Alternative Yeast Strains in Beer Production: Impacts on Quality and Nutritional Value

Abstract

1. Introduction

2. Materials and Methods

- Preparation of the applied yeasts

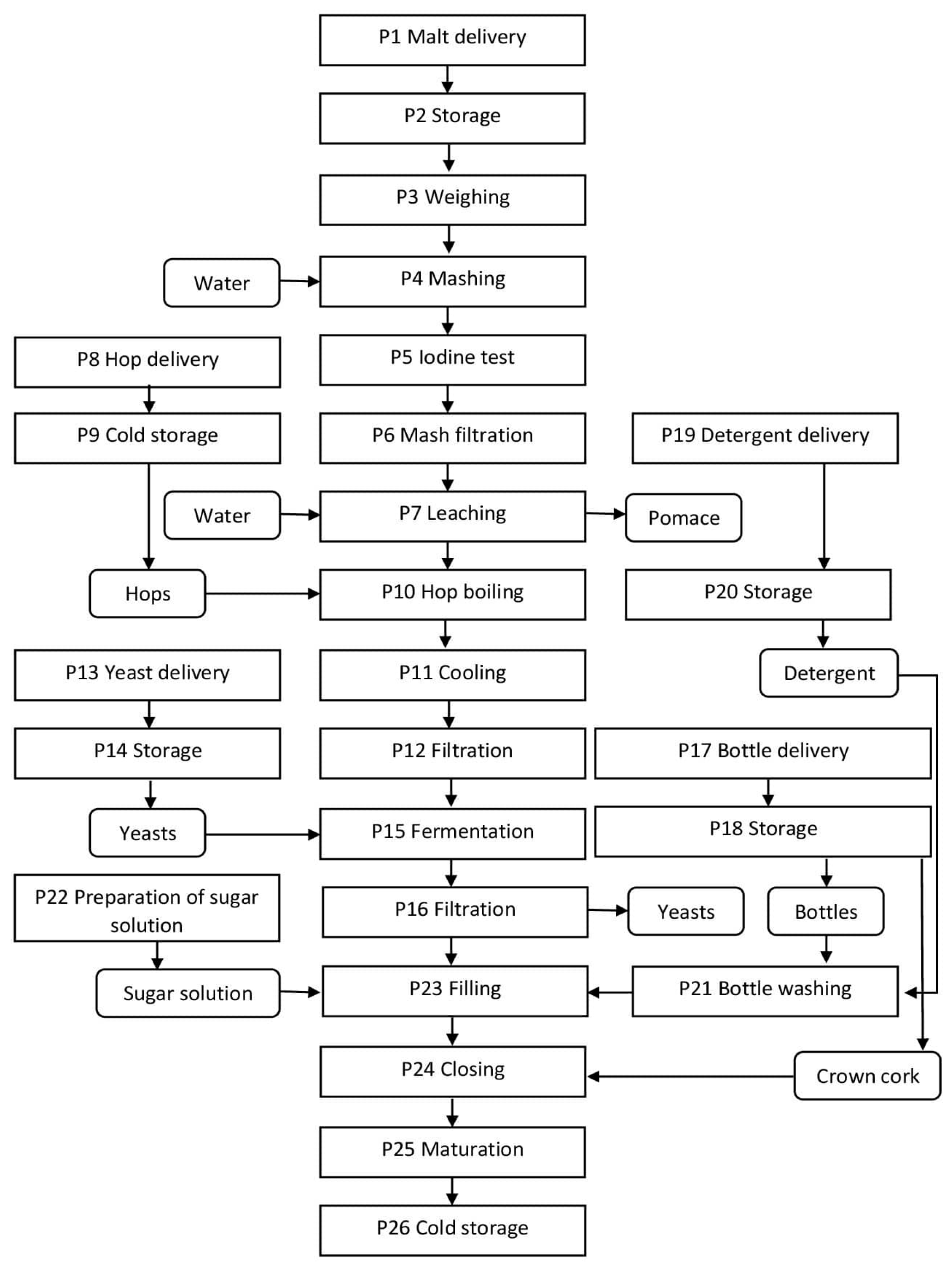

- Brewing

- Analytical methods

- Sample preparation

- Determination of total phenolic content (TPC)

- Determination of flavonoid content

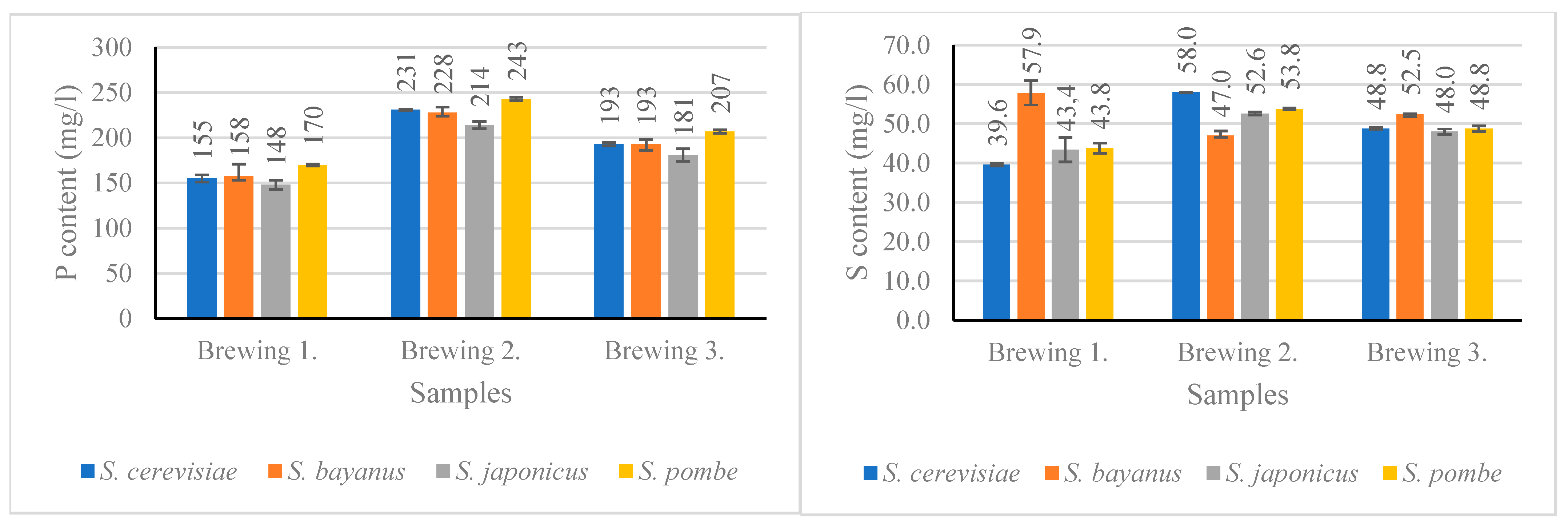

- Determination of element content

- Determination of beer’s colour

- Determination of total acidity

- Determination of bitterness

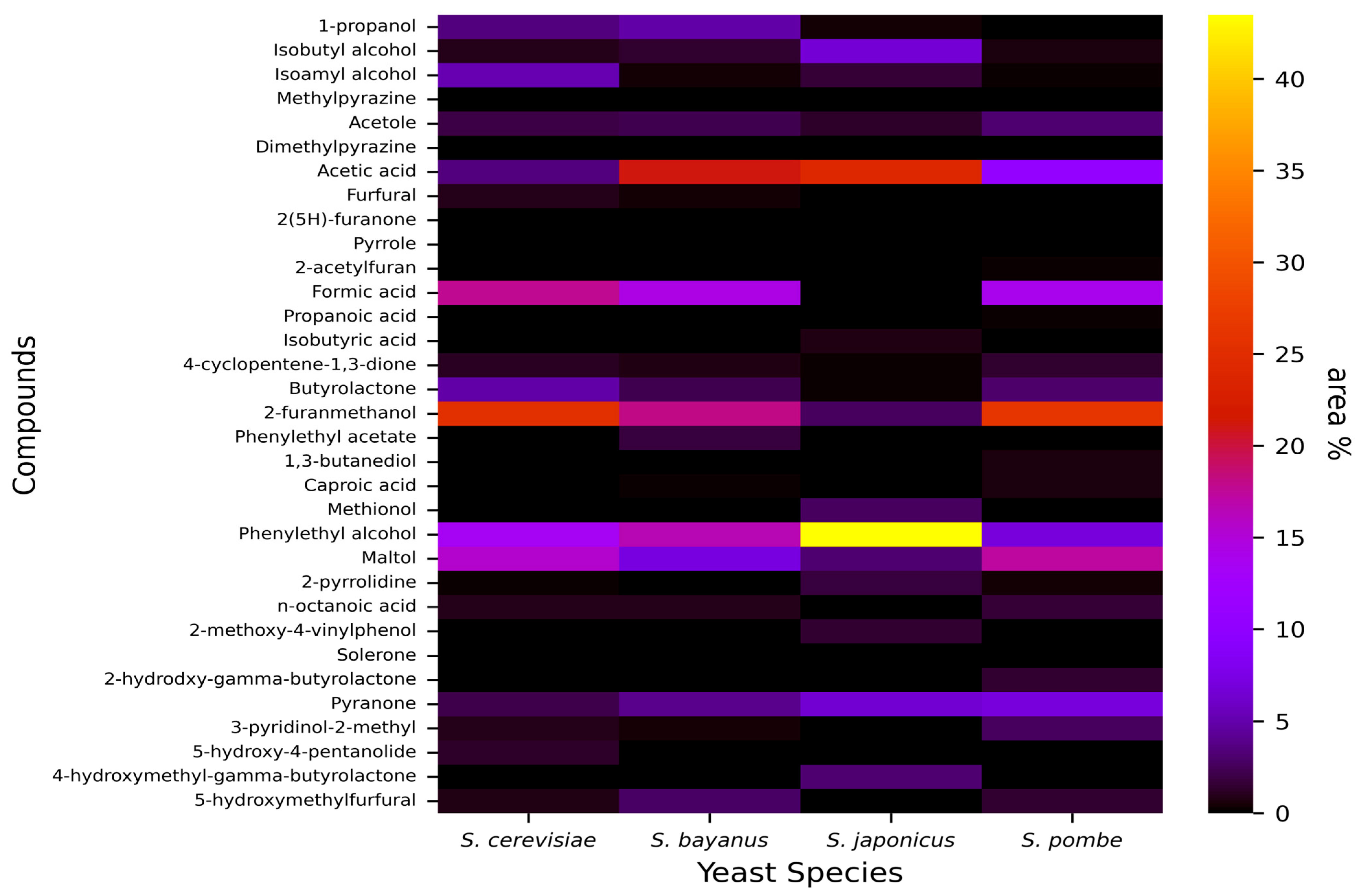

- Analysis of aroma profile

- Sensory Analysis

- Statistical Analysis

3. Results

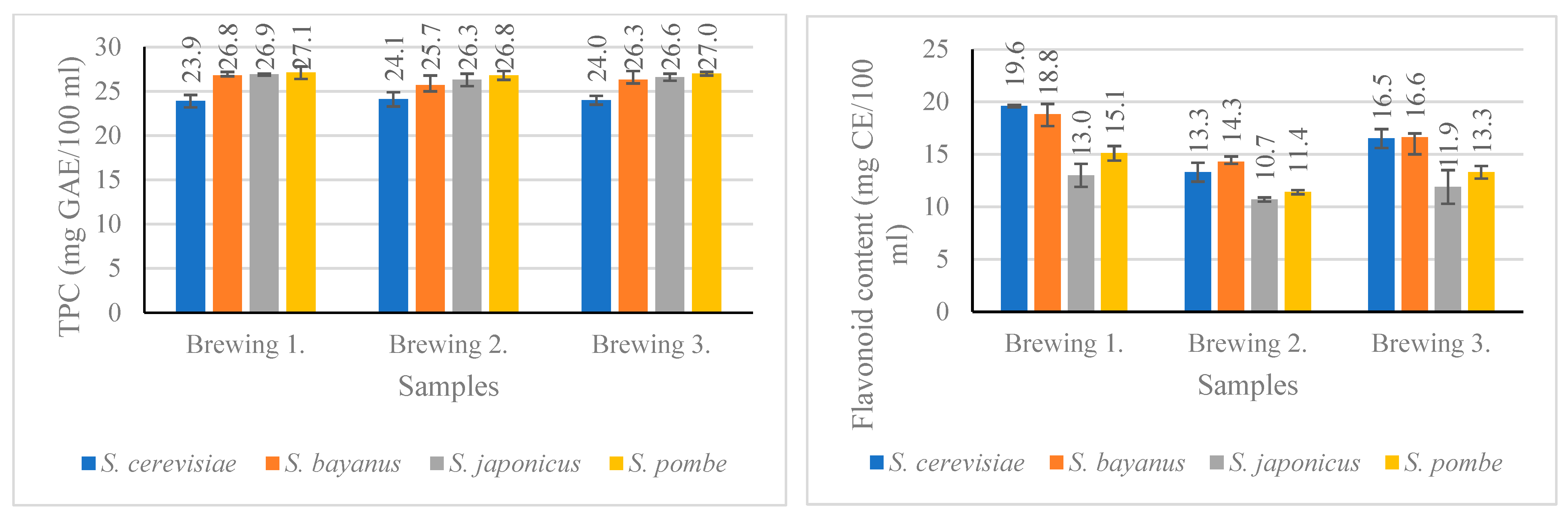

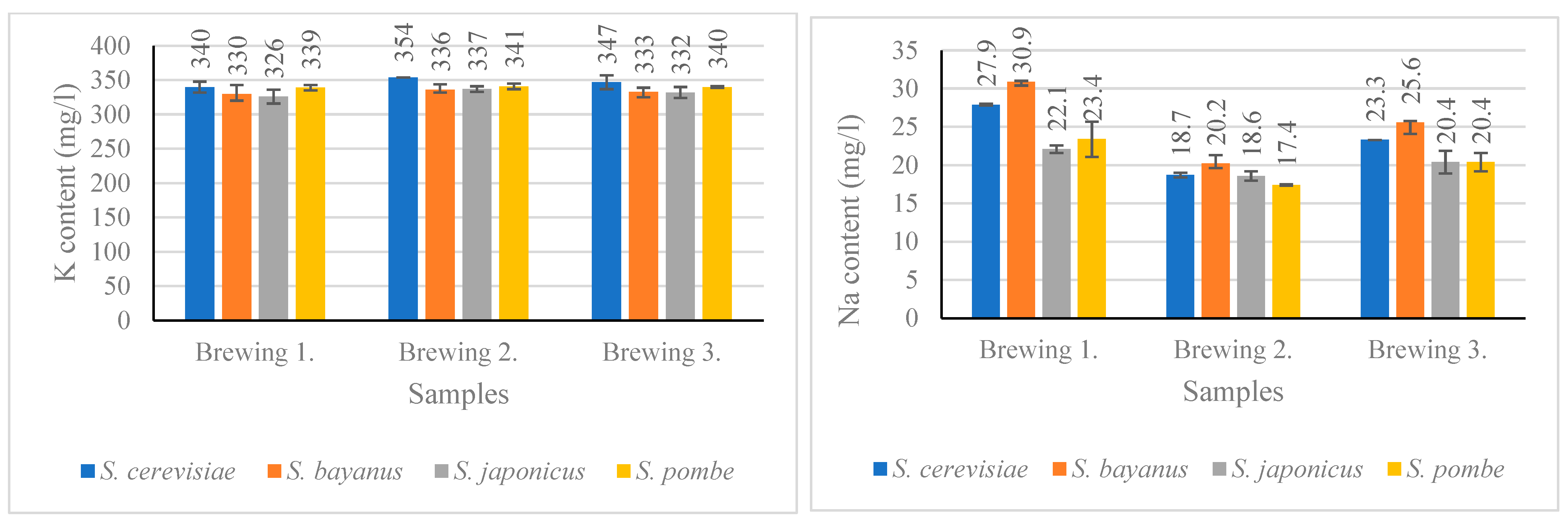

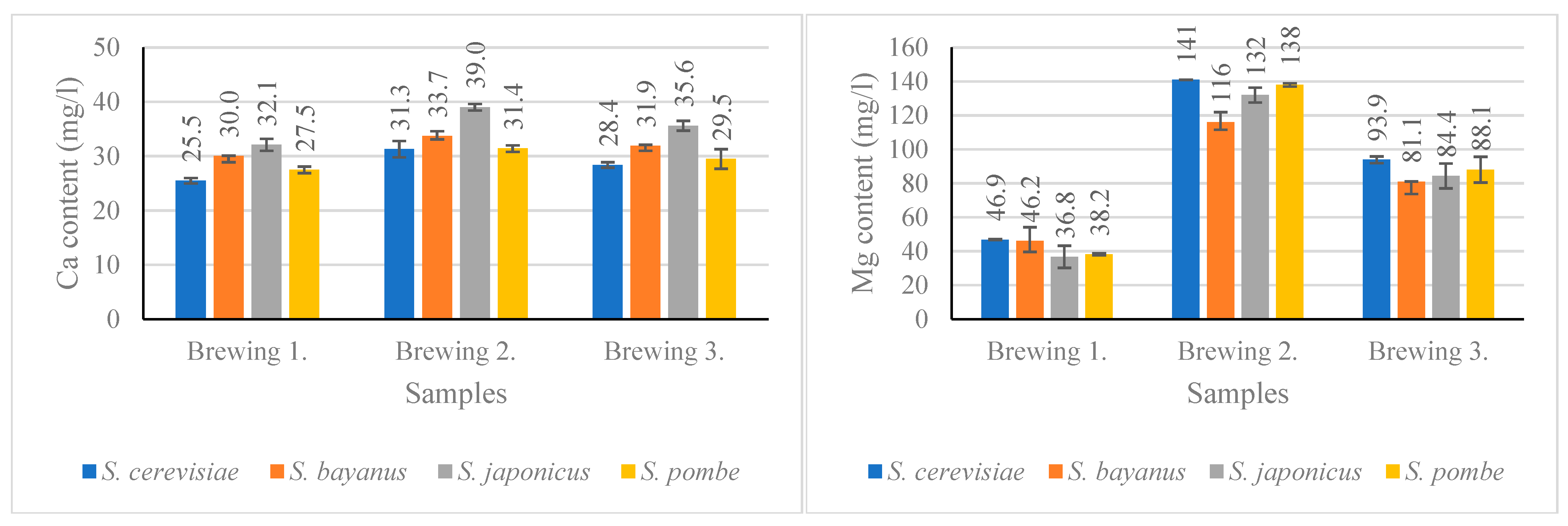

3.1. Nutritional Value

3.2. Beer Quality Parameters

3.3. Organoleptic Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of Variance |

| CE | Catechin Equivalent |

| EBC | European Brewing Convention |

| GAE | Gallic Acid Equivalent |

| GC-MS | Gas Chromatography-Mass Spectrometry |

| IBU | International Bitterness Unit |

| ICP-OES | Inductively Coupled Plasma Optical Emission Spectrometry |

| NIST | National Institute of Science and Technology |

| TPC | Total Phenolic Content |

| YPA | Yeast Peptone Agar |

| YPL | Yeast Peptone Liquid |

References

- Bettenhausen, H.M.; Barr, L.; Broeckling, C.D.; Chaparro, J.M.; Holbrook, C.; Sedin, D.; Heuberger, A.L. Influence of malt source on beer chemistry, flavor, and stability. J. Agric. Food Chem. 2018, 66, 2250–2260. [Google Scholar] [CrossRef]

- Gasior, J.; Kawa-Rygielska, J.; Kucharska, A.Z. Carbohydrates profile, polyphenols content and antioxidative properties of beer wort produced with different dark malts varieties or roasted barley grains. Molecules 2020, 25, 3882. [Google Scholar] [CrossRef]

- Punčochářová, L.; Pořízka, J.; Diviš, P.; Štursa, V. Study of the influence of brewing water on selected analytes in beer. Potr. S. J. F. Sci. 2019, 13, 507–514. [Google Scholar] [CrossRef]

- Steenackers, B.; De Cooman, L.; De Vas, D. Chemical transformations of characteristic hop secondary metabolites in relation to beer properties and the brewing process: A review. Food Chem. 2015, 172, 742–756. [Google Scholar] [CrossRef]

- Narziss, L. Die Bierbrauerei, 8th ed.; Wiley-VCH: Weinheim, Germany, 2012; pp. 1–1702. [Google Scholar]

- Chrisfield, B.J.; Hopfer, H.; Elias, R.J. Impact of copper-based fungicides on the antioxidant quality of ethanolic hop extracts. Food Chem. 2021, 355, 129551. [Google Scholar] [CrossRef] [PubMed]

- Palombi, L.; Tufariello, M.; Durante, M.; Fiore, A.; Baiano, A.; Grieco, F. Assessment of the impact of unmalted cereals, hops, and yeast strains on volatolomic and olfactory profiles of Blanche craft beers: A chemometric approach. Food Chem. 2023, 416, 135783. [Google Scholar] [CrossRef] [PubMed]

- Hellborg, L.; Piškur, J. Yeast diversity in the brewing industry. In Beer in Health and Disease Prevention, 1st ed.; Preedy, V.R., Ed.; Academic Press: Cambridge, UK, 2009; pp. 77–88. [Google Scholar]

- Castro, R.; Díaz, A.B.; Durán-Guerrero, E.; Lasanta, C. Influence of different fermentation conditions on the analytical and sensory properties of craft beers: Hopping, fermentation temperature and yeast strain. J. Food. Compos. Anal. 2022, 106, 104278. [Google Scholar] [CrossRef]

- Legras, J.L.; Merdinoglu, D.; Cornuet, J.; Karst, F. Bread, beer and wine: Saccharomyces cerevisae diversity reflect human history. Mol. Ecol. 2007, 16, 2091–2102. [Google Scholar] [CrossRef] [PubMed]

- Naumov, G.L.; Nguyen, H.V.; Naumova, E.S.; Miche, A.; Aigle, M.; Gaillardin, C. Genetic identification of Saccharomyces bayanus var. uvarum, a cider-fermenting yeast. Int. J. Food Microbiol. 2001, 65, 163–171. [Google Scholar] [CrossRef]

- Le Jeune, C.; Lollier, M.; Demuyter, C.; Erny, C.; Legras, J.L.; Aigle, M.; Masneuf-Pomarede, I. Characterization of natural hybrids of Saccharomyces cerevisieae and Saccharomyces bayanus var. uvarum. FEMS Yeast Res. 2007, 7, 540–549. [Google Scholar] [CrossRef][Green Version]

- Acs-Szabo, L.; Papp, L.A.; Sipiczki, M.; Miklos, I. Genome comparisons of the fission yeasts reveal ancient collinear loci maintained by natural selection. J. Fungus 2021, 7, 864. [Google Scholar] [CrossRef] [PubMed]

- Aoki, K.; Furuya, H.; Niki, H. Schizosaccharomyces japonicus: A distinct dimorphic yeast among the fission yeasts. Cold Spring Harb. Protoc. 2017, 2017, pdb-top082651. [Google Scholar] [CrossRef]

- Choi, J.; Park, S.Y.; Park, M.K.; Kim, Y.S.; Ahn, C.; Kim, Y.J.; Park, C.S. Application of Schizosaccharomyces japonicus in makgeolli fermentation and its brewing characteristics. Food Sci. Biotechnol. 2023, 32, 1383–1393. [Google Scholar] [CrossRef]

- Leali Ferremi, N.; Salvetti, E.; Luzzini, G.; Salini, A.; Slaghenaufi, D.; Fusco, S.; Ugliano, M.; Torriani, S.; Binati, R.L. Differences in the volatile profile of apple cider fermented with Schizosaccharomyces pombe and Schizosaccharomyces japonicus. Fermentation 2024, 10, 128. [Google Scholar] [CrossRef]

- Domizio, P.; Liu, Y.; Bisson, L.F.; Barile, D. Cell wall polysaccharides released during the alcoholic fermentation by Schizosaccharomyces pombe and S. japonicus: Quantification and characterization. Food Microbiol. 2017, 61, 136–149. [Google Scholar] [CrossRef]

- Martínez-Lapuente, L.; Guadalupe, Z.; Ayestarán, B. Properties of wine polysaccharides. In Pectins—Extraction, Purification, Characterization and Applications, 1st ed.; Mauselli, M., Ed.; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Jones-Moore, H.R.; Jelley, R.E.; Marangon, M.; Fedrizzi, B. The polysaccharides of winemaking: From grape to wine. Trends Food Sci. Technol. 2021, 111, 731–740. [Google Scholar] [CrossRef]

- Benito, Á.; Calderón, F.; Benito, S. Combined use of S. pombe and L. thermotolerans in winemaking. Beneficial effects determined through the study of wine’s analytical characteristics. Molecules 2016, 21, 1744. [Google Scholar] [CrossRef]

- Benito, Á.; Calderón, F.; Benito, S. Schizosaccharomyces pombe biotechnological applications in winemaking. Methods Mol. Biol. 2018, 1721, 217–226. [Google Scholar] [CrossRef]

- Loira, I.; Morata, A.; Palomero, F.; González, C.; Suárez-Lepe, J.A. Schizosaccharomyces pombe: A promising biotechnology for modulating wine composition. Fermentation 2018, 4, 70. [Google Scholar] [CrossRef]

- Benito, S.; Palomero, F.; Calderón, F.; Palmero, D.; Suárez-Lepe, J.A. Selection of appropriate Schizosaccharomyces strains for winemaking. Food Microbiol. 2014, 42, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Giga-Hama, Y.; Kumagai, H. Expression system for foreing genes using the fission yeast Schizosaccharomyces pombe. Biotechnol. Appl. Biochem. 1999, 30, 235–244. [Google Scholar] [CrossRef]

- Pownall, B.; Reid, S.J.; Hill, A.E.; Jenkins, D. Schizosaccharomyces pombe in the brewing process: Mixed-Culture fermentation for more complete attenuation of high-gravity wort. Fermentation 2022, 8, 643. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Zhang, Z.; Yang, Z.; Zhou, W.; He, J.; Song, A.; Wu, Y.; Qiu, S.; Han, L. Targeting indigenous Schizosaccharomyces japonicus for genotype exploration and organic acid degradation analysis. Front. Microbiol. 2025, 16, 1569585. [Google Scholar] [CrossRef]

- Qin, X.; Li, F.; Bo, W.; Li, W.; Dong, X. The non-Saccharomyces yeasts as novel starter cultures to innovate beer brewing. CyTA J. Food 2025, 23, 2459819. [Google Scholar] [CrossRef]

- Zapryanova, P.; Gaytanska, Y.; Shopska, V.; Kostov, G. Non-conventional yeasts in beer production—A review. BIO Web Conf. 2025, 170, 01015. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, M. Analysis of total phenols and other oxidation substrates and antioxidants by the means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Kim, D.O.; Jeong, S.W.; Lee, C.J. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 2003, 81, 321–326. [Google Scholar] [CrossRef]

- Kovács, B.; Győri, Z.; Csapó, J.; Loch, J.; Dániel, P. A study of plant sample preparation and inductively coupled plasma mass spectrometry parameters. Commun. Soil Sci. Plant Anal. 1996, 27, 1177–1198. [Google Scholar] [CrossRef]

- AOAC. Color of beer. Spectrophotometric method (Standard Reference Color Method). In AOAC Official Method 976.08; AOAC: Rockville, MD, USA, 1976. [Google Scholar]

- AOAC. Acidity (total) of beer. Indicator titration method. In AOAC Official Method 950.07; AOAC: Rockville, MD, USA, 1995. [Google Scholar]

- AOAC. Bitterness of beer. Iso-alpha acid method. In AOAC Official Method 965.21; AOAC: Rockville, MD, USA, 1995. [Google Scholar]

- Rakonczás, N.; Juhászné Tóth, R.; Soós, Á.; Kállai, Z.; Kovács, B.; Holb, I.; Kovács, S. Could bentonite product choice fit the desired wine style? Mitt. Klosterneuburg. 2020, 70, 87–101. [Google Scholar]

- Yao, J.; Ma, Z.; Wang, Y.; Sun, L.; Liu, X. Effects of dandelion addition on antioxidant property, sensory characteristics and inhibitory activity against xanthine oxidase of beer. Curr. Res. Food Sci. 2022, 5, 927–939. [Google Scholar] [CrossRef]

- Nardini, M.; Garaguso, I. Characterization of bioactive compounds and antioxidant activity of fruit beers. Food Chem. 2020, 305, 125437. [Google Scholar] [CrossRef] [PubMed]

- Gama, E.M.; Nascentes, C.C.; Matos, R.P.; Rodrigues, G.C.; Rodrigues, G.D. A simple method for the multi-elemental analysis of beer using total reflection X-ray fluorescence. Talanta 2017, 174, 274–278. [Google Scholar] [CrossRef] [PubMed]

- Pires, L.N.; Dias, F.S.; Teixeira, L.S.G. Assessing the internal standardization of the direct multi-element determination in beer samples through microwave-induced plasma optical emission spectrometry. Anal. Chim. Acta. 2019, 1090, 31–38. [Google Scholar] [CrossRef]

- Codex Alimentarius Hungaricus. 2-702 sz. irányelv. Sör. Magyar Élelmiszerkönyv Bizottság. 2013. Available online: https://elelmiszerlanc.kormany.hu/download/d/4b/a2000/2-702.pdf (accessed on 23 July 2025).

- Vermote, L.; Roos, J.; Cnockaert, M.; Vandamme, P.; Weckx, S.; Vuyst, L. New insights into the role of key microorganisms and wooden barrels during lambic beer fermentation and maturation. J. Food Microbiol. 2023, 394, 110163. [Google Scholar] [CrossRef] [PubMed]

- Montanari, L.; Mayer, H.; Marconi, O.; Fantozzi, P. Minerals in beer. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: Cambridge, MA, USA, 2009; pp. 359–365. [Google Scholar]

| Registration Number | Strain | Origin |

|---|---|---|

| 10-1676 | Saccharomyces cerevisiae | Fermentis SafAle “T-58” |

| 10-1688 | Saccharomyces bayanus | Mangrove Jack’s M02 |

| 7-286 | Schizosaccharomyces japonicus | CCY 44-5-1 |

| 9-1 | Schizosaccharomyces pombe var. malidevorans | CCY 44-6-1 |

| Evaluation Form | ||||

|---|---|---|---|---|

| Gender (underline) | ||||

| Female | Male | |||

| Age (underline) | ||||

| 18–25 years | 26–35 years | 36–45 years | 46–55 years | 56–65 years |

| Sensory evaluation of the samples | ||||

| Evaluation of colour-1: dislike extremely; 5: like extremely | ||||

| 1 | 2 | 3 | 4 | 5 |

| Evaluation of foam-1: dislike extremely; 5: like extremely | ||||

| 1 | 2 | 3 | 4 | 5 |

| Evaluation of aroma-1: dislike extremely; 5: like extremely | ||||

| 1 | 2 | 3 | 4 | 5 |

| Evaluation of flavour-1: dislike extremely; 5: like extremely | ||||

| 1 | 2 | 3 | 4 | 5 |

| Characteristics that come to mind after tasting the sample (please underline at least 3 of these) | ||||

| refreshing | bread flavour (yeast) | citrus aroma | cheesy | |

| hazy | fruity | clear | honey | |

| foot smell | bitter | sweet | sour | |

| acidic | light | corn | musty | |

| grass taste | metal flavour | alcoholic | buttery | |

| caramel aroma | spicy | medicinal | sulphurous | |

| Sample | Quality Parameter | ||

|---|---|---|---|

| Colour (EBC) | Total Acidity (%Lactic Acid) | Bitterness (IBU) | |

| S. cerevisiae | 14.0 ± 0.5 ab | 0.0503 ± 0.0003 a | 84.8 ± 1.0 a |

| S. bayanus | 17.1 ± 0.3 c | 0.0606 ± 0.0041 b | 84.7 ± 0.9 a |

| S. japonicus | 12.6 ± 0.7 a | 0.0670 ± 0.0041 b | 81.9 ± 2.3 a |

| S. pombe | 14.7 ± 0.7 b | 0.0627 ± 0.0041 b | 84.3 ± 1.5 a |

| Compound | Effect | Presence | |||

|---|---|---|---|---|---|

| S. cerevisiae | S. bayanus | S. japonicus | S. pombe | ||

| 1-propanol | Mild, alcoholic | + | + | + | |

| Isobutyl alcohol | Sweet, musty | + | + | + | + |

| Isoamyl alcohol | Balmy, alcoholic | + | + | + | + |

| Methylpyrazine | Roasted, peanut | + | |||

| Acetole | Sweet, caramel | + | + | + | + |

| Dimethylpyrazine | Roasted, peanut | + | + | + | + |

| Acetic acid | Sour | + | + | + | + |

| Furfural | Rancid, dry | + | + | ||

| 2(5H)-furanone | Curry, walnut, sweet | + | |||

| Pyrrole | Sweet, peanut | + | + | + | |

| 2-acetylfuran | Smoky, caramel | + | |||

| Formic acid | Strong, acidic | + | + | + | |

| Propanoic acid | Hot, unpleasant | + | |||

| Isobutyric acid | Sour | + | + | + | |

| 4-cyclopentene-1,3-dione | Bitter, smoky | + | + | + | + |

| Butyrolactone | Bitter | + | + | + | + |

| 2-furanmethanol | Roasted, smoky | + | + | + | + |

| Phenylethyl acetate | Rose, honey | + | |||

| 1,3-butanediol | Fruity | + | |||

| Caproic acid | Fatty, cheesy | + | + | ||

| Methionol | Cauliflower | + | |||

| Phenylethyl alcohol | Floral, rose | + | + | + | + |

| Maltol | Sweet, caramel | + | + | + | + |

| 2-pyrrolidine | Tart, sour | + | + | + | |

| n-octanoic acid | Rancid | + | + | + | |

| 2-methoxy-4-vinylphenol | Clove | + | |||

| Solerone | Caramel, roasted | + | |||

| 2-hydrodxy-gamma-butyrolactone | Mildly sweet | + | |||

| Pyranone | Caramel, roasted | + | + | + | + |

| 3-pyridinol-2-methyl | Tarty | + | + | + | |

| 5-hydroxy-4-pentanolide | Caramel, sweet | + | |||

| 4-hydroxymethyl-gamma-butyrolactone | Mildly buttery | + | |||

| 5-hydroxymethylfurfural | Sweet | + | + | + | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alexa, L.; Csoma, H.; Ungai, D.; Kovács, B.; Czipa, N.; Miklós, I.; Kállai, Z.; Papp, L.A.; Takács, S. Alternative Yeast Strains in Beer Production: Impacts on Quality and Nutritional Value. Beverages 2025, 11, 142. https://doi.org/10.3390/beverages11050142

Alexa L, Csoma H, Ungai D, Kovács B, Czipa N, Miklós I, Kállai Z, Papp LA, Takács S. Alternative Yeast Strains in Beer Production: Impacts on Quality and Nutritional Value. Beverages. 2025; 11(5):142. https://doi.org/10.3390/beverages11050142

Chicago/Turabian StyleAlexa, Loránd, Hajnalka Csoma, Diána Ungai, Béla Kovács, Nikolett Czipa, Ida Miklós, Zoltán Kállai, László Attila Papp, and Szonja Takács. 2025. "Alternative Yeast Strains in Beer Production: Impacts on Quality and Nutritional Value" Beverages 11, no. 5: 142. https://doi.org/10.3390/beverages11050142

APA StyleAlexa, L., Csoma, H., Ungai, D., Kovács, B., Czipa, N., Miklós, I., Kállai, Z., Papp, L. A., & Takács, S. (2025). Alternative Yeast Strains in Beer Production: Impacts on Quality and Nutritional Value. Beverages, 11(5), 142. https://doi.org/10.3390/beverages11050142