Klinkenberg-Corrected and Water Permeability Correlation for a Sarawak Carbonate Field

Abstract

:1. Introduction

Field Geological Background

2. Methodology

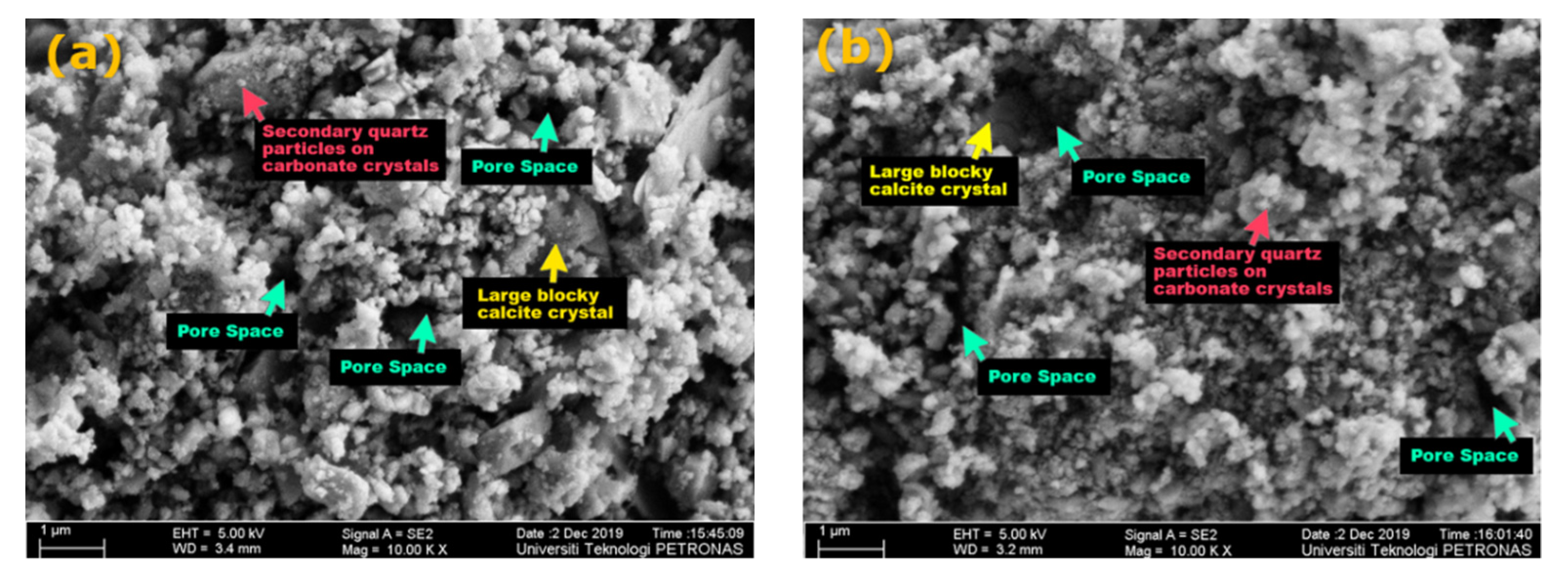

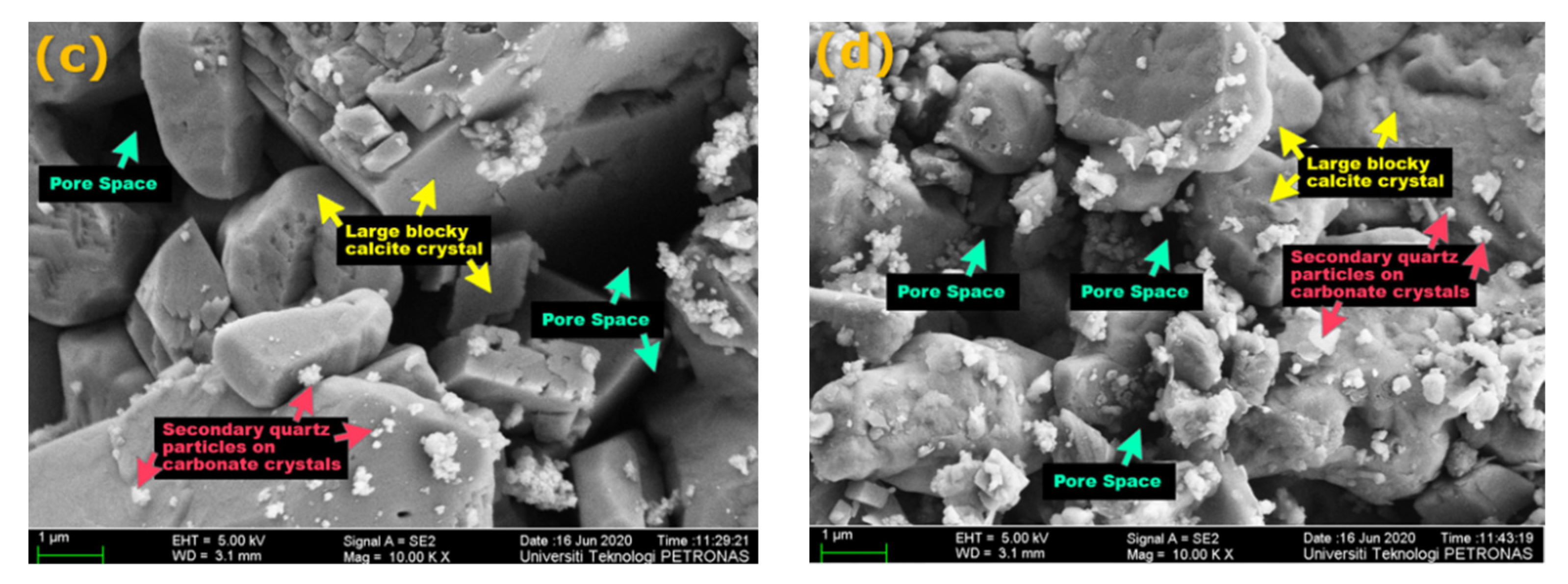

2.1. XRD & FESEM-EDX Analysis

2.2. Klinkenberg-Corrected Permeability Measurement

2.3. Water Permeability Measurement

- Brine Preparation;

- Core Sample Preparation;

- Vacuum Saturation of the Core Plugs;

- Core Flood Equipment Preparation;

- Water Flooding.

2.3.1. Brine Preparation

- Brine Preparation;

- A beaker was filled with a required amount of distilled water for preparing brine.

- The distilled water was degassed using a vacuum pump while stirring the distilled water using a magnetic stirrer (1 h).

- Mixing of Salt;

- After removing from degasification process, the distilled water was stirred using magnetic stirrer while adding the salts required one at a time.

- Before adding the salt, the required amount of salt was weighted according to the specific composition for a specific field.

- Each salt was added little by little and we waited until each salt was totally dissolved before adding the next salt. This step was repeated for all the salts.

- Filtering and Degasification of Brine;

- After acquiring the specified volume of brine, the brine was filtered (using filter assembly) with the help of a vacuum pump.

- After filtering the brine, the brine was degassed to remove any gas present in the brine using the same step as (1).

2.3.2. Core Sample Preparation

2.3.3. Core Sample Vacuum Saturation

2.3.4. Water Flooding

3. Results

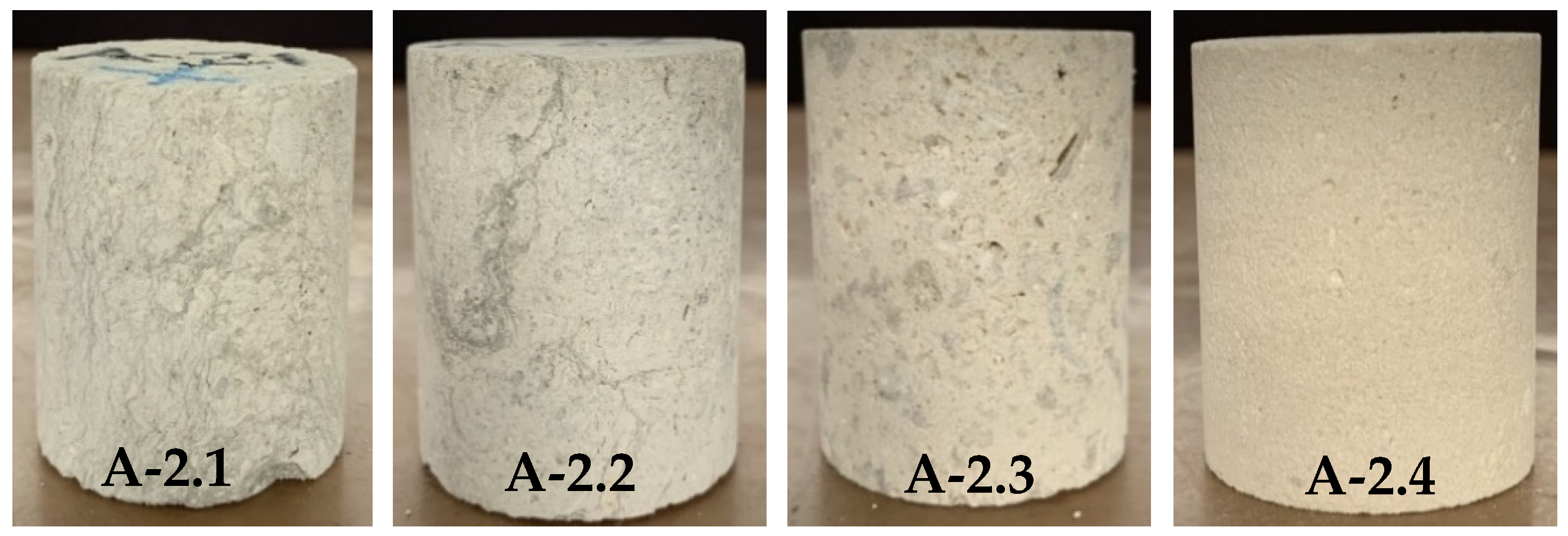

3.1. Core Samples Background

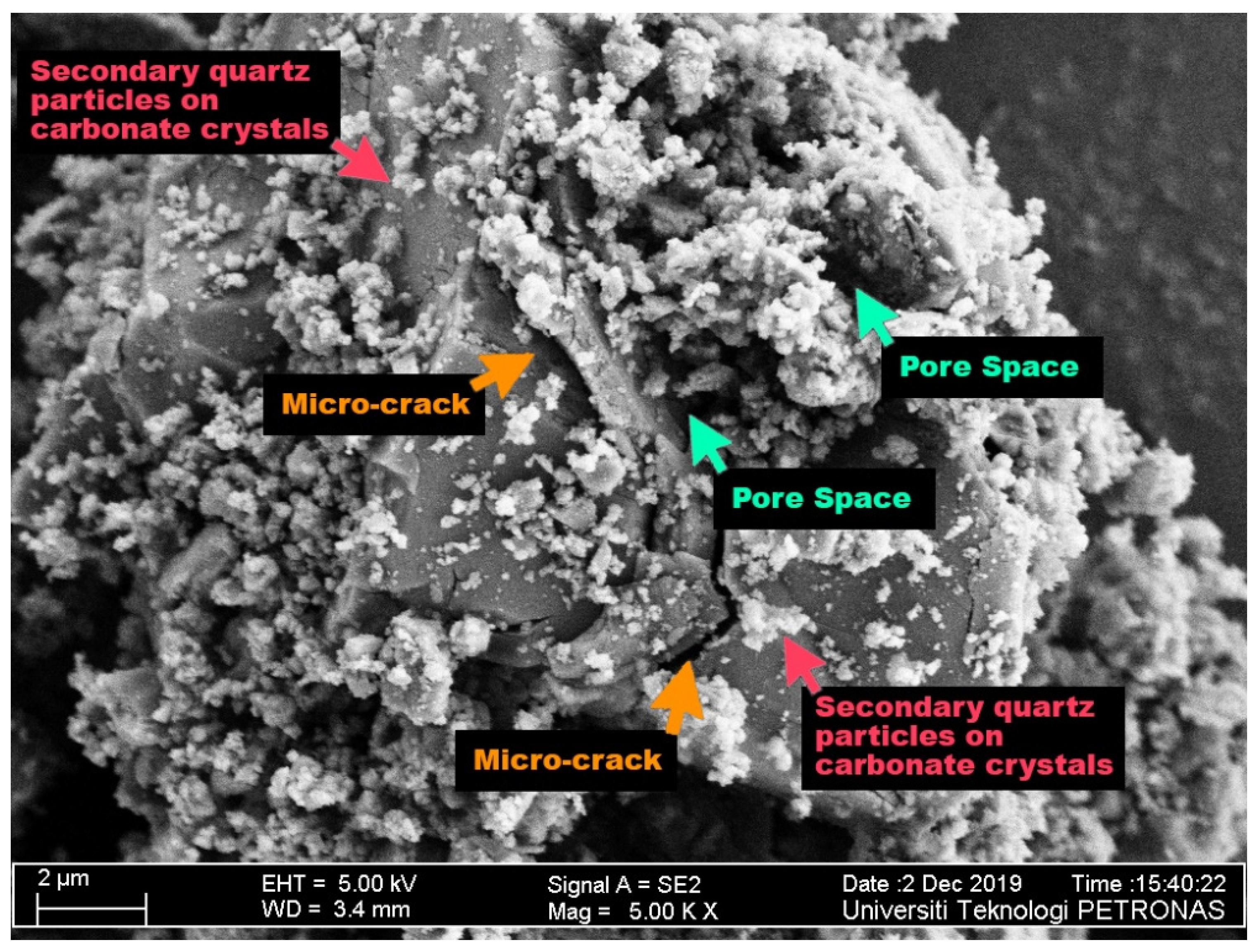

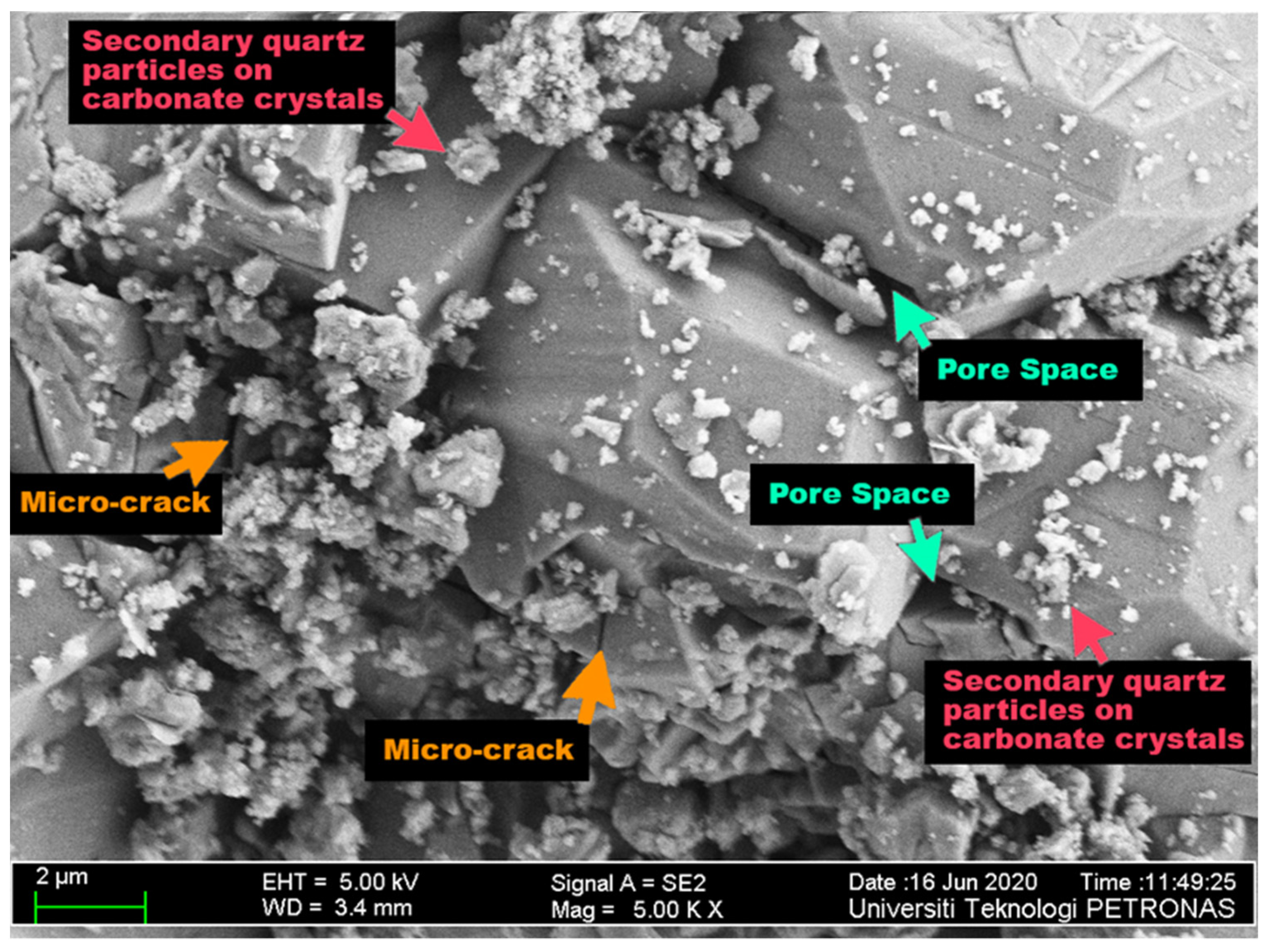

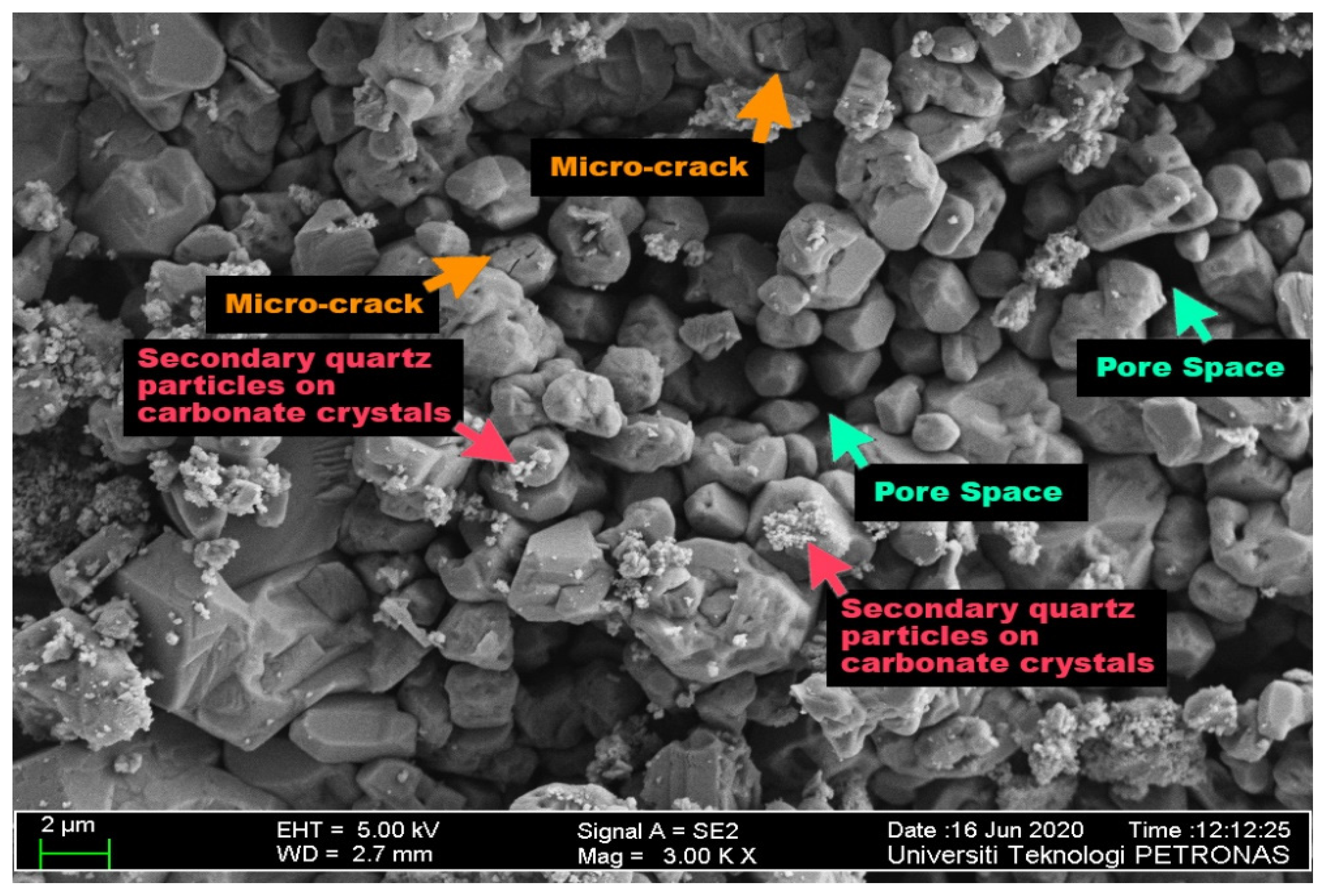

3.2. FESEM and EDX Analaysis

3.3. Klinkenberg-Corrected Permeability Measurement

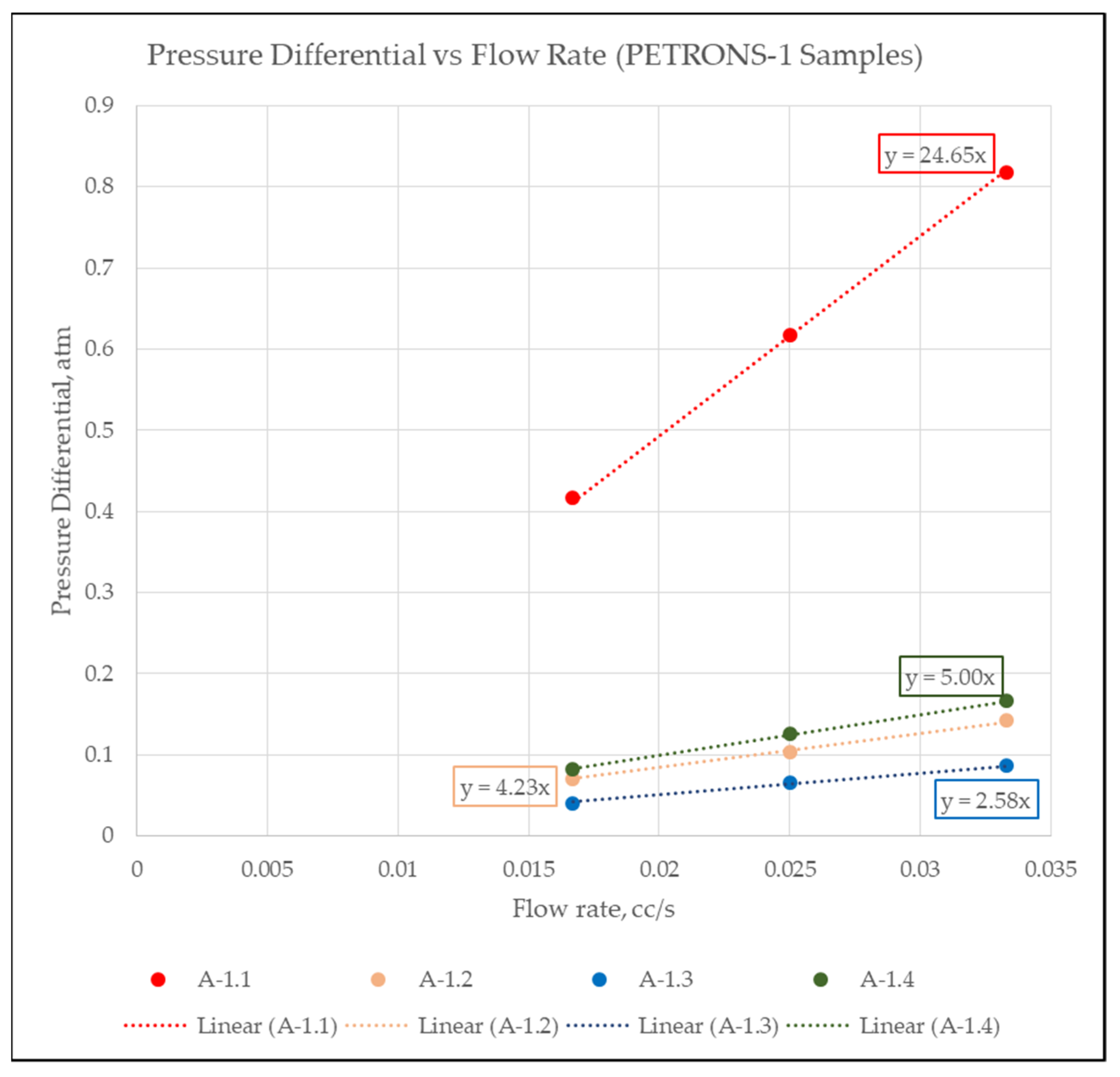

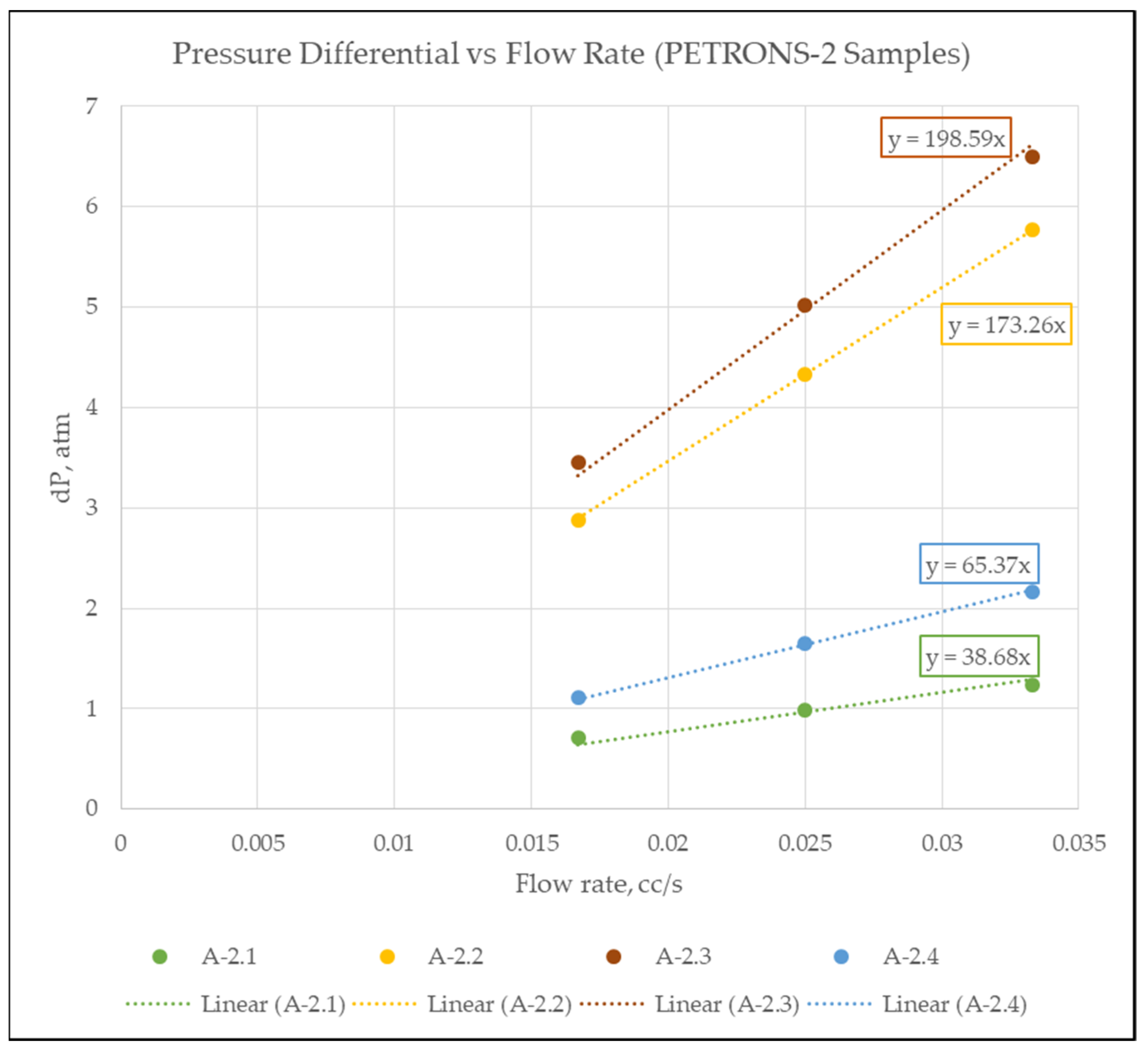

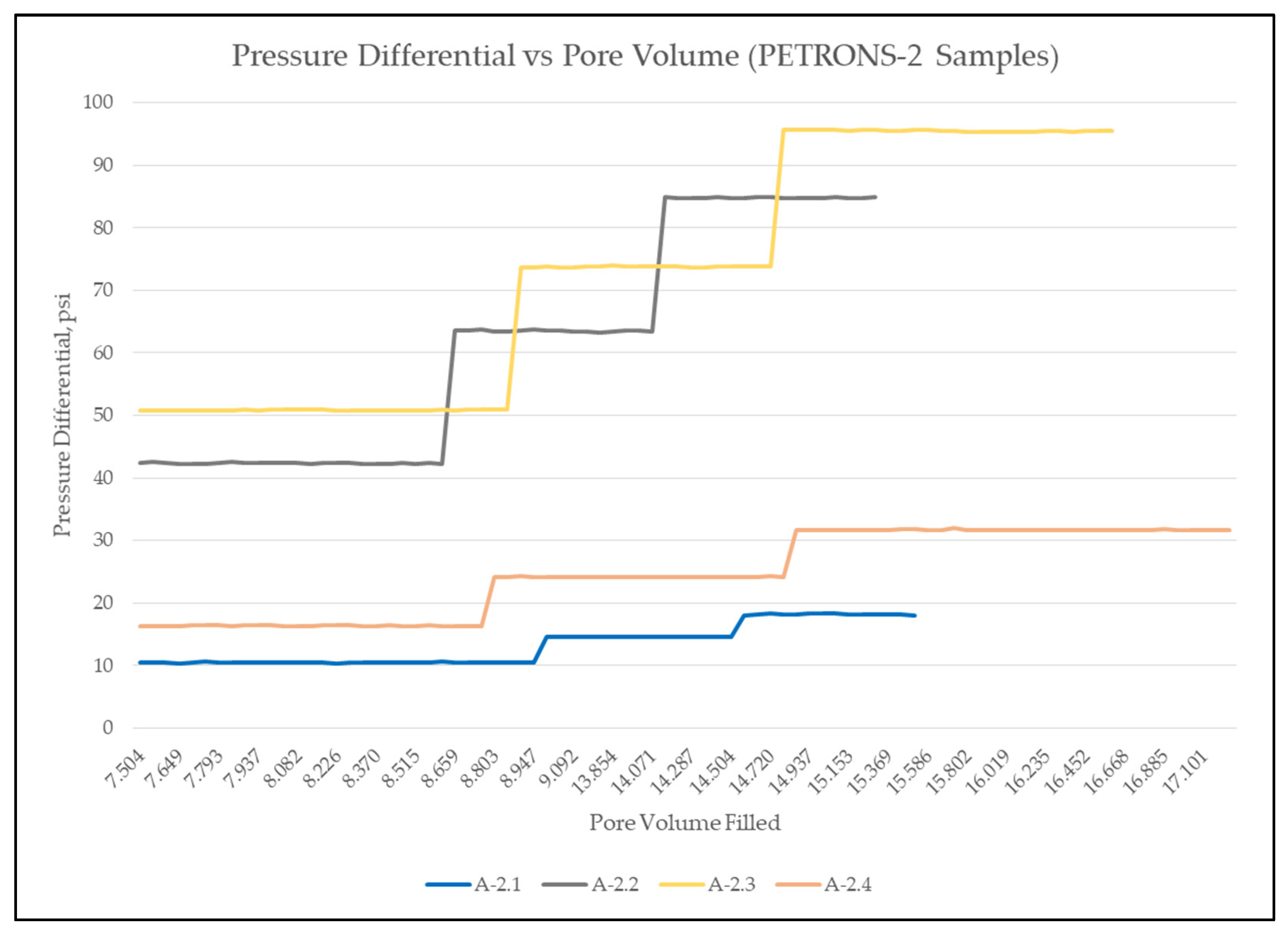

3.4. Water Permeability Results

- k = liquid permeability, Darcies

- Q = flow rate, cc/s

- ∆P = pressure differential, atm

- A = surface area, cm2

- µ = viscosity, cp

- L = length, cm

| Sample Number | Brine Flow Rate (cc/s) | ∆P (atm) | Sample Number | Brine Flow Rate (cc/s) | ∆P (atm) |

|---|---|---|---|---|---|

| A-1.1 | 0.017 | 0.417 | A-2.1 | 0.017 | 0.707 |

| 0.025 | 0.618 | 0.025 | 0.990 | ||

| 0.033 | 0.818 | 0.033 | 1.240 | ||

| A-1.2 | 0.017 | 0.071 | A-2.2 | 0.017 | 2.882 |

| 0.025 | 0.104 | 0.025 | 4.332 | ||

| 0.033 | 0.142 | 0.033 | 5.775 | ||

| A-1.3 | 0.017 | 0.040 | A-2.3 | 0.017 | 3.456 |

| 0.025 | 0.066 | 0.025 | 5.020 | ||

| 0.033 | 0.087 | 0.033 | 6.502 | ||

| A-1.4 | 0.017 | 0.082 | A-2.4 | 0.017 | 1.113 |

| 0.025 | 0.126 | 0.025 | 1.645 | ||

| 0.033 | 0.166 | 0.033 | 2.158 |

4. Discussions

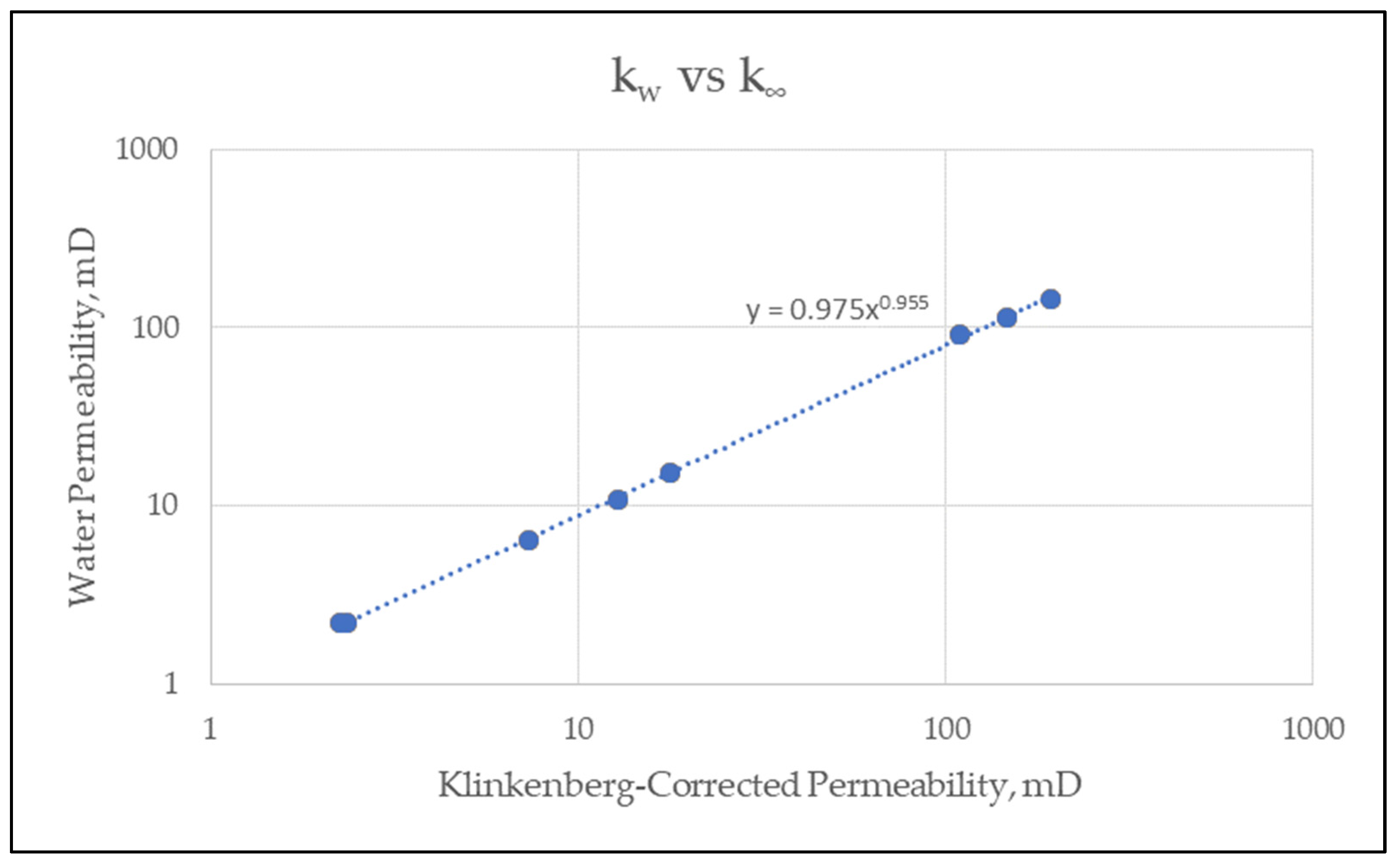

4.1. Correlation between Klinkenberg-Corrected Permeability and Water Permeability

4.2. Factors Affecting Variations in Permeability Values

4.2.1. Effect of Fines Migration

4.2.2. Effect of Micro-Pores

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al-Bulushi, I.R.; Al-Maamari, R.S.; Wilson, O.B. Brine versus Klinkenberg corrected gas permeability correlation for Shuaiba carbonate formation. J. Pet. Sci. Eng. 2012, 92, 24–29. [Google Scholar] [CrossRef]

- Al-Jabri, R.A.; Al-Maamari, R.S.; Wilson, O.B. Klinkenberg-corrected gas permeability correlation for Shuaiba carbonate formation. J. Pet. Sci. Eng. 2015, 131, 172–176. [Google Scholar] [CrossRef]

- Klinkenberg, L. The permeability of porous media to liquids and gases. In Drilling and Production Practice; American Petroleum Institute: Washington, DC, USA, 1941. [Google Scholar]

- Muskat, M. The flow of homogeneous fluids through porous media. Soil Sci. 1938, 46, 169. [Google Scholar] [CrossRef]

- McPhee, C.A.; Arthur, K.G. Klinkenberg permeability measurements: Problems and practical solutions. In Advances in Core Evaluation II: Reservoir Appraisal: Reviewed Proceedings; CRC Press: Boca Raton, FL, USA, 1991; pp. 371–392. [Google Scholar]

- Firouzi, M.; Alnoaimi, K.; Kovscek, A.; Wilcox, J. Klinkenberg effect on predicting and measuring helium permeability in gas shales. Int. J. Coal Geol. 2014, 123, 62–68. [Google Scholar] [CrossRef]

- Tanikawa, W.; Shimamoto, T. Klinkenberg effect for gas permeability and its comparison to water permeability for porous sedimentary rocks. Hydrol. Earth Syst. Sci. Discuss. 2006, 3, 1315–1338. [Google Scholar]

- Wu, Y.-S.; Pruess, K. Gas flow in porous media with Klinkenberg effects. Transp. Porous Media 1998, 32, 117–137. [Google Scholar] [CrossRef]

- Tanikawa, W.; Shimamoto, T. Comparison of Klinkenberg-corrected gas permeability and water permeability in sedimentary rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Wojnarowski, P.; Czarnota, R.; Janiga, D.; Stopa, J. Novel liquid-gas corrected permeability correlation for dolomite formation. Int. J. Rock Mech. Min. Sci. 2018, 112, 11–15. [Google Scholar] [CrossRef]

- Al-Muthana, A.S.; Ma, S.; Okasha, T. Best Practices in Conventional Core Analysis—A Laboratory Investigation. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, Al-Khobar, Saudi Arabia, 10–12 May 2008. [Google Scholar]

- Bhandari, A.; Flemings, P.; Ramiro-Ramirez, S.; Hofmann, R.; Polito, P. Gas and liquid permeability measurements in Wolfcamp samples. Fuel 2018, 236, 11. [Google Scholar] [CrossRef]

- Bloomfield, J.; Williams, A. An empirical liquid permeability—Gas permeability correlation for use in aquifer properties studies. Q. J. Eng. Geol. Hydrogeol. 1995, 28, S143–S150. [Google Scholar] [CrossRef]

- Chen, M.; Li, M.; Wang, Y.; Zhao, J.-Z.; Xiao, W.-L. The permeability of fontainebleau sandstone to gases and liquids. Pet. Sci. Technol. 2016, 34, 845–852. [Google Scholar] [CrossRef]

- Gupta, S.P.; Pugh, V.J.; Thomas, D.C. Correlations of Liquid and Air Permeabilities for Use in Reservoir Engineering Studies. Log Anal. 1991, 32, 493–497. [Google Scholar]

- Heap, M.; Reuschlé, T.; Farquharson, J.; Baud, P. Permeability of volcanic rocks to gas and water. J. Volcanol. Geotherm. Res. 2018, 354, 29–38. [Google Scholar] [CrossRef]

- Macary, S.M. Conversion of Air Permeability to Liquid Permeabilities Extracts Huge Source of Information for Reservoir Studies. In Proceedings of the Middle East Oil Show and Conference, Manama, Bahrain, 20–23 February 1999. [Google Scholar]

- Mahesar, A.; Memon, K.R.; Tunio, A. Comparison of Klinkenberg-Corrected Gas and Liquid Permeability in Kirthar Fold Belt Tight Gas Sands. Mehran Univ. Res. J. Eng. Technol. 2017, 36, 957–964. [Google Scholar] [CrossRef] [Green Version]

- Loosveldt, H.; Lafhaj, Z.; Skoczylas, F. Experimental study of gas and liquid permeability of a mortar. Cem. Concr. Res. 2002, 32, 1357–1363. [Google Scholar] [CrossRef]

- Osman, A.M.; Halim, N.H.; Alwi, N.; Sedaralit, M.F.; Ibrahim, J.M.; Hamid, P.A.; Ohen, H.A. Investigation of Fine Migration, Clay Swelling and Injectivity problem during FAWAG Study in West Malaysia Oil Field. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 10–12 December 2014. [Google Scholar]

- Priisholm, S.; Nielsen, B.; Haslund, O. Fines migration, blocking, and clay swelling of potential geothermal sandstone reservoirs, Denmark. SPE Form. Eval. 1987, 2, 168–178. [Google Scholar] [CrossRef]

- Kanimozhi, B.; Thamizhmani, V.; Pranesh, V.; Senthil, S.; Selvakumar, T.A. Kaolinite fines colloidal flow in high temperature porous carbonate media during saline water injection. J. Pet. Sci. Eng. 2019, 175, 775–784. [Google Scholar] [CrossRef]

- Qajar, J.; Francois, N.; Arns, C.H. Micro-tomographic characterization of dissolution-induced local porosity changes including fines migration in carbonate rock. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Uli, D.A.; Mithani, A.H.; Ali, K.; Abu Mansur, R.B.; Masoudi, R.; Tewari, R.D.; Jirim, S.; Harith, Z.Z.T.; Mohammad, M.H.H.; Kanesan, T.; et al. Integrated Carbonate Field Management Using Forward Stratigraphic Modelling Approach: Case Study of a Field in Central Luconia. In Proceedings of the Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Clews, P.J.; Soo, D.; Veeriah, T. Final Report of Petrographic Study—PETRONS-1; Occidental Petroleum Malaysia LTD: Kuala Lumpur, Malaysia, 1993. [Google Scholar]

- Ngah, T.B.T. Geological Evaluation—PETRONS-2; PETRONAS Carigali Sdn Bhd: Kuala Lumpur, Malaysia, 1993. [Google Scholar]

- Ali, M.Y.; Aqrawi, A.; Ahmad, Z. An Integrated Sedimentological Study of PETRONS-2 Well; PETRONAS Carigali Sdn Bhd: Kuala Lumpur, Malaysia, 1997. [Google Scholar]

- Singh, S.P. Borehole Stability, Compaction, and Petrophysical Evaluation of the PETRONS-2 Well; PETRONAS Carigali Sdn Bhd: Kuala Lumpur, Malaysia, 1997. [Google Scholar]

| Well Name | Sample Number | Depth (m) | Dry Weight (g) | Diameter (in) | Length (in) |

|---|---|---|---|---|---|

| PETRONS-1 | A-1.1 | 1636.55 | 99.38 | 1.5 | 1.68 |

| PETRONS-1 | A-1.2 | 1641.55 | 109.89 | 1.5 | 2.17 |

| PETRONS-1 | A-1.3 | 1688.74 | 82.91 | 1.5 | 1.69 |

| PETRONS-1 | A-1.4 | 1694.87 | 113.45 | 1.5 | 2.04 |

| PETRONS-2 | A-2.1 | 1654.80 | 118.45 | 1.5 | 1.86 |

| PETRONS-2 | A-2.2 | 1655.70 | 115.17 | 1.5 | 1.70 |

| PETRONS-2 | A-2.3 | 1696.24 | 115.38 | 1.5 | 1.97 |

| PETRONS-2 | A-2.4 | 1730.53 | 114.25 | 1.5 | 1.89 |

| Sample Number | Depth (m) | Core Lithofacies | Core Microfacies |

|---|---|---|---|

| A-1.1 | 1636.55 | Mouldic | Foraminiferal Algal Coral Packstone/Floatstone |

| A-1.2 | 1641.55 | Mouldic–Chalkified | Foraminiferal Algal Coral Packstone/Floatstone |

| A-1.3 | 1688.74 | Mouldic–Chalkified | Foraminiferal Algal Packstone/Wackestone/Floatstone |

| A-1.4 | 1694.87 | Mouldic–Chalkified | Foraminiferal Wackstone/Packstone |

| A-2.1 | 1654.80 | Argillaceous | Foraminiferal Algal Wackestone |

| A-2.2 | 1655.70 | Argillaceous | Larger Foraminiferal Wackestone/Packstone |

| A-2.3 | 1696.24 | Mouldic–Chalkified | Bioclastic Packstone/Grainstone |

| A-2.4 | 1730.53 | Mouldic | Bioclastic Grainstone |

| Sample Number | kg (mD) | k∞ (mD) | b (psi) |

|---|---|---|---|

| A-1.1 | 20.063 | 17.744 | 5.482 |

| A-1.2 | 153.501 | 146.314 | 2.062 |

| A-1.3 | 201.448 | 192.616 | 1.915 |

| A-1.4 | 118.591 | 109.021 | 3.689 |

| A-2.1 | 14.597 | 12.814 | 5.847 |

| A-2.2 | 2.796 | 2.342 | 8.152 |

| A-2.3 | 2.707 | 2.261 | 8.274 |

| A-2.4 | 8.470 | 7.350 | 6.408 |

| Sample Number | Wet Weight with Wrapping (gm) | Weight of Lead & Mesh (gm) | Wet Weight (gm) | Dry Weight (gm) | Pore Volume (cm3) |

|---|---|---|---|---|---|

| A-1.1 | 115.813 | 4.925 | 110.888 | 99.384 | 11.504 |

| A-1.2 | 136.340 | 5.507 | 130.833 | 109.892 | 20.941 |

| A-1.3 | 105.440 | 4.889 | 100.551 | 82.910 | 17.641 |

| A-1.4 | 134.263 | 5.390 | 128.873 | 113.452 | 15.421 |

| A-2.1 | 132.980 | 5.127 | 127.853 | 118.451 | 9.402 |

| A-2.2 | 126.500 | 4.927 | 121.573 | 115.165 | 6.408 |

| A-2.3 | 132.030 | 5.333 | 126.697 | 115.375 | 11.322 |

| A-2.4 | 129.760 | 5.115 | 124.645 | 114.251 | 10.394 |

| Sample Number | Average dP/Q (atm/cc/s) | kw (mD) |

|---|---|---|

| A-1.1 | 24.654 | 15.185 |

| A-1.2 | 4.2326 | 114.138 |

| A-1.3 | 2.584 | 145.563 |

| A-1.4 | 5.000 | 90.665 |

| A-2.1 | 38.675 | 10.723 |

| A-2.2 | 173.260 | 2.186 |

| A-2.3 | 198.59 | 2.212 |

| A-2.4 | 65.372 | 6.424 |

| Sample Number | k∞ (mD) | kw (mD) |

|---|---|---|

| A-1.1 | 17.744 | 15.185 |

| A-1.2 | 146.314 | 114.138 |

| A-1.3 | 192.616 | 145.563 |

| A-1.4 | 109.021 | 90.665 |

| A-2.1 | 12.814 | 10.723 |

| A-2.2 | 2.342 | 2.186 |

| A-2.3 | 2.261 | 2.212 |

| A-2.4 | 7.350 | 6.424 |

| Calculation Using New Developed Correlation | ||||

|---|---|---|---|---|

| Sample Number | Measured k∞ (mD) | Measured kw (mD) | Calculated kw (mD) | Percentage Difference |

| 1P | 1.028 | 0.943 | 1.001 | 6.158 |

| 2P | 18.77 | 17.05 | 16.062 | 5.795 |

| 3P | 6.865 | 6.434 | 6.143 | 4.515 |

| 4P | 7.47 | 7.06 | 6.660 | 5.668 |

| Calculation Using Correlation from [10] | ||||

| Sample Number | Measured k∞ (mD) | Measured kw (mD) | Calculated kw (mD) | Percentage Difference |

| 1P | 1.028 | 0.943 | 0.955 | 1.312 |

| 2P | 18.77 | 17.05 | 16.025 | 6.009 |

| 3P | 6.865 | 6.434 | 6.036 | 6.188 |

| 4P | 7.47 | 7.06 | 6.552 | 7.201 |

| Calculation Using Correlation by [1] | ||||

| Sample Number | Measured k∞ (mD) | Measured kw (mD) | Calculated kw (mD) | Percentage Difference |

| 1P | 1.028 | 0.943 | 0.889 | 5.711 |

| 2P | 18.77 | 17.05 | 18.182 | 6.640 |

| 3P | 6.865 | 6.434 | 6.394 | 0.619 |

| 4P | 7.47 | 7.06 | 6.981 | 1.124 |

| Sample | TSS (mg/L) | Sample | TSS (mg/L) |

|---|---|---|---|

| A-1 Brine | 2 | A-2 Brine | 10 |

| A-1.1 | 7 | A-2.1 | 22 |

| A-1.2 | 6 | A-2.2 | 14 |

| A-1.3 | 12 | A-2.3 | 37 |

| A-1.4 | 14 | A-2.4 | 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, I.; Ahmad, M.; Ali, I. Klinkenberg-Corrected and Water Permeability Correlation for a Sarawak Carbonate Field. Fluids 2021, 6, 339. https://doi.org/10.3390/fluids6100339

Ahmad I, Ahmad M, Ali I. Klinkenberg-Corrected and Water Permeability Correlation for a Sarawak Carbonate Field. Fluids. 2021; 6(10):339. https://doi.org/10.3390/fluids6100339

Chicago/Turabian StyleAhmad, Izzat, Maqsood Ahmad, and Imtiaz Ali. 2021. "Klinkenberg-Corrected and Water Permeability Correlation for a Sarawak Carbonate Field" Fluids 6, no. 10: 339. https://doi.org/10.3390/fluids6100339

APA StyleAhmad, I., Ahmad, M., & Ali, I. (2021). Klinkenberg-Corrected and Water Permeability Correlation for a Sarawak Carbonate Field. Fluids, 6(10), 339. https://doi.org/10.3390/fluids6100339