Pasting and Gel Behavior of Durum Wheat Derivatives

Abstract

1. Introduction

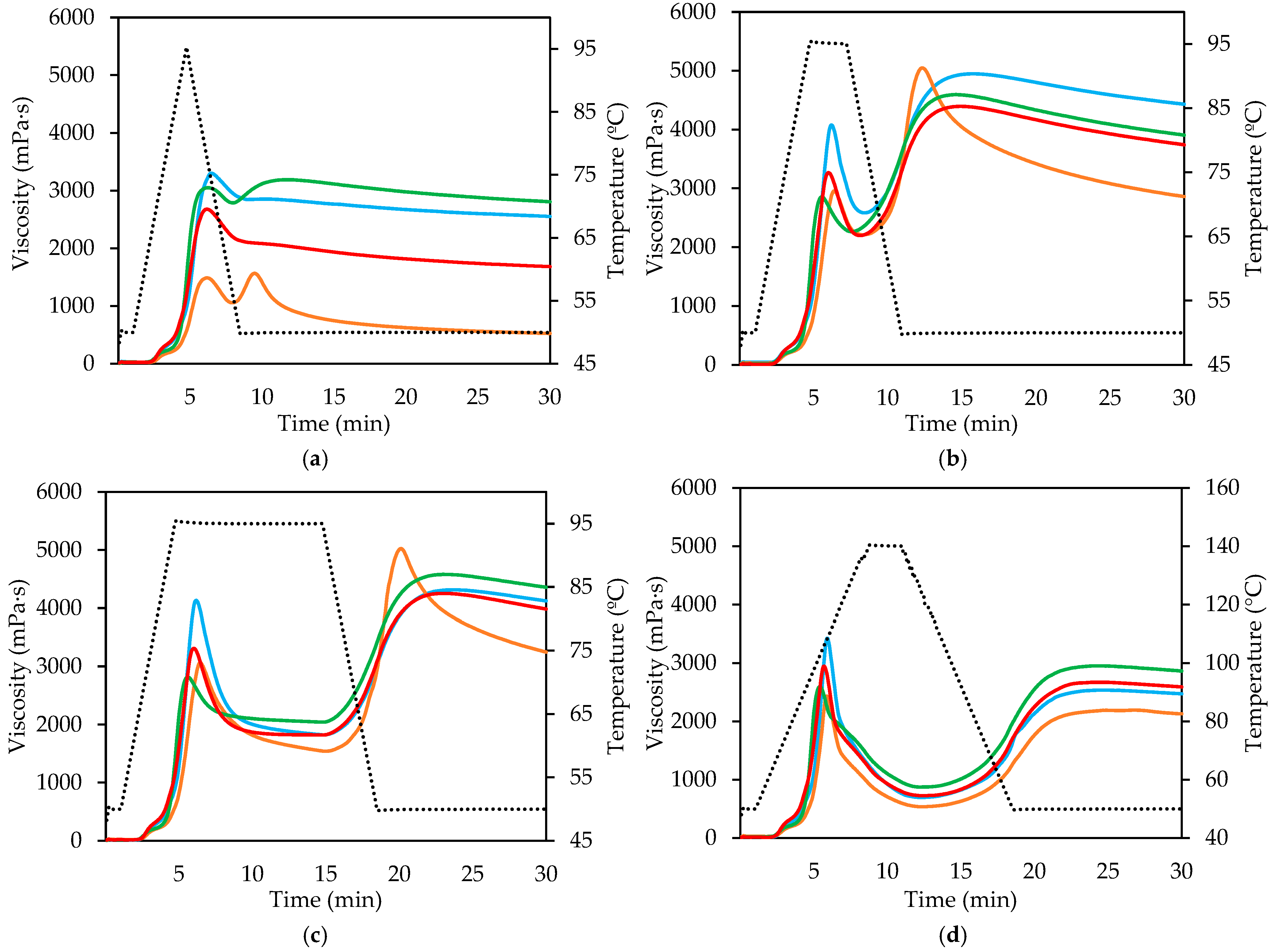

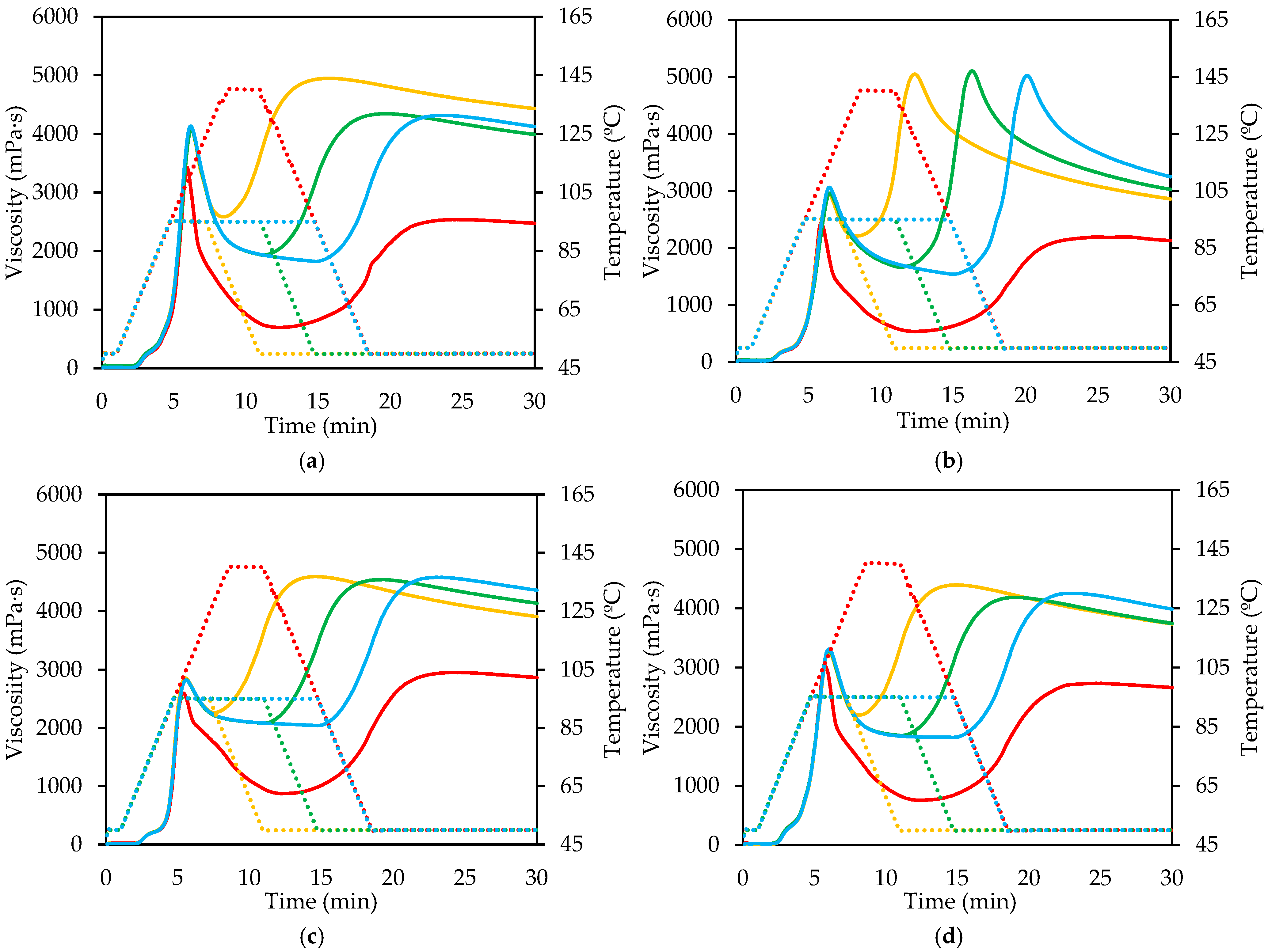

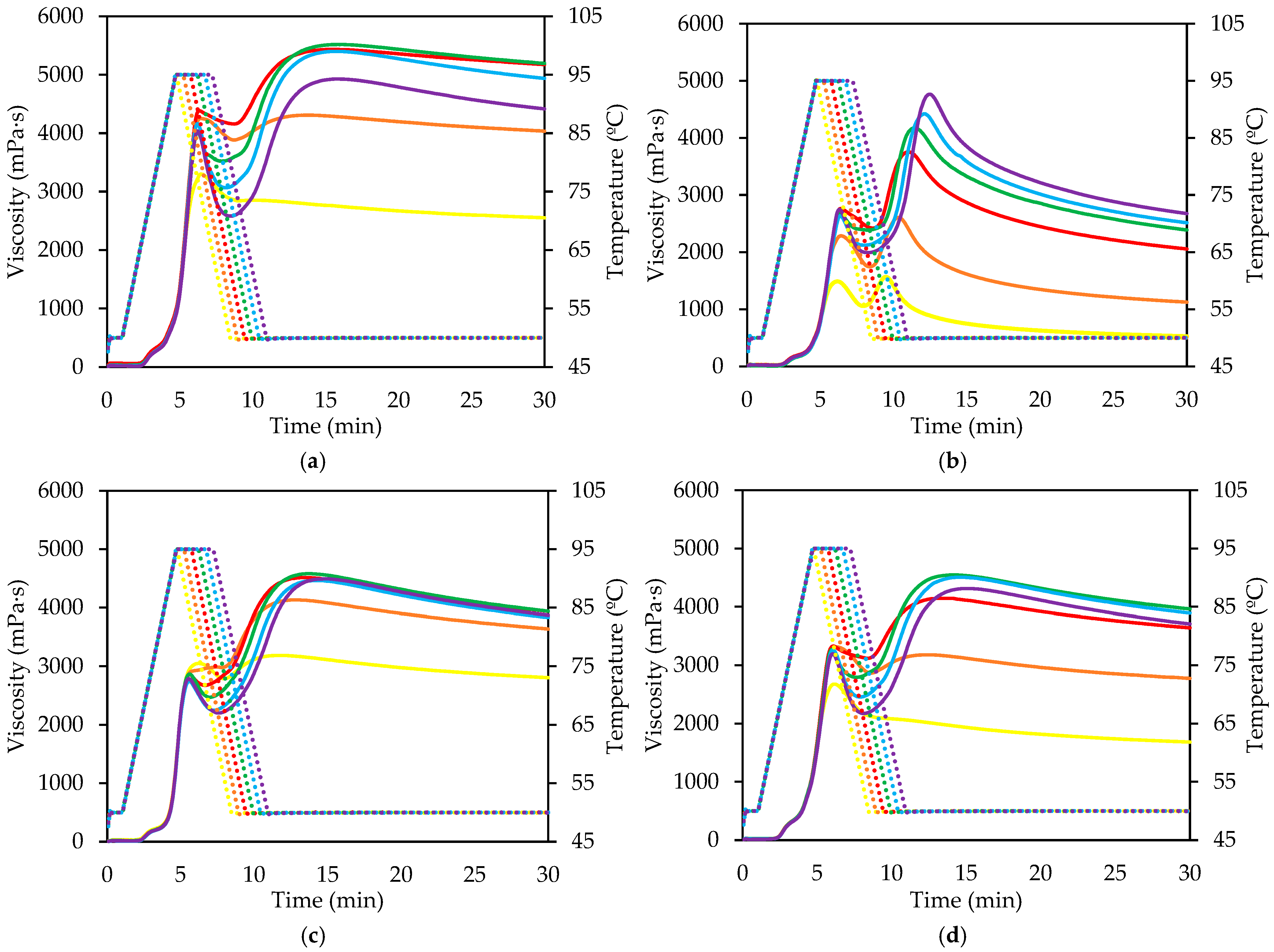

2. Results and Discussion

3. Conclusions

4. Materials and Methods

4.1. Materials

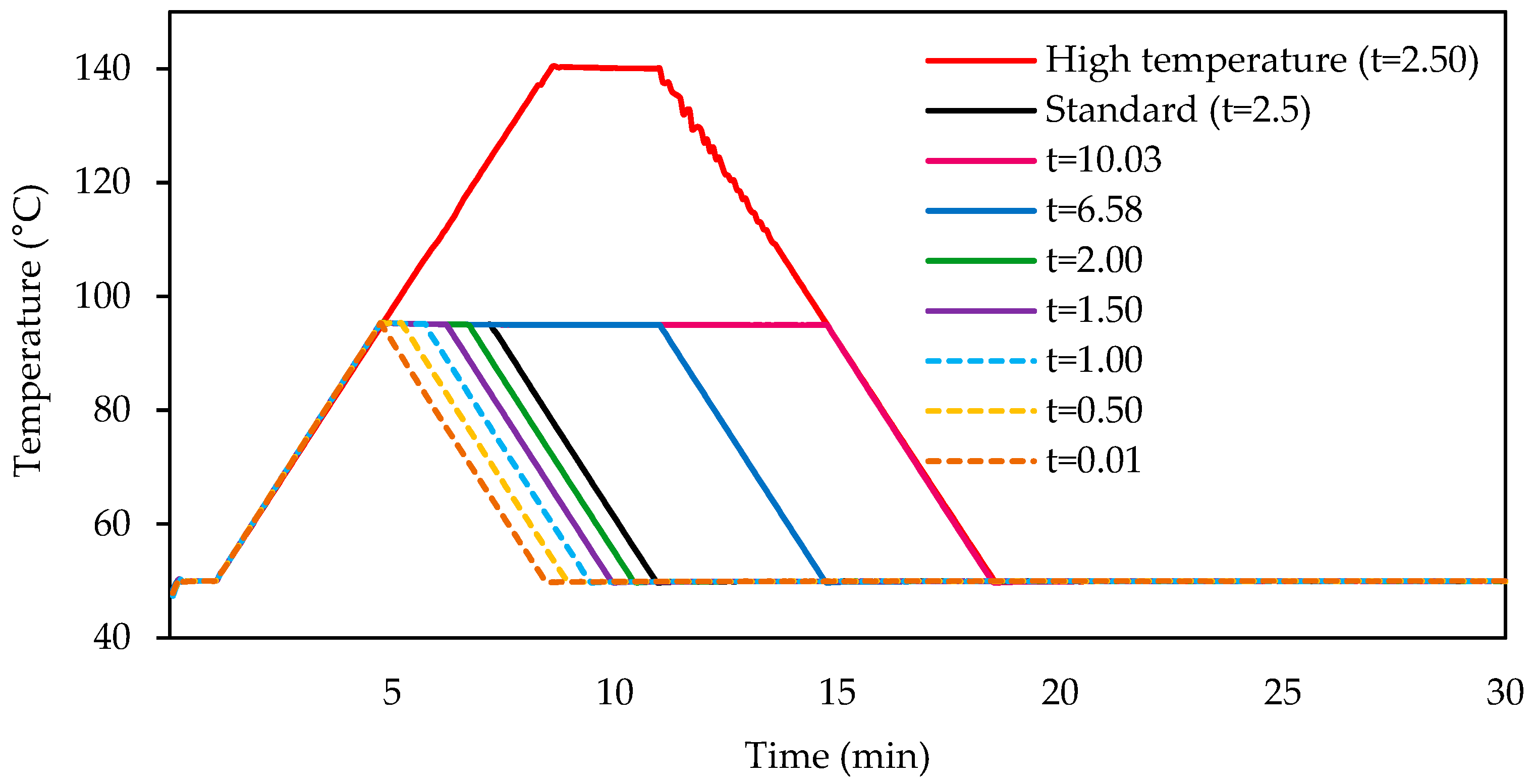

4.2. Methods

4.2.1. Semolina and Flour Characterization

4.2.2. Hydrothermal Treatment

4.2.3. Textural Properties of Gels

4.2.4. Statistical Analysis

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hancock, R.D.; Tarbet, B.J. The Other Double Helix—The Fascinating Chemistry of Starch. J. Chem. Educ. 2000, 77, 988. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Huang, T.; Gong, B.; Yu, W.W. A combined action of amylose and amylopectin fine molecular structures in determining the starch pasting and retrogradation property. Int. J. Biol. Macromol. 2020, 164, 2717–2725. [Google Scholar] [CrossRef]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016, 191, 45–51. [Google Scholar] [CrossRef]

- Saleh, M.I.; Abu-Waar, Z.Y.; Akash, M.W.; Al-Dabbas, M. Effect of stabilized rice bran fractions on the formation of rice flour pasting properties. Cereal Chem. 2014, 91, 603–609. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Guo, X.; Zhu, K.; Wu, Z. A Review of the Impact of Starch on the Quality of Wheat-Based Noodles and Pasta: From the View of Starch Structural and Functional Properties and Interaction with Gluten. Foods 2024, 13, 1507. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013, 4, 1564. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Fu, B.X. Impact of quality improvement and milling innovations on durum wheat and end products. Foods 2022, 11, 1796. [Google Scholar] [CrossRef] [PubMed]

- Sissons, M.J.; Batey, I.L.; Balfe, S.; Hare, R.; MacRitchie, F. Use of durum residue flour, a lower value product of durum milling, by incorporation into wheat flour dough without deterioration in baking quality. J. Sci. Food Agric. 2008, 88, 1194–1200. [Google Scholar] [CrossRef]

- Jalgaonkar, K.; Jha, S.K. Influence of particle size and blend composition on quality of wheat semolina-pearl millet pasta. J. Cereal Sci. 2016, 71, 239–245. [Google Scholar] [CrossRef]

- Arena, E.; Muccilli, S.; Mazzaglia, A.; Giannone, V.; Brighina, S.; Rapisarda, P.; Fallico, B.; Allegra, M.; Spina, A. Development of durum wheat breads low in sodium using a natural low-sodium sea salt. Foods 2020, 9, 752. [Google Scholar] [CrossRef]

- Giannone, V.; Giarnetti, M.; Spina, A.; Todaro, A.; Pecorino, B.; Summo, C.; Caponio, F.; Paradiso, V.M.; Pasqualone, A. Physico-chemical properties and sensory profile of durum wheat Dittaino PDO (Protected Designation of Origin) bread and quality of re-milled semolina used for its production. Food Chem. 2018, 241, 242–249. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists International, 11th ed.; Methods: 44-15.02 (moisture), 935.42 (ash), 989.05 (fat), 945.18B (protein), 76-21.02 (RVA); American Association of Cereal Chemists: St. Paul, MN, USA, 2012. [Google Scholar]

- Lee, D.-J.; Cheng, F.; Li, D.; Ding, K.; Carlin, J.; Moore, E.; Ai, Y. Important roles of coarse particles in pasting and gelling performance of different pulse flours under high-temperature heating. Food Chem. 2024, 447, 138896. [Google Scholar] [CrossRef]

- Yuan, T.Z.; Liu, S.; Reimer, M.; Isaak, C.; Ai, Y. Evaluation of pasting and gelling properties of commercial flours under high heating temperatures using Rapid Visco Analyzer 4800. Food Chem. 2021, 344, 128616. [Google Scholar] [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of particle size on the properties of rice flour and quality of gluten-free rice bread. LWT 2021, 151, 112236. [Google Scholar] [CrossRef]

- Roman, L.; Gomez, M.; Li, C.; Hamaker, B.R.; Martinez, M.M. Biophysical features of cereal endosperm that decrease starch digestibility. Carbohydr. Polym. 2017, 165, 180–188. [Google Scholar] [CrossRef] [PubMed]

- Edwards, C.H.; Warren, F.J.; Campbell, G.M.; Gaisford, S.; Royall, P.G.; Butterworth, P.J.; Ellis, P.R. A study of starch gelatinisation behaviour in hydrothermally-processed plant food tissues and implications for in vitro digestibility. Food Funct. 2015, 6, 3634–3641. [Google Scholar] [CrossRef] [PubMed]

- Korompokis, K.; de Brier, N.; Delcour, J.A. Differences in endosperm cell wall integrity in wheat (Triticum aestivum L.) milling fractions impact on the way starch responds to gelatinization and pasting treatments and its subsequent enzymatic in vitro digestibility. Food Funct. 2019, 10, 4674–4684. [Google Scholar] [CrossRef]

- Li, E.; Dhital, S.; Hasjim, J. Effects of grain milling on starch structures and flour/starch properties. Starch—Stärke 2014, 66, 15–27. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, L.; Li, D.; Zhou, Y.; Adhikari, B. The effect of partial gelatinization of corn starch on its retrogradation. Carbohydr. Polym. 2013, 97, 512–517. [Google Scholar] [CrossRef]

- BeMiller, J.N.; Huber, K.C. Physical Modification of Food Starch Functionalities. Annu. Rev. Food Sci. Technol. 2015, 6, 19–69. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Wang, P.; Zhao, Y.; Zhu, Y.; Xiao, X. The Effect of Protein–Starch Interaction on the Structure and Properties of Starch, and Its Application in Flour Products. Foods 2025, 14, 778. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, T.Z.; Wang, X.; Reimer, M.; Isaak, C.; Ai, Y. Behaviors of starches evaluated at high heating temperatures using a new model of Rapid Visco Analyzer—RVA 4800. Food Hydrocoll. 2019, 94, 217–228. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Ai, Y. Gelation mechanisms of granular and non-granular starches with variations in molecular structures. Food Hydrocoll. 2022, 129, 107658. [Google Scholar] [CrossRef]

- Hoover, R.; Hughes, T.; Chung, H.J.; Liu, Q. Composition molecular structure, properties, and modification of pulse starches: A review. Food Res. Int. 2010, 43, 399–413. [Google Scholar] [CrossRef]

- Fadda, C.; Sanguinetti, A.M.; Del Caro, A.; Collar, C.; Piga, A. Bread staling: Updating the view. Compr. Rev. Food Sci. Food Saf. 2014, 13, 473–492. [Google Scholar] [CrossRef] [PubMed]

| Sample | Treatment | Hardness (g) | Final Viscosity (mPa·s) |

|---|---|---|---|

| CWF | 2.50 (HT) | 328.12 ± 16.87 ef | 4448.50 ± 106.77 k |

| 10.00 | 352.53 ± 33.77 fg | 4266.50 ± 198.70 k | |

| 2.50 (S) | 383.16 ± 11.99 fgh | 4365.00 ± 11.31 k | |

| 1.00 | 474.05 ± 37.28 ij | 5167.50 ± 91.22 l | |

| 0.50 | 530.51 ± 53.82 kl | 4028.50 ± 10.61 j | |

| 0.01 | 291.40 ± 16.32 de | 2549.50 ± 112.43 e | |

| DWF | 2.50 (HT) | 156.20 ± 64.52 c | 2072.00 ± 32.53 d |

| 10.00 | 64.91 ± 2.22 b | 3113.00 ± 206.48 h | |

| 2.50 (S) | 140.05 ± 7.73 c | 2697.50 ± 44.55 ef | |

| 1.00 | - | 2043.00 ± 101.82 d | |

| 0.50 | - | 1155.50 ± 62.93 b | |

| 0.01 | 559.24 ± 7.86 kl | 2921.50 ± 24.75 g | |

| DWS | 2.50 (HT) | 368.22 ± 11.80 fg | 2815.00 ± 77.78 fg |

| 10.00 | 473.29 ± 34.29 ij | 4376.00 ± 45.25 k | |

| 2.50 (S) | 371.01 ± 7.67 fg | 3941.50 ± 44.55 j | |

| 1.00 | 435.39 ± 39.62 hi | 3986.50 ± 167.58 j | |

| 0.50 | 515.13 ± 2.18 jk | 3654.00 ± 15.56 i | |

| 0.01 | 559.24 ± 7.86 kl | 2921.50 ± 24.75 g | |

| RMS | 2.50 (HT) | 284.44 ± 50.68 de | 2607.00 ± 66.47 e |

| 10.00 | 265.31 ± 20.38 d | 3966.00 ± 45.25 j | |

| 2.50 (S) | 391.86 ± 6.46 gh | 3677.00 ± 114.55 i | |

| 1.00 | 581.41 ± 25.64 l | 3727.00 ± 94.75 i | |

| 0.50 | 473.25 ± 9.57 ij | 2871.00 ± 45.25 fg | |

| 0.01 | 252.71 ± 5.60 d | 1744.50 ± 4.95 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvati, D.; Moreno, L.; Antolín-Rodríguez, J.M.; Gómez, M. Pasting and Gel Behavior of Durum Wheat Derivatives. Gels 2025, 11, 991. https://doi.org/10.3390/gels11120991

Salvati D, Moreno L, Antolín-Rodríguez JM, Gómez M. Pasting and Gel Behavior of Durum Wheat Derivatives. Gels. 2025; 11(12):991. https://doi.org/10.3390/gels11120991

Chicago/Turabian StyleSalvati, Diogo, Laura Moreno, Juan Manuel Antolín-Rodríguez, and Manuel Gómez. 2025. "Pasting and Gel Behavior of Durum Wheat Derivatives" Gels 11, no. 12: 991. https://doi.org/10.3390/gels11120991

APA StyleSalvati, D., Moreno, L., Antolín-Rodríguez, J. M., & Gómez, M. (2025). Pasting and Gel Behavior of Durum Wheat Derivatives. Gels, 11(12), 991. https://doi.org/10.3390/gels11120991