Study on Road Performance and Ice-Breaking Effect of Rubber Polyurethane Gel Mixture

Abstract

1. Introduction

2. Results and Discussion

2.1. Performance Analysis of Modified Rubber Particles

2.1.1. Analysis of Hydrophilic Properties of Modified Rubber Particles

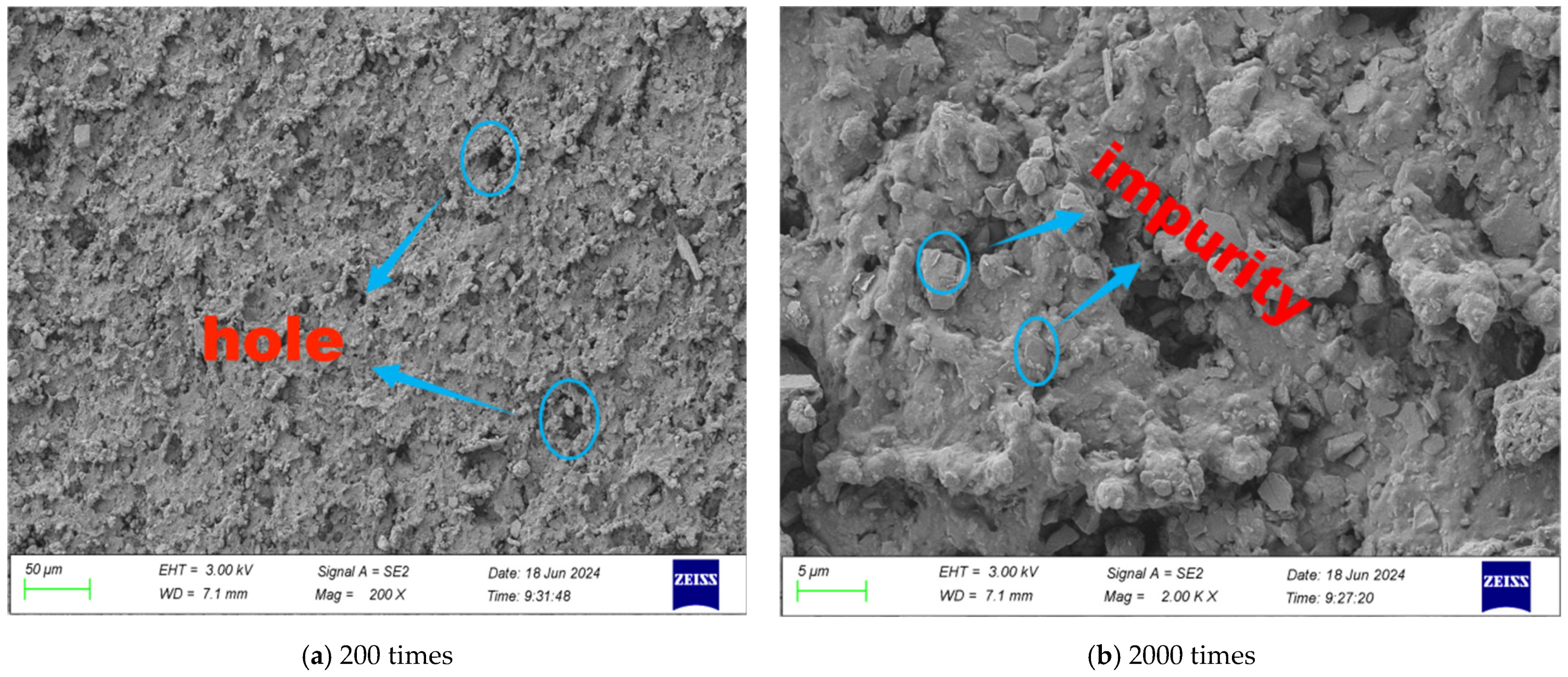

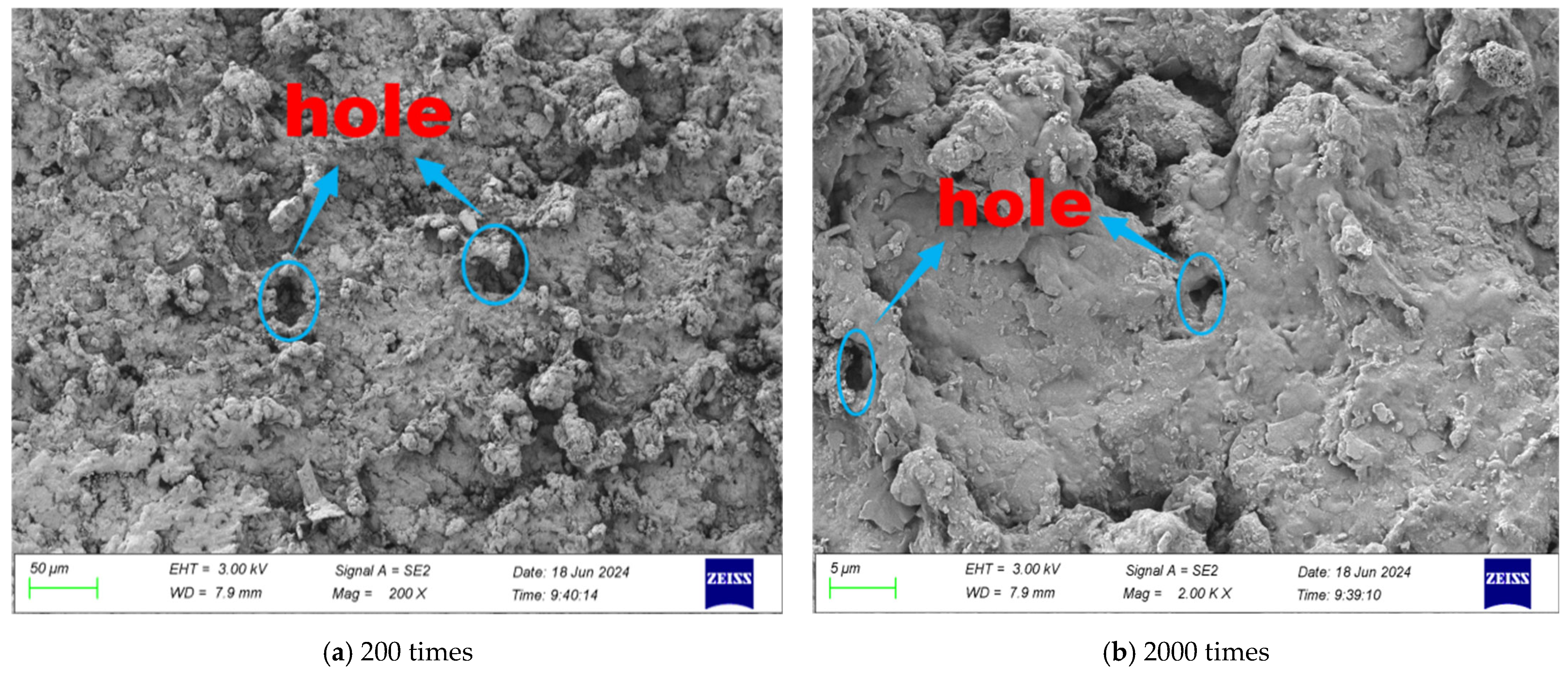

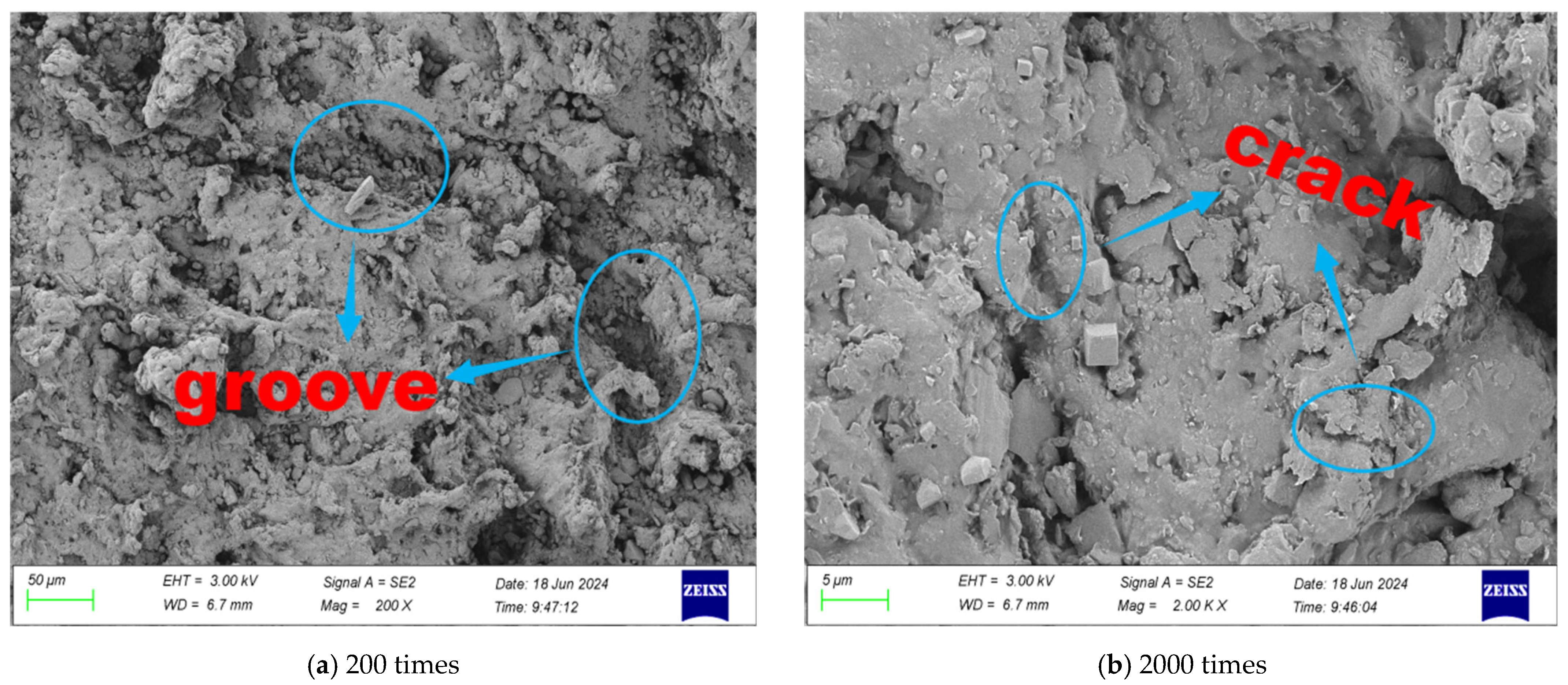

2.1.2. Fine Microstructure Analysis of Modified Rubber Particles

2.1.3. Phase Composition Analysis of Modified Rubber Particles

2.2. Polyurethane Gel Dosage Test Analysis

2.3. Road Performance Analysis of Mixture

2.3.1. Elevated Temperature Property

2.3.2. Low-Temperature Performance

2.3.3. Water Stability

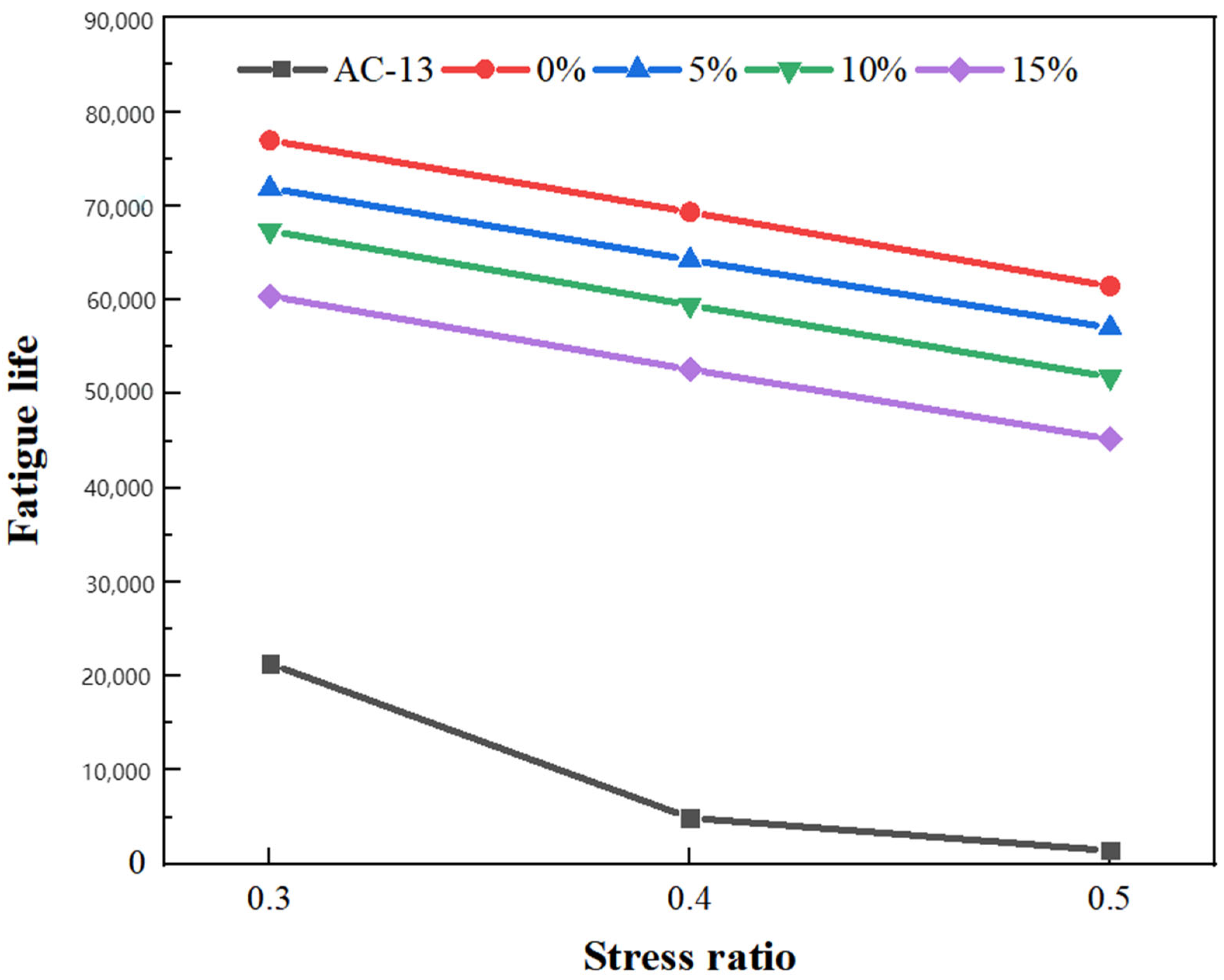

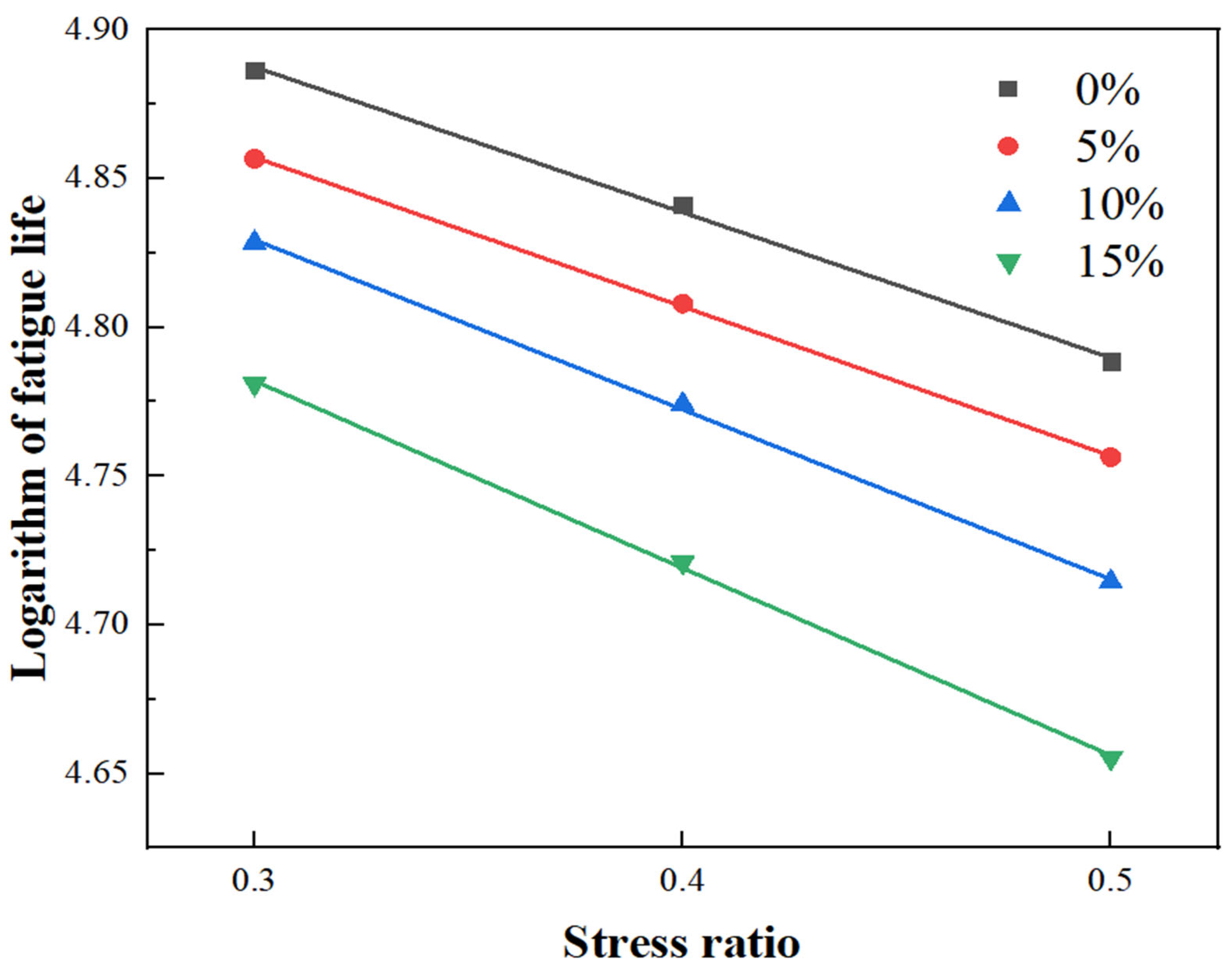

2.3.4. Fatigue Property

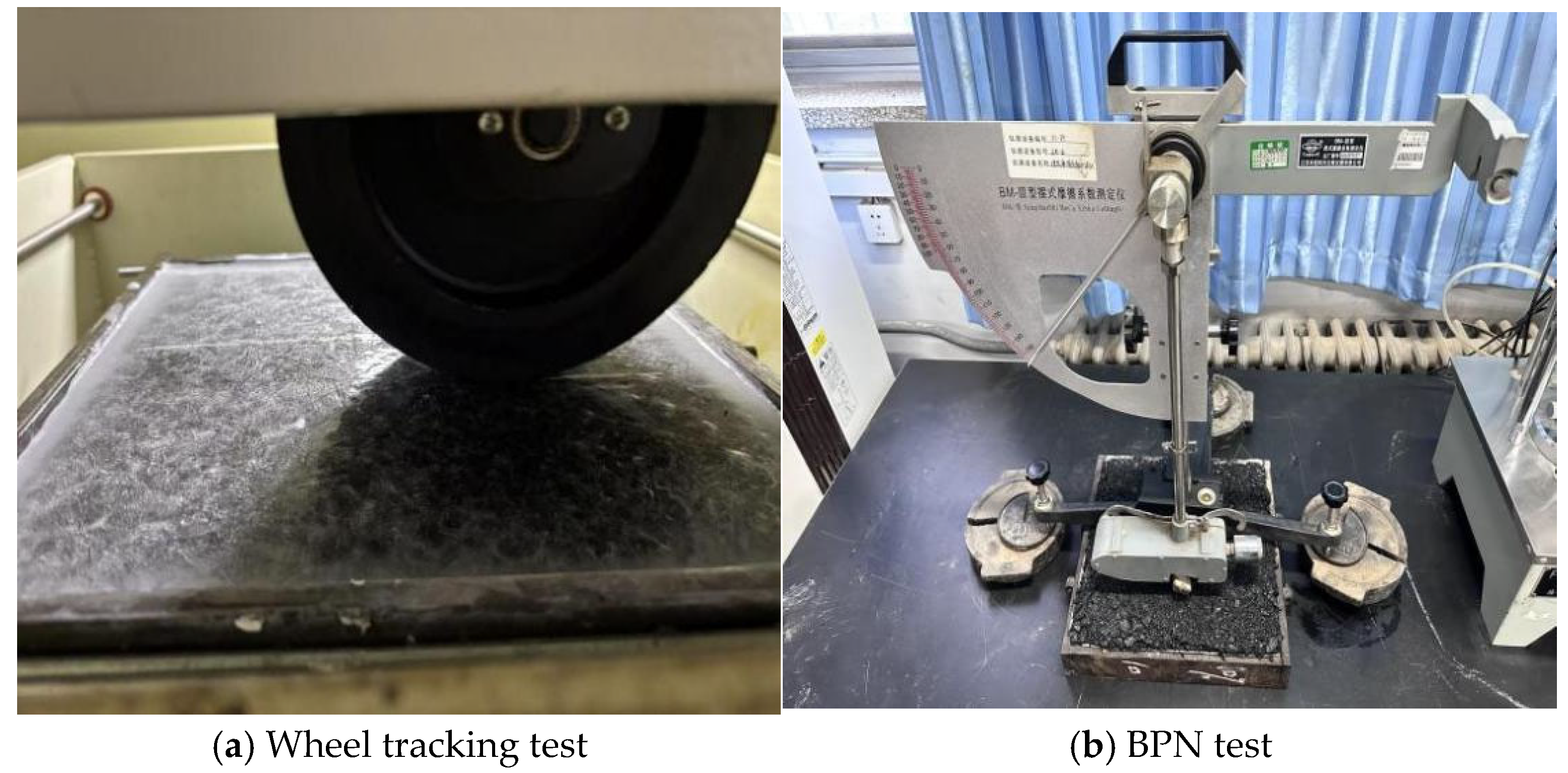

2.3.5. Slip Resistance

2.4. Analysis of Ice-Breaking Effect and Mechanism of Mixture

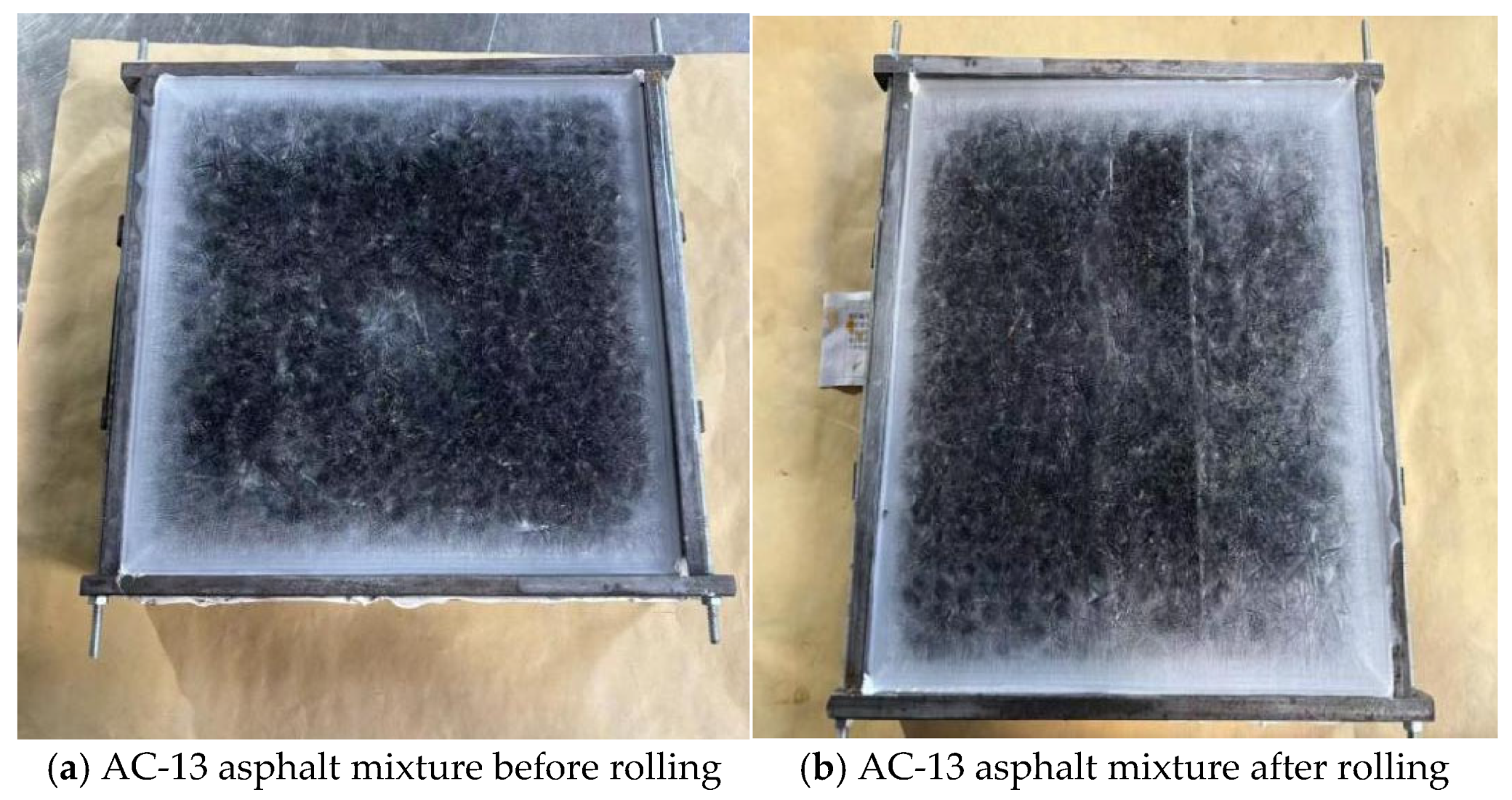

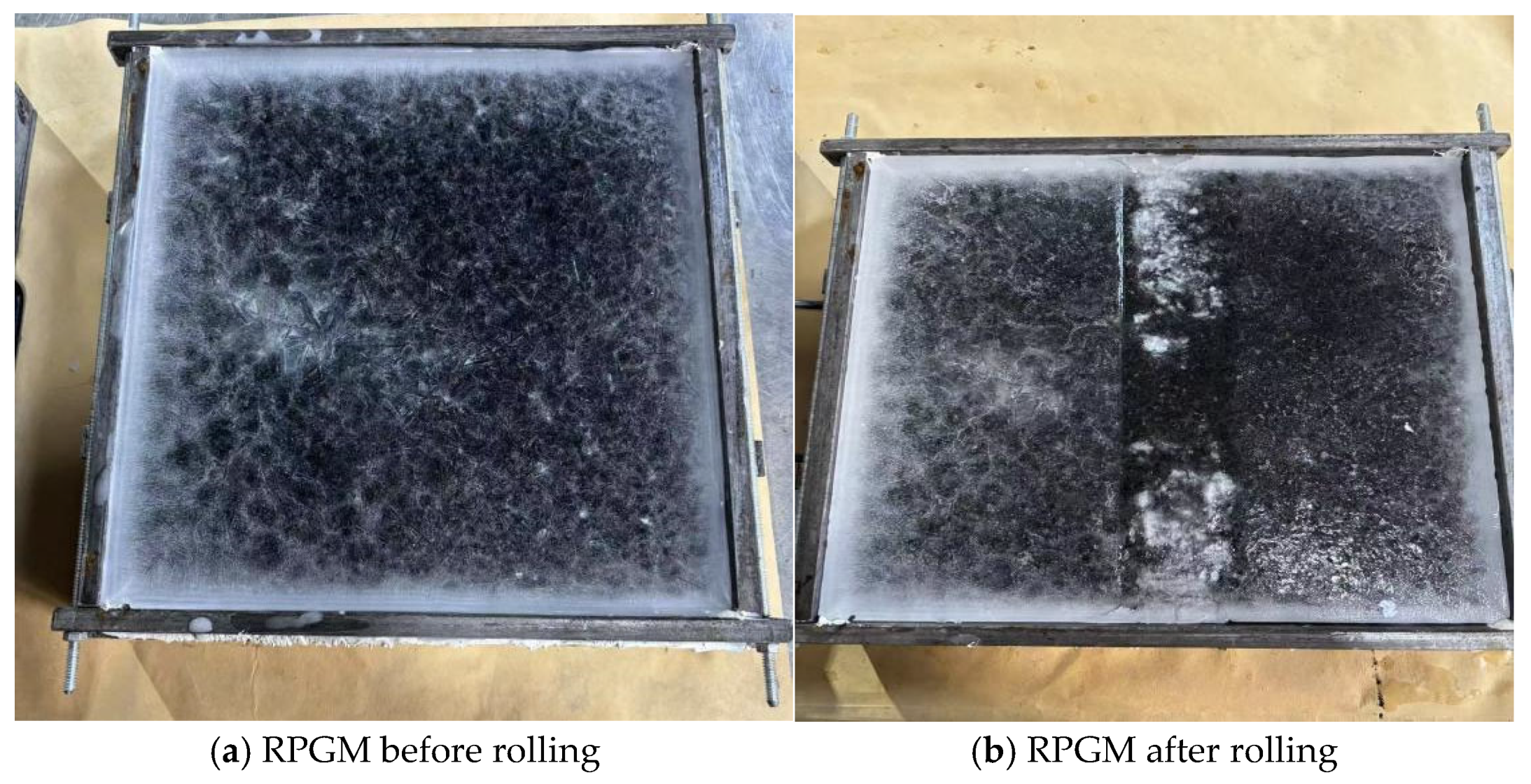

2.4.1. Phenomenon Analysis of Ice-Breaking Test

2.4.2. The Effect of Rubber Particle Content on Ice-Breaking Effect

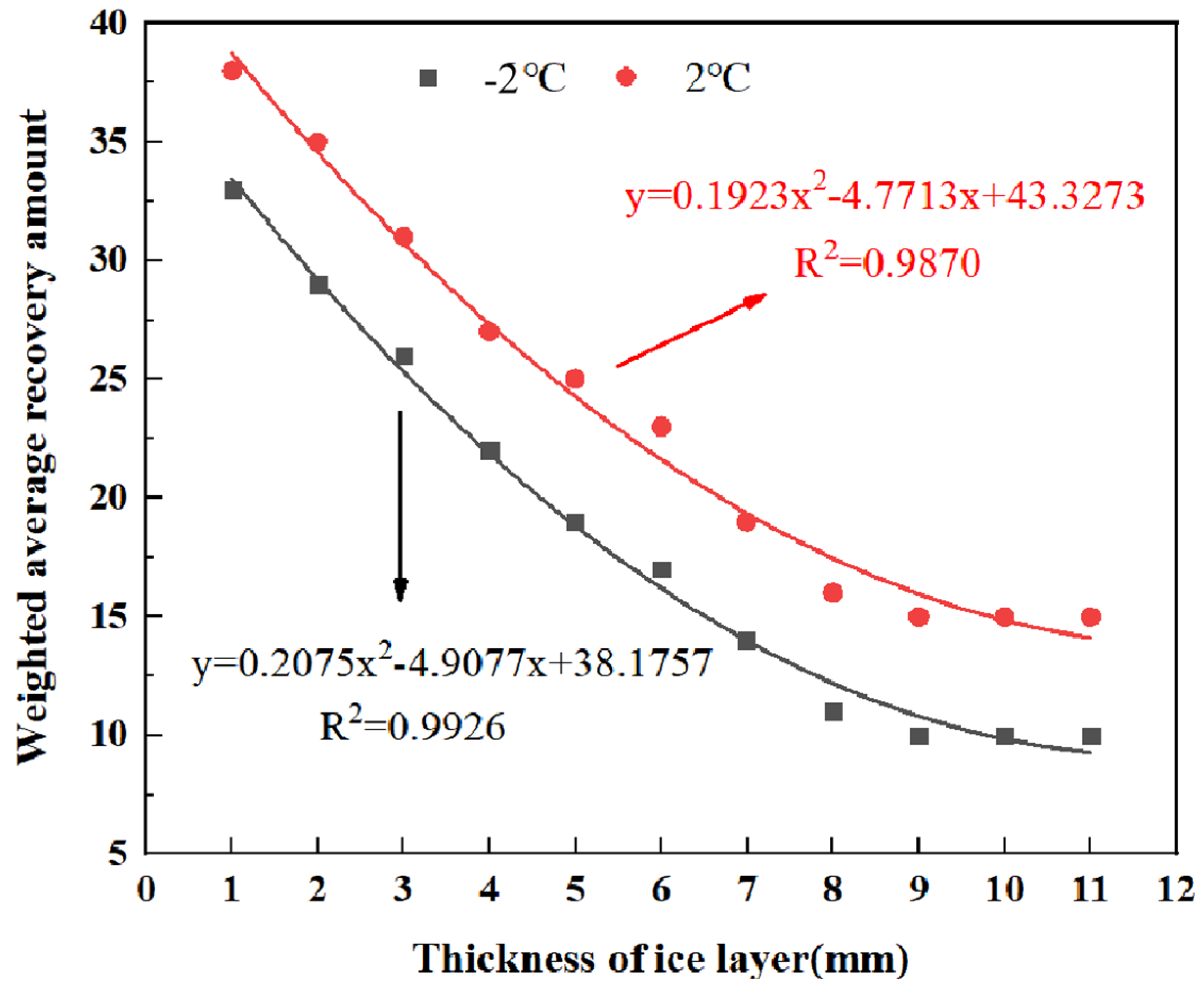

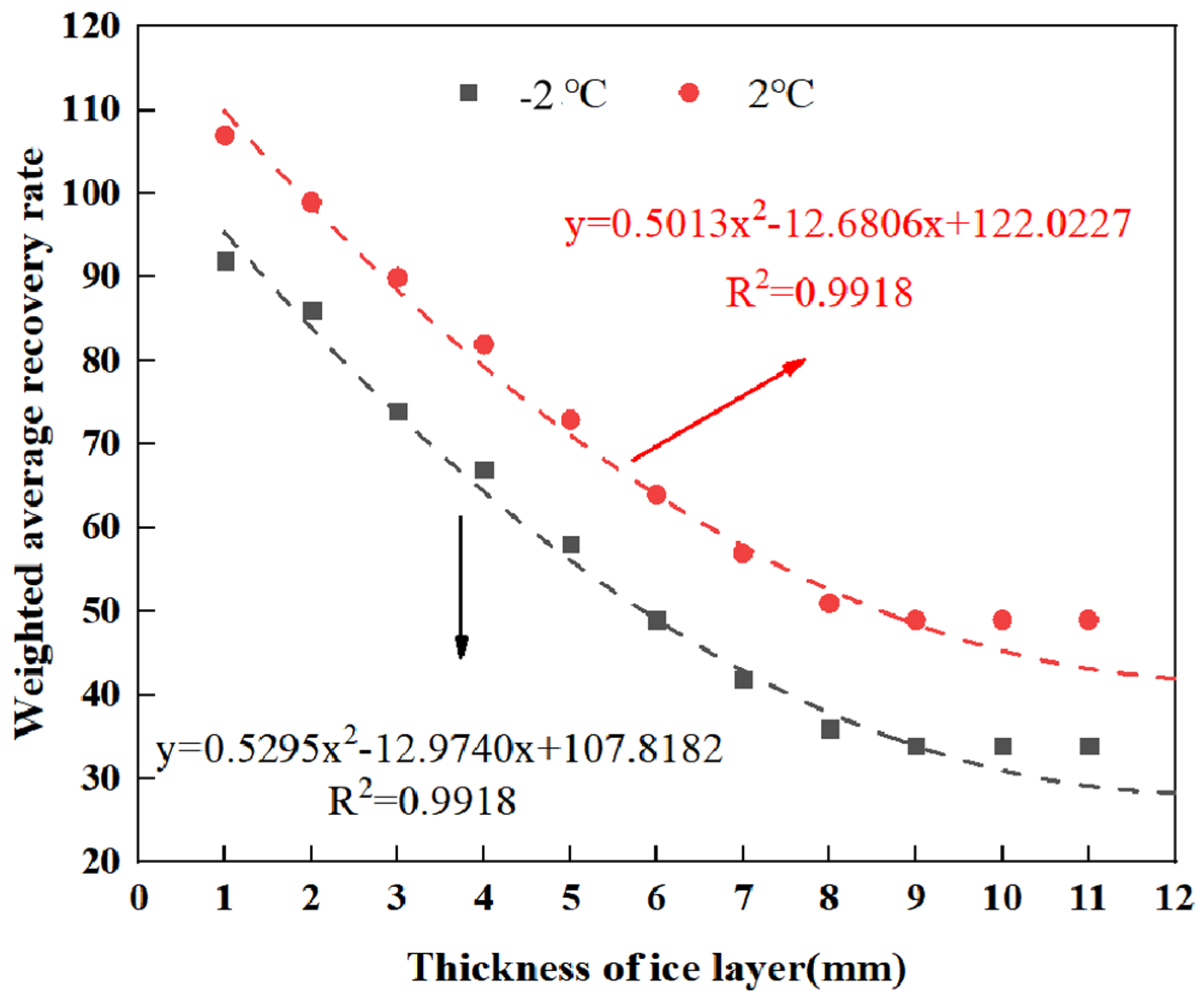

2.4.3. The Influence of Ice Thickness on Ice-Breaking Effect

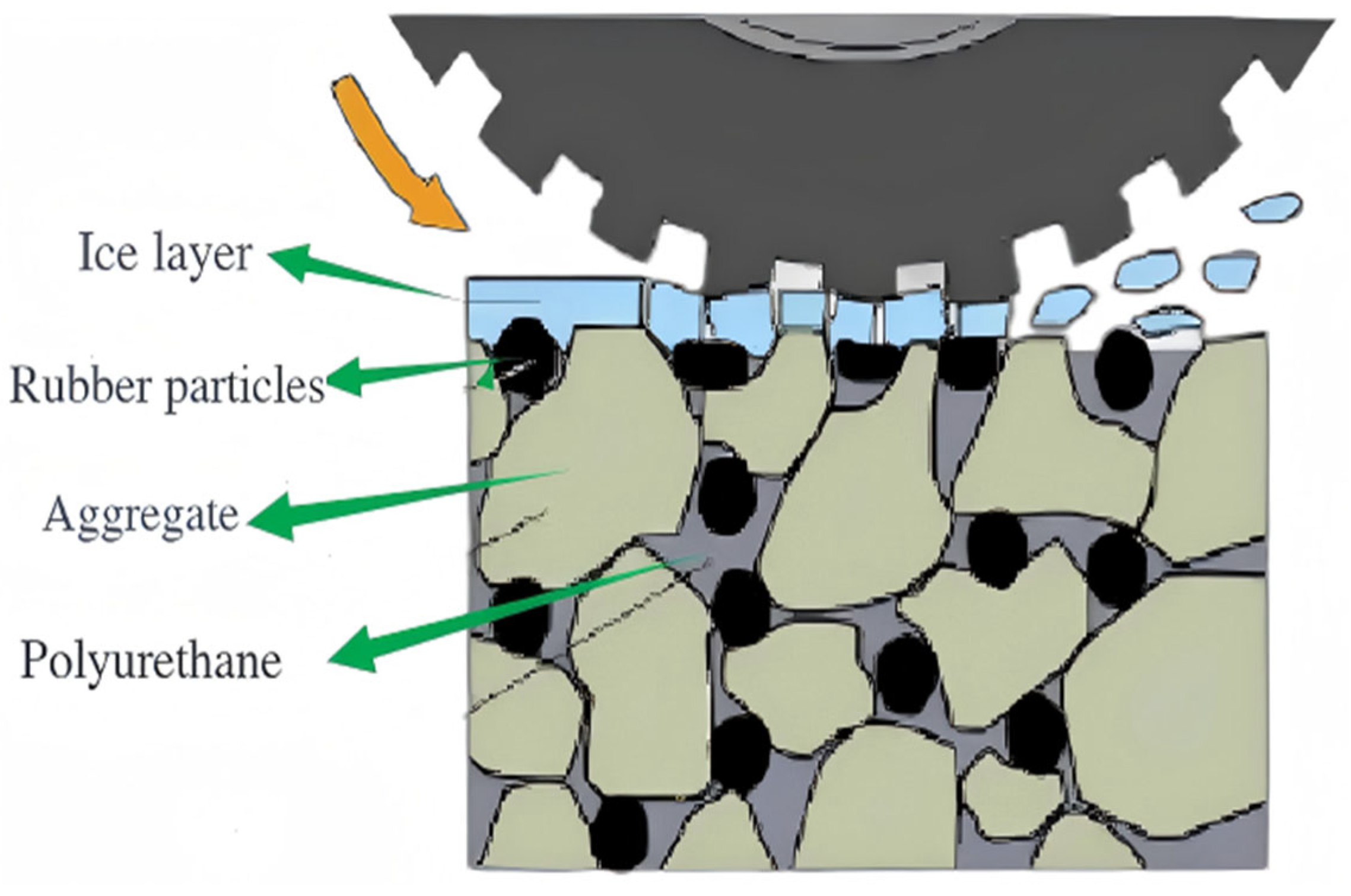

2.4.4. Analysis of Ice-Breaking Mechanism

3. Conclusions

- (1)

- The contact angle of rubber particles treated with NaOH, NaClO and KH550 decreased by 22.5%, 30.2% and 36.7%, respectively. NaOH solution improves the adhesive strength of rubber particles and polyurethane gels by eliminating zinc stearate on the rubber surface and forming a rough porous surface. The NaClO solution promoted the penetration of the adhesive molecules by removing the residual solvent on the surface of the rubber particles and forming a pore structure, thereby enhancing the bonding strength. The KH550 solution further improves the roughness of the surface of the rubber particles and the number of corrosion pores; enhances the air-entraining effect, fluidity and interfacial bonding strength; and significantly improves the working performance of the rubber particle mixture. After surface modification by three methods, the element types of rubber particles were significantly reduced, among which the element types of rubber particles treated by the KH550 solution decreased the most, indicating that the removal effect of surface impurities was the most significant.

- (2)

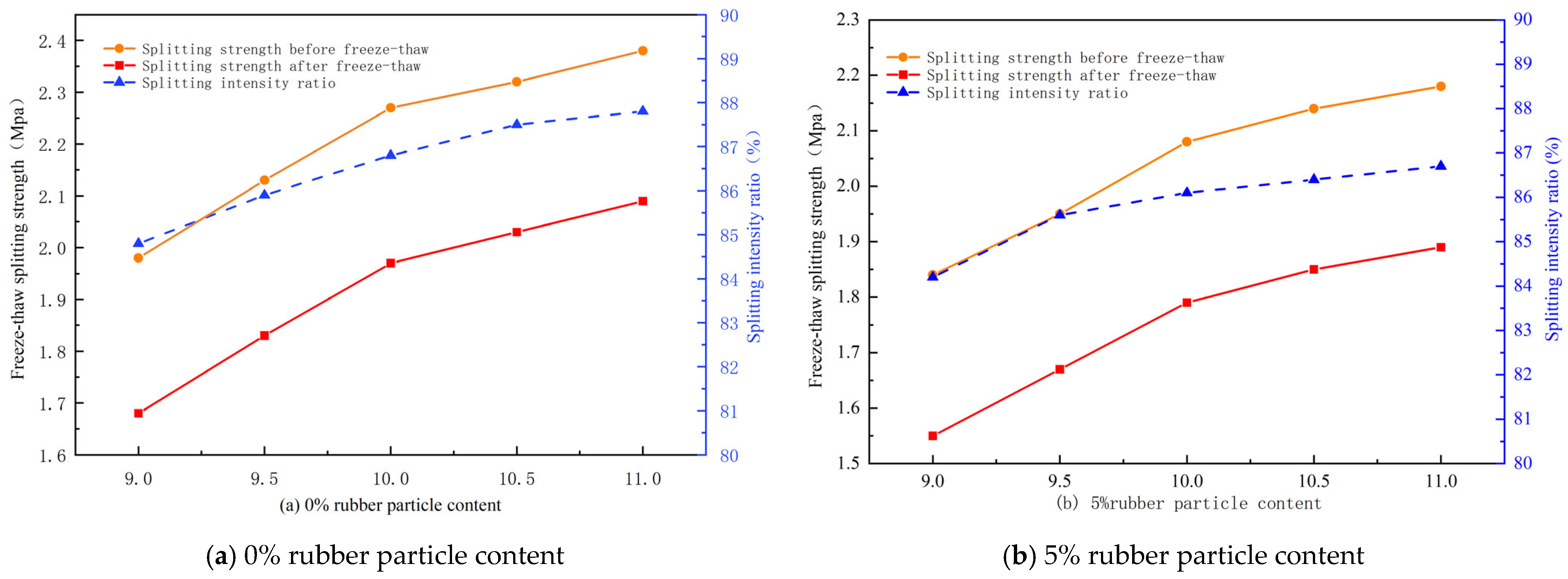

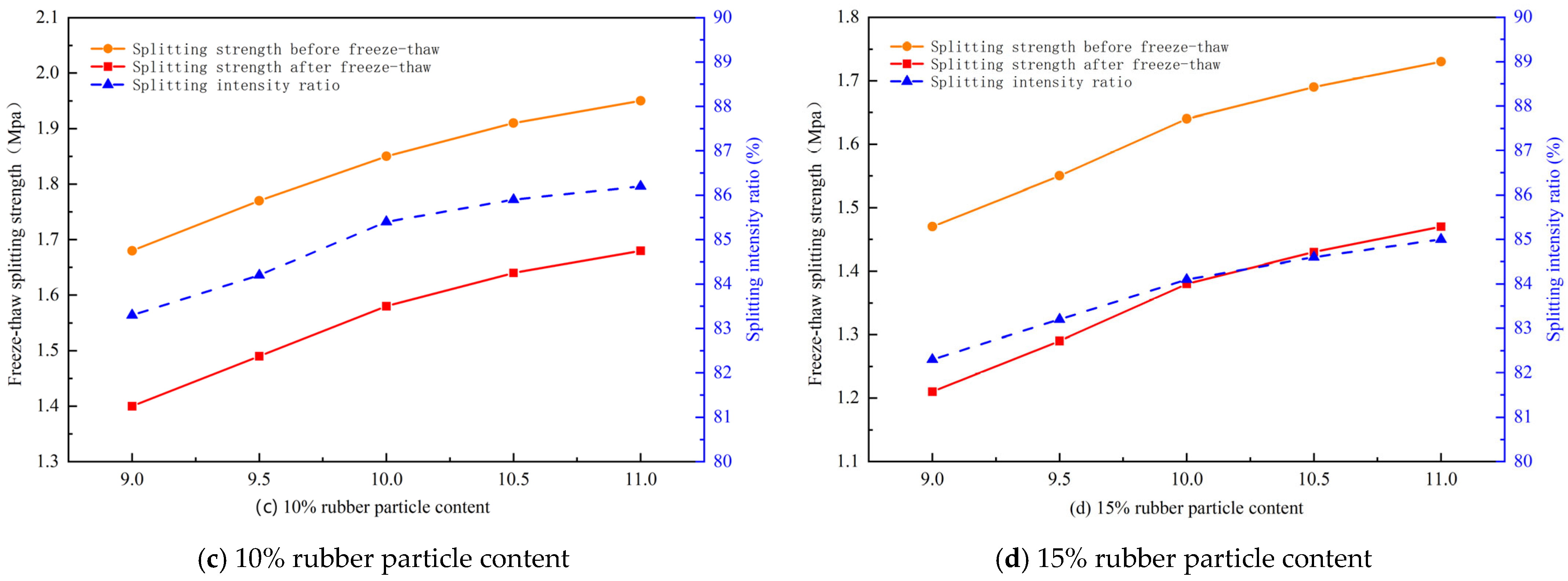

- The freeze–thaw splitting strength of the mixture with four kinds of rubber particles increased greatly when the amount of polyurethane gel reached 10%. Under the condition of fixed rubber particle content, the growth trend of freeze–thaw splitting strength of the specimen increases first and then slows down with the increase in polyurethane gel content. When the content of rubber particles is 10%, the splitting strength ratio increases by 1.1%, 1.4%, 0.5% and 0.3%, respectively, when the content of polyurethane gels increases from 9–11%. When the content of polyurethane gels is 10%, its water damage resistance can meet the requirements of use, and the optimum polyurethane gel content of the mixture is determined to be 10%.

- (3)

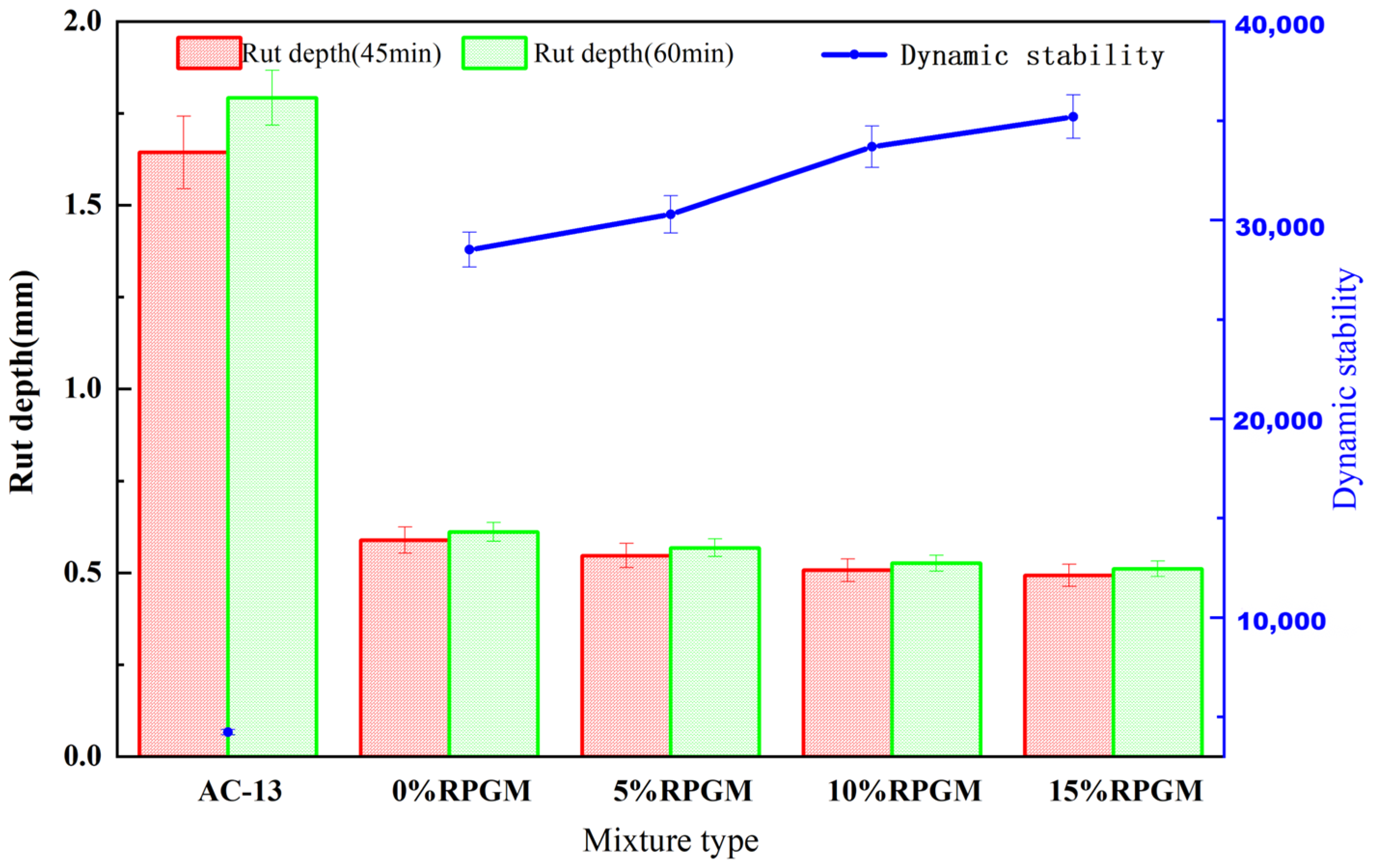

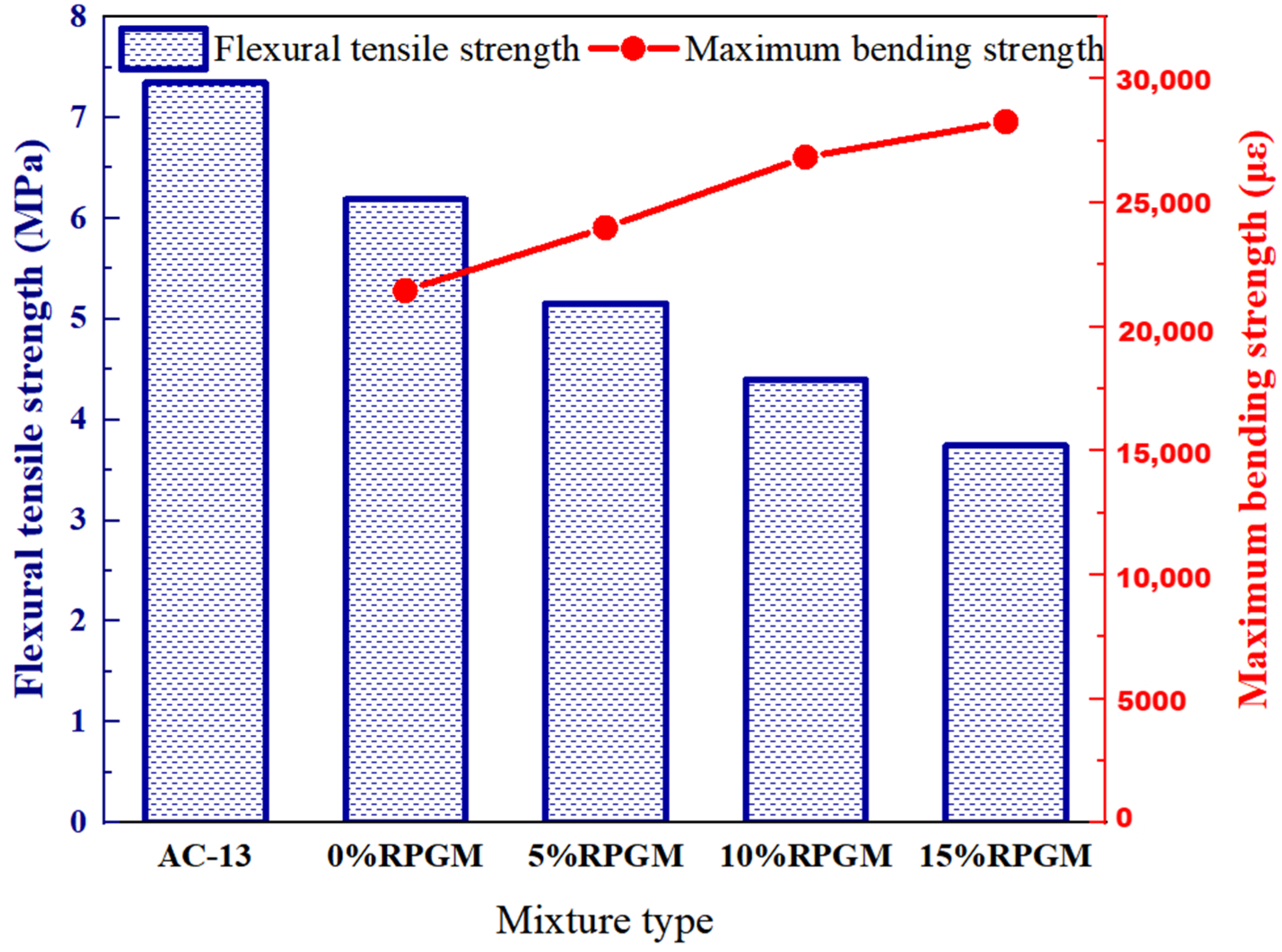

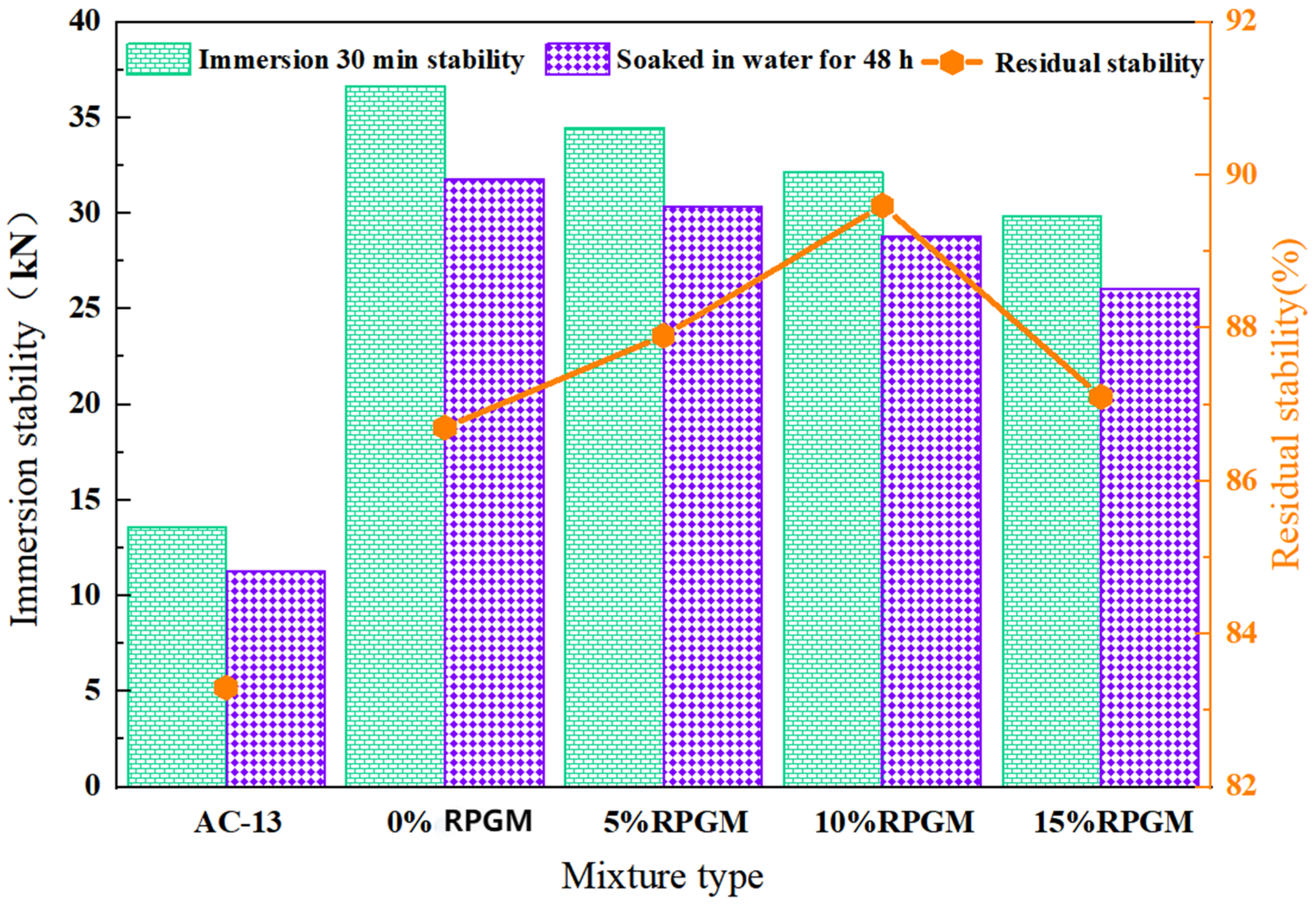

- With an increase in rubber particle content, the dynamic stability of the polyurethane gel mixture shows a trend of gradual increase, which is 6.2%, 18.2% and 23.5% higher than that of undoped rubber particles, respectively, and much higher than that of asphalt mixture, indicating that its anti-rutting performance is significantly enhanced. Compared with the mixture without rubber particles, the maximum bending strain increased by 11.8%, 25.1% and 31.7%, respectively, showing excellent deformation ability. The residual stability increased first and then decreased with the increase in rubber particle content, and the residual stability increased by 1.4%, 3.3% and 0.5%, respectively. The anti-scattering performance increased with the increase in rubber content, and an excessive amount would lead to an increase in scattering loss rate, but it could still be maintained below 5%, indicating that it still had good water stability under immersion conditions. Compared with the AC-13 asphalt mixture, the fatigue life of four kinds of rubber particle content mixtures increased by 2.9 times, 3.8 times, 4.3 times and 4.0 times, respectively. The fatigue performance of the polyurethane gel mixture decreased with an increase in rubber particle content. Compared with the ordinary asphalt mixture, the friction coefficient of four kinds of rubber particle content increased by 14.7%, 16.1%, 19.1% and 22.3%, respectively, which further verified its excellent skid resistance.

- (4)

- Compared with the traditional asphalt mixture, RPGM shows superior de-icing performance, and with an increase in rubber particle content, its ice-breaking effect is significantly improved. Compared with the AC-13 asphalt mixture, the BPN change values of polyurethane gel mixtures with different rubber particle contents increased by 0.6 times, 1.8 times, 2.4 times and 2.8 times, respectively, under the rolling time of 30 min. The BPN change values of 5%, 10% and 15% RPGMs increased by 71.4%, 109.5% and 133.3%, respectively, compared with those of polyurethane gel mixtures without rubber particles. The average weighted recovery of the ice thickness to the pendulum value and the average weighted recovery rate of the pendulum value decrease with an increase in ice thickness, especially when the ice thickness is 1–6 mm. When the ice thickness reaches 9 mm, the two tend to be stable, indicating that the ice-breaking ability of the RPGM is significantly weakened. Under the action of traffic load, the RPGM can make the ice layer gradually fall off through stress, thermal effect and interface damage, indicating that RPGM exhibits strong potential for field application, subject to further long-term durability verification in real-world conditions. The ice layer damage is characterized by a mixed fracture mode dominated by a type II fracture.

4. Materials and Methods

4.1. Rubber Particles

4.2. Polyurethane Gels

4.3. Modifier

- (1)

- NaOH modifier

- (2)

- NaClO modifier

- (3)

- KH550 modifier

4.4. Natural Aggregate

4.5. Rubber Particle Performance Test

- (1)

- Contact angle test

- (2)

- SEM test

- (3)

- EDS test

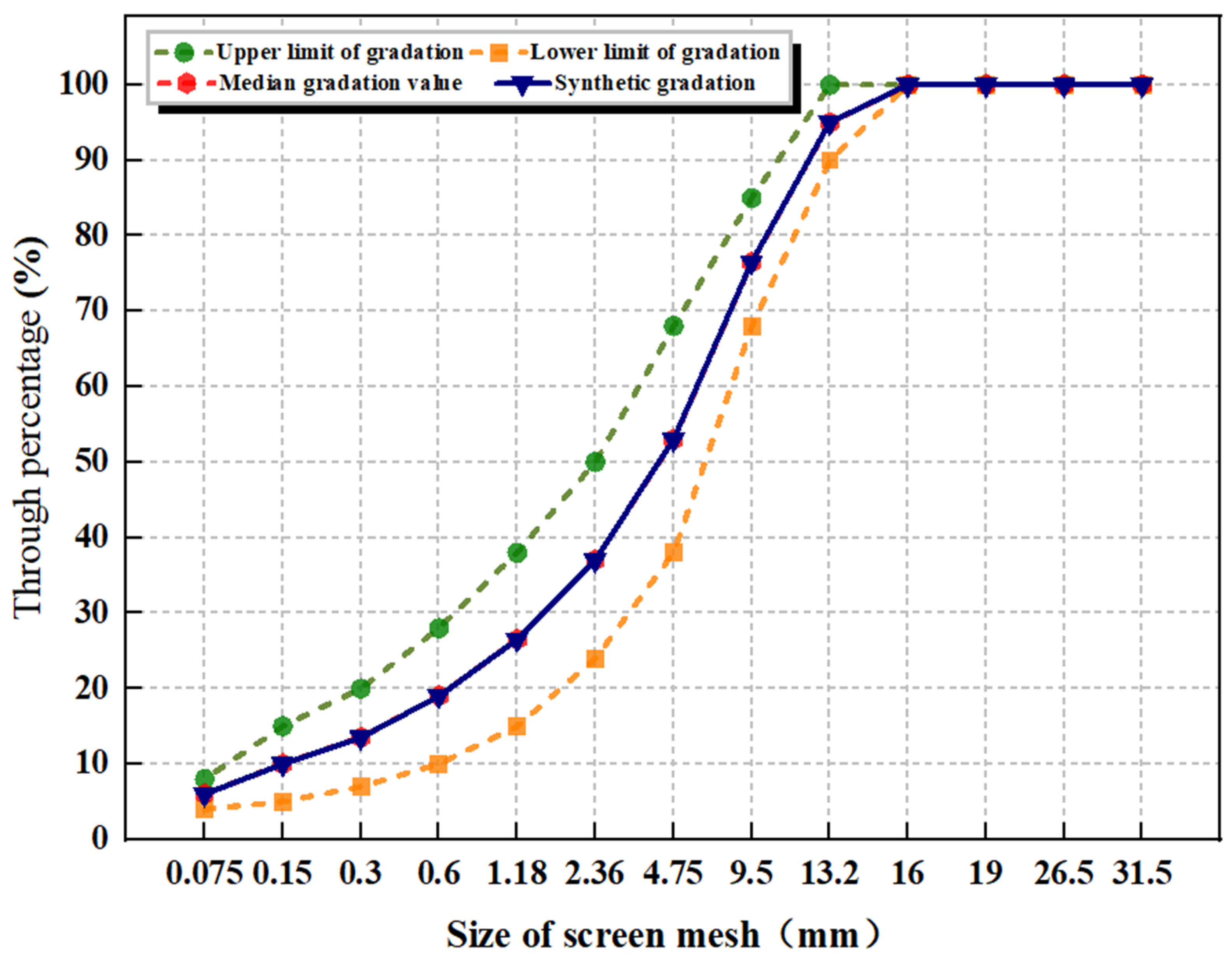

4.6. Gradation Design

4.7. Determination of Polyurethane Gel Dosage

4.8. Road Performance Test of Mixture

4.8.1. High-Temperature Performance

4.8.2. Low-Temperature Performance

4.8.3. Water Stability

4.8.4. Fatigue Property

4.8.5. Slip Resistance

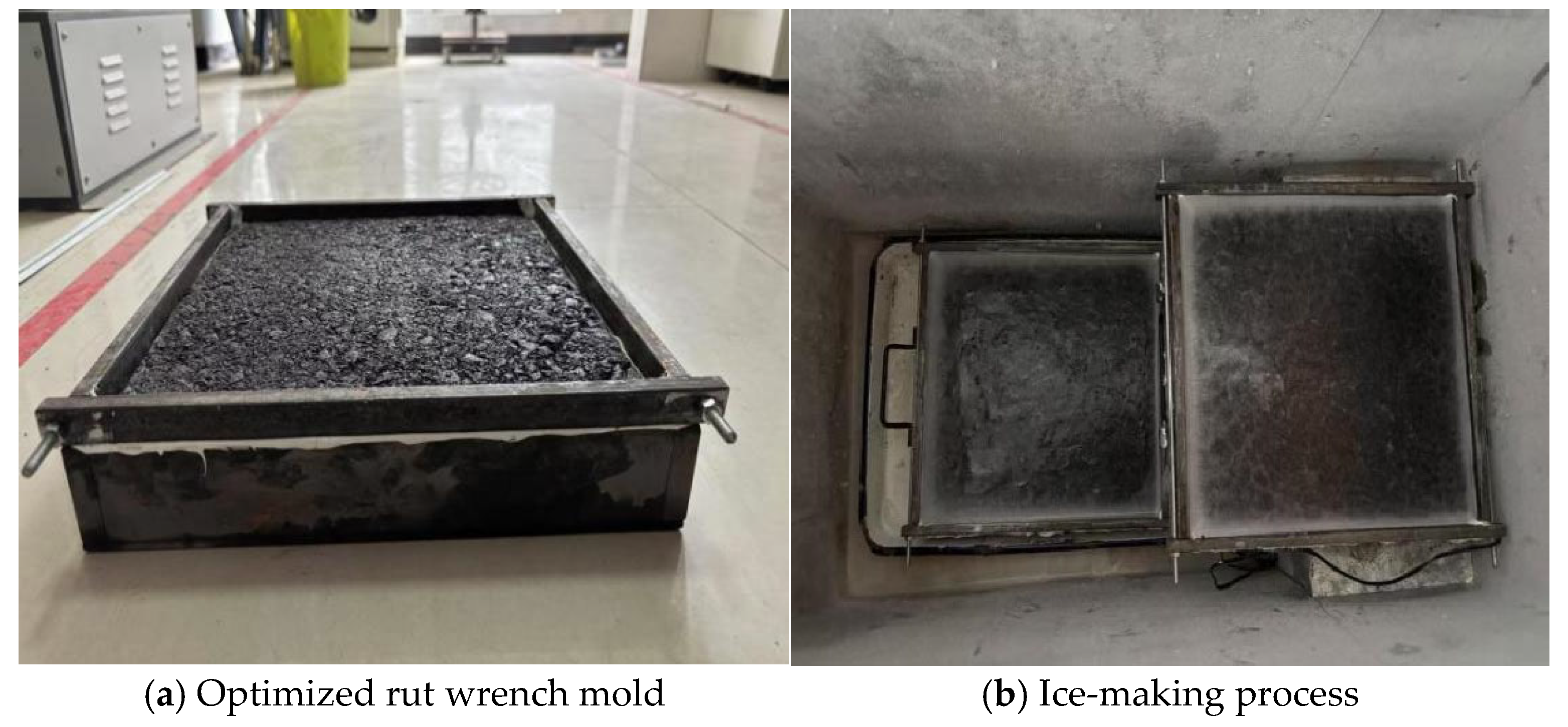

4.9. Indoor Ice-Breaking Test

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, T.; Guo, N.; Tan, Y.; You, Z.; Jin, X. Research status and development trend of phase change materials for road use. Mater. Introd. 2020, 34, 23179–23189. [Google Scholar]

- Das, B.P.; Das, S.; Siddagangaiah, A.K. Probabilistic modeling of fatigue damage in asphalt mixture. Constr. Build. Mater. 2021, 269, 121300. [Google Scholar] [CrossRef]

- Tan, Y.; Li, J.; Xu, H. Perception and early warning of snow and ice conditions on cold roads. Basic Sci. China 2020, 22, 9–15+34. [Google Scholar]

- Dong, Q.; Du, Y.C.; Guo, M. Review of Academic Research on Pavement Engineering in China. Chin. J. Highw. 2024, 37, 1–81. [Google Scholar]

- Liu, Z.; Sha, A.; Jiang, W. Salt asphalt pavement research progress: Salt material, mixture and its performance and evaluation. Chin. J. Highw. 2019, 32, 18–31+72. [Google Scholar]

- Sajid, H.U.; Kiran, R.; Qi, X.; Bajwa, D.S.; Battocchi, D. Employing corn derived products to reduce the corrosivity of pavement deicing materials. Constr. Build. Mater. 2020, 263, 120662. [Google Scholar] [CrossRef]

- Chen, Y.; Tan, Y.; She, H.; Zhang, M.; Jiang, X.; Guo, P.; Li, Y.; Zhang, Y. Characteristics of slow-release ice and snow melting micro-surfacing materials. Int. J. Pavement Eng. 2023, 24, 2120986. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Zhao, C.; Guo, T.; Wang, Z.; Li, J.; Gao, D. Study on environmentally friendly slow-release active melting ice and snow coating materials. Chin. J. Highw. 2020, 33, 155–167. [Google Scholar]

- Li, Z.; Guo, T.; Chen, Y.; Yu, L.; Niu, X.; Yang, X.; Jin, L. Study on road performance and electrothermal performance of poured conductive asphalt concrete. Adv. Mater. Sci. Eng. 2022, 2022, 1–15. [Google Scholar] [CrossRef]

- Wang, C.; Han, X.; Chen, J.; Hou, R.; Zheng, S. Conductive heat effect of guss conductive asphalt concrete. Mater. Introd. 2018, 32, 3891–3899. [Google Scholar]

- Hasan, R.; Ali, A.; Decarlo, C.; Elshaer, M.; Mehta, Y. Laboratory evaluation of electrically conductive asphalt mixtures for snow and ice removal applications. Transp. Res. Rec. 2021, 2675, 48–62. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, C.; Xu, H.; Tian, D. Summarization of research on snow melting and ice melting characteristics and road performance of active de-icing pavement. Chin. J. Highw. 2019, 4, 1–17. [Google Scholar]

- Chen, Y.; Li, Z. Deicing mechanism of crumb rubber asphalt pavement. J. Cent. South Univ. (Nat. Sci. Ed.) 2013, 44, 2073–2081. [Google Scholar]

- Liang, C.; Zhang, H.; Gu, Z.; Xu, X.; Hao, J. Study on Mechanical and Viscoelastic Properties of Asphalt Mixture Modified by Diatomite and Crumb Rubber Particles. Appl. Sci. 2020, 10, 8748. [Google Scholar] [CrossRef]

- Li, S.; Ke, Y.; Xie, L.; Zhao, Z.; Huang, X.; Wang, Y.; Wang, Z. Study on the aging of three typical rubber materials under high-and low-temperature cyclic environment. e-Polymers 2023, 23, 20228089. [Google Scholar] [CrossRef]

- Ma, Z.; Wei, H.; Wei, D.; Jiang, B.; Wang, X. Study on snow melting performance evaluation and optimization design of conductive rubber electric heating pavement. Constr. Build. Mater. 2025, 470, 140556. [Google Scholar] [CrossRef]

- Shan, W.; Zhang, S. Study on the road performance of terminal carboxylated nitrile rubber-modified epoxy asphalt permeable concrete. Materials 2025, 18, 1691. [Google Scholar] [CrossRef]

- Sun, M.; Hou, D.; Geng, L.; Yan, Z.; Bi, Y.; Huang, Z.; Ren, S.; Wang, B. Study on road performance and mechanical properties of multi-gravel polyurethane concrete. Silic. Bull. 2024, 43, 746–756. [Google Scholar]

- Cao, Z.; Hao, Q.; Xu, S.; Han, X.; Yi, J.; Sun, G. Preparation and performance evaluation of bio-based polyurethane modified asphalt binders: Towards greener and more sustainable asphalt modifier. Constr. Build. Mater. 2025, 476, 141209. [Google Scholar] [CrossRef]

- Hesami, S.; Sadeghi, V.; Azizi, A. Investigation of modified bitumen’s rheological properties with synthesized polyurethane by MDI-PPG reactive prepolymers. J. Thermoplast. Compos. Mater. 2019, 143, 741–749. [Google Scholar] [CrossRef]

- Torzs, T.; Lu, G.; Monteiro, A.O. Hydraulic properties of polyurethane-bound permeable pavement materials considering unsaturated flow. Constr. Build. Mater. 2019, 212, 422–430. [Google Scholar] [CrossRef]

- Zheng, Y.; Han, S.; Zheng, H. Design, fabrication, and laboratory performance evaluation of polyurethane poroelastic road surfaces (PERS) mixtures. Constr. Build. Mater. 2025, 473, 141030. [Google Scholar] [CrossRef]

- Gao, J.; Chen, J.; Meng, X.; Wang, H.; Xu, N. Research on the selection of polyurethane adhesive and direct tensile properties of polyurethane rubber particle mixture. Case Stud. Constr. Mater. 2023, 18, e01728. [Google Scholar] [CrossRef]

- Chen, J.; Xie, M.; Hao, W.; Xie, P.; Huang, W. Experimental study on anti-icing and deicing performance of polyurethane concrete as road surface layer. Constr. Build. Mater. 2018, 161, 598–605. [Google Scholar] [CrossRef]

- Chen, J.; Yin, X.; Wang, H.; Ding, Y. Evaluation of durability and functional performance of porous polyurethane mixture in porous pavement. J. Clean. Prod. 2018, 188, 12–19. [Google Scholar] [CrossRef]

- Zou, B.; Yin, J.; Cao, C.; Long, X. Mechanical performance analysis of rubber elastic polymer-polyurethane reinforced cement-based composite grouting materials. J. Polym. Mat. 2025, 42, 255–275. [Google Scholar] [CrossRef]

- Agaavriloaie, L.; Oprea, S.; Barbuta, M.; Florentina, L. Characterisation of polymer concrete with epoxy polyurethane gel acryl matrix. Constr. Build. Mater. 2012, 37, 190–196. [Google Scholar] [CrossRef]

- Min, S.; Bi, Y.; Zheng, M.; Chen, S.; Li, J. Evaluation of a cold-mixed high-performance polyurethane mixture. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Li, G.; Tian, X.; Gao, K.; Wu, Q.; Huang, S.; Xie, Z. Study on the performance and microscopic mechanism of activated crumb rubber synergistic polyurethane composite modified asphalt. Constr. Build. Mater. 2024, 450, 138739. [Google Scholar] [CrossRef]

- Wang, D.; Liu, P.; Leng, Z.; Leng, C.; Lu, G.; Buch, M.; Oeser, M. Suitability of PoroElastic Road Surface (PERS) for urban roads in cold regions: Mechanical and functional performance assessment. J. Clean. Prod. 2017, 165, 1340–1350. [Google Scholar] [CrossRef]

- JTG 3450-2019; Specification for Field Test of Highway Subgrade and Pavement. Ministry of Transport: Beijing, China, 2019.

- GB/T 16777-2008; Test Method for Architectural Waterproofing Coatings. Quality Inspection Press: Beijing, China, 2008.

- GB/T 4472-2011; Determination of Relative Density of Chemical Products. Standard Press: Beijing, China, 2011.

- JTG E20-2011; Test code for asphalt and asphalt mixture of highway engineering. People’ s Traffic Press: Beijing, China, 2011.

| Surface Modification Methods | Without Modification | NaOH Modification | NaClO Modification | KH550 Modification |

|---|---|---|---|---|

| contact angle (°) | 125.5 | 88.6 | 79.8 | 72.3 |

| Without Modification | NaOH Modification | NaClO Modification | KH550 Modification | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ele. | Wt% | At% | ele. | Wt% | At% | ele. | Wt% | At% | ele. | Wt% | At% |

| C | 59.3 | 69.7 | C | 67.2 | 74.9 | C | 60.1 | 70.2 | C | 61.4 | 70.7 |

| O | 17.2 | 18.8 | O | 21.9 | 21.4 | O | 26.3 | 25.3 | O | 21.1 | 20.8 |

| Zn | 17.9 | 6.7 | Zn | 6.3 | 1.4 | Zn | 9.2 | 2.1 | Zn | 7.6 | 2.2 |

| Cl | 1.5 | 2.6 | Cl | 1.9 | 1.0 | Cl | 3.5 | 1.7 | Cl | 1.8 | 1.7 |

| Zr | 0.6 | 0.3 | Zr | 0.2 | 0.2 | Zr | 0.3 | 0.1 | Si | 4.3 | 2.8 |

| S | 0.2 | 0.3 | S | 1.1 | 0.4 | S | 0.2 | 0.4 | Ca | 0.2 | 0.1 |

| K | 0.3 | 0.1 | Ca | 1.2 | 0.4 | Al | 0.1 | 0.1 | N | 3.6 | 1.7 |

| Ca | 2.5 | 0.4 | Al | 0.2 | 0.3 | Ca | 0.3 | 0.1 | — | ||

| Al | 0.5 | 1.1 | — | — | — | ||||||

| Temperature (°C) | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 40 |

|---|---|---|---|---|---|---|---|---|

| temperature correctionΔBPN | −6 | −4 | −3 | 0 | +2 | +3 | +5 | +7 |

| Mix Type | BPN Value | Mean Value | Standard Deviation | Coefficient of Variation | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| AC-13 Asphalt mixture | 71.2 | 70.4 | 69.4 | 70.3 | 0.90 | 1.28 |

| 0% RPGM | 79.4 | 81.8 | 80.5 | 80.6 | 1.20 | 1.49 |

| 5% RPGM | 81.6 | 82.3 | 80.9 | 81.6 | 0.70 | 0.86 |

| 10% RPGM | 83.4 | 84.9 | 82.7 | 83.7 | 1.12 | 1.34 |

| 15% RPGM | 85.9 | 85.4 | 86.8 | 86.0 | 0.71 | 0.82 |

| Technology Index | Moisture Content/% | Apparent Density/g/cm3 | Shore Hardness/% | Elastic Modulus/MPA | Slender Flat Particle Content/% | Carbon Black Content/% |

|---|---|---|---|---|---|---|

| technical requirement | <1 | 1.10–1.30 | 55–80 | ≥5 | ≤10 | 25–38 |

| test result | 0.22 | 1.153 | 69 | 10 | 3.9 | 32 |

| Testing Item | Technical Requirement | Test Result |

|---|---|---|

| density | actual measurement | 1.4 g/cm3 |

| viscosity | ≥1 | 3.5 mPa·s |

| tensile strength | ≥2 | 7.0 MPa |

| breaking elongation | ≥150 | 298% |

| surface dry time | - | 2 h |

| hard drying time | - | 10 h |

| Project | Purity | Active Chlorine | Free Alkali (in NaOH) | Fe | As | Heavy Metals (in Pb) |

|---|---|---|---|---|---|---|

| index | analytically pure | ≥5.5% | 0.1–1.0% | ≤0.003% | ≤0.0005% | ≤0.002% |

| Physical Property | Appearance | Boiling Point/°C | Specific Gravity | Solubility |

|---|---|---|---|---|

| Numerical and Description | Colorless Liquid | 208 | 0.947 | Soluble in water and organic solvents |

| NO. | Type | Materials | Technical Indexes |

|---|---|---|---|

| 1 | Coarse aggregate | Basalt | Apparent specific gravity (13.2 mm~16 mm) 2.745 Apparent specific gravity (9.5 mm~13.2 mm) 2.736 Apparent specific gravity (4.75 mm~9.5 mm) 2.724 Apparent specific gravity (2.36 mm~4.75 mm) 2.753 Water absorption (13.2 mm~16 mm) 1.1% Water absorption (9.5 mm~13.2 mm) 0.9% Water absorption (4.75 mm~9.5 mm) 0.7% Water absorption (2.36 mm~4.75 mm) 1.2% Crush value 18.2% |

| 2 | Fine aggregate | Limestone | Apparent specific gravity (1.18 mm~2.36 mm) 2.776 Apparent specific gravity (0.6 mm~1.18 mm) 2.792 Sand equivalent (1.18 mm~2.36 mm) 75% Sand equivalent (0.6 mm~1.18 mm) 77% |

| 3 | Mineral fines | Limestone | Apparent specific gravity 2.654 No agglomeration Hydrophilicity 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Li, Z.; Guo, T.; Fang, C.; Yang, J.; Guo, P.; Wang, C.; Bai, B.; Zhang, W.; Tang, D.; et al. Study on Road Performance and Ice-Breaking Effect of Rubber Polyurethane Gel Mixture. Gels 2025, 11, 505. https://doi.org/10.3390/gels11070505

Chen Y, Li Z, Guo T, Fang C, Yang J, Guo P, Wang C, Bai B, Zhang W, Tang D, et al. Study on Road Performance and Ice-Breaking Effect of Rubber Polyurethane Gel Mixture. Gels. 2025; 11(7):505. https://doi.org/10.3390/gels11070505

Chicago/Turabian StyleChen, Yuanzhao, Zhenxia Li, Tengteng Guo, Chenze Fang, Jingyu Yang, Peng Guo, Chaohui Wang, Bing Bai, Weiguang Zhang, Deqing Tang, and et al. 2025. "Study on Road Performance and Ice-Breaking Effect of Rubber Polyurethane Gel Mixture" Gels 11, no. 7: 505. https://doi.org/10.3390/gels11070505

APA StyleChen, Y., Li, Z., Guo, T., Fang, C., Yang, J., Guo, P., Wang, C., Bai, B., Zhang, W., Tang, D., & Feng, J. (2025). Study on Road Performance and Ice-Breaking Effect of Rubber Polyurethane Gel Mixture. Gels, 11(7), 505. https://doi.org/10.3390/gels11070505