This study aims to investigate both the effect the bubbles exert on the flow characteristics of the surrounding flow, as well as the influence the power-law behavior in the continuous phase has on the dispersed phase. To gain the respective insights, a number of quantities is evaluated after reaching the statistically steady state. Statistics are collected for a period corresponding to approximately 180 flow-through times () of the selected channel, starting after approximately 20 flow-through times () to exclude the initial transient. In this context, the reference time T is defined as , with the friction velocity of the initialization setup.

4.1. Average Wall Shear Stress and Viscosity Profiles

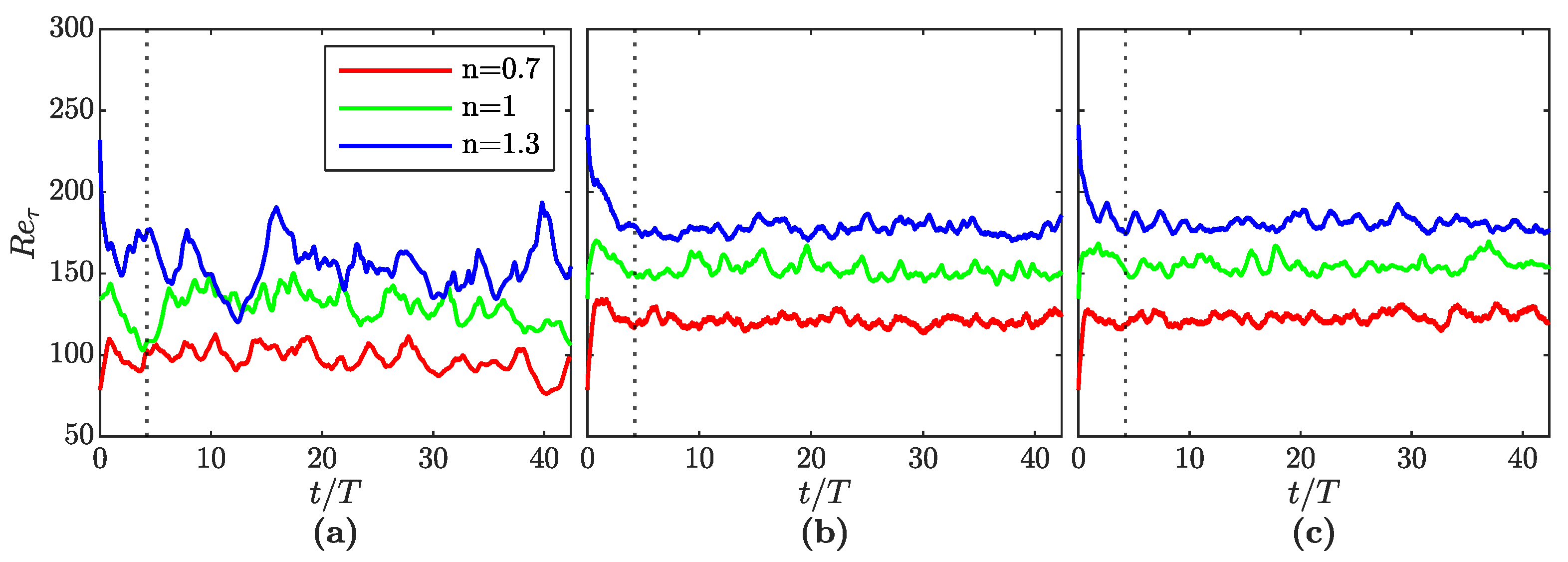

Typically, the convergence of bubble-laden channel flows towards a statistically steady state is measured using the average wall shear stress

[

15,

19]. By normalizing it with

,

can be expressed in terms of the friction Reynolds number

.

Figure 4 shows

, based on the wall-averaged shear stress

, for all setups as a function of the time. The starting time of statistical averaging is illustrated by the dotted line at

. As explained in

Section 3.2, all cases are initialized from a single-phase channel flow of a Newtonian fluid controlled by a constant pressure gradient corresponding to

. This value can be observed at

for the three cases corresponding to

. While

of the single-phase case continues to fluctuate around this theoretical value when the flow control is changed to a constant volumetric flow rate, the presence of the dispersed gas fraction increases the average wall shear stress by approximately 20%. This effect was already reported in [

19], where the authors attributed it to the stirring of the bubbles, which affects the near wall region above a certain gas fraction. The observed increase is 19.5% for

and 21.7% for

. Although the time-averaged wall shear stress of the single-phase setup for

deviates from the theoretical value by less than 2%, the respective fluctuations are found to be stronger compared to the two-phase cases. The presence of the bubbles has a clearly visible dampening effect on the fluctuations of

, irrespective of the power-law index.

As

Figure 4 shows, the wall shear stress increases when the continuous liquid phase exhibits shear-thickening behavior (

), while the opposite effect can be observed for the shear-thinning scenario (

). This behavior is dominated by the viscosity values close to the walls. Due to the high shear rates

in the near-wall region, the viscosity of the shear-thickening fluid exceeds the viscosity of the Newtonian fluid, while the viscosity of the shear-thinning fluid follows an opposite trend, see

Figure 5. Although the mean velocity gradient at the wall is slightly higher (lower) for the shear-thinning (shear-thickening) fluid (see Figure 7), the wall shear stress still reveals the lowest (highest) values due to the viscosity behavior. The findings observed for the Newtonian fluid, i.e., smoother curves of

with fluctuations around an increased average value for two-phase setups, also hold true for the non-Newtonian fluids.

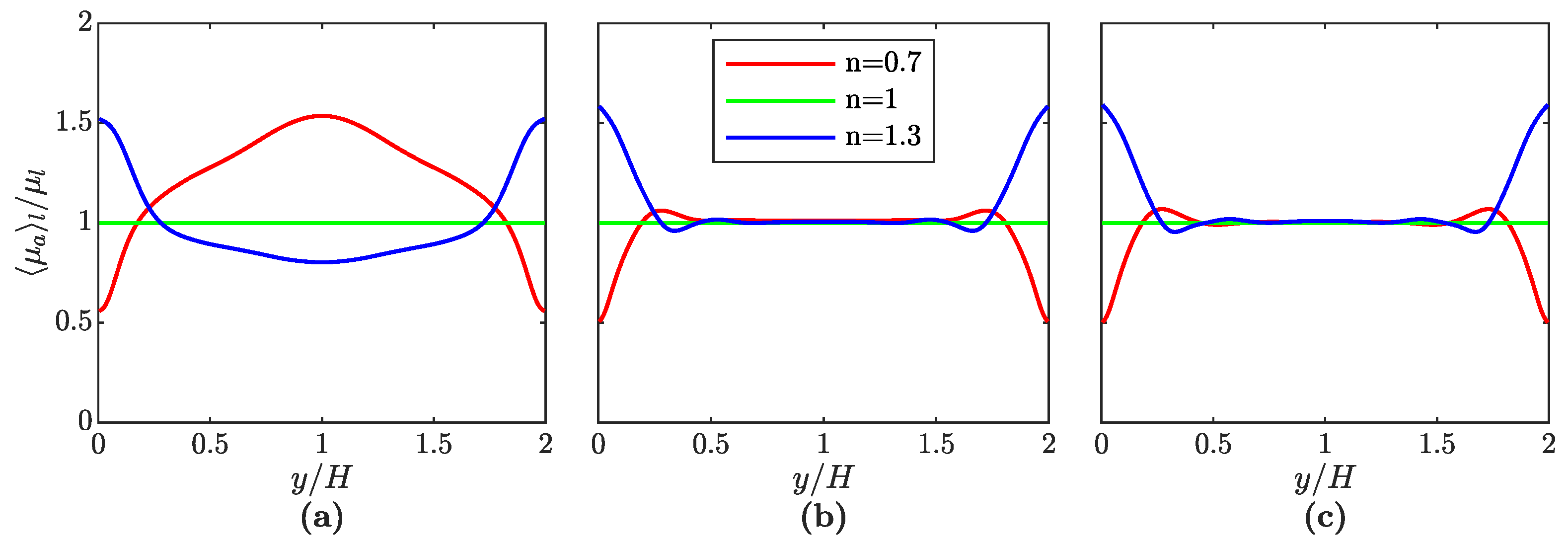

Since the three cases in each setup category, i.e., single-phase or two-phase with either quasi-spherical or deformable bubbles, are identical apart from the different power-law indexes, it is expedient to initially investigate the viscosity statistics of each case. The viscosity values do not only explain the above-mentioned observations regarding the average wall shear stress, but they are also responsible for all other differences occurring in the results of one setup category.

Figure 5 shows the average apparent dynamic viscosity of the liquid phase

, normalized with the viscosity for

, as a function of the wall-normal coordinate

y.

For the single-phase cases with a non-Newtonian continuous phase, the dynamic liquid viscosity obeys a monotonic trend from the wall to channel center. As the shear rate is high close to the walls and low in the channel center, the shear-thinning fluid produces the minimum viscosity at the walls, while the maximum can be found in the center. The opposite behavior can be observed for the shear-thickening fluid. While the profiles for the two-phase cases are relatively similar to those of the respective single-phase setups close to the walls, they clearly show the range where the bubbles are present, which spans from

to

(see

Section 4.2). Due to the bubbles accumulating in this part of the domain, there are elevated local velocity differences causing the shear rate to exceed the values from the single-phase setups. As a consequence, the viscosity increases (decreases) for the shear-thickening (shear-thinning) fluid and the profiles for different power-law indexes are very close to each other in the section around the channel center. Moreover, due to the homogeneous bubbly flow in the core part of the channel (see Figures 7 and 9),

, the average shear rate (see

Section 2) as well as the average apparent viscosity are almost independent of

y and constant in this region. It is also interesting to note that the Eötvös-number, and therefore the bubble deformability, seem to have a negligible influence on the viscosity profiles.

Table 2 provides the normalized average viscosities of the liquid phase, which result from averaging over all spatial directions and over the time.

When investigating the average viscosity profiles for the bubble-laden flows, the quasi-identical values in the channel center lead to the question of whether there is some underlying physical cause for this behavior. As discussed in

Section 2, the apparent liquid viscosity for the power-law fluids is determined as

. In order to observe identical average liquid viscosities across all investigated power-law indexes in the channel center, the average shear rate in this region would have to be equal to one. Since there is no obvious reason why this should generally be the case, it is assumed that this is just a characteristic of this specific setup and not a general observation. To verify this, a set of additional simulations has been performed at an increased void fraction of 10%. Indeed, the results support this assumption. For 120 instead of 72 bubbles, the average shear rate in the channel center increases further. This leads to a situation where, in contrast to the results illustrated in

Figure 5, the viscosity profiles, including the peaks, for the shear-thinning fluid fall below the constant viscosity

of the Newtonian fluid for all values of

y. The same effect, yet in the opposite direction, holds for the shear-thickening fluid: the minima are still larger than

. While, in principle, the shape of the profiles remains very similar, this shows that increased shear rates in the channel center due to higher gas fractions shift the viscosity profiles in the center towards the values at the wall. The single-phase setups in

Figure 5 demonstrate this observation for the opposite extreme case. Another change to the setup that should, in principle, evoke similar consequences on the viscosity profiles would be to choose the power-law indexes for the shear-thinning and thickening fluid to be further away from 1. However, additionally verifying this assumption was beyond the scope of this work, as, with regard to

Figure 5, it should only be clarified that the quasi-identical values in the channel center are indeed a characteristic of this specific setup and not a general observation.

4.2. First- and Second-Order Fluid Statistics

As was already reported in earlier studies investigating bubble-laden downflow channels [

15,

16,

19], the bubbles show a clear tendency to accumulate in the channel center, see

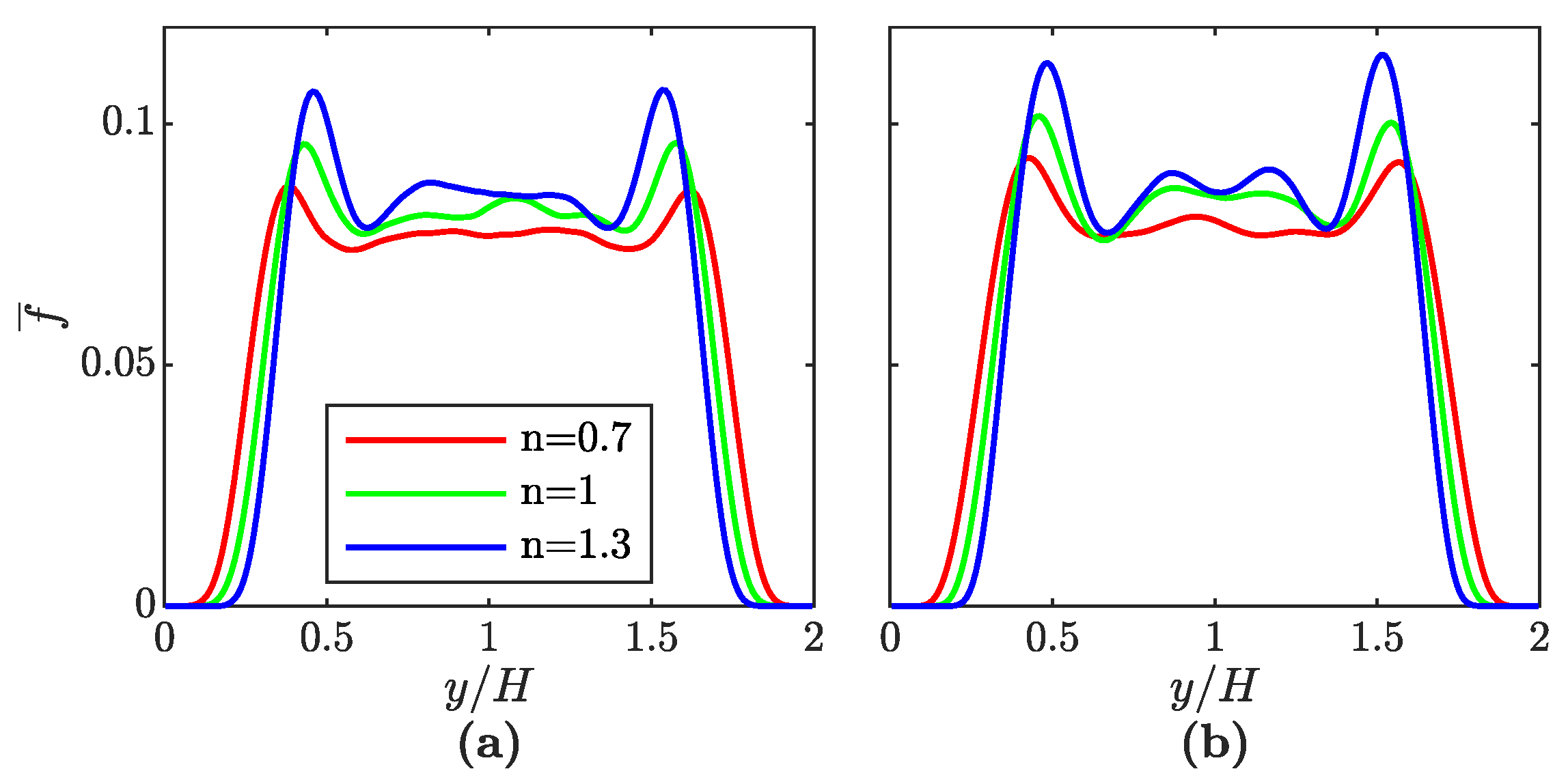

Figure 6. According to Lu and Tryggvason [

15], this can be explained by the lift force acting on the bubbles. While all profiles exhibit the characteristics known from earlier studies, namely a relatively constant distribution in the channel center together with peaks in the transition to the bubble-free regions near the walls, there are clear tendencies arising for the shear-thinning and the shear-thickening fluid. It is important to note that the profiles shown in

Figure 6 have not been averaged over the two channel halves. As can be recognized, the profiles are not perfectly symmetric. This indicates that the volume fraction field tends to converge slower than the other statistics provided in the following sections, which achieved a high degree of symmetry. Nevertheless, the profiles illustrated in

Figure 6 are very similar to what is known from literature, with only one exception: the distribution is less uniform in the channel center. In order to make sure that this behavior only occurs due to a lack of convergence, identical setups have been simulated for a void fraction of 10%. As was observed in [

19], statistics collected for dense cases tend to converge faster than those gathered at dilute gas fractions. For the increased gas fraction, it was possible to observe profiles that exhibit a high degree of symmetry together with flat profiles in the bubble-rich core. Consequently, it can be estimated that the profiles presented in

Figure 6 would only flatten in the center for significantly longer simulation periods, while otherwise retaining their characteristics. Since the gathered statistics have already been computed over 180 flow-through times it is likely that, in order to reach void fraction profiles exhibiting perfect symmetry, a significantly longer simulation is required. As this study primarily aims to show tendencies arising for a non-Newtonian continuous liquid phase, it was decided to not continue the simulations.

When comparing the void fraction profiles for the cases with

to the profiles with a non-Newtonian liquid phase, clear tendencies can be observed. First of all, the bubble-free zone near the walls is wider for the shear-thickening and narrower for the shear-thinning setup. As a consequence, the profiles for

are shifted towards the channel center. Since the overall gas fraction is identical for all cases, this results in a stronger accumulation of bubbles in the core of the channel. Therefore, both the peaks in the transition between core and walls as well as the plateau-like section in the center are shifted to higher values. The opposite holds for

, where the bubbles are distributed more uniformly along the wall-normal direction. The shear lift force occurs due to the mean flow gradient near the wall. As the boundary layer becomes thinner (thicker) for shear-thinning (shear-thickening) fluids (see

Figure 7), the bubbles move closer to (stay away further from) the wall compared to the Newtonian case. However, the peaks do not only increase for higher values of

n. A comparison of the profiles for

and

reveals that, independent of the power-law index, the profiles are also shifted towards the channel center for increased

. This impacts the peaks in the same way as described for increased values of

n.

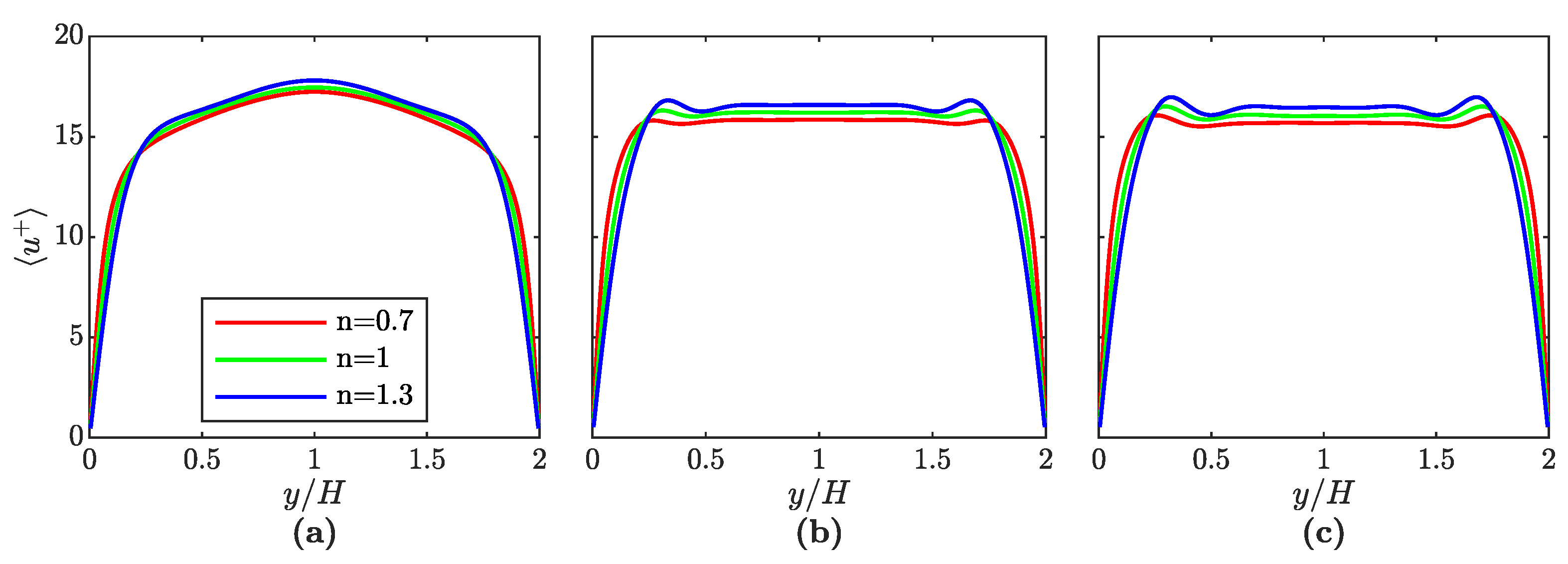

The profiles for the average stream-wise velocity

, normalized with the friction velocity

to yield

, are shown in

Figure 7. Since the actual friction velocity

is different for each of the nine setups (see

Figure 4), the value

is taken from the initialization setup. The theoretical value for the respective case is provided in [

15]. All profiles are similar to the ones shown in the literature, i.e., the single-phase setups show a monotonous increase towards their maximum value in the channel center, while the two-phase setups exhibit an almost uniform profile in the region of the bubble-rich core. In principle, the effect of increasing or decreasing

n is the same as shown for the void fraction profiles in

Figure 6. Once again, the profiles for the shear-thickening setups are shifted towards the channel core and, due to the constant volumetric flow rate, exhibit higher average velocities there. On the other hand, the profiles for the cases considering the shear-thinning fluid are wider and reach lower maximum flow velocities. The thickness of the wall boundary layer increases with

n. This observation is consistent with the viscosity profiles illustrated in

Figure 5, which demonstrate that the viscosity in the near-wall region is high for the shear-thickening fluid and low for the shear-thinning fluid. It is also interesting to note that a plateau-like section is formed in the middle of the two-phase velocity profiles, between the locations of the volume fraction peaks. In this regard, the profiles resemble the one shown in [

18], although the plateaus are more pronounced in the present study, especially for

. This can be partly attributed to the fact that, instead of excluding the velocities of the gas phase, the velocities of both phases are taken into consideration here. Since the bubbles rise relative to the continuous liquid phase, including the gas-phase velocity would result in lower flow velocities in the bubble-rich channel core. For the two-phase setups, the velocity profiles exhibit only minor differences between

and

. As can be seen, the peaks and plateau-like sections of the profiles are slightly more pronounced for the higher Eötvös number.

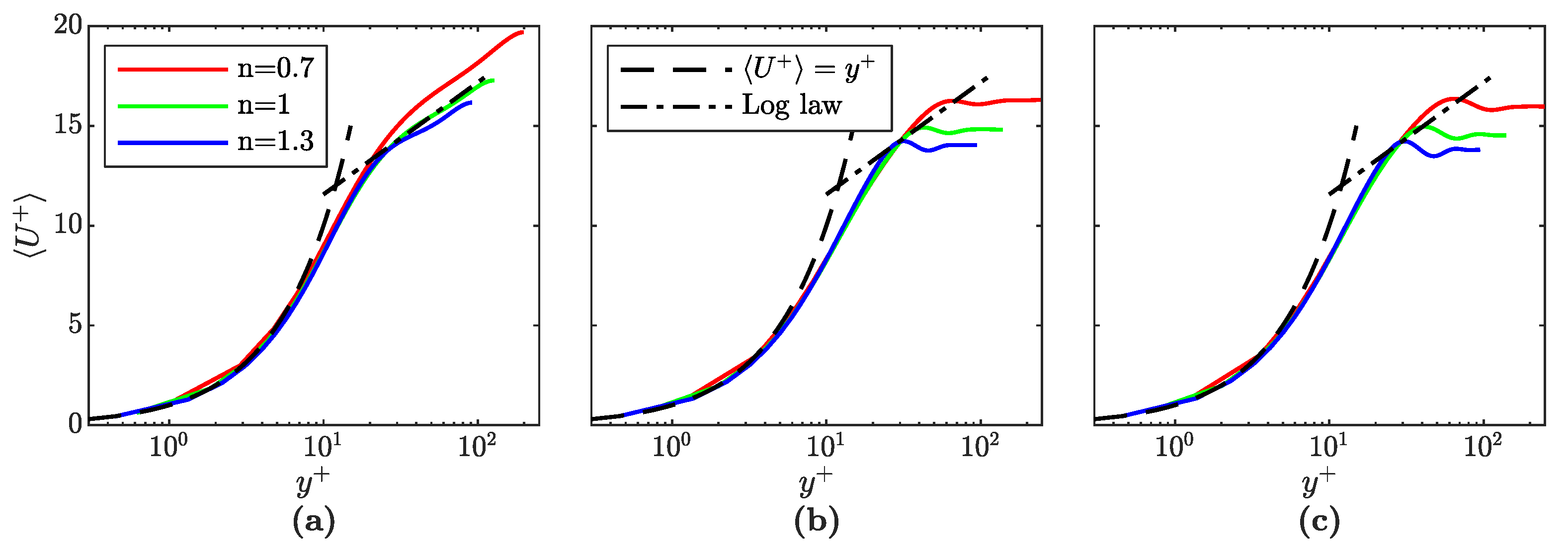

Figure 8 shows a semilogarithmic plot of the stream-wise velocity

, normalized by the friction velocity

to yield the dimensionless velocity

, over the the dimensionless wall distance

. It is important to note that, in this context,

is determined using the actual value of the wall shear stress

for each setup (see

Figure 4) instead of the theoretical value corresponding to the initialization setup, which was used for the profiles in

Figure 7. This is indicated by using

instead of

in the following. For the calculation of the friction velocity,

is averaged over the same time span as all other statistics. The dimensionless wall distance is defined as

. However, the kinematic viscosity

is not constant for the non-Newtonian fluids. Since the aim is to investigate the flow behavior close to the wall, the viscosity values for the power-law fluids are taken from the first cells at the wall, i.e.,

corresponds to the average apparent viscosity values

of the liquid phase at

and

, see profiles shown in

Figure 5. Since the near-wall region is free of bubbles, the kinematic viscosity of the gas phase does not play a role for the determination of

. The resulting profiles are compared to the theoretical approximations suggested in the literature. For the viscous sublayer (

), the predicted behavior is

. In the logarithmic layer (

), the figure compares the normalized velocity to the logarithmic “law of the wall”, or “log law”, which is defined as

. Here,

is the von Karman constant and

B is taken to be 5.95 [

15].

As

Figure 8 shows, all nine profiles agree very well with

in the viscous sublayer. While the velocity of the single-phase flow at

also matches the “log law” very accurately, the profiles are shifted to higher values for the shear-thinning and to lower values for the shear-thickening fluid. Due to the absence of bubbles close to the walls, the two-phase profiles are relatively similar to those of the single-phase flow up to the position where the velocity peaks are formed. At larger distances from the wall, the stream-wise velocity profiles for the bubble-laden flows increasingly deviate and flatten towards the bubble-rich core region. As has also been reported in [

15,

18], the thickness of the wall boundary layer is reduced due to the presence of the bubbles and the formation of a logarithmic layer can therefore not be observed.

Figure 9,

Figure 10 and

Figure 11 show the root mean square of the stream-wise, the wall-normal and the span-wise velocity fluctuations, normalized by the friction velocity of the initialization case

. Overall, the fluctuations for

strongly resemble the profiles reported in the literature [

15,

18,

19]. The introduction of a dispersed phase at a significant void fraction leads to clear deviations of all profiles from their single-phase counterparts. The stream-wise velocity fluctuations for the single-phase setups, illustrated in

Figure 9, reach their maximum close to the wall, followed by a decrease towards the channel center. Independent of the power-law index, the opposite behavior can be observed for the two-phase setups.

Figure 9 shows that, although the first peaks of the bubble-laden flows are located at the same values of

y, they are significantly lower. This indicates a strong turbulent intensity reduction in the near-wall region. As discussed in [

18], the reason for this observation might be that, due to their lower velocity compared to the liquid bulk, the bubbles act as obstacles and intermit the otherwise present turbulence structures. On the other hand, compared to the single-phase setups, the two-phase flows reveal increasing fluctuations of the stream-wise velocity component in the channel core, which are generated by the high number of bubbles present in this region [

15]. As can be seen, the stream-wise fluctuations are virtually independent of

y in the bubble-rich core, where the bubbles are distributed evenly (see

Figure 6).

The latter observation also holds true for the velocity fluctuations in the other spatial directions. While the two-phase profiles for the wall-normal fluctuations, illustrated in

Figure 10, show a slight increase from the locations of the void fraction peaks towards the channel center for

, the profiles for

and those for the span-wise velocity fluctuations, shown in

Figure 11, are relatively independent of

y in the middle section. As shown in [

18,

19], all fluctuation profiles generally tend to flatten completely in the core region, if the void fraction is increased to values of 10% or more.

In the next step, the influence of the power-law index on the velocity fluctuations is investigated. For the single-phase setups, the difference in the velocity fluctuations close to the wall is insignificant. However, this changes towards the channel center, where the highest fluctuations can be observed for

, while the single-phase flow at

reveals the lowest fluctuations. These findings hold true for the stream-wise, the wall-normal and the span-wise direction. The observed profiles can be explained by the differences in the shear rate. For the single-phase channel, the shear rates are high in the near-wall region and low in the channel center. As a consequence, the shear-thinning (shear-thickening) fluid exhibits a low (high) dynamic viscosity close to the wall and a high (low) dynamic viscosity in the channel center, see

Figure 5. As the strength of the fluctuations is expected to increase with decreasing dynamic viscosity, this explains the trends observed for the single-phase setups. However, this effect is partially countered by the increasing gradients close to the wall for decreasing power-law indexes, such that the peaks of the stream-wise velocity fluctuations remain more or less comparable for all cases.

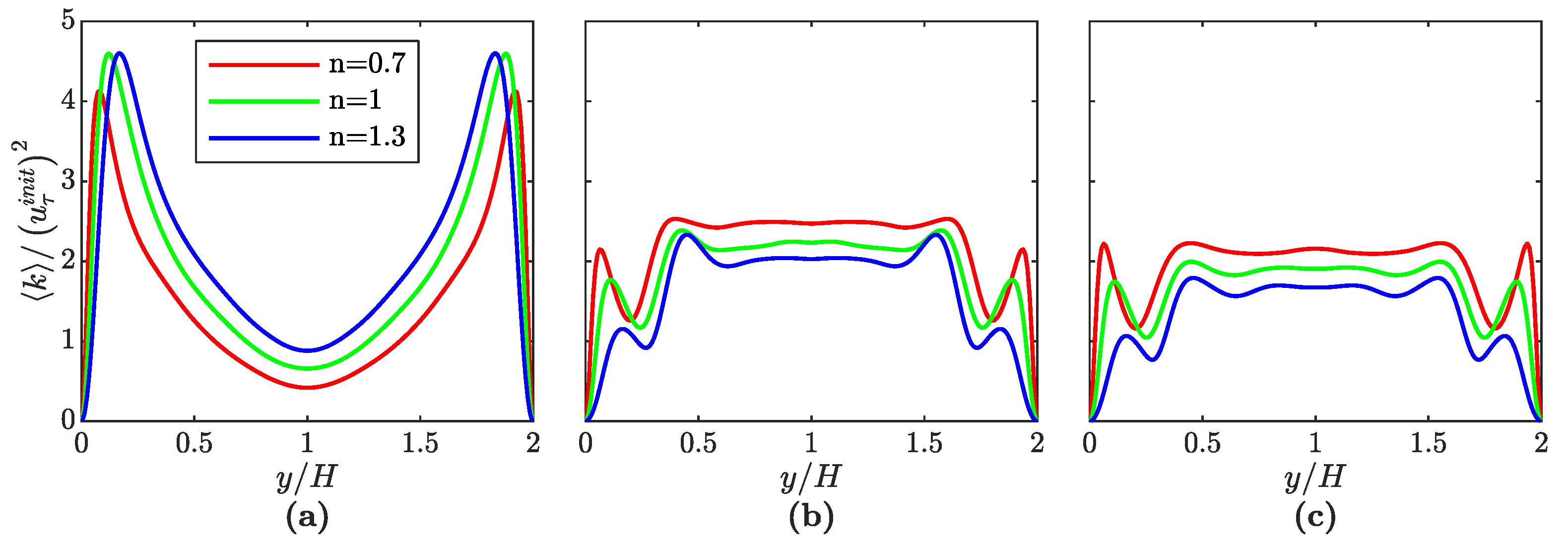

As shown in

Figure 9,

Figure 10 and

Figure 11, the two-phase profiles for the fluctuations of all three velocity components reveal remarkable differences compared to their single-phase counterparts. It is especially interesting to note that the order regarding the fluctuation strength is reversed in the bubble-rich core once a significant amount of bubbles is present. The two-phase setups with a shear-thinning continuous phase not only exhibit the strongest fluctuations close to the walls, but also in the bubble-rich core and for almost all values of

in the transition between these regions. While the three profiles of the stream-wise fluctuations overlap marginally for some small sections of

, the wall-normal and span-wise velocity fluctuations for

are higher than those for

independent of the wall-normal coordinate. The profiles for

are generally located between those of the non-Newtonian fluids apart from small overlaps on each side. The introduction of a significant number of bubbles leads to higher local velocity differences and increasing shear rates in the bubble-rich core. As a result, the apparent viscosity of the shear-thinning fluid decreases compared to the single-phase setup, while the opposite effect holds for the shear-thickening fluid. However, as shown in

Figure 5, the profiles of the average apparent viscosities are quasi identical in the channel core and therefore cannot fully explain the results observed for the fluctuations. The findings can, however, be reasoned by the different viscosities in the vicinity of the phase interface, where the velocity fluctuations are generated. For the single-phase setups, the fluctuations for

-positions very close to the walls are strongest (weakest) for

(

), as the shear rate is high close to the walls. As an additional analysis revealed, high shear rates occur in the vicinity of the phase interface as well. This can also be recognized in Figure 15, where strong velocity gradients are clearly visible around the bubbles. As a consequence, the apparent liquid viscosity for the shear-thinning (shear-thickening) fluid is significantly lower (higher) than the one of the Newtonian fluid in the vicinity of the phase interface. Although, partly due to the migration of the bubbles, this effect is not visible in the averaged profiles (see

Figure 5), it is responsible for the stronger (weaker) velocity fluctuations (compared to

) observed for the shear-thinning (shear-thickening) fluid in the core region. Moreover, the fluctuations in the core occur mainly due to the vortex shedding in the bubble wake and the velocity differences between the bubbles and the surrounding liquid. As discussed in

Section 3.2, all other conditions remaining identical, the relative velocity of the bubbles, and therefore also the bubble Reynolds number, increases with decreasing power-law index. This also explains the trends observed for the velocity fluctuations in the channel core.

Compared to the strong influence of the power-law index, the changes observed when increasing the Eötvös number from 0.3125 to 3.75 are relatively small. For the stream-wise velocity fluctuations (see

Figure 9), the peaks in the near-wall region are slightly more pronounced. Moreover, a minimal displacement of the profiles away from each other in the transition to the bubble-rich core can be observed. The same applies to the span-wise (

Figure 11) and the wall-normal (

Figure 10) fluctuations. For the latter,

additionally leads to a flattening in the center. However, it is interesting to note that the fluctuation of all velocity components is generally stronger for the lower Eötvös number. Although the differences are small when comparing the velocity fluctuation profiles, this effect is clearly visible when investigating the turbulent kinetic energy

k, see Figure 13. Further analysis regarding this observation, as well as the impact on the dissipation rate

, can be found in

Section 4.3.

4.3. Dissipation Rates

In this section, the dissipation rate

of the turbulent kinetic energy

is investigated. It can be defined as

with the apparent kinematic viscosity

and the velocity fluctuations

. The averaging over time and the homogeneous directions are consistent with the procedure used for the first and second order fluid statistics (see

Section 4.2). The apparent kinematic viscosity is

.

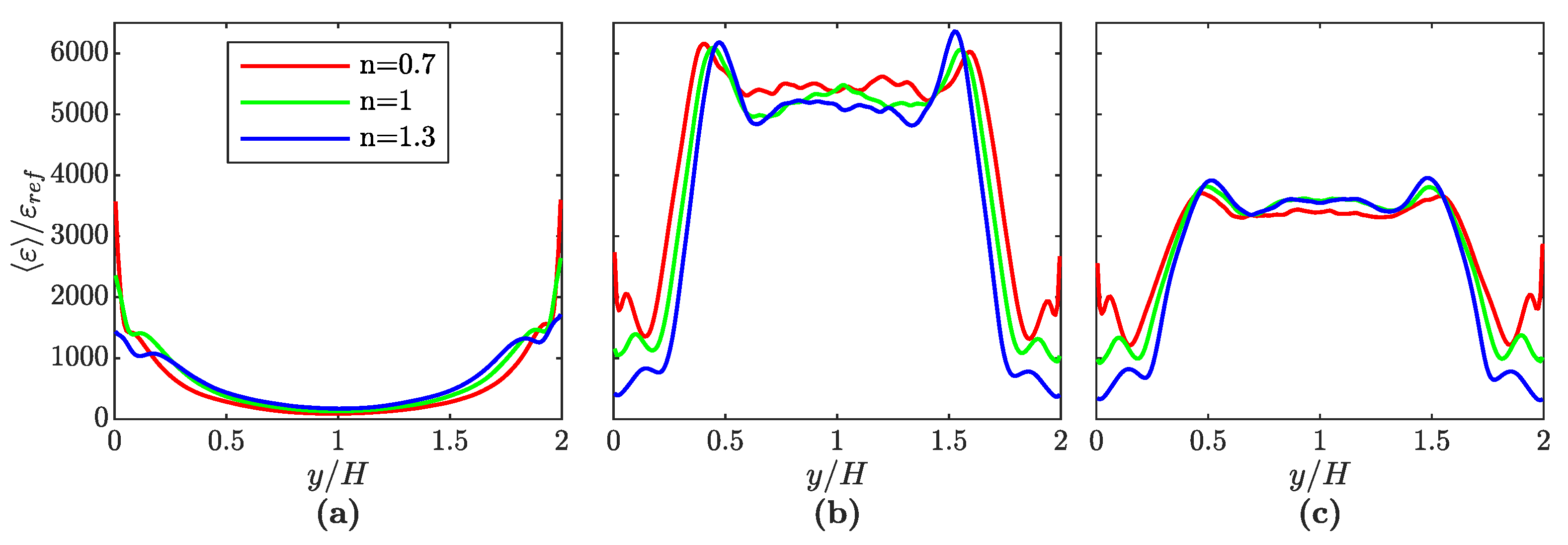

Figure 12 shows the dissipation rate, normalized with the reference value

for

and evaluated without phase-dependent conditioning, as a function of the wall-normal coordinate. The profiles have not been averaged over the two channel halves.

For the three single-phase setups, the dissipation rate reaches its maximum at the walls, while the minimum is located in the channel center. In the near-wall region, the dissipation rate decreases with increasing power-law index. However, the order reverses at a distance of approximately

from the walls. This behavior can be deduced from the fluctuations of the three velocity components (see

Figure 9,

Figure 10 and

Figure 11), where similar trends can be observed. It is worth noting that viscosity plays a role as well, but the velocity fluctuation gradients have a quadratic contribution to the dissipation rate. The two-phase setups are dominated by the presence of the bubbles in the core of the channel. Since

(see

Section 3.2), the kinematic viscosity of the gas phase is significantly higher than the apparent kinematic viscosity of the liquid phase. For the Newtonian fluid,

is 10. As a consequence, there is a direct relation between the void fraction (see

Figure 6) and the dissipation rate profiles (see

Figure 12) and the corresponding profiles exhibit a very similar shape. The two-phase profiles do not only deviate from their single-phase counterparts in the center of the channel, but also close to the walls. This reflects the significant deviations of the two-phase velocity fluctuation profiles from their single-phase counterparts, occurring for practically all values of

y (see

Figure 9,

Figure 10 and

Figure 11).

The Eötvös number has a negligible influence on the dissipation rate in the near-wall region. In the channel center, however, the dissipation rates for

are significantly higher than those for

. This can be reasoned by the behavior of the average turbulent kinetic energy

, illustrated in

Figure 13, and the integral turbulent length scale

ℓ. The relation between the dissipation rate and the turbulent kinetic energy is

. As shown, the profiles of

k for the setups at

are shifted to higher values compared to their counterparts at

. As the difference in

k is less pronounced than the difference in

, the behavior of

ℓ must also be considered. As will also be discussed in

Section 4.4, the bubbles are deformed to an ellipsoidal shape for

, while they remain quasi-spherical for

. For spherical bubbles, it is possible to assume

. For the ellipsoidal bubbles, on the other hand, the integral length scale approximately corresponds to the lateral expansion of the ellipsoid perpendicular to the main flow direction. Therefore, it is reasonable to assume that

for the setups at

. Combined, the differences in

k and

ℓ explain the observations for the dissipation rate. It is, however, not trivial to identify the reason for the dependency of

k on the the bubble deformability. As discussed in

Section 3.2, the bubble Reynolds numbers

are higher for the setups at

(see

Table 1), which is indicative of stronger velocity fluctuations in the bubble wake. These higher values of

are caused by higher stream-wise velocity differences between the bubbles and the liquid phase. Nearly spherical bubbles encounter less resistance while rising through the liquid, which allows them to rise faster than the deformable bubbles. Moreover, it is worth noting that there is a constant interplay between interfacial surface energy and turbulent kinetic energy, as discussed by Dodd and Ferrante [

36].

In order to exclude the effect the high kinematic viscosity of the bubbles has on the dissipation rate,

Figure 14 provides the average normalized dissipation rate conditioned on the liquid phase

. The profiles have not been averaged over the two channel halves. The single-phase profiles, given for comparison, are identical to those shown in

Figure 12. As observed for

, the presence of the bubbles completely changes the profiles for all power-law indexes. In the near-wall region, the two-phase cases for

and

exhibit significantly lower dissipation rates compared to the single-phase flow. For

, this observation only holds true directly at the wall. At larger distances from the wall and especially in the core of the channel, the bubbles significantly increase the liquid phase dissipation rate irrespective of the power-law index. For

, the dissipation rate in the channel center is approximately as high as its peak value in the near-wall region. It is especially interesting to note that, for the shear-thickening fluid, the presence of the bubbles completely reverses the trends resulting for the single-phase setups. The minimum dissipation rate can be observed at the walls. The highest dissipation rates occur from

to

in the form of a plateau-like section. This behavior can partly be attributed to the apparent viscosity in the channel core, which, compared to the corresponding single-phase flow, reaches higher values for the bubbly flow setups at

(see

Figure 5). Moreover, we refer to the relation between

k and

explained above. Compared to the single-phase flows, including the bubbles significantly lowers the values of

k close to the walls (see

Figure 13), in particular for

. Together with the higher turbulent kinetic energy in the channel core, which can be observed irrespective of

n, this explains the two-phase profiles of the dissipation rate at

, shown in

Figure 14.

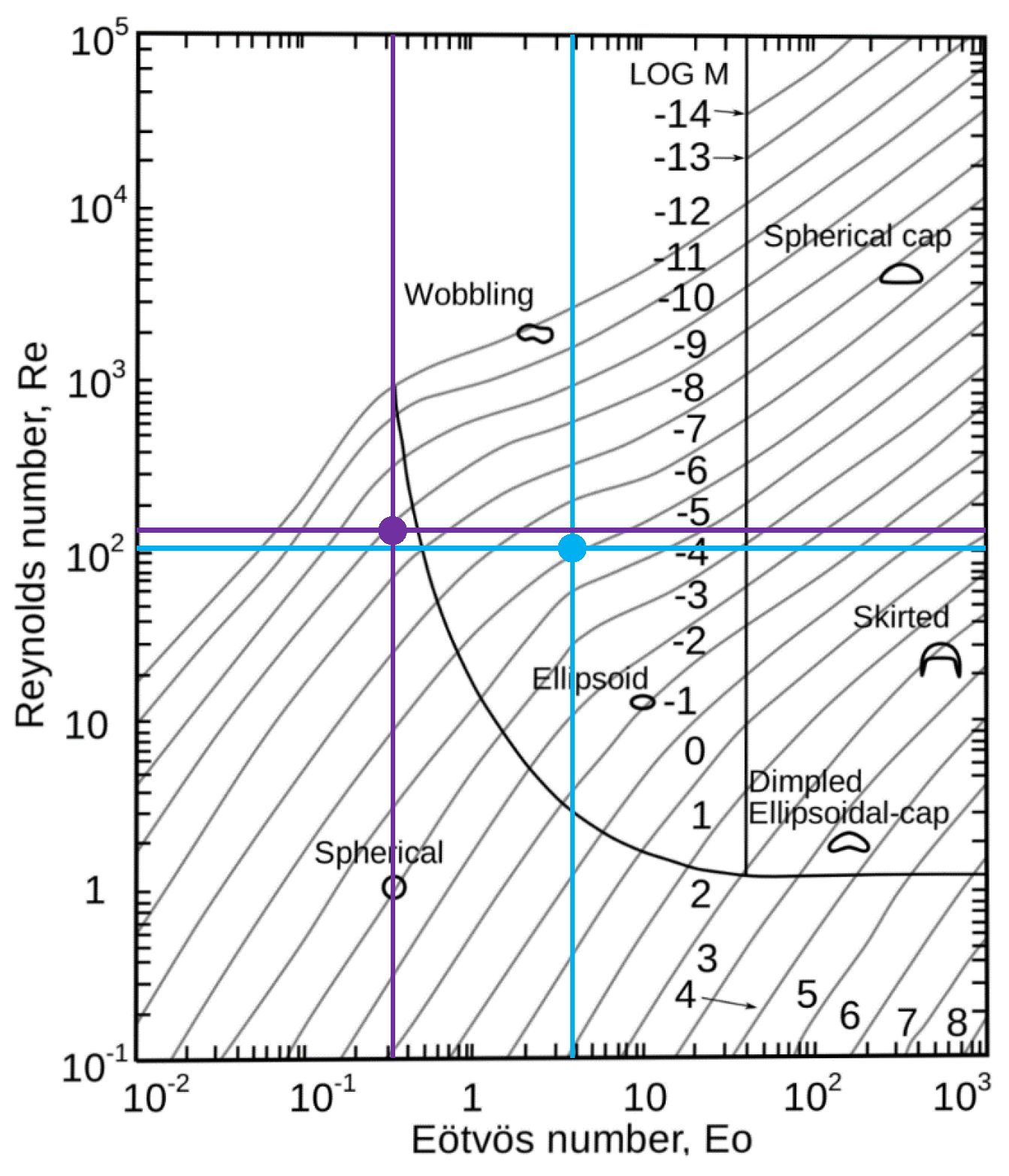

4.4. Bubble Deformation

As explained in

Section 3.2, the dynamic bubble behavior can be estimated from the Eötvös number

and the bubble Reynolds number

using the Grace diagram, see

Figure 3. A straightforward way to investigate the bubble shapes occurring for the different setups is to visualize the isocontours corresponding to

, i.e., the interface between gas and liquid phase. Snapshots for the bubbly-flow cases with a Newtonian fluid in the continuous phase are shown in

Figure 15. Since there are hardly any visible differences for the non-Newtonian fluids, the respective plots are omitted. The isosurfaces confirm the prediction of the Grace diagram. As expected, the bubbles are quasi-spherical for

. However, when

is increased to

, the bubbles are wobbling and assume an ellipsoidal shape.

While this allows a first qualitative assessment of the bubble deformations, snapshots at a single time step do not yield further insights into the transient deformation behavior as well as the effects of different power-law indexes. In order to provide a meaningful quantitative measure for the bubble deformation, it is expedient to analyze the temporal behavior of the interface area for the single bubbles. For this purpose, the interface area of a bubble

b is numerically approximated as the volume integral of

, which can be interpreted as the surface density, over all cells belonging to the bubble’s individual VOF marker field. It is necessary to perform this analysis for all bubbles separately. Otherwise, the oscillations of the individual bubbles would annihilate each other due to the different instantaneous deformation behavior. In the following,

denotes the the surface area of bubble

b at the time

t, normalized by the surface area of a sphere of the same volume

V. The time-averaged, normalized surface area is given as

with the start and end times

and

for gathering statistics. The fluctuation of the normalized surface area around this value is then evaluated using the root mean square:

Finally, the time-averaged, normalized surface areas

and the fluctuations

are averaged over all 72 bubbles. The results are presented in

Table 3.

Table 3 shows that the normalized surface area averaged over time and all bubbles grows by 6.40% for the shear-thinning, by 5.84% for the Newtonian and by 5.08% for the shear-thickening fluid when the Eötvös number is increased from 0.3125 to 3.75. Moreover, it is clearly visible that the bubbles are not only deformed to ellipsoids for

. Measured in terms of their surface area fluctuations, they are also subject to much stronger oscillations. Compared to

, the values of

increase by a factor of 40.42 for

, by a factor of 48.25 for

and by a factor of 55.73 for

. Finally,

and

show clear tendencies across the investigated power-law indexes. Both quantities increase for decreasing values of

n. This behavior can be explained by the values of the bubble Reynolds number

given in

Table 1, which also increase with decreasing power-law index. As shown in the Grace diagram (see

Figure 3), the bubble deformability is governed by the combination of

and

. At identical

, higher values of

are indicative of stronger deformations and oscillations. It was found that the differences in the values of

are almost exclusively caused by the different relative stream-wise velocities

of both phases, see Equation (

8). On the other hand, the apparent liquid dynamic viscosities in the center part of the channel (

) seem to only have a negligible influence, as can be seen in

Figure 5.