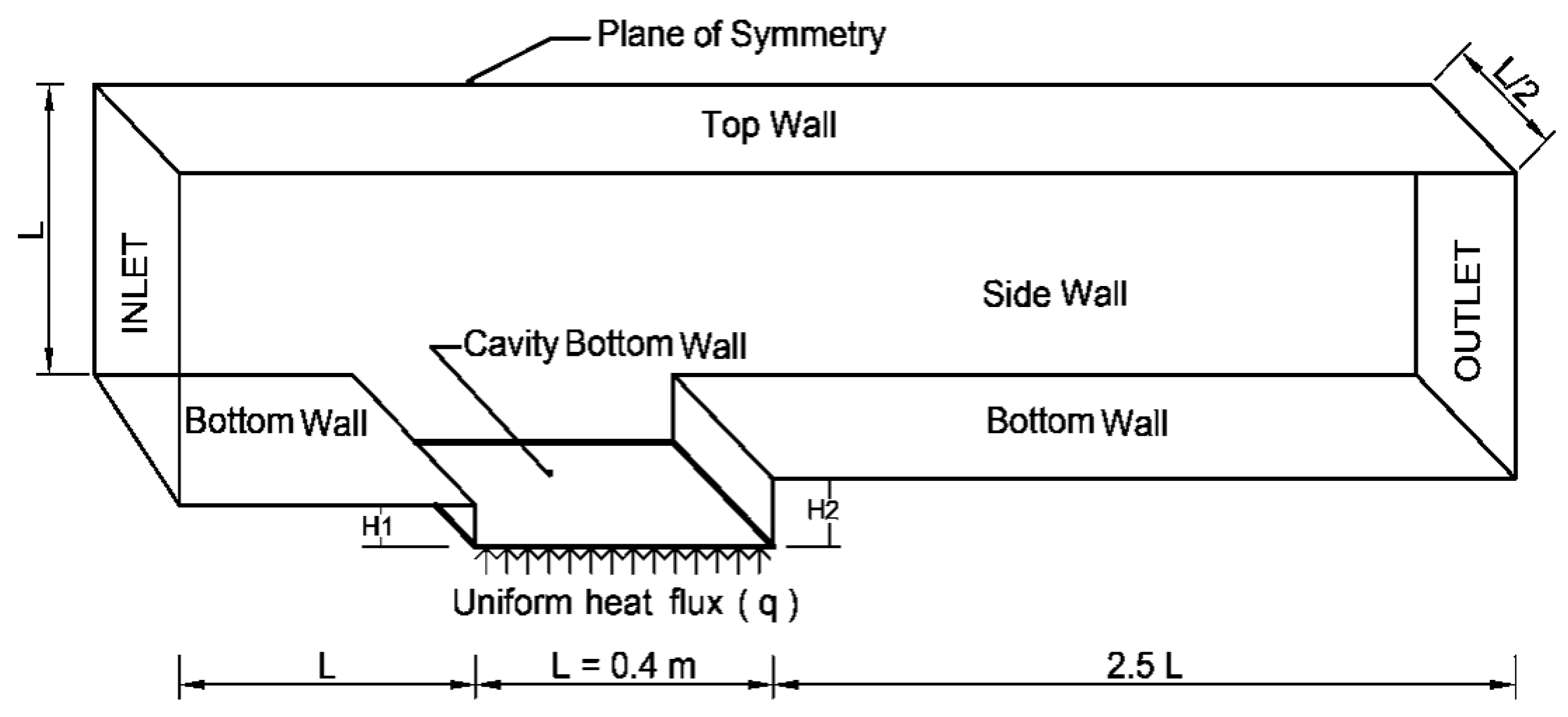

2.1. Problem Geometry

2.2. Governing Equations and Turbulence Modeling

2.3. Boundary Conditions

2.4. Numerical Procedures

2.5. Flow and Heat Transfer Relations

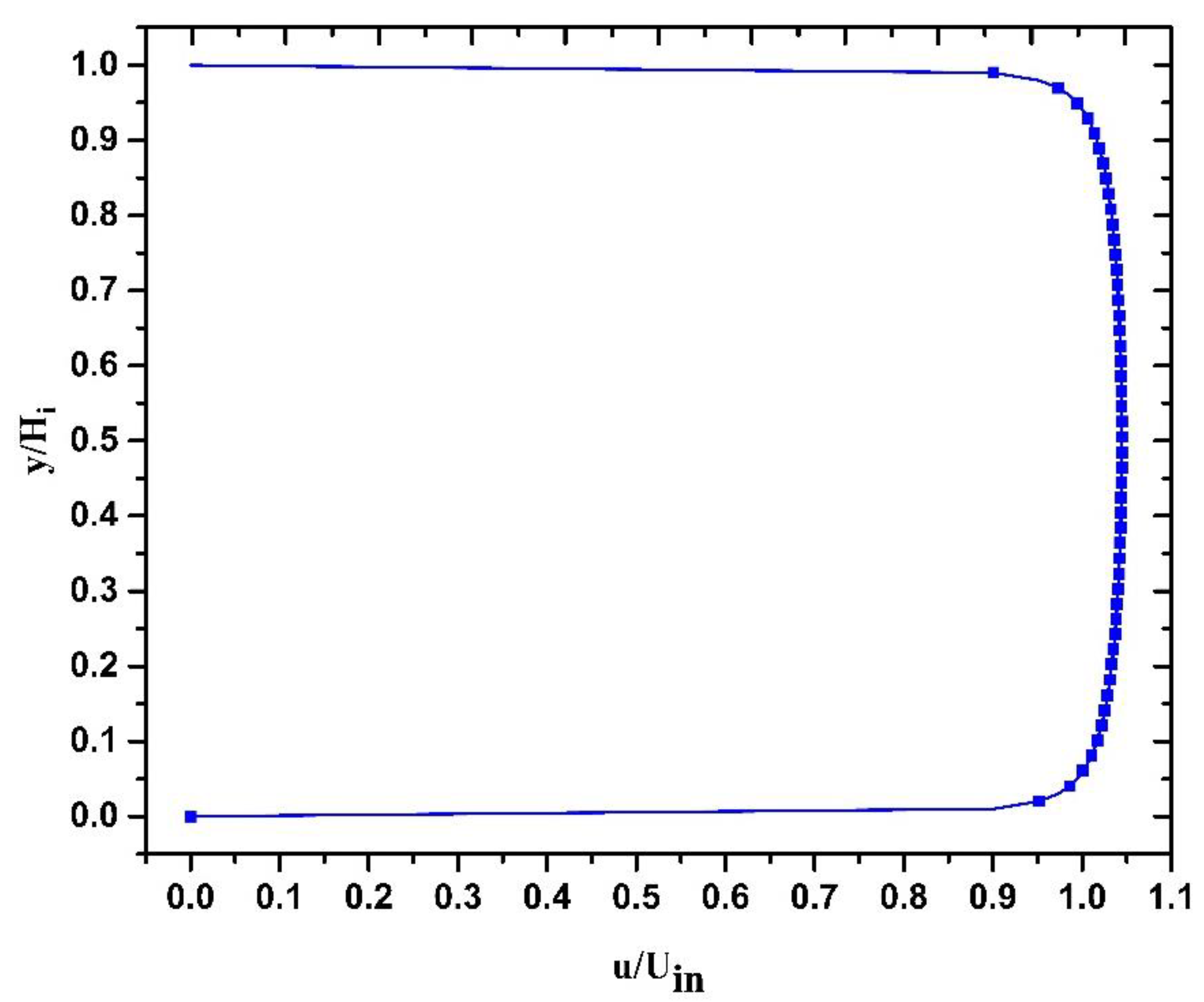

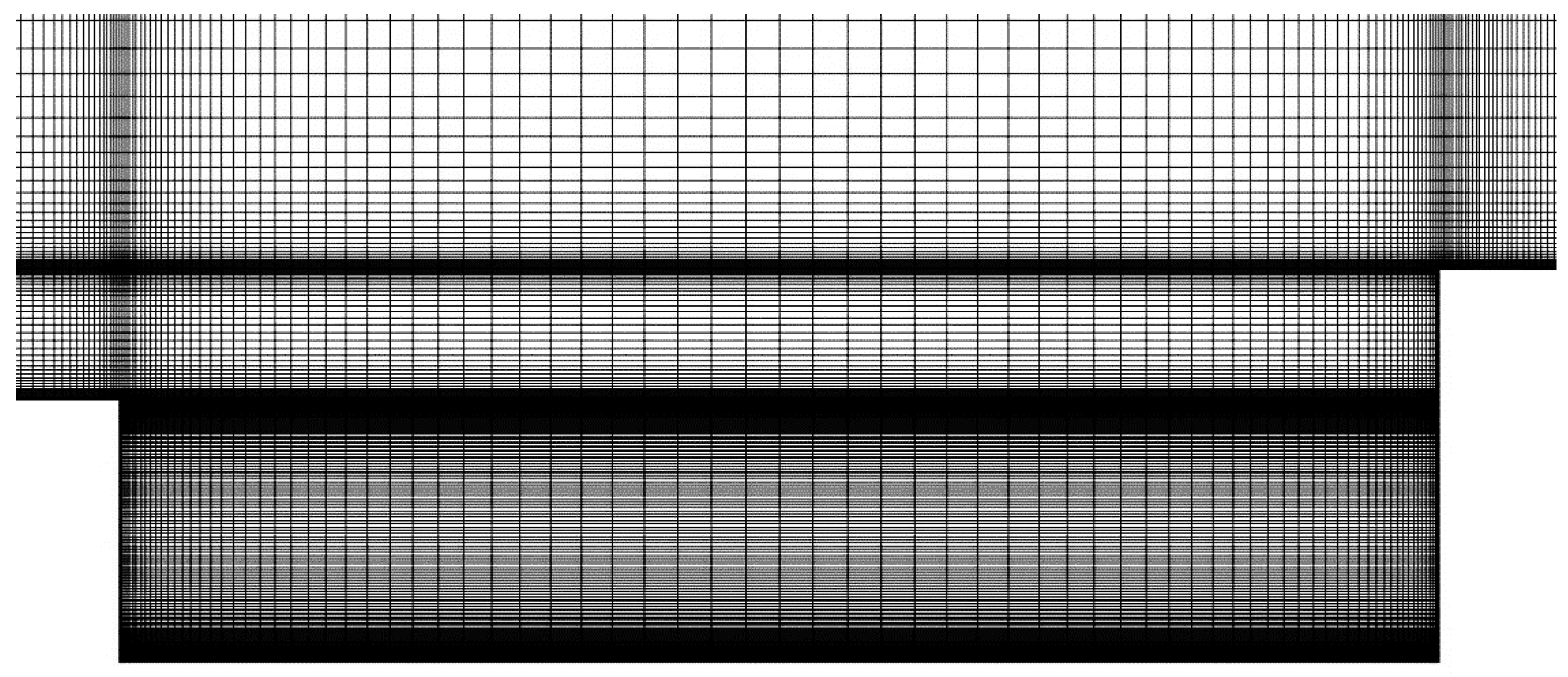

2.6. Grid Structure and Code Validation

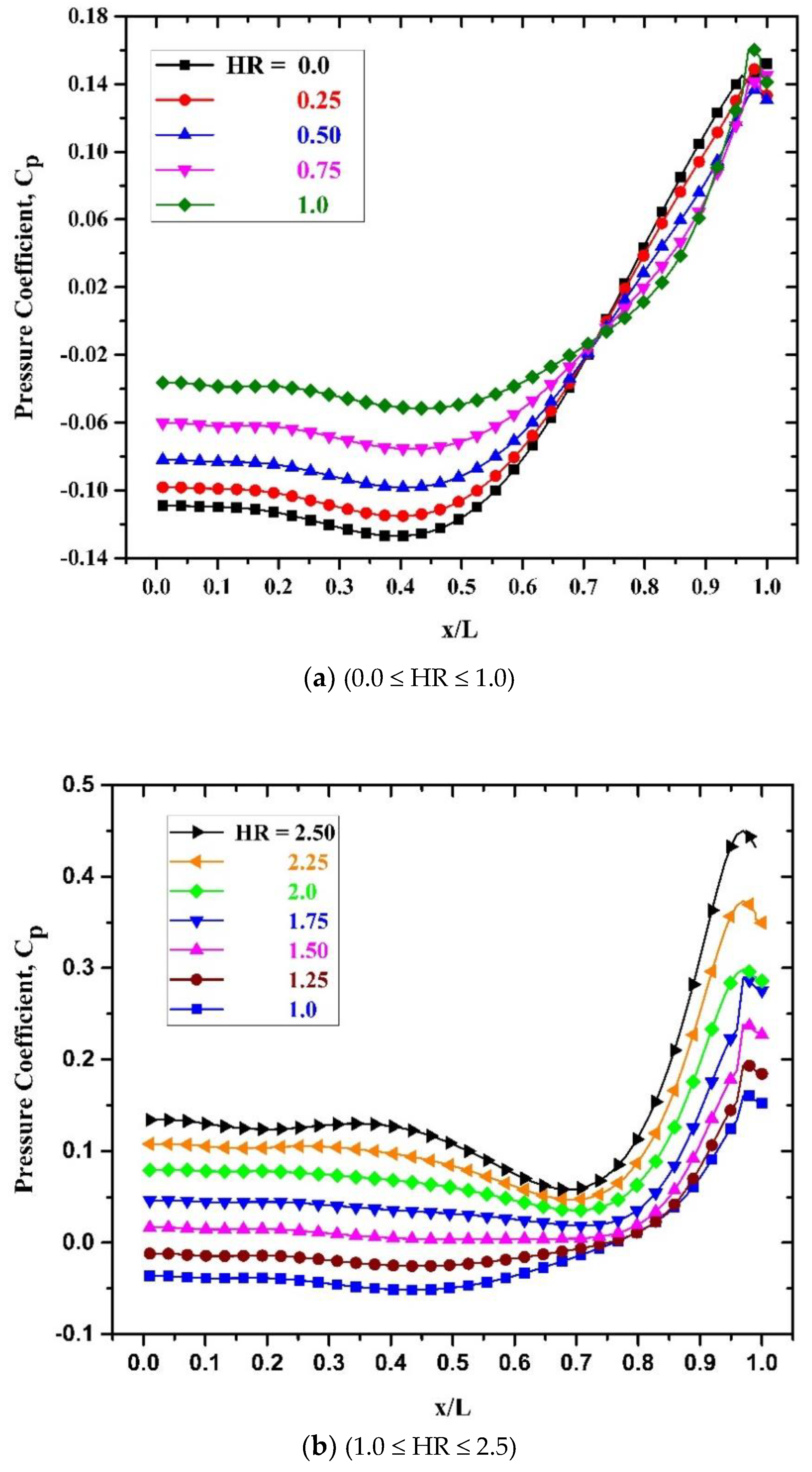

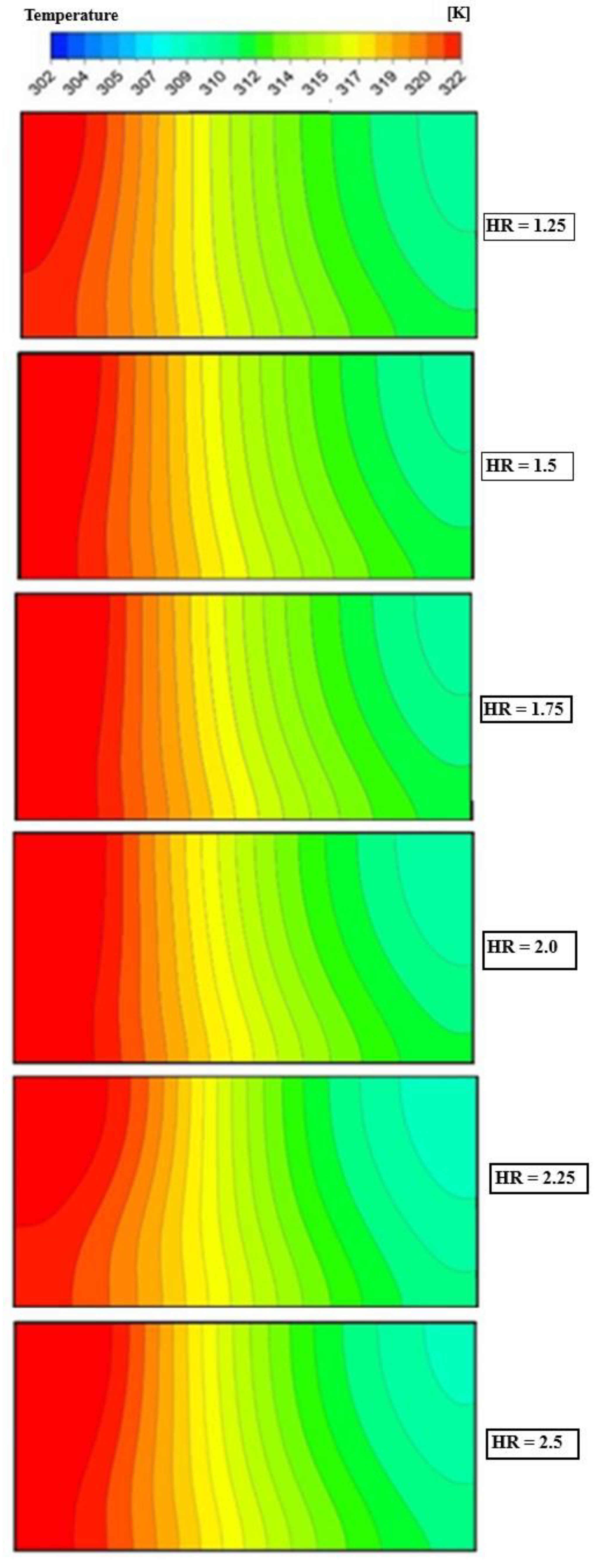

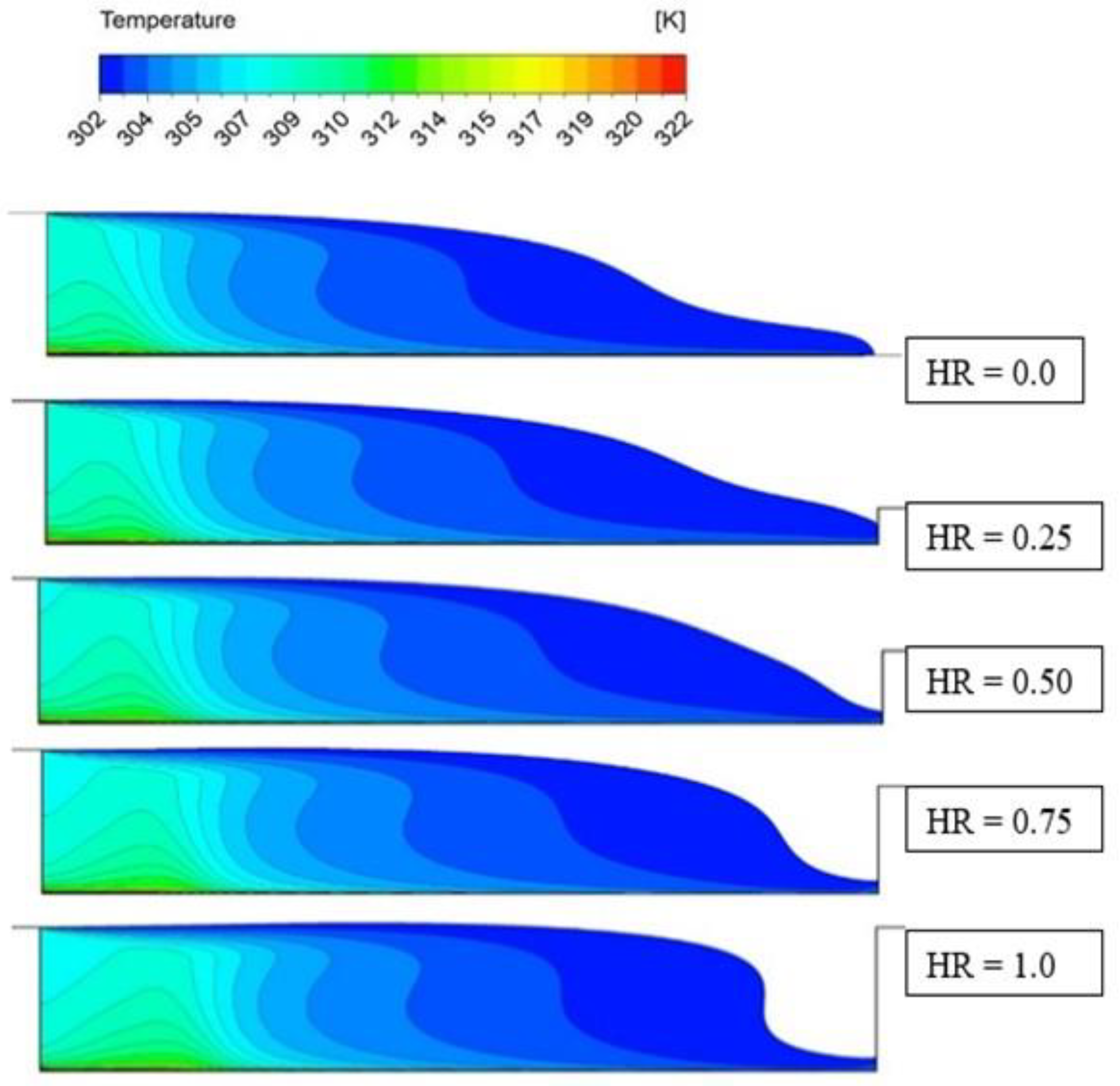

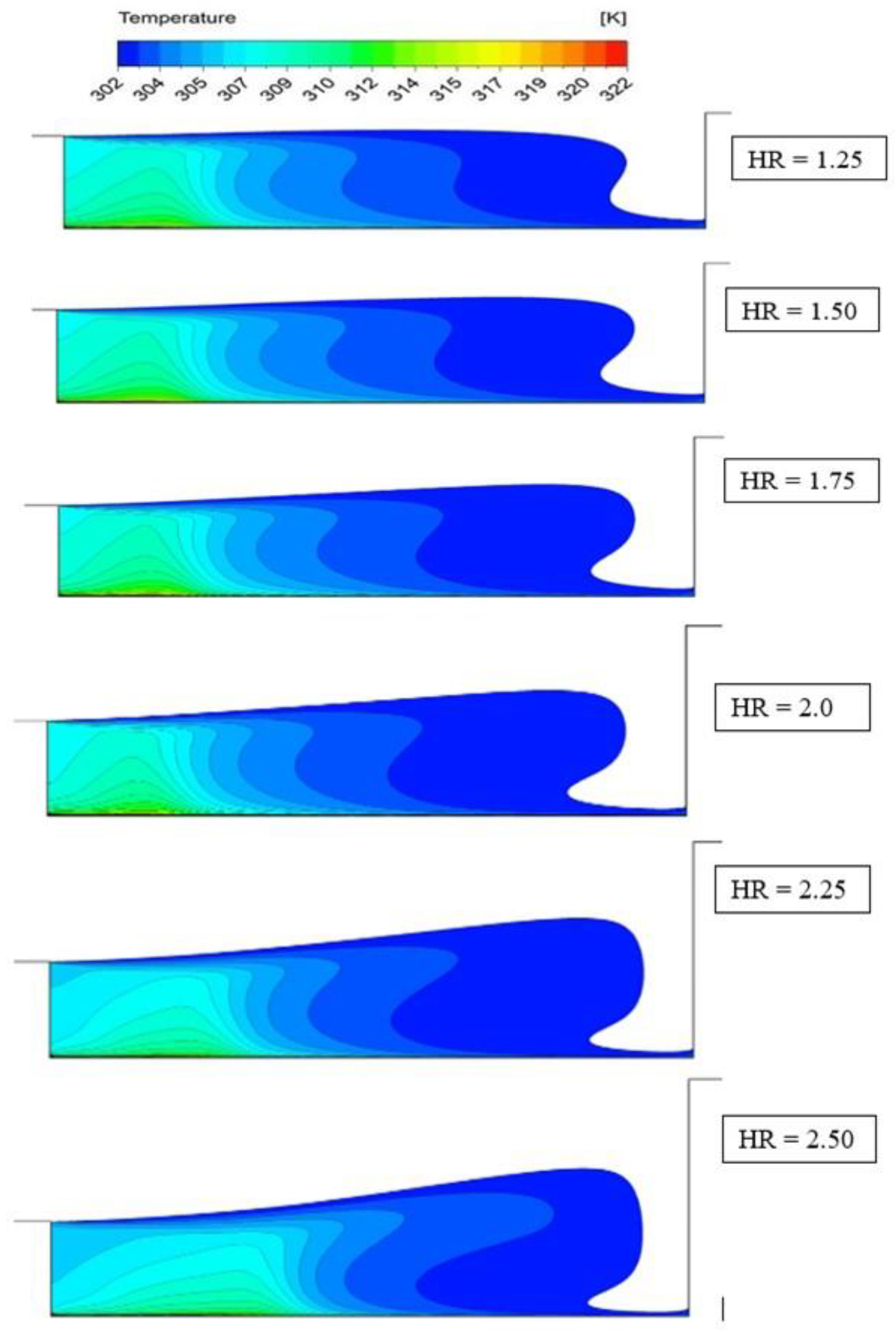

3. Results and Discussion

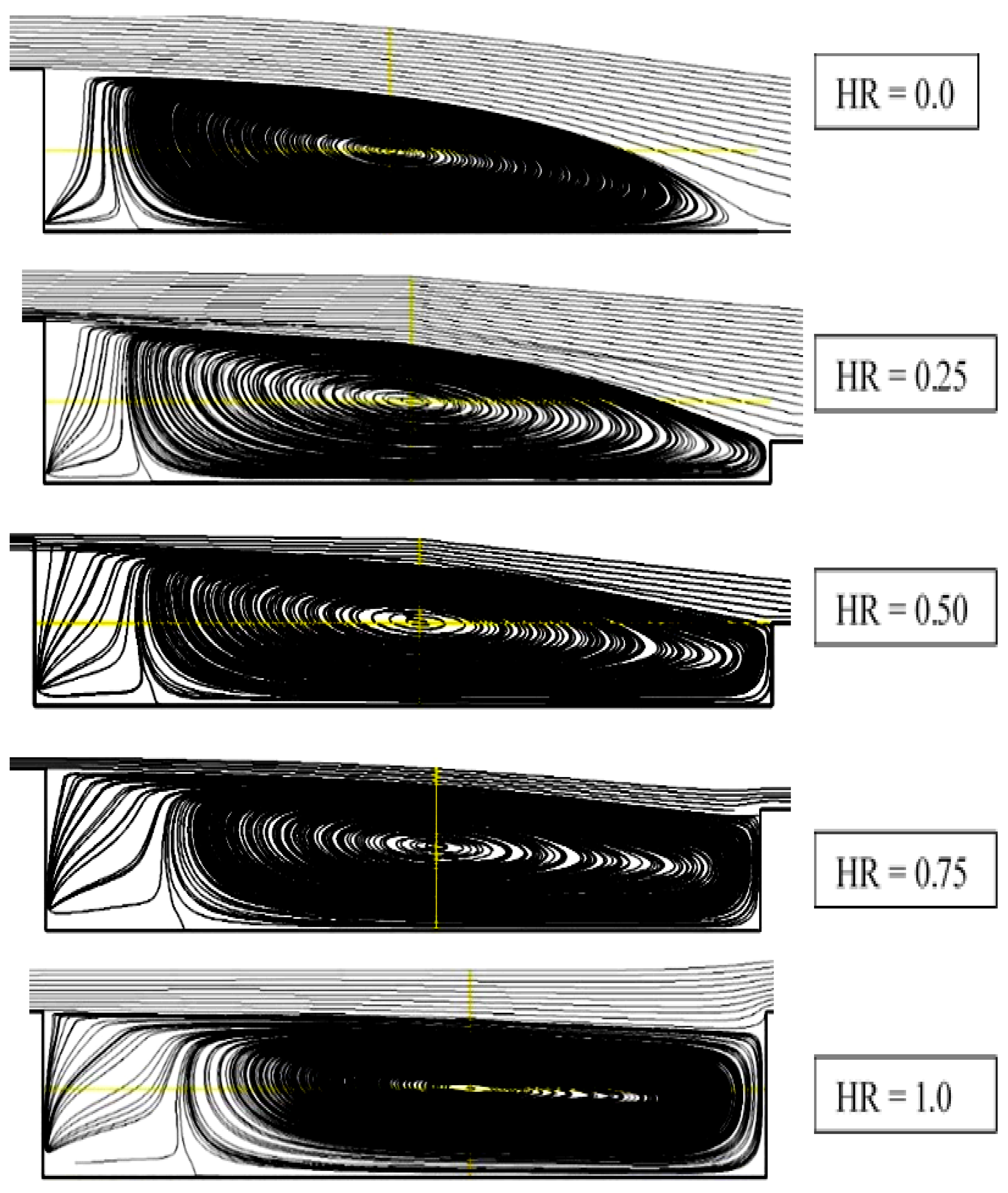

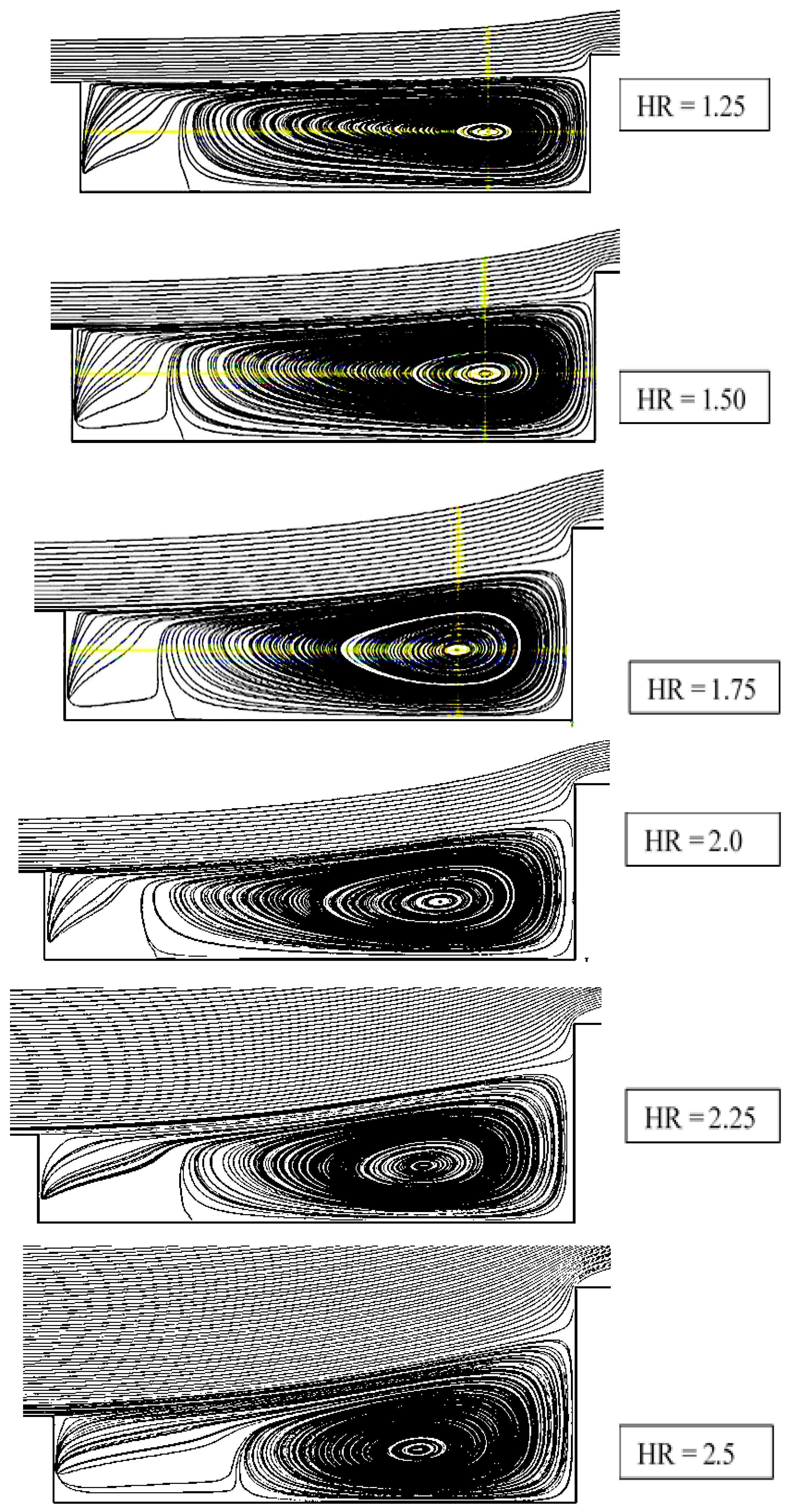

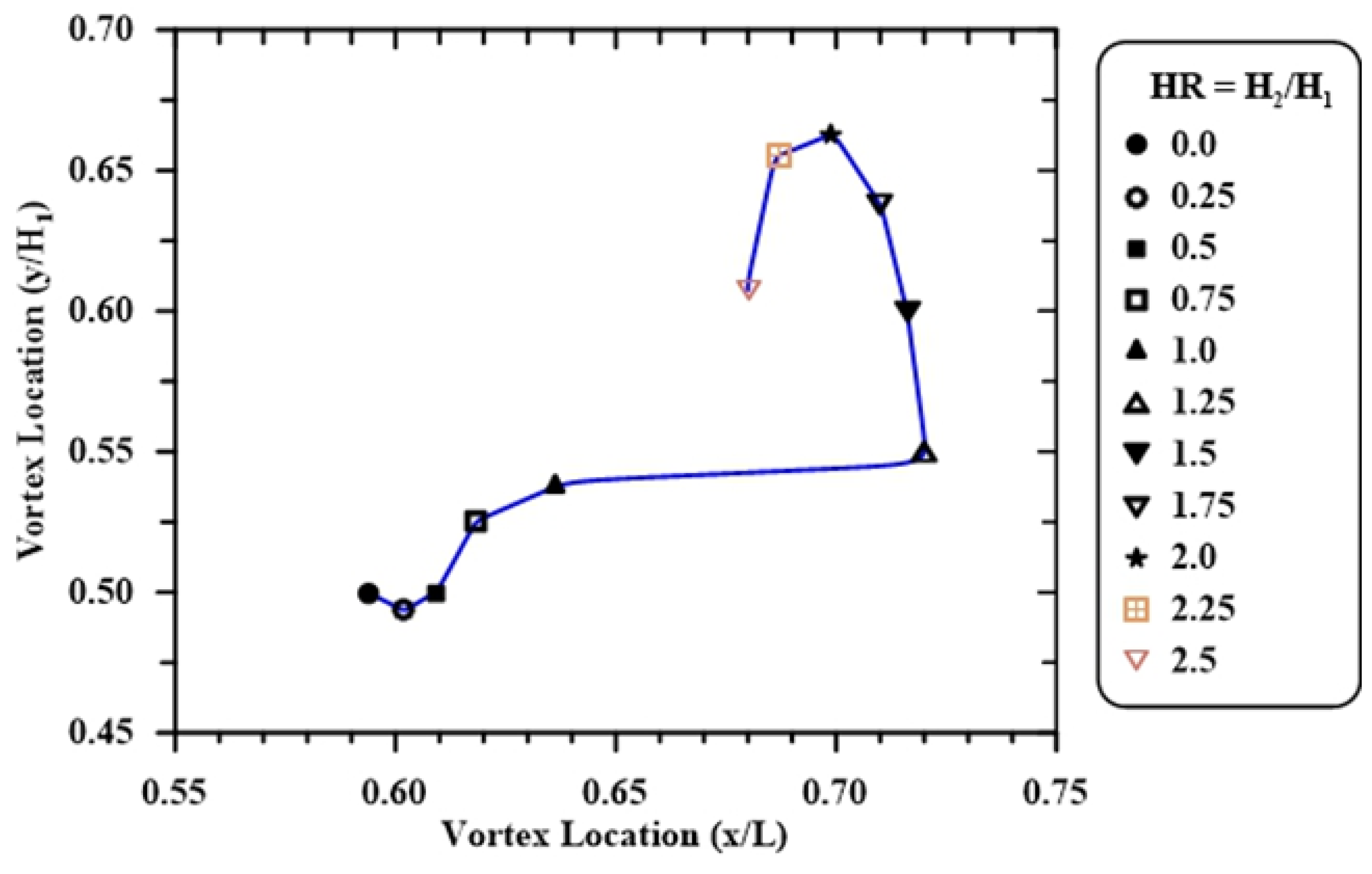

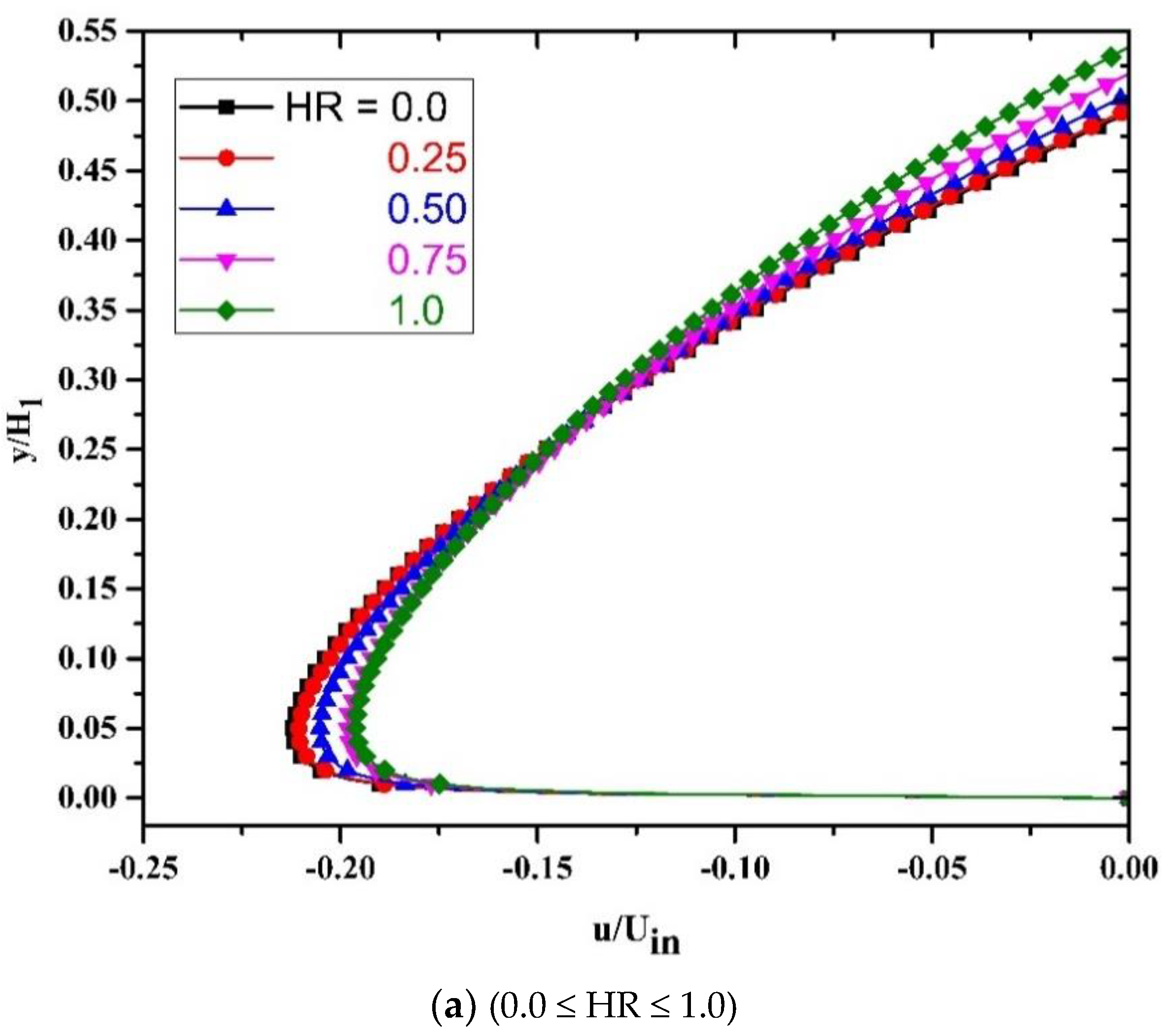

3.1. Flow Fields Results

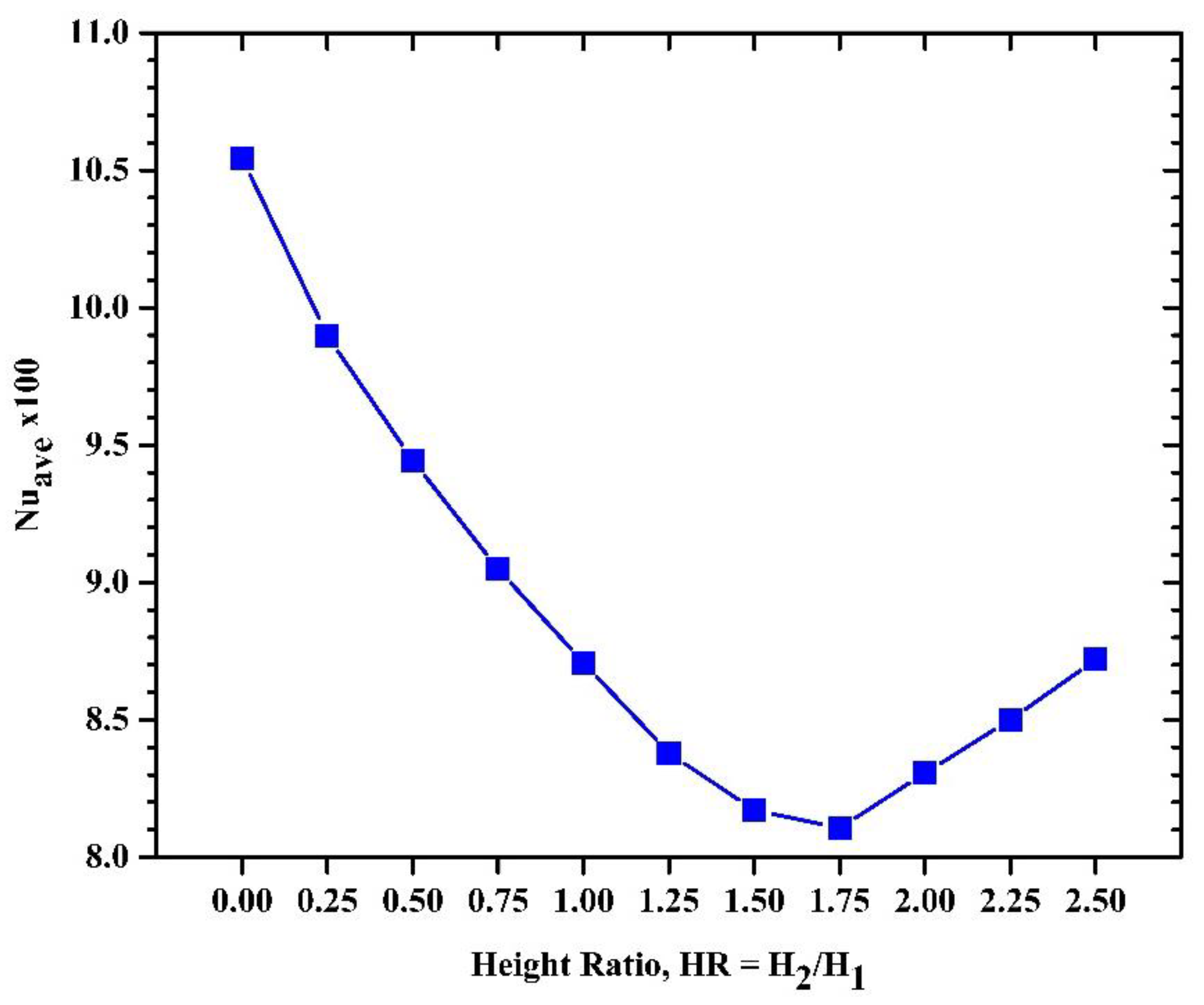

3.2. Heat Transfer Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AR | Cavity aspect ratio: symmetry (L/H): asymmetry (L/H1), dimensionless |

| Cp | Pressure coefficient along cavity bottom wall, dimensionless |

| C1ε, C2ε and Cμ | Numerical constants of turbulence model |

| cp | Specific heat at constant pressure, J/(kg·K) |

| Gk | Turbulence kinetic energy production |

| h | Heat transfer coefficient, W/(m2·K) |

| Hi | Upstream channel vertical height, m |

| He | Downstream channel vertical height, m |

| H1 | Cavity front wall height, m |

| H2 | Cavity back wall height, m |

| HR | Cavity height ratio (H2/H1), dimensionless |

| i, j | Tensor notation |

| K | Turbulent kinetic energy, m2/s2 |

| k | Thermal conductivity, W/(m·K) |

| L | Cavity bottom wall length, m |

| Li | Upstream channel length, m |

| Le | Downstream channel length, m |

| Nux | Local Nusselt number, dimensionless |

| Nuave | Average Nusselt number, dimensionless |

| p | Static pressure along cavity bottom wall, Pa |

| Pr | Prandtl number, dimensionless |

| po | Reference static pressure at the inlet, Pa |

| q | Heat flux rate from cavity bottom wall, W/m2 |

| Re | Reynolds number based on cavity bottom length, dimensionless |

| T | Static temperature, K |

| Tin | Inlet temperature, K |

| Tw | Cavity bottom wall temperature, K |

| u | Velocity in streamwise direction, m/s |

| ui | Velocity in direction i, m/s |

| Uin | Reference inlet velocity, m/s |

| v | Velocity normal to streamwise direction, m/s |

| W | Spanwise width of the geometry, m |

| WR | Cavity width ratio (L/W), dimensionless |

| x | Position along cavity bottom wall measured from cavity upstream wall, m |

| x, y, z | Coordinates in streamwise, cavity depth, and cavity width directions |

| Greek symbols | |

| ρ | Density of fluid, (kg/m3) |

| μ | Dynamic viscosity, (kg/m·s) |

| μt | Turbulent viscosity, (m2/s) |

| ε | Rate of dissipation of turbulence kinetic energy, (m2/s3) |

| σk and σε | Prandtl numbers for turbulence kinetic energy and rate of dissipation, respectively. |

| σt | Turbulent Prandtl number |

| ν | Kinematic viscosity (m2/s) |

| νt | Turbulent kinematic viscosity (m2/s) |

| Subscripts | |

| ave | Average |

| i | Direction, i |

| in | Channel inlet |

| t | Turbulent |

| w | Cavity heated bottom wall |

| x | Local |

References

- Garcia, R.P.; del Rio Oliveira, S.; Scalon, V.L. Thermal efficiency experimental evaluation of solar flat plate collectors when introducing convective barriers. Sol. Energy 2019, 182, 278–285. [Google Scholar] [CrossRef]

- Weihing, P.; Younis, B.A.; Weigand, B. Heat transfer enhancement in a ribbed channel: Development of turbulence closures. Int. J. Heat Mass Transf. 2014, 76, 509–522. [Google Scholar] [CrossRef]

- Xue, S.; Ng, W.F. Turbine Blade Tip External Cooling Technologies. Aerospace 2018, 5, 90. [Google Scholar] [CrossRef]

- Jiang, Y.; Poozesh, A.; Marashi, S.M.; Moradi, R.; Gerdroodbary, M.B.; Shafee, A.; Li, Z.; Babazadeh, H. Effect of cavity back height on mixing efficiency of hydrogen multi-jets at supersonic combustion chamber. Int. J. Hydrog. Energy 2020, 45, 27828–27836. [Google Scholar] [CrossRef]

- Larchevêque, L.; Sagaut, P.; Mary, I.; Labbé, O.; Comte, P. Large-eddy simulation of a compressible flow past a deep cavity. Phys. Fluids 2003, 15, 193–210. [Google Scholar] [CrossRef]

- Plentovich, E.B.; Stalling, R.L., Jr.; Tracy, M.B. Experimental cavity pressure measurements at subsonic and transonic speeds. NASA Tech. Pap. 1993, 3358, 1–128. [Google Scholar]

- Yamamoto, H.; Seki, N.; Fukusako, S. Forced convection heat transfer on heated bottom surface of a cavity. J. Heat Transf. 1979, 101, 475–479. [Google Scholar] [CrossRef]

- Sinha, S.N.; Gupta, A.K.; Oberai, M.M. Laminar separating flow over back-steps and cavities Part II: Cavities. AIAA J. 1982, 20, 370–375. [Google Scholar] [CrossRef]

- Aung, W. An interferometric investigation of separated forced convection in laminar flow past cavities. J. Heat Transf. 1983, 105, 505–512. [Google Scholar] [CrossRef]

- Richards, R.F.; Young, M.F.; Haiad, J.C. Turbulent forced convection heat transfer from a bottom heated open surface cavity. Int. J. Heat Mass Transf. 1987, 30, 2281–2287. [Google Scholar] [CrossRef]

- Metzger, D.E.; Bunker, R.S.; Chyu, M.K. Cavity heat transfer on a transverse grooved wall in a narrow flow channel. J. Heat Transf. 1989, 111, 73–79. [Google Scholar] [CrossRef]

- Esteve, M.J.; Reulet, P.; Millan, P. Flow field characterisation within a rectangular cavity. In Proceedings of the 10th International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisbon, Portugal, 10–13 July 2000. [Google Scholar]

- Ozsoy, E.; Rambaud, P.; Stitou, A.; Riethmuller, M.A. Vortex characteristics in laminar cavity flow at very low Mach number. Exp. Fluids 2005, 38, 133–145. [Google Scholar] [CrossRef]

- Faure, T.M.; Adrianos, P.; Lusseyran, F.; Pastur, L. Visualizations of the flow inside an open cavity at medium range Reynolds numbers. Exp. Fluids 2007, 42, 169–184. [Google Scholar] [CrossRef]

- D’yachenko, A.Y.; Terekhov, V.I.; Yarygina, N.I. Turbulent flow past a transverse cavity with inclined side walls. 2. Heat transfer. J. Appl. Mech. Tech. Phys. 2007, 48, 486–491. [Google Scholar] [CrossRef]

- D’yachenko, A.Y.; Terekhov, V.I.; Yarygina, N.I. Vortex formation and heat transfer in turbulent flow past a transverse cavity with inclined frontal and rear walls. Int. J. Heat Mass Transf. 2008, 51, 3275–3286. [Google Scholar] [CrossRef]

- Avelar, A.C.; Fico, N.G.C.R., Jr.; Mello, O.A.F. Study of flow over shallow cavities: An Experimental Analysis. In Proceedings of the 19th International Congress of Mechanical Engineering, Brasília, Brazil, 5–9 November 2007. [Google Scholar]

- Avelar, A.C.; Nide, G.C., Jr.; Mello, O.A.F.; Chisaki, M. An experimental investigation of the flow over shallow cavities. In Proceedings of the 38th Fluid Dynamics Conference and Exhibit, Seattle, WA, USA, 23–26 June 2008; pp. 23–26. [Google Scholar]

- Avelar, A.C.; Banhara, J.R.; Nide, G.C., Jr.; de Andrade, C.R.; Zaparoli, E.L. Experimental and numerical investigation of roughness and three-dimensional effects on the flow over shallow cavities. In Proceedings of the 39th AIAA Fluid Dynamics Conference, San Antonio, TX, USA, 22–25 June 2009. [Google Scholar]

- Zdanski, P.S.B.; Ortega, M.A.; Nide, G.C.R.; Fico, N.G., Jr. On the flow over cavities of large aspect ratio: A physical analysis. Int. Commun. Heat Mass Transf. 2006, 33, 458–466. [Google Scholar] [CrossRef]

- Mesalhy, O.M.; Aziz, S.S.A.; El-Sayed, M.M. Flow and heat transfer over shallow cavities. Int. J. Therm. Sci. 2010, 49, 514–521. [Google Scholar] [CrossRef]

- Crook, S.D.; Lau TC, W.; Kelso, R.M. Three-dimensional flow within shallow, narrow cavities. J. Fluid Mech. 2013, 735, 587–612. [Google Scholar] [CrossRef]

- Yang, G.; Sun, J.; Liang, Y.; Chen, Y. Effect of geometry parameters on low-speed cavity flow by wind tunnel experiment. AASRI Procedia 2014, 9, 44–50. [Google Scholar] [CrossRef]

- Singh, S.K.; Chowdhury, J.; Ghosh, S.; Raushan, P.K.; Debnath, K.; Kumar, P. Experimental and numerical investigation of flow characteristics in an open rectangular cavity. ISH J. Hydraul. Eng. 2019. [Google Scholar] [CrossRef]

- Bhatti, A.; Aung, W. Finite difference analysis of laminar separated forced convection in cavities. J. Heat Transf. 1984, 106, 49–54. [Google Scholar] [CrossRef]

- Ooi, A.; Iaccarino, G.; Behnia, M. Heat transfer predictions in cavities. In Annual Research Briefs; Center for Turbulence Research, NASA Ames/Stanford Univ.: Stanford, CA, USA, 1998; pp. 185–196. [Google Scholar]

- Ooi, A.; Iaccarino, G.; Durbin, P.A.; Behnia, M. Reynolds averaged simulation of flow and heat transfer in ribbed ducts. Int. J. Heat Fluid Flow 2002, 23, 750–757. [Google Scholar] [CrossRef]

- Matos, A.; Pinho, F.A.A.; Silveira-Neto, A.S. Large-eddy simulation of turbulent flow over a two-dimensional cavity with temperature fluctuations. Int. J. Heat Mass Transf. 1999, 42, 49–59. [Google Scholar] [CrossRef]

- Zdanski, P.S.B.; Ortega, M.A.; Nide, G.C.R.; Fico, N.G., Jr. Numerical simulations of turbulent flows over shallow cavities. In Proceedings of the 2nd International Conference on Computational Heat and Mass Transfer, Rio de Janeiro, Brazil, 22–26 October 2001. [Google Scholar]

- Zdanski PS, B.; Ortega, M.A.; Nide, G.C.R.; Fico, N.G., Jr. Numerical study of the flow over shallow cavities. Comput. Fluids 2003, 32, 953–974. [Google Scholar] [CrossRef]

- Zdanski, P.S.B.; Ortega, M.A.; Nide, G.C.R.; Fico, N.G., Jr. Heat transfer studies in the flow over shallow cavities. J. Heat Transf. ASME 2005, 127, 699–712. [Google Scholar] [CrossRef]

- Yao, H.; Cooper, R.; Raghunathan, S. Numerical simulation of incompressible laminar flow over three-dimensional rectangular cavities. J. Fluids Eng. 2004, 126, 919–927. [Google Scholar] [CrossRef]

- Alammar, K.N. Effect of cavity aspect ratio on flow and heat transfer characteristics in pipes: A numerical study. Heat Mass Transf. 2006, 42, 861–866. [Google Scholar] [CrossRef]

- Stalio, E.; Angeli, D.; Barozzi, G.S. Numerical simulation of forced convection over a periodic series of rectangular cavities at low Prandtl number. Int. J. Heat Fluid Flow 2011, 32, 1014–1023. [Google Scholar] [CrossRef]

- Arous, F.M.; Mataoui, A.; Bouahmed, Z. Influence of upstream flow characteristics on the reattachment phenomenon in shallow cavities. Therm. Sci. 2011, 15, 721–734. [Google Scholar]

- Arous, F.M.; Mataoui, A.; Terfous, A.; Ghenaim, A. Jet cavity interaction: Effect of the cavity depth. Prog. Comput. Fluid Dyn. 2012, 12, 322–332. [Google Scholar] [CrossRef]

- Prabu, P.M.; Padmanaban, K.P. Laminar wall jet flow and heat transfer over a shallow cavity. Sci. World J. 2015, 16. [Google Scholar] [CrossRef]

- Arous, F.M. Heat transfer prediction in a shallow cavity effect of incoming flow characteristics. Therm. Sci. 2016, 20, 1519–1532. [Google Scholar]

- Arous, F.M. Numerical simulation with a Reynolds stress turbulence model of flow and heat transfer in rectangular cavities with different aspect ratios. J. Therm. Sci. Technol. 2016, 11, JTST0012. [Google Scholar]

- Yamamoto, H.; Seki, N.; Fukusako, S. Forced convection heat transfer on heated bottom surface of a cavity with different wall-height. Heat Mass Transf. 1983, 17, 73–83. [Google Scholar] [CrossRef]

- Cornu, D.; Keirsbulck, L.; Kerherv, F.; Aloui, F.; Lippert, M. On the vortex dynamics of shear-driven deep cavity flows with asymmetrical walls. Can. J. Phys. 2016, 94, 1344–1352. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flow. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- ANSYS Fluent 14.0 Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2011.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdel Aziz, S.S.; Saber Salem Said, A.-H. Numerical Investigation of Flow and Heat Transfer over a Shallow Cavity: Effect of Cavity Height Ratio. Fluids 2021, 6, 244. https://doi.org/10.3390/fluids6070244

Abdel Aziz SS, Saber Salem Said A-H. Numerical Investigation of Flow and Heat Transfer over a Shallow Cavity: Effect of Cavity Height Ratio. Fluids. 2021; 6(7):244. https://doi.org/10.3390/fluids6070244

Chicago/Turabian StyleAbdel Aziz, Salem S., and Abdel-Halim Saber Salem Said. 2021. "Numerical Investigation of Flow and Heat Transfer over a Shallow Cavity: Effect of Cavity Height Ratio" Fluids 6, no. 7: 244. https://doi.org/10.3390/fluids6070244

APA StyleAbdel Aziz, S. S., & Saber Salem Said, A.-H. (2021). Numerical Investigation of Flow and Heat Transfer over a Shallow Cavity: Effect of Cavity Height Ratio. Fluids, 6(7), 244. https://doi.org/10.3390/fluids6070244