A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models

Abstract

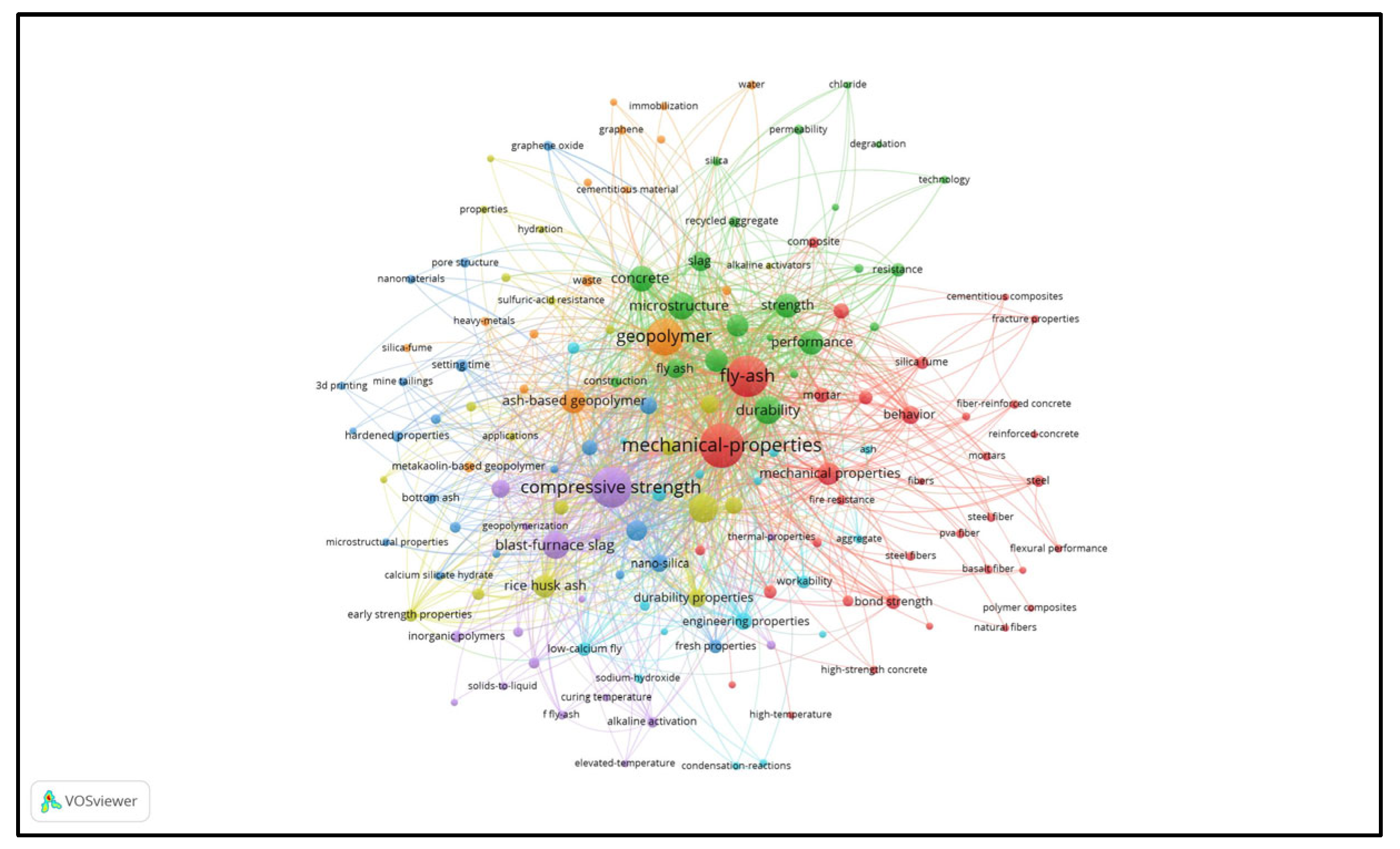

1. Introduction

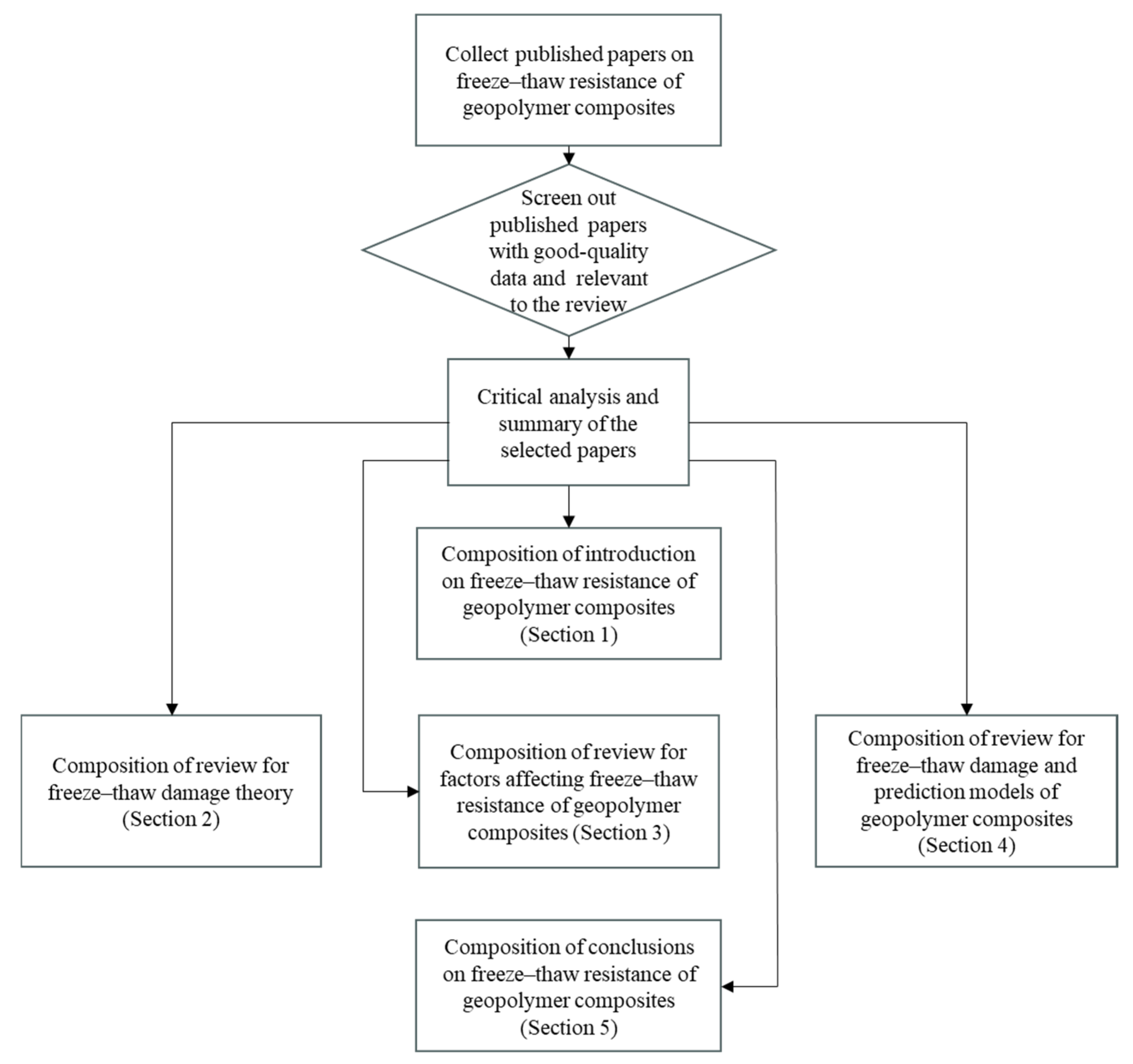

2. Freeze–Thaw Damage Mechanism and Theory of Geopolymer Composites

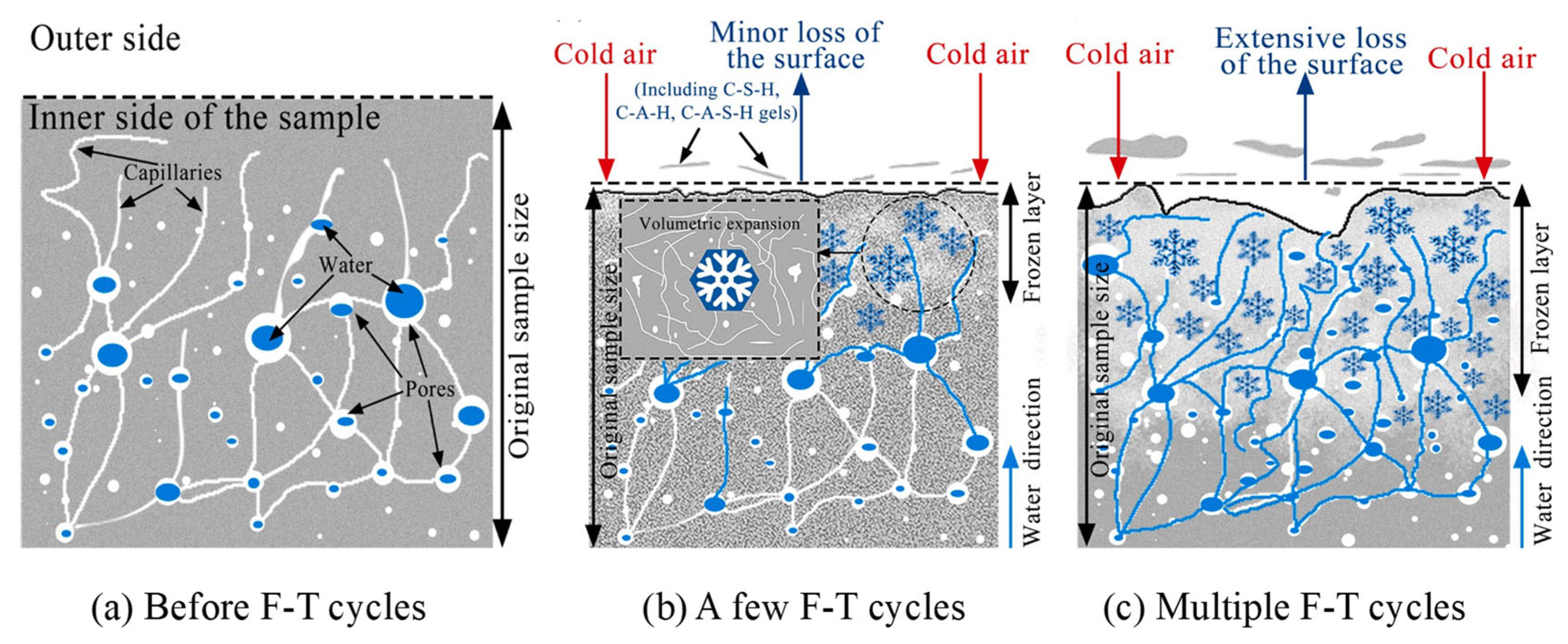

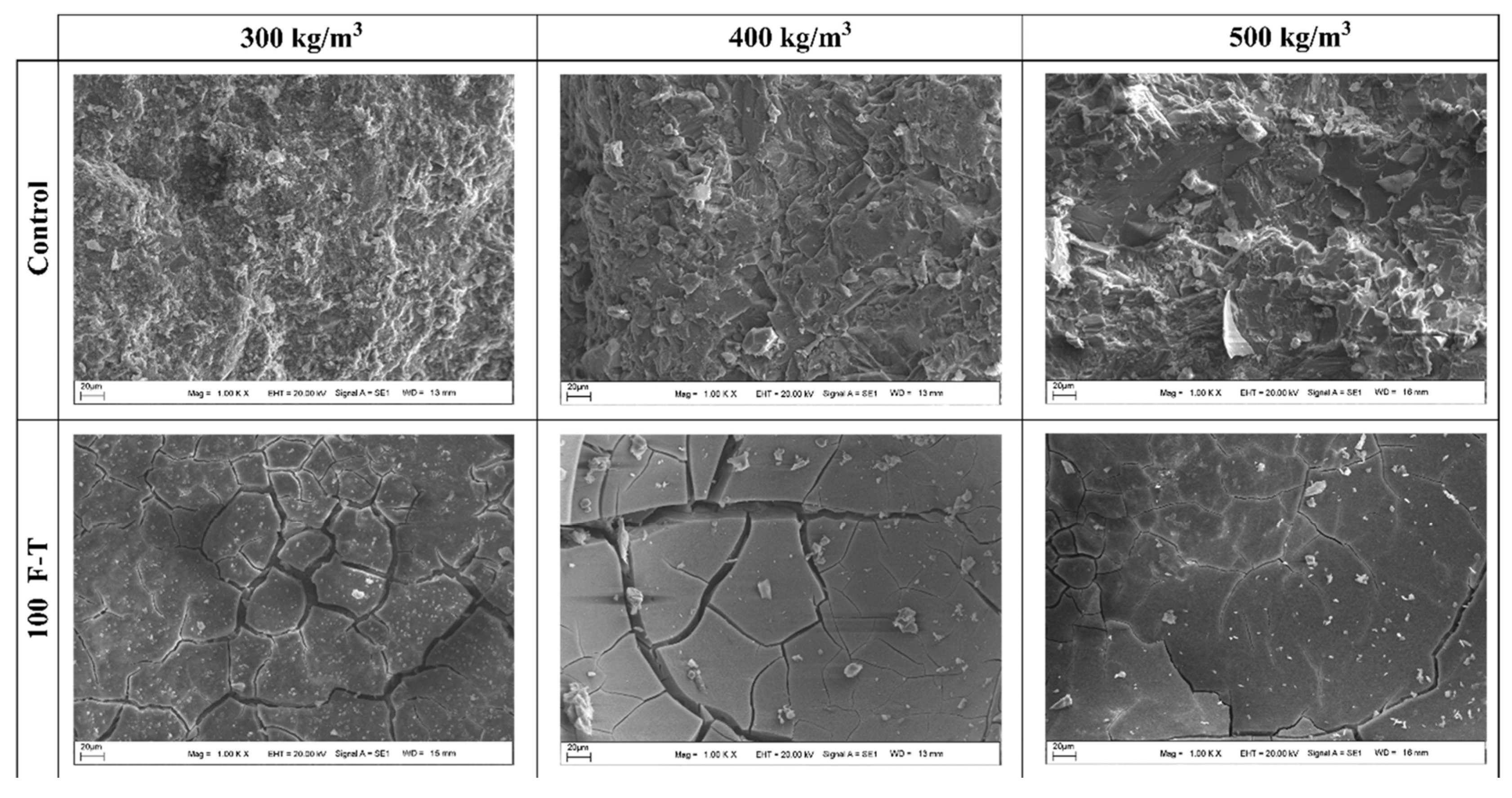

2.1. Freeze–Thaw Damage Mechanism of Geopolymer Composites

2.2. Freeze–Thaw Damage Theory

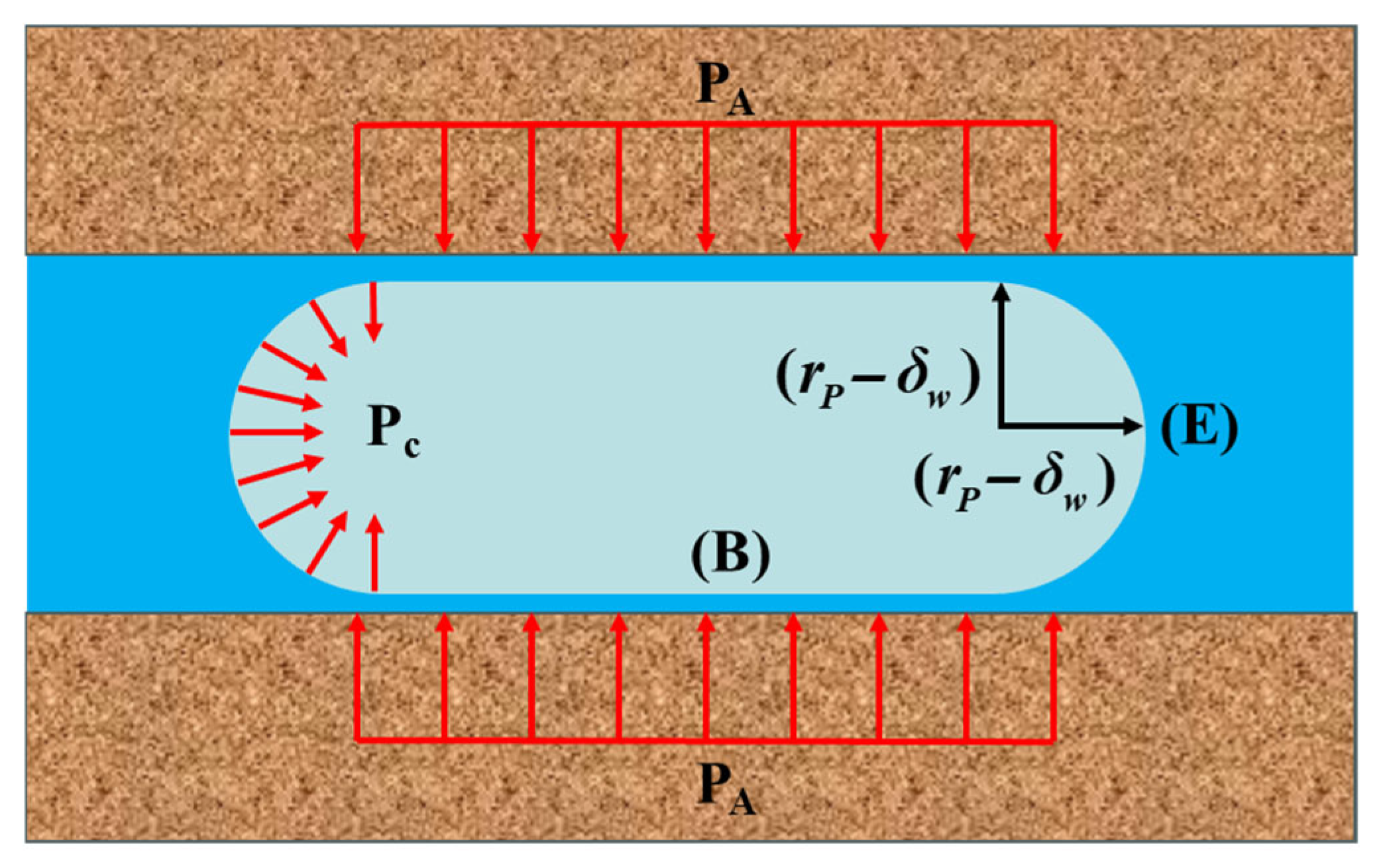

2.2.1. Crystallization Pressure Theory

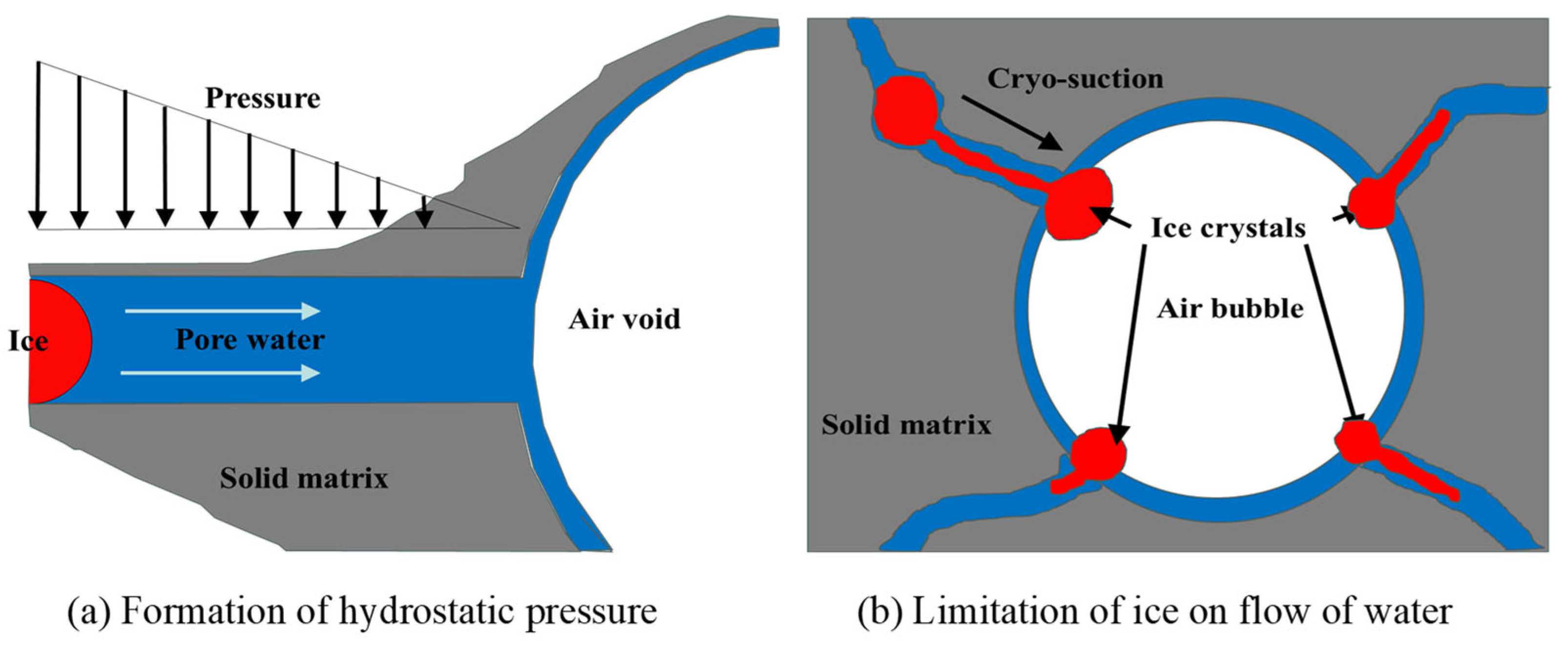

2.2.2. Hydraulic Pressure Theory

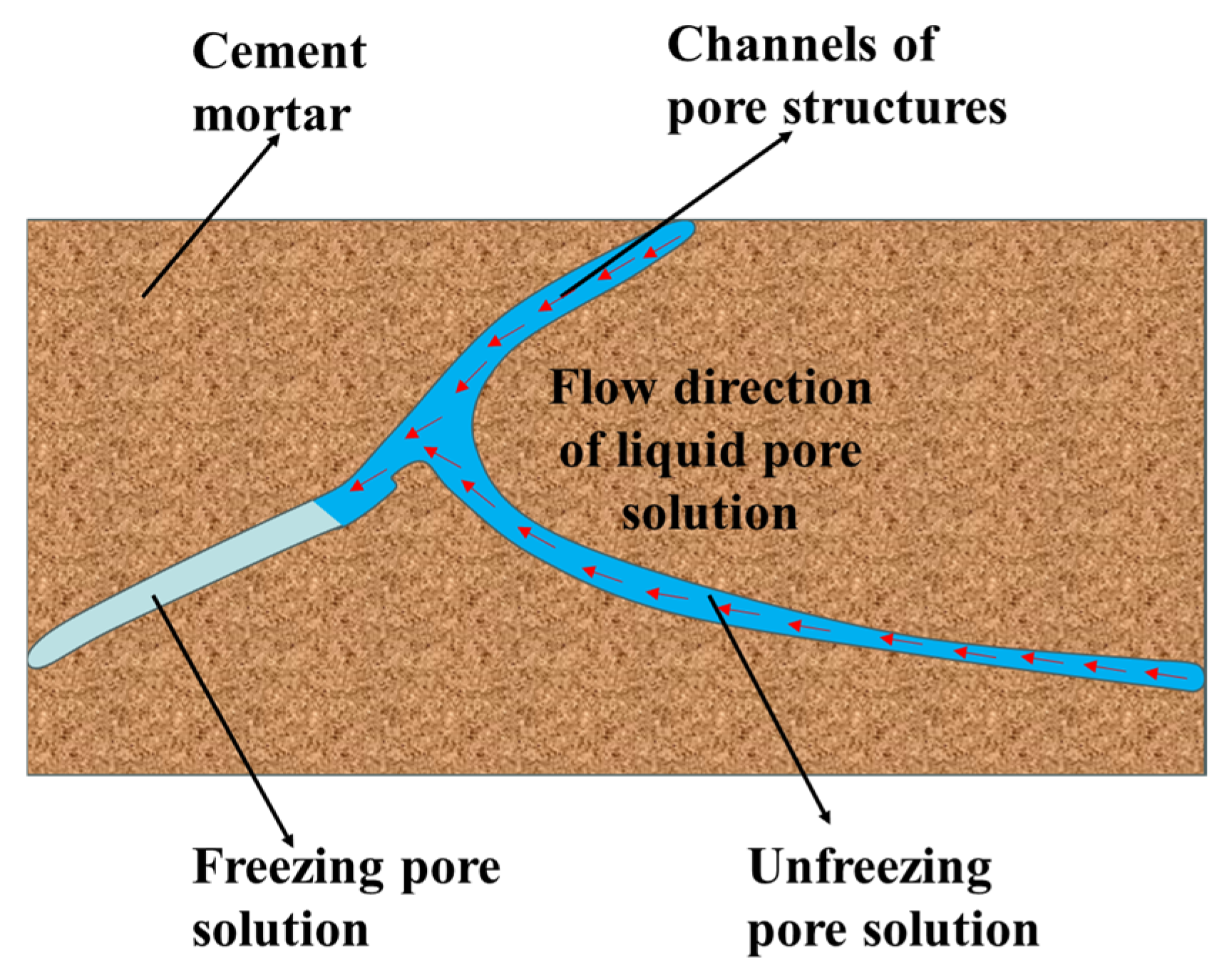

2.2.3. Osmotic Pressure Theory

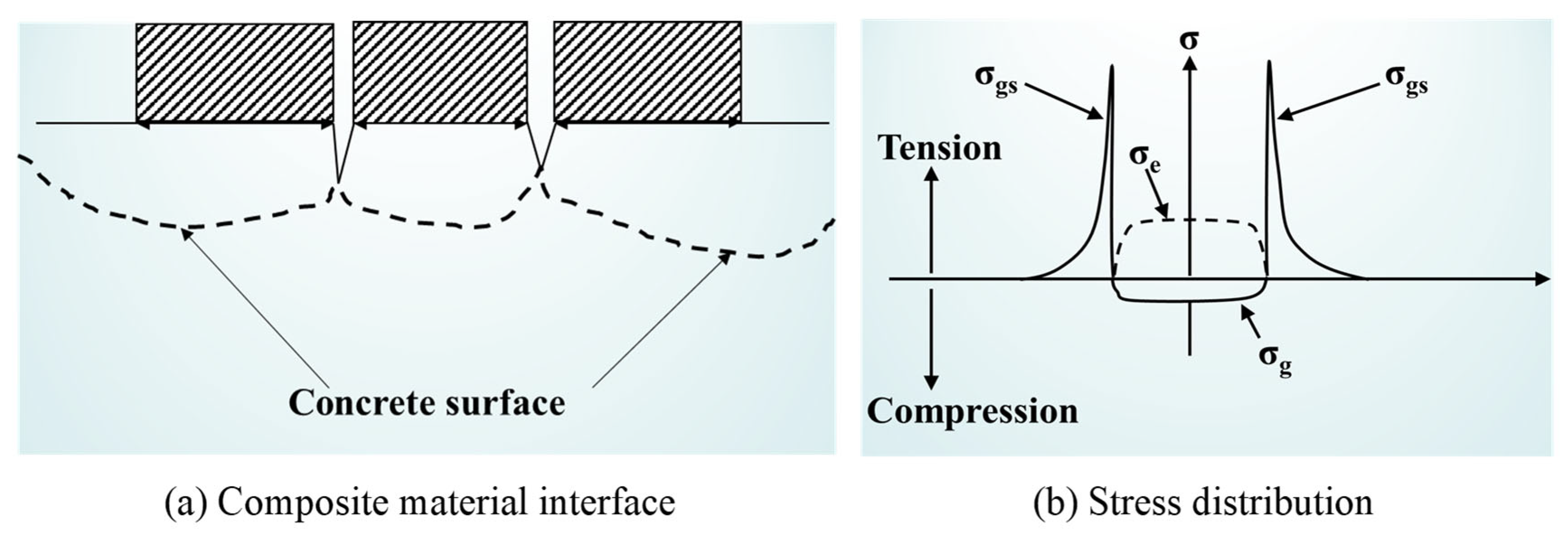

2.2.4. Glue Spall Theory

3. Factors Affecting the Freeze–Thaw Resistance of Geopolymer Composites

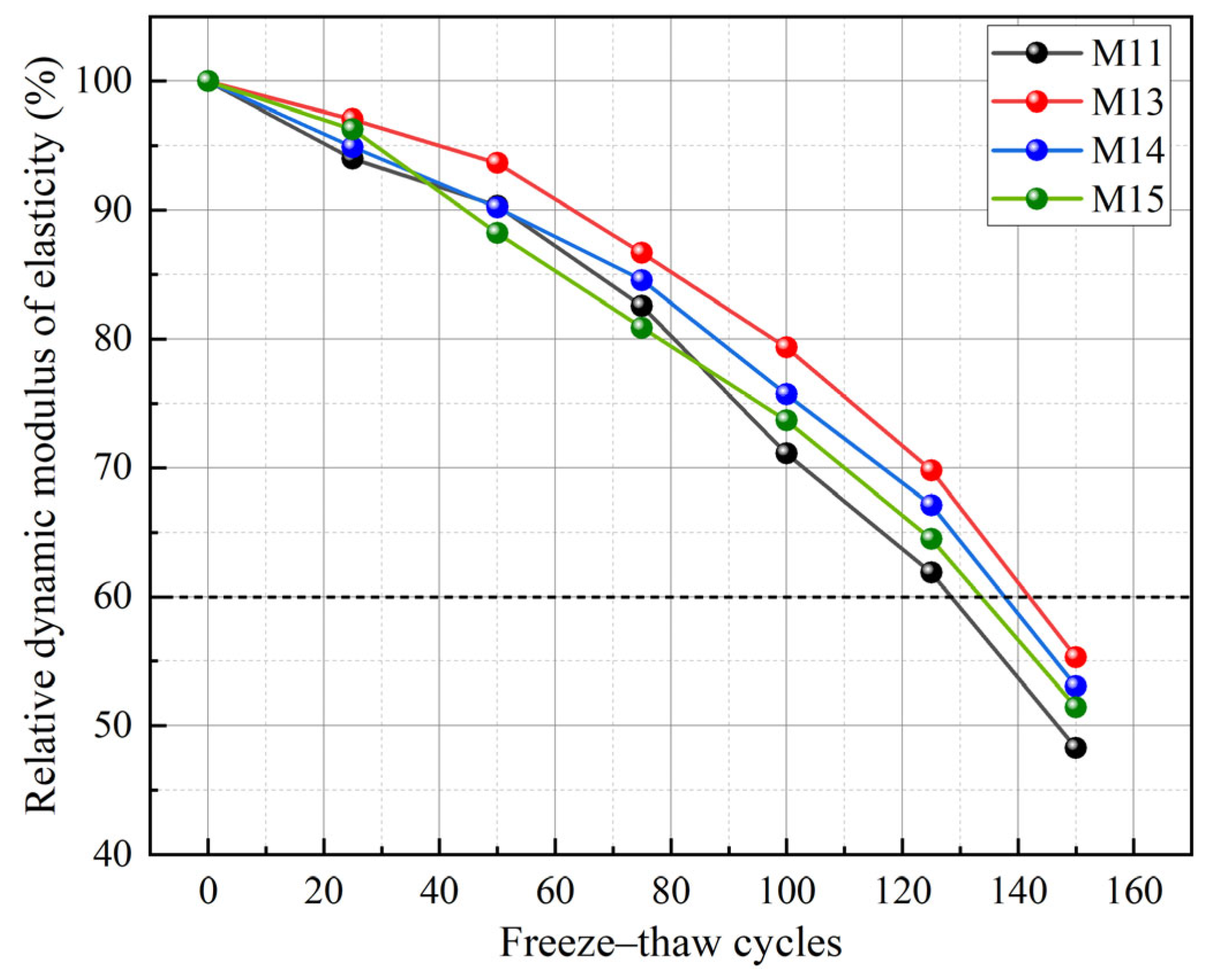

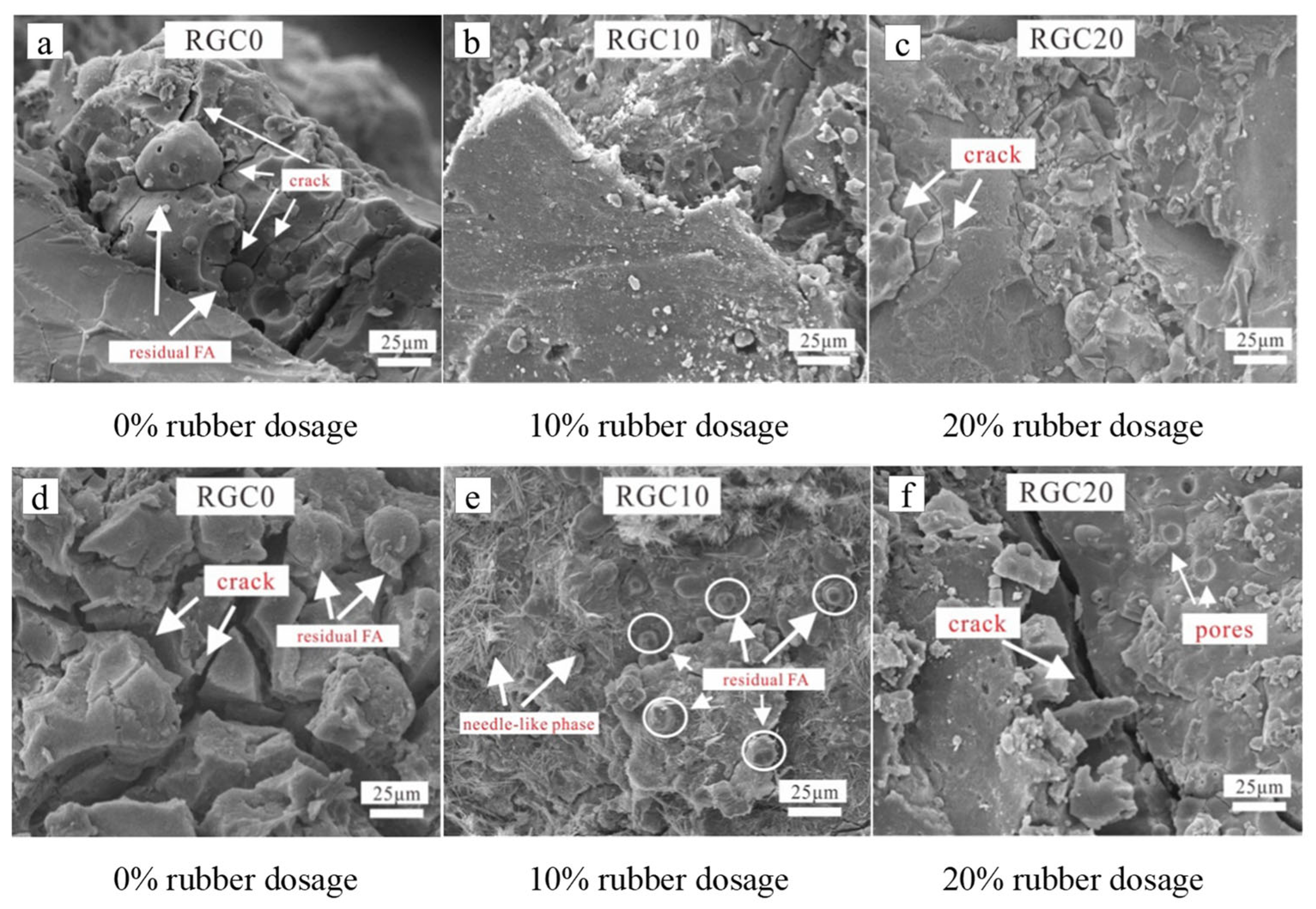

3.1. Raw Materials

3.1.1. Precursors

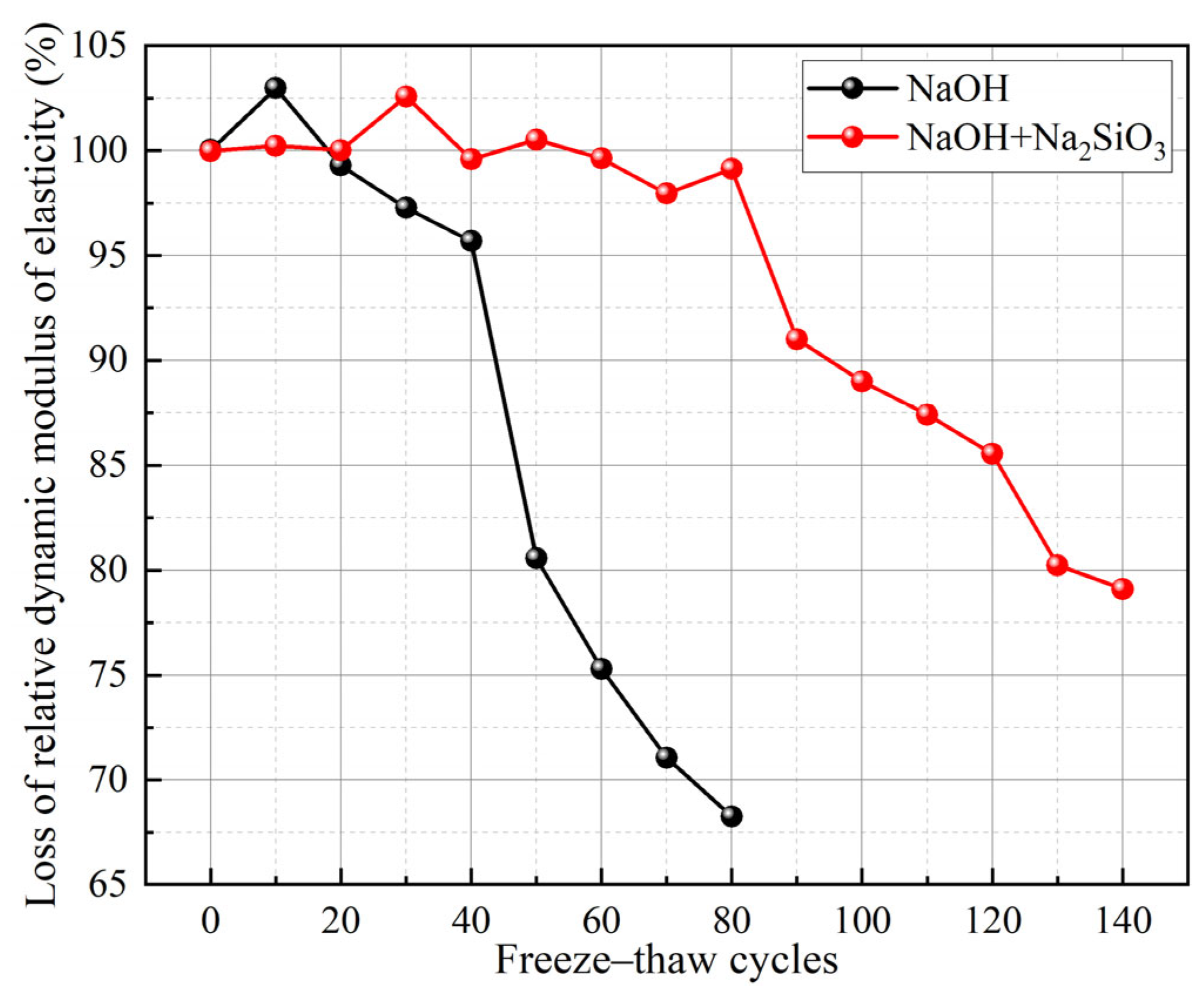

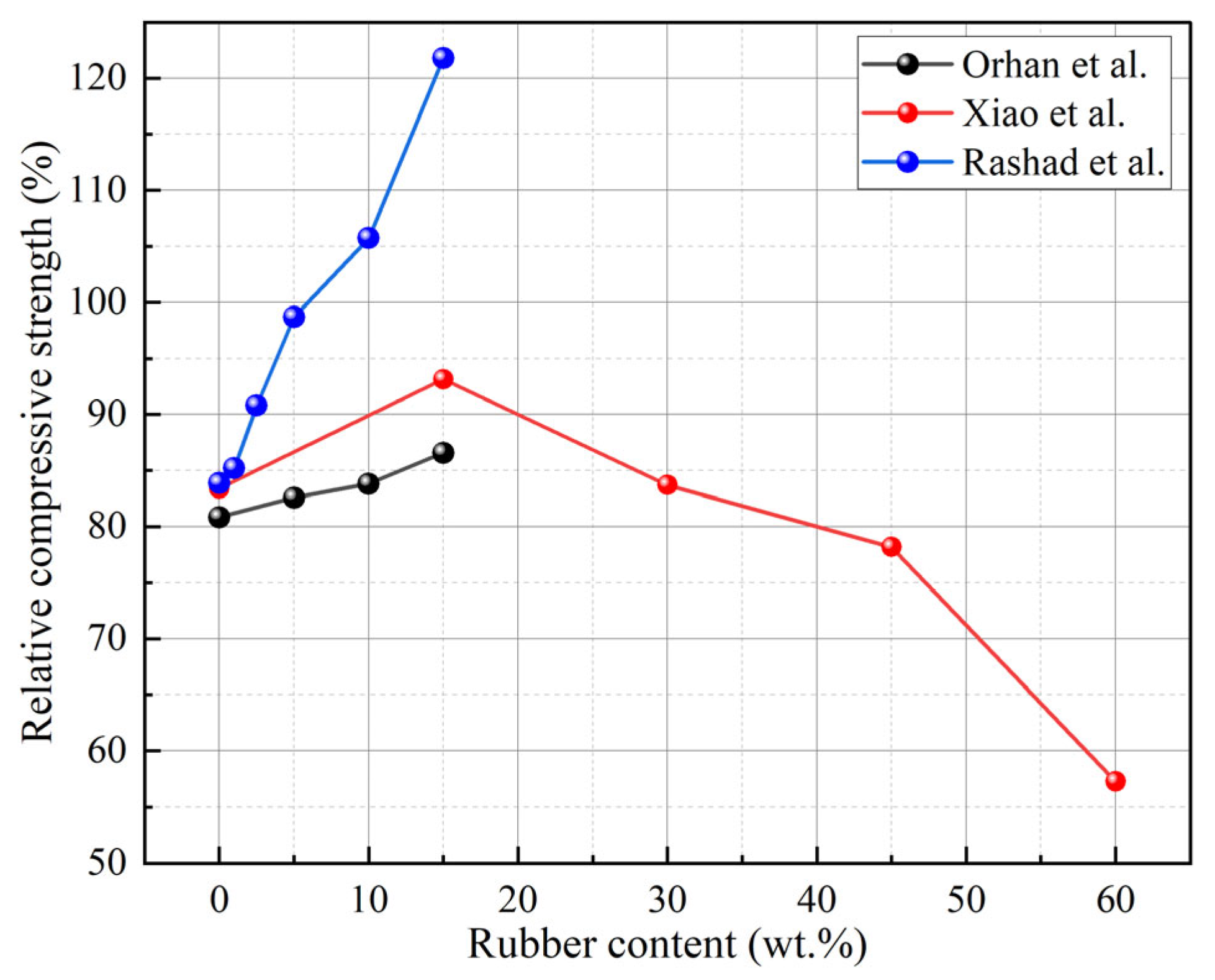

3.1.2. Activator

3.1.3. Aggregates

3.2. Curing Conditions

3.3. Modified Materials

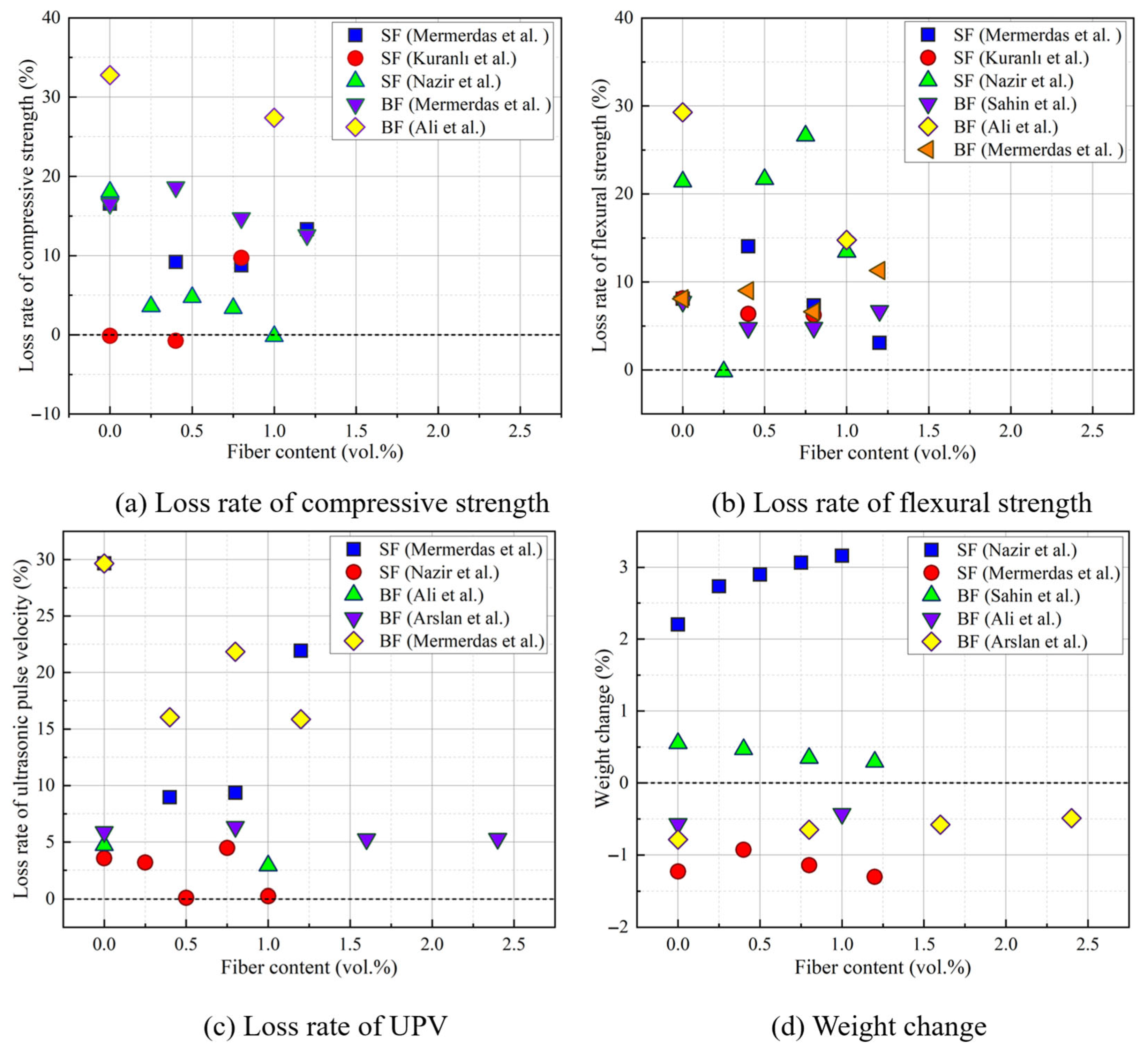

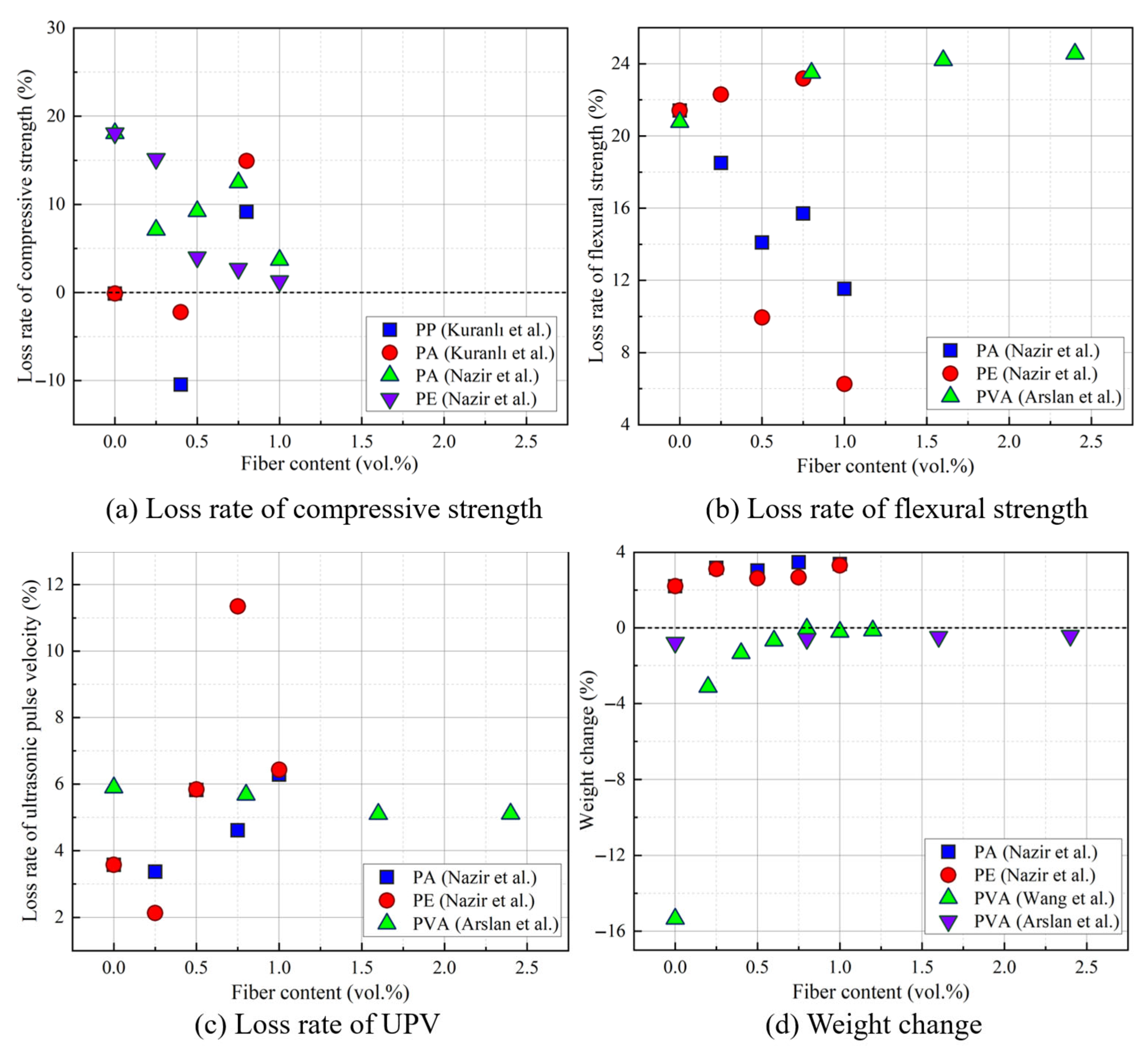

3.3.1. Fiber

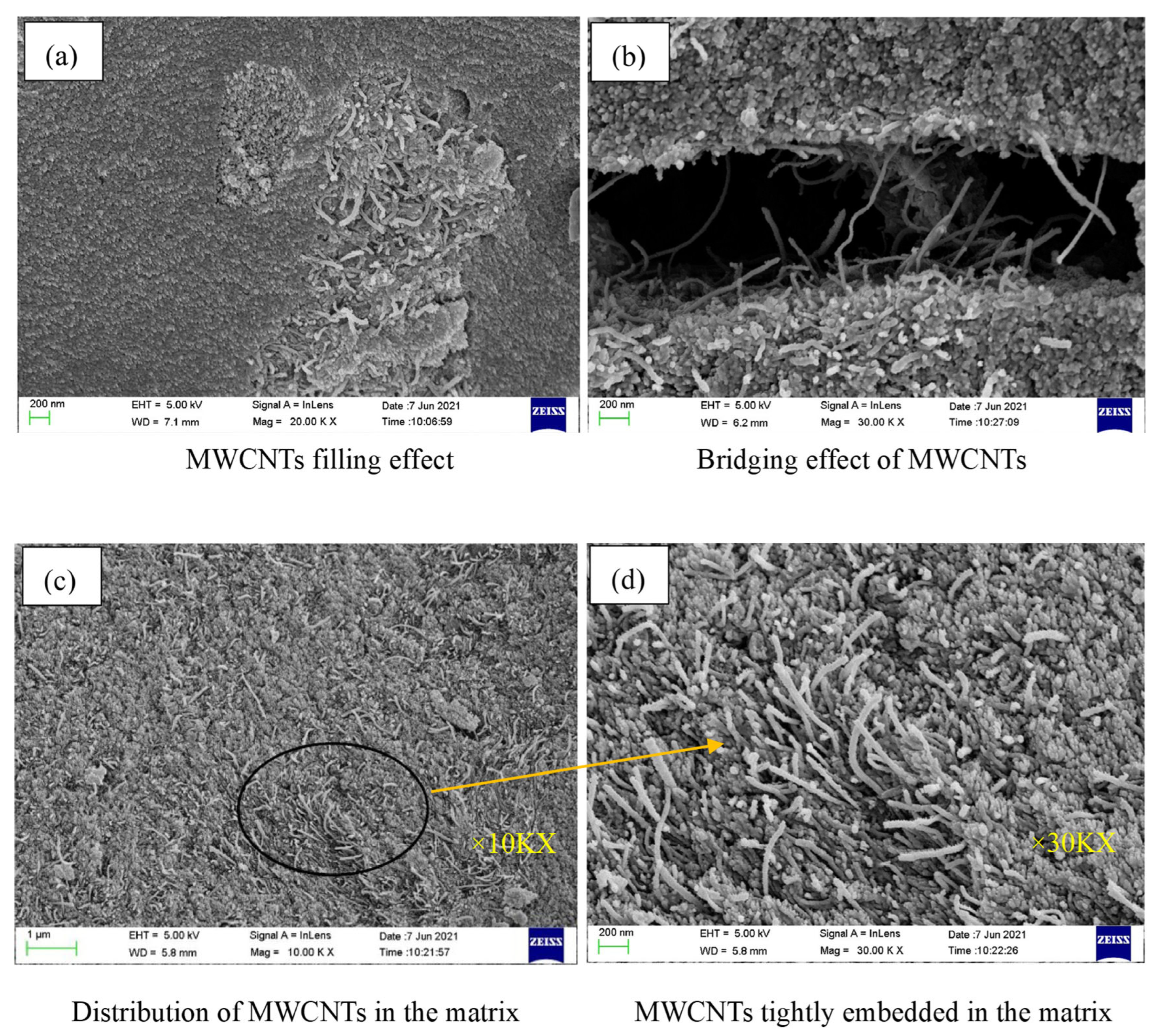

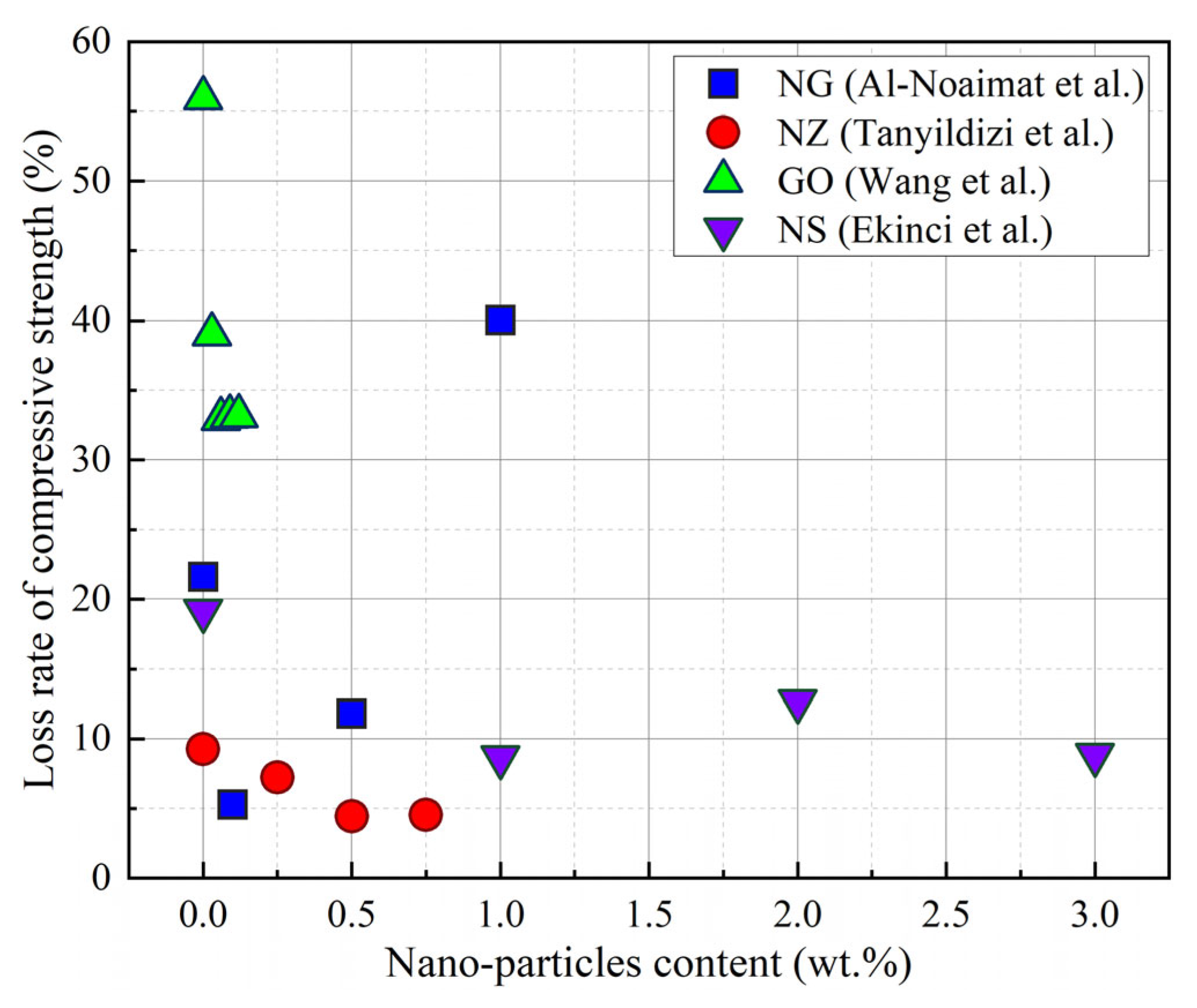

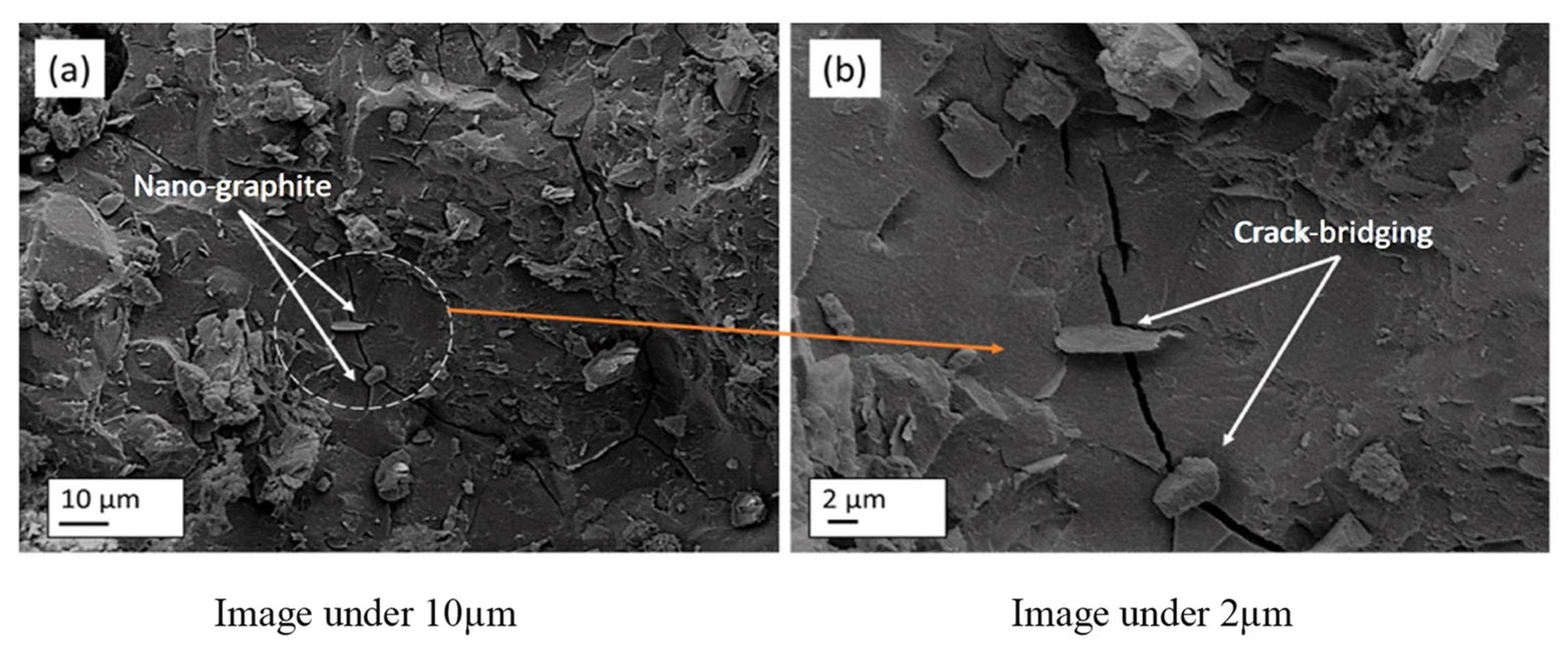

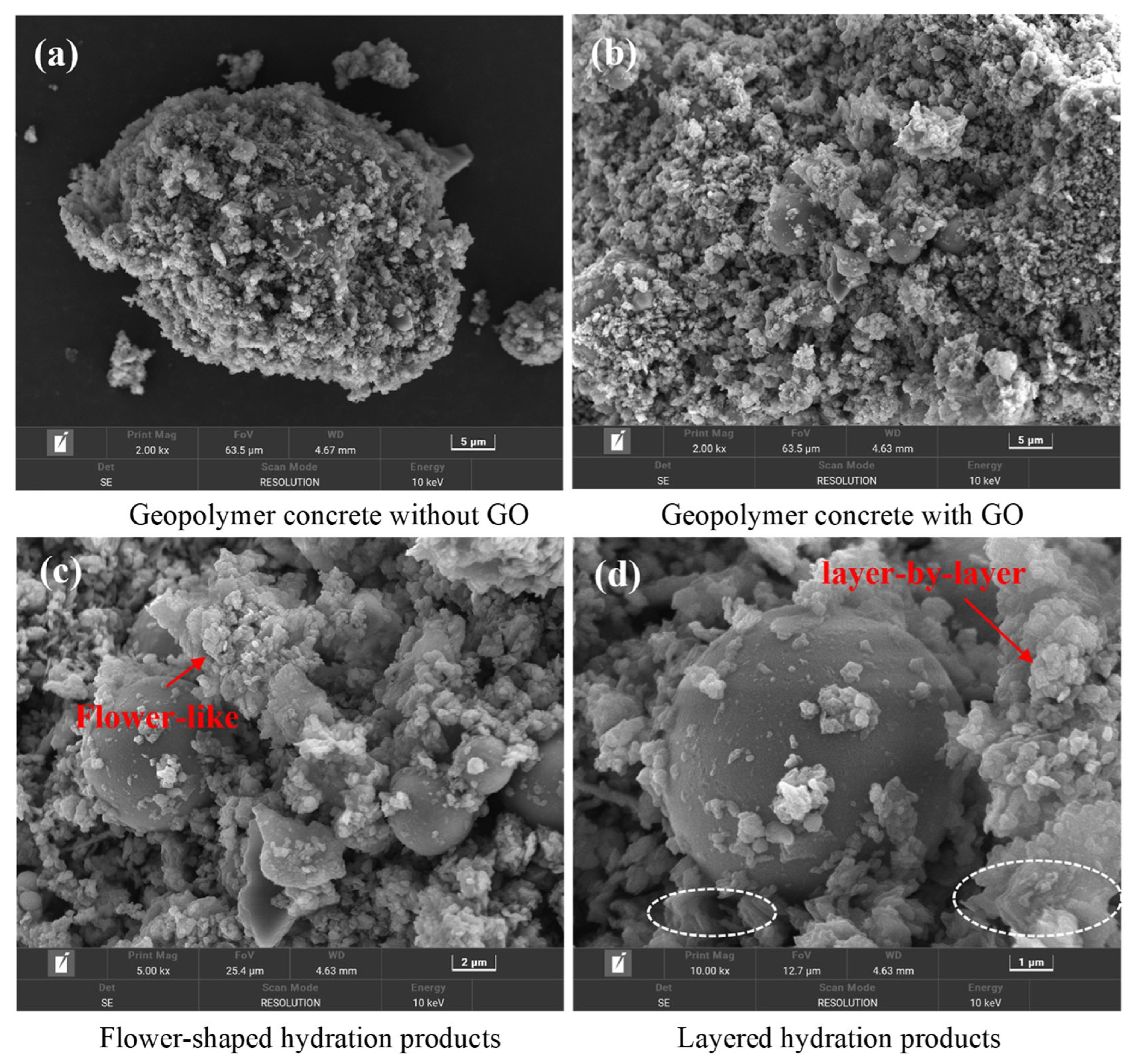

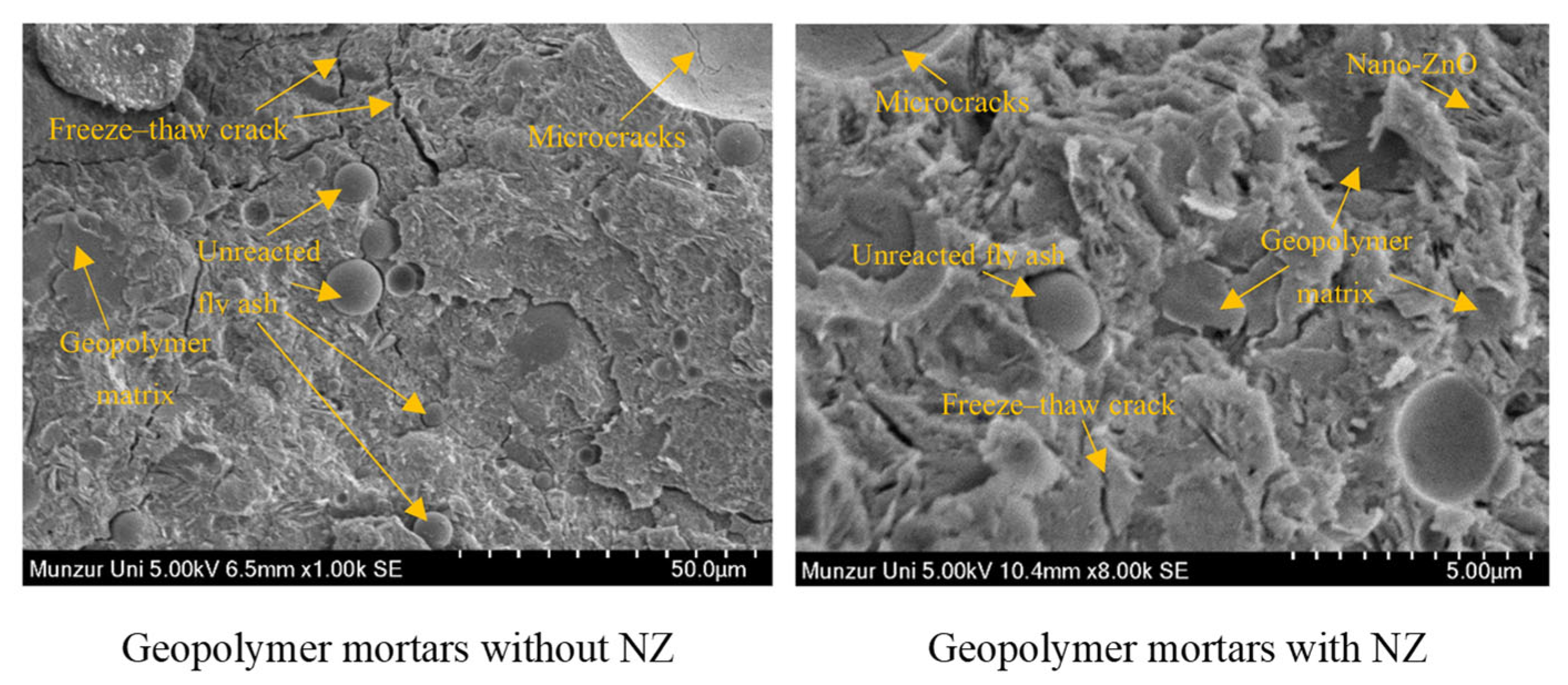

3.3.2. Nano-Materials

3.3.3. Air-Entraining Agents

4. Freeze–Thaw Damage and Prediction Models of Geopolymer Composites

4.1. Experience Model

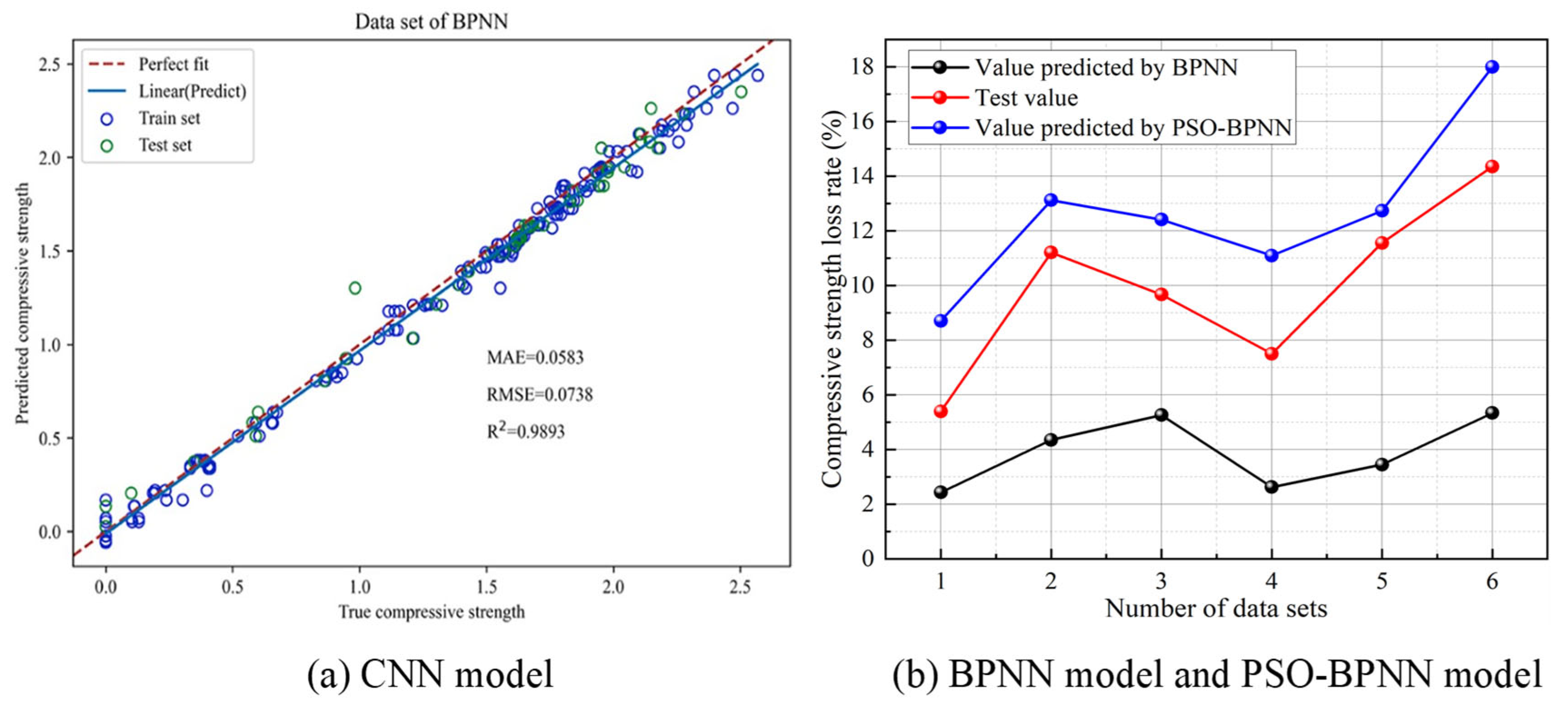

4.2. Machine Learning Models

5. Conclusions

- (1)

- The degree of F-T damage of GCs is influenced by pore water pressure and crystallization pressure. The F-T failure process of GCs is predominantly categorized into three distinct stages: water absorption and saturation, ice crystallization during the freezing phase, and microstructural damage leading to macroscopic failure. As the quantity of F-T cycles rises, the surface layer of the geopolymer will start to flake off, and fissures will develop within its internal structure. Three commonly used F-T damage theories are introduced, namely the crystallization pressure theory, hydrostatic pressure theory, and osmotic pressure theory. The theory of crystallization pressure elucidates the process of crystal failure in porous materials.

- (2)

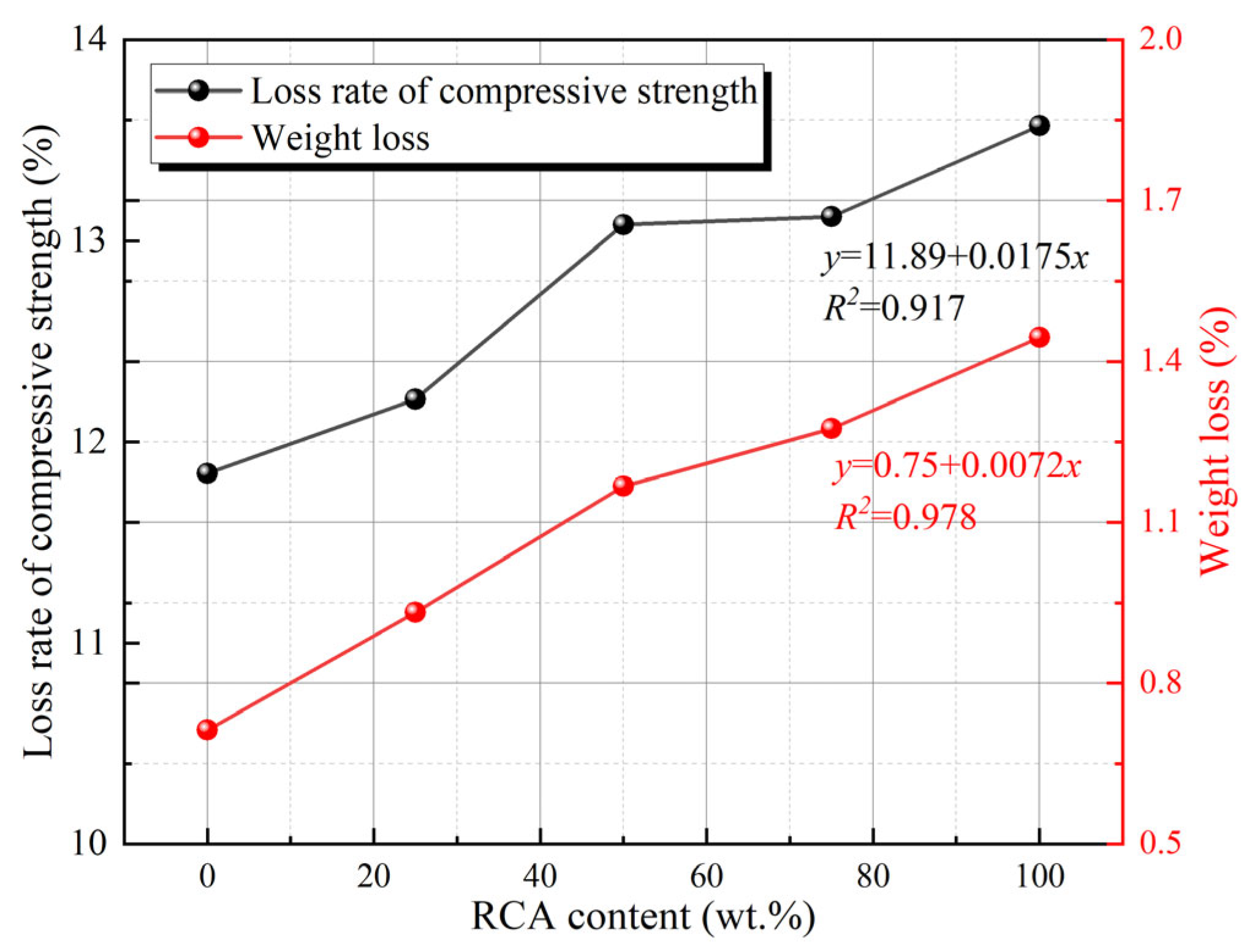

- The Ca content in the precursor can affect the F-T resistance of the geopolymer. GCs with a high Ca content exhibit better F-T resistance than those with a low Ca content. Multiple studies have shown that GCs activated by a mixture of sodium hydroxide and sodium silicate possess better F-T resistance compared to those activated using sodium hydroxide alkaline activator alone. The modulus of the alkaline activator is most effective within the range of 1.3. Replacing natural aggregates with recycled aggregates weakens the F-T resistance of GCs, although this effect is not pronounced. When the proportion of RPs replacing fine aggregates is in the range of approximately 15%, it can augment the F-T resistance of GCs.

- (3)

- The suitable curing conditions for GCs are influenced by the source and amount of Ca contained in the precursor. The F-T resistance of GCs can be enhanced by appropriately increasing the curing temperature to the range of approximately 50 °C to 80 °C, particularly for low-Ca GCs. Desirable results can be obtained when the curing temperature is set within the range of 50 °C to 70 °C.

- (4)

- Fibers, nano-particles, and AEAs are modified materials that influence the F-T resistance of GCs. Extensive experimental studies have demonstrated that fibers can strengthen the F-T resistance of GCs. However, an excessive amount of fibers can form aggregates and cause defects within the matrix. Incorporating an appropriate amount of nano-particles (ranging from 0.45% to 2%) into GCs can improve their F-T resistance. The impact of AEAs on the F-T resistance of GCs is relatively limited, and the findings reported in the literature are still highly controversial.

- (5)

- In this review, the assessment and prediction models of F-T damage were summarized, and the coefficient of determination R2 values of these models were all above 0.9. Most of the empirical models for F-T damage were established based on exponential and power functions. When compared with traditional empirical models, most of the prediction models of geopolymer F-T damage established using neural network algorithms possess higher accuracy and broader applicability. Among these models, the prediction results of the CNN model and the ANN model are relatively accurate. Their coefficient of determination R2 values are all above 0.99.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OPC | ordinary Portland cement |

| GC | geopolymer composite |

| FA | fly ash |

| GGBFS | ground granulated blast furnace slag |

| MK | metakaolin |

| F-T | freeze–thaw |

| RDME | relative dynamic modulus of elasticity |

| UPV | ultrasonic pulse velocity |

| Ca | calcium |

| AEA | air-entraining agent |

| SF | steel fiber |

| PE | polyethylene |

| GO | graphene oxide |

| RP | rubber particle |

| NS | nano-silica |

| ML | machine learning |

| SEM | scanning electron microscopy |

| N-A-S-H | sodium aluminosilicate hydrate |

| OPCC | ordinary Portland cement concrete |

| C-S-H | calcium silicate hydrate |

| C-A-S-H | calcium aluminosilicate hydrate |

| RCA | recycled concrete aggregate |

| BS | basalt sand |

| FA-RMS | fly ash–red mud slurry |

| RH | relative humidity |

| BF | basalt fiber |

| PP | polypropylene |

| PVA | polyvinyl alcohol |

| MWCNTs | multi-walled carbon nanotubes |

| NG | nano-graphite |

| NA | nano-alumina |

| NC | nano-clay |

| NZ | nano-zinc oxide |

| RMSE | root mean square error |

| ANN | artificial neural network |

| BPNN | backpropagation neural network |

| CNN | convolutional neural network |

| GRU | gated recurrent unit |

| PSO | particle swarm optimization |

References

- Wang, A.; Zheng, Y.; Zhang, Z.; Liu, K.; Li, Y.; Shi, L.; Sun, D. The durability of alkali-activated materials in comparison with Ordinary Portland Cements and concretes: A review. Engineering 2020, 6, 695–706. [Google Scholar] [CrossRef]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Li, V.C. High-Performance and multifunctional cement-based composite material. Engineering 2019, 5, 250–260. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Wang, W.S.; Zhang, P.; Guo, J.J.; Wang, F. Abrasion resistance assessment of geopolymer concrete reinforced with nano-SiO2 and steel-polyvinyl alcohol hybrid fiber. Constr. Build. Mater. 2025, 487, 15. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.; Guo, J.J.; Zheng, Y.X.; Gao, Z. Mechanical Properties of Cement-Based Gel Composites Reinforced by Plant Fiber: A Review. Gels 2025, 11, 33. [Google Scholar] [CrossRef]

- Davidovits, J. Synthesis of New High-Temperature Geo-Polymers for Reinforced Plastics/Composites. 1979; pp. 151–154. Available online: https://www.scopus.com/pages/publications/0024630792?inward= (accessed on 6 July 2025).

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Yin, H.; Guan, J.; Wang, L. Effects of freeze-thaw damage on fracture properties and microstructure of hybrid fibers reinforced cementitious composites containing calcium carbonate whisker. Constr. Build. Mater. 2021, 300, 123872. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Q.; Li, Y. Deterioration of concrete under the coupling effects of freeze-thaw cycles and other actions: A review. Constr. Build. Mater. 2022, 319, 126045. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. ACI 1945, 14, 245–272. [Google Scholar]

- Li, F.; Chen, D.; Lu, Y.; Zhang, H.; Li, S. Influence of mixed fibers on fly ash based geopolymer resistance against freeze-thaw cycles. J. Non-Cryst. Solids 2022, 584, 121517. [Google Scholar] [CrossRef]

- Bao, W.X.; Yin, Y.; Mi, W.J.; Chen, R.; Lin, X.H. Durability and microstructural evolution of high-performance ecological geopolymer concrete under low-pressure-salt-erosion-freeze-thaw cycling conditions. Constr. Build. Mater. 2024, 426, 136197. [Google Scholar] [CrossRef]

- Zheng, Y.; Rao, F.; Yang, L.; Zhong, S. Comparison of ternary and dual combined waste-derived alkali activators on the durability of volcanic ash-based geopolymers. Cem. Concr. Compos. 2023, 136, 104886. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Wu, Y. Freeze-thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Ekinci, E.; Türkmen, İ.; Kantarci, F.; Karakoç, M.B. The improvement of mechanical, physical and durability characteristics of volcanic tuff based geopolymer concrete by using nano silica, micro silica and Styrene-Butadiene Latex additives at different ratios. Constr. Build. Mater. 2019, 201, 257–267. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Tong, K.T. Mechanical and durability properties of alkali-activated fly ash concrete with increasing slag content. Constr. Build. Mater. 2021, 124330, 124330. [Google Scholar] [CrossRef]

- Yan, D.M.; Xie, L.J.; Qian, X.Q.; Ruan, S.Q.; Zeng, Q. Compositional dependence of pore structure, strengthand freezing-thawing resistance of metakaolin-based geopolymers. Materials 2020, 13, 2973. [Google Scholar] [CrossRef]

- Min, Y.F.; Wu, J.; Li, B.; Zhang, M.Y.; Zhang, J.J. Experimental study of freeze-thaw resistance of a one-part geopolymer paste. Case Stud. Constr. Mater. 2022, 17, e01269. [Google Scholar] [CrossRef]

- Bilir, T.; Aygörmez, Y.; Bastan, Z.; Uysal, M.; Aygun, B.F. Unraveling the characteristics of geopolymer mortars: A deep dive into the impact of marble powder as fine aggregate and varied activators. Constr. Build. Mater. 2024, 422, 135767. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, Z.; Wang, H. Early hydration kinetics and microstructure development of hybrid alkali activated cements (HAACs) at room temperature. Cem. Concr. Compos. 2021, 123, 104200. [Google Scholar] [CrossRef]

- Mazaheri, A.; Bayat, A.; Hosinzadeh, F. Investigating the effect of alkali-activated slag on the strength of clay soil. Arab. J. Geosci. 2021, 14, 2662. [Google Scholar] [CrossRef]

- Sun, K.K.; Peng, X.Q.; Chu, S.H.; Wang, S.P.; Zeng, L.; Ji, G.X. Utilization of BOF steel slag aggregate in metakaolin-based geopolymer. Constr. Build. Mater. 2021, 300, 124024. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M. Behavior of alkali-activated slag pastes blended with waste rubber powder under the effect of freeze/thaw cycles and severe sulfate attack. Constr. Build. Mater. 2020, 265, 120716. [Google Scholar] [CrossRef]

- Xiao, R.; Shen, Z.; Si, R.; Polaczyk, P.; Li, Y.; Zhou, H.; Huang, B. Alkali-activated slag (AAS) and OPC-based composites containing crumb rubber aggregate: Physico-mechanical properties, durability and oxidation of rubber upon NaOH treatment. J. Clean. Prod. 2022, 367, 132896. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; Lai, D.; Yu, T.; Huang, D. Rubberized geopolymer concrete: Dependence of mechanical properties and freeze-thaw resistance on replacement ratio of crumb rubber. Constr. Build. Mater. 2021, 310, 125248. [Google Scholar] [CrossRef]

- Orhan, T.Y.; Karakoç, M.B.; Özcan, A. Durability characteristics of slag based geopolymer concrete modified with crumb rubber. Constr. Build. Mater. 2023, 404, 132851. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Benli, A.; Bodur, B.; Öz, A.; Kaplan, G. Performance assessment and cost analysis of slag/metakaolin based rubberized semi-lightweight geopolymers with perlite aggregate: Sustainable reuse of waste tires. Constr. Build. Mater. 2024, 411, 134655. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, G.; Htet, K.W.; Kwon, M.; Liu, C.; Xu, Y.; Tao, M. Freeze-thaw durability of red mud slurry-class F fly ash-based geopolymer: Effect of curing conditions. Constr. Build. Mater. 2019, 215, 381–390. [Google Scholar] [CrossRef]

- Yılmaz, A.; Degirmenci, F.N.; Aygörmez, Y. Effect of initial curing conditions on the durability performance of low-calcium fly ash-based geopolymer mortars. Bol. Soc. Esp. Cerám. Vidr. 2023, 63, 238–254. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, X.; Yu, Q. Effect of curing conditions on freeze-thaw resistance of geopolymer mortars containing various calcium resources. Constr. Build. Mater. 2021, 313, 125507. [Google Scholar] [CrossRef]

- Malik, M.A.; Sarkar, M.; Xu, S.L.; Li, Q.H. Effect of PVA/SiO2 NPs additive on the structural, durability, and fire resistance properties of geopolymers. Appl. Sci. 2019, 9, 1953. [Google Scholar] [CrossRef]

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Sorptivity and acid resistance of ambient-cured geopolymer mortars containing nano-silica. Cem. Concr. Compos. 2016, 72, 235–245. [Google Scholar] [CrossRef]

- Mustakim, S.M.; Das, S.K.; Mishra, J.; Aftab, A.; Alomayri, T.S.; Assaedi, H.S.; Kaze, C.R. Improvement in fresh, mechanical and microstructural properties of fly ash- blast furnace slag based geopolymer concrete by addition of nano and micro silica. Silicon 2021, 13, 2415–2428. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, P.; Dai, X.B.; Zheng, Y.X.; Feng, H. Assessment of bonding behavior of hybrid fiber alkali-activated concrete for tunnel lining concrete restoration. J. Clean. Prod. 2025, 514, 14. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, P.; Guo, J.J.; Zheng, Y.X.; Hu, S.W. Single and synergistic effects of nano-SiO2 and hybrid fiber on rheological property and compressive strength of geopolymer concrete. Constr. Build. Mater. 2025, 472, 15. [Google Scholar] [CrossRef]

- Zada Farhan, K.; Azmi Megat Johari, M.; Demirboğa, R. Evaluation of properties of steel fiber reinforced GGBFS-based geopolymer composites in aggressive environments. Constr. Build. Mater. 2022, 345, 128339. [Google Scholar] [CrossRef]

- Mermerdas, K.; Ipek, S.; Mahmood, Z. Visual inspection and mechanical testing of fly ash-based fibrous geopolymer composites under freeze-thaw cycles. Constr. Build. Mater. 2021, 283, 122756. [Google Scholar] [CrossRef]

- Nazir, K.; Canpolat, O.; Uysal, M. Durability properties of steel, polyamide, and polyethylene fiber-reinforced geopolymer mortar made with recycled concrete aggregate and glass powder as fillers. J. Build. Eng. 2023, 76, 107313. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Structural performance of nano-silica modified fly-ash based geopolymer concrete. Constr. Build. Mater. 2017, 135, 430–439. [Google Scholar] [CrossRef]

- Wang, W.S.; Zhang, P.; Dai, X.B.; Zheng, Y.X.; Hu, S.W. Workability of self-compacting geopolymer concrete: The effect of nano-SiO2 and steel-polyvinyl alcohol hybrid fiber. Constr. Build. Mater. 2025, 460, 12. [Google Scholar] [CrossRef]

- Wang, W.J.; Zhong, Z.W.; Kang, X.; Ma, X.Y. Physico-mechanical properties and micromorphological characteristics of graphene oxide reinforced geopolymer foam concrete. J. Build. Eng. 2023, 72, 106732. [Google Scholar] [CrossRef]

- Miyan, N.; Omur, T.; Amed, B.; Özkan, H.; Aydin, R.; Kabay, N. Recycled waste concrete and metakaolin based alkali-activated paste: Characterization, optimization, and life cycle assessment. Constr. Build. Mater. 2024, 416, 16. [Google Scholar] [CrossRef]

- Pilehvar, S.; Szczotok, A.M.; Rodríguez, J.F.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjoniksen, A.L. Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 2019, 200, 94–103. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. A review of salt scaling: II. Mechanisms. Cem. Concr. Res. 2007, 37, 1022–1034. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-thaw resistance of class F fly ash-based geopolymer concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Tian, L.Y.; He, D.P.; Zhao, J.N.; Wang, H.G. Durability of geopolymers and geopolymer concretes: A review. Rev. Adv. Mater. Sci. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- Zhang, P.; Wen, Z.; Han, X.; Guo, J.; Hu, S. A state-of-the-art review on frost resistance of fiber-reinforced geopolymer composites. Sustain. Chem. Pharm. 2025, 45, 102006. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Rao, F.; Tian, X. Gel Evolution of Copper Tailing-Based Green Geopolymers in Marine Related Environments. Materials 2022, 15, 4599. [Google Scholar] [CrossRef]

- Chen, J.; Bai, B.; Du, Q. Durability evaluation of a high-performance red mud-based composite material. Mater. Today Commun. 2024, 39, 108684. [Google Scholar] [CrossRef]

- Bahafid, S.; Hendriks, M.; Jacobsen, S.; Geiker, M. Revisiting concrete frost salt scaling: On the role of the frozen salt solution micro-structure. Cem. Concr. Res. 2022, 157, 106803. [Google Scholar] [CrossRef]

- Zhang, H.E.; Sarker, P.K.; Xiao, L.; Ai, J.H.; He, B.; Ren, Q.; Zhu, X.P.; Zhang, Y. Durability of low-carbon geopolymer mortar: Different responses to cryogenic attack caused by water content and freeze-thaw mediums. Cem. Concr. Compos. 2023, 139, 105065. [Google Scholar] [CrossRef]

- Fan, L.F.; Zhong, W.L.; Wang, G.; Xi, Y. Optimal slag content for geopolymer composites under freeze-thaw cycles with different freezing temperatures. J. Zhejiang Univ.-SCI A 2023, 24, 366–376. [Google Scholar] [CrossRef]

- Zhong, W.L.; Wang, G.; Xi, Y.; Fan, L.F. Damage evaluation of geopolymer under three freezing-thawing treatments with different freezing temperatures based on ultrasonic technique. J. Build. Eng. 2023, 69, 106268. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen-Chong, T.; Dangla, P. A study of the behaviors of cement-based materials subject to freezing. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, MACE 2010, Wuhan, China, 26–28 June 2010; pp. 1611–1616. [Google Scholar] [CrossRef]

- Das, S.; Yang, P.; Singh, S.S.; Mertens, J.C.E.; Xiao, X.; Chawla, N.; Neithalath, N. Effective properties of a fly ash geopolymer: Synergistic application of X-ray synchrotron tomography, nanoindentation, and homogenization models. Cem. Concr. Res. 2015, 78, 252–262. [Google Scholar] [CrossRef]

- Powers, T.C.; Helmuth, R.A. Theory of Volume Changes in Hardened Portland Cement Paste During Freezing. In Proceedings of the Highway Research Board Proceedings, Washington, DC, USA, 13–16 January 1953. [Google Scholar]

- Sun, M.; Xin, D.; Zou, C. Damage evolution and plasticity development of concrete materials subjected to freeze-thaw during the load process. Mech. Mater. 2019, 139, 103192. [Google Scholar] [CrossRef]

- Valenza II, J.J.; Scherer, G.W. Mechanism for Salt Scaling. J. Am. Ceram. Soc. 2006, 89, 1161–1179. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. Mechanism for salt scaling of a cementitious surface. Mater. Struct. 2007, 40, 259–268. [Google Scholar] [CrossRef]

- Scherer, G.W. Characterization of saturated porous bodies. Mater. Struct. 2004, 37, 21–30. [Google Scholar] [CrossRef]

- Ali, N.; Canpolat, O.; Aygörmez, Y.; Al-Mashhadani, M.M. Evaluation of the 12-24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Constr. Build. Mater. 2020, 251, 118976. [Google Scholar] [CrossRef]

- Liang, G.W.; Zhu, H.J.; Li, H.X.; Liu, T.J.; Guo, H.H. Comparative study on the effects of rice husk ash and silica fume on the freezing resistance of metakaolin-based geopolymer. Constr. Build. Mater. 2021, 293, 123486. [Google Scholar] [CrossRef]

- Nemecek, J.; Smilauer, V.; Kopecky, L. Nanoindentation characteristics of alkali-activated aluminosilicate materials. Cem. Concr. Compos. 2011, 33, 163–170. [Google Scholar] [CrossRef]

- Feng, B.W.; Liu, J.S. Durability of repair metakaolin geopolymeric cement under different factors. Processes 2022, 10, 1818. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J. Experimental study on the durability of alkali-activated slag concrete after freeze-thaw cycle. Adv. Mater. Sci. Eng. 2021, 2021, 9915639. [Google Scholar] [CrossRef]

- Provis, J.L.; Myers, R.J.; White, C.E.; Rose, V.; van Deventer, J.S.J. X-ray microtomography shows pore structure and tortuosity in alkali-activated binders. Cem. Concr. Res. 2012, 42, 855–864. [Google Scholar] [CrossRef]

- Ravikumar, D.; Peethamparan, S.; Neithalath, N. Structure and strength of NaOH activated concretes containing fly ash or GGBFS as the sole binder. Cem. Concr. Compos. 2010, 32, 399–410. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjigmaa, A.; Davaabal, B.; Bayarzul, U.; Ankhtuya, A.; Jadambaa, T.; MacKenzie, K.J.D. Utilization of radioactive high-calcium Mongolian flyash for the preparation of alkali-activated geopolymers for safe use as construction materials. Ceram. Int. 2014, 40, 16475–16483. [Google Scholar] [CrossRef]

- Ugurlu, A.I.; Karakoc, M.B.; Ozcan, A. Effect of binder content and recycled concrete aggregate on freeze-thaw and sulfate resistance of GGBFS based geopolymer concretes. Constr. Build. Mater. 2021, 301, 124246. [Google Scholar] [CrossRef]

- Melo Neto, A.A.; Cincotto, M.A.; Repette, W. Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Zhang, B.; Yan, B.; Li, Y. Study on mechanical properties, freeze–thaw and chlorides penetration resistance of alkali activated granulated blast furnace slag-coal gangue concrete and its mechanism. Constr. Build. Mater. 2023, 366, 130218. [Google Scholar] [CrossRef]

- Turkoglu, M.; Bayraktar, O.Y.; Benli, A.; Kaplan, G. Effect of cement clinker type, curing regime and activator dosage on the performance of one-part alkali-activated hybrid slag/clinker composites. J. Build. Eng. 2023, 68, 106164. [Google Scholar] [CrossRef]

- Tekle, B.H.; Ly, T.V.; Hertwig, L.; Holschemacher, K. Freeze-thaw resistance and sorptivity of fine-grained alkali-activated cement concrete. Struct. Concr. 2023, 24, 4286–4296. [Google Scholar] [CrossRef]

- Ling, Y.F.; Wang, K.J.; Wang, X.H.; Hua, S.D. Effects of mix design parameters on heat of geopolymerization, set time, and compressive strength of high calcium fly ash geopolymer. Constr. Build. Mater. 2019, 228, 116763. [Google Scholar] [CrossRef]

- Ruiz-Santaquiteria, C.; Skibsted, J.; Fernández-Jiménez, A.; Palomo, A. Alkaline solution/binder ratio as a determining factor in the alkaline activation of aluminosilicates. Cem. Concr. Res. 2012, 42, 1242–1251. [Google Scholar] [CrossRef]

- Han, X.Y.; Ding, N.; Chen, A.J.; Wang, Z.H.; Xu, Y.; Feng, L.Y.; Ji, Y.T.; Li, K.L.; Jing, J.L.; Sun, S.; et al. Experimental study on freeze-thaw failure of concrete incorporating waste tire crumb rubber and analytical evaluation of frost resistance. Constr. Build. Mater. 2024, 439, 137356. [Google Scholar] [CrossRef]

- Coussy, O.; Monteiro, P.J.M. Poroelastic model for concrete exposed to freezing temperatures. Cem. Concr. Res. 2008, 38, 40–48. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, B.; He, Y.Z.; Li, F.; Long, G.C.; Du, Y.F. Preparation and properties of sustainable magnesium phosphate cement composites with recycled tire rubber particles. J. Clean. Prod. 2020, 262, 121253. [Google Scholar] [CrossRef]

- Nazarpour, H.; Jamali, M. Mechanical and freezing cycles properties of geopolymer concrete with recycled aggregate. Struct. Concr. 2020, 21, 1004–1012. [Google Scholar] [CrossRef]

- Saccani, A.; Manzi, S.; Lancellotti, I.; Barbieri, L. Manufacturing and durability of alkali activated mortars containing different types of glass waste as aggregates valorisation. Constr. Build. Mater. 2020, 237, 117733. [Google Scholar] [CrossRef]

- Zhu, H.G.; Yang, S.; Li, W.J.; Li, Z.H.; Fan, J.C.; Shen, Z.Y. Study of mechanical properties and durability of alkali-activated coal gangue-slag concrete. Materials 2020, 13, 5576. [Google Scholar] [CrossRef]

- Tammam, Y.; Uysal, M.; Canpolat, O.; Kuranli, Ö. Effect of waste filler materials and recycled waste aggregates on the production of geopolymer composites. Arab. J. Sci. Eng. 2023, 48, 4823–4840. [Google Scholar] [CrossRef]

- Wang, D.H.; Shi, C.J.; Farzadnia, N.; Shi, Z.G.; Jia, H.F.; Ou, Z.H. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Tammam, Y.; Uysal, M.; Canpolat, O. Effects of alternative ecological fillers on the mechanical, durability, and microstructure of fly ash-based geopolymer mortar. Eur. J. Environ. Civ. Eng. 2022, 26, 5877–5900. [Google Scholar] [CrossRef]

- Sahin, F.; Uysal, M.; Canpolat, O. Systematic evaluation of the aggregate types and properties on metakaolin based geopolymer composites. Constr. Build. Mater. 2021, 278, 122414. [Google Scholar] [CrossRef]

- Ahiskali, A.; Ahiskali, M.; Bayraktar, O.Y.; Kaplan, G.; Assaad, J. Mechanical and durability properties of polymer fiber reinforced one-part foam geopolymer concrete: A sustainable strategy for the recycling of waste steel slag aggregate and fly ash. Constr. Build. Mater. 2024, 440, 137492. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Sahin, F.; Uysal, M.; Canpolat, O.; Cosgun, T.; Dehghanpour, H. The effect of polyvinyl fibers on metakaolin-based geopolymer mortars with different aggregate filling. Constr. Build. Mater. 2021, 300, 124257. [Google Scholar] [CrossRef]

- Moghadam, A.S.; Roshan, A.M.G.; Omidinasab, F. Utilization of agricultural wastes as fiber, binder and aggregates of geopolymer mortars: Application of taguchi method for strength and durability optimization. J. Build. Eng. 2023, 75, 106906. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of curing schedule on the integrity of geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M. Assessment of geopolymer composites durability at one year age. J. Build. Eng. 2020, 32, 101453. [Google Scholar] [CrossRef]

- Alnkaa, A.A.; Danish, A.; Yaprak, H.; Memis, S.; Gencel, O.; Amran, M.; Ozbakkaloglu, T. Performance evaluation and cost analysis of ternary blended geopolymers for sustainable built environment under different curing regimes. Constr. Build. Mater. 2023, 409, 133842. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Nicolas, R.S.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Kuranlı, Ö.F.; Uysal, M.; Abbas, M.T.; Cosgun, T.; Niş, A.; Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M. Evaluation of slag/fly ash based geopolymer concrete with steel, polypropylene and polyamide fibers. Constr. Build. Mater. 2022, 325, 126747. [Google Scholar] [CrossRef]

- Şahin, F.; Uysal, M.; Canpolat, O.; Aygörmez, Y.; Cosgun, T.; Dehghanpour, H. Effect of basalt fiber on metakaolin-based geopolymer mortars containing rilem, basalt and recycled waste concrete aggregates. Constr. Build. Mater. 2021, 301, 124113. [Google Scholar] [CrossRef]

- Arslan, A.A.; Uysal, M.; Yilmaz, A.; Al-mashhadani, M.M.; Canpolat, O.; Sahin, F.; Aygörmez, Y. Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Falah, M.; Shaad, K.M.; Luukkonen, T.; Illikainen, M. Durability of the reinforced one-part alkali-activated slag mortars with different fibers. Waste Biomass Valorization 2021, 12, 487–501. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, P.; Guo, J.; Gao, Z. Single and synergistic enhancement on durability of geopolymer mortar by polyvinyl alcohol fiber and nano-SiO2. J. Mater. Res. Technol.-JMRT 2021, 15, 1801–1814. [Google Scholar] [CrossRef]

- Zhang, P.; Feng, Z.; Guo, J.J.; Zheng, Y.X.; Yuan, P. Mechanical behavior and microscopic damage mechanism of hybrid fiber-reinforced geopolymer concrete at elevated temperature. Ceram. Int. 2024, 50, 53851–53866. [Google Scholar] [CrossRef]

- Ozcelikci, E.; Ozdogru, E.; Tugluca, M.S.; Ilcan, H.; Sahmaran, M. Comprehensive investigation of performance of construction and demolition waste based wood fiber reinforced geopolymer composites. J. Build. Eng. 2024, 84, 108682. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar—A review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Yio, M.H.N.; Wong, H.S.; Ghaffar, S.H. Upcycling end-of-life bricks in high-performance one-part alkali-activated materials. Dev. Built Environ. 2023, 16, 100231. [Google Scholar] [CrossRef]

- Zeng, H.Y.; Lai, Y.M.; Qu, S.; Yu, F. Exploring the effect of graphene oxide on freeze-thaw durability of air-entrained mortars. Constr. Build. Mater. 2022, 324, 126708. [Google Scholar] [CrossRef]

- Zidi, Z.; Ltifi, M.; Ben Ayadi, Z.; El Mir, L.; Nóvoa, X.R. Effect of nano-ZnO on mechanical and thermal properties of geopolymer. J. Asian Ceram. Soc. 2020, 8, 1–9. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Seloglu, M.; Coskun, A. The effect of nano zinc oxide on freeze-thaw resistance of 3D-printed geopolymer mortars. J. Build. Eng. 2024, 96, 110431. [Google Scholar] [CrossRef]

- Farooq, M.A.; Sato, Y.; Niitani, K. Experimental investigation of monotonic behavior and stress-strain models of AE and non-AE high strength concrete with BFS fine aggregates under freezing and thawing. Constr. Build. Mater. 2020, 249, 118679. [Google Scholar] [CrossRef]

- Shang, H. Triaxial T-C-C behavior of air-entrained concrete after freeze–thaw cycles. Cold Reg. Sci. Technol. 2013, 89, 1–6. [Google Scholar] [CrossRef]

- Liu, K.; Yan, J.; Hu, Q.; Sun, Y.; Zou, C. Effects of parent concrete and mixing method on the resistance to freezing and thawing of air-entrained recycled aggregate concrete. Constr. Build. Mater. 2016, 106, 264–273. [Google Scholar] [CrossRef]

- Wu, Z.; Libre, N.A.; Khayat, K.H. Factors affecting air-entrainment and performance of roller compacted concrete. Constr. Build. Mater. 2020, 259, 120413. [Google Scholar] [CrossRef]

- Li, X.; Sun, G.X. Optimal freeze-thaw resistance air-entrained concrete with designed nanoparticle stabilised bubble system. Constr. Build. Mater. 2024, 435, 136769. [Google Scholar] [CrossRef]

- Sun, P.; Wu, H.-C. Chemical and freeze-thaw resistance of fly ash-based inorganic mortars. Fuel 2013, 111, 740–745. [Google Scholar] [CrossRef]

- Brooks, R.M.; Bahadory, M.; Tovia, F.; Rostami, H. Properties of alkali-activated fly ash: High performance to lightweight. Int. J. Sustain. Eng. 2010, 3, 211–218. [Google Scholar] [CrossRef]

- Zahedi, A.; Komar, A.; Sanchez, L.F.M.; Boyd, A.J. Global assessment of concrete specimens subjected to freeze-thaw damage. Cem. Concr. Compos. 2022, 133, 104716. [Google Scholar] [CrossRef]

- Sun, Q.; Li, B.T.; Wang, H.; Wang, Y.T. Degradation mechanism and life prediction of tailings and waste rock aggregate geopolymer concrete under freeze-thaw corrosion (vol 9, 015506, 2022). Mater. Res. Express 2022, 9, 049502. [Google Scholar] [CrossRef]

- Wu, T.Y.; Wu, J.; Zheng, C.J.; Wang, J. Evaluation of freeze-thaw resistance of geopolymer concrete incorporating GFRP waste powder. J. Build. Eng. 2024, 90, 109465. [Google Scholar] [CrossRef]

- Moein, M.M.; Saradar, A.; Rahmati, K.; Mousavinejad, S.H.G.; Bristow, J.; Aramali, V.; Karakouzian, M. Predictive models for concrete properties using machine learning and deep learning approaches: A review. J. Build. Eng. 2023, 63, 41. [Google Scholar] [CrossRef]

- Abadel, A.A.; Alghamdi, H. Effect of high volume tile ceramic wastes on resistance of geopolymer mortars to abrasion and freezing-thawing cycles: Experimental and deep learning modelling. Ceram. Int. 2023, 49, 15065–15081. [Google Scholar] [CrossRef]

- Yao, C.Q.; Hu, G.; Chen, Q.Y.; Wu, J. Prediction on the freeze-thaw resistance of a one-part geopolymer stabilized soil by using deep learning method. Case Stud. Constr. Mater. 2024, 21, e03530. [Google Scholar] [CrossRef]

- Zhang, X.M.; Zhang, P.; Yuan, W.S.; Hu, S.W. Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network. Nanotechnol. Rev. 2024, 13, 20230214. [Google Scholar] [CrossRef]

| Precursor | Type | Sample Size (mm) | Temperature Range (°C) | F-T Cycles | Compressive Strength Loss | RDME Loss | Weight Loss | Ref. |

|---|---|---|---|---|---|---|---|---|

| FA | Geopolymer concrete | 100 × 100 cylinder | −22~24 | 21 | / | / | 28.20% | [19] |

| FA/slag | Geopolymer concrete | 100 × 100 × 400 prism | −18~4 | 125 | 4.30% | 53.10% | 0.70% | [48] |

| FA/slag | Geopolymer concrete | 100 × 100 cylinder | −22~24 | 56 | / | / | 0.10% | [19] |

| Slag | Geopolymer concrete | 100 × 100 × 400 prism | −18~5 | 300 | / | 8.51% | −0.48% | [17] |

| Slag | Geopolymer concrete | 100 × 100 × 400 prism | −18~5 | 300 | 13.41% | 36.33% | 1.02% | [68] |

| FA/slag | Geopolymer mortar | 100 × 100 × 400 prism | −18~5 | 300 | / | / | 0.80% | [33] |

| Volcanic tuff | Geopolymer mortar | 50 × 50 × 50 cube | −16~3 | 300 | 19.70% | 37.70% | / | [18] |

| MK/slag | Geopolymer mortar | 50 × 50 × 50 cube | −20~20 | 90 | 34.33% | / | 0.74% | [64] |

| MK | Geopolymer mortar | 30 × 30 × 30 cube | −18~5 | 50 | 63.30% | / | 20.24% | [65] |

| Precursor | Curing Condition | Temperature Range (°C) | Sample Size (mm) | F-T Cycles | Compressive Strength Loss | RDME Loss | Weight Loss | Ref. |

|---|---|---|---|---|---|---|---|---|

| FA-RMS | ① Sealed curing under 23 °C and RH 40–50%—14 d | −10~4 | 50.8 × 101.6 cylinder | 50 | 34.40% | / | 3.83% | [31] |

| FA-RMS | ① Sealed curing under 23 °C and RH 40–50%—14 d ② Standard curing-14 d | −10~4 | 50.8 × 101.6 cylinder | 44 | / | / | 20.57% | [31] |

| FA-RMS | ① Sealed curing under 50 °C—7 d ② Sealed curing under 23 °C and RH 40–50%—7 d | −10~4 | 50.8 × 101.6 cylinder | 50 | 1.63% | / | −3.09% | [31] |

| FA-RMS | ① Sealed curing under 50 °C—7 d ② Sealed curing under 23 °C and RH 40–50%—7 d ③ Ambient curing under 23 °C and RH 40–50%—14 d | −10~4 | 50.8 × 101.6 cylinder | 50 | 50.2% | / | −9.49% | [31] |

| FA-RMS | ① Sealed curing under 80 °C—24 h ② Sealed curing under 23 °C and RH 40–50%—13 d | −10~4 | 50.8 × 101.6 cylinder | 50 | 3.83% | / | −8.18% | [31] |

| FA-RMS | ① Sealed curing under 80 °C—24 h ② Sealed curing under 23 °C and RH 40–50%—13 d ③ Ambient curing under 23 °C and RH 40–50%—14 d | −10~4 | 50.8 × 101.6 cylinder | 50 | 51.21% | / | −2.87% | [31] |

| MK | ① Sealed curing under 60 °C—3 d ② Sealed curing—25 d | −20~20 | 100 × 100 × 100 cube | 90 | 34.28% | / | 0.74% | [64] |

| MK | ① Sealed curing under 60 °C—3 d ② Sealed curing—25 d | −18~4 | 100 × 100 × 400 prism | 300 | 28.70% | / | 0.43% | [90] |

| MK | ① Steam curing under 50 °C—28 d | −18~5 | 30 × 30 × 30 cube | 50 | 63.30% | / | 20.24% | [65] |

| Class F FA–Slag | ① Standard curing—24 d | −18~5 | 100 × 100 × 400 prism | 100 | / | −2.41% | 0.12% | [33] |

| Class F FA–Slag | ① Steam curing under 60 °C—24 h ② Standard curing—23 d | −18~5 | 100 × 100 × 400 prism | 100 | / | 40.12% | −0.47% | [33] |

| Class C FA | ① Standard curing—24 d | −18~5 | 100 × 100 × 400 prism | 100 | / | 3.89% | 16.50% | [33] |

| Class C FA | ① Steam curing under 60 °C—24 h ② Standard curing—23 d | −18~5 | 100 × 100 × 400 prism | 100 | / | 4.51% | 1.05% | [33] |

| Slag | ① Steam curing under 85 °C—12 h ② Standard curing—27.5 d | −20~20 | 40 × 40 × 160 prism | 150 | 17.05% | / | 1.77% | [96] |

| Slag | ① Standard curing—24 d | −18~5 | 100 × 100 × 400 prism | 150 | 21.87% | 6.74% | 0.54% | [68] |

| Slag | ① Water curing—90 d | −18~4 | 100 × 100 × 100 cube | 300 | 6.14% | / | 4.50% | [97] |

| Slag | ① Sealed curing under 80 °C—24 h ② Water curing—27 d | −18~4 | 50 × 50 × 50 cube | 100 | 12.04% | / | 0.71% | [72] |

| Type | AEA Content | Sample Size (mm) | Temperature Range (°C) | F-T Cycles | Compressive Strength Loss | RDME Loss | Weight Loss | Ref. |

|---|---|---|---|---|---|---|---|---|

| Geopolymer mortar | 0% | 23.5 × 23.5 × 50.8 prism | −18~4 | 300 | 5.00% | 8.40% | 0.12% | [117] |

| Geopolymer mortar | 0.20% | 23.5 × 23.5 × 50.8 prism | −18~4 | 300 | 0% | 6.80% | 0.17% | [117] |

| Geopolymer mortar | 0% | 100 × 100 × 400 prism | −18~4 | 300 | 28.31% | / | 0.43% | [90] |

| Geopolymer mortar | 0.10% | 100 × 100 × 400 prism | −18~4 | 300 | 23.73% | / | 0.12% | [90] |

| F-T Evaluation Model | F-T Damage Model | Evaluating Index | Ref. |

|---|---|---|---|

| R2: 0.910~0.986 | [14] | ||

| R2: 0.936~0.992 | [84] | ||

| R2: 0.974~0.996 | [84] | ||

| R2: 0.950 | [15] | ||

| R2: 0.790 | [15] | ||

| R2: 0.958 | [15] | ||

| R2: 0.998 | [15] | ||

| R2: 0.860 | [15] | ||

| R2: 0.600 | [15] | ||

| R2: 0.971 | [15] | ||

| R2: 0.897 | [15] | ||

| RSME: 0.030 | [120] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Shi, B.; Dai, X.; Chen, C.; Lai, C. A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models. Gels 2025, 11, 537. https://doi.org/10.3390/gels11070537

Zhang P, Shi B, Dai X, Chen C, Lai C. A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models. Gels. 2025; 11(7):537. https://doi.org/10.3390/gels11070537

Chicago/Turabian StyleZhang, Peng, Baozhi Shi, Xiaobing Dai, Cancan Chen, and Canhua Lai. 2025. "A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models" Gels 11, no. 7: 537. https://doi.org/10.3390/gels11070537

APA StyleZhang, P., Shi, B., Dai, X., Chen, C., & Lai, C. (2025). A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models. Gels, 11(7), 537. https://doi.org/10.3390/gels11070537