Abstract

The brewing industry is regarded as a fiercely competitive and insatiable sector of activity, driven by the significant technological improvements observed in recent years and the most recent consumer trends pointing to a sharp demand for sensory enhanced beers. Some emergent and sustainable technologies regarding food processing such as pulsed electric fields (PEF), ultrasound (US), thermosonication (TS), high-pressure processing (HPP), and ohmic heating (OH) have shown the potential to contribute to the development of currently employed brewing methodologies by both enhancing the quality of beer and contributing to processing efficiency with a promise of being more environmentally friendly. Some of these technologies have not yet found their way into the industrial brewing process but already show potential to be embedded in continuous thermal and non-thermal unit operations such as pasteurization, boiling and sterilization, resulting in beer with improved organoleptic properties. This review article aims to explore the potential of different advanced processing technologies for industrial application in several key stages of brewing, with particular emphasis on continuous beer production.

1. Introduction

Beer is a carbonated, fermented alcoholic beverage that is believed to have been one of the first drinks ever to be produced by humans, dating back to the beginnings of civilization by the Sumerians [1]. This beverage is the fifth most consumed drink and is currently the most consumed alcoholic beverage in the world [2,3]. In 2021, the global production of beer was approximately 1.86 billion hL, where China, the United States and Brazil stand out as leading producers of this beverage [4].

The brewing industry is a global business composed by many multinational companies and many thousands of smaller breweries, craft breweries and brewpubs [5]. Dominant brewery groups such as Anheuser-Busch InBev (Leuven, Belgium), Heineken (Amsterdam, The Netherlands), Carlsberg (Copenhagen, Denmark) and Asahi Group Holding (Japan) make up the largest portion of the beer market, consolidating such a tendency by acquiring and fusing large commercial breweries and smaller breweries, thus increasing their portfolio [5]. In 2021, the previously mentioned companies produced a combined amount of around 41% of all the beer consumed worldwide [6]. Despite its high demand, commercial beer produced by these large beer groups is regarded as very undifferentiated and lacking distinctive appearances, flavors and aromas [7,8]. Additionally, public awareness of themes such as environmental sustainability and health has triggered consumers’ preferences to shift towards good quality, healthy and ecologically sustainable products, which feature attractive novelties and sophistications [9,10,11]. These factors are contributing to increased popularity of and consumer preferences for the craft beer sector. Such rapidly evolving preferences have been achieved mainly through craft breweries’ commitment to consumers to prioritize the production of a wide range of beer styles, with peculiar organoleptic properties promoted by distinctive brewing methodologies and a careful hand selection of ingredients [12,13].

The brewing industry is a mature, well-organized and competitive sector of activity. It is well known for its dynamic behavior in trying to address ever-evolving consumer trends. Additionally, it is trying to integrate new and emergent technologies that become available as result of research, development and innovation activities developed worldwide. It is crucial to obtain a more comprehensive understanding of how to establish efficient and sustainable production processes while maintaining safety standards and premium quality. Innovative technologies based on the reduction of thermal load or indirect heat transfer can contribute to reduced energy inputs and use of non-renewable resources. Several chemical and physical events can be triggered in the presence of treatment variables such as temperature, electric fields, pressure and others, which contributes to unique properties at the functional and sensory level that should be explored. This review intends to overview the role of emergent and innovative processing technologies in the brewing industry with particular emphasis on the replacement of conventional thermal processing. For that purpose, traditional brewing unit operations and brewing materials will be also addressed in the following sections.

2. Brewing Raw Materials

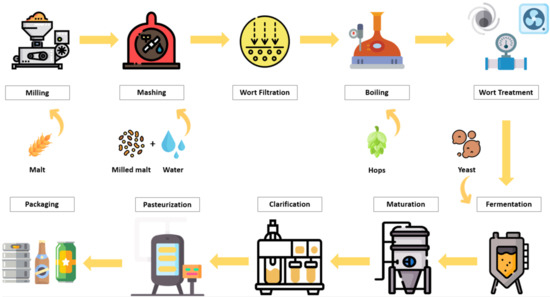

Beer is traditionally produced using four main ingredients: water, malted cereal, hops and yeast (Figure 1) [14]. Different beer styles arise from the conjugation of different ingredients and brewing techniques throughout beer production [15].

Water is the main raw material used for brewing, representing around 94% of a beer’s weight [16]. The term “malt” defines the material that results from germination, under controlled conditions, of any cereal (e.g., barley, rice, corn, wheat etc.) [17]. Among many other compounds, malt contains three highly valuable constituents from a brewer’s perspective: starch, proteins and hydrolytic enzymes. Starch is the major source of carbohydrates in beer’s wort and is hydrolyzed by enzymes (i.e., amylases) to convert it into fermentable sugars, which in turn determine the alcoholic content of the final beer product [18,19]. Moreover, other hydrolytic enzymes (i.e., proteases) convert a fraction of proteins into amino acids that are essential for yeast’s nutrition during fermentation, and the remaining intact fraction of proteins are responsible for beer foam properties [20,21].

Hops are plants classified as Humulus lupulus which are typical from cold regions and thus require strict cultivation conditions [22]. This plant possesses glands where lupulin granules are produced, which contain brewing’s substances of interest such as α-acids and essential oils that are responsible for the typical beer’s bitterness and aroma [23,24].

Yeast is a eukaryotic, single-celled organism that belongs to the fungi kingdom [25]. Currently, beer is classified in one of the following categories: ale, lager and lambic. The main criterion that divides these categories is the yeast species used in the production of the beer: Saccharomyces cerevisiae strains (i.e., top-fermenting yeasts) are responsible for ale beers, Saccharomyces pastorianus (i.e., bottom-fermenting yeasts) generate lager beers and indigenous yeasts strains (i.e., wild yeasts) present both in the atmosphere of the brewery and in beer’s raw materials generate lambic beers [26].

Figure 1.

Schematic diagram of the brewing process and the involved raw materials. The icons used in this figure were retrieved from Flaticon.com [27].

Figure 1.

Schematic diagram of the brewing process and the involved raw materials. The icons used in this figure were retrieved from Flaticon.com [27].

3. Brewing Process

The brewing process (Figure 1) can be divided into nine essential unit operations, which are: milling, mashing, wort filtration, wort boiling, wort treatment, fermentation, maturation, filtration and pasteurization. Some of these brewing steps are not mandatory for beer production; however, large industrial breweries prefer to employ them, seeking better consumer acceptance regarding the final product.

The milling stage aims to uniformly reduce malt grain to obtain: peeling of the bark in the longitudinal direction, thus exposing the endosperm (i.e., internal portion of the grain); the total disintegration of the endosperm (promoting better enzymatic performance on the exposed starches and proteins); and the minimum production of flour with very fine granulometry [28,29].

Mashing comprises the mixture of milled malt along with water at a controlled temperature according to a previously established program. This operation aims to solubilize malt substances that are directly soluble in water and to promote the enzymatic hydrolysis of starch and proteins into fermentable sugars and amino acids [30,31].

After mashing, wort filtration is carried out in a container called lauter tun, where the wort is filtered with malt husks serving as the filtering layer, and the result is a clear wort that is free of husks, seedlings and other insoluble materials [32]. The filtering layer is further washed with water in order to increase sugar extraction and, consequently, to increase the yield of the process [33].

The boiling stage includes several purposes, such as biochemical stabilization of the wort composition; clarification through the coagulation and precipitation of tannins and proteins; sterilization to eliminate bacteria; extraction of bitter precursor compounds (α-acids) from hops; isomerization of α-acids into the bitter molecules that provide bitterness to beer (iso-α-acids); extraction of aromatic hops compounds that contribute to the taste and aroma of beer; and evaporation of undesirable volatile compounds [34,35].

Wort treatment is the subsequent step to wort boiling, which allows the removal of precipitated hops and proteins, cooling and aeration [36]. After precipitate separation, the wort is cooled to the fermentation temperature, which is dictated by the yeast strain to be employed in fermentation [37]. Finally, after the wort is cooled, oxygen is injected into the fermentation tank in order to obtain a desirable oxygen concentration for yeast growth during fermentation [38].

The fermentation stage dictates the addition of yeasts, which begin to uptake fermentable sugars, amino acids, minerals and other nutrients [39]. Thereafter, yeasts, as a result of complex cellular biochemical pathways, initiate the production of a great variety of compounds such as ethanol, CO2, higher alcohols and esters, which are released into the beer’s matrix [40,41]. The wide range of compounds produced by yeasts are essential products of beer fermentation that influence the chemical composition, color and, most importantly, the sensory quality of beer [40].

Throughout fermentation, undesirable compounds can be produced (e.g., acetaldehyde, diacetyl, sulfur-containing compounds etc.), which negatively affect beer’s flavor profile and quality [26,42]. For this reason, maturation (sometimes referred to as the conditioning step) is performed, where beer is placed into tanks and cooled to temperatures ranging from 0 to 10 °C, allowing yeasts to slowly metabolize undesirable flavor compounds which are further removed [43]. Additionally, maturation also allows solid materials (insoluble at lower temperatures) to sediment and precipitate, resulting in a clear beer [43]. Overall, maturation contributes to enhanced flavor and colloidal stability of beer and delivers important organoleptic characteristics to the final product.

If an additional clarification of the beer is intended, which typically occurs during the industrial production process, then a filtration step is performed. The main purpose of beer filtration is to increase the retention of yeast cells, macrocolloids, suspended matter and solutes that cause the formation of beer haze [44]. Currently, three different approaches to clarify beer are employed dead-end filtration, crossflow filtration and dynamic microfiltration [45]. These allow the beer to be bottled thereafter.

Pasteurization of beer is a mild thermal process that can be performed at around 60 °C for several minutes (typically between 15 to 20 min) or from 70 to 90 °C for a few seconds following the high-temperature short-time principle (HTST). Pasteurization aims to inactivate fermenting yeast and potential spoilage microorganisms which would otherwise promote undesirable chemical reactions [46]. Beer pasteurization has the advantage of extending beer’s shelf-life, but it can also negatively affect its organoleptic properties (i.e., color, flavor and aroma) [47].

4. Processing Technologies for the Brewing Industry

Recent technological advances, coupled with the need of higher production efficiency, product quality and process sustainability, have created opportunities for developing new processing approaches. Table 1 summarizes some examples about the effects that emergent technologies display in different brewing stages. The following sections also review and discuss possible alternatives to conventional thermal processes such as boiling and pasteurization.

Table 1.

Summary of the main effects of each technology in the different stages of the brewing process.

4.1. PEF

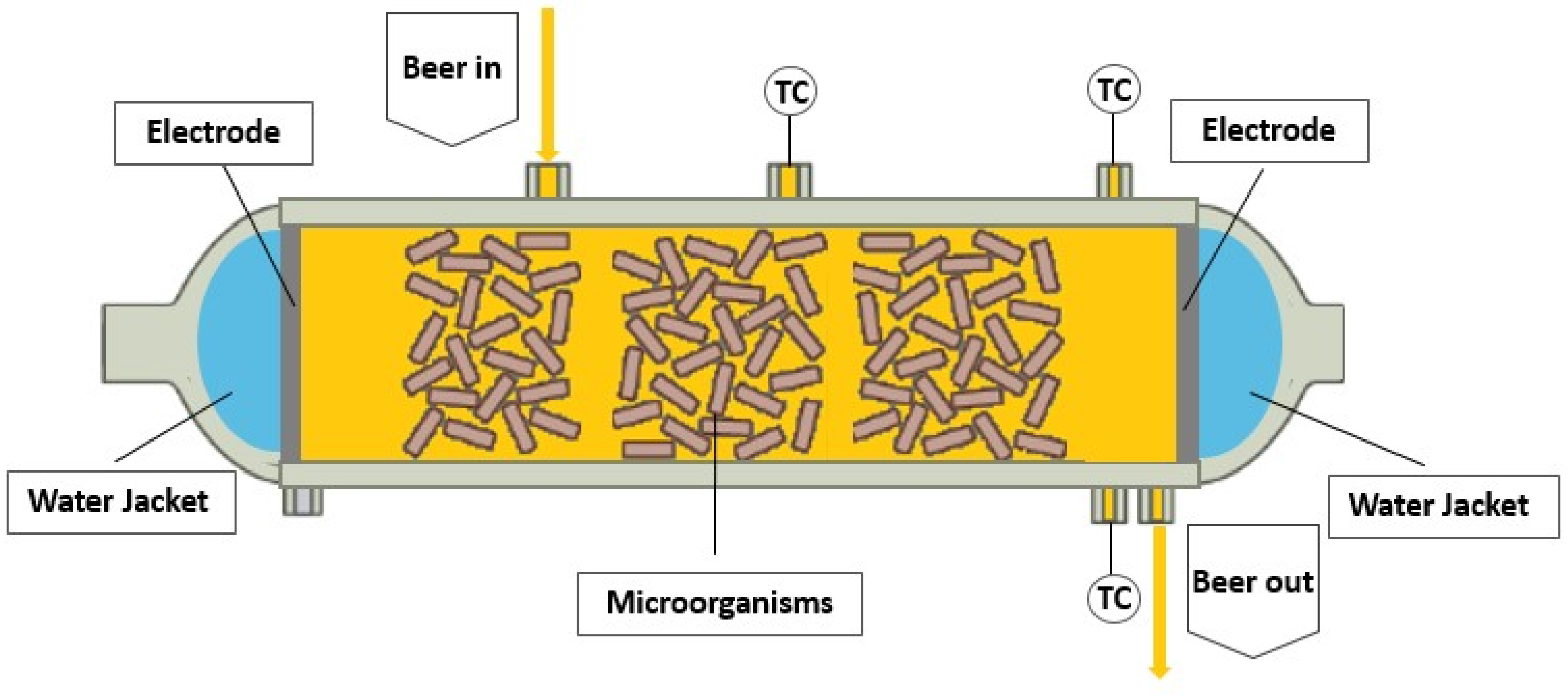

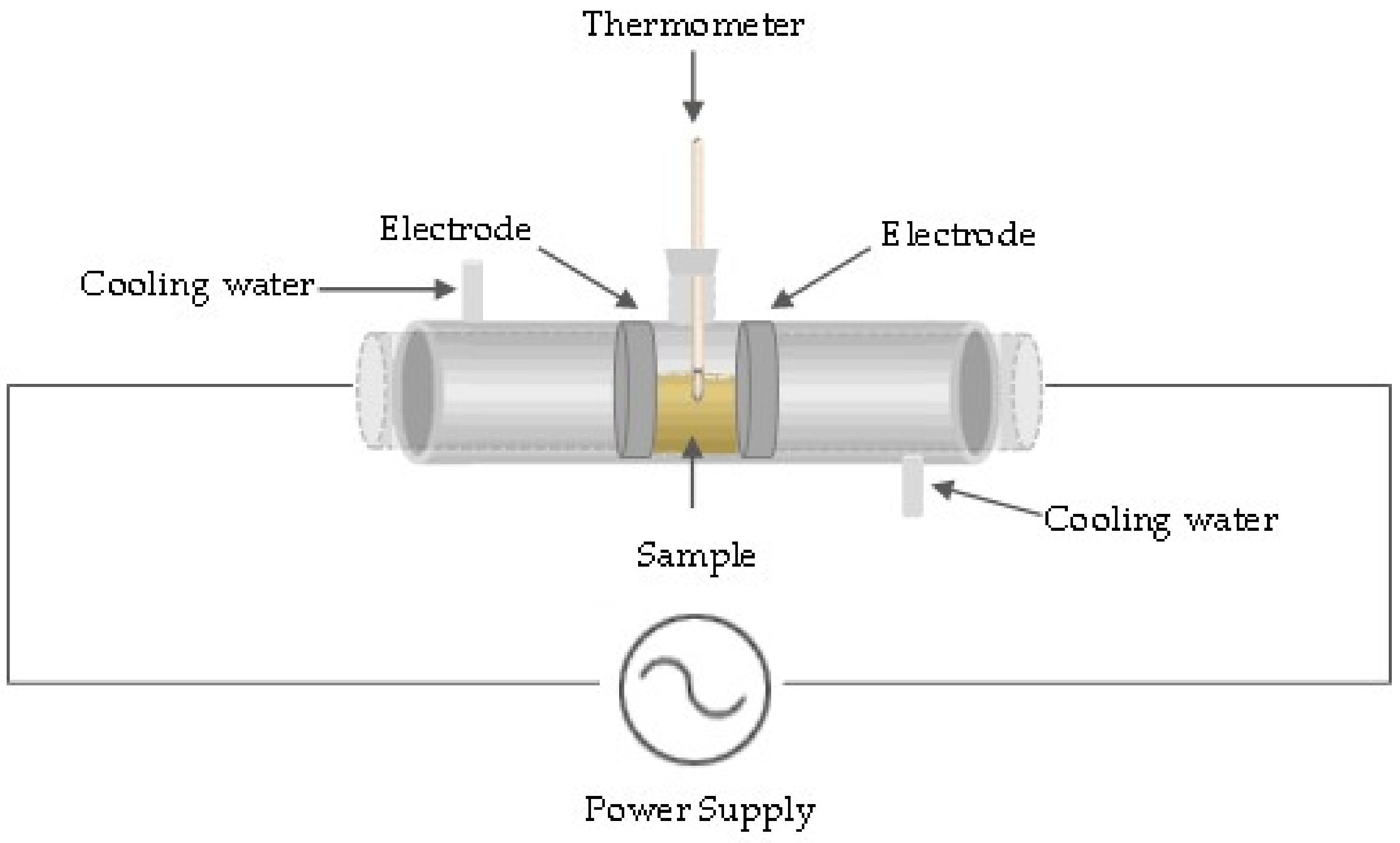

Non-thermal technologies have gained popularity and prominence in recent years by promising minimal processing and high nutritional quality [85]. PEF is one of these so-called emerging non-thermal technologies that is attracting attention for several applications. PEF can simultaneously promote microbial inactivation while greatly reducing adverse changes in the sensory, physical and nutritional properties (e.g., color, flavor, texture and nutritional value) across a wide variety of food matrixes [86]. PEF consists of the application of short (i.e., micro- to milliseconds), high-intensity electric field pulses (i.e., on the order of 10–80 kV/cm) delivered into a given (semi-)conducting food product placed between a set of electrodes [87]. Food allows the passage of an electrical current because it contains several ions and charged molecules. When PEF are applied, an electrical current flows through the food and gets conveyed to each point on its matrix [88]. This can lead to a wide range of phenomena in the food matrix, resulting in non-thermal microbial inactivation through electroporation. Electroporation consists of the formation of permanent or temporary pores on cells due to disruption of the phospholipid bilayer of the cell membrane caused by an applied electrical pulse. The formation of these pores in the cell membranes of microorganisms can modify its permeability and can consequently promote cell lysis [89]. For this reason, the commercial use of PEF to inactivate vegetative cells of microorganisms in liquid foods such as juice, milk and egg products is becoming popular [90]. PEF technology holds great potential to be used for pasteurization purposes in a continuous mode of operation, with a setup as represented in Figure 2 [46,91].

Figure 2.

Schematic diagram of a continuous PEF unit for pasteurization with cooling system. The thermocouples are referred to as TC on the diagram.

According to Milani et al. (2015) a PEF treatment under certain controlled conditions (i.e., room temperature, 45 kV/cm electrical field intensity, 46 pulses and a total treatment time of 70 μs) resulted in the inactivation of Saccharomyces cerevisiae ascospores by 0.2 and 2.2 log reductions for 0 and 7% alc/vol beers, respectively, when compared to thermal inactivation. This study also revealed, that when these same PEF processing conditions were combined with the thermal processing (52–53 °C) of 0 and 7% alc/vol beers, at least an additional 0.7 and 1.8 log reductions in the yeast spore population was accomplished, respectively [92]. Another study, carried out by Walkling-Ribeiro et al. (2011), investigated the inactivation of Saccharomyces cerevisiae vegetative cells by non-thermal and temperature-assisted PEF treatment of a lager beer with an alcoholic content of 3.5% alc/vol. This group’s experiments revealed that the non-thermal PEF treatments of 35 kV/cm for 574 μs and 45 kV/cm for 402 μs yielded a 3.8 and ≥6.8 log reduction in cells, respectively. Thermal-assisted PEF treatments at 55 °C, using 35 kV/cm for a total treatment time of 1145 μs, led to a ≥6.8 log reduction of cells [48]. Further evidence of the effect of PEF treatments on vegetative yeasts were provided by Evrendilek et al. (2004), where using 22 kV/cm for 216 μs on kegged beer at 10 °C (non-thermal processing) resulted in a 4.1 and 4.3 log reduction in Saccharomyces uvarum and Rhodotorula rubra, respectively [49].

PEF technology has also proved to be effective against the inactivation of vegetative bacteria. A study conducted by Ulmer et al. (2022) found that non-thermal PEF treatments (35 kV/cm for a non-reported period of time) in model beer led to a >3.0 log reduction in Lactobacillus plantarum vegetative bacteria [93]. Moreover, Evrendilek et al. (2004) concluded that non-thermal PEF treatment (41 kV/cm for a total treatment time of 175 μs) in kegged beer was effective at inactivating Lactobacillus plantarum, Pediococus damnosus and Bacillus subtilis vegetative cells with 4.7, 5.8 and 4.8 log reductions, respectively [49]. Walkling-Ribeiro et al. (2011) also reported that non-thermal PEF treatment (35 kV/cm for a total treatment time 574 μs) of a 3.5% alc/vol lager beer delivered a 1.8, 2.0 and 1.8 log reduction in Lactobacillus plantarum, Salmonella enterica and Bacillus subtilis vegetative bacteria, respectively [48]. Finally, in this same study, Walkling et al. (2011) concluded that thermally-assisted PEF treatments are also a robust technique for inactivating bacteria since a 5.7 log reduction in Salmonella enterica cells was obtained when treating beer at 49 °C with pulses of 45 kV/cm for a total of 804 μs; a 3.4 log reduction in Bacillus subtilis cells was obtained by treating beer at 49 °C with pulses of 45 kV/cm for 402 μs [48].

Regarding beer’s flavor, breweries fear an undesirable off-flavor that is typically referred to as “light-struck flavor”, which is mainly induced by 3-methyl-2-butene-1-thiol (MBT) and is easily detected in the flavor and aroma of beer when present above its flavor threshold [94]. The formation of such character, described as “skunky-like”, is mostly triggered by the degradation of iso-α-acids present in beer by light (350–500 nm), and this has the negative consequence of limiting beer’s shelf-life [95]. To investigate this issue, Milani et al. (2015) investigated whether PEF technology has the potential to induce the “light-struck character” in nine beers (of different beer styles and alcoholic contents). Three different types of samples were compared as follows: i) positive control sample (non-light-struck, not PEF treated and kept in a dark place–i.e., not exposed to light; and light-struck); ii) PEF treated and kept in a dark place (not exposed to light; and light-struck) and iii) negative control sample (not PEF treated and exposed to sunlight for 8 h to develop the light-struck character). These beers were treated with PEF (45 kV/cm for a total of 70 μs) and compared with their positive and negative controls (untreated beer samples kept in the dark and induced light-struck beer samples exposed to light for 8 h, respectively). As a result of this experiment, the sensory panel was not able to notice differences in the aroma or flavor of PEF-treated, control and induced light-struck Pilsner and dark ale beers, meaning that these beers are not prone to form the “light-struck character” under PEF treatment. The panel could, however, perceive the “light-struck” flavor or aroma in light lager beers treated under PEF [92]. As such, these results suggest that the application of PEF technology for beer processing should be carefully considered regarding the physical and chemical beer characteristics to avoid the development of such undesirable off-flavor. PEF treatments may be linked with biochemical events that are not yet controlled, such as the interaction between molecules or changes in their structure, as well as the occurrence of electrochemical reactions.

Another example of the impact that PEF treatments exhibit on beer was reported by Evrendilek et al., (2004), where a panel of 25 judges attributed a lower rating in terms of flavor and mouth feeling to beer treated by PEF (41 kV/cm for a total treatment time of 175 μs) when compared with untreated control samples. The judges of this panel detected a metallic mouth feeling, which was most likely connected to compounds’ migration from the PEF electrodes into beer during processing. This was also supported by a significant increase in metal ion concentrations, such as Fe, Cr, Zn and Mn in the beverage after the PEF treatment [49]. This evidence suggests that when processing beer with PEF, attention should be given to the choice of the materials that compose the electrodes, which should preferably be inert, thus not harming the flavor of the beer. Finally, Oziemblowski et al. (2017) observed that when beer was pasteurized by PEF treatments (41.1 kV/cm applied in 200, 300 and 400 pulses, with a pulse every 30 s to prevent excessive heating), a significant decrease in beer bitterness and turbidity occurred when compared with control unpasteurized beer [50]. This study highlighted the beneficial effect of PEF pasteurization of beer in terms of bitterness and turbidity; however, its application must be carefully considered depending on the style of beer to be processed since, for example, India Pale Ale (IPA) and Weiss beers are known for their characteristic bitterness and turbidity, respectively.

Another promising application of PEF technology is related to tissue softening and the extraction of a wide range of compounds of interest for the food industry across a vast array of matrixes [96,97,98]. Concerning brewing, Ntourtoglou et al. (2020) assessed the ability of PEF treatments to extract α-acids and β-acids (humulones and lupulones) as well as important essential oils (caryophyllene, humulene and β-myrcene) from hop pellets of two distinct hop varieties (one bitter and one aromatic). The results of this study revealed that PEF treatments (1.5 kV/cm; 15 μs and 1800 pulses) had a positive impact on extraction of α-acids from bitter hop pellets when compared with methanol extraction (control); the extraction rate of these acids was increased by 20%, while increases of 5.6 and 7.4% were also noticed in the extraction of essential oils such as humulene and caryophyllene, respectively. On the other hand, PEF treatments appeared to have no noteworthy effects on the aromatic variety of hop pellets [51]. These results suggest that PEF technology has the potential to extract α-acids, β-acids and essential oils, which can be used to enhance their concentration during wort boiling or reduce the time of PEF treatment in pilot plant conditions prior to its industrial application. Moreover, brewing generates large amounts of by-products (i.e., brewer’s spent grain (BSG), spent hops and surplus brewing yeast), which are known for their rich chemical and nutritional composition with bioactive properties [99]. Different studies conducted by several authors highlighted the contribution of the application of PEF technology for the recovery of a wide range of valuable compounds, i.e., phenolic compounds, proteins, sugars and other compounds, present in different brewing by-products [52,53,100]. Such studies emphasize how PEF technology can contribute to overcoming the growing scarcity of natural resources and the rising unsustainability of waste management, as it offers the possibility of reusing these wastes in a more efficient manner, thus committing to reinforcing the circular economy of the brewing industry.

Overall, the application of PEF technology in the brewing industry is not yet established; however, it has been regarded as promising in different stages of the brewing process. Brewers recognize that PEF technology has great potential for enhancing beer’s flavor, bitterness, turbidity and microbiological stability while reducing processing times and production costs. Several studies have shown a positive impact of PEF technology on beer quality [49,50,51], which may contribute to a rapid implementation in the brewing industry in forthcoming years. One of the major drawbacks of PEF applications is still related to the lack of well-standardized information and specific protocols regarding a specific aim. Most of the described applications combine electric fields ranging between 20 and 40 kV/cm, total treatment times varying from 70 to 800 µs and a number of pulses between 40 to 400. In addition, PEF outcomes vary with the kind of target microorganism, media complexity and amount of dissipated heat, which make it difficult to harmonize efficient treatments.

4.2. US

US technology has been transforming the food industry because of its wide application in a variety of processes, relatively low cost and sustainability. This emergent technique is well known as “green and creative” for pasteurization and extraction unit operations, and it can use renewable energy, produce less waste and reduce water and solvent usage [54,101]. In this operation, energy is transferred to a given fluid via propagation of ultrasonic waves in frequency range from 20 to100 kHz for a brief period that can go up to several minutes. These waves’ alternate zones of compression and rarefaction, resulting in the creation and collapse of small cavitation bubbles [102]. The impact of cavitation on microbial cell walls underlies the microbial inactivation caused by US. These cavitating bubbles produce micro streaming and high hydrodynamic shear stresses which damage cell membranes and consequently inactivates bacteria, molds and yeasts, thus contributing to intended food safety [103].

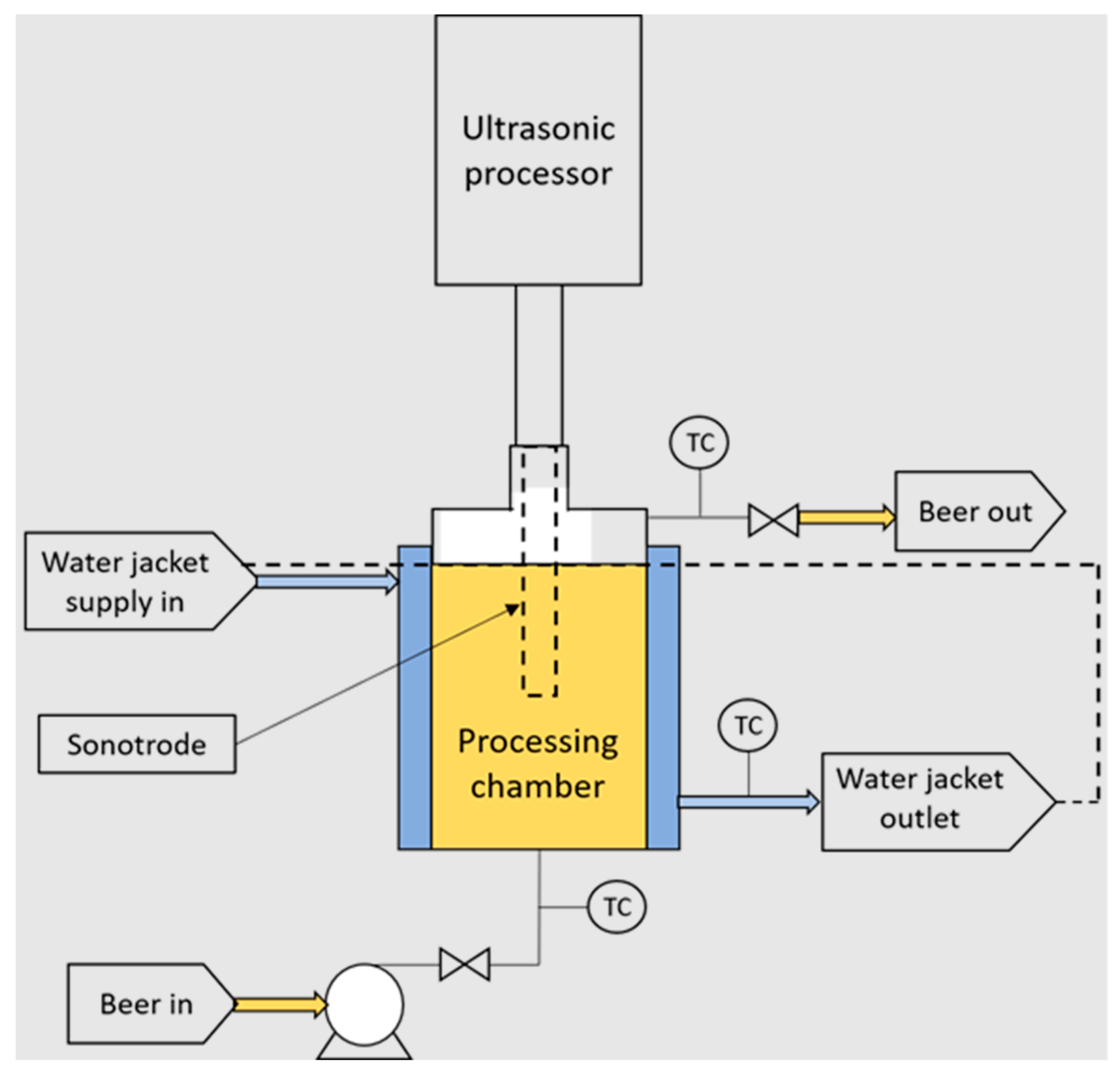

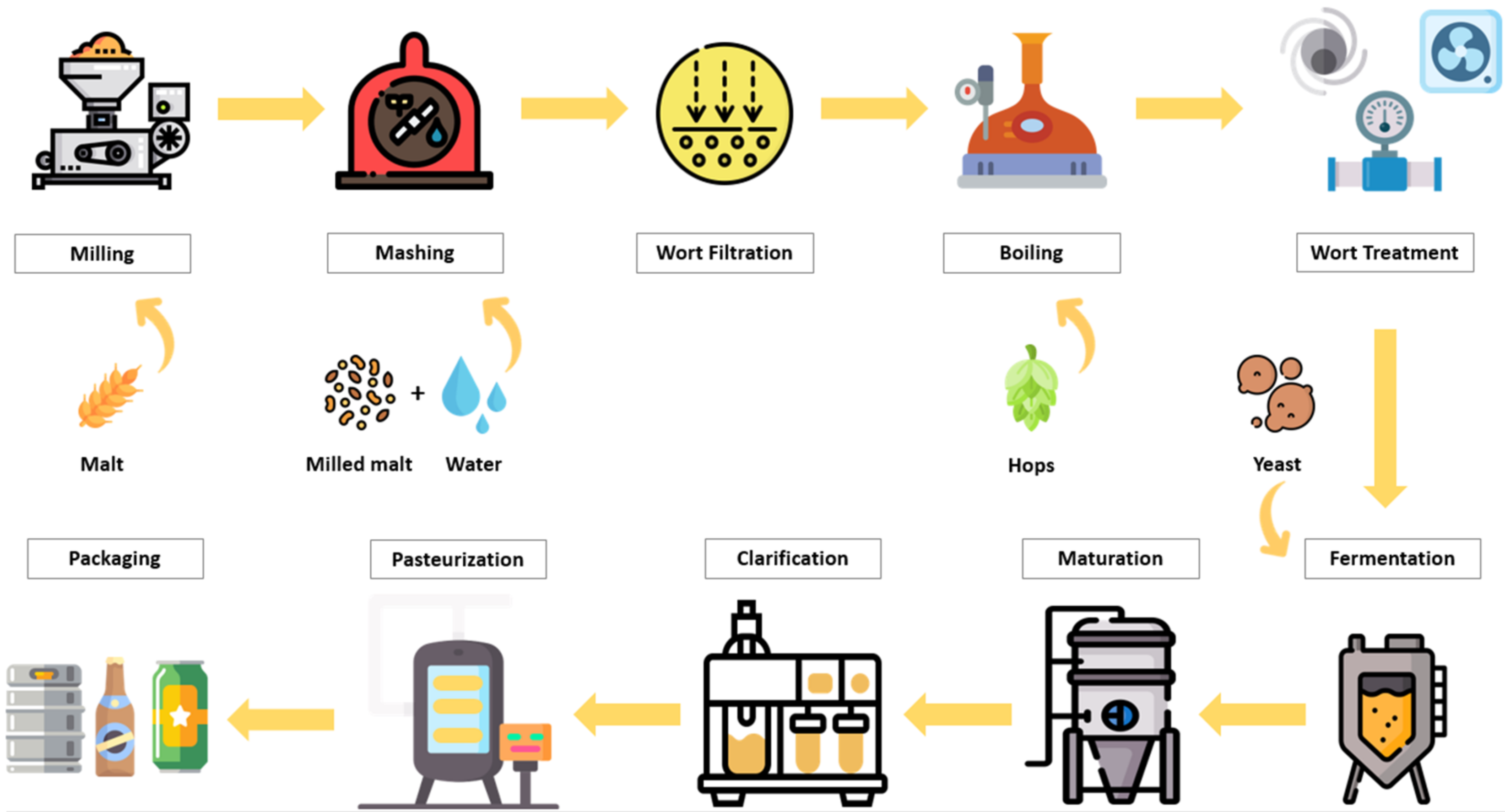

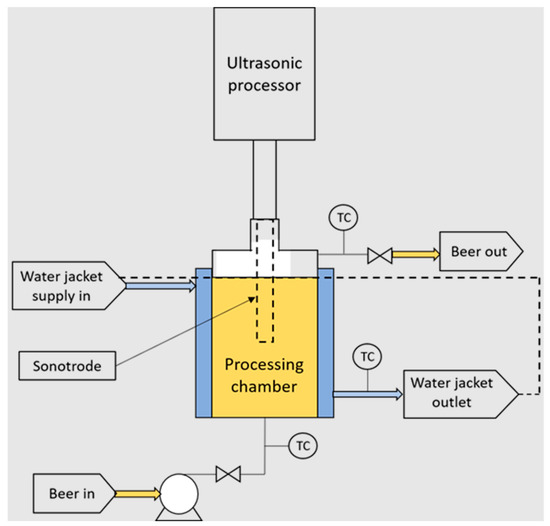

In the brewing industry in particular, US technology has generated a lot of interest given its promising effects on beer processing and preservation, such as increased product yields; reduced processing times; lower operating and maintenance expenses; improved taste, flavor and color; and the elimination of pathogens at lower temperatures [55,104]. Furthermore, ultrasonic technology accelerates the transport of waste materials away from cells as well as the oxygen and nutrients required for cell growth, which consequently allows faster microbial growth and a more effective beer fermentation [102,104]. Currently, this innovation has been mostly used in beer production at the laboratory scale to increase beer yield at the beginning of the mashing process, to hasten fermentation and to defog beer before bottling [54,55]. Despite this, there is still much to discover regarding the use of this technology to pasteurize beer. Figure 3 displays a schematic representation of a continuous power ultrasonic (sonotrode) unit and cooling system.

Figure 3.

Schematic diagram of a continuous power ultrasonic (sonotrode) unit and cooling system. The thermocouples are referred to as TC on the diagram. Reprinted/adapted from [59]. 2023, Elham A. Milani and Filipa V.M. Silva.

Early research from 1994 conducted by Matsuura et al. (1994) showed that the exposure of beer to US with a 43 kHz frequency decreased the time required for fermentation by 64%. Additionally, the US technique accelerated the synthesis of esters and higher alcohols and repressed an increase in total acidity [56]. Later, the first use of ultrasonic technology for pasteurization of beer was documented by Milani and Silva (2017) with the goal of inactivating Saccharomyces cerevisiae ascospores. In this investigation, beers were subjected to US-assisted thermal pasteurization or thermosonication (TS) technology, which combines the effect of heat with US. According to the study, TS processing (with a 24 kHz frequency and 161.6 W) could pasteurize beers to a 15 PU (pasteurization unit) level (corresponding to 1.34 log reduction) in 26.4 s as opposed to 37.7 min used for beer thermal processing alone at 55 °C. This was only possible with a batch power US system since continuous TS induced log reductions of 0.2 and 1.0 at 0.0 and 4.8% alc/vol, respectively, which were not sufficient to pasteurize S. cerevisiae to the required minimum. Nevertheless, results revealed that, between 50 and 55 °C, beers could be pasteurized more efficiently using TS regardless of their alcohol content. In addition, it was concluded that in continuous operation, the minimum pasteurization times for TS at 50 °C were 3.0, 1.9 and 4.5 min for beers with 0.0, 4.8 and 7.0% alc/vol, respectively [59]. Later, Milani et al. (2016) conducted supplementary TS experiments at 50, 55 and 60 °C (using the same conditions), and in this instance, the treatment was successful in inhibiting S. cerevisiae ascospores; a spore reduction of 2.5 log was easily attained after 2.5 min at 60 °C TS, whereas 50 and 55 °C TS needed over 40 min to reach the same level of inactivation. Interestingly, it was discovered that the inactivation rate can be reduced during processing, indicating that some ascospores may have developed ultrasonic resistance; regardless, US proved to be effective in inactivating pathogenic microorganisms [60].

Several investigations have demonstrated that in general, TS performs better than sonication without heat and other traditional heat treatments in terms of microbial inactivation. However, it is important to emphasize that excessive processing could change the product’s organoleptic properties [61,62]. In this sense, Deng et al. (2017) studied the effect of TS on specific physicochemical and sensory characteristics of lager beers such ethanol level, original extract, pH, color and bitterness. Besides determining that TS treatment of beers at 50 and 60 °C (24 kHz frequency and 2.7 W/mL volumetric power for 2 min) inhibited the growth of both yeast and spoilage bacteria for 12 months, they also discovered a noticeable improvement in color during storage after a TS treatment at 60 °C. TS-treated beers showed a modest increase in colloidal haze and protein sensitivity. The beer treated at 50 °C demonstrated comparable flavor stability to the untreated sample; however, at 60 °C, TS treatment increased staling chemicals, which had a modest detrimental influence on the volatile profile [63]. Therefore, when applying TS to beers, it is necessary to consider the effects that the treatment temperature will have on the organoleptic and physicochemical properties of the product.

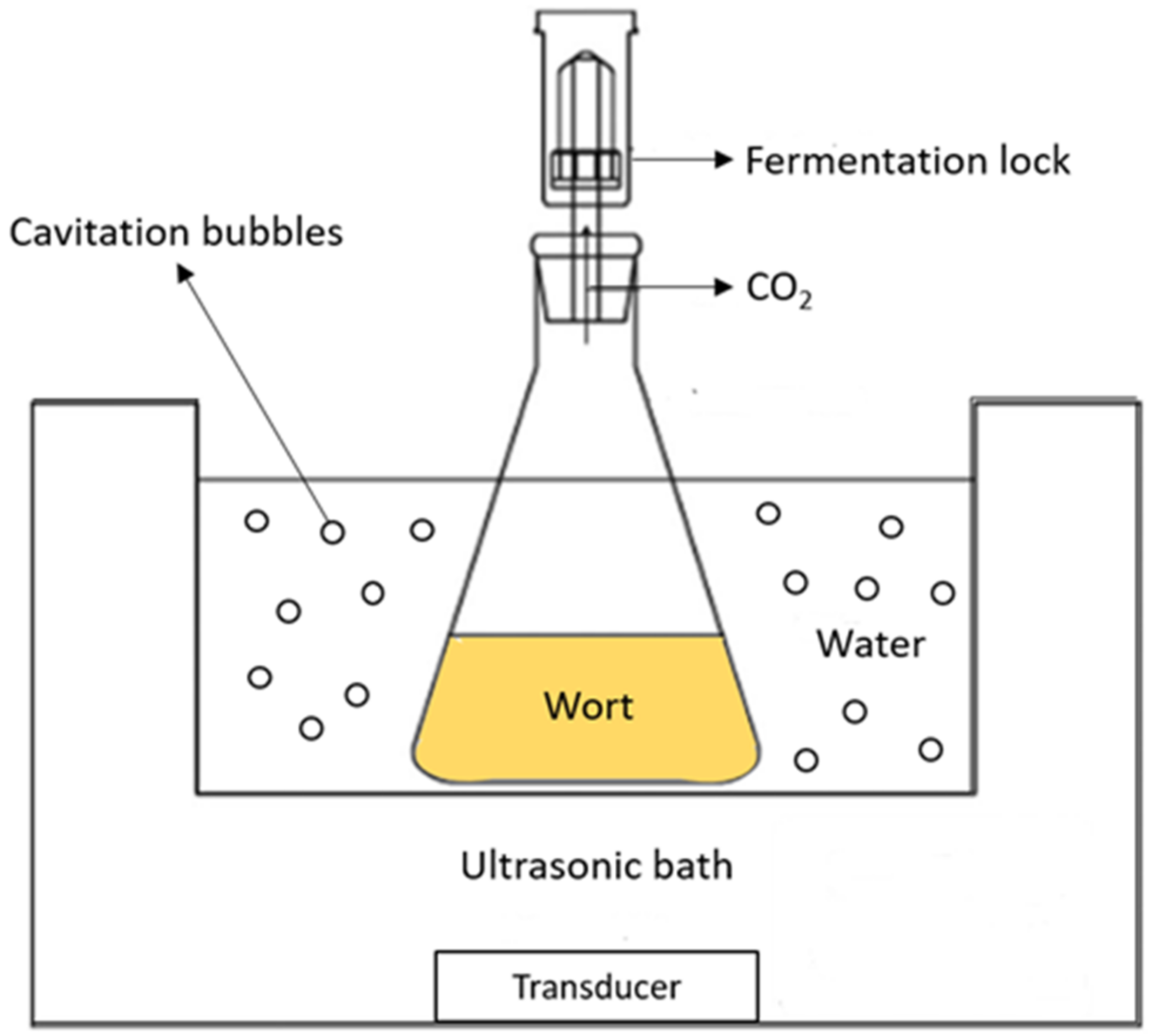

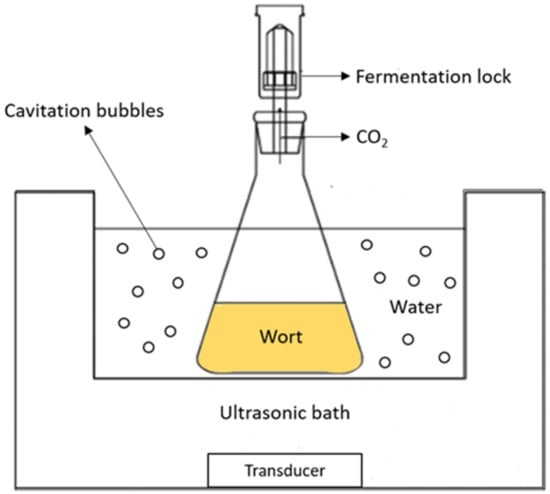

There are two types of US techniques available: direct application with an ultrasonic probe/sonotrode and indirect using an ultrasonic bath (Figure 4). The indirect application offers several benefits. For instance, it is less expensive than ultrasonic probes and can be employed through the sample container, allowing the sample to be sealed and preventing the contamination of samples and the loss of volatile substances [102,105].

Figure 4.

Representation of ultrasonic bath.

Choi E. et al. (2015) examined the impact of continuous high-intensity ultrasonic bathing (400 kHz with 120, 160 and 200 W of input power for 2, 6 and 12 h) on the initial fermentation of beer brewed from six-row Korean barley. Here it was discovered that ultrasonication enabled the brewing process to be hastened and allowed the production of more ethanol content. Higher ultrasonic power and longer ultrasonic periods resulted in the production of more alcohol, except for the 200 W treatment, which had a negative effect on the viability of the yeast. Particularly, intermediate power (120 and 160 W) significantly increased the final alcohol content by 13.18%. The sample produced the most alcohol when sonicated at 160 W for 12 h. Apart from the 200 W treatment, the samples exposed to US had generally acceptable sensory qualities; however, some direct effects on the organoleptic characteristics of beer were found, as they displayed a stronger carbonation flavor, aroma, mouthfeel and aftertaste than young beer [57].

The latter results contradict the information gathered by Kalugina et al. (2021) regarding US residence time and its effects. Their study revealed that lower periods of two-minute ultrasonic bath treatment (with a lower frequency of 44 kHz and an intensity of 1.0 W/cm2) increased brewer’s yeast’s physiological activity and reduced the time needed to produce yeast by 12 h. They also proved how effectively a two-minute ultrasonic treatment paired with 2% yeast extract during the preparation of yeast sped up the brewing process [58].

Finally, in a study by Huezo et al. (2019), different US conditions were tested by applying intermittent treatment with a duty cycle of 6.67% and a lower frequency of 20 kHz. Glucose-to-ethanol fermentations were carried out using Saccharomyces cerevisiae with direct and indirect treatments at various intensities of 23 W/L, 32 W/L and 1.4 W/L, respectively. Both direct and indirect US had detrimental effects on the performance and viability of the yeast, and they decreased glucose uptake rates and ethanol production [106]. Therefore, these results showed that the application of US during fermentation can be inhibitory and is not expected to improve mass transfer limitations at the levels and conditions applied. Despite the study’s unfavorable findings, earlier research claimed that US increased the rate of ethanol generation during Saccharomyces cerevisiae’s fermentation of glucose [107].

The results from this literature review highlight that there is an evident growing interest in US technology in the field of food science and technology due to its potentially beneficial impacts on food processing and preservation. In the brewing industry in particular, this treatment could be very advantageous mainly for speeding up the brewing process, producing more ethanol or degassing the beer before bottling. Furthermore, it has already been established that ultrasonication allows a more efficient pasteurization with an increase in product yield and in the physiological activity of the yeast and that when employing TS, the rate of microbial destruction is greatly improved. In addition, TS can significantly reduce the intensity that conventional heat treatments require to achieve microbiological stability of beer. Given all these promising and advantageous features, the US technique should be considered in the future as a strong candidate for industrial beer application.

4.3. HPP

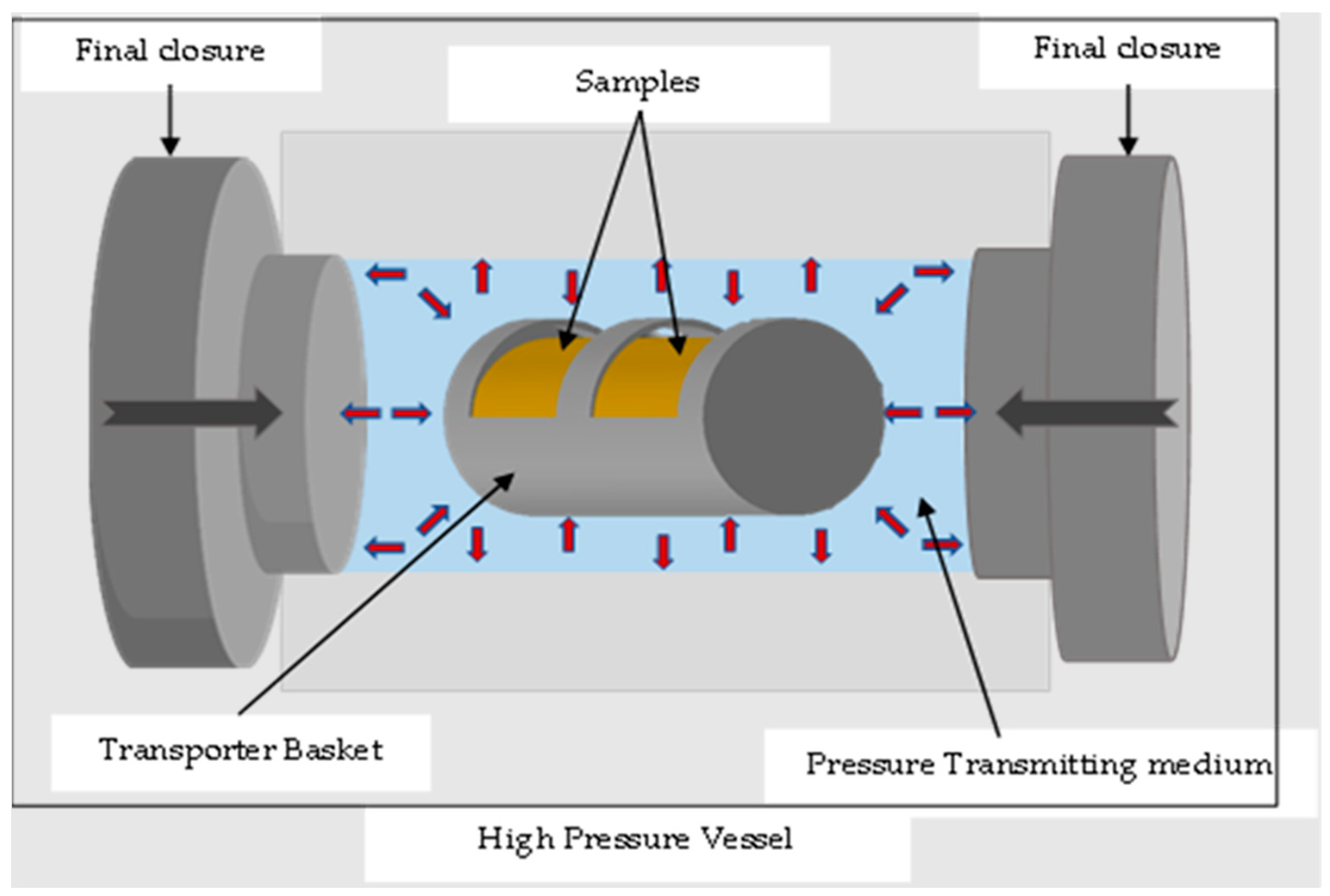

HPP is a unique food-processing method that has been researched and developed in order to deliver safe, fresh-tasting, nutritious foods without the need for using heat or chemical preservatives [108]. HPP has gained recognition as a viable alternative to thermal treatments to assure safety and reduce adverse effects of processing on qualitative attributes. In contrast to heat treatment, HPP treatment does not compromise the quality of food, and since pressure is instantly and evenly distributed throughout the sample, it is possible to obtain products without overly treated areas [109,110]

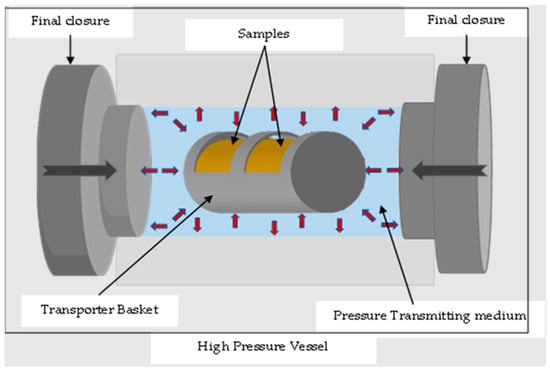

Two general principles have a direct impact on the application of HPP in the food processing industry. The first one is based on the idea that, regardless of the size or shape of the item, foods that undergo HPP in a vessel adhere to the isostatic rule. This means that whether a sample is in direct contact with the pressure medium or is hermetically sealed in flexible packaging, pressure is instantly and uniformly conveyed throughout the sample. As a result, unlike thermal processing, the time required for HPP should not rely on the sample size (Figure 5) [110,111]. The second claims that Le Chatelier’s principle governs how HPP affects food chemistry and microbiology. According to this principle, when an equilibrium state is disrupted, the system responds in a way that seeks to minimize the disruption. Pressure can accelerate several physical and chemical events, such as chemical reactions, phase transitions and molecular arrangements [112,113].

Figure 5.

Schematic representation of an HPP unit. Adapted from [114].

HPP and high-pressure homogenization (HPH) are two separate techniques that fall under the category of HPP [66]. With pressures ranging from 100 to 600 MPa and time ranging from 3 to 30 min, HPP is a batch process based on the Le Chatelier principle that has already been employed in several food industrial sectors. Pre-packaged products are placed inside the pressure chamber and compressed for the designated amount of time. The HPH, also known as dynamic high pressure (DHP), is a continuous process that is better suited for liquids. Turbulence, cavitation and shear forces are produced on the fluid when it passes through a small orifice at high pressures (up to 1000 MPa) and flow rates.

In the brewing industry, HPP may provide numerous benefits, such as beer freshness and appearance preservation, high nutritional quality and high vitamin content. Nevertheless, other sorts of applications have been examined, including the possible use as a potential treatment for the preservation of unfiltered beer [115]. According to the findings of several studies that have been performed so far, HPP has no impact on the crucial beer quality criteria (ethanol level, pH, extract and bitterness), and it can be effectively used as a cold pasteurization method, assuring a microbiological stabilization identical to traditional thermal pasteurization [65,116].

Thermal pasteurization is still prevalent as the final stage in the commercial manufacturing of beer; however, high pressure has been explored as a potential alternative to thermal approach for decades. Early research from Castellari et al. (2000) examined the effects of HPP and heat pasteurization on pale ales and mild ale beers. After being heated for 10 min at 60 °C, samples were subjected to 600 MPa for 5 min. The outcomes showed that HPP and the applied heat treatments did not change color or the main chemical components of beer (insignificant differences were found for pH, ethanol, extract, bitterness, iso-acids and catechins). In addition, in both treated beer samples, no lactic acid bacteria were found, and overall aerobic, yeast and mold counts were decreased by roughly four log10 cycles. Microbiological results proved that the inactivation of microorganisms caused by both HPP and heat treatments was equivalent. Throughout the entire 49-day storage period at 20 °C, heat-pasteurized and HPP samples did not show any appreciable increases in microbiological counts, including the growth of lactic acid bacteria [64]. Similar results were reported by Buzrul et al. (2005), who discovered that both filtered lager beer treated with HPP (350 MPa for 3 and 5 min at 20 °C) or pasteurized by conventional heat (60 °C for 15 min) during a storage period of 56 days demonstrated microbiological stability and suppression of lactic and acetic acid bacteria. Furthermore, at the end of the storage period, the HPP-treated samples also showed greater cold haze values and lower bitterness than the heat-pasteurized samples [65].

Other studies have also reported the effectiveness of this treatment when considering microbial inactivation. For instance, Milani et al. (2016) demonstrated that HPP resulted in greater inactivation of Saccharomyces cerevisiae ascospores with shorter processing times than conventional thermal methods and that it also required less energy to achieve a 2.5 log reduction in S. cerevisiae ascospores. HPP shows potential to be used as a pasteurization method and to substitute the traditional thermal treatment [60]. It is believed that the action of denaturation of nucleic acids and proteins, which results in irreversible alterations in yeast and bacterial cell shape and eventual death, ensures the needed microbiological stability by HPP [117].

Regarding the impact of HPP on the quality characteristics of beers, Buzrul et al. (2005) analyzed unpasteurized lager beer that had been subjected to either HPP (200, 250, 300 and 350 MPa for 3 and 5 min at 20 °C) or traditional thermal pasteurization (60 °C for 15 min) [65]. They discovered that important characteristics of beer, such as ethanol content, density, extract, level of fermentation and pH, were unaffected by any of the treatments; however, as pressure and pressurization time increased, some effects on color, cold haze, protein sensitivity and bitterness were observed. Though pressures up to 300 MPa had no discernible impact on bitterness, it is interesting to note that variations in bitterness were greatest during traditional heat pasteurization [65]. Another study conducted by Milani et al. (2016) also demonstrated the efficiency of HPP technology on beer pasteurization, mainly by using an HPP process at 600 MPa for 5 s, which resulted in a seven-log reduction in S. cerevisiae ascospores. The authors also established how alcohol content affects the reduction of yeast ascospores; it was concluded that under the same conditions, a higher alcohol content allowed a greater reduction. Additionally, the authors found that the overall flavor of HPP and untreated lager and ale beers did not change noticeably [60].

HPP treatment can have an impact on other steps of the brewing process. According to the aforementioned work of Santos et al. (2017), high pressure can enhance chemical reactions, alter molecular availability and affect phase transitions. As a result, HPP has been used in the malting process to replicate the process, which aims to provide the moisture required to the barley grain. For that purpose, pressures of 40, 60, 100, 200 and 400 MPa were applied to a mixture of barley and water for 20 min. The results at 400 MPa were comparable to those obtained with the control sample (barley seed regularly macerated at ambient temperature), which showed an increase in moisture from 12% to 20% in the barley. The viability of the treated grain was also examined, and it was discovered that neither hydrogen peroxide nor coloring techniques had any negative effects on the grains [66].

HPP might be especially useful during the mashing process since it affects the selectivity of α- and β-amylases, which are enzymes responsible for total starch breakdown, resulting in activation/inactivation depending on the pressure level [67]. Numerous studies have shown that applying high pressure to both α- and β-amylases increased their hydrolytic activity [68,69,70]. The behavior of α-amylase in beer wort processed by high pressure was investigated by Buckow et al. (2007), which considered the relationship between enzyme activity and HPP. They discovered that enzymes can be denatured with pressure application even at room temperature, but that pressure and temperature have an antagonistic effect up to 200 MPa and a synergistic effect above this value. Due to the synergy between the HPP and temperature, it was observed that substrate conversion at 152 MPa and 64 °C was 25% higher when compared with processing temperatures of 59° C applied at atmospheric pressure [69]. Additionally, the presence of calcium ions (3.8 mM CaCl2) and pH 6.1 can further increase the resistance of α-amylase to temperature and pressure. Because α-amylase is a calcium-dependent metalloenzyme, it was hypothesized that higher enzyme activity would occur in the presence of calcium [118]. Heinz et al. (2005) discovered notable enzyme stabilization at 200 MPa as compared with heat denaturation regarding the β-amylase of barley malt. However, for all temperatures investigated (20 to 70 °C), increased pressure also interfered with the catalytic activity of this enzyme. The optimal conditions, i.e., 106 MPa, 63 °C and pH 5.6, resulted in activity enhancement, which led to a 15% improvement in the conversion yield of maltose [70]. The production of fermentable sugar and its relationship to applied pressure were both subjects of investigation by Choi et al. (2016). By applying pressure above atmospheric pressure to an English Pale Ale wort, they were able to confirm that saccharification was higher. Furthermore, the ideal situation was found at 2 MPa, but saccharification decreased when the applied pressure ranged between 50 and 100 MPa. In addition, lower pressures would result in less expensive equipment or reduce equipment depreciation rates, making HPP less viable for this application. It has been observed that 67 °C (at 2 MPa) was the ideal temperature to promote the production of fermentable sugars [67]. There is a substantial level of interest in enhancing enzymes’ activity and stability for improved efficiency and industrial application because they are generally unstable in their native condition and have greater associated costs when compared to chemical reactions [68]. Although some enzymes show stability under pressure, they can lose their functionality as well [72,119].

Wort boiling determines the isomerization of α-acids, which is a critical step that gives beer its bitter flavor [66]. In assessing the impact of HPP on beer wort, Fischer et al. (2002) found that isomerization was higher at 700 MPa and more efficient with 30 min of treatment than with 5 min. Due to the lack of agitation and shorter treatment times, the HPP-treated samples had lower isomerization values than the heat-treated samples [71]. According to Santos et al. (2017), wort samples treated at 200, 400 and 600 MPa for 20 min exhibited lower isomerization when compared with boiled samples [66]. Additionally, Fischer et al. (2002) investigated the effects of a treatment at 600 MPa for 30 min by evaluating isomerization through high-performance liquid chromatography (HPLC), which confirmed the development of molecules similar to iso-α-acids but different from the compounds produced by heat treatment [71]. These investigations demonstrated the need for temperature to increase bitterness during the boiling process, indicating the possibility of combining temperature and HPP to accomplish the desired isomerization of α-acids. Wort boiling also results in a rapid evaporation of undesirable volatile components, such as dimethyl sulfide (DMS), from the produced beer. As a result, identical DMS values were observed in the untreated and HPP-treated samples, which was similar to the case of hops, but the boiled samples showed reduced amounts of this compound. The combined method would also be more effective in this situation to produce the desired volatile profile result [71]. Furthermore, the wort’s coloring components are formed during boiling. It could be interesting to combine HPP and temperature to produce the desired color. According to Santos et al. (2017), researchers investigated the influence of HPP on the color of wort subjected to 200, 400 and 600 MPa for 20 min, and they concluded that color was 25% less intense than that observed in heat-treated samples [66]. This is likely because HPP does not provide the necessary conditions for Maillard reactions to occur.

Filtration is an important stage in the brewing process because it can affect the appearance, flavor and shelf-life of beer. This operation is responsible for removing sediment, yeast and other bacteria from the beer, thus preventing beer contamination. Additionally, it stops the beer from turning tasteless and hazy [45]. In the brewing process, the presence of β-glucans can increase wort and beer viscosity, thus resulting in filtration issues [66]. Fischer et al. (2002) also analyzed two samples of beer, one containing high-molecular-weight proteins, polyphenols and β-glucans, which can impair filtration, and the other without them, to conclude if high pressures could influence the substances removed from beer during filtering. Treatments at 300 MPa improved their filterability (using a cellulose filter), resulting in a 50% reduction in filtration time. The use of a diatomaceous earth filter also revealed a considerable improvement as well. Nevertheless, at 500 MPa, a better effect was shown [71]. This fact becomes even more remarkable since the disposal of waste is a limitation of filtration processes; therefore, if the filterability is increased, less waste is produced. The polyphenol concentrations, anthocyanogenic substances, protein fractions and β-glucans were also further examined by Fischer et al. (2006). They discovered reduced values only for β-glucans after HPP treatment once they were below the technique detection limit, 10 mg/L, after 300 to 500 MPa treatments [72].

β-glucan molecules become soluble at pressures greater than 300 MPa because weaker Van der Waals forces may be destroyed. Additionally, varying β-glucan concentrations resulted in a decrease in beer viscosity, particularly at 500 MPa [72]. As a result, in relation to beer filtration, since the fundamental problem being investigated is the presence of β-glucans, and since β-glucanases can be activated by pressure, treating beer with HPP during the mashing step may help solve the problem. This would result in a lower concentration of this compound in the final product.

Finally, it is interesting to note that it was discovered that high hydrostatic pressure may be employed to increase the content of xanthohumol in beer’s wort. Isoxanthohumol (IXN), an isomeric flavanone of xanthohumol (XN) extracted from hops during wort boiling, displays significant biological activity as a functional molecule due to its anti-cariogenic, antioxidant, anti-inflammatory and anti-infective properties. According to Santos et al. (2013), beer processed by HPP (250 MPa for 5 min) had greater amounts of XN than beer solely processed by boiling; thus, it can be concluded that this method can be utilized to create XN-enriched beers with improved health-promoting properties [119].

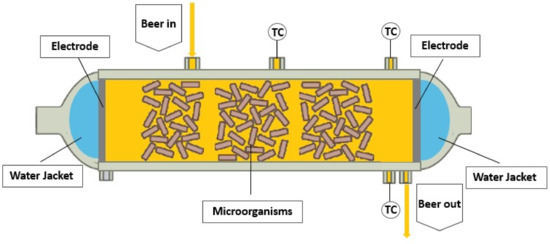

4.4. OH

OH is another example of a emergent technology for continuous thermal processing of food, which is currently receiving more attention from the scientific community and the industrial sector [76]. This technology is frequently referred to as “Joule heating” because James Prescot Joule found, in 1841, that heat generated due to flow of electric current was directly proportional to the wire’s resistance times one square of the electric current [82,120]. Ohm (ꭥ) units are used to measure electrical resistance. Currently, this technology is commercially known as “ohmic” heating because it depends on electrical resistance of a semi-conductive material [120]. However, heat dissipation is always an attendant effect of the application of an electric field. In this regard, this technology can also be named as moderate electric field. For the purposes of this article, the terminology OH will be used knowing that emphasis will be placed on beer thermal pasteurization.

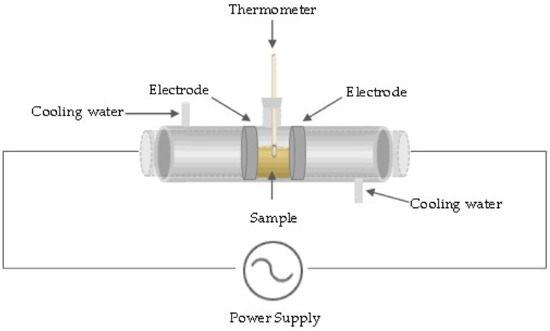

The fundamentals of OH are relatively simple and are shown in Figure 6. The principle of OH is the generation of heat by the passage of an alternating electrical current through an electrically resistive material, such as a liquid particle food system. At both ends of the product body, voltage is applied to the electrodes [120]. Electrical conductivity and the square of the electric field strength determine the rate of heating. Adjusting the electrode distance or the applied voltage will change the intensity of the electric field applied. The product’s electrical conductivity and its temperature sensitivity are, however, the most crucial factors. The electrical conductivity of all stages must be considered in a multiphasic product, such as in the case of a mixture of liquid and particles [121]. OH can be used to heat food with an electrical conductivity in the range of 0.01 to 10 S/m. Electrical conductivity of wort and beer will vary; it is very dependent on the mineral composition of water as well as on the total dissolved solute’s concentration. According to the reported literature, beer has an electrical conductivity above 0.1 S/m at 25 °C, which is perfectly suited for the application of OH technology [76,77,83,122].

Figure 6.

Schematic representation of an OH reactor.

Due to the potential to promote fast and uniform heating in the product, the use of OH has considerable advantages over conventional methods of processing beverages. The advantages of OH include rapid uniform heating, and it can provide simultaneous heating of the solid and liquid phases. This technology can heat foods of higher viscosity, liquid–particle combinations and food particles, and it is easy to handle due to the instant switch-on and shut-down system (there is no residual heat after system shut-down) [77]. Furthermore, OH has a high energy efficiency since around 95% of the electrical energy used in this process is converted into heat [77,78,82]. Given that OH allows a direct way of heating—heat is dissipated within the sample—there is no need produce heat (no need of boilers) and transfer it, thus reducing water consumption and heat losses. Balthazar et al. (2022) used pasteurization of sheep’s milk with OH and electric field strengths of 8.33 and 5.83 V/cm as an example of the procedure’s effectiveness. This pasteurization required 72–73% less energy than pasteurization using conventional heating [123]. Because there are no hot surfaces, OH decreases the possibility of fouling, and the chance of burning food is also minimized [124]. However, high frequencies (>17 kHz) should be used to avoid electrode corrosion and electrolysis, which can contribute to appearance of protein deposits [125]. This fact reduces the expense of cleaning, which consequently cuts down the processing time. Additionally, OH is considered an environmentally sustainable system due to its high energetic efficiency, possibility of using renewable energy sources (i.e., photovoltaic) and reduction of water consumption [77,78]. Nevertheless, some disadvantages persist, such as the absence of generalized knowledge for certain applications and expensive investment costs [82].

In terms of its application in the food industry, the use OH in food processing became primarily known through electric pasteurization of milk in the last century [83]. Currently, this technology is also being industrially implemented for tomato products, liquid egg, sauces, tofu and juice processing, for example [126,127]. However, according to the literature review, there are no studies addressing OH applied to beer or beer’s wort for brewing purposes. Nevertheless, the potential of OH technology to carrying out microbial inactivation, fermentation, extraction, continuous sterilization and pasteurization of foods and beverages is highlighted in the literature [128]. More research on the effects of OH technology in different brewing thermal steps (such as boiling and pasteurization) is required to fully understand the potential that such technology has for being implemented in large-scale breweries.

OH technology has been proposed by different authors as an effective way to influence the activity of food enzymes at different stages of food processing [73,74,75]. In the scope of brewing, research applied to the effect of OH treatment in the mashing stage, where several hydrolytic enzymes (e.g., amylases, peptidases, glucanases etc.) are involved, should be addressed with the aim of unveiling the impact of this technology on such enzymes and, consequently, on beer quality and processing.

It is already known that throughout the wort-boiling stage of the brewing process, beer’s wort is subject to high thermal load. The high processing temperature and time required to accomplish traditional wort boiling is reported to cause the accumulation of Maillard intermediates, which might lead to the development of undesirable off-flavors during beer ageing [129]. Additionally, the thermal effects of wort boiling are regarded as one of the major factors leading to the degradation of functional compounds present in beer’s wort, mainly polyphenols extracted from malt and hops, which play a crucial role in the antioxidant activity of beer [130]. Considering these events, research involving OH technology and its impact on wort boiling should be conducted in order to determine if this technique has the potential to reduce both the generation of Maillard intermediates and the degradation of polyphenolic bioactive compounds by reducing the thermal load applied to beer’s wort. This hypothesis should actively be considered given the overwhelming evidence found in the literature reporting very high energy efficiencies and heating rates as well as the uniform heat distribution and absence of hot surfaces in systems where OH technology is applied [76,77,78].

Food products are frequently pasteurized using OH, giving rise to food products of high quality, as reported in several studies conducted with different types of milk [123,131,132]. In the brewing industry, thermal treatments in tunnel pasteurizers or plate heat exchangers are frequently used to extend the shelf-life of beer. Instead of using conventional food-processing methods, OH can be employed since it uniformly and rapidly distributes heat throughout the product. OH offers higher preservation of sensory qualities of the food, extending its shelf-life without compromising the fresh product’s aroma quality [84]. The presence of moderate electric fields during treatment also contributes to enhanced microbiological inactivation, which means that it is not necessary to achieve high temperatures to reduce microbiological hazards to a certain level.

Considering the positive effects reported by the application of OH technology in different foods, it is expected that OH treatments of beer could also generate favorable and promising outcomes for its dissemination in the brewing industry. An OH system for continuous beer processing can be simply integrated into existing processing lines by assuring the presence of a reactor where electrodes are positioned to make contact for the purpose of applying an electric field, thus defining heating sections during beer flow.

5. Conclusions

The present study reviewed the potential of employing innovative processing technologies, namely PEF, US, TS, HPP and OH, in the brewing process. PEF technology can be used to perform continuous cold pasteurization of beer and support extraction of interesting compounds from brewing raw materials without harming the sensory profile of the product. Moreover, the extraction potential of this technology is extended to brewing by-products, thus allowing them to be economically attractive and contributing to the establishment of a circular economy in the food industry. US and TS technologies display a wide range of convenient features for brewing, such as speeding up the process, producing ethanol more effectively during fermentation and degassing beer before bottling, and they preserve organoleptic properties of beer. HPP is another technology that can be regarded as promising for beer processing given its effectiveness at eliminating microorganisms. HPP does not employ heat (or at least reduces its need), and it preserves the original characteristics of the beverage. Finally, OH technology, despite not being reported in the literature for brewing purposes, is known to contribute to a higher heating efficiency, to modulate enzyme activity and to inactivate harmful microorganisms. OH is attracting attention for brewing processes, and more fundamental and applied studies will be developed in a near future.

Overall, these innovative and emergent processing technologies have not yet found a wide application in the brewing process. This literature review provides a solid background of evidence which highlights the advantages of the application of such technologies in beer production, particularly for microbiological inactivation. These technologies also have the potential to improve the sensory characteristics of beer as well as its nutritional value, functionality and shelf-life, and they have the potential to reducing processing costs and times. These premises, together with the possibility of integrating novel technologies in continuous beer production, constitute a strong and considerable opportunity for the progress and development of the industrial brewing sector.

Author Contributions

Conceptualization, R.P.; investigation, G.C., A.C.L., R.L. and R.P.; writing—original draft preparation, G.C., A.C.L., R.L. and R.P.; writing—review and editing, R.P.; supervision, R.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This study was supported by the Portuguese Foundation for Science and Technology (FCT) under the scope of the strategic funding of UIDB/04469/2020 unit and by LABBELS—Associate Laboratory in Biotechnology, Bioengineering and Microelectromechnaical Systems, LA/P/0029/2020. Ricardo N. Pereira acknowledges FCT for its Assistant Research program under the scope of Scientific Stimulus Employment with reference CEECIND/02903/2017.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sewell, S.L. The Spatial Diffusion of Beer from Its Sumerian Origins to Today. In The Geography of Beer: Regions, Environment, and Societies; Springer: Berlin/Heidelberg, Germany, 2014; pp. 23–29. ISBN 9789400777873. [Google Scholar]

- Paiva, R.A.M.; Mutz, Y.S.; Conte-Junior, C.A. A Review on the Obtaining of Functional Beers by Addition of Non-Cereal Adjuncts Rich in Antioxidant Compounds. Antioxidants 2021, 10, 1332. [Google Scholar] [CrossRef] [PubMed]

- Rachwał, K.; Waśko, A.; Gustaw, K.; Polak-Berecka, M. Utilization of Brewery Wastes in Food Industry. PeerJ 2020, 8, e9427. [Google Scholar] [CrossRef] [PubMed]

- Statista Beer Production Worldwide from 1998 to 2021. Available online: https://www.statista.com/statistics/270275/worldwide-beer-production/ (accessed on 4 October 2022).

- Březinová, M. Beer Industry in the Czech Republic: Reasons for Founding a Craft Brewery. Sustainability 2021, 13, 9680. [Google Scholar] [CrossRef]

- Jantyik, L.; Balogh, J.M.; Török, Á. What Are the Reasons behind the Economic Performance of the Hungarian Beer Industry? The Case of the Hungarian Microbreweries. Sustainability 2021, 13, 2829. [Google Scholar] [CrossRef]

- Aquilani, B.; Laureti, T.; Poponi, S.; Secondi, L. Beer Choice and Consumption Determinants When Craft Beers Are Tasted: An Exploratory Study of Consumer Preferences. Food Qual. Prefer. 2015, 41, 214–224. [Google Scholar] [CrossRef]

- Baiano, A. Craft Beer: An Overview. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1829–1856. [Google Scholar] [CrossRef]

- Machado, J.C.; Faria, M.A.; Ferreira, I.M.P.L.V.O. Hops: New Perspectives for an Old Beer Ingredient. In Natural Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 280–282. [Google Scholar]

- Jesús Callejo, M.; Tesfaye, W.; Carmen González, M.; Morata, A. Craft Beers: Current Situation and Future Trends. In New Advances on Fermentation Processes; IntechOpen: London, UK, 2020. [Google Scholar]

- Violino, S.; Figorilli, S.; Costa, C.; Pallottino, F. Internet of Beer: A Review on Smart Technologies from Mash to Pint. Foods 2020, 9, 950. [Google Scholar] [CrossRef]

- Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Borșa, A.; Pasqualone, A.; Zhao, H. Non-Alcoholic and Craft Beer Production and Challenges. Processes 2020, 8, 1382. [Google Scholar] [CrossRef]

- Craine, E.B.; Bramwell, S.; Ross, C.F.; Murphy, K.M. From Ground to Glass: Evaluation of Unique Barley Varieties for Craft Malting, Craft Brewing, and Consumer Sensory. Beverages 2022, 8, 30. [Google Scholar] [CrossRef]

- Olivares-Galván, S.; Marina, M.L.; García, M.C. Extraction of Valuable Compounds from Brewing Residues: Malt Rootlets, Spent Hops, and Spent Yeast. Trends Food Sci. Technol. 2022, 127, 181–197. [Google Scholar] [CrossRef]

- Pferdmenges, L.E.; Schröter, A.; Lohmayer, R.; Striegel, L.; Rychlik, M.; Müller, A.; Meinhardt, A.K.; Trierweiler, B.; Hartmann, B.M.; Frommherz, L. Characterization of the Nutrient Composition of German Beer Styles for the German Nutrient Database. J. Food Compos. Anal. 2022, 105, 104181. [Google Scholar] [CrossRef]

- Punčochářová, L.; Pořízka, J.; Diviš, P.; Štursa, V. Study of the Influence of Brewing Water on Selected Analytes in Beer Study of the Influence of Brewing Water on Selected Analytes in Beer View Project Authentification of Wine View Project. Potravin. Slovak J. Food Sci. 2019, 13, 507–514. [Google Scholar] [CrossRef]

- Agwanande Ambindei, W.; Dibengue, D.; Florentin, J.; Pride Ndasi, N.; Afek, A.A.; Bienvenu, S.; Jong, N.E. Optimisation of Malting of Cameroonian Rice (Oryza Sativa) Cultivars for Beer Production. J. Brew. Distill. 2022, 11, 1–17. [Google Scholar] [CrossRef]

- Yin Tan, W.; Li, M.; Devkota, L.; Attenborough, E.; Dhital, S. Mashing Performance as a Function of Malt Particle Size in Beer Production. Crit. Rev. Food Sci. Nutr. 2021, 1–16. [Google Scholar] [CrossRef] [PubMed]

- De Schepper, C.F.; Buvé, C.; Van Loey, A.M.; Courtin, C.M. A Kinetic Study on the Thermal Inactivation of Barley Malt α-Amylase and β-Amylase during the Mashing Process. Food Res. Int. 2022, 157, 111201. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Gao, X. Progress of the Use of Alternatives to Malt in the Production of Gluten-Free Beer. Crit. Rev. Food Sci. Nutr. 2020, 62, 2820–2835. [Google Scholar] [CrossRef]

- Hung, N.T.; Thuy, N.T.; Ha, N.C. Evaluation of Using the Rice in Mekong Delta for Beer Making: Nutritional, Heat Resistant, Protease Resistant and Inhibitor Properties of Protein. J. Food Process. Preserv. 2022, e17222. [Google Scholar] [CrossRef]

- Da Rosa Almeida, R.; de Oliveira Brisola Maciel, M.V.; Machado, M.H.; Bazzo, G.C.; de Armas, R.D.; Vitorino, V.B.; Vitali, L.; Block, J.M.; Barreto, P.L.M. Bioactive Compounds and Antioxidant Activities of Brazilian Hop (Humulus Lupulus L.) Extracts. Int. J. Food Sci. Technol. 2020, 55, 340–347. [Google Scholar] [CrossRef]

- Kimura, M.; Ito, T.; Sato, H.; Higashi, M. Theoretical Study on Isomerization of α-Acids: A DFT Calculation. Food Chem. 2021, 364, 130418. [Google Scholar] [CrossRef]

- Féchir, M.; Weaver, G.; Roy, C.; Shellhammer, T.H. Exploring the Regional Identity of Cascade and Mosaic® Hops Grown at Different Locations in Oregon and Washington. J. Am. Soc. Brew. Chem. 2022. [Google Scholar] [CrossRef]

- Sahaya Glingston, R.; Yadav, J.; Rajpoot, J.; Joshi, N.; Nagotu, S. Contribution of Yeast Models to Virus Research. Appl. Microbiol. Biotechnol. 2021, 105, 4855–4878. [Google Scholar] [CrossRef]

- Iorizzo, M.; Coppola, F.; Letizia, F.; Testa, B.; Sorrentino, E. Processes Role of Yeasts in the Brewing Process: Tradition and Innovation. Processes 2021, 9, 839. [Google Scholar] [CrossRef]

- Freepik Company, S.L. Flaticon Free Icons. Available online: https://www.flaticon.com/ (accessed on 8 November 2022).

- Mosher, M.; Trantham, K. Milling and Mashing. In Brewing Science: A Multidisciplinary Approach; Springer: Berlin/Heidelberg, Germany, 2021; pp. 167–197. [Google Scholar] [CrossRef]

- Bachmann, S.A.L.; Calvete, T.; Féris, L.A. Potential Applications of Brewery Spent Grain: Critical an Overview. J. Environ. Chem. Eng. 2022, 10, 106951. [Google Scholar] [CrossRef]

- Aredes, R.S.; Peixoto, F.C.; Sphaier, L.A.; Marques, F.F. de C. Evaluation of Craft Beers through the Direct Determination of Amino Acids by Capillary Electrophoresis and Principal Component Analysis. Food Chem. 2021, 344, 128572. [Google Scholar] [CrossRef]

- De Schepper, C.F.; Michiels, P.; Buvé, C.; Van Loey, A.M.; Courtin, C.M. Starch Hydrolysis during Mashing: A Study of the Activity and Thermal Inactivation Kinetics of Barley Malt α-Amylase and β-Amylase. Carbohydr. Polym. 2021, 255, 117494. [Google Scholar] [CrossRef]

- Blšáková, L.; Gregor, T.; Mešt’ánek, M.; Hřivna, L.; Kumbár, V. The Use of Unconventional Malts in Beer Production and Their Effect on the Wort Viscosity. Foods 2021, 11, 31. [Google Scholar] [CrossRef]

- Hennemann, M.; Gastl, M.; Becker, T. Influence of Particle Size Uniformity on the Filter Cake Resistance of Physically and Chemically Modified Fine Particles. Sep. Purif. Technol. 2021, 272, 118966. [Google Scholar] [CrossRef]

- Adetokunboh, A.H.; Obilana, A.O.; Jideani, V.A. Physicochemical Characteristics of Bambara Groundnut Speciality Malts and Extract. Molecules 2022, 27, 4332. [Google Scholar] [CrossRef] [PubMed]

- Kalb, V.; Seewald, T.; Hofmann, T.; Granvogl, M. Investigations into the Ability to Reduce Cinnamic Acid as Undesired Precursor of Toxicologically Relevant Styrene in Wort by Different Barley to Wheat Ratios (Grain Bill) during Mashing. J. Agric. Food Chem. 2021, 69, 9450. [Google Scholar] [CrossRef]

- Ciont, C.; Epuran, A.; Kerezsi, A.D.; Coldea, T.E.; Mudura, E.; Pasqualone, A.; Zhao, H.; Suharoschi, R.; Vriesekoop, F.; Pop, O.L. Beer Safety: New Challenges and Future Trends within Craft and Large-Scale Production. Foods 2022, 11, 2693. [Google Scholar] [CrossRef]

- Bhonsale, S.; Mores, W.; Van Impe, J.; Gonzalez Viejo, C.; Fuentes, S. Dynamic Optimisation of Beer Fermentation under Parametric Uncertainty. Fermentation 2021, 7, 285. [Google Scholar] [CrossRef]

- Donnelly, D.; Blanchard, L.; Dabros, M.; O’Hara, S.; Brabazon, D.; Foley, G.; Freeland, B. Fed-Batch System for Propagation of Brewer’s Yeast. J. Am. Soc. Brew. Chem. 2021, 80, 190–200. [Google Scholar] [CrossRef]

- Liu, S.; Kerr, E.D.; Pegg, C.L.; Schulz, B.L. Proteomics and Glycoproteomics of Beer and Wine. Proteomics 2022, 22, 2100329. [Google Scholar] [CrossRef] [PubMed]

- Sclifos, A.; Scutaru, I. The Influence of Microorganisms on Beer Quality. J. Eng. Sci. 2022, 29, 161–171. [Google Scholar] [CrossRef] [PubMed]

- Madrera, R.R.; Bedriñana, R.P.; Valles, B.S. Evaluation of Indigenous Non-Saccharomyces Cider Yeasts for Use in Brewing. Eur. Foor Res. Technol. 2021, 247, 819–828. [Google Scholar] [CrossRef]

- Postigo, V.; García, M.; Cabellos, J.M.; Arroyo, T. Wine Saccharomyces Yeasts for Beer Fermentation. Fermentation 2021, 7, 290. [Google Scholar] [CrossRef]

- Mosher, M.; Trantham, K. The Purpose of Maturation. In Brewing Science: A Multidisciplinary Approach; Springer: Berlin/Heidelberg, Germany, 2021; pp. 332–333. ISBN 978-3-030-73419-0. [Google Scholar]

- Kahle, E.-M.; Zarnkow, M.; Jacob, F. Beer Turbidity Part 1: A Review of Factors and Solutions. J. Am. Soc. Brew. Chem. 2020, 79, 99–114. [Google Scholar] [CrossRef]

- Rogener, F. Filtration Technology for Beer and Beer Yeast Treatment. In IOP Conference Series Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Milani, E.A.; Silva, F.V.M. Pasteurization of Beer by Non-Thermal Technologies. Front. Food Sci. Technol. 2022, 1, 798676. [Google Scholar] [CrossRef]

- Nunes Filho, R.C.; Galvan, D.; Effting, L.; Terhaag, M.M.; Yamashita, F.; de Toledo Benassi, M.; Spinosa, W.A. Effects of Adding Spices with Antioxidants Compounds in Red Ale Style Craft Beer: A Simplex-Centroid Mixture Design Approach. Food Chem. 2021, 365, 130478. [Google Scholar] [CrossRef]

- Walkling-Ribeiro, M.; Rodríguez-González, O.; Jayaram, S.H.; Griffiths, M.W. Processing Temperature, Alcohol and Carbonation Levels and Their Impact on Pulsed Electric Fields (PEF) Mitigation of Selected Characteristic Microorganisms in Beer. Food Res. Int. 2011, 44, 2524–2533. [Google Scholar] [CrossRef]

- Evrendilek, G.A.; Li, S.; Dantzer, W.R.; Zhang, Q.H. Pulsed Electric Field Processing of Beer: Microbial, Sensory, and Quality Analyses. J. Food Sci. 2004, 69, M228–M232. [Google Scholar] [CrossRef]

- Oziemblowski, M.; Drozdz, M.; Kielbasa, P.; Drozdz, T.; Gliniak, M.; Nawara, P.; Ostafin, M. Impact of Pulsed Electric Field on the Quality of Unpasteurized Beer. In Proceedings of the Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 25–30 June 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Ntourtoglou, G.; Tsapou, E.A.; Drosou, F.; Bozinou, E.; Lalas, S.; Tataridis, P.; Dourtoglou, V. Pulsed Electric Field Extraction of α and β-Acids From Pellets of Humulus Lupulus (Hop). Front. Bioeng. Biotechnol. 2020, 8, 297. [Google Scholar] [CrossRef] [PubMed]

- Martín-García, B.; Tylewicz, U.; Verardo, V.; Pasini, F.; Gómez-Caravaca, A.M.; Caboni, M.F.; Dalla Rosa, M. Pulsed Electric Field (PEF) as Pre-Treatment to Improve the Phenolic Compounds Recovery from Brewers’ Spent Grains. Innov. Food Sci. Emerg. Technol. 2020, 64, 102402. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, M.; Lin, S.; Liu, J.; Yang, Y.; Jin, Y. Optimization of Extraction Parameters for Protein from Beer Waste Brewing Yeast Treated by Pulsed Electric Fields (PEF). Afr. J. Microbiol. Res. 2012, 6, 4739–4746. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications. A Review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Knorr, D.; Zenker, M.; Heinz, V.; Lee, D. Applications and Potential of Ultrasonics in Food Processing. Trends Food Sci. Technol. 2004, 15, 261–266. [Google Scholar] [CrossRef]

- Matsuura, K.; Hirotsune, M.; Nunokawa, Y.; Satoh, M.; Honda, K. Acceleration of Cell Growth and Ester Formation by Ultrasonic Wave Irradiation. J. Ferment. Bioeng. 1994, 77, 36–40. [Google Scholar] [CrossRef]

- Choi, E.J.; Ahn, H.; Kim, M.; Han, H.; Kim, W.J. Effect of Ultrasonication on Fermentation Kinetics of Beer Using Six-Row Barley Cultivated in Korea. J. Inst. Brew. 2015, 121, 510–517. [Google Scholar] [CrossRef]

- Kalugina, O.; Nafikova, A.; Chernenkov, E.; Leonova, S. Application of Ultrasound for Enhancing Fermentation Rates in Brewing Technology. Acta Sci. Pol. Technol. Aliment. 2021, 20, 301–312. [Google Scholar] [CrossRef]

- Milani, E.A.; Silva, F.V.M. Ultrasound Assisted Thermal Pasteurization of Beers with Different Alcohol Levels: Inactivation of Saccharomyces Cerevisiae Ascospores. J. Food Eng. 2017, 198, 45–53. [Google Scholar] [CrossRef]

- Milani, E.A.; Ramsey, J.G.; Silva, F.V.M. High Pressure Processing and Thermosonication of Beer: Comparing the Energy Requirements and Saccharomyces Cerevisiae Ascospores Inactivation with Thermal Processing and Modeling. J. Food Eng. 2016, 181, 35–41. [Google Scholar] [CrossRef]

- Ciccolini, L.; Taillandier, P.; Wilhem, A.M.; Delmas, H.; Strehaiano, P. Low Frequency Thermo-Ultrasonication of Saccharomyces Cerevisiae Suspensions: Effect of Temperature and of Ultrasonic Power. Chem. Eng. J. 1997, 65, 145–149. [Google Scholar] [CrossRef]

- Evelyn, E.; Silva, F.V.M. Thermosonication versus Thermal Processing of Skim Milk and Beef Slurry: Modeling the Inactivation Kinetics of Psychrotrophic Bacillus Cereus Spores. Food Res. Int. 2015, 67, 67–74. [Google Scholar] [CrossRef]

- Deng, Y.; Bi, H.; Yin, H.; Yu, J.; Dong, J.; Yang, M.; Ma, Y. Influence of Ultrasound Assisted Thermal Processing on the Physicochemical and Sensorial Properties of Beer. Ultrason—Sonochemistry 2017, 40, 166–173. [Google Scholar] [CrossRef]

- Castellari, M.; Arfelli, G.; Riponi, C.; Carpi, G.; Amati, A. High Hydrostatic Pressure Treatments for Beer Stabilization Food Engineering and Physical Properties. Food Eng. Phys. Prop. High 2000, 65, 974–977. [Google Scholar] [CrossRef]

- Buzrul, S.; Alpas, H.; Bozoglu, F. Effect of High Hydrostatic Pressure on Quality Parameters of Lager Beer. J. Sci. Food Agric. 2005, 85, 1672–1676. [Google Scholar] [CrossRef]

- Santos, L.; Oliveira, F.A.; Ferreira, E.H.; Rosenthal, A. Application and Possible Benefits of High Hydrostatic Pressure or High-Pressure Homogenization on Beer Processing: A Review. Food Sci. Technol. Int. 2017, 23, 561–581. [Google Scholar] [CrossRef]

- Choi, J.H.; Kang, J.W.; Mijanur Rahman, A.T.M.; Lee, S.J. Increasing Fermentable Sugar Yields by High-Pressure Treatment during Beer Mashing. J. Inst. Brew. 2016, 122, 143–146. [Google Scholar] [CrossRef]

- Eisenmenger, M.J.; Reyes-De-Corcuera, J.I. High Pressure Enhancement of Enzymes: A Review. Enzym. Microb. Technol. 2009, 45, 331–347. [Google Scholar] [CrossRef]

- Buckow, R.; Weiss, U.; Heinz, V.; Knorr, D. Stability and Catalytic Activity of A-Amylase From Barley Malt at Different Pressure–Temperature Conditions. Biotechnol. Bioeng. 2007, 97, 1–11. [Google Scholar] [CrossRef]

- Heinz, V.; Buckow, R.; Knorr, D. Catalytic Activity of β-Amylase from Barley in Different Pressure/Temperature Domains. Biotechnol. Prog. 2005, 21, 1632–1638. [Google Scholar] [CrossRef]

- Fischer, S.; Russ, W.; Meyer-Pittroff, R. High Pressure Advantages for Brewery Processes. Prog. Biotechnol. 2002, 19, 397–404. [Google Scholar] [CrossRef]

- Fischer, S.; Ruß, W.; Buckow, R.; Heinz, V.; Ulmer, H.; Behr, J.; Meyer-Pittroff, R.; Knorr, D.; Vogel, R.F. Effects of Hydrostatic High Pressure on Microbiological and Technological Characteristics of Beer. Mon. Fur Brauwiss 2006, 59, 90–99. [Google Scholar]

- Li, X.; Xu, X.; Wang, L.; Regenstein, J.M. Effect of Ohmic Heating on Physicochemical Properties and the Key Enzymes of Water Chestnut Juice. J. Food Process. Preserv. 2019, 43, e13919. [Google Scholar] [CrossRef]

- Jakób, A.; Bryjak, J.; Wójtowicz, H.; Illeová, V.; Annus, J.; Polakovič, M. Inactivation Kinetics of Food Enzymes during Ohmic Heating. Food Chem. 2010, 123, 369–376. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. Optimization of Ohmic Heating Applications for Pectin Methylesterase Inactivation in Orange Juice. J. Food Sci. Technol. 2014, 51, 1826. [Google Scholar] [CrossRef] [PubMed]

- Sakr, M.; Liu, S. A Comprehensive Review on Applications of Ohmic Heating (OH). Renew. Sustain. Energy Rev. 2014, 39, 262–269. [Google Scholar] [CrossRef]

- Cappato, L.P.; Ferreira, M.V.S.; Guimaraes, J.T.; Portela, J.B.; Costa, A.L.R.; Freitas, M.Q.; Cunha, R.L.; Oliveira, C.A.F.; Mercali, G.D.; Marzack, L.D.F.; et al. Ohmic Heating in Dairy Processing: Relevant Aspects for Safety and Quality. Trends Food Sci. Technol. 2017, 62, 104–112. [Google Scholar] [CrossRef]

- Kaur, N.; Singh, A.K. Ohmic Heating: Concept and Applications—A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 2338–2351. [Google Scholar] [CrossRef]

- Cho, H.; Yousef, A.E.; Sastry, A.K. Growth Kinetics of Lactobacillus Acidophilus under Ohmic Heating. Biotechnol. Bioeng. 1996, 49, 334–340. [Google Scholar] [CrossRef]

- Loghavi, L.; Sastry, S.K.; Yousef, A.E. Effect of Moderate Electric Field Frequency and Growth Stage on the Cell Membrane Permeability of Lactobacillus Acidophilus. Biotechnol. Prog. 2009, 25, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Loghavi, L.; Sastry, S.K.; Yousef, A.E. Effect of Moderate Electric Field Frequency on Growth Kinetics and Metabolic Activity of Lactobacillus Acidophilus. Biotechnol. Prog. 2008, 24, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Aurina, K.; Sari, A. Ohmic Heating: A Review and Application in Food Industry. In Proceedings of the 2nd International Conference on Smart and Innovative Agriculture (ICoSIA 2021), Yogyakarta, Indonesia, 3–4 November 2021; Volume 19, pp. 107–113. [Google Scholar] [CrossRef]

- Varghese, K.S.; Pandey, M.C.; Radhakrishna, K.; Bawa, A.S. Technology, Applications and Modelling of Ohmic Heating: A Review. J. Food Sci. Technol. 2014, 51, 2304–2317. [Google Scholar] [CrossRef] [PubMed]

- Fanari, M.; Forteschi, M.; Sanna, M.; Piu, P.P.; Porcu, M.C.; D’hallewin, G.; Secchi, N.; Zinellu, M.; Pretti, L. Pilot Plant Production of Craft Fruit Beer Using Ohmic-Treated Fruit Puree. J. Food Process. Preserv. 2020, 44, e14339. [Google Scholar] [CrossRef]