A Study on the Performance of Gel-Based Polyurethane Prepolymer/Ceramic Fiber Composite-Modified Asphalt

Abstract

1. Introduction

2. Results and Discussion

2.1. The Best Preparation Scheme of PUP/CF Composite-Modified Asphalt

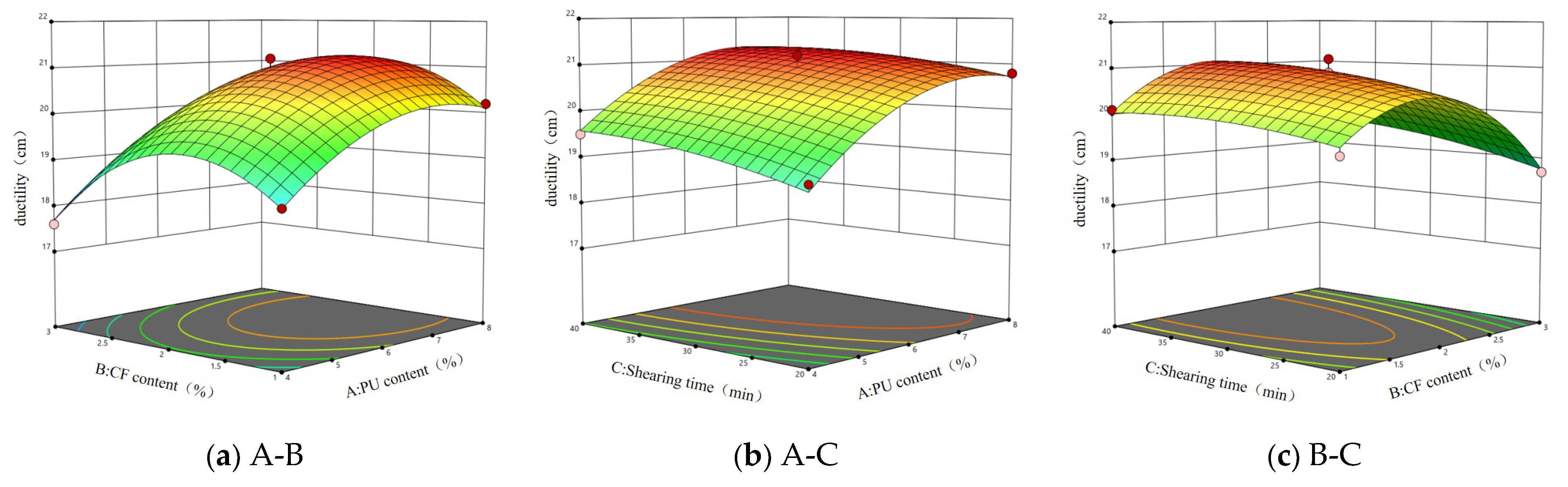

2.1.1. Analysis of Response Surface Method Test Results

2.1.2. Response Surface Optimization

2.1.3. Validation of the Best Dosage of Composite Modification

2.2. Aging Performance Analysis

2.3. Analysis of Dynamic Shear Rheological Test

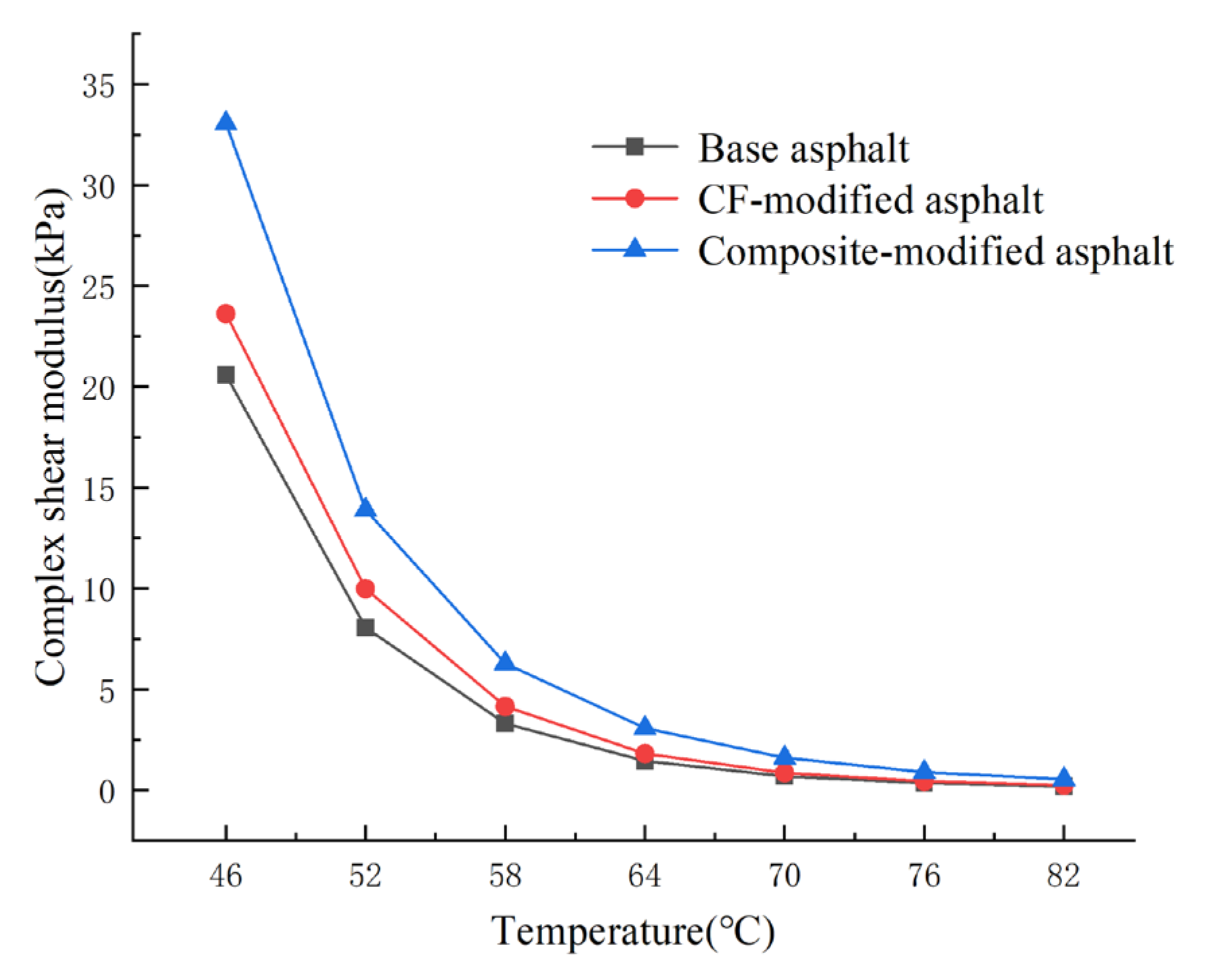

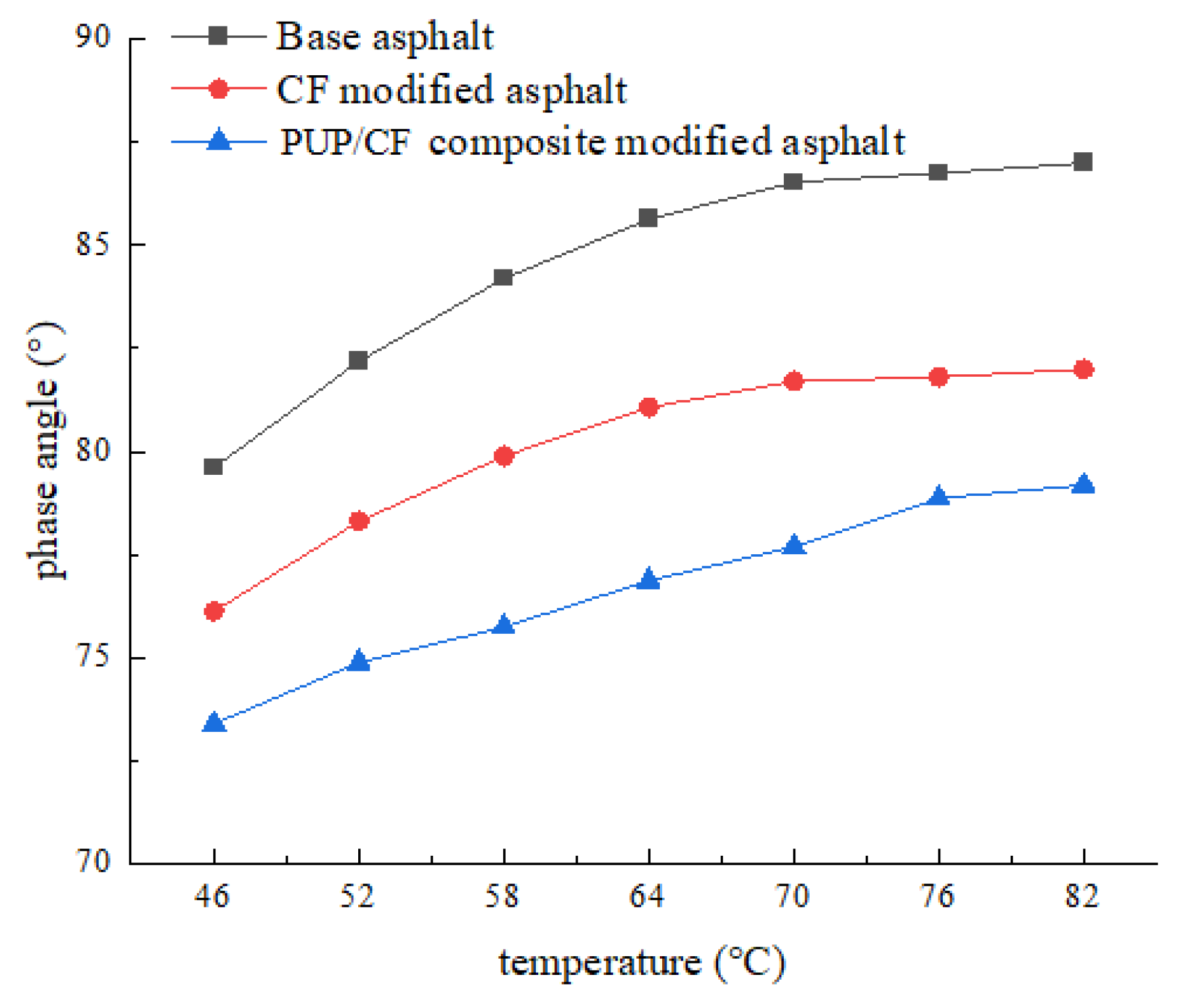

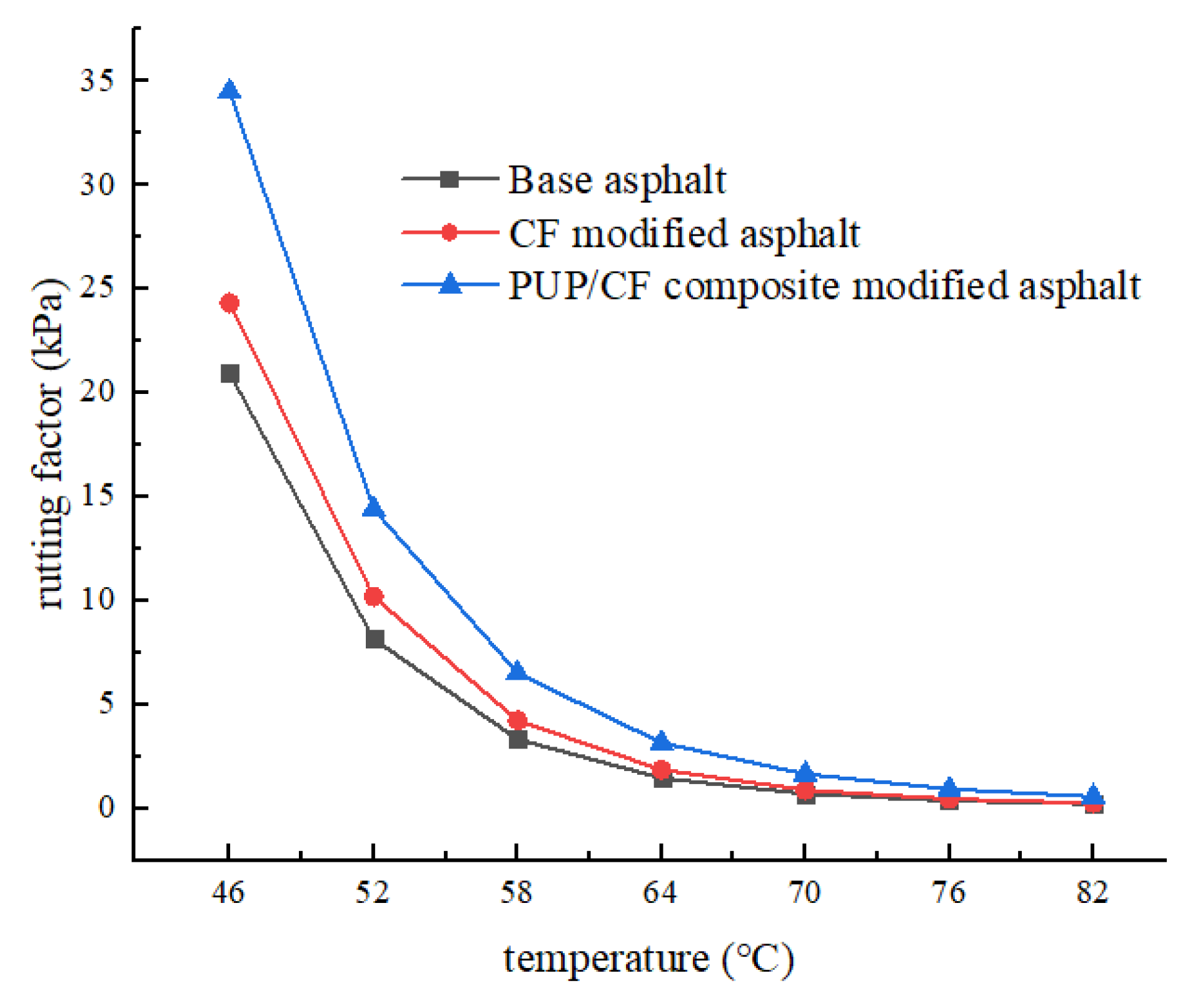

2.3.1. Temperature Scanning Analysis

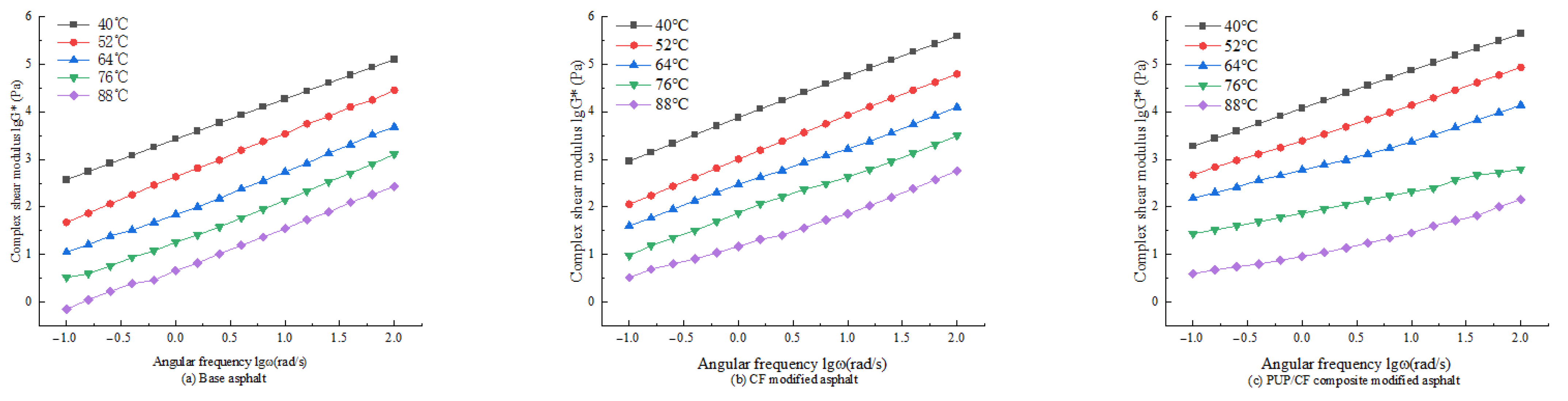

2.3.2. Frequency Scanning Analysis

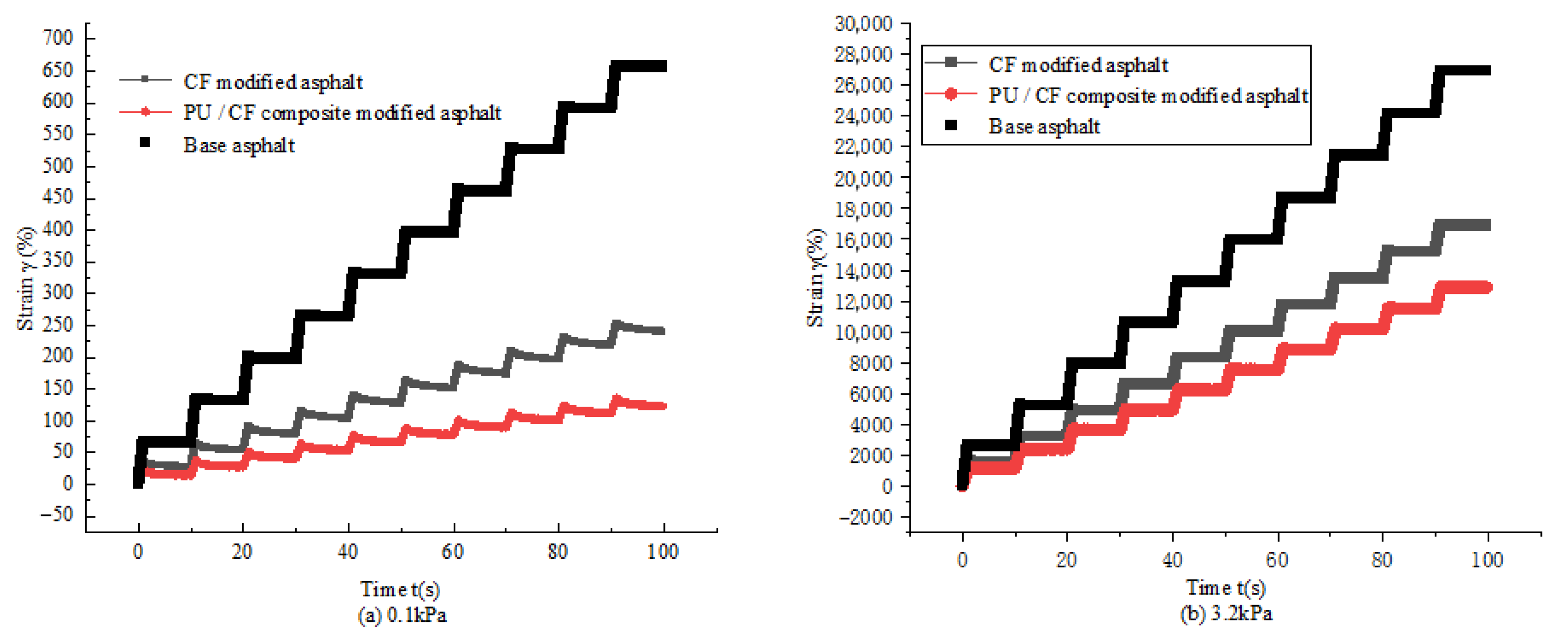

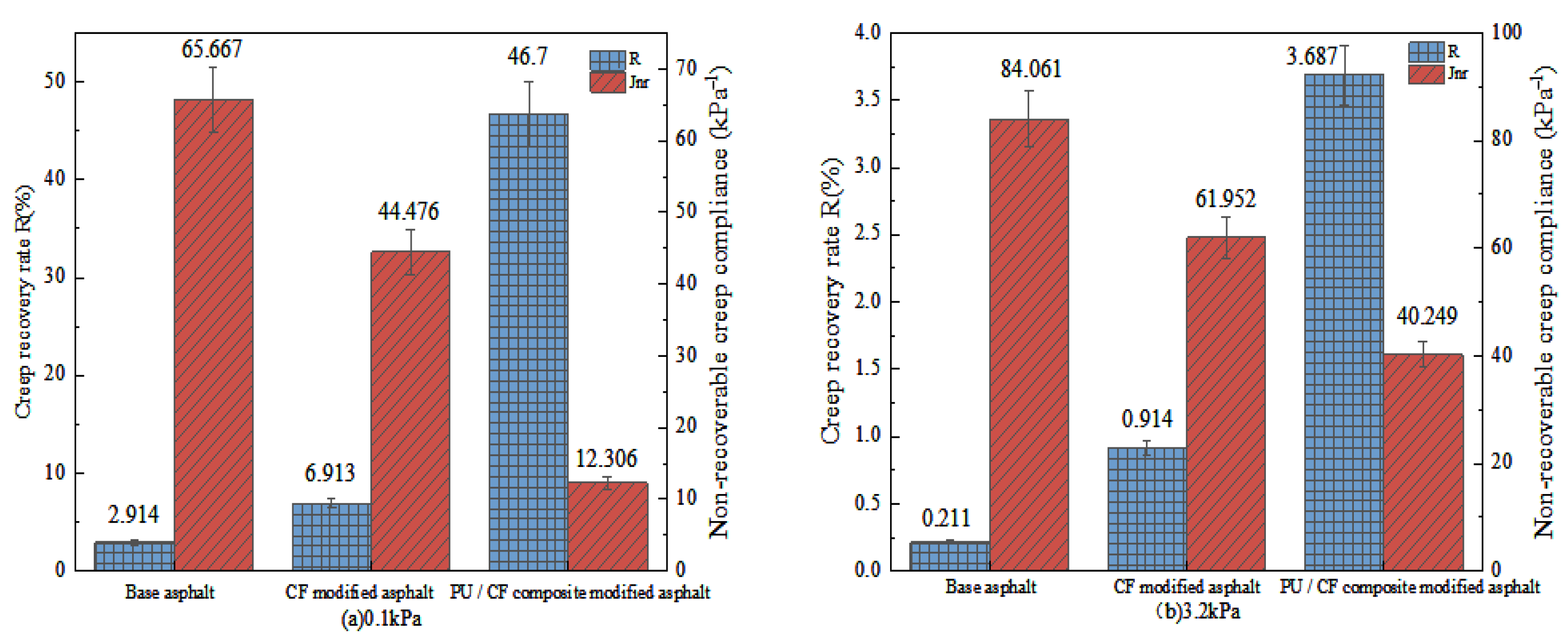

2.4. Multi-Stress Creep Recovery Test

2.5. Bending Creep Stiffness Test Analysis

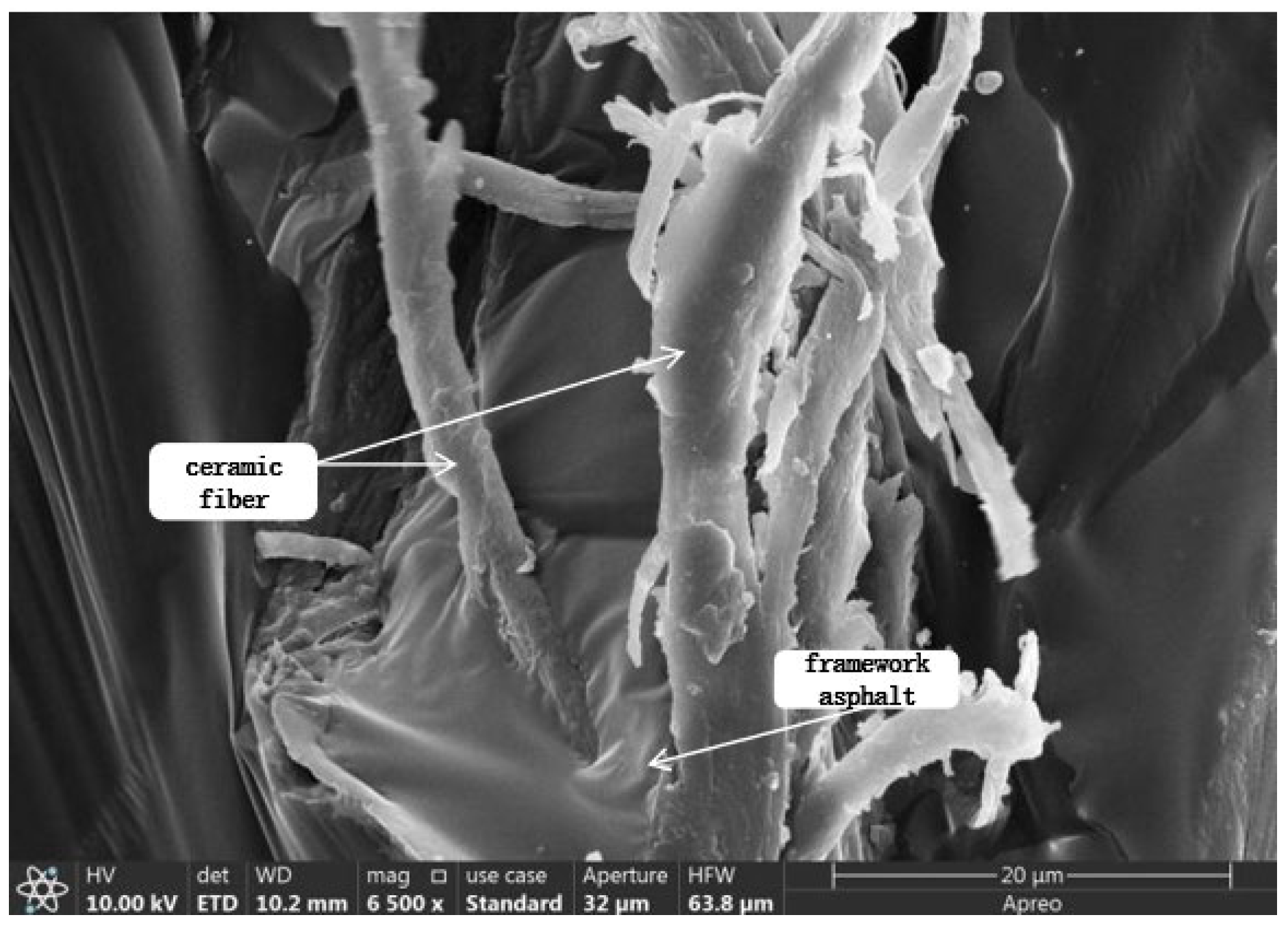

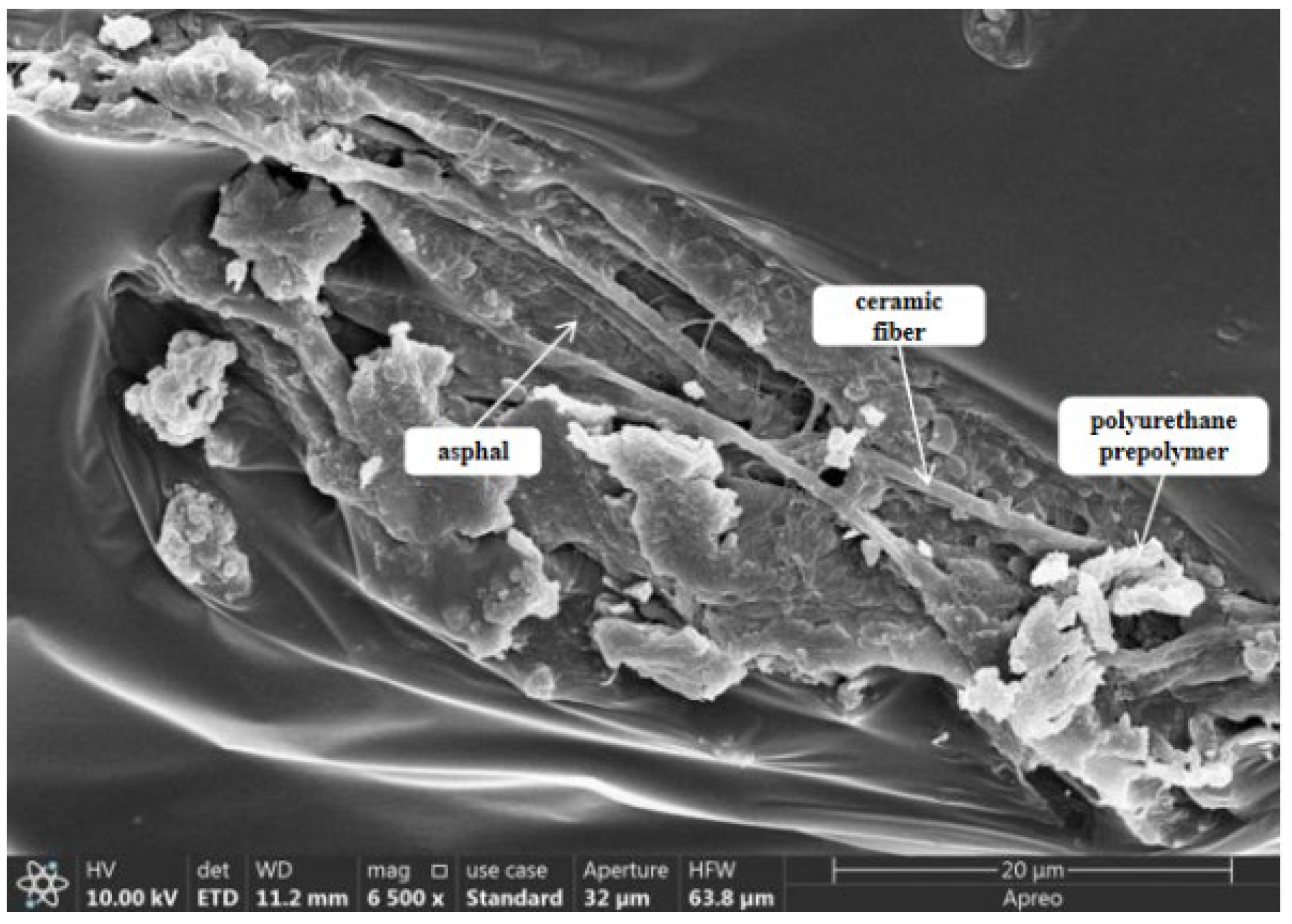

2.6. Scanning Electron Microscope Test Analysis

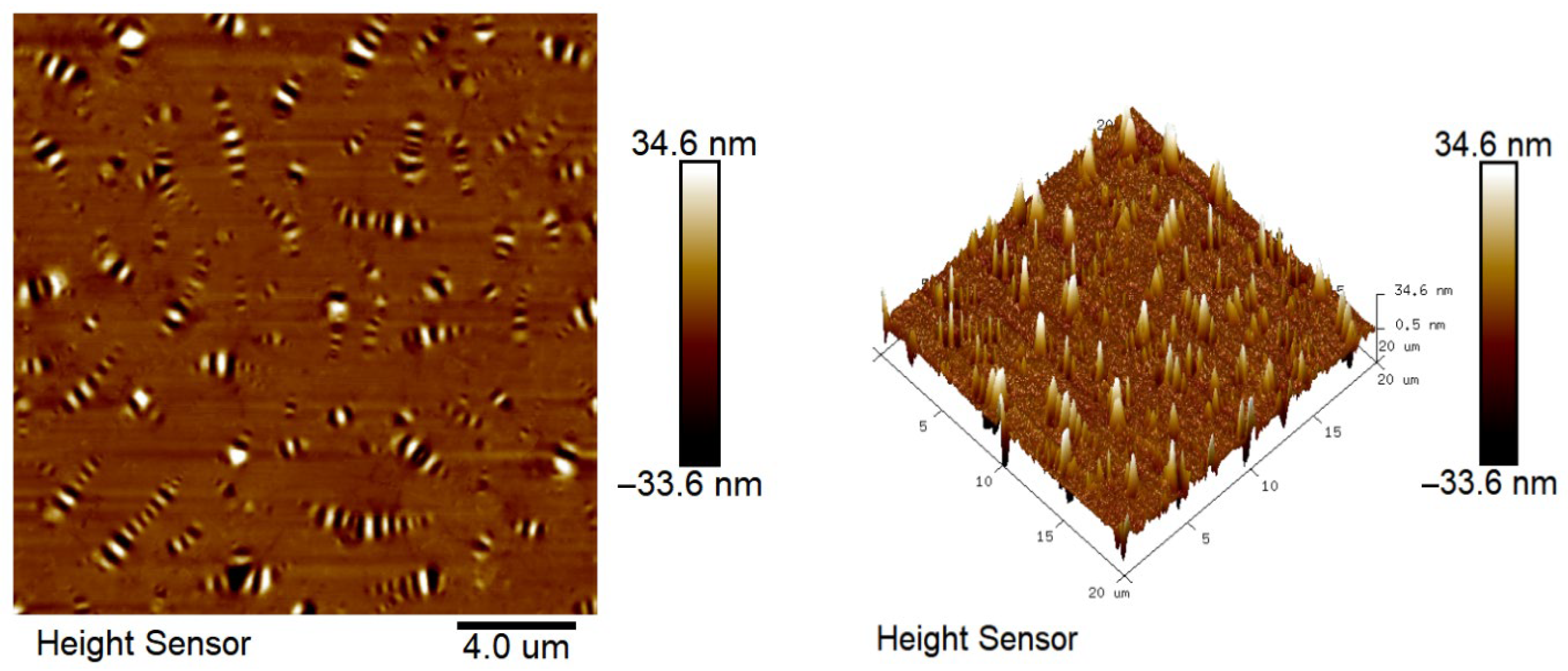

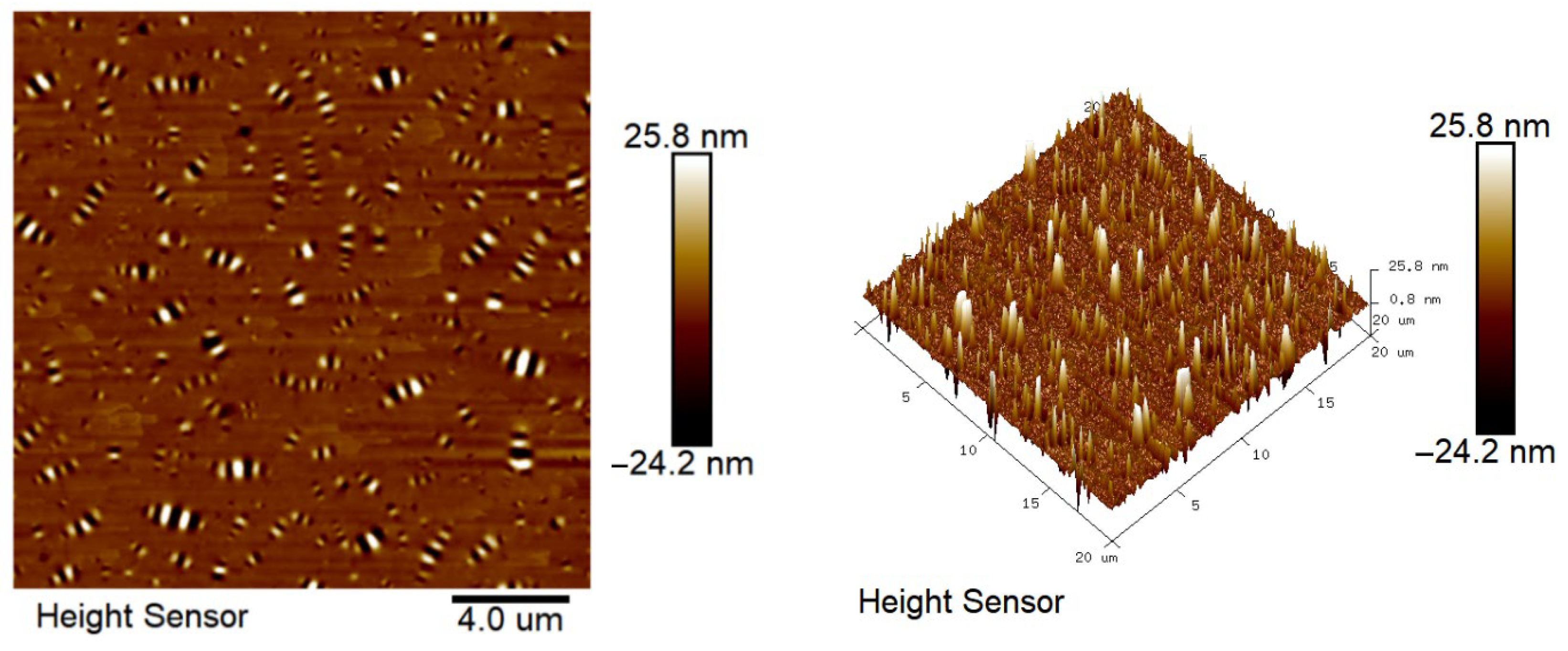

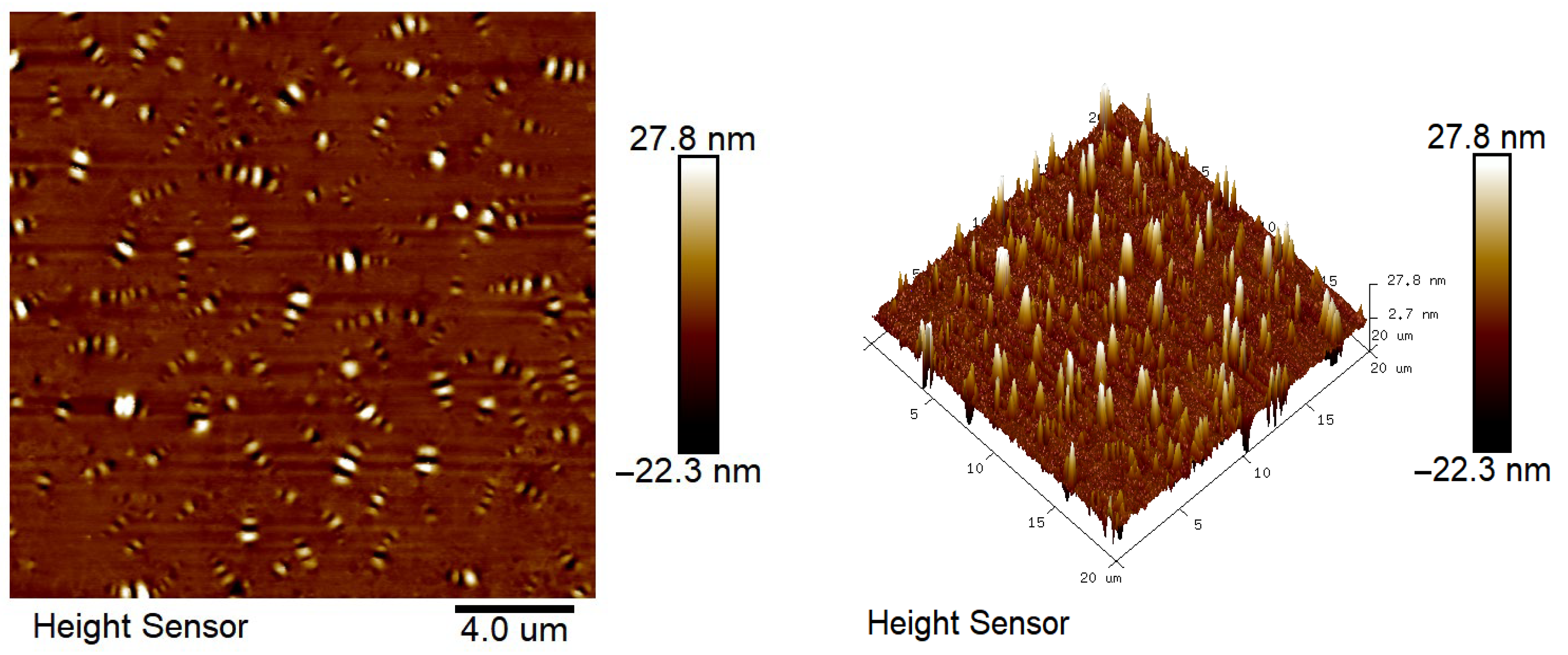

2.7. Atomic Force Microscope Test Analysis

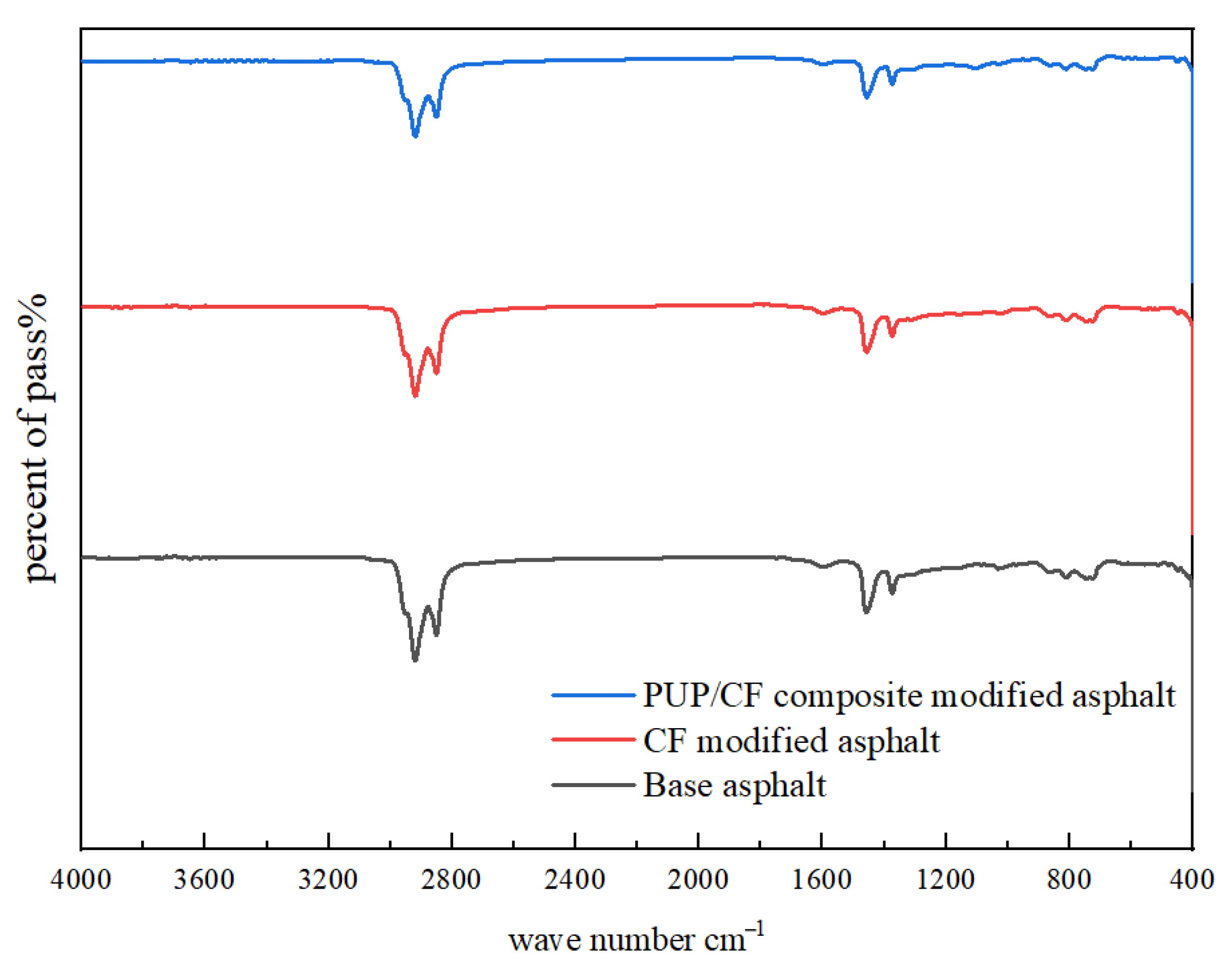

2.8. Infrared Spectrum Test Analysis

3. Conclusions

- (1)

- The three-factor and three-level optimization test was designed using the response surface method, and 17 groups of modified asphalt preparation schemes were created. The penetration, softening point, and ductility were used as response values. The influence of each factor on the response values and the interactions between each influencing factor were analyzed. The preparation scheme was optimized, and the optimal preparation scheme for composite-modified asphalt was determined. The polyurethane prepolymer content was 7.4%, the ceramic fiber content was 2.1%, and the shear time was 40 min.

- (2)

- PUP/CF composite-modified asphalt exhibits the largest residual penetration ratio before and after aging, along with the smallest mass loss and softening point increment, indicating that PUP and CF enhance asphalt’s aging resistance, leading to superior aging performance. Its rutting factor is higher than that of CF-modified asphalt and matrix asphalt, showing better anti-rutting ability. Based on the time–temperature equivalence principle, the fitted complex shear modulus–frequency curve and viscoelastic master curve (using displacement factors) reveal that it has better high-temperature performance under low-temperature and high-frequency or high-temperature and low-frequency conditions.

- (3)

- PUP/CF composite-modified asphalt has the best recovery strain capacity under low stress. At high stress levels, the recovery strain capacity of PUP/CF composite-modified asphalt is weakened, but the cumulative strain is significantly lower than that of matrix asphalt. Unlike previous studies focusing on single modifiers, this work combines gel-forming PUP with ceramic fibers (CFs) to form a hybrid microstructure, which not only results in significantly enhanced rheological and aging properties but also improves the flexibility and elasticity of composite-modified asphalt while enhancing its resistance to deformation.

- (4)

- The stiffness modulus of PUP/CF composite-modified asphalt was significantly lower than that of matrix asphalt, which decreased by 35.1%, 49.1%, and 118.4% at −6 °C, −12 °C, and −18 °C, respectively. Compared with CF-modified asphalt, it is reduced by 11.8%, 13%, and 41.7%. The creep rate of PUP/CF composite-modified asphalt is large at three temperatures, indicating that PUP and CF have a good effect on the low-temperature rheological properties of asphalt.

- (5)

- SEM observations show that carbon fiber (CF) is encapsulated by asphalt with minor voids which are filled by polyurethane prepolymer (PUP), strengthening CF–asphalt interfacial bonding via co-encapsulation for more stable performance. AFM micrographs reveal that PUP/CF composite-modified asphalt has more and larger ‘honeycomb-like structures’, indicating greater structural stability. Infrared analysis shows that PUP engages in hydrogen bonding and weak chemical reactions with asphalt, achieving modification through a synergistic combination of physical (predominant) and chemical means. This leverages PUP and ceramic fiber advantages: PUP physically encapsulates CF to reduce voids and enhance load transfer, and acts as a precursor to form a 3D elastic gel network that bridges CF–asphalt interfaces, boosting durability, mechanical resilience, and thermal stability under stress.

- (6)

- In contrast to existing studies that investigate CF or PUP in isolation, this work focuses on the synergistic effects of gel-forming polyurethane prepolymers and ceramic fibers to enhance asphalt’s durability, stability, and resistance to deformation. The purpose is to develop a composite-modified asphalt suitable for extreme temperature conditions. Compared with base asphalt, the PUP/CF composite modification significantly improves tensile strength (by ~25%), fatigue life (by ~30%), and high-temperature rutting resistance (by ~20%) while also enhancing interfacial bonding and microstructural uniformity.

4. Materials and Methods

4.1. Matrix Asphalt

4.2. Polyurethane Prepolymer

4.3. Ceramic Fiber

4.4. Surface Modification of Ceramic Fiber

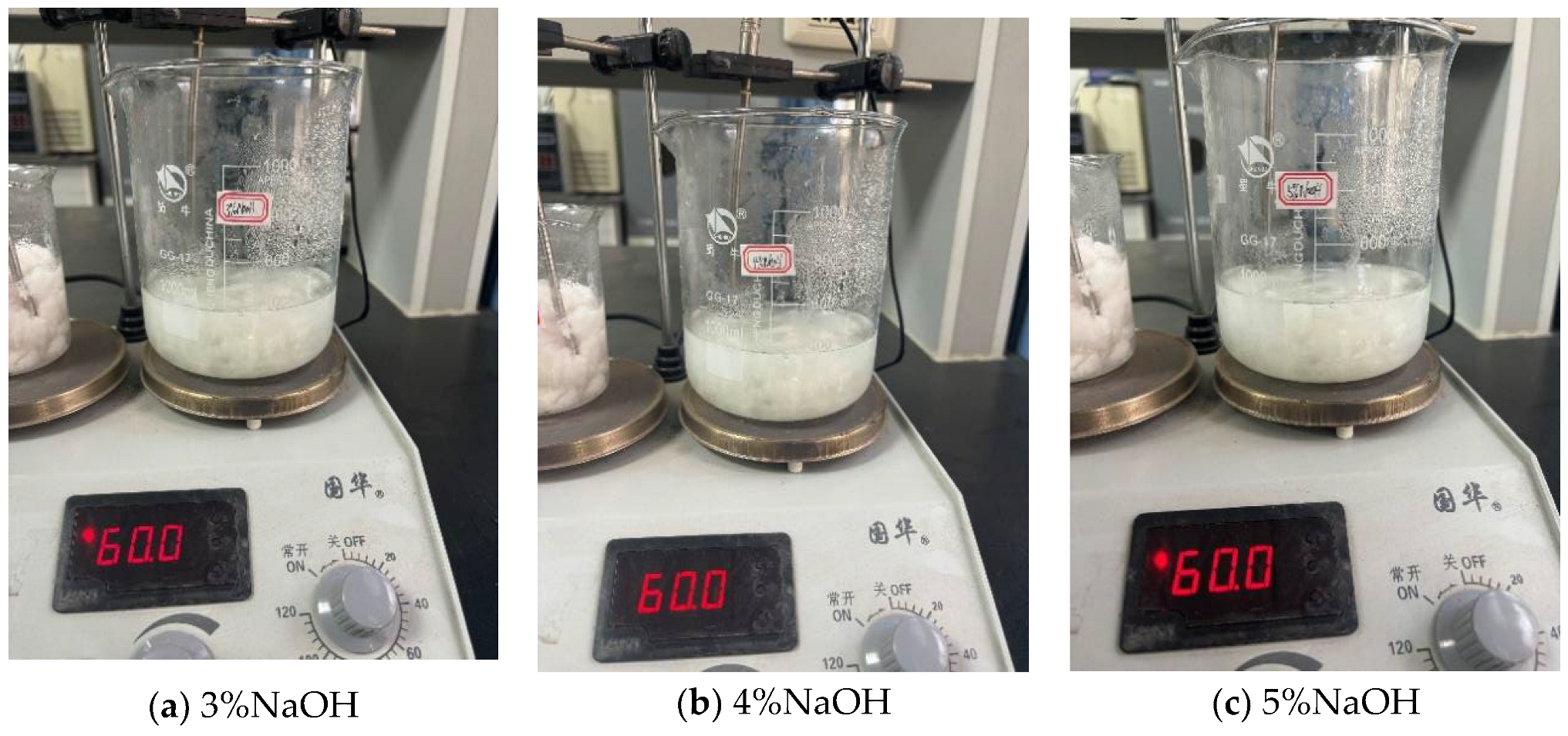

4.4.1. Ceramic Fiber Modified by NaOH Solution

4.4.2. KH-550 Solution-Modified Ceramic Fibers

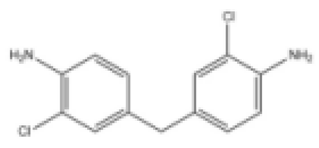

4.5. MOCA

4.6. Test Scheme

4.6.1. The Optimum Preparation of PUP/CF Composite-Modified Asphalt Based on Response Surface Methodology

4.6.2. Rotating Film Oven Aging Test

4.6.3. Dynamic Shear Rheological Test

4.6.4. MSCR Test

4.6.5. Bending Creep Stiffness Test

4.6.6. Scanning Electron Microscopy Test

4.6.7. Atomic Force Microscope Test

4.6.8. Infrared Spectroscopy Test

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rao, Z.; Wang, Y.; Cui, S.; Li, M. Interpretation of the key points of highway construction in the 14th Five-Year Plan. China Highw. 2022, 623, 28–32. [Google Scholar]

- Bai, X.; Jia, Q. Disease analysis and treatment maintenance of asphalt pavement of expressway. Road Constr. Mach. Constr. Mech. 2016, 33, 76–79. [Google Scholar]

- Chen, Q.; Ge, T.; Li, X.; Wang, C. Road area pollution cleaning technology for asphalt pavement: Literature review and research propositions. J. Clean. Prod. 2025, 493, 144975. [Google Scholar] [CrossRef]

- Wang, C.; Lan, X.; Cong, Y.; Peng, S.; Huang, S.; Chen, Q. Evaluation of skid resistance of pavement maintenance energy-absorbing seal based on surface texture characteristics. Measurement 2025, 245, 116588. [Google Scholar] [CrossRef]

- Chen, Q.; Lan, X.; Li, A.; Sun, X.; Wang, C. The novel rapid curing pavement maintenance seal with a low environmental impact: Preparation and performance evaluation. Wear 2025, 566–567, 205919. [Google Scholar] [CrossRef]

- Huang, S.; Liu, G.; Wu, Y.; Zhao, Y.; Zhai, J.; Xiong, R. Study on crack resistance of fiber modified asphalt under medium temperature. Highway 2025, 70, 328–335. [Google Scholar]

- Mrema, A.H.; Noh, S.-H.; Kwon, O.-S.; Lee, J.-J. Performance of Glass Wool Fibers in Asphalt Concrete Mixtures. Materials 2020, 13, 4699. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, L.; Liu, L. Experimental study on road performance of mixed fiber asphalt mixture. Highway 2018, 63, 5. [Google Scholar]

- Tang, G. Study on the Properties of Bamboo Fiber Asphalt Mortar and Its Mixture Performance; Xi’an University of Science and Technology: Xi’an, China, 2021. [Google Scholar]

- Fan, Z.; Wang, C.; Wang, Z.; Li, Y.; Feng, L.; Tan, S. Fog seal with polymer composite modified emulsified asphalt: Road performance and environmental adaptability. Wear 2025, 562–563, 205672. [Google Scholar] [CrossRef]

- Feng, G.; Jiang, W.; Liu, J.; Zhang, Q. A novel green nonaqueous sol-gel process for preparation of partially stabilized zirconia nanopowder. Process. Appl. Ceram. 2017, 11, 220–224. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, W.H.; Liu, J.M.; Guo, F. Low temperature synthesis of ultrafine Al2TiO5 powders by hydrolytic sol-gel method. Mater. Sci. Forum 2016, 848, 324–327. [Google Scholar]

- Zhang, X.; Wang, G.; Liu, Z.; Su, J.; Hu, M.; Zhao, Y. Study on the properties and modification mechanism of polyether TPUP modified asphalt. Highway 2024, 69, 63–71. [Google Scholar]

- Zhou, L.; Zhang, H. Research on rheological properties and road performance of polyurethane modified asphalt. J. Chongqing Univ. Technol. Nat. Sci. 2022, 36, 142–147. [Google Scholar]

- Wei, B.; Gong, X.; Jiang, W.; Qin, L.; Fan, Y. Study on the properties of magnetorheological gel based on polyurethane. J. Appl. Polym. Sci. 2010, 118, 2765–2771. [Google Scholar] [CrossRef]

- Jiang, W.H.; Hu, Z.; Liu, J.M. Study on low-tanperature synthesis of iron-stabilized aluminium titanate via non-hydrolytic sol-gel method. J. Syn. Cryst. 2011, 40, 465–469. [Google Scholar]

- Feng, G.; Jiang, F.; Jiang, W.; Liu, J.; Zhang, Q.; Wu, Q.; Hu, Q.; Miao, L.; Liang, J. Low-temperature preparation of novel stabilized aluminum titanate ceramic fibers via nonhydrolytic sol-gel method through linear self-assembly of precursors. Ceram. Int. 2019, 45, 18704–18709. [Google Scholar] [CrossRef]

- Bao, Y.; Jiang, W.H.; Feng, G.; Liu, J.; Wu, Q. Low Temperature Preparation of Aluminum Titanate Film via Sol-Gel Method. Adv. Mater. Res. 2014, 936, 238–242. [Google Scholar] [CrossRef]

- Fu, K.L.; Jiang, W.H.; Liu, J.M.; Feng, G.; Pan, M. Study on mullite whiskers preparation via non-hydrolytic sol-gel process combined with molten salt method. Mater. Sci. Forum 2016, 848, 295–300. [Google Scholar] [CrossRef]

- Wei, H.Y.; Jiang, W.H.; Lin, J. Comparative research on the synthesis of aluminum titanate powders by nonhydrolytic and hydrolytic sol-gel method. J. Inorg. Mater. 2009, 24, 199–203. [Google Scholar] [CrossRef]

- Jiang, W.; Wei, H.; Feng, G.; Zhou, Y.; Yu, Y. Effect of oxygen donor alcohols on low temperature nonhydrolytic sol-gel synthesis of aluminum titanate. J. Chin. Ceram. Soc. 2008, 36, 11. [Google Scholar]

- Jiang, W.H.; Yang, Y.H.; Zhu, Q.X.; Liu, J.M. Iron-zircon pigments prepared by non-hydrolytic sol-gel method at low temperature. Adv. Mater. Res. 2012, 412, 223–226. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, T.; Zhu, Y.; Lv, W.; Sun, J. The effect of PUP soft segment structure type on the performance of PUP modified asphalt. J. Chang’an Univ. Nat. Sci. Ed. 2021, 41, 1–9. [Google Scholar]

- Yu, C.; Wang, J.; Li, J.; Sun, Y. Application progress of polyurethane prepolymer modified asphalt. Polym. Mater. Sci. Eng. 2024, 40, 156–168. [Google Scholar]

- Guo, G.; Cong, L.; Yang, F.; Tan, L. Progress in the application of polyurethane materials in pavement engineering. Road Traffic Sci. Technol. 2020, 37, 1–10. [Google Scholar]

- Lv, W.; Liu, H.; Chang, P.; Huang, T.; Zhang, Z. Research progress on the application of polyurethane modified asphalt in pavement engineering. New Chem. Mater. 2022, 50, 227–230. [Google Scholar]

- Park, D.; Wu, W.; Wang, Y. A functionalizable reverse thermal gel based on a polyurethane/PEG block copolymer. Biomaterials 2011, 32, 777–786. [Google Scholar] [CrossRef]

- Baillif, P.Y.; Tabellout, M.; Emery, J.R. Ultrasonic investigation of polyurethane gel forming systems. Macromolecules 1999, 32, 3432–3437. [Google Scholar] [CrossRef]

- Liu, X.; Yu, K.; Sun, J.; Guo, W.; Qian, K. Effect of shear thickening gel on structure and properties of flexible polyurethane foam. Smart Mater. Struct. 2021, 30, 125008. [Google Scholar] [CrossRef]

- Akimov, A.E.; Valentina, V.Y.; Mikhail, S.L.; Vasilij, P.D.; Sergei, S.I.; Aleksandr, S.I.; Andrey, V.K.; Anton, S.P. Development of an energy-efficient method of obtaining polymer-modified bitumen with high operational characteristics via polymer–bitumen concentrate application. J. Compos. Sci. 2024, 8, 337. [Google Scholar] [CrossRef]

- Liu, M.; Han, S.; Shang, W.; Qi, X. New polyurethane modified coating for maintenance of asphalt pavement potholes in winter-rainy condition. Prog. Org. Coat. 2019, 133, 368–375. [Google Scholar] [CrossRef]

- Fang, Y.; Xie, W.; Yang, J. Preparation and rheological behavior of polyurethane prepolymer modified asphalt. Funct. Mater. 2019, 50, 6197–6205. [Google Scholar]

- Cuadri, A.A.; García-Morales, M.; Navarro, F.J.; Partal, P. Processing of bitumens modified by a bio-oil-derived polyurethane. Fuel 2014, 118, 83–90. [Google Scholar] [CrossRef]

- Baha, V.K.; Ercan, A.; Mehmet, Y.; Mustafa, A. Investigation on the properties of new palm-oil-based polyurethane modified bitumen. Constr. Build. Mater. 2021, 289, 123152. [Google Scholar]

- Padhan, R.K.; Gupta, A.A. Preparation and evaluation of waste PET derived polyurethane polymer modified bitumen through in situ polymerization reaction. Constr. Build. Mater. 2018, 158, 337–345. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Z.; Li, B.; Ru, Y. Research Progress of Artificial Ceramic Fibers. Synth. Fiber Ind. 2021, 44, 76–80. [Google Scholar]

- Wang, Q.; Zhao, B.; Han, X. Properties and Preparation of Ceramic Fibers. China Ceram. 2019, 55, 10–18, 26. [Google Scholar]

- Wan, J.; Wu, S.; Xiao, Y.; Liu, Q.; Schlangen, E. Characteristics of Ceramic Fiber Modified Asphalt Mortar. Materials 2016, 9, 788. [Google Scholar] [CrossRef]

- Mahyar, A.; Amir, S.; Hossein, H.G. Evaluation of the ceramic fiber modified asphalt binder. Constr. Build. Mater. 2019, 205, 377–386. [Google Scholar] [CrossRef]

- Arabani, M.; Shabani, A.; Hamedi, G.H. Experimental Investigation of Effect of Ceramic Fibers on Mechanical Properties of Asphalt Mixtures. J. Mater. Civ. Eng. 2019, 31, 04019203.1–04019203.12. [Google Scholar] [CrossRef]

- Zhou, H.; Pan, Q. Study on the effect of ceramic fiber addition on the rheological properties of asphalt. Highw. Eng. 2022, 47, 166–171. [Google Scholar]

- Wang, X.; Zhou, H.; Zhang, X.; Fan, T. Analysis of road performance and modification mechanism of ceramic fiber asphalt mixture. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2022, 41, 100–106. [Google Scholar]

- Xiao, Z. Study on Properties of Nano AAT/Ceramic Fiber Composite Modified Asphalt and Mixture; Chongqing Jiaotong University: Chongqing, China, 2023. [Google Scholar]

- JTG E20-2011; Test Procedures for Asphalt and Asphalt Mixtures for Highway Engineering. People’s Transportation Publishing House: Beijing, China, 2011.

- GB/T 16777-2008; Test Methods for Building Waterproofing Coatings. China Quality Inspection Press: Beijing, China, 2008.

| Serial Number | Polyurethane Prepolymer Content% | Ceramic Fiber Content% | Shear Time Min | Penetration | Softening Point | Ductility |

|---|---|---|---|---|---|---|

| 1 | 4 | 1 | 30 | 42.7 | 52.1 | 18.5 |

| 2 | 8 | 1 | 30 | 40.5 | 53.3 | 20.2 |

| 3 | 4 | 3 | 30 | 38.1 | 55.6 | 17.6 |

| 4 | 8 | 3 | 30 | 36.5 | 56.5 | 19.6 |

| 5 | 4 | 2 | 20 | 40.6 | 54.6 | 18.9 |

| 6 | 8 | 2 | 20 | 38.7 | 55.7 | 20.8 |

| 7 | 4 | 2 | 40 | 40.0 | 55.1 | 19.5 |

| 8 | 8 | 2 | 40 | 37.8 | 56.0 | 21.0 |

| 9 | 6 | 1 | 20 | 42.2 | 52.7 | 19.5 |

| 10 | 6 | 3 | 20 | 38.8 | 56.2 | 18.7 |

| 11 | 6 | 1 | 40 | 41.2 | 53.0 | 20.1 |

| 12 | 6 | 3 | 40 | 37.3 | 56.4 | 19.8 |

| 13 | 6 | 2 | 30 | 38.2 | 55.4 | 20.9 |

| 14 | 6 | 2 | 30 | 38.5 | 55.5 | 20.8 |

| 15 | 6 | 2 | 30 | 39.1 | 55.7 | 20.9 |

| 16 | 6 | 2 | 30 | 38.7 | 55.6 | 21.2 |

| 17 | 6 | 2 | 30 | 38.5 | 55.5 | 20.9 |

| Preparation Parameters | PUP (%) | CF (%) | Shearing Time (min) |

|---|---|---|---|

| optimal value | 7.4 | 2.1 | 40 |

| Indicators | Needle Penetration (0.1 mm) | Softening Point (°C) | Ductility (cm) |

|---|---|---|---|

| Predicted value | 38.6 | 55.54 | 20.94 |

| Measured value | 38.2 | 56.2 | 20.4 |

| Performance Index | Matrix Asphalt | CF-Modified Asphalt | PUP/CF Composite-Modified Asphalt | |||

|---|---|---|---|---|---|---|

| Before Aging | After Aging | Before Aging | After Aging | Before Aging | After Aging | |

| Mass (g) | 35.140 | 35.018 | 35.312 | 35.258 | 35.374 | 35.344 |

| Penetration at 25 °C (0.1 mm) | 66.1 | 53.7 | 55.9 | 40.5 | 40.6 | 34.7 |

| Softening Point (°C) | 50.8 | 53.7 | 53.3 | 56.4 | 57.5 | 60.2 |

| Mass Loss (%) | 0.348 | 0.152 | 0.086 | |||

| Penetration Ratio (%) | 69.6 | 72.5 | 85.4 | |||

| Softening Point Increase (°C) | 2.9 | 2.1 | 1.7 | |||

| Performance Index | Test Results | Unit | Technical Requirements | |

|---|---|---|---|---|

| Penetration (25 °C) | 66.1 | 0.1 mm | 60~80 | |

| Softening point | 50.8 | °C | ≥46 | |

| Ductility (5 cm/min, 10 °C) | 30.2 | cm | ≥20 | |

| Flash point | 270 | °C | ≥260 | |

| Density (15 °C) | 1.136 | g/cm3 | measured value | |

| After aging | Quality change | −0.122 | % | ≤±0.8 |

| Softening point increment | 2.9 | °C | ≤8 °C | |

| Penetration ratio | 69.6 | % | ≥61 | |

| Performance Index | Unit | Test Results |

|---|---|---|

| NCO content | (%) | 5.1 ± 0.2 |

| State | / | Colorless transparent liquid |

| Viscosity | (85 °C/MPa.s) | 350 |

| Hardness | Shore A | 90 ± 2 |

| Tensile strength | (MPa) | 30 |

| Elongation at break | (%) | 420 |

| Rebound | (%) | 32 |

| Performance Index | Ceramic Fiber (Aluminum Silicate Fiber) | |

|---|---|---|

| Classification Temperature (°C) | 1400 | |

| Diameter (m) | 3–5 | |

| Slag ball content (%) | ≤15 | |

| Chemical composition (%) | Al2O3 | 38–40 |

| Fe2O3 | 0.2 | |

| ZrO2 | 15–17 | |

| Performance Index | Appearance | Molecular Weight | Melting Point (°C) | Structural Formula |

|---|---|---|---|---|

| Test results | Yellow particles | 267.16 | 105 |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, T.; Guo, X.; Chen, Y.; Fang, C.; Yang, J.; Li, Z.; Feng, J.; Huang, H.; Li, Z.; Chen, H.; et al. A Study on the Performance of Gel-Based Polyurethane Prepolymer/Ceramic Fiber Composite-Modified Asphalt. Gels 2025, 11, 558. https://doi.org/10.3390/gels11070558

Guo T, Guo X, Chen Y, Fang C, Yang J, Li Z, Feng J, Huang H, Li Z, Chen H, et al. A Study on the Performance of Gel-Based Polyurethane Prepolymer/Ceramic Fiber Composite-Modified Asphalt. Gels. 2025; 11(7):558. https://doi.org/10.3390/gels11070558

Chicago/Turabian StyleGuo, Tengteng, Xu Guo, Yuanzhao Chen, Chenze Fang, Jingyu Yang, Zhenxia Li, Jiajie Feng, Hao Huang, Zhi Li, Haijun Chen, and et al. 2025. "A Study on the Performance of Gel-Based Polyurethane Prepolymer/Ceramic Fiber Composite-Modified Asphalt" Gels 11, no. 7: 558. https://doi.org/10.3390/gels11070558

APA StyleGuo, T., Guo, X., Chen, Y., Fang, C., Yang, J., Li, Z., Feng, J., Huang, H., Li, Z., Chen, H., & Wang, J. (2025). A Study on the Performance of Gel-Based Polyurethane Prepolymer/Ceramic Fiber Composite-Modified Asphalt. Gels, 11(7), 558. https://doi.org/10.3390/gels11070558