Heat Integration of a Boiler and Its Corresponding Environmental Study in an Oleochemical Production Plant: An Industry Case Study in Malaysia

Abstract

:1. Introduction

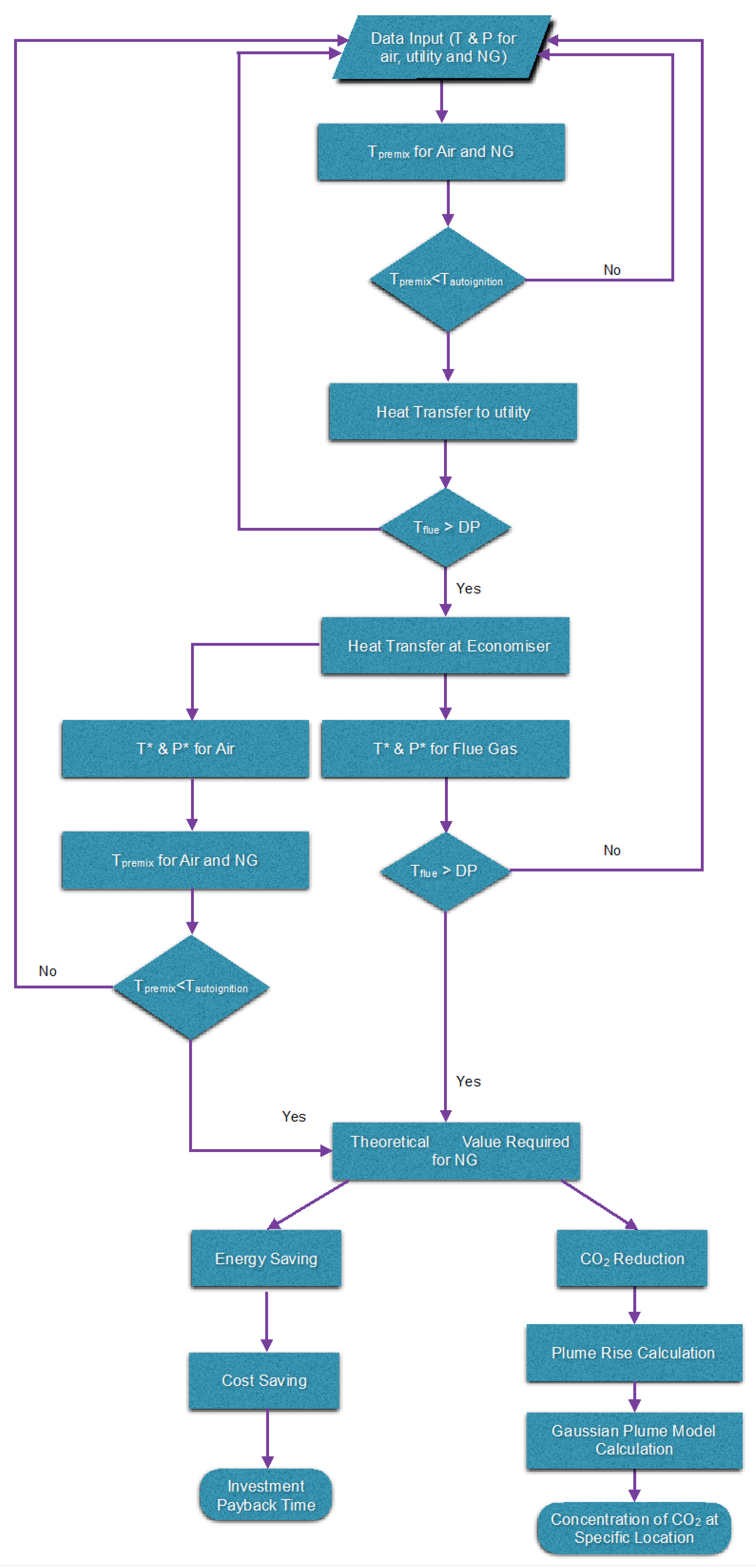

2. Materials and Methods

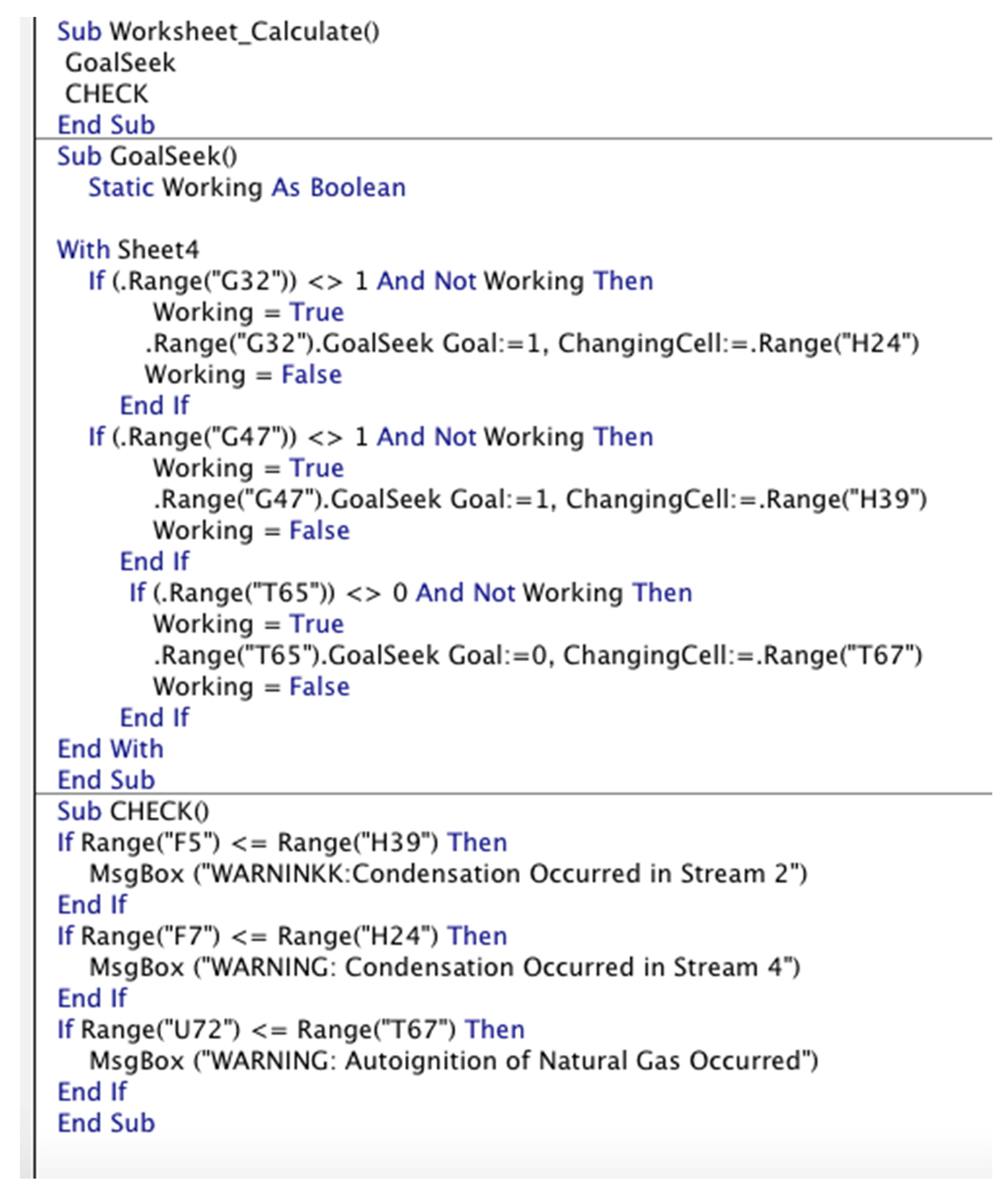

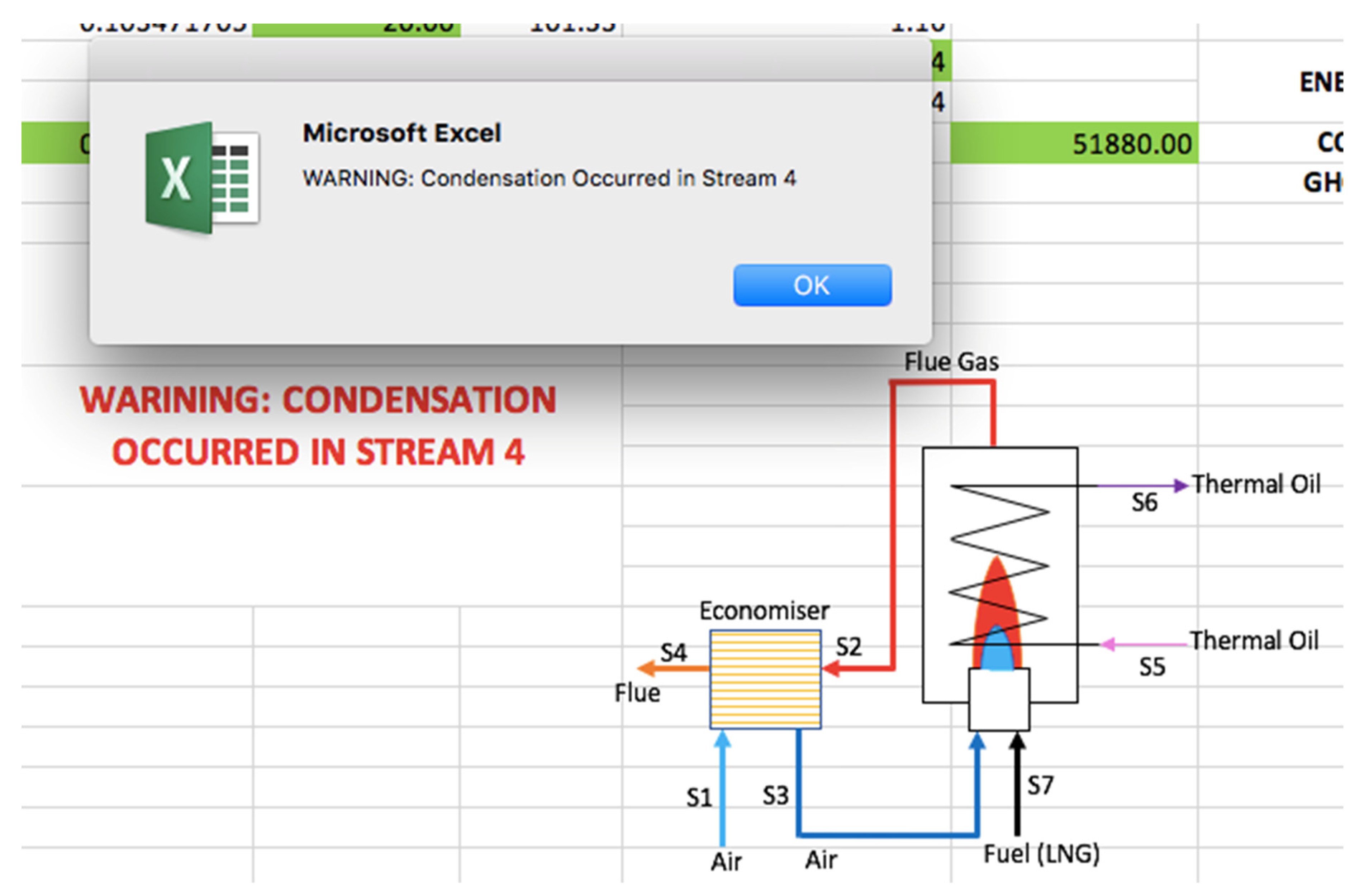

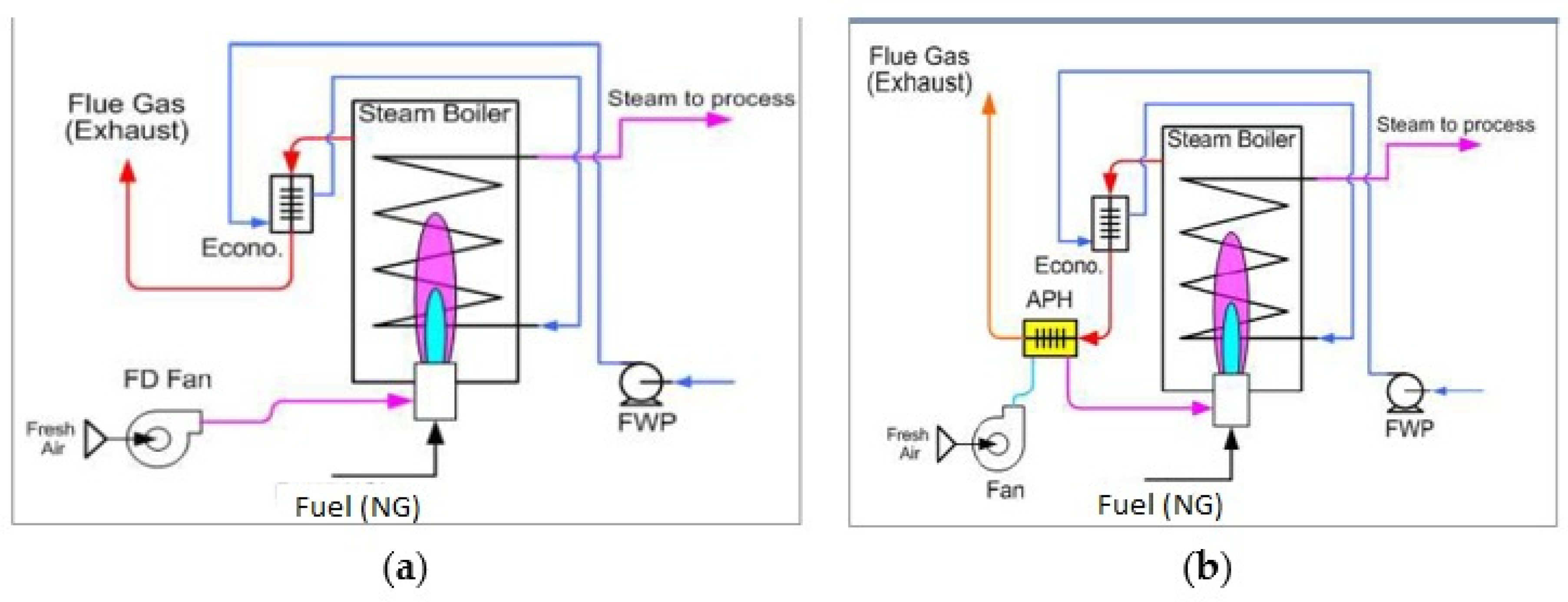

2.1. Boiler System Heat Integration

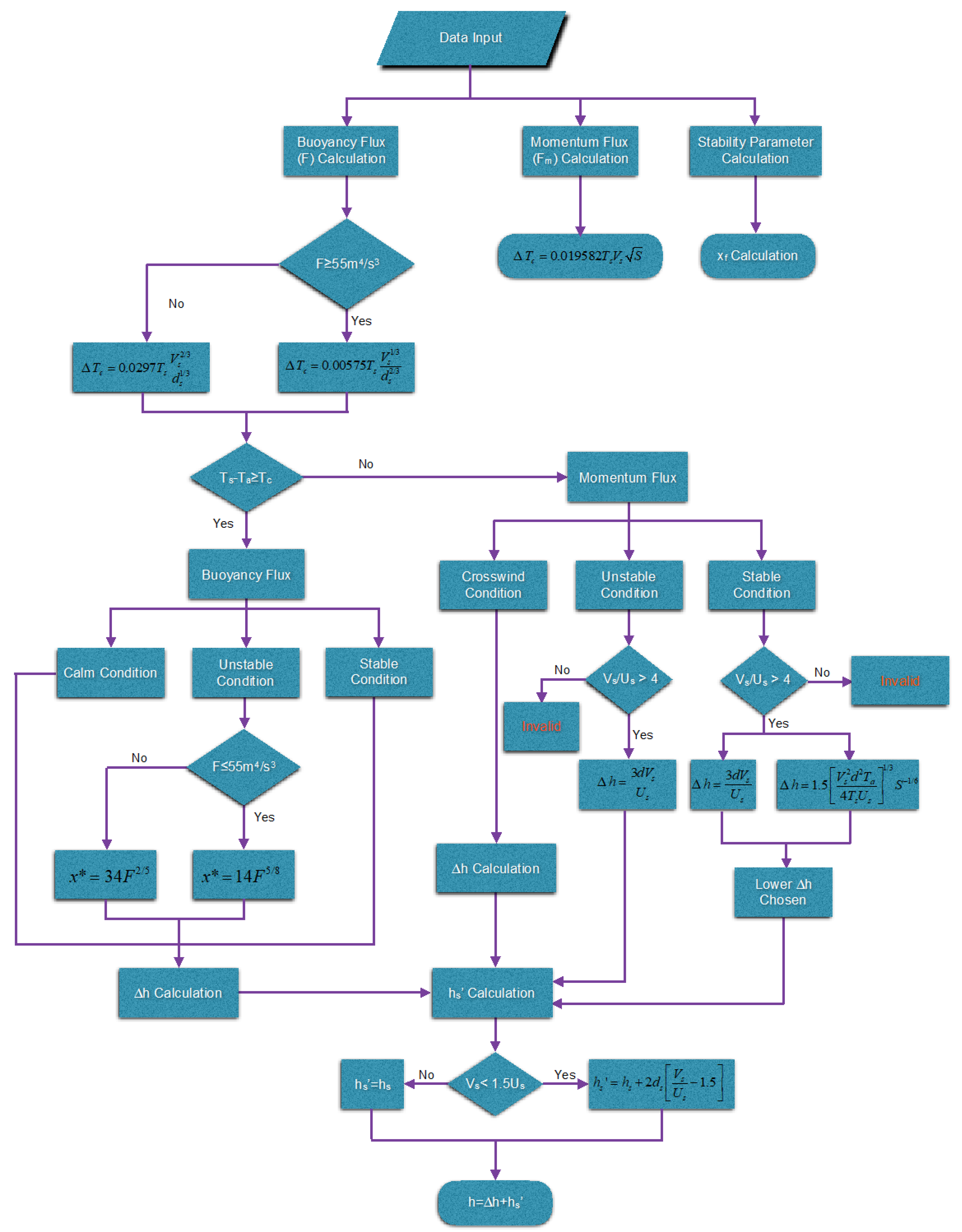

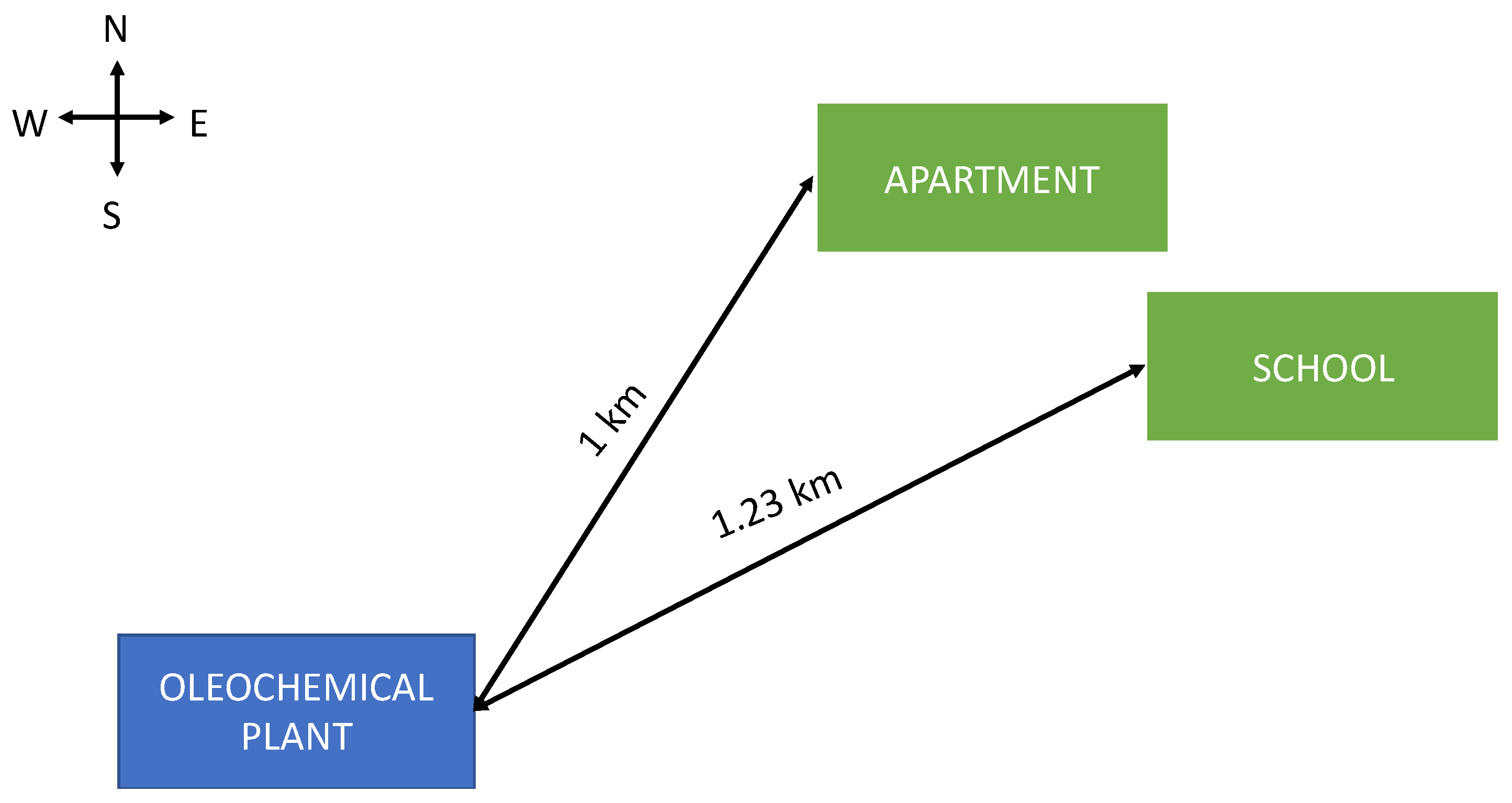

2.2. Gausian Plume Model

- Q = emission rate of carbon dioxide gas from boiler

- u = the direction x, defined by the wind speed

- y = the direction of the wind of which is perpendicular to horizontal distance

- z = vertical direction

- h = effective height of plume

- σy and σz = dispersion coefficients with respect to the directions in y and z

3. Results and Discussion

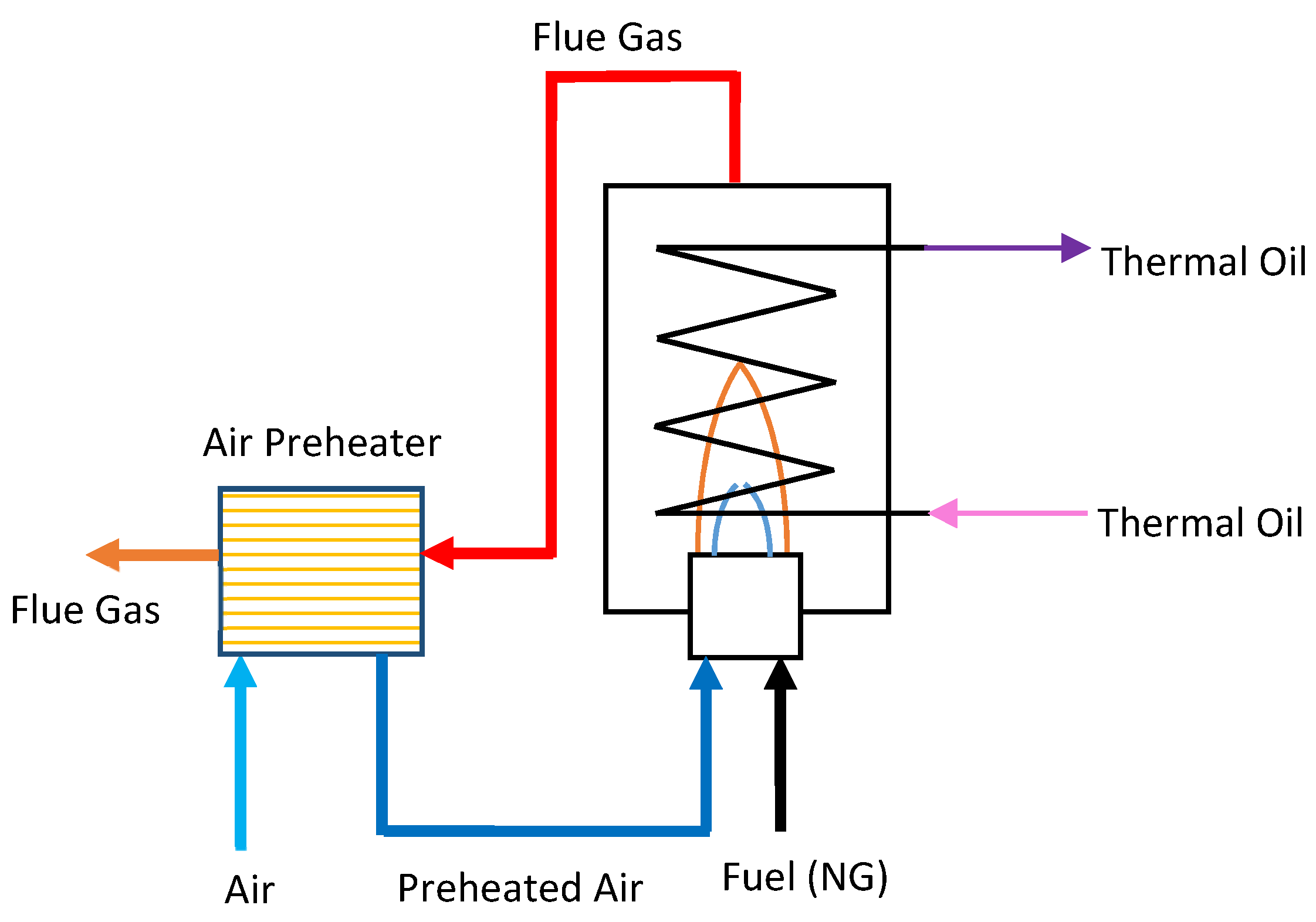

3.1. A Case Study on Thermal Oil Boiler (B01)

3.1.1. Waste Heat Recovery

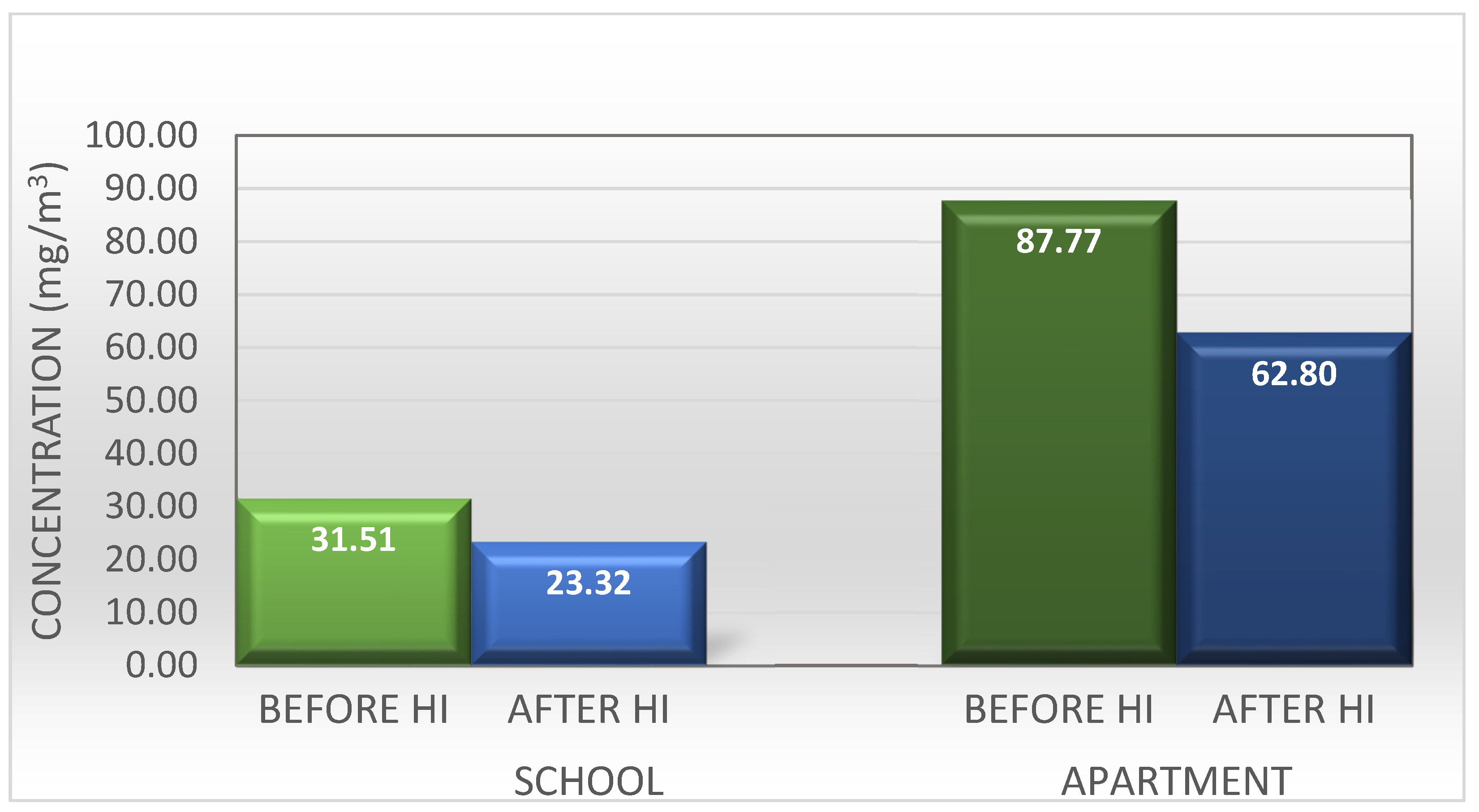

3.1.2. Gaussian Plume Model

3.2. Feasibility Study on Thermal Oil Boiler (B01)

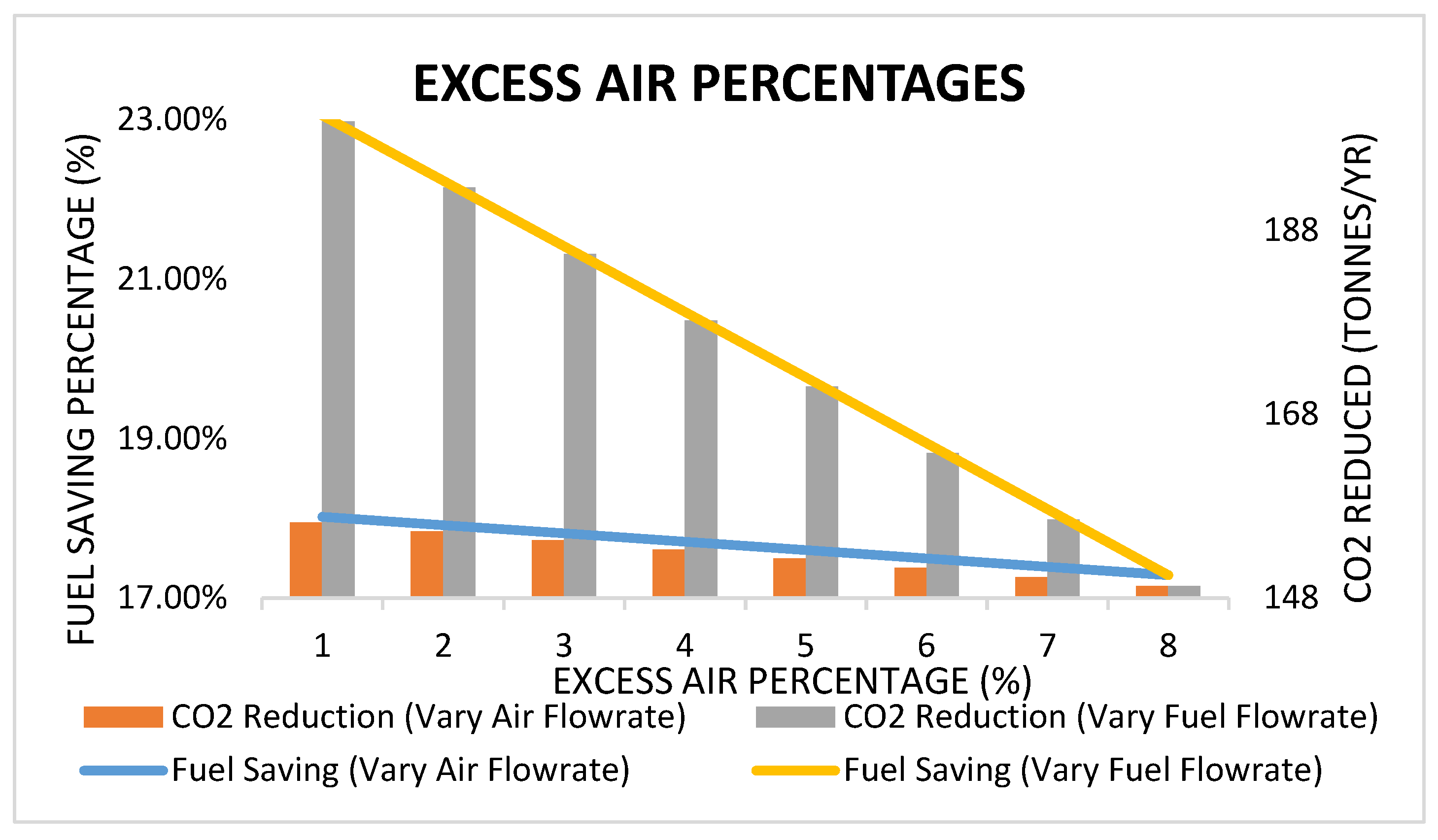

3.2.1. Excess Air Percentages

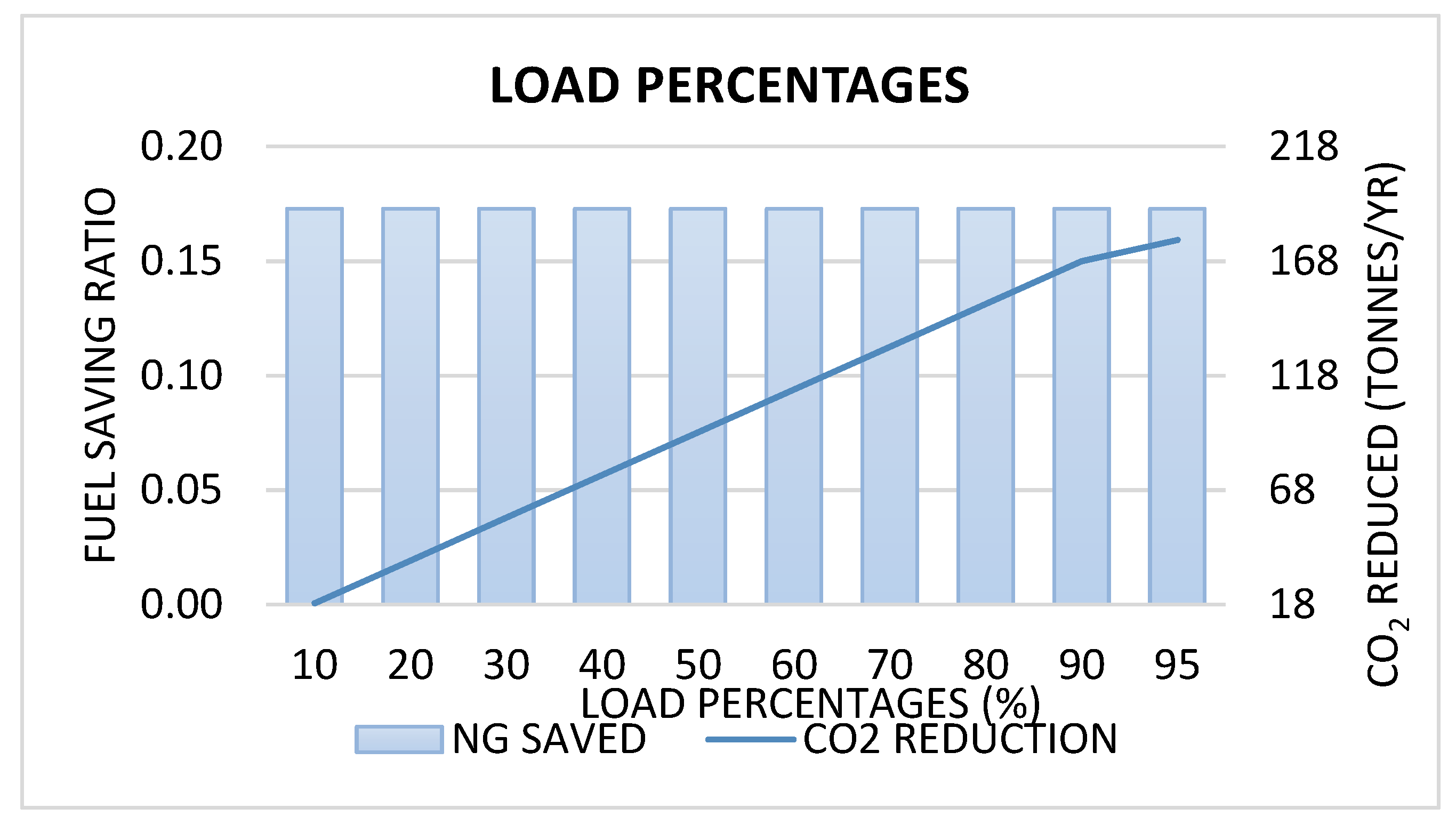

3.2.2. Boiler Load Percentage

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| APH | Air Preheater |

| CO2 | Carbon Dioxide Gas |

| CTST | Conventional Total Site Targeting |

| DOE | Department of Environment Malaysia |

| DP | Dew Point |

| EPA | United States Environmental Protection Agency |

| HI | Heat Integration |

| LNG | Liquefied Natural Gas |

| NG | Natural Gas Fuel |

| P | Pressure |

| P * | Newly Conditioned Flue Gas Pressure |

| PBT | Payback Period |

| ROR | Rate of Return |

| T | Temperature |

| T * | Newly Conditioned Flue Gas Temperature |

| Tpremix | Premix Temperature |

| TSHI | Total Site Heat Integration |

| UTST | Unified Total Site Targeting |

Appendix A

| FUEL TYPE | POLLUTANT | CAPACITY | LIMIT VALUE | MONITORING |

|---|---|---|---|---|

| Solid and Liquid Fuels | Sum of SO2 and SO3, expressed of SO2 | >10 MWe | 500 mg/m3 | Continuous * |

| Sum of NO2 and NO3, expressed of NO2 | >10 MWe | 500 mg/m3 | Continuous * | |

| Hydrogen Chloride (HCl) | 10< C <100 MWe | 200 mg/m3 | Periodic | |

| Hydrogen Chloride (HCl) | ≥100 MWe | 100 mg/m3 | Periodic | |

| Hydrogen Fluoride (HF) | 10< C <100 MWe | 30 mg/m3 | Periodic | |

| Hydrogen Fluoride (HF) | ≥100 MWe | 15 mg/m3 | Periodic | |

| Carbon Monoxide (CO) | >10 MWe | 200 mg/m3 | Continuous * | |

| Total PM | >10 MWe | 50 mg/m3 | Continuous * | |

| Mercury (Hg) | >10 MWe | 0.03 mg/m3 | Periodic | |

| PCDD/PCDF | >10 MWe | 0.1 ng TEQ/m3 | Periodic | |

| Gaseous Fuels | Sum of NO2 and NO3, expressed of NO2 | >10 MWe | 350 mg/m3 | Continuous * |

| Carbon Monoxide (CO) | >10 MWe | 50 mg/m3 | Continuous * | |

| Total PM | >10 MWe | 5 mg/m3 | Periodic |

| POLLUTION | EMISSION SOURCES | STANDARDS |

|---|---|---|

| 1. Dark Smoke | 1.1. Solid Fuel Equipment to Facilities | Ringlemann Chart No.2 |

| 1.2. Equipment Using Other Types of Fuel | Ringlemann Chart No.1 | |

| 2. Dust | 2.1. Facilities Used for the Heating of Metal Other Thank Cold Blast Foundry Cupola | 0.2 gm/Nm3 |

| 2.2. Facilities Discharging Dust Containing Asbestos and Free Silica | 0.12 gm/Nm3 | |

| 2.3. Portland Cement Manufacturing: | ||

| 2.3.1. Kiln | 0.2 gm/Nm3 | |

| 2.3.2. Clinker, Cooler, Grinder, Others | 0.1 gm/Nm3 | |

| 2.4. Asphalt Concrete/Bituminous Mixing Plant: | ||

| 2.4.1. Stationary Plant | 0.3 gm/Nm3 | |

| 2.4.2. Mobile Plant | 0.4 gm/Nm3 | |

| 2.5. Other Sources | 0.4 gm/Nm3 | |

| 3. Metal and Metallic Compound | ||

| 3.1. Mercury | Industry | 0.01 gm/Nm3 |

| 3.2. Cadmium | Industry | 0.015 gm/Nm3 |

| 3.3. Lead | Industry | 0.025 gm/Nm3 |

| 3.4. Antimony | Industry | 0.025 gm/Nm3 |

| 3.5. Arsenic | Industry | 0.025 gm/Nm3 |

| 3.6. Zinc | Industry | 0.1 gm/Nm3 |

| 3.7. Copper | Industry | 0.1 gm/Nm3 |

| 4. Gases | ||

| 4.1. Acid Gases | Sulphuric Acid Manufacturing | 3.5 gm of SO3/Nm3 and No Persistent Mist |

| 4.2. Sulphuric Acid Mist or SO3 | Any Sources Other Than 4.1. | 0.2 gm of SO3/Nm3 and No Persistent Mist |

| 4.3. Chlorine Gas | Any Source | 0.2 gm of HCl/Nm3 |

| 4.4. HCl | Any Source | 0.2 gm of HCl/Nm3 |

| 4.5. Fluorine, Hydrofluoric Acid, Inorganic Compound | Aluminium Manufacturing from Alumina | 0.2 gm of Hydrofluoric Acid/Nm3 |

| 4.6. - do - | Any Sources Other Than 4.5. | 0.1 gm of Hydrofluoric Acid/Nm3 |

| 4.7. Hydrogen Sulphide | Any Source | 5 ppm (Vol%) |

| 4.8. NOX | Acid Nitric Manufacturing | 1.7 gm of SO3/Nm3 and Substantially Colourless |

| 4.9. SOX | Any Sources Other Than 4.8. | 2.0 gm SO3/Nm3 |

References

- Yang, S.T. Bioprocessing—From Biotechnology to Biorefinery. In New Technologies and Applications; Elsevier: Dublin, OH, USA, 2007; pp. 1–24. [Google Scholar]

- European Oleochemcials & Allied Products Group, Challenges and Potential of Biomass & Biofuels for the European Oleochemical Industry. 1 June 2006. Available online: http://www.europarl.europa.eu/hearings/20060601/itre/decooman_en.pdf (accessed on 22 September 2018).

- Malaysia Palm Oil Council (MPOC). “Palm Oil”. 2006. Available online: http://www.mpoc.org.my/Palm_Oil.aspx (accessed on 22 September 2018).

- Malaysia Palm Oil Council (MPOC). Malaysian Palm Oil Industry. 7 April 2014. Available online: http://www.mpoc.org.my/Malaysian_Palm_Oil_Industry.aspx (accessed on 22 September 2018).

- Hazimah, A.H. Palm Oil: Going Beyong Basic Oleochemicals. 12 April 2012. Available online: http://www.mpoc.org.my/upload/DrHazimah_POTS_PHP.pdf (accessed on 22 September 2018).

- Research, G.V. Oleochemicals Market Analysis and Segment Forecasts to 2020; Grand View Research: San Francisco, CA, USA, 2019. [Google Scholar]

- Tenaga, S. National Energy Balance 2016; Suruhanjaya Tenaga: Putrajaya, Malaysia, 2018. [Google Scholar]

- Tenaga, S. Final Energy Demand; Malaysia Energy Information Hub: Putrajaya, Malaysia, 2019. [Google Scholar]

- Info, W.D. Energy Consumption in Malaysia, World Data Info. Available online: https://www.worlddata.info/asia/malaysia/energy-consumption.php (accessed on 22 September 2018).

- Linnhoff, B.; Flower, J.R. Synthesis of heat exchanger networks: I. Systematic generation of energy optimal networks. AiChe J. 1978, 24, 633–642. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Kravanja, Z. Forty years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP). Curr. Opin. Chem. Eng. 2013, 2, 461–474. [Google Scholar] [CrossRef]

- Klemeš, J.; Friedler, F.; Bulatov, I.; Varbanov, P. Sustainability in the Process Industry—Integration and Optimization; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Dhole, V.R.; Linnhoff, B. Total site targets for fuel, co-generation, emissions, and cooling Author links open overlay panel. Comput. Chem. Eng. 1993, 17, 101–109. [Google Scholar] [CrossRef]

- Tarighaleslami, A.H.; Walmsley, T.G.; Atkins, M.J.; Walmsley, M.R.; Neale, J.R. A Comparison of Utility Heat Exchanger Network Synthesis for Total Site Heat Integration Methods. Chem. Eng. Trans. 2017, 61, 775–780. [Google Scholar]

- Marto, S.; Svensson, E.; Harvey, S. Investigating Operability Issues of Heat Integration for Implementation in the Oil re Ning Industry; ECEEE Industry Proceedings: Stockholm, Sweden, 2016. [Google Scholar]

- Liew, P.Y.; Theo, W.L.; Alwi, S.R.W.; Lim, J.S.; Manan, Z.A.; Klemeš, J.J.; Varbanov, P.S. Total Site Heat Integration planning and design for industrial, urban and renewable systems. Renew. Sustain. Energy Rev. 2017, 68, 964–985. [Google Scholar] [CrossRef]

- Sang, L.K.; Kee, C.K. Air Quality Impact Analysis; Malaysia Meteorological Service & University of Malaya: Kuala Lumpur, Malaya, 1985. [Google Scholar]

- Indra, E.; Sinha, N.; Ghose, M.K.; Singh, G.; Srivastava, S.; Sinha, I. Classification of air pollution dispersion MODELS: A critical review. In Proceedings of the National Seminar on Environmental Engineering with Special Emphasis on Mining Environment, Shibpur, India, 19–20 March 2004; pp. 19–20. [Google Scholar]

- Lutman, E.R.; Jones, S.R.; Hill, R.A.; McDonald, P.; Lambers, B. Comparison between the predictions of a Gaussian plume model and a Lagrangian particle dispersion model for annual average calculations of long-range dispersion of radionuclides. J. Environ. Radioact. 2004, 75, 339–355. [Google Scholar] [CrossRef]

- Abdel-rahman, A.A. On the atmospheric dispersion and gaussian plume model. In Proceedings of the 2nd International Conference on Waste Management, Water Pollution, Air Pollution, Indoor Climate, Corfu, Greece, 26 October 2008. [Google Scholar]

- Taylor, G. Diffusion by Continuous Movements. Proc. Lond. Math. Soc. 1922, 2, 196–212. [Google Scholar] [CrossRef]

- Lents, J.; Walsh, M.; He, K.; Davis, N.; Osses, M.; Tolvett, S.; Liu, H. Air Quality Modelling. Available online: http://www.aqbook.org/read/?page=254 (accessed on 8 November 2018).

- Sutton, O.G. The problem of diffusion in the lower atmosphere. Q. J. R. Meteorol. Soc. 1947, 73, 257–281. [Google Scholar] [CrossRef]

- Sutton, O.G. The Theoretical Distribution of Airborne Pollution from Factory Chimneys. Q. J. R. Meteorol. Soc. 1947, 73, 426–436. [Google Scholar] [CrossRef]

- Lagzi, I.; Mészáros, R.; Gelybó, G.; Leelőssy, Á. Gaussian Dispersion Models; Eötvös Loránd University, Consortium: Budapest, Hungary, 2013. [Google Scholar]

- Brusca, S.; Farnoso, F.; Lanzafame, R.; Mauro, S.; Farrano, A.M.C.; Monforte, P. Theoretical and experimental study of Gaussian Plume model in small scale system. In Proceedings of the 71st Conference of the Italian Thermal Machines Engineering Association, ATI2016, Turin, Italy, 14–16 September 2016. [Google Scholar]

- Khaniabadi, Y.O.; Sicard, P.; Taiwo, A.M.; Marco, A.D.; Esmaeili, S.; Rashidi, R. Modeling of particulate matter dispersion from a cement plant: Upwind- downwind case study. J. Environ. Chem. Eng. 2018, 6, 3104–3110. [Google Scholar] [CrossRef]

- DoItYourself, 5 Common Chimney Flue Problems to Avoid, DoItYourself. Available online: https://www.doityourself.com/stry/5-common-chimney-flue-problems-to-avoid (accessed on 12 December 2018).

- Earth System Research Laboratory. Trends in Atmospheric Carbon Dioxide, National Oceanic and Atmospheric Administration. 2019. Available online: https://www.esrl.noaa.gov/gmd/ccgg/trends/global.html (accessed on 10 March 2019).

- NGIFSS. (GISS). Global Temperature. NASA, 6 March 2019. Available online: https://climate.nasa.gov/vital-signs/global-temperature/ (accessed on 10 March 2019).

- Ministry of Internationa Trade and Industry (MITI). Malaysia and the United Nations Framework Convention on Climate Change (UNFCCC)–The Paris Agreement. 11 December 2017. Available online: https://www.miti.gov.my/miti/resources/Article_on_Malaysia_UNFCCC-_Paris_Agreement.pdf?mid=572 (accessed on 10 March 2019).

- Lindsey, R. Climate Change: Atmospheric Carbon Dioxide,” Climate.Gov. 1 August 2018. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-atmospheric-carbon-dioxide (accessed on 12 March 2019).

- Wisconsin Department of Health Services, Carbon Dioxide, Wisconsin Department of Health Services. 20 November 2018. Available online: https://www.dhs.wisconsin.gov/chemical/carbondioxide.htm (accessed on 10 March 2019).

- Gazette, F.G. Environmental Quality (Clean Air) Regulations 2014. 4 June 2014. Available online: http://www.federalgazette.agc.gov.my/outputp/pua_20140604_P.U.%20%28A%29%20151-peraturan-peraturan%20kualiti%20alam%20sekeliling%20%28udara%20bersih%29%202014.pdf (accessed on 8 November 2018).

- Department of Environment Malaysia, Environmental Requirements: A Guide for Investors. October 2010. Available online: http://www.doe.gov.my/eia/wp-content/uploads/2012/03/A-Guide-For-Investors1.pdf (accessed on 8 November 2018).

| TSHI APPROACHES | UTST | CTST |

|---|---|---|

| Matching of Utility Heat Exchanger | Series | Series and Parallel |

| Drawback of System | Slightly lower heat recovery targets | Dependency on separate processes, resulting in complications with regards to operation and control. |

| B01 Working Conditions | |

|---|---|

| Thermal Capacity | 2.5 MW |

| Load Percentage | 80% |

| Air Excess Percentage | 8% |

| Utility Temperature Difference | 15 °C |

| Flue Gas Dew Point | 52.46 °C |

| Autoignition Temperature | 537 °C |

| Fuel Consumption | 326.26 T/Year |

| Flue Gas Emission Temperature | 300 °C |

| RESULTS | |

|---|---|

| Fuel Saving | 17.29% |

| 56.41 T/Year | |

| Cost Saving | RM 85k/Year |

| Payback Time | 85.16 Months |

| CO2 Reduction | 149.29 T/Year |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koh, K.S.; Chew, S.J.; Choo, C.M.; Chok, V.S. Heat Integration of a Boiler and Its Corresponding Environmental Study in an Oleochemical Production Plant: An Industry Case Study in Malaysia. ChemEngineering 2019, 3, 82. https://doi.org/10.3390/chemengineering3040082

Koh KS, Chew SJ, Choo CM, Chok VS. Heat Integration of a Boiler and Its Corresponding Environmental Study in an Oleochemical Production Plant: An Industry Case Study in Malaysia. ChemEngineering. 2019; 3(4):82. https://doi.org/10.3390/chemengineering3040082

Chicago/Turabian StyleKoh, Kai Seng, Shee Jia Chew, Chee Ming Choo, and Vui Soon Chok. 2019. "Heat Integration of a Boiler and Its Corresponding Environmental Study in an Oleochemical Production Plant: An Industry Case Study in Malaysia" ChemEngineering 3, no. 4: 82. https://doi.org/10.3390/chemengineering3040082

APA StyleKoh, K. S., Chew, S. J., Choo, C. M., & Chok, V. S. (2019). Heat Integration of a Boiler and Its Corresponding Environmental Study in an Oleochemical Production Plant: An Industry Case Study in Malaysia. ChemEngineering, 3(4), 82. https://doi.org/10.3390/chemengineering3040082