Abstract

In this paper, the rheological behaviour of a petroleum-based epoxy (EL2 laminating epoxy) was compared with the Super Sap CLR clear bio-resin epoxy. The focus of the work was on the viscous and viscoelastic performance of these epoxy resins. Rheological tests were carried out at 15, 30, and 60 min after the mixing of the pure epoxies and the hardeners at a constant temperature of 25 °C. The results obtained from the rheometer tests showed that the viscosity of both epoxy systems decreased with increasing shear rate, which is typical behaviour of a shear thinning fluid. Regarding the oscillatory rheology tests, the viscoelastic properties of both epoxy resins were studied within their linear viscoelastic region (LVER) by amplitude sweep test, which was also carried out 15, 30, and 60 min after mixing the epoxies with the hardeners. It was noticed that the petroleum-based epoxy possessed a more significant LVER relative to the bio-based resin. Finally, the storage modulus (G′), the loss modulus (G″), and the phase angle were extracted, and these parameters were investigated over low and high frequencies. From the test results, we observed that both epoxy resins showed a liquid-like viscoelastic behaviour due to their phase angle values, which were always between 45° and 90°, and by the general tendency of the G″ predominance over G′ at low and high frequencies.

1. Introduction

Epoxy resins have been widely used in structural components in engineering applications due to their outstanding adhesion, thermal, mechanical, and low cure shrinkage properties [1]. In the last decade, the development of bio-based epoxy resins has been significantly noticed as an alternative to petroleum-based thermosetting resins. Bio-based epoxy resin is partially or entirely derived from renewable materials, and its main benefits are sustainability, reduction of CO2 emission and power and water consumption during production, lower toxicity in manufacturing processing, and no reliance on fossil fuels [2].

Epoxies are thermosetting polymers that, unlike thermoplastics, during the transformation phase undergo an irreversible chemical modification associated with the creation of covalent bonds between the chains of the starting prepolymers, called cross-links. The cross-linking reaction, also called cure, takes place after the addition of the hardener causing linear growth of polymeric chains that begin to branch. The transformation from viscous liquid to elastic gel, called gelation transition, is a sudden and irreversible process. The high crosslink density makes the epoxy resins brittle, but the properties of epoxy resin system can be modified by incorporation of a secondary phase such as thermoplastics, rubber, carbon-based nanoparticles, combination of rubber/thermoplastics and nanoparticles, and block-copolymers as secondary phase materials [3,4,5,6,7,8,9]. Incorporation of the secondary phase contributes to the increase in fracture toughness and increase the strength of the matrix [10,11]. In addition, the fracture toughness of the fracture toughness of bisphenol-A diglycidyl ether (DGEBA) epoxy resin has been significantly improved by incorporation of higher bio-based content flexible chain polymers without affecting the processability and other mechanical properties [12]. The monomers most commonly used in commercial epoxy resins are the derivatives of DGEBA. They can provide high resistance against mechanical stress, chemical attack, corrosion, and humidity and possess excellent thermal, electrical, and adhesion properties. Epoxies are being widely used in automotive and aerospace industries. The global epoxy resin market size was valued at about USD 7592 million in 2019, and is anticipated to grow at a compound annual growth rate (CAGR) of 6.2% to reach USD 10,264 million by 2022 [13] due to their extensive use in applications for coating, adhesive, and composite materials. The only downside of the DGEBA epoxies is that they are petroleum-based and non-recyclable and their products at the end of their service life can harm the environment.

Fibre-reinforced polymer (FRP) composite materials are being increasingly used in advanced structural applications. The chemical and mechanical characteristics of the epoxy, also combined with its excellent adhesive properties, make them ideal candidates for fulfilling the role of the matrix in FRP composites. Parallel to the epoxy market expansion, the aerospace industry also had an increment in the utilisation of FRP. For instance, 50% of the skin of the structure of the latest version of the Boeing 787 Dreamliner is made from CFRP composite, and because of high strength-to-weight ratio and stiffness of CFRP, reduced fuel consumption of aircrafts without compromising the rigidity of the aircraft structure [14]. The epoxy demands forecasted for the aerospace sector has shown a steady growth rate per year.

Although epoxy resins offer versatile integrated features such as outstanding mechanical properties, chemical resistance, and shape integrity in hard condition [15,16], the use of them brings about some problems, such as toxicity for living organisms, higher cost, and CO2 emission [17]. In addition, epoxies are brittle and moisture-sensitive materials, and due to crosslinking, they are difficult to recycle. For these reasons, feasible alternatives to replace synthetic epoxies with the bio-based epoxy are in demand [15,18].

Due to the environmental challenges, using green composite materials that are environmentally friendly for different applications are in demand more than any time before [19]. Biopolymers derived from natural resources are replacing the traditional petroleum-based plastics in designing eco-friendly bio-composites [19,20].

Liquid composite moulding (LCM) encompasses all the composite manufacturing methods that the liquid state polymer matrix (e.g., epoxy resin) is forced into in the dry preformed fibre reinforcing material (e.g., glass fibre fabric). A full impregnation of the resin between the fibre bundles and fibres should be achieved for a good quality FRP composite product. The impregnation driving force is usually generated by pressure difference. For example, in resin transfer moulding (RTM), positive operating pressures are applied to the resin, while in vacuum infusion, the pressure in the mould is lower than the atmospheric pressure level. In vacuum-assisted resin transfer moulding (VARTM), positive injection pressures are applied to the resin while the mould cavity is kept under vacuum. A crucial parameter that can influence the timing of the impregnation process is the viscosity of the resin, which is affected by the temperature, curing time, and the shear rate. Hence, the rheology of epoxies needs to be investigated, and much research has been done on this area previously [21,22]. Meier and Kirdar [23] investigated how a standard epoxy resin (EPIKOTETM Resin MGS RIMR 135 and EPIKURETM Curing Agent MGS RIMH 1366) that behaves as a shear thinning fluid can be utilised for improving mould fitting in LCM processes. For achieving this goal, the authors carried out a series of rheological experiments for studying the flow characteristic under different temperatures, curing times, and shear rates. They evaluated the changes in viscous and viscoelastic properties that can influence the infiltration step involved during LCM. It was found that the epoxy behaved in a shear-thinning manner and its viscosity did not change during curing but depended more on the processing temperatures. This pseudoplastic feature was also more evident at a shear rate higher than 1000 s−1 and temperature below 30 °C.

Regarding the viscoelastic properties, the storage modulus () of the epoxy was predominate over the loss modulus () until 35 °C, and after this temperature, the resin showed a pure viscous behaviour. However, the curing time influenced the G′ and G″ since a change in those values were noticed when oscillatory tests were performed at a constant temperature but different timing after mixing. The curing process of epoxy showed an increment on the G′ and G″, which can be considered as an improvement of the ability to resist deformations by the resin [23].

Samper et al. (2019) measured the gel time through an oscillatory rheometry test for a commercial bio-based epoxidised linseed oil (ELO) with an epoxy equivalent weight (EEW) of 178 g·equiv−1. At the gel time, in the mid-point when the epoxy is located in between a fully viscous liquid and fully elastic solid behaviour, the resin has a phase angle of 45°, and it is the crossover point when G′ and G″ are equal. For studying the gel time, the authors collected the curing conditions, the evolution of the storage modulus (G″), loss modulus (G″), and the phase angle (δ) on liquid resins cured at 110 °C by an oscillatory rheometry at isothermal conditions (110 °C) [24]. From this study, it was found that with the correct mixing ratio between epoxy and hardener it is possible to gain satisfactory thermo-mechanical properties even with a bio-based hardener [24].

Amiri et al. (2016) studied methacrylated epoxidised sucrose soyate (MESS) bio-based resin (ESS was 100% bio-based and was synthesized from fully esterified sucrose soyate) reinforced with flax fibre as thermo-rheologically complex materials, i.e., the significance of nonlinear viscoelastic behaviour possessed by natural fibres and thermoset bio-based resin on long-term performance of the composite were analysed [25]. Time–temperature superposition (TTS) was used for determining temperature-dependent mechanical properties of linear viscoelastic materials at a reference temperature.

There are many steps involved in the production process of bio-epoxy resin, and these processing steps play a very important role in determining the quality of the final product. Therefore, understanding the cure kinematics of thermosets is essential for process development and quality control. Viscosity control during processing of thermosets is particularly critical because the viscosity varies with temperature, flow condition, and also time due to the polymerisation reaction. To control the cure process and the properties of the final product, it is essential to understand the relationship between the curing kinetics and rheological behaviour [26].

Zhao et al. studied the thermo-rheological and mechanical properties of a flax fibre moulded with a methacrylated epoxidised sucrose soyate (MESS) resin by frequency sweep rheological test [26]. The test results showed that the G′ and G″ were correlated with the direction of the shift factor, which can be horizontal or vertical. When a shift factor was applied, the curves of the modulus did not change shape as the temperature changed but appeared only to shift to the left or to the right. This implies that a master curve at a given temperature can be used as the reference to predict the behaviour at various temperatures by applying a shift operation. However, it was shown that the use of both horizontal and vertical shift factor was not adequate for achieving linear viscoelastic properties, whereas by using only the horizontal shift factor, the authors could obtain stable master curves.

For facilitating the application of bio-based resin in manufacturing aircraft structures, Samper et al. used a bio thermosetting resin derived from epoxidised linseed oil (ELO) and mixed it with two different crosslinking agents, one from petroleum-derived methyl-nadic anhydride (MNA) and the other one from bio-based maleinised linseed oil (MLO) [24]. They compared the mechanical and thermo-mechanical characteristics of the ELO during the curing process. The curing study was evaluated by oscillatory rheometry test and differential scanning calorimetry (DSC). The results of the DSC analysis showed the exothermic peak to the crosslinking process of the ELO mixed with the petroleum-based and bio-based hardener, which in both cases started between 98 and 107 °C and ended between 225 and 235 °C. Thus, both hardeners showed similar exothermic behaviour.

In this work, the rheological behaviour of a petroleum-based epoxy (EL2 laminating epoxy) was compared with the Super Sap CLR clear epoxy bio-resin. The bio-resin was produced by Entropy Resins, Spain, and EL2 was purchased from Easy Composites, United Kingdom. The viscoelastic properties of both epoxy resins were studied within their linear viscoelastic region (LVER) from amplitude sweep test. The storage modulus (G′), the loss modulus (G″), and the phase angle were extracted, and these parameters were investigated over low and high frequencies.

2. Materials and Methods

The two epoxies investigated were “EL2 laminating epoxy” (petroleum-based epoxy) and “Super Sap CLR clear epoxy bio-resin” (bio-based epoxy). EL2 laminating epoxy (petroleum-based epoxy) has an average molecular weight ≤700, is composed of 1-(2,3-epoxypropoxy)-2,2-bis[(2,3-epoxypropoxy) methyl]butane, and is a reaction product from bisphenol F and epichlorohydrin. EL2 is a high-performance epoxy suitable for use in wet-laying of Kevlar, glass, or carbon fibre lamination, with a tensile strength of 70–80 MPa and density of 1.08–1.12 g/cm3 at 20 °C. Due to its low viscosity, this resin exhibits excellent wetting performances when used as a matrix for carbon fibre and aramid fibre. In this study, AT30 SLOW hardener, a formulated amine, was used, which is provided a pot-life of 95–115 min at 25 °C. The mixing ratio suggested by the supplier is 100:30 by weight and its cure time is 20 to 30 h at 25 °C.

Super Sap CLR clear epoxy bio-resin is a clear, low viscosity bio-derived epoxy resin that is suitable for both hand lay-up and vacuum resin infusion with 16% bio-based carbon content. Super Sap CLR epoxy has good mechanical properties with high levels of UV stability. This resin has been manufactured by using renewable plant-based carbon to reduce their environmental footprint through the use of sustainable materials without compromising performance. The raw materials used for producing this bio-based epoxy are waste products of other industrially relevant processes including by-products of bio-fuels production, which means they do not compete with food sources or displace food-based agriculture. For producing this epoxy, a 50% reduction in gas emission has been achieved compared to conventional petroleum-based epoxies. In this project, the Super Sap CLS (SLOW) hardener was used, which provided a pot-life of 70–90 min. The mix ratio suggested by the supplier is 100:40 by weight and its cure time is 11 to 13 h.

A total of 19 rheological tests were carried out by using the Malvern Kineux rheometer machine. Each rheological analysis was performed 15, 30, and 60 min after mixing the pure epoxy resins with their specific hardeners. Since it we decided to evaluate the alteration in viscosity and viscoelasticity properties at different times during the cross-linking process, both epoxy systems were tested at room temperature of 25 °C. Each experiment was performed within a 90 min limit after mixing, which is the max pot-life time for both resins, as reported in their data sheets.

A standard flat geometry plate was used for all rheological tests, and a quantity less than 15 mL of a sample was loaded for each analysis. Before any test, we were required to set up the “zero gap”, which allows the rheometer to set the gap distance used for each rheological experiment accurately. The input gap distance was set to 0.5 mm in each experiment. Both epoxy systems were mixed with their corresponding hardener according to the mix ratio provided by their manufacturer.

Rheological Studies

Oscillatory amplitude sweeps were performed to measure the LVER, the range in which the test can be carried out without destroying the structure of the sample, i.e., the range with the lowest strain values. This test is used to study the stability of a material. Any subsequent oscillation tests were kept within the LVER. In a frequency sweep, measurements are made over a range of oscillation frequencies at a constant oscillation amplitude and temperature. Frequency sweep tests were performed at the stress or strain determined from the LVER. This test shows the viscoelastic behaviour of the epoxies. Low frequencies represent how the material would behave over long timescales; high frequencies represent how the material would behave over short/fast timescales.

3. Rheological Test Results

3.1. Viscometry Tests

A series of rheological viscometry measurements were performed to measure the flow properties of both epoxy systems, and the viscosity value obtained from each experiment was evaluated. These viscosity measurements were evaluated for classifying whether the bio-based and synthetic resins were shear thinning, shear thickening, or Newtonian fluids.

Flow Curve Results

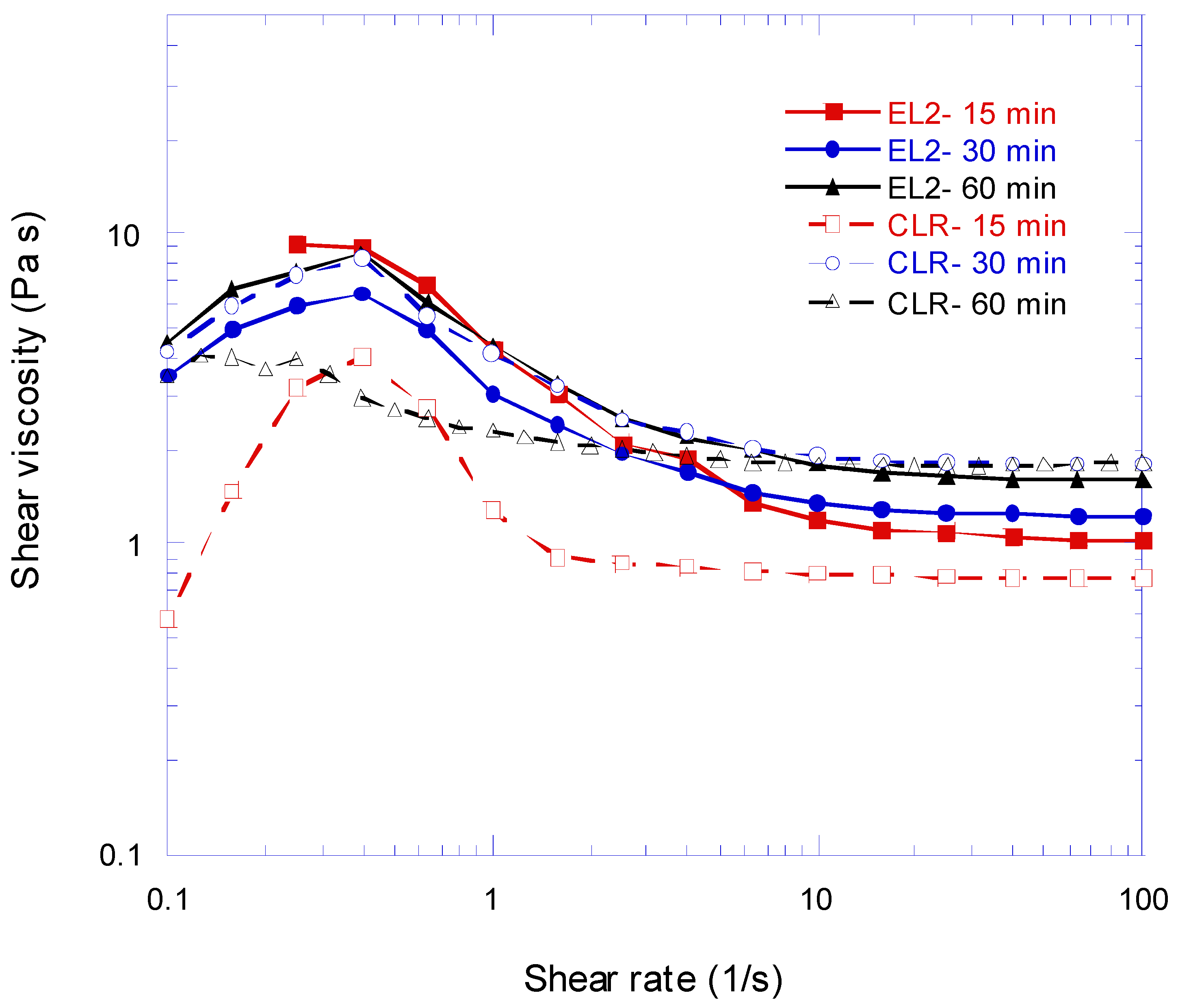

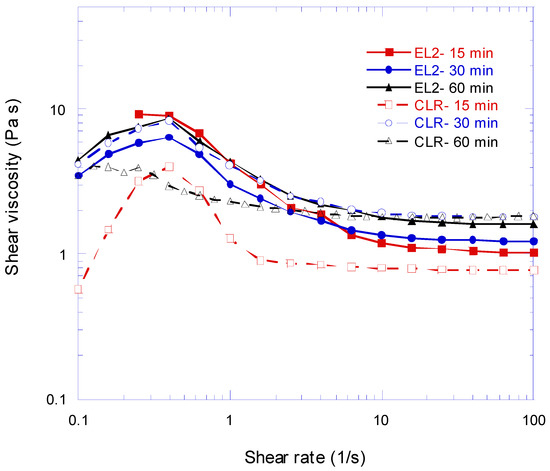

Figure 1 illustrates the viscosity curve of the EL2 epoxy 15, 30, and 60 min after mixing with the AT30 SLOW hardener and the CLR epoxy 15, 30, and 60 min after mixing with the CLV hardener obtained from the V001 test at shear rates between 0.1 and 100 s−1. The results show that the synthetic epoxy had a non-Newtonian fluid behaviour because its viscosity did not remain constant when stress was applied. In addition, since the viscosity of the epoxy decreased by an increment in the applied stress, the characteristic of EL2 epoxy was a shear thinning fluid. The CLR resin can be classified as a shear thinning non-Newtonian fluid as its viscosity decreased with increasing shear rate.

Figure 1.

Viscosity versus shear rate for EL2 epoxy and CLR bio-based epoxy at three different time points after mixing with the hardener.

Both materials showed very similar viscosity results; at the 0.1 (s−1) shear rate, the viscosity values in each experiment were in the range between 3.3 and 16 (Pa·s), whereas at 100 (s−1) shear rate, the viscosity values were between 0.773 and 1.835 (Pa·s). In conclusion, both epoxy systems possessed similar viscosity at low and high share rates.

3.2. Oscillatory Tests

There were fundamentally two parameters of the oscillation that could be controlled. One was oscillation amplitude, stress or strain, for which we ran an amplitude sweep experiment to determine the LVER. The second one was oscillation timescale, frequency, for which we ran a frequency sweep experiment to determine the response for different timescales. Oscillation tests give information about how the sample behaves before flowing and measure the stiffness (modulus) of a material. Therefore, oscillatory tests [27] probe the structure of the material, unlike viscometry tests in which the material is forced to flow.

In oscillatory shear tests, the complex shear modulus describes the entire viscoelastic behaviour of a material and is measured from

where is shear-stress amplitude, and is shear strain amplitude.

The storage modulus represents the elastic portion of the viscoelastic behaviour, which describes the solid-state behavior of the material. The loss modulus characterises the viscous portion of the viscoelastic behaviour, which can be seen as the liquid-state behavior of the material. The relationship between complex shear modulus , storage modulus , and loss modulus using the phase-shift angle are

For ideal elastic behaviour , and there is no viscous portion; therefore, and with that, . For ideally viscous behaviour , and there is no elastic portion; therefore, and thus the value of approaches infinity.

Several oscillatory tests were carried out to assess structural deformation performance of the bio-based and synthetic epoxy resins without causing bulk material flow. These measurements were able to characterise the viscoelastic behaviour on different timescales of the two resins, and could provide a material “fingerprint” to exemplify timescales over which material behaviour is more solid-like or more liquid-like.

3.2.1. Amplitude Sweep Oscillatory Tests

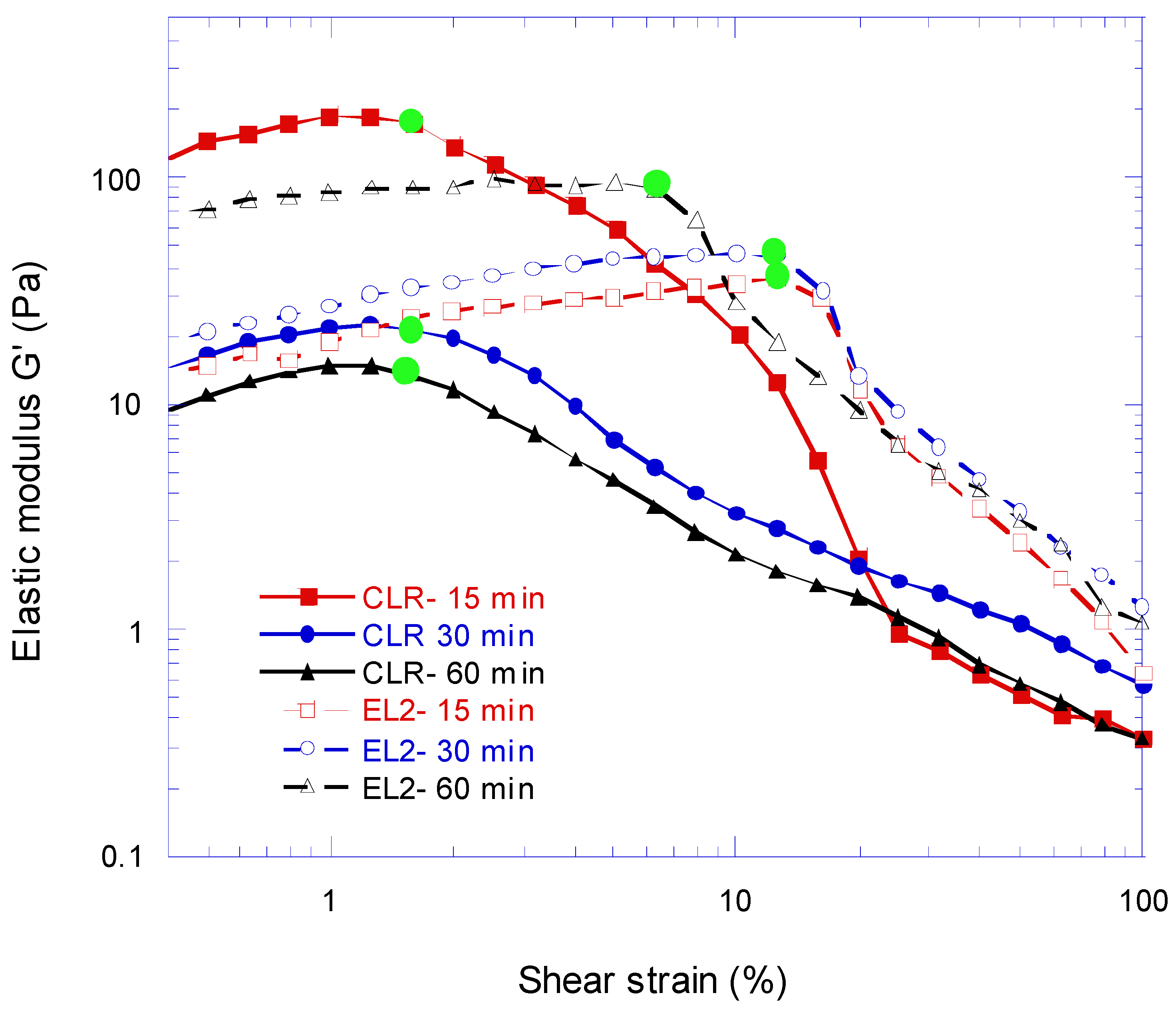

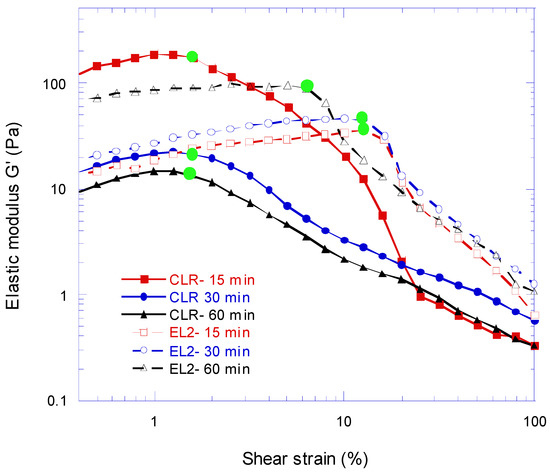

The amplitude sweep oscillatory test was performed 15, 30, and 60 min after mixing the hardeners with the epoxies for both epoxy resin systems. In each experiment, the frequency was kept at 1 Hz, and the shear strain varied between 0.1 and 100%. The results obtained are presented in Figure 2, where the y-axis is the storage modulus G′ values and the x-axis is the shear rate values. By monitoring the G′ of the bio-based and synthetic epoxy resins, we were able to find the value of shear strain rate when the structure of both materials started to break down. This point is the end of the LVER. Once LVER for both resins was determined, the values obtained were used to perform the frequency sweep tests. The pot-life of EL2 epoxy was 95–115 min at 25 °C and 70–90 min. Sixty minutes after the mixing of hardener, the viscosity increased, causing some cross-linking to occur, which resulted in the shortening of the linear elastic region for EL2.

Figure 2.

The storage modulus versus shear strain for EL2 synthetic and CLR bio-based epoxies at different time points after mixing of the hardener.

The values obtained from the amplitude sweep tests for determining LVER are summarised in Table 1.

Table 1.

Linear viscoelastic region (LVER) results for bio-based and synthetic epoxies.

The results show that EL2 synthetic epoxy indicated a much greater LVER response in comparison to the CLR bio-based epoxy in each test performed at different time points after mixing the hardener. Therefore, a more significant strain could be applied on the EL2 in comparison with CLR material without deforming its structure. However, by analysing the complete test results, we noticed that in both materials, their loss modulus G″ (which is a direct measure of the material’s viscosity) was strongly predominant compared to their storage modulus G′. Thus, higher LVER value of the EL2 epoxy over the CLR bio-based resin could not be considered as a proof of its better ability to resist deformation. The aim of these tests was to find the correct shear strain value required for carrying out frequency sweep experiments, which provides information on the behaviour of the epoxies in the non-destructive deformation range. However, for comparison, a shear strain value of 1% for both epoxy systems was chosen.

3.2.2. Frequency Sweep Tests

For an oscillatory excitation, the shear deformation with the angular frequency ω and shear strain amplitude is given by [28]

and as a result, the shear rate becomes

Most materials have non-ideal viscous behaviour. Therefore, the resulting shear stress (τ) is out of phase with shear strain, and the complex shear modulus consists of an elastic storage modulus and viscous loss modulus , i.e.,

The magnitude of complex modulus is .

Note that for a fully elastic material, would be equal to , and for a fully viscous fluid it would be equal to . The phase difference δ can be derived from the following equation:

For the behaviour is solid-like, and for the behavior is fluid-like; when , fluid solid cross over occurs.

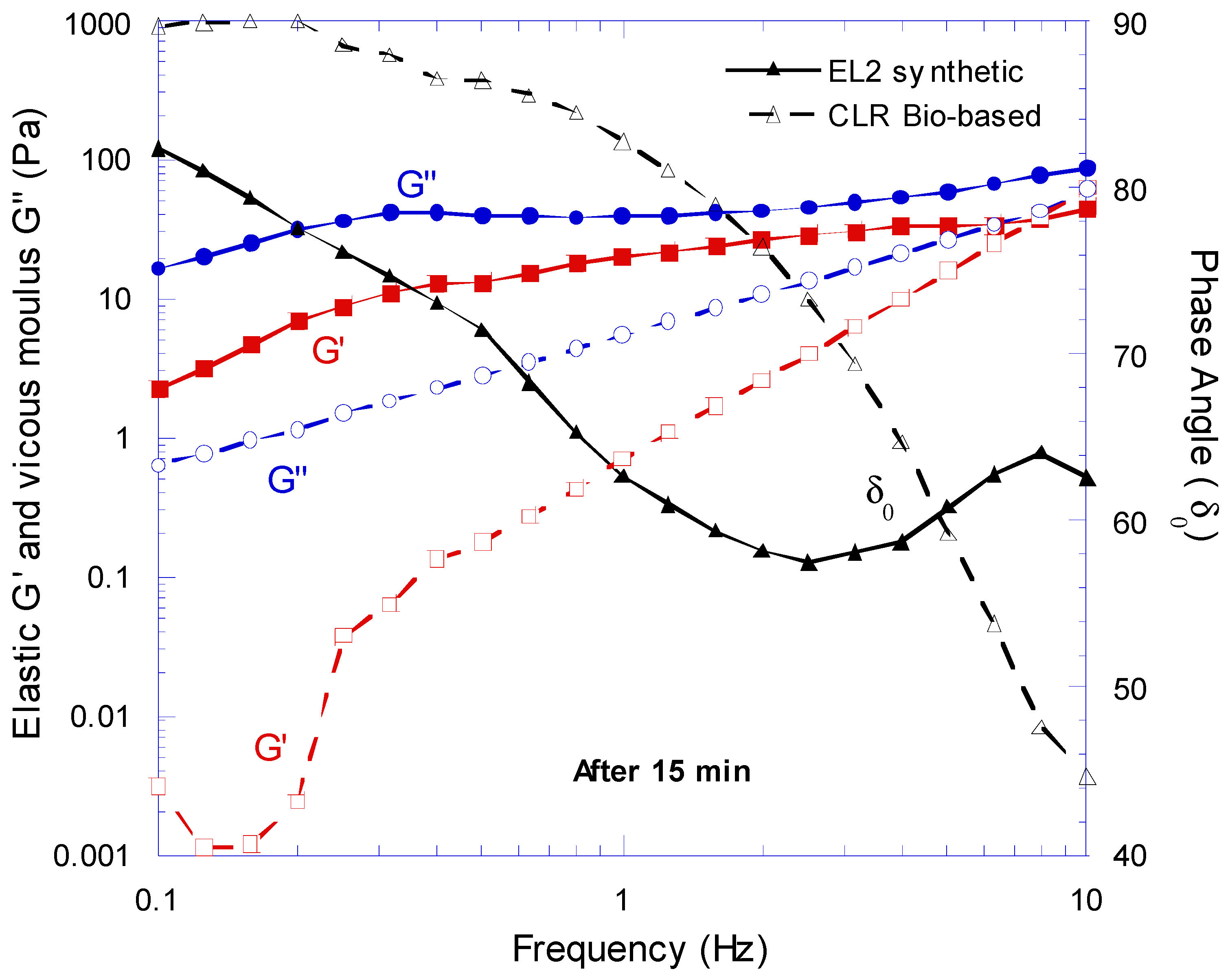

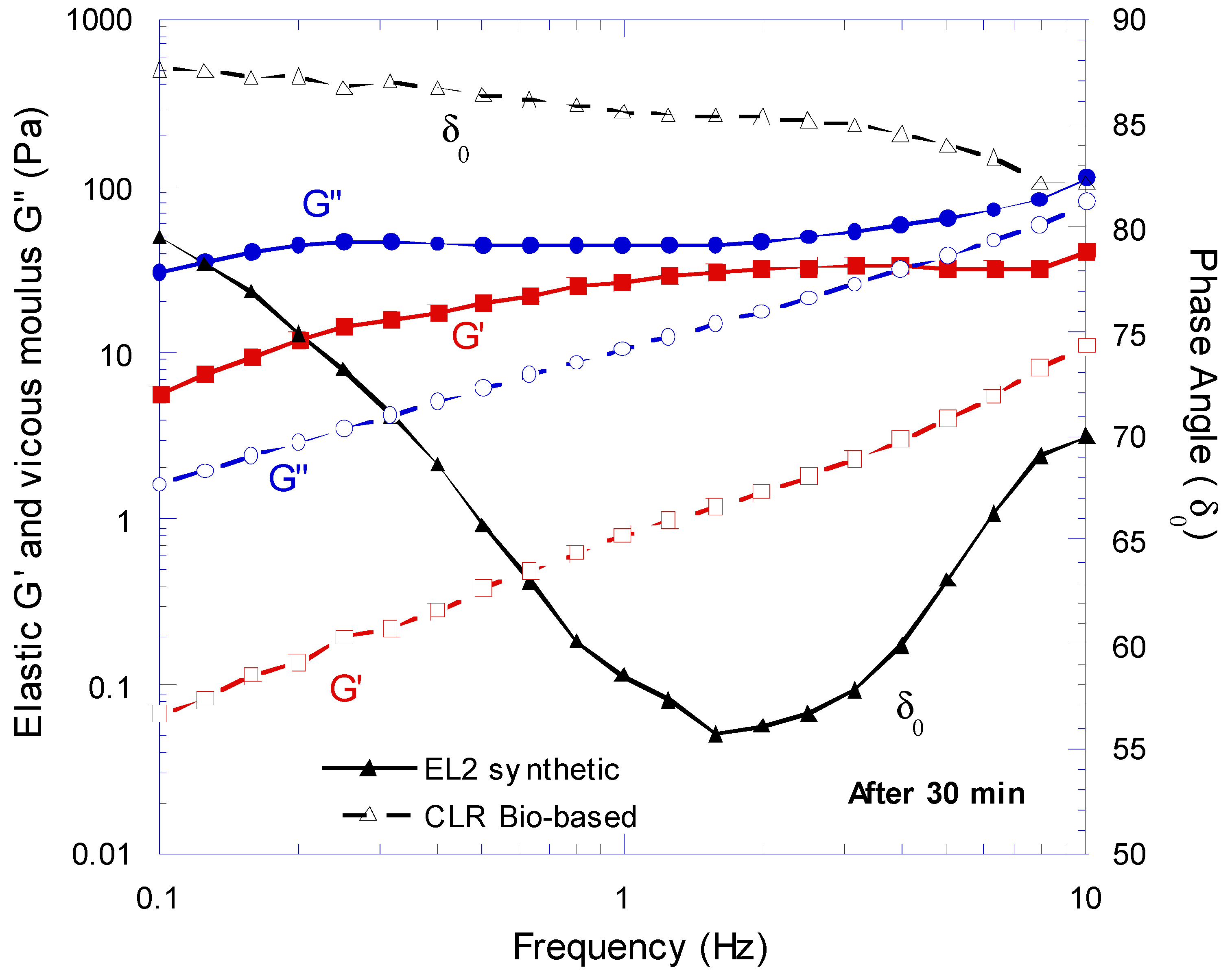

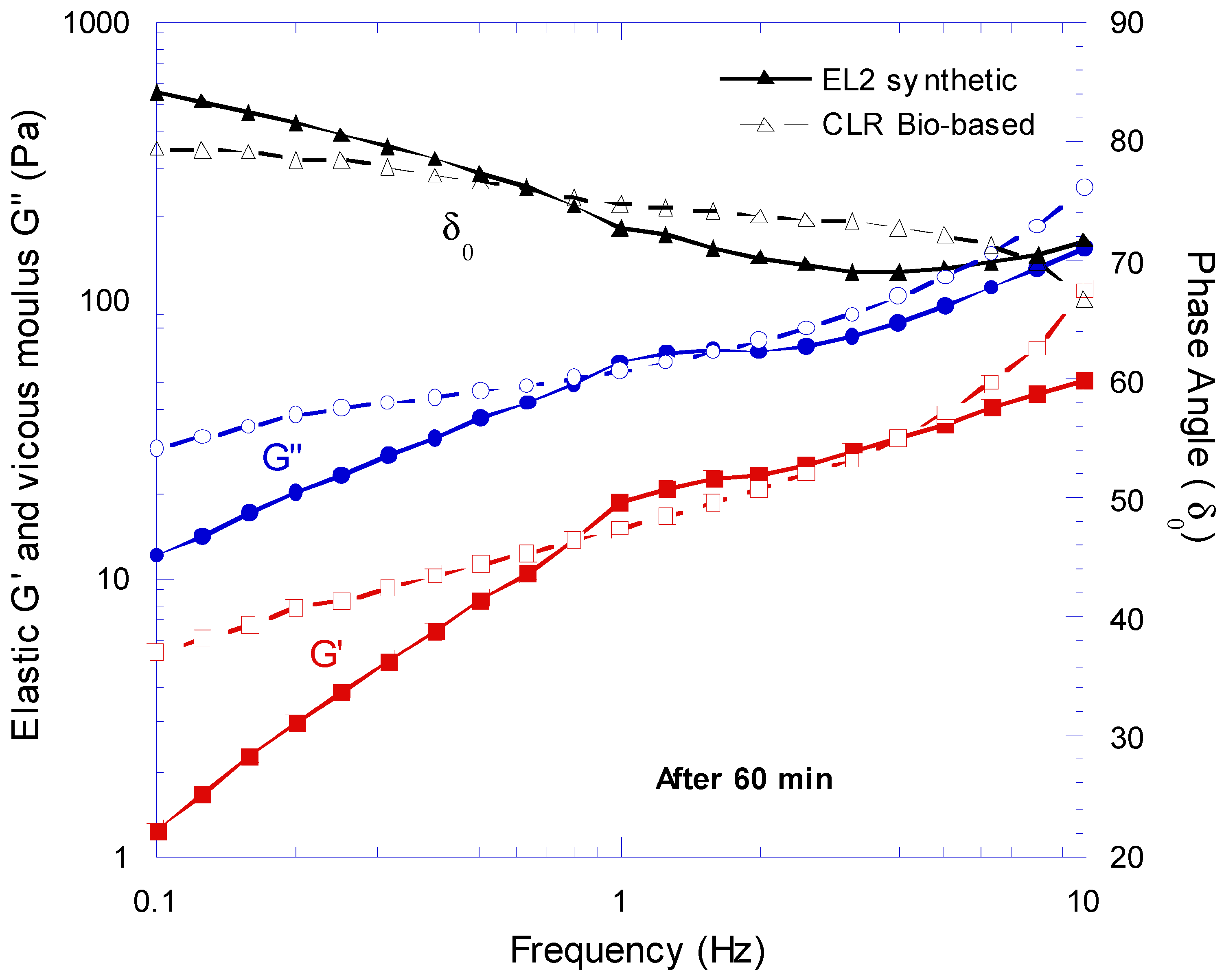

A series of oscillatory frequency sweep tests was carried out on the bio-based and synthetic epoxy systems between 0.1 and 10 Hz. These experiments were performed at 1% shear strain determined from the LVER for 15, 30, and 60 min after mixing of the hardeners and the epoxies for evaluating the change in viscoelastic properties of both epoxy resins with time. From these tests, we measured the storage modulus G′, loss modulus G″, and shift phase angle δ. The values obtained were analysed for evaluating the viscoelastic behaviour of both resins and to classify them as a solid or liquid-like viscoelastic material. In the plotted graphs, the low frequencies represent how the materials would behave over long timescales, and high frequencies represent how the materials would behave over short/fast timescales.

- (1)

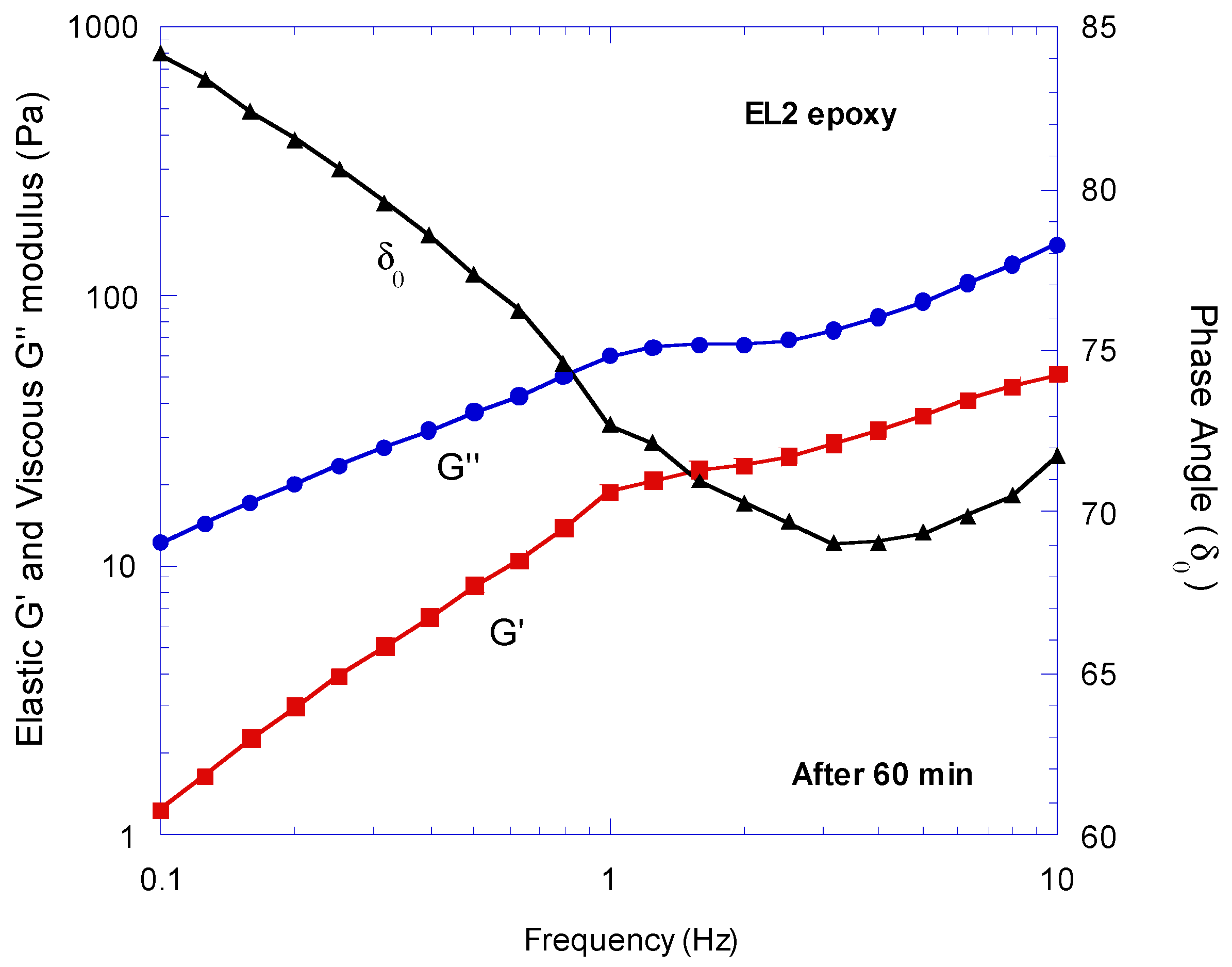

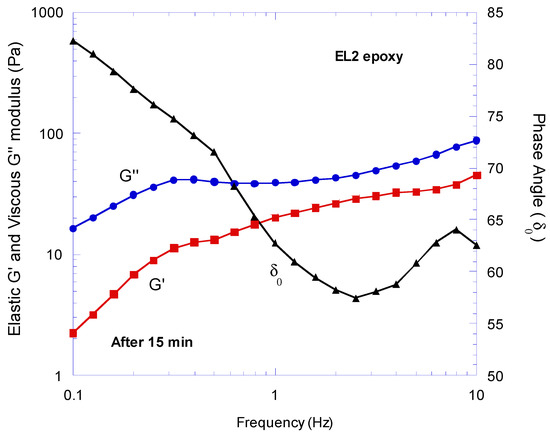

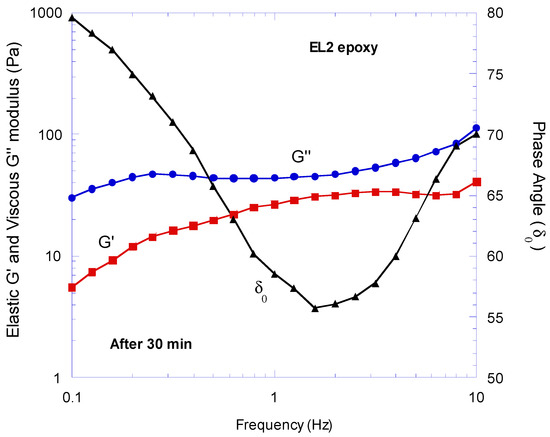

- EL2 Synthetic Epoxy Frequency Sweep Tests Results

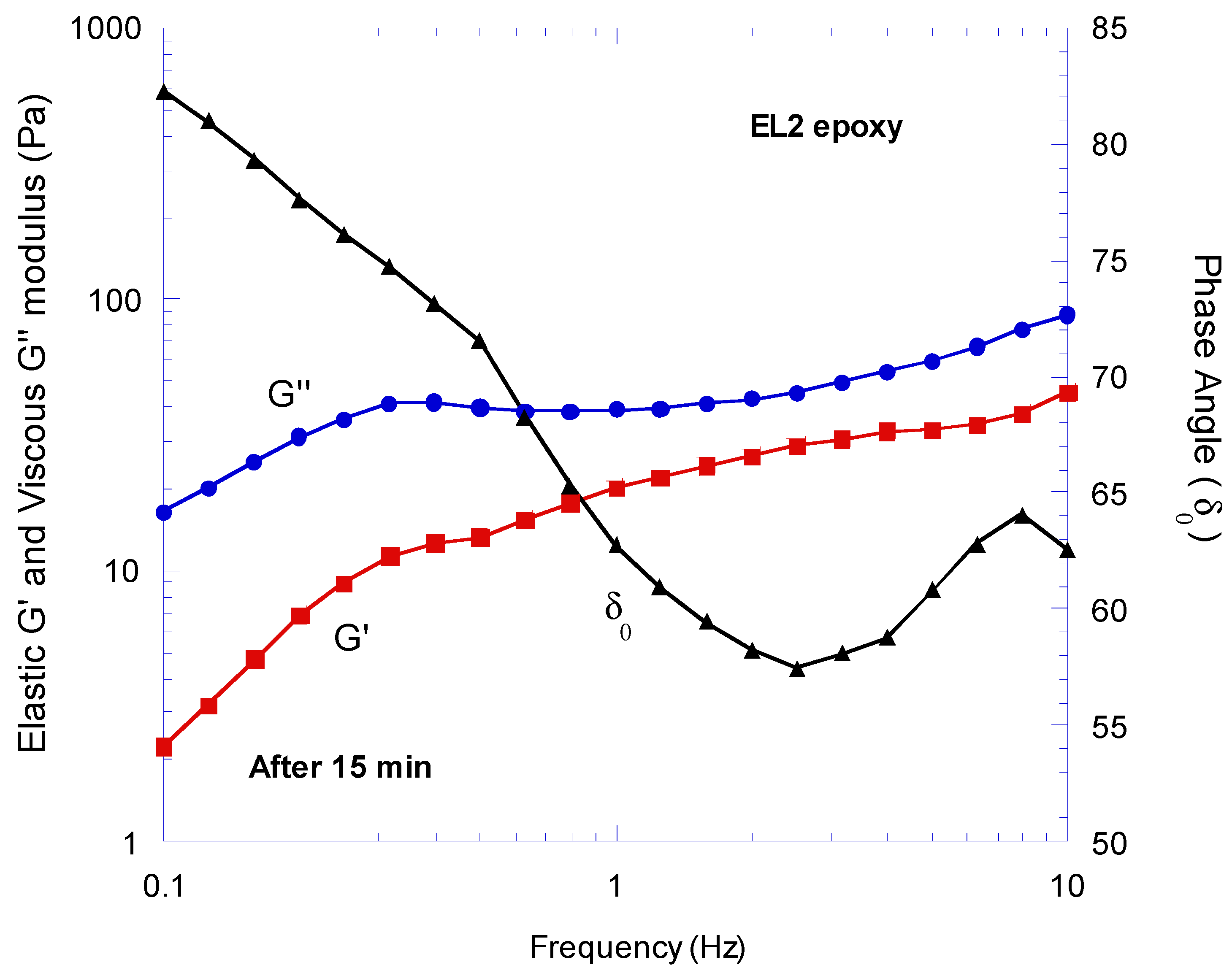

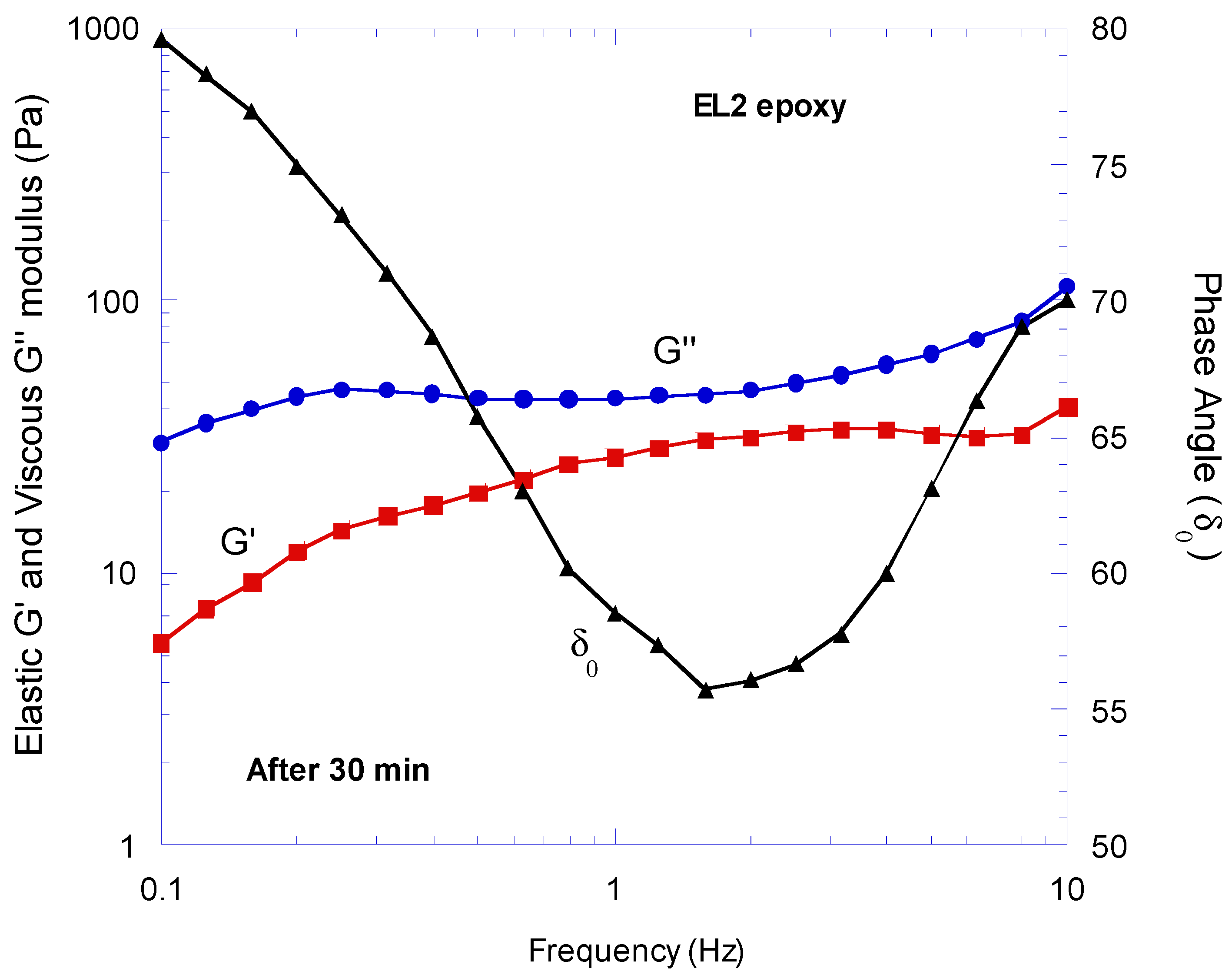

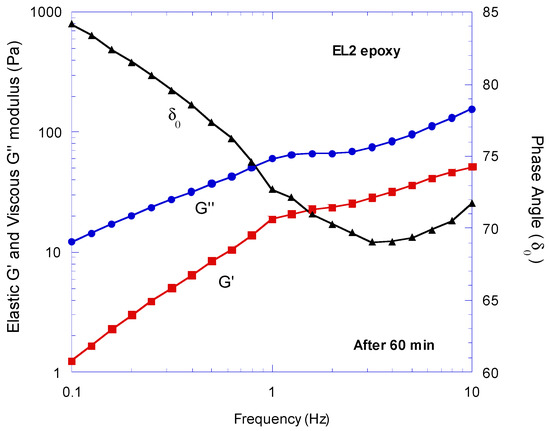

The shear strain value used for carrying out the experiment on the EL2 synthetic epoxy was set to 1% as per the LVER test result since this value is within the material’s linear viscoelastic region. Therefore, the material’s viscoelastic behaviour was evaluated within its non-destructive deformation range. Figure 3, Figure 4 and Figure 5 illustrate the evaluation of the viscoelastic properties of the synthetic EL2 epoxy at different times after the hardener mixing with the epoxy. In each graph, it can be noticed that the G″ (viscous component) was always the predominate viscoelastic modulus compared to the G′ (elastic components). This behaviour was observed at high and low frequencies and at different time points after mixing the epoxy with the hardener. Thus, EL2 is a liquid-like viscoelastic material. This hypothesis was confirmed by the shift angle δ values obtained, which in each experiment were always within the 45–90° range (area of variation characteristic of a liquid-like viscoelastic material). This behaviour can also be confirmed by the fact that the epoxy was tested within its pot-life limit and therefore before its gel time, which is when a thermoset resin system converts from a liquid mixture to a solid material that has a highly cross-linked polymer.

Figure 3.

Frequency sweep result of EL2 epoxy 15 min after the mixing of the hardener.

Figure 4.

Frequency sweep result of EL2 epoxy 30 min after the mixing of the hardener.

Figure 5.

Frequency sweep result of EL2 epoxy 60 min after the mixing of the hardener.

- (2)

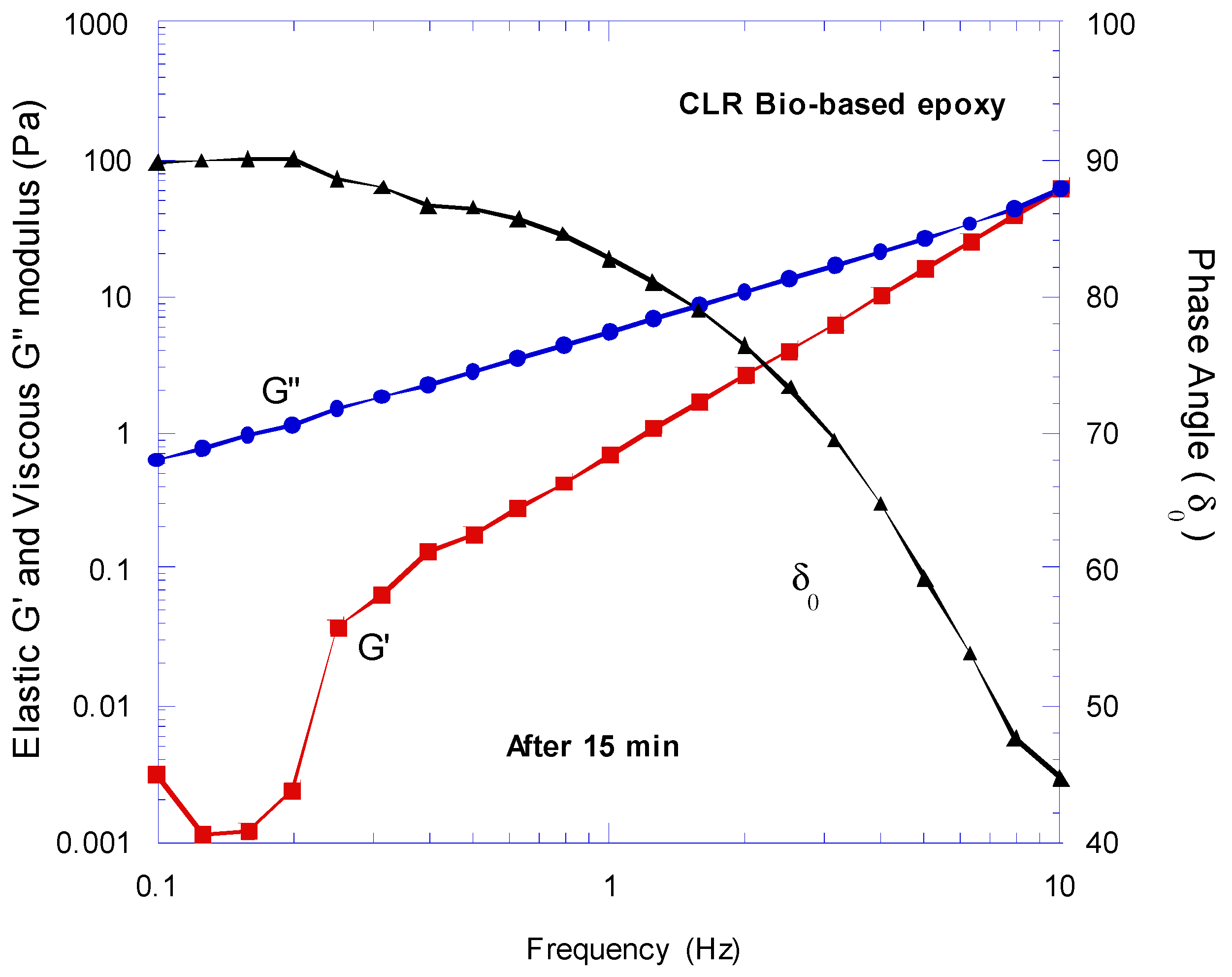

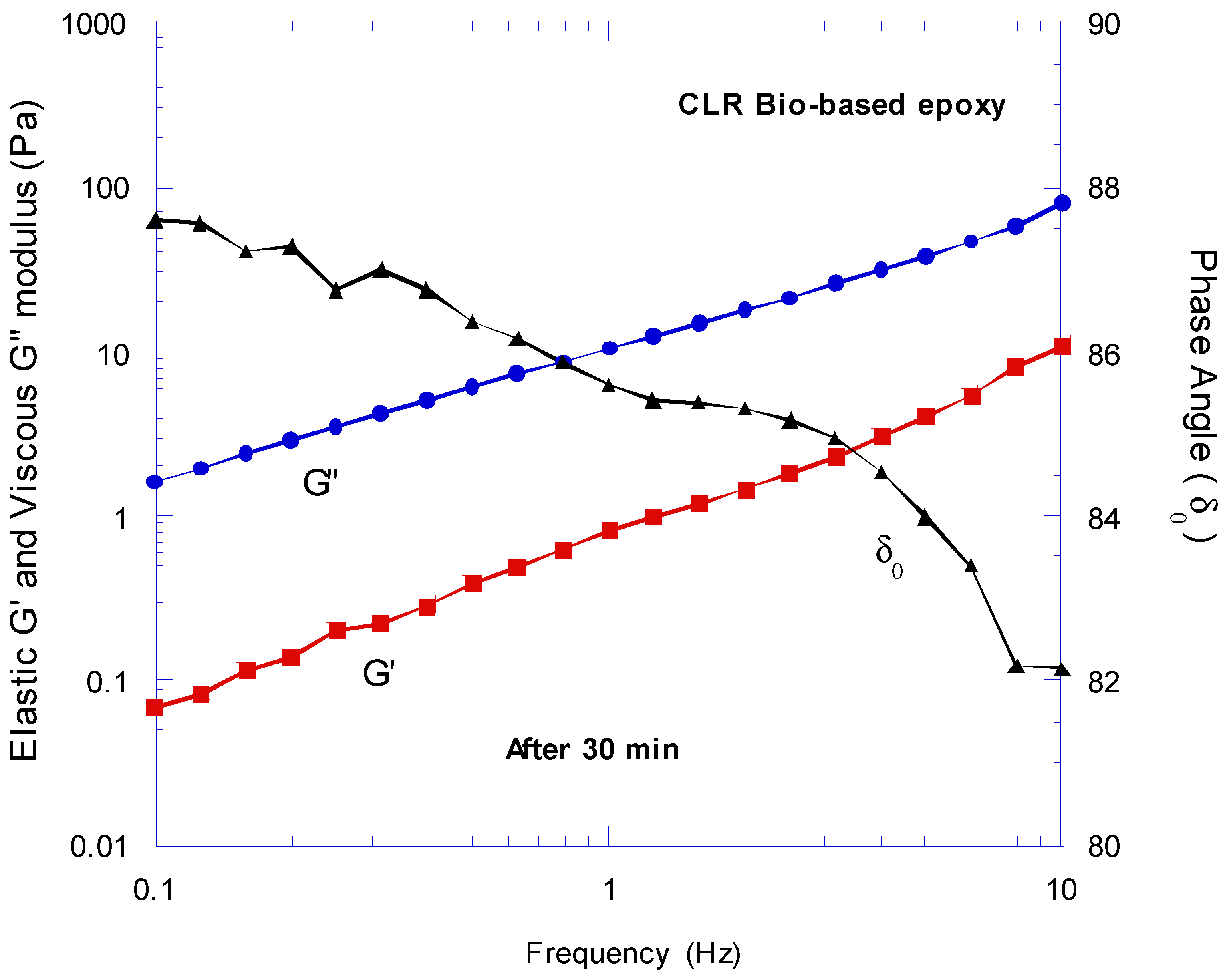

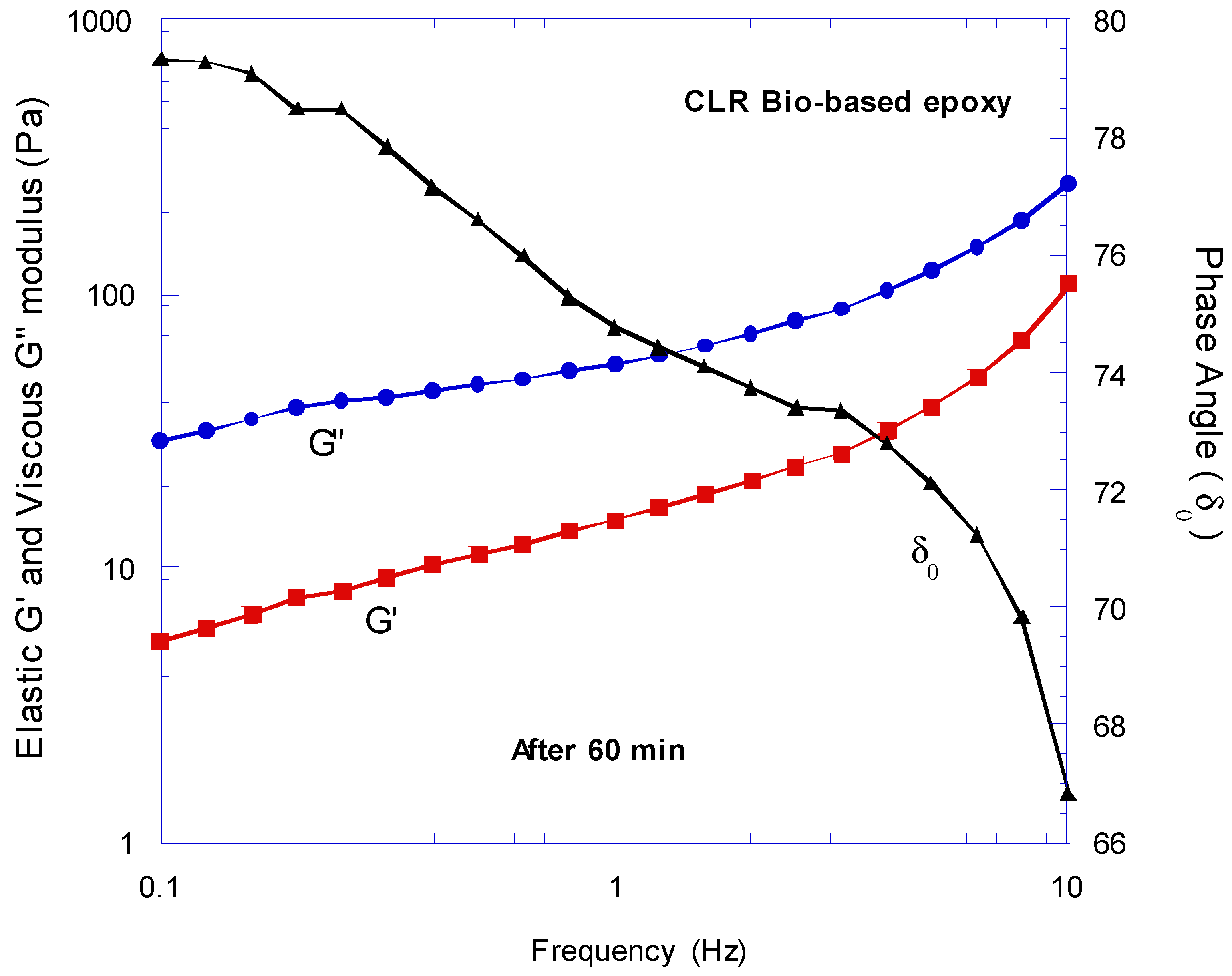

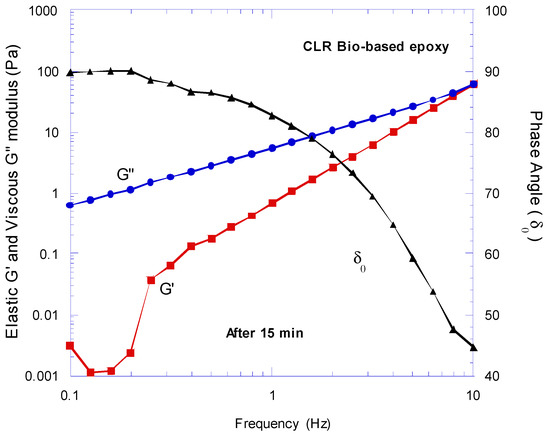

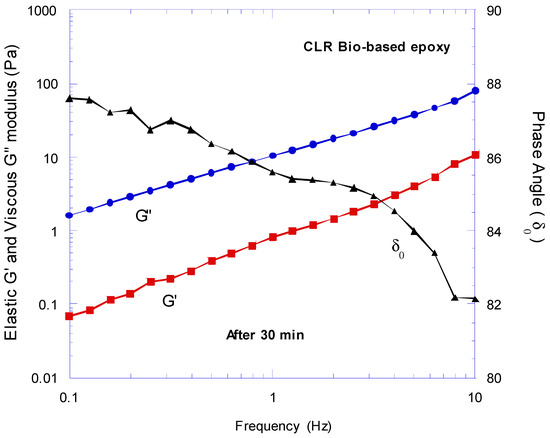

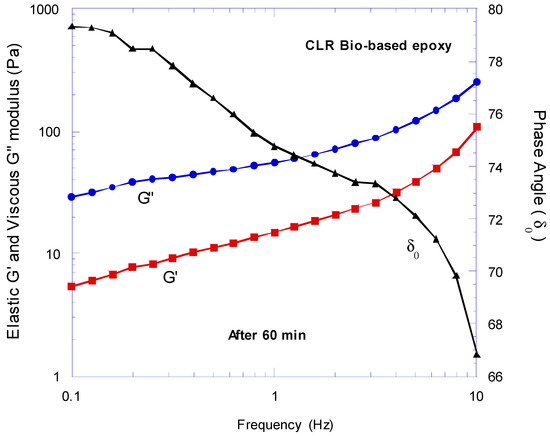

- CLR Bio-Based Epoxy Frequency Sweep Tests Results

The shear strain used for carrying out the experiment on the CLR bio-based epoxy was also set at 1% as per the LVER test result since this value was within the material’s linear viscoelastic region. Therefore, the material’s viscoelastic behaviour was evaluated within its non-destructive deformation range.

Figure 6 , Figure 7 and Figure 8 illustrate the evaluation of the viscoelasticity properties of the CLR bio-based epoxy at different frequencies. Similar to the synthetic epoxy, the bio-based epoxy showed a liquid-like behaviour in each individual test performed, due to its phase angle, δ, values. In this case, we also noticed that the G″ was predominant compared to the G′ at low and high frequencies and at different times after mixing the hardener with the epoxy. This behaviour was because these experiments were carried out within the pot-life limit of the epoxy.

Figure 6.

Frequency sweep result of CLR epoxy 15 min after the mixing of the hardener.

Figure 7.

Frequency sweep result of CLR epoxy 30 min after the mixing of the hardener.

Figure 8.

Frequency sweep result of CLR epoxy 60 min after the mixing of the hardener.

3.2.3. Comparison of the Results of Frequency Sweep Tests

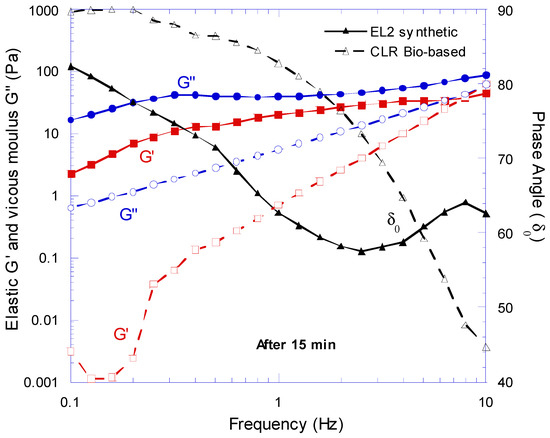

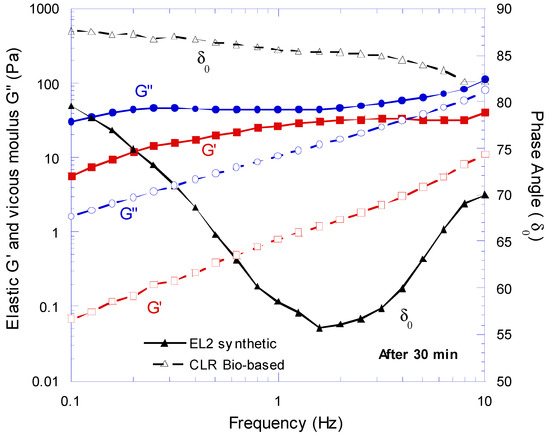

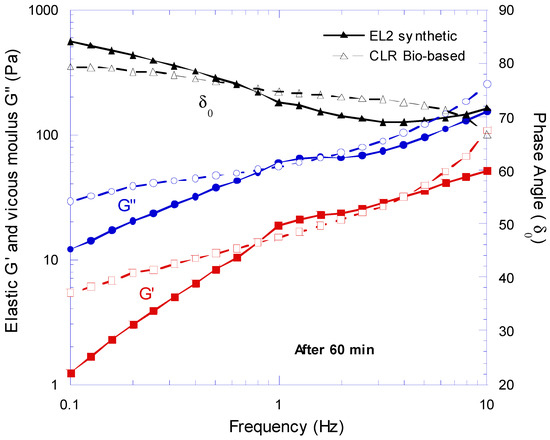

The results of frequency sweep for both epoxies are compared in Figure 9, Figure 10 and Figure 11. It can be seen that after 15 min of mixing (Figure 9), the EL2 synthetic epoxy showed a more significant G′ and G″ compared to the CLR bio-based epoxy at high and low frequencies, whereas for both resins the G″ was predominate to G′, and their phase angle was between 45° and 90°. Therefore, they were in the viscoelastic liquid region. However, due to the cross-linking process, the structure of both epoxies became more stable with time. For instance, the curves of the 60 min mixing (Figure 11) compared with the one after 15 min mixing (Figure 9) seemed to be more balanced and “smoother”, since no sudden modulus behaviour alteration was observed. The change in microstructure had an important consequence in the viscoelastic behaviour of both epoxies. After 60 min of mixing (Figure 11), the G′ (which measures the elastic component) and G″ (which measures the plastic component) values of CLR bio-based epoxy were predominant compared to the viscoelastic parameters of the EL2 synthetic epoxy at high and low frequencies. Therefore, due to the cross-linking process, the bio-resin gained a more significant shear modulus compared to the synthetic epoxy. Thus, the bio-based epoxy showed a better ability to resist deformation in the longer period compared to the synthetic epoxy.

Figure 9.

Comparison of frequency sweep test results of CLR bio-based (dash lines) and EL2 synthetic (solid lines) epoxies after 15 min hardener mixing.

Figure 10.

Comparison of frequency sweep test results of CLR bio-based (dash lines) and EL2 synthetic (solid lines) epoxies after 30 min of hardener mixing.

Figure 11.

Comparison of frequency sweep test results of CLR bio-based (dash lines) and EL2 synthetic epoxies (solid lines) after 60 min of hardener mixing.

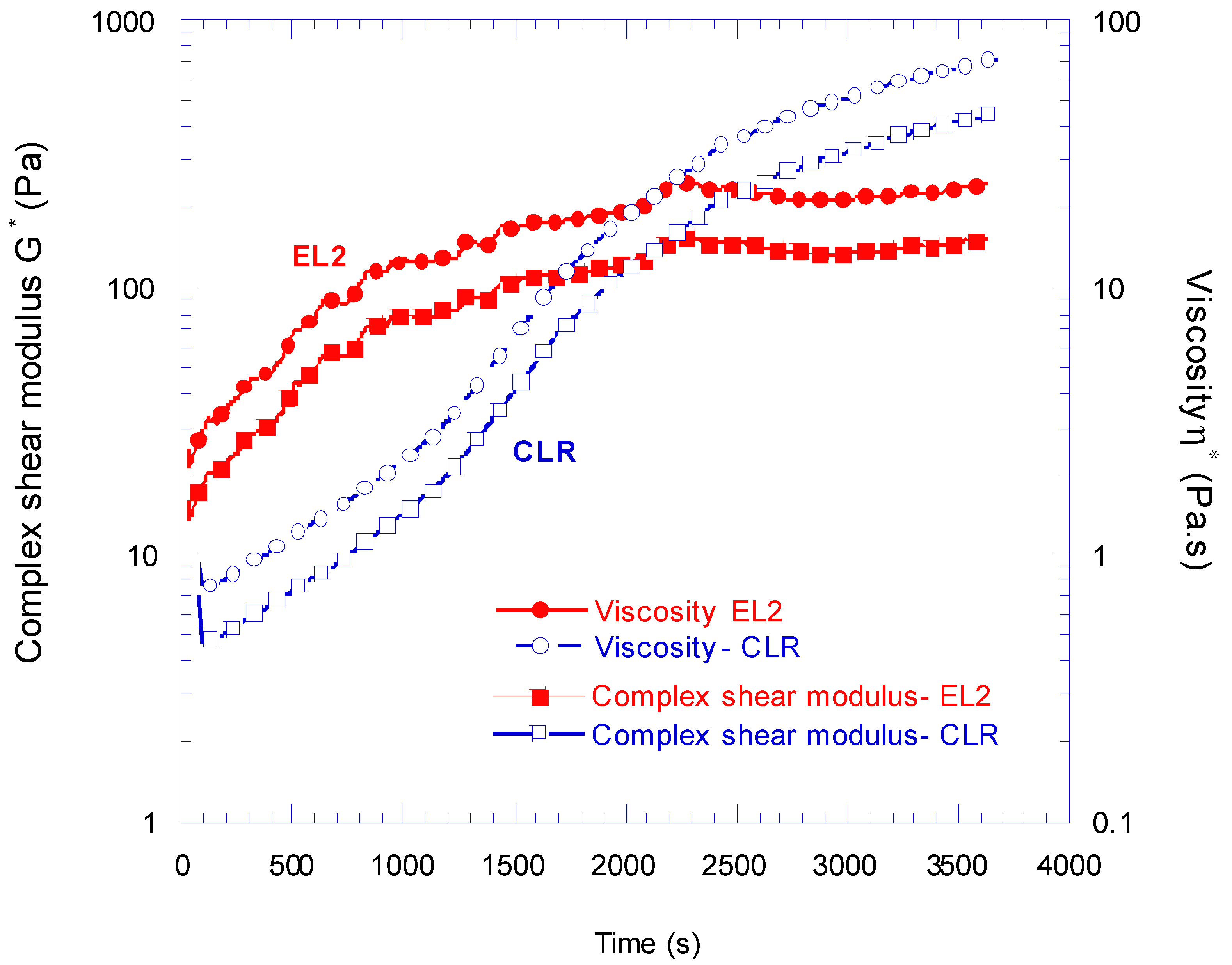

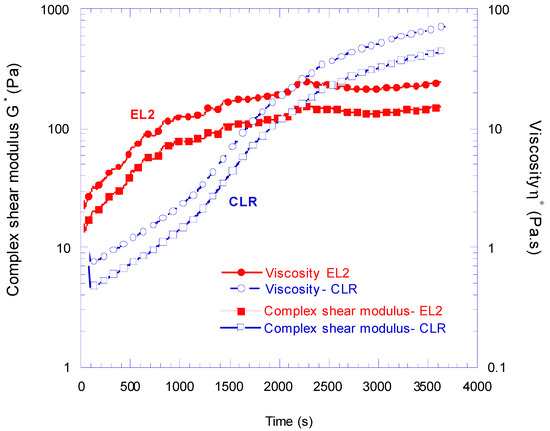

3.3. Single Frequency Test for Evaluating the Change in Material Structure with Time

This test was carried out for comparing the change in complex modulus and complex viscosity of both epoxies after 60 min of mixing the hardeners, as shown in Figure 12. It can be seen that both the complex modulus and the complex viscosity of both epoxies increased during curing. This was due to formation of cross-linking when the reaction between the pure epoxy with the hardener in both materials occurred, and as a result, both epoxies became more resistant to deformation and their viscosities increased.

Figure 12.

Variation of complex modulus (G*) and complex viscosity (η*) of CLR bio-based and EL2 synthetic epoxies after 60 min of mixing with hardeners.

A closer analysis of the results shows that the bio-based epoxy was more favourable to be used as a matrix for a structural composite material compared to the synthetic epoxy since

- The bio-based CLR epoxy had lower viscosity relative to the synthetic EL2 epoxy in the short time period after mixing, making it more suitable for wet-layup applications.

- The bio-based CLR epoxy could better resist deformation compared to the synthetic epoxy EL2 in the extended period. At the end of the test, the G* of the bio-based epoxy was higher than the G* of the synthetic epoxy. This means that once over the pot-life time limit, the bio-epoxy jointed with a fabric becomes solid and its G* value can guarantee better resistance to deformation to the composite material compared to the synthetic epoxy. However, in continuation of this research, the delamination test should be carried out to compare the fracture resistance of both epoxies.

4. Mathematical Models

Two mathematical models, power law and Maxwell models [29], were used to fit the rheometry experimental results. Power law model (PLM) is a non-Newtonian relation used to evaluate the viscosity curve of shear thinning fluids. This model describes the shape and curvature of the slope of the viscosity curve across different shear rates. The shear stress and apparent viscosity can be calculated from the PLM using the following equations

where K is the consistency index, which is equal to the value of viscosity when the shear rate is 1 s−1, and the constant n is the flow index parameter, which describes the curvature tendency of the viscosity curve for different non-Newtonian fluids. When n < 1, the fluid is shear-thinning, and when n > 1, it is shear-thickening. The value of K and n can be obtained from the graph of versus . The slope line gives the value of , from which can be calculated. The intercept at gives the value of K.

The and indices for both epoxies at different curing time after mixing of the hardeners are calculated and summarised in Table 2.

Table 2.

Results of the power law model.

It is noticeable that the flow behaviour index for both epoxies and at all times after mixing the hardeners was less than 1, which is characteristic of a shear thinning fluid.

The Maxwell model [30] is represented by a purely viscous dashpot and a purely elastic spring connected in series. The model describes viscoelastic materials that behave elastically over short time intervals and viscously over long time intervals. When stress is applied to the Maxwell model, the response of it at a very short time (t) is principally elastic and is governed by G (elastic modulus of the spring), whereas when the stress is applied for a longer time (t), the model has a viscous response and is governed by η (viscosity coefficient of the dashpot). The expression that describes this strain evolution is as follows

where σ is the shear stress and is elapsed time. According to the Maxwell model, and can be calculated at any angular frequency using the following equations:

where ω is the angular frequency and τ is the relaxation time. The angular frequency can be calculated by

The relaxation time is the time that decays by approximately 63% of its initial value. For finding the relaxation time, it is necessary to calculate the 63% of for obtaining the oscillation frequency when the relaxation time occurred. Then, once this frequency is found, the relaxation time can be calculated from

It is also possible to graphically estimate the relaxation time by taking the frequency at which and cross (δ = 45°), since this frequency is equal to 1/τ. In our case, the graphical method was not suitable since the epoxies were tested within their pot-life limit and was not crossing over since the epoxy resins showed a liquid-like behaviour for the entire time of the test, where the phase angle was always in the liquid-like limit.

Due to the absence of the overlap between and , the Maxwell model equation for calculating was not valid since the (elastic module of the spring) value required by the formula was not applicable in this case. However, it was possible to calculate the since the model had a viscous response. The calculated values are presented in Table 3, and the results from the model are very close to the rheometer test results.

Table 3.

Result of Maxwell model.

5. Conclusions

This paper focused on the evaluation of the viscous and viscoelastic performance of a petroleum-based (EL2) epoxy resin and a bio-based (CLR) epoxy resin after mixing of the hardeners. The rheological tests were carried out at 15, 30, and 60 min after the mixing of the epoxies and their corresponding hardeners were at a constant temperature of 25 °C less than the pot life of each resin.

The results obtained from the viscometry tests showed that both epoxy systems had shear thinning behaviour. The bio-based epoxy, as well as the petroleum-based epoxy, possessed very similar viscosity values. It was noticed that the viscosity of both epoxy systems decreased with increasing shear rate, which is a typical behaviour of a shear thinning fluid. The viscosity values in each experiment carried out at different times after mixing of the hardeners were in the range between 3.3 and 16 (Pa·s) at 0.1 s−1 shear rate, whereas at 100 s−1 shear rate, the viscosities were between 0.773 and 1.835 (Pa·s).

With regard to the oscillatory rheological tests, initially the linear viscoelastic regions for both epoxies were obtained from amplitude sweep tests that were carried out at 15, 30, and 60 min after mixing of the hardeners with the epoxies. It was noticed that the petroleum-based epoxy possessed a more significant LVER range relative to the bio-based resin. The better ability by the petroleum-based epoxy to sustain strain without deforming its structure in comparison to the bio-based resin was not, however, evidenced by better mechanical/viscoelastic ability to resist deformation compared to the bio-based epoxy. In fact, the loss modulus G″ of both epoxy systems was predominately viscoelastic. In addition, it was noticed that the LVER of the bio-based epoxy was not influenced by the curing time, while the LVER of the petroleum-based resin had a decrement with time.

Next, frequency sweep tests were carried out at 15, 30, and 60 min after mixing the hardeners between 0.1 and 10 Hz. The G′, G″, and phase angle were extracted, and these parameters were studied at low and high frequencies. It was noticed that in each case, both epoxy resins showed a liquid-like viscoelastic behaviour since their phase angle values were always between 45° and 90°, and the G″ was predominate to G′ at low and high frequencies.

Finally, to ensure the reliability of the viscometry and oscillatory test results, we carried out a single frequency sweep test. This experiment was used to monitor sample change with time, where the alteration in complex modulus G* and the complex viscosity η* of both epoxy resins systems were measured after 60 min of adding the hardeners. The bio-based epoxy showed more significant complex modulus G* values compared to the petroleum-based epoxy after 60 min of curing time.

Author Contributions

Conceptualisation, S.V. and V.B.; methodology, S.V.; validation, S.V., V.B., and A.D.; formal analysis, S.V., V.B., and A.D.; investigation, S.V., V.B., and A.D.; resources, S.V. and S.A.; data curation, V.B. and S.V.; writing—original draft preparation, V.B. and S.V.; writing—review and editing, S.V., A.D., and S.A.; supervision, S.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank Associate Homayoun Hadavinia from Kingston University for his invaluable comments and the mechanical testing technician Dean Wells for helping in conducting rheology tests.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wright, C.; Muggee, J. Epoxy Structural Adhesives. In Structural Adhesives, Chemistry and Technology; Springer: Boston, MA, USA, 1986; pp. 113–179. [Google Scholar]

- Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Recent Development of Bio-Based Epoxy Resins: A Review. Polym. Plast. Technol. Eng. 2018, 57, 133–155. [Google Scholar] [CrossRef]

- Durairaj, R.; Man, L.W.; Leong, K.C.; Ping, L.J.; Ekere, N.N.; Pheng, L.S. Rheological Characterisation of Diglycidylether of Bisphenol-A (DGEBA) and Polyurethane (PU) Based Isotropic Conductive Adhesives; IntechOpen: London, UK, 2013. [Google Scholar]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 54–63. [Google Scholar] [CrossRef] [PubMed]

- Baroncini, E.A.; Yadav, S.K.; Palmese, G.R. Recent advances in bio-based epoxy and bio-based epoxy curing agents. Appl. Polym. Sci. 2016, 10, 44–103. [Google Scholar] [CrossRef]

- Fakhari, A.; Rahmat, A.R. Synthesis of new bio-based thermoset resin from palm oil. Adv. Mater. Res. 2014, 931, 78–82. [Google Scholar] [CrossRef]

- Francois, C.; Pouchet, S.; Boni, G. Design and synthetis of biobased epoxy thermosets from bioreneawable resources. Comptes Rendus Chim. 2017, 20, 1006–1016. [Google Scholar] [CrossRef]

- Kuman, S.; Samal, S.K.; Mohanty, S. Bio-based tri-functional epoxy resin blend cured with anhydride based cross-linker: Therma, mechanical and morphological characterization. J. Macromol. Sci. 2018, 55, 496–506. [Google Scholar]

- Ma, S.; Li, T.; Liu, X. Research progress on bio-based thermosetting resin. Soc. Chem. Ind. 2015, 10, 674–792. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.; Vahid, V. Improving the fracture toughness and the strength of epoxy using nanomaterials – a review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Liaghat, G.; Vahid, S.; Paton, K.; Spacie, C.; Sainsbury, T. Improving the fracture toughness properties of epoxy using graphene nanoplatelets at low filler content. Nanocomposites 2017, 3, 85–96. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Toughening of Petroleum Based (DGEBA) Epoxy Resins with Various Renewable Resources Based Flexible Chains for High Performance Applications: A Review. Ind. Eng. Chem. Res. 2018, 57, 2711–2726. [Google Scholar] [CrossRef]

- Research, P.M. Epoxy Resins Market Share, Size, Trends 2020–2026. 2020. Available online: https://www.polarismarketresearch.com/industry-analysis/epoxy-resins-market (accessed on 15 July 2020).

- Modern Airliners. 2015. Available online: http://www.modernairliners.com/boeing-787-dreamliner/boeing-787-dreamliner-specs/ (accessed on 20 April 2020).

- Ramon, E.; Sguazzo, C.; Moreira, A. Review of Recent Research on Bio-Based Epoxy Systems for Engineering Applications and Potentialities in the Aviation Sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Roudsari, G.M.; Misra, M. A study of mechanical properties of biobased epoxy network: Effect of addition of epoxidized soybean oil and poly(furfuryl alcohol). J. Appl. Polym. Sci. 2017, 134, 345–376. [Google Scholar]

- Rad, E.; Vahabi, H.; de Anda, A.; Saeb, M.; Thomas, S. Bio-epoxy resins with inherent flame retardancy. Prog. Org. Coat. 2019, 135, 608–612. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Hamidi, S.; Moradi, Y.; Barzegar, S.; Ahmadi, M.; Naebe, M. A renewable bio-based epoxy resin with improved mechanical performance that can compete with DGEBA. RSC Adv. 2016, 7, 8694–8701. [Google Scholar] [CrossRef]

- Soutis, C.; Yi, X.; Bachmann, J. How green composite materials could benefit aircraft construction. Sci. China Technol. Sci. 2019, 62, 1478–1480. [Google Scholar] [CrossRef]

- Niedermann, P.; Szebenyi, G.; Toldy, A. Effect of Epoxidized Soybean Oil on Curing, Rheological, Mechancial and Thermal Properties of Aromatic and Aliphatic Epoxy Resins. J. Polym. Environ. 2014, 22, 525–536. [Google Scholar] [CrossRef]

- Mravljak, M.; Sernek, M. The influnec of curing temperature on rheological properties of epoxy adhesives. Drv. Ind. 2011, 62, 19–25. [Google Scholar] [CrossRef]

- Gernaat, C.R. Correlation between Rheological and Mechanical Properties in Low-Temperature Cure Prepreg Composite. MSc Thesis, Wichita State University, Wichita, KS, USA, 2008. [Google Scholar]

- Meier, R.; Kirdar, C.; Rudolph, N.; Zaremba, S.; Drechsler, K. Investigation of the Shear Thinning Behavior of Epoxy Resins for Utilization in Vibration Assisted Liquid Composite Molding Processes. AIP Conf. Proc. 2014, 1593, 458. [Google Scholar]

- Samper, M.D.; Ferri, J.M.; Carbonell-Verdu, A.; Balart, R.; Fenollar, O. Properties of biobased epoxy resin from epoxidized linseed oil (ELO) crosslinked with a mixture of cyclinc anhydride and maleniezed linseed oil. Express Polym. 2019, 13, 407–418. [Google Scholar] [CrossRef]

- Amiri, A.; Yu, A.; Webster, D.; Ulven, C. Bio-based Resin Reinforced with Flax Fiber as Thermorheologically Complex Materials. Polymers 2016, 8, 153. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, G.; Zhao, L. Effect of Curing Agent and Temperature on the Rheological Behavior of Epoxy Resin Systems. Molecules 2012, 17, 8587–8594. [Google Scholar] [CrossRef] [PubMed]

- Hyun, K.; Wilhelm, M.; Klein, C.O.; Cho, K.S.; Nam, J.G.; Ahn, K.H.; Lee, S.J.; Ewoldt, R.H.; McKinley, G.H. A review of nonlinear oscillatory shear tests: Analysis and application of large amplitude oscillatory shear (LAOS). Prog. Polym. Sci. 2011, 36, 1697–1753. [Google Scholar] [CrossRef]

- Meeuw, H.; Wisniewski, V.; Fiedler, B. Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems. Polymers 2018, 10, 999. [Google Scholar] [CrossRef] [PubMed]

- Adewale, F.J.; Lucky, A.P.; Oluwabunmi, A.P.; Boluwaji, E.F. Selecting the most appropriate model for rheological characterization of synthetic based drilling mud. Int. J. Appl. Eng. Res. 2017, 12, 7614–7649. [Google Scholar]

- Serra-Aguila, A.; Puigoriol-Forcada, J.M.; Reyes, G.; Menacho, J. Viscoelastic models revisited: Characteristics and interconversion formulas for generalized Kelvin–Voigt and Maxwell models. Acta Mech. Sin. 2019, 35, 1191–1209. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).