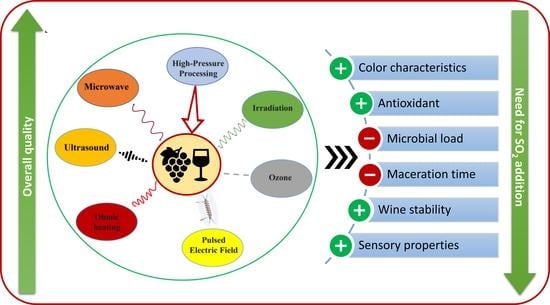

The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement

Abstract

1. Introduction

2. Novel Processing Techniques

2.1. High-Pressure Processing (HPP)

| Conditions | Type of Wine | Effect | References |

|---|---|---|---|

| 500 MPa for 5 min at 40 °C | White and red |

| [18,23] |

| 600 MPa for 5 min | Syrah, Pinot Noir, Rosé, Sauvignon blanc, Pinot Gris |

| [22] |

| 100–350 MPa, 25 °C, 0–30 min | Low-alcohol red |

| [24] |

| 600 MPa, 70 °C, 30 min and 1 h | Dornfelder |

| [25] |

| 650 MPa for 15 min | Red wine |

| [21] |

| 551 MPa for 10 min | Red grape must |

| [26] |

| 350 MPa for 10 min at 8 °C | Red wine |

| [27] |

| 200–600 MPa for 5 min at 20 °C | Red raspberry wine |

| [28,29,30] |

2.2. Ultrasound (US)

2.3. Pulsed Electric Field (PEF)

| Conditions | Type of Wine | Effect | References |

|---|---|---|---|

| 23 kV/cm, 95 KJ/Kg, 8 µs, continuous flow, T < 22 °C | Tempranillo |

| [52] |

| 50 kV/cm, 117–121 KJ/kg, 1.7 µs, square bipolar pulses, T = 10 °C | Red wine |

| [51] |

| 16–31 kV/cm, 10–350 KJ/kg, decay waveform pulses, T = 24 °C | Red wine and must |

| [46] |

| 1.5 kV/cm, 8 µs at 11 kJ /kg and 16 µs at 22 kJ/ kg, square wave pulses, frequency of 600 Hz, T = 20 °C | Garganega white wine |

| [53] |

| 1.5 kV/cm, 1 µs at 2 kJ /kg, 5 µs at 10 kJ /kg and 10 µs at 20 kJ/ kg, square wave pulses, frequency 400 Hz at 22 °C | Rondinella red wine |

| [54] |

| 3 kV/cm, 3 and 10 kJ/kg, 3 s. Rectangular wave pulses at 15 °C + enzymes | Traminer and Grüner Veltliner white wines |

| [55] |

| 0.9–3 kV/cm, 10.4–32.5 kJ/kg, square waveform pulses, 1500 Hz frequency for 10 µs | Sangiovese red grape must and wine |

| [56] |

2.4. Microwave (MW)

| Conditions | Type of Wine | Effect | References |

|---|---|---|---|

| 1150 W, for 2 min, 1 min and 14–40 s | Pinot noir red wine |

| [62] |

| 1200 W, for 10 min | Merlot red wine |

| [63] |

| 400 W, for 10 min | Tempranillo red wine |

| [64]. |

| 200 W and 300 W | Wine lees (Syrah grapes & Port wine lees) |

| [66,67] |

| 700 W for 12 min | Cabernet sauvignon red wine |

| [65] |

| 500 W at 5, 10, 15, and 20 min | Red wine |

| [68] |

| Industrial microwave at 70 °C (whites) or 60 °C (reds) for 4 min 0 W, for 10 min | Red and white wine |

| [69] |

| Domestic microwave 700 W for 4 min repeated 3 times | Cabernet sauvignon red wine |

| [70] |

2.5. Irradiation (IR)

2.6. Other Non-Thermal Technologies

2.6.1. Ozone (O3)

2.6.2. Ohmic Heating (OH)

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Panesar, P.S.; Joshi, V.K.; Bali, V.; Panesar, R. Chapter 9—Technology for Production of Fortified and Sparkling Fruit Wines. In Science and Technology of Fruit Wine Production; Kosseva, M.R., Joshi, V.K., Panesar, P.S., Eds.; Academic Press: San Diego, CA, USA, 2017; pp. 487–530. ISBN 978-0-12-800850-8. [Google Scholar]

- Wine Market Size, Share, Analysis and Industry Trends (2028). Available online: https://www.fortunebusinessinsights.com/wine-market-102836 (accessed on 9 February 2023).

- OIV—International Organisation of Vine and Wine. State of the World Vitivinicultuyral Sector in 2021; Intergovernmental Organisation: Paris, France, 2022; p. 20. [Google Scholar]

- Lisanti, M.T.; Blaiotta, G.; Nioi, C.; Moio, L. Alternative Methods to SO2 for Microbiological Stabilization of Wine. Compr. Rev. Food Sci. Food Saf. 2019, 18, 455–479. [Google Scholar] [CrossRef] [PubMed]

- Avramova, M.; Vallet-Courbin, A.; Maupeu, J.; Masneuf-Pomarède, I.; Albertin, W. Molecular Diagnosis of Brettanomyces Bruxellensis’ Sulfur Dioxide Sensitivity Through Genotype Specific Method. Front. Microbiol. 2018, 9, 1260. [Google Scholar] [CrossRef] [PubMed]

- du Toit, M.; Pretorius, I.S. Microbial Spoilage and Preservation of Wine: Using Weapons from Nature’s Own Arsenal—A Review. S. Afr. J. Enol. Vitic. 2000, 21, 74–96. [Google Scholar] [CrossRef]

- Golombek, P.; Wacker, M.; Buck, N.; Durner, D. Impact of UV-C Treatment and Thermal Pasteurization of Grape Must on Sensory Characteristics and Volatiles of Must and Resulting Wines. Food Chem. 2021, 338, 128003. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.S. Post-Fermentation Treatments and Related Topics. In Wine Science; Elsevier: Amsterdam, The Netherlands, 2014; pp. 535–676. ISBN 978-0-12-381468-5. [Google Scholar]

- Tiwari, B.K.; O’Donnell, C.P.; Cullen, P.J. Effect of Non Thermal Processing Technologies on the Anthocyanin Content of Fruit Juices. Trends Food Sci. Technol. 2009, 20, 137–145. [Google Scholar] [CrossRef]

- van Wyk, S.; Silva, F.V.M. High Pressure Inactivation of Brettanomyces Bruxellensis in Red Wine. Food Microbiol. 2017, 63, 199–204. [Google Scholar] [CrossRef]

- Chakka, A.K.; Sriraksha, M.S.; Ravishankar, C.N. Sustainability of Emerging Green Non-Thermal Technologies in the Food Industry with Food Safety Perspective: A Review. LWT 2021, 151, 112140. [Google Scholar] [CrossRef]

- Hernández-Hernández, H.M.; Moreno-Vilet, L.; Villanueva-Rodríguez, S.J. Current Status of Emerging Food Processing Technologies in Latin America: Novel Non-Thermal Processing. Innov. Food Sci. Emerg. Technol. 2019, 58, 102233. [Google Scholar] [CrossRef]

- Roos, Y.H.; Fryer, P.J.; Knorr, D.; Schuchmann, H.P.; Schroën, K.; Schutyser, M.A.I.; Trystram, G.; Windhab, E.J. Food Engineering at Multiple Scales: Case Studies, Challenges and the Future—A European Perspective. Food Eng. Rev. 2016, 8, 91–115. [Google Scholar] [CrossRef]

- Shahbaz, H.M.; Kim, J.U.; Kim, S.-H.; Park, J. Advances in Nonthermal Processing Technologies for Enhanced Microbiological Safety and Quality of Fresh Fruit and Juice Products. In Food Processing for Increased Quality and Consumption; Elsevier: Amsterdam, The Netherlands, 2018; pp. 179–217. ISBN 978-0-12-811447-6. [Google Scholar]

- Lukić, K.; Brnčić, M.; Ćurko, N.; Tomašević, M.; Jurinjak Tušek, A.; Kovačević Ganić, K. Quality Characteristics of White Wine: The Short- and Long-Term Impact of High Power Ultrasound Processing. Ultrason. Sonochem. 2020, 68, 105194. [Google Scholar] [CrossRef]

- Falguera, V.; Forns, M.; Ibarz, A. UV–Vis Irradiation: An Alternative to Reduce SO2 in White Wines? LWT Food Sci. Technol. 2013, 51, 59–64. [Google Scholar] [CrossRef]

- van Wyk, S.; Silva, F.V.M. Nonthermal Preservation of Wine. In Preservatives and Preservation Approaches in Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 203–235. ISBN 978-0-12-816685-7. [Google Scholar]

- Santos, M.C.; Nunes, C.; Saraiva, J.A.; Coimbra, M.A. Chemical and Physical Methodologies for the Replacement/Reduction of Sulfur Dioxide Use during Winemaking: Review of Their Potentialities and Limitations. Eur. Food Res. Technol. 2012, 234, 1–12. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Kwaw, E.; Zhang, H.; Xiao, L.; Apaliya, M.T. Statistical Interpretation of Chromatic Indicators in Correlation to Phytochemical Profile of a Sulfur Dioxide-Free Mulberry (Morus Nigra) Wine Submitted to Non-Thermal Maturation Processes. Food Chem. 2018, 239, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Evelyn; Kim, H.J.; Silva, F.V.M. Modeling the Inactivation of Neosartorya Fischeri Ascospores in Apple Juice by High Pressure, Power Ultrasound and Thermal Processing. Food Control 2016, 59, 530–537. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.-W.; Górecki, A.; Błaszczak, W.; Lamparski, G.; Amarowicz, R.; Fornal, J.; Jeliński, T. Effects of High Hydrostatic Pressure Processing on the Physicochemical and Sensorial Properties of a Red Wine. Innov. Food Sci. Emerg. Technol. 2012, 16, 409–416. [Google Scholar] [CrossRef]

- van Wyk, S.; Hong, L.; Silva, F.V.M. Non-Thermal High Pressure Processing, Pulsed Electric Fields and Ultrasound Preservation of Five Different Table Wines. Beverages 2021, 7, 69. [Google Scholar] [CrossRef]

- Puig, A.; Vilavella, M.; Daoudi, L.; Guamis, B.; Mínguez, S. Microbiological and Biochemical Stabilization of Wines by Application of the High Pressure Technique. Bulletin de l’ OIV 2003, 76, 596–617. [Google Scholar]

- Mok, C.; Song, K.-T.; Park, Y.-S.; Lim, S.; Ruan, R.; Chen, P. High Hydrostatic Pressure Pasteurization of Red Wine. J. Food Sci. 2006, 71, M265–M269. [Google Scholar] [CrossRef]

- Corrales, M.; Butz, P.; Tauscher, B. Anthocyanin Condensation Reactions under High Hydrostatic Pressure. Food Chem. 2008, 110, 627–635. [Google Scholar] [CrossRef]

- Takush, D.G.; Osborne, J.P. Investigating High Hydrostatic Pressure Processing as a Tool for Studying Yeast during Red Winemaking. Am. J. Enol. Vitic. 2011, 62, 536–541. [Google Scholar] [CrossRef]

- Christofi, S.; Malliaris, D.; Katsaros, G.; Panagou, E.; Kallithraka, S. Limit SO2 Content of Wines by Applying High Hydrostatic Pressure. Innov. Food Sci. Emerg. Technol. 2020, 62, 102342. [Google Scholar] [CrossRef]

- Cao, Z.; Li, Y.; Yu, C.; Li, S.; Zhang, X.; Tian, Y. Effect of High Hydrostatic Pressure on the Quality of Red Raspberry Wine. Food Process. Preserv. 2022, 46, e16030. [Google Scholar] [CrossRef]

- Liu, Y.; He, F.; Shi, Y.; Zhang, B.; Duan, C.-Q. Effect of the High Pressure Treatments on the Physicochemical Properties of the Young Red Wines Supplemented with Pyruvic Acid. Innov. Food Sci. Emerg. Technol. 2018, 48, 56–65. [Google Scholar] [CrossRef]

- Santos, M.C.; Nunes, C.; Cappelle, J.; Gonçalves, F.J.; Rodrigues, A.; Saraiva, J.A.; Coimbra, M.A. Effect of High Pressure Treatments on the Physicochemical Properties of a Sulphur Dioxide-Free Red Wine. Food Chem. 2013, 141, 2558–2566. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.C.; Nunes, C.; Jourdes, M.; Teissedre, P.-L.; Rodrigues, A.; Amado, O.; Saraiva, J.A.; Coimbra, M.A. Evaluation of the Potential of High Pressure Technology as an Enological Practice for Red Wines. Innov. Food Sci. Emerg. Technol. 2016, 33, 76–83. [Google Scholar] [CrossRef]

- OIV. International Code of Oenological Practices; OIV: Paris, France, 2022. [Google Scholar]

- Bevilacqua, A.; Sinigaglia, M.; Corbo, M.R. Ultrasound and Antimicrobial Compounds: A Suitable Way to Control Fusarium Oxysporum in Juices. Food Bioprocess Technol. 2013, 6, 1153–1163. [Google Scholar] [CrossRef]

- Kumar, Y.; Roy, S.; Devra, A.; Dhiman, A.; Prabhakar, P.K. Ultrasonication of Mayonnaise Formulated with Xanthan and Guar Gums: Rheological Modeling, Effects on Optical Properties and Emulsion Stability. LWT 2021, 149, 111632. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Murray, B.; Flynn, C.; Norton, I. The Effect of Ultrasound Treatment on the Structural, Physical and Emulsifying Properties of Animal and Vegetable Proteins. Food Hydrocoll. 2016, 53, 141–154. [Google Scholar] [CrossRef]

- Pingret, D.; Fabiano-Tixier, A.-S.; Chemat, F. Degradation during Application of Ultrasound in Food Processing: A Review. Food Control 2013, 31, 593–606. [Google Scholar] [CrossRef]

- Sharma, H.; Singh, A.K.; Borad, S.; Deshwal, G.K. Processing Stability and Debittering of Tinospora Cordifolia (Giloy) Juice Using Ultrasonication for Potential Application in Foods. LWT 2021, 139, 110584. [Google Scholar] [CrossRef]

- Wang, H.; Tao, Y.; Li, Y.; Wu, S.; Li, D.; Liu, X.; Han, Y.; Manickam, S.; Show, P.L. Application of Ultrasonication at Different Microbial Growth Stages during Apple Juice Fermentation by Lactobacillus Plantarum: Investigation on the Metabolic Response. Ultrason. Sonochem. 2021, 73, 105486. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; García, J.F.; Sun, D.-W. Advances in Wine Aging Technologies for Enhancing Wine Quality and Accelerating Wine Aging Process. Crit. Rev. Food Sci. Nutr. 2014, 54, 817–835. [Google Scholar] [CrossRef] [PubMed]

- Celotti, E.; Osorio Barahona, M.S.; Bellantuono, E.; Cardona, J.; Roman, T.; Nicolini, G.; Natolino, A. High-Power Ultrasound on the Protein Stability of White Wines: Preliminary Study of Amplitude and Sonication Time. LWT 2021, 147, 111602. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Peng, Z.; Zhao, Y.; Wu, K.; Zhou, N.; Yan, Y.; Ramaswamy, H.S.; Sun, J.; Bai, W. The Impact of Ultrasonic Treatment on Blueberry Wine Anthocyanin Color and Its In-Vitro Anti-Oxidant Capacity. Food Chem. 2020, 333, 127455. [Google Scholar] [CrossRef]

- Pérez-Porras, P.; Bautista-Ortín, A.B.; Jurado, R.; Gómez-Plaza, E. Using High-Power Ultrasounds in Red Winemaking: Effect of Operating Conditions on Wine Physico-Chemical and Chromatic Characteristics. LWT 2021, 138, 110645. [Google Scholar] [CrossRef]

- Gracin, L.; Jambrak, A.R.; Juretić, H.; Dobrović, S.; Barukčić, I.; Grozdanović, M.; Smoljanić, G. Influence of High Power Ultrasound on Brettanomyces and Lactic Acid Bacteria in Wine in Continuous Flow Treatment. Appl. Acoust. 2016, 103, 143–147. [Google Scholar] [CrossRef]

- Zhang, Q.-A.; Wang, T.-T. Effect of Ultrasound Irradiation on the Evolution of Color Properties and Major Phenolic Compounds in Wine during Storage. Food Chem. 2017, 234, 372–380. [Google Scholar] [CrossRef]

- Gómez-Plaza, E.; Gil-Muñoz, R.; López-Roca, J.M.; Martínez, A. Color and Phenolic Compounds of a Young Red Wine. Influence of Wine-Making Techniques, Storage Temperature, and Length of Storage Time. J. Agric. Food Chem. 2000, 48, 736–741. [Google Scholar] [CrossRef]

- Puértolas, E.; López, N.; Condón, S.; Álvarez, I.; Raso, J. Potential Applications of PEF to Improve Red Wine Quality. Trends Food Sci. Technol. 2010, 21, 247–255. [Google Scholar] [CrossRef]

- Raso, J.; Heinz, V. Pulsed Electric Fields Technology for the Food Industry: Fundamentals and Applications; Food Engineering Series; Springer: New York, NY, USA; London, UK, 2006; ISBN 978-0-387-31122-7. [Google Scholar]

- Álvarez, I.; Condón, S.; Raso, J. Microbial Inactivation by Pulsed Electric Fields. In Pulsed Electric Fields Technology for the Food Industry; Raso, J., Heinz, V., Eds.; Food Engineering Series; Springer: Boston, MA, USA, 2006; pp. 97–129. ISBN 978-0-387-31053-4. [Google Scholar]

- González-Neves, G.; Gil, G.; Barreiro, L. Influence of Grape Variety on the Extraction of Anthocyanins during the Fermentation on Skins. Eur. Food Res. Technol. 2008, 226, 1349–1355. [Google Scholar] [CrossRef]

- van Wyk, S.; Farid, M.M.; Silva, F.V.M. SO2, High Pressure Processing and Pulsed Electric Field Treatments of Red Wine: Effect on Sensory, Brettanomyces Inactivation and Other Quality Parameters during One Year Storage. Innov. Food Sci. Emerg. Technol. 2018, 48, 204–211. [Google Scholar] [CrossRef]

- van Wyk, S.; Silva, F.V.M.; Farid, M.M. Pulsed Electric Field Treatment of Red Wine: Inactivation of Brettanomyces and Potential Hazard Caused by Metal Ion Dissolution. Innov. Food Sci. Emerg. Technol. 2019, 52, 57–65. [Google Scholar] [CrossRef]

- González-Arenzana, L.; López-Alfaro, I.; Gutiérrez, A.R.; López, N.; Santamaría, P.; López, R. Continuous Pulsed Electric Field Treatments’ Impact on the Microbiota of Red Tempranillo Wines Aged in Oak Barrels. Food Biosci. 2019, 27, 54–59. [Google Scholar] [CrossRef]

- Comuzzo, P.; Marconi, M.; Zanella, G.; Querzè, M. Pulsed Electric Field Processing of White Grapes (Cv. Garganega): Effects on Wine Composition and Volatile Compounds. Food Chem. 2018, 264, 16–23. [Google Scholar] [CrossRef]

- Comuzzo, P.; Voce, S.; Grazioli, C.; Tubaro, F.; Marconi, M.; Zanella, G.; Querzè, M. Pulsed Electric Field Processing of Red Grapes (Cv. Rondinella): Modifications of Phenolic Fraction and Effects on Wine Evolution. Foods 2020, 9, 414. [Google Scholar] [CrossRef]

- Fauster, T.; Philipp, C.; Hanz, K.; Scheibelberger, R.; Teufl, T.; Nauer, S.; Scheiblhofer, H.; Jaeger, H. Impact of a Combined Pulsed Electric Field (PEF) and Enzymatic Mash Treatment on Yield, Fermentation Behaviour and Composition of White Wine. Eur. Food Res. Technol. 2020, 246, 609–620. [Google Scholar] [CrossRef]

- Ricci, A.; Parpinello, G.P.; Banfi, B.A.; Olivi, F.; Versari, A. Preliminary Study of the Effects of Pulsed Electric Field (PEF) Treatments in Wines Obtained from Early-Harvested Sangiovese Grapes. Beverages 2020, 6, 34. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Altunakar, B. Pulsed Electric Fields Processing of Foods: An Overview. In Pulsed Electric Fields Technology for the Food Industry; Raso, J., Heinz, V., Eds.; Food Engineering Series; Springer: Boston, MA, USA, 2006; pp. 3–26. ISBN 978-0-387-31053-4. [Google Scholar]

- Gupta, M.; Wai Leong Eugene, W. Microwaves and Metals: Gupta/Microwaves and Metals; John Wiley & Sons (Asia) Pte Ltd.: Singapore, 2007; ISBN 978-0-470-82274-6. [Google Scholar]

- Salazar-González, C.; San Martín-González, M.F.; López-Malo, A.; Sosa-Morales, M.E. Recent Studies Related to Microwave Processing of Fluid Foods. Food Bioprocess Technol. 2012, 5, 31–46. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave Food Processing—A Review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Pinto, L.; Baruzzi, F.; Cocolin, L.; Malfeito-Ferreira, M. Emerging Technologies to Control Brettanomyces Spp. in Wine: Recent Advances and Future Trends. Trends Food Sci. Technol. 2020, 99, 88–100. [Google Scholar] [CrossRef]

- Carew, A.L.; Sparrow, A.M.; Curtin, C.D.; Close, D.C.; Dambergs, R.G. Microwave Maceration of Pinot Noir Grape Must: Sanitation and Extraction Effects and Wine Phenolics Outcomes. Food Bioprocess Technol. 2014, 7, 954–963. [Google Scholar] [CrossRef]

- Casassa, L.; Sari, S.; Bolcato, E.; Fanzone, M. Microwave-Assisted Extraction Applied to Merlot Grapes with Contrasting Maturity Levels: Effects on Phenolic Chemistry and Wine Color. Fermentation 2019, 5, 15. [Google Scholar] [CrossRef]

- Sánchez-Córdoba, C.; Durán-Guerrero, E.; Castro, R. Olfactometric and Sensory Evaluation of Red Wines Subjected to Ultrasound or Microwaves during Their Maceration or Ageing Stages. LWT 2021, 144, 111228. [Google Scholar] [CrossRef]

- Muñoz García, R.; Oliver Simancas, R.; Díaz-Maroto, M.C.; Alañón Pardo, M.E.; Pérez-Coello, M.S. Effect of Microwave Maceration and SO2 Free Vinification on Volatile Composition of Red Wines. Foods 2021, 10, 1164. [Google Scholar] [CrossRef]

- Pérez-Serradilla, J.A.; Luque de Castro, M.D. Microwave-Assisted Extraction of Phenolic Compounds from Wine Lees and Spray-Drying of the Extract. Food Chem. 2011, 124, 1652–1659. [Google Scholar] [CrossRef]

- Romero-Díez, R.; Matos, M.; Rodrigues, L.; Bronze, M.R.; Rodríguez-Rojo, S.; Cocero, M.J.; Matias, A.A. Microwave and Ultrasound Pre-Treatments to Enhance Anthocyanins Extraction from Different Wine Lees. Food Chem. 2019, 272, 258–266. [Google Scholar] [CrossRef]

- Yuan, J.-F.; Wang, T.-T.; Chen, Z.-Y.; Wang, D.-H.; Gong, M.-G.; Li, P.-Y. Microwave Irradiation: Impacts on Physicochemical Properties of Red Wine. CyTA J. Food 2020, 18, 281–290. [Google Scholar] [CrossRef]

- Kwiatkowski, M.; Kravchuk, O.; Skouroumounis, G.K.; Taylor, D.K. Microwave-Assisted and Conventional Phenolic and Colour Extraction from Grape Skins of Commercial White and Red Cultivars at Veraison and Harvest. J. Clean. Prod. 2020, 275, 122671. [Google Scholar] [CrossRef]

- Pérez-Porras, P.; Gómez-Plaza, E.; Muñoz García, R.; Díaz-Maroto, M.C.; Moreno-Olivares, J.D.; Bautista-Ortín, A.B. Prefermentative Grape Microwave Treatment as a Tool for Increasing Red Wine Phenolic Content and Reduce Maceration Time. Appl. Sci. 2022, 12, 8164. [Google Scholar] [CrossRef]

- Diffey, B.L. Sources and Measurement of Ultraviolet Radiation. Methods 2002, 28, 4–13. [Google Scholar] [CrossRef]

- Mahapatra, A.K.; Muthukumarappan, K.; Julson, J.L. Applications of Ozone, Bacteriocins and Irradiation in Food Processing: A Review. Crit. Rev. Food Sci. Nutr. 2005, 45, 447–461. [Google Scholar] [CrossRef] [PubMed]

- Keyser, M.; Műller, I.A.; Cilliers, F.P.; Nel, W.; Gouws, P.A. Ultraviolet Radiation as a Non-Thermal Treatment for the Inactivation of Microorganisms in Fruit Juice. Innov. Food Sci. Emerg. Technol. 2008, 9, 348–354. [Google Scholar] [CrossRef]

- Alighourchi, H.; Barzegar, M.; Abbasi, S. Effect of Gamma Irradiation on the Stability of Anthocyanins and Shelf-Life of Various Pomegranate Juices. Food Chem. 2008, 110, 1036–1040. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Song, H.; Lim, S.; Yun, H.; Chung, J. Effects of Gamma Irradiation on the Radiation-Resistant Bacteria and Polyphenol Oxidase Activity in Fresh Kale Juice. Radiat. Phys. Chem. 2007, 76, 1213–1217. [Google Scholar] [CrossRef]

- Błaszak, M.; Nowak, A.; Lachowicz, S.; Migdał, W.; Ochmian, I. E-Beam Irradiation and Ozonation as an Alternative to the Sulphuric Method of Wine Preservation. Molecules 2019, 24, 3406. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Bañuelos, M.A.; Tesfaye, W.; Loira, I.; Palomero, F.; Benito, S.; Callejo, M.J.; Villa, A.; González, M.C.; Suárez-Lepe, J.A. Electron Beam Irradiation of Wine Grapes: Effect on Microbial Populations, Phenol Extraction and Wine Quality. Food Bioprocess Technol. 2015, 8, 1845–1853. [Google Scholar] [CrossRef]

- Parish-Virtue, K.; Herbst-Johnstone, M.; Bouda, F.; Fedrizzi, B. The Impact of Postharvest Ultra-Violet Light Irradiation on the Thiol Content of Sauvignon Blanc Grapes. Food Chem. 2019, 271, 747–752. [Google Scholar] [CrossRef]

- Mihaljević Žulj, M.; Bandić, L.M.; Bujak, I.T.; Puhelek, I.; Jeromel, A.; Mihaljević, B. Gamma Irradiation as Pre-Fermentative Method for Improving Wine Quality. LWT 2019, 101, 175–182. [Google Scholar] [CrossRef]

- Gupta, S.; Padole, R.; Variyar, P.S.; Sharma, A. Influence of Radiation Processing of Grapes on Wine Quality. Radiat. Phys. Chem. 2015, 111, 46–56. [Google Scholar] [CrossRef]

- Falguera, V.; Pagán, J.; Ibarz, A. Effect of UV Irradiation on Enzymatic Activities and Physicochemical Properties of Apple Juices from Different Varieties. LWT Food Sci. Technol. 2011, 44, 115–119. [Google Scholar] [CrossRef]

- Song, J.; Smart, R.; Wang, H.; Dambergs, B.; Sparrow, A.; Qian, M.C. Effect of Grape Bunch Sunlight Exposure and UV Radiation on Phenolics and Volatile Composition of Vitis vinifera L. Cv. Pinot Noir Wine. Food Chem. 2015, 173, 424–431. [Google Scholar] [CrossRef] [PubMed]

- Gregan, S.M.; Wargent, J.J.; Liu, L.; Shinkle, J.; Hofmann, R.; Winefield, C.; Trought, M.; Jordan, B. Effects of Solar Ultraviolet Radiation and Canopy Manipulation on the Biochemical Composition of Sauvignon Blanc Grapes: Effects of Ultraviolet on Grape Berry Biochemistry. Aust. J. Grape Wine Res. 2012, 18, 227–238. [Google Scholar] [CrossRef]

- Diesler, K.; Golombek, P.; Kromm, L.; Scharfenberger-Schmeer, M.; Durner, D.; Schmarr, H.-G.; Stahl, M.R.; Briviba, K.; Fischer, U. UV-C Treatment of Grape Must: Microbial Inactivation, Toxicological Considerations and Influence on Chemical and Sensory Properties of White Wine. Innov. Food Sci. Emerg. Technol. 2019, 52, 291–304. [Google Scholar] [CrossRef]

- Englezos, V.; Rantsiou, K.; Cravero, F.; Torchio, F.; Giacosa, S.; Río Segade, S.; Gai, G.; Dogliani, E.; Gerbi, V.; Cocolin, L.; et al. Minimizing the Environmental Impact of Cleaning in Winemaking Industry by Using Ozone for Cleaning-in-Place (CIP) of Wine Bottling Machine. J. Clean. Prod. 2019, 233, 582–589. [Google Scholar] [CrossRef]

- Mostashari, P.; Gavahian, M.; Jafarzadeh, S.; Guo, J.; Hadidi, M.; Pandiselvam, R.; Huseyn, E.; Mousavi Khaneghah, A. Ozone in Wineries and Wine Processing: A Review of the Benefits, Application, and Perspectives. Comp. Rev. Food Sci. Food Saf. 2022, 21, 3129–3152. [Google Scholar] [CrossRef]

- Pereira, R.N.; Coelho, M.I.; Genisheva, Z.; Fernandes, J.M.; Vicente, A.A.; Pintado, M.E.; Teixeira, J.A. Using Ohmic Heating Effect on Grape Skins as a Pretreatment for Anthocyanins Extraction. Food Bioprod. Process. 2020, 124, 320–328. [Google Scholar] [CrossRef]

- Jesus, M.S.; Ballesteros, L.F.; Pereira, R.N.; Genisheva, Z.; Carvalho, A.C.; Pereira-Wilson, C.; Teixeira, J.A.; Domingues, L. Ohmic Heating Polyphenolic Extracts from Vine Pruning Residue with Enhanced Biological Activity. Food Chem. 2020, 316, 126298. [Google Scholar] [CrossRef]

- Junqua, R.; Carullo, D.; Ferrari, G.; Pataro, G.; Ghidossi, R. Ohmic Heating for Polyphenol Extraction from Grape Berries: An Innovative Prefermentary Process. OENO One 2021, 55, 39–51. [Google Scholar] [CrossRef]

- Fumagalli, I.; Cieslik, S.; De Marco, A.; Proietti, C.; Paoletti, E. Grapevine and Ozone: Uptake and Effects. Climate 2019, 7, 140. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Hajeb, P.; Ehsani, R.J. Application of Ozone for Degradation of Mycotoxins in Food: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1777–1808. [Google Scholar] [CrossRef]

- Shah, N.N.A.K.; Supian, N.A.M.; Hussein, N.A. Disinfectant of Pummelo (Citrus Grandis L. Osbeck) Fruit Juice Using Gaseous Ozone. J. Food Sci. Technol. 2019, 56, 262–272. [Google Scholar] [CrossRef] [PubMed]

- Bellincontro, A.; Catelli, C.; Cotarella, R.; Mencarelli, F. Postharvest Ozone Fumigation of Petit Verdot Grapes to Prevent the Use of Sulfites and to Increase Anthocyanin in Wine: Ozone Treatment of Petit Verdot Grape. Aust. J. Grape Wine Res. 2017, 23, 200–206. [Google Scholar] [CrossRef]

- Cravero, F.; Englezos, V.; Rantsiou, K.; Torchio, F.; Giacosa, S.; Segade, S.R.; Gerbi, V.; Rolle, L.; Cocolin, L. Ozone Treatments of Post Harvested Wine Grapes: Impact on Fermentative Yeasts and Wine Chemical Properties. Food Res. Int. 2016, 87, 134–141. [Google Scholar] [CrossRef] [PubMed]

- García-Martínez, M.M.; Campayo, A.; Carot, J.M.; Hoz, K.S.; Salinas, M.R.; Alonso, G.L. Oenological Characteristics of Vitis vinifera L. Cabernet Sauvignon Grapes from Vineyards Treated with Ozonated Water. Aust. J. Grape Wine Res. 2020, 26, 388–398. [Google Scholar] [CrossRef]

- Knirsch, M.C.; Alves dos Santos, C.; Martins de Oliveira Soares Vicente, A.A.; Vessoni Penna, T.C. Ohmic Heating—A Review. Trends Food Sci. Technol. 2010, 21, 436–441. [Google Scholar] [CrossRef]

- Varghese, K.S.; Pandey, M.C.; Radhakrishna, K.; Bawa, A.S. Technology, Applications and Modelling of Ohmic Heating: A Review. J. Food Sci. Technol. 2014, 51, 2304–2317. [Google Scholar] [CrossRef]

| Conditions | Type of Wine | Effect | References |

|---|---|---|---|

| Flat tip probe US (30, 60, 90% amplitude; 20 kHz frequency; 5, 10 min; 13 mm diameter) | White wine |

| [40] |

| US bath (40, 60, 80, 100% amplitude; 20, 40, 60 °C; 20, 50, 65, 90 min) US probe (diameter 12.7, 19.1, 25.4 mm; 3, 6 and 9 min; immersion depth: 2 cm) | White wine |

| [15] |

| Ultrasound < 100 kHz | Rice wine |

| [39] |

| US probe power levels (90, 180, 270, 360 W), treatment time (10, 20, 30, 40 min), treatment cycles (1, 2, 3, and 4 cycles), frequency 20 kHz, probe diameter 10 mm | Blueberry wine |

| [41] |

| US at 20 kHz. Accelerated aging cycles (0, 4, 8, 12 and 16 times) | Monastrell red grapes |

| [42,43] |

| US probe at 20 kHz, 950 W, 16 °C for 14 & 28 min. 70 days storage | Cabernet sauvignon |

| [44] |

| Conditions | Type of Wine | Effect | References |

|---|---|---|---|

| E-Beam irradiation 1–10 kGy | Red wine |

| [76,77] |

| UV light irradiation 334 W/m2 for 30 min | Sauvignon blanc grapes and wine |

| [78] |

| Gamma irradiation panoramic 60Co at 670, 1300, 2000, 2700 Gy | Traminer and Merlot grapes and wine |

| [79,80] |

| UV-vis irradiation 400 W for 3 h and 30 min | Xarel·lo and Parellada white wines |

| [16] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, Y.; Marangon, M.; Mayr Marangon, C. The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement. Beverages 2023, 9, 30. https://doi.org/10.3390/beverages9020030

Kumar Y, Marangon M, Mayr Marangon C. The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement. Beverages. 2023; 9(2):30. https://doi.org/10.3390/beverages9020030

Chicago/Turabian StyleKumar, Yogesh, Matteo Marangon, and Christine Mayr Marangon. 2023. "The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement" Beverages 9, no. 2: 30. https://doi.org/10.3390/beverages9020030

APA StyleKumar, Y., Marangon, M., & Mayr Marangon, C. (2023). The Application of Non-Thermal Technologies for Wine Processing, Preservation, and Quality Enhancement. Beverages, 9(2), 30. https://doi.org/10.3390/beverages9020030