Physicochemical Fingerprint of “Pera Rocha do Oeste”. A PDO Pear Native from Portugal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Nutritional Parameters

2.3. Quality Parameters

2.4. NIR

2.5. Statistical Analysis

3. Results and Discussion

3.1. Influence of Storage Conditions and Orchard Origin of “Pera Rocha do Oeste” on Its Physicochemical Characteristics

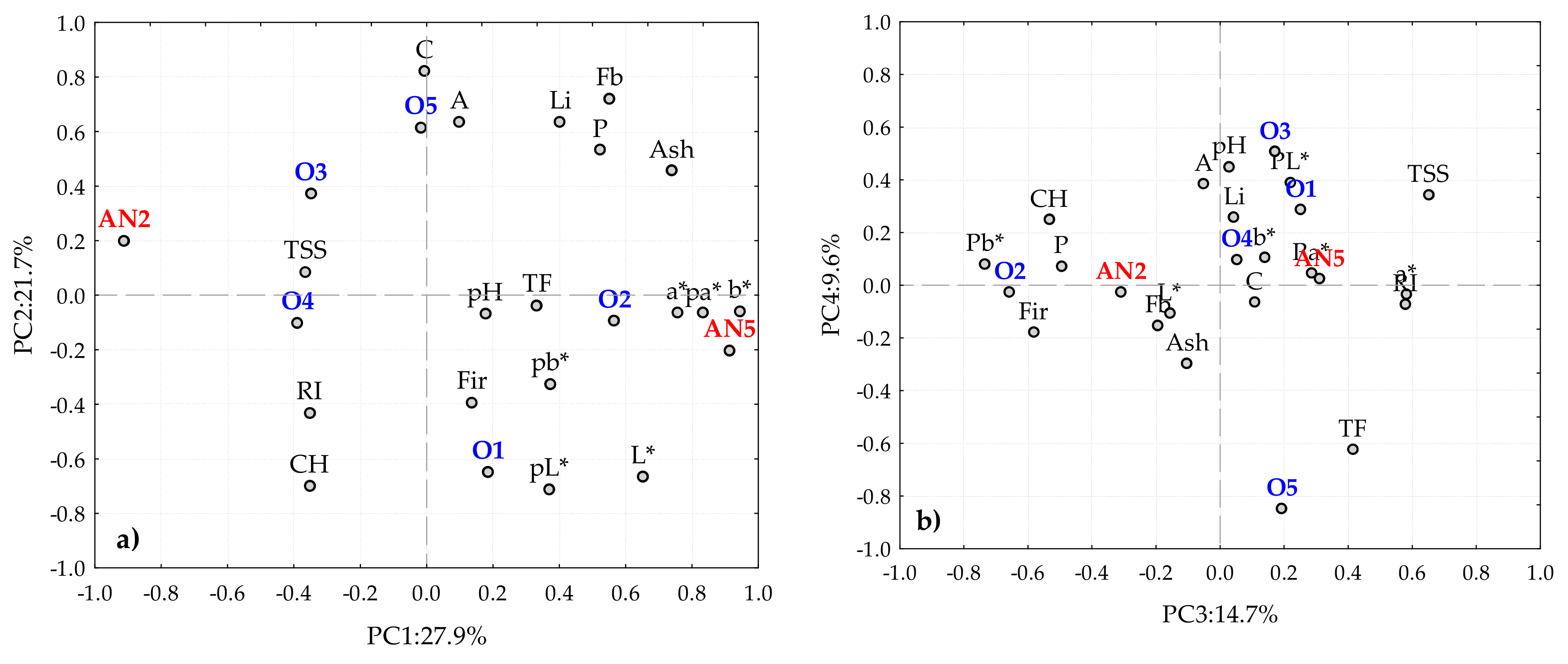

3.2. Identification of Fingerprint Parameters

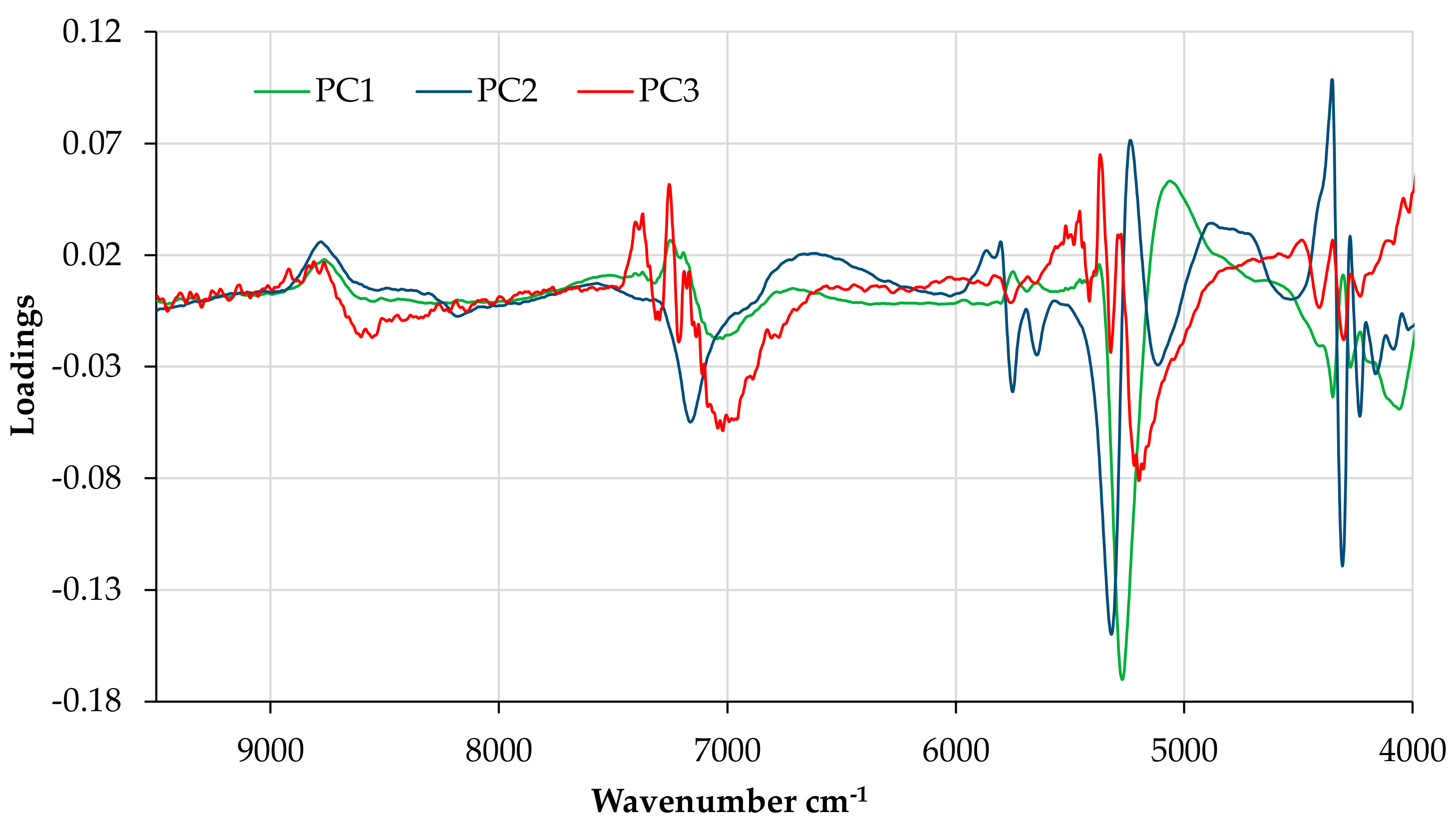

3.3. NIR Spectroscopy Analysis of the “Pera Rocha do Oeste” PDO Pear

3.4. Validation of the Fingerprint Physicochemical Parameters of the “Pera Rocha do Oeste” PDO Pear

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- GPP Market Information-Plant Products; MAFDR; Gabinete de Planeamento Políticas e Administração Geral: Lisbon, Portugal, 2016.

- Kader, A.A. Fruit maturity, ripening, and quality relationships. Acta Hortic. 1999, 485, 203–208. [Google Scholar] [CrossRef]

- Salta, J.; Martins, A.; Santos, R.G.; Neng, N.R.; Nogueira, J.M.F.; Justino, J.; Rauter, A.P. Phenolic composition and antioxidant activity of Rocha pear and other pear cultivars—A comparative study. J. Funct. Foods 2010, 2, 153–157. [Google Scholar] [CrossRef]

- Yahia, E. Modified and Controlled Atmospheres for the Storage, Transportation, and Packaging of Horticultural Commodities. Available online: https://doi.org/10.1201/9781420069587 (accessed on 18 August 2020).

- Almeida, D.P.; Carvalho, R.; Dupille, E. Efficacy of 1-methylcyclopropene on the mitigation of storage disorders of “Rocha” pear under normal refrigerated and controlled atmospheres. Food Sci. Technol. Int. 2016, 22, 399–409. [Google Scholar] [CrossRef] [PubMed]

- Yahia, E.M. Modified and Controlled Atmospheres for the Storage, Transportation, and Packaging of Horticultural Commodities; Yahia, E.M., Ed.; CRC Press: Boca Raton, FL, USA, 2009; ISBN 9780429136955. [Google Scholar]

- Deuchande, T.; Larrigaudière, C.; Guterres, U.; Carvalho, S.M.P.; Vasconcelos, M.W. Biochemical markers to predict internal browning disorders in ‘Rocha’ pear during storage under high CO2. J. Sci. Food Agric. 2017, 97, 3603–3612. [Google Scholar] [CrossRef] [PubMed]

- Deuchande, T.; Carvalho, S.M.P.; Guterres, U.; Fidalgo, F.; Isidoro, N.; Larrigaudière, C.; Vasconcelos, M.W. Dynamic controlled atmosphere for prevention of internal browning disorders in ‘Rocha’ pear. LWT Food Sci. Technol. 2016, 65, 725–730. [Google Scholar] [CrossRef]

- Silva, F.J.P.; Gomes, M.H.; Fidalgo, F.; Rodrigues, J.A.; Alemida, D.P.F. Antioxidant properties and fruit quality during long-term storage of “Pocha” pear: Effects of maturity and storage conditions. J. Food Qual. 2010, 33, 1–20. [Google Scholar] [CrossRef]

- Jayas, D.S.; Jeyamkondan, S. PH—Postharvest technology. Biosyst. Eng. 2002, 82, 235–251. [Google Scholar] [CrossRef]

- Chapman, J.; Elbourne, A.; Truong, V.K.; Newman, L.; Gangadoo, S.; Rajapaksha-Pathirannahalage, P.; Cheeseman, S.; Cozzolino, D. Sensomics—From conventional to functional NIR spectroscopy—Shining light over the aroma and taste of foods. Trends Food Sci. Technol. 2019, 91, 274–281. [Google Scholar] [CrossRef]

- Genisheva, Z.; Quintelas, C.; Mesquita, D.P.; Ferreira, E.C.; Oliveira, J.M.; Amaral, A.L. New PLS analysis approach to wine volatile compounds characterization by near infrared spectroscopy (NIR). Food Chem. 2018, 246, 172–178. [Google Scholar] [CrossRef] [Green Version]

- Anjos, O.; Caldeira, I.; Roque, R.; Pedro, S.I.; Lourenço, S.; Canas, S. Screening of Different ageing technologies of wine spirit by application of near-infrared (NIR) spectroscopy and volatile quantification. Processes 2020, 8, 736. [Google Scholar] [CrossRef]

- Giovanelli, G.; Sinelli, N.; Beghi, R.; Guidetti, R.; Casiraghi, E. NIR spectroscopy for the optimization of postharvest apple management. Postharvest Biol. Technol. 2014, 87, 13–20. [Google Scholar] [CrossRef]

- Moscetti, R.; Raponi, F.; Ferri, S.; Colantoni, A.; Monarca, D.; Massantini, R. Real-time monitoring of organic apple (var. Gala) during hot-air drying using near-infrared spectroscopy. J. Food Eng. 2018, 222, 139–150. [Google Scholar] [CrossRef]

- Cavaco, A.M.; Pinto, P.; Antunes, M.D.; Silva, J.M.; Guerra, R. ‘Rocha’ pear firmness predicted by a Vis/NIR segmented model. Postharvest Biol. Technol. 2009, 51, 311–319. [Google Scholar] [CrossRef]

- Goke, A.; Serra, S.; Musacchi, S. Postharvest dry matter and soluble solids content prediction in d’Anjou and bartlett pear using near-infrared spectroscopy. HortScience 2018, 53, 669–680. [Google Scholar] [CrossRef]

- Luo, X.; Ye, Z.; Xu, H.; Zhang, D.; Bai, S.; Ying, Y. Robustness improvement of NIR-based determination of soluble solids in apple fruit by local calibration. Postharvest Biol. Technol. 2018, 139, 82–90. [Google Scholar] [CrossRef]

- Escribano, S.; Biasi, W.V.; Lerud, R.; Slaughter, D.C.; Mitcham, E.J. Non-destructive prediction of soluble solids and dry matter content using NIR spectroscopy and its relationship with sensory quality in sweet cherries. Postharvest Biol. Technol. 2017, 128, 112–120. [Google Scholar] [CrossRef]

- Malegori, C.; Nascimento-Marques, E.J.; de Freitas, S.T.; Pimentel, M.F.; Pasquini, C.; Casiraghi, E. Comparing the analytical performances of Micro-NIR and FT-NIR spectrometers in the evaluation of acerola fruit quality, using PLS and SVM regression algorithms. Talanta 2017, 165, 112–116. [Google Scholar] [CrossRef]

- Arendse, E.; Fawole, O.A.; Magwaza, L.S.; Nieuwoudt, H.; Opara, U.L. Fourier transform near infrared diffuse reflectance spectroscopy and two spectral acquisition modes for evaluation of external and internal quality of intact pomegranate fruit. Postharvest Biol. Technol. 2018, 138, 91–98. [Google Scholar] [CrossRef]

- European Commission. Commission regulation (EEC) No 920/89 laying down quality standards for carrots, citruis fruit and dessert apples and pears and amending commission regulation No 58. Off. J. Eur. Communities 1989, 97, 19–39.

- AOAC. Official Methods of Analysis of AOAC, 17th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2020. [Google Scholar]

- Regulation (EU) No 1169/2011 of the European parliament and of the council of 25 October 2011. Off. J. Eur. Communities 2011, 304, 18–23.

- Nielsen, S.S. Food Analysis Laboratory Manual; Nielsen, S.S., Ed.; Springer US: Boston, MA, USA, 2010; ISBN 978-1-4419-1462-0. [Google Scholar]

- Serra, A.T.; Matias, A.A.; Frade, R.F.M.; Duarte, R.O.; Feliciano, R.P.; Bronze, M.R.; Figueira, M.E.; de Carvalho, A.; Duarte, C.M.M. Characterization of traditional and exotic apple varieties from Portugal. Part 2—Antioxidant and antiproliferative activities. J. Funct. Foods 2010, 2, 46–53. [Google Scholar] [CrossRef]

- Galvis-Sánchez, A.C.; Fonseca, S.C.; Morais, A.M.M.; Malcata, F.X. Effects of preharvest, harvest and postharvest factors on the quality of pear (cv. ‘Rocha’) stored under controlled atmosphere conditions. J. Food Eng. 2004, 64, 161–172. [Google Scholar] [CrossRef]

- Sánchez, C.; Lidon, F.C.; Vivas, M.; Ramos, P.; Santos, M.; Barreiro, M.G. Effect of chitosan coating on quality and nutritional value of fresh-cut “Rocha” pear. Emirates J. Food Agric. 2015, 27, 206–214. [Google Scholar] [CrossRef] [Green Version]

- Fawole, O.A.; Opara, U.L. Developmental changes in maturity indices of pomegranate fruit: A descriptive review. Sci. Hortic. 2013, 159, 152–161. [Google Scholar] [CrossRef]

- Rosenbloom, R.A.; Wang, W.; Zhao, Y. Delaying ripening of ‘Bartlett’ pears (Pyrus communis) during long-term simulated industrial cold storage: Mechanisms and validation of chitosan coatings with cellulose nanocrystals Pickering emulsions. LWT 2020, 122, 109053. [Google Scholar] [CrossRef]

- Galvis Sánchez, A.C.; Gil-Izquierdo, A.; Gil, M.I. Comparative study of six pear cultivars in terms of their phenolic and vitamin C contents and antioxidant capacity. J. Sci. Food Agric. 2003, 83, 995–1003. [Google Scholar] [CrossRef]

- Veltman, R.; Kho, R.; van Schaik, A.C.; Sanders, M.; Oosterhaven, J. Ascorbic acid and tissue browning in pears (Pyrus communis L. cvs Rocha and Conference) under controlled atmosphere conditions. Postharvest Biol. Technol. 2000, 19, 129–137. [Google Scholar] [CrossRef]

- Hussain, P.R.; Meena, R.S.; Dar, M.A.; Wani, A.M. Carboxymethyl Cellulose coating and low-dose gamma irradiation improves storage quality and shelf life of pear (Pyrus communis L., Cv. Bartlett/William). J. Food Sci. 2010, 75, M586–M596. [Google Scholar] [CrossRef]

- Barroca, M.J.; Guiné, R.P.F.; Pinto, A.; Gonçalves, F.M.; Ferreira, D.M.S. Chemical and microbiological characterization of portuguese varieties of pears. Food Bioprod. Process. 2006, 84, 109–113. [Google Scholar] [CrossRef]

- Murayama, H.; Katsumata, T.; Horiuchi, O.; Fukushima, T. Relationship between fruit softening and cell wall polysaccharides in pears after different storage periods. Postharvest Biol. Technol. 2002, 26, 15–21. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory, 2nd ed.; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Raileanu, L.E.; Stoffel, K. Theoretical comparison between the Gini index and information gain criteria. Ann. Math. Artif. Intell. 2004, 41, 77–93. [Google Scholar] [CrossRef]

- Kader, A.A. Mode of action of oxygen and carbon dioxide on postharvest physiology of “Bartlett” pears. Acta Hortic. 1989, 258, 161–168. [Google Scholar] [CrossRef]

- Papadakis, I.E.; Protopapadakis, E.; Dimassi, K.N.; Therios, I.N. Nutritional status, yield, and fruit quality of “encore” mandarin trees grown in two sites of an orchard with different soil properties. J. Plant Nutr. 2005, 27, 1505–1515. [Google Scholar] [CrossRef]

- Li, J.; Huang, W.; Zhao, C.; Zhang, B. A comparative study for the quantitative determination of soluble solids content, pH and firmness of pears by Vis/NIR spectroscopy. J. Food Eng. 2013, 116, 324–332. [Google Scholar] [CrossRef]

- Bobelyn, E.; Serban, A.-S.; Nicu, M.; Lammertyn, J.; Nicolai, B.M.; Saeys, W. Postharvest quality of apple predicted by NIR-spectroscopy: Study of the effect of biological variability on spectra and model performance. Postharvest Biol. Technol. 2010, 55, 133–143. [Google Scholar] [CrossRef]

- Alamar, M.C.; Bobelyn, E.; Lammertyn, J.; Nicolaï, B.M.; Moltó, E. Calibration transfer between NIR diode array and FT-NIR spectrophotometers for measuring the soluble solids contents of apple. Postharvest Biol. Technol. 2007, 45, 38–45. [Google Scholar] [CrossRef]

- Louw, E.D.; Theron, K.I. Robust prediction models for quality parameters in Japanese plums (Prunus salicina L.) using NIR spectroscopy. Postharvest Biol. Technol. 2010, 58, 176–184. [Google Scholar] [CrossRef]

- Polesello, A.; Giangiacomo, R.; Dull, G.G. Application of near infrared spectrophotometry to the nondestructive analysis of foods: A review of experimental results. CRC Crit. Rev. Food Sci. Nutr. 1983, 18, 203–230. [Google Scholar] [CrossRef]

- Rungpichayapichet, P.; Mahayothee, B.; Nagle, M.; Khuwijitjaru, P.; Müller, J. Robust NIRS models for non-destructive prediction of postharvest fruit ripeness and quality in mango. Postharvest Biol. Technol. 2016, 111, 31–40. [Google Scholar] [CrossRef]

- Ambrose, A.; Lohumi, S.; Lee, W.-H.; Cho, B.K. Comparative nondestructive measurement of corn seed viability using Fourier transform near-infrared (FT-NIR) and Raman spectroscopy. Sens. Actuators B Chem. 2016, 224, 500–506. [Google Scholar] [CrossRef]

- Gómez, A.H.; He, Y.; Pereira, A.G. Non-destructive measurement of acidity, soluble solids and firmness of Satsuma mandarin using Vis/NIR-spectroscopy techniques. J. Food Eng. 2006, 77, 313–319. [Google Scholar] [CrossRef]

- Shenk-John, S.; Workman, J.; Jerome-Westerhaus, M.O. Application of NIR spectroscopy to agricultural products. In Handbook of Near-Infrared Analysis; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

| SM | O | Peel | Pulp | ||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||

| RA2 | 1 | 72.07 ± 2.62 | −8.99 ± 2.03 | 44.07 ± 0.41 | 80.66 ± 2.64 | −9.54 ± 1.63 | 9.31 ± 1.39 |

| 2 | 73.49 ± 1.89 | −5.72 ± 3.01 | 43.35 ± 0.48 | 79.88 ± 1.42 | −8.28 ± 1.44 | 9.08 ± 0.96 | |

| 3 | 73.96 ± 3.17 | −10.19 ± 1.90 | 43.97 ± 1.15 | 81.25 ± 1.94 | −0.77 ± 0.74 | 13.73 ± 0.82 | |

| RA5 | 1 | 69.88 ± 1.39 | −1.52 ± 2.03 | 42.60 ± 0.64 | 77.18 ± 1.57 | −0.17 ± 1.61 | 12.54 ± 0.72 |

| 2 | 72.37 ± 2.51 | 3.39 ± 3.01 | 42.88 ± 0.92 | 79.07 ± 0.56 | −0.33 ± 1.49 | 14.75 ± 1.97 | |

| 3 | 76.04 ± 0.90 | −2.92 ± 1.90 | 40.88 ± 1.93 | 79.05 ± 1.25 | 0.74 ± 1.27 | 13.63 ± 2.44 | |

| DCA | 1 | 72.69 ± 5.84 | −7.31 ± 2.94 | 42.60 ± 1.57 | 79.33 ± 1.92 | −1.87 ± 0.57 | 11.81 ± 1.72 |

| 2 | 72.12 ± 1.41 | −10.22 ± 2.07 | 42.88 ± 0.80 | 78.42 ± 0.88 | −1.71 ± 0.14 | 11.51 ± 1.67 | |

| 3 | 68.49 ± 2.78 | −2.92 ± 2.24 | 40.88 ± 1.58 | 82.40 ± 3.50 | −1.42 ± 0.55 | 13.03 ± 2.88 | |

| μ ± σ | 72.34 ± 3.33 66.69; 79.55 | −4.79 ± 5.16 −12.87; 5.64 | 42.40 ± 1.63 39.17; 45.52 | 79.69 ± 2.60 75.40; 87.19 | −2.59 ± 3.60 −11.07; 2.25 | 12.15 ± 2.46 8.15; 17.68 | |

| Min; Max | |||||||

| SM | O | TSS (°Brix) | pH | TA (g malic acid/100 mL) | RI | Firmness (N) | Vitamin C (mg/100 g) | Total Phenols (mg GAE/100 g) |

|---|---|---|---|---|---|---|---|---|

| RA2 | 1 | 12.10 ± 0.12 | 4.69 ± 0.01 | 0.13 ± 0.01 | 94.77 ± 1.53 | 12.51 ± 1.92 | 5.42 ± 1.02 | 65.84 ± 5.49 |

| 2 | 12.57 ± 0.19 | 4.91 ± 0.01 | 0.09 ± 0.01 | 139.63 ± 2.10 | 10.15 ± 0.88 | 2.08 ± 0.59 | 44.67 ± 6.17 | |

| 3 | 12.57 ± 0.05 | 4.76 ± 0.00 | 0.14 ± 0.01 | 90.19 ± 0.64 | 11.47 ± 1.61 | 4.17 ± 0.59 | 72.33 ± 4.76 | |

| RA5 | 1 | 13.37 ± 0.31 | 4.76 ± 0.00 | 0.22 ± 0.03 | 61.54 ± 8.18 | 9.41 ± 0.28 | 10.42 ± 0.59 | 66.37 ± 4.74 |

| 2 | 11.40 ± 0.07 | 4.91 ± 0.00 | 0.28 ± 0.01 | 40.33 ± 0.20 | 10.59 ± 1.46 | 5.83 ± 0.51 | 47.99 ± 3.28 | |

| 3 | 11.23 ± 0.10 | 4.71 ± 0.0 | 0.11 ± 0.01 | 106.57 ± 5.51 | 13.37 ± 1.36 | 5.42 ± 0.59 | 83.95 ± 6.03 | |

| DCA | 1 | 11.07 ± 0.45 | 4.84 ± 0.02 | 0.29 ± 0.01 | 38.07 ± 0.62 | 16.72 ± 0.28 | 5.83 ± 1.18 | 58.77 ± 1.21 |

| 2 | 11.07 ± 0.05 | 4.84 ± 0.01 | 0.23 ± 0.02 | 48.61 ± 3.80 | 11.11 ± 0.20 | 7.08 ± 1.56 | 69.50 ± 7.67 | |

| 3 | 12.10 ± 0.01 | 4.92 ± 0.00 | 0.28 ± 0.01 | 42.62 ± 0.74 | 14.58 ± 2.12 | 6.67 ± 0.59 | 86.48 ± 7.51 | |

| μ ± σ | 11.94 ± 0.79 | 4.81 ± 0.08 | 0.20 ± 0.08 | 73.59 ± 34.41 | 12.21 ± 2.51 | 5.87 ± 2.29 | 66.21 ± 14.51 | |

| Min; Max | 13.80; 10.70 | 4.68; 4.92 | 0.09; 0.30 | 37.24; 141.11 | 9.12; 17.39 | 1.25; 11.25 | 39.26; 93.10 | |

| SM | O | Protein (%) | Lipids (%) | Fibre (%) | Ash (%) | Other including Carbohydrates (%) | Energy (kcal/100 g) |

|---|---|---|---|---|---|---|---|

| RA2 | 1 | 2.13 ± 0.05 | 0.30 ± 0.02 | 10.03 ± 0.06 | 2.25 ± 0.04 | 17.03 ± 0.10 | 20.21 ± 0.44 |

| 2 | 2.37 ± 0.0 | 0.36 ± 0.01 | 10.43 ± 0.18 | 1.84 ± 0.02 | 29.11 ± 0.02 | 20.04 ± 0.07 | |

| 3 | 1.81 ± 0.01 | 0.35 ± 0.01 | 13.01 ± 0.37 | 1.65 ± 0.03 | 18.12 ± 0.03 | 17.00 ± 0.11 | |

| RA5 | 1 | 2.00 ± 0.01 | 0.42 ± 0.01 | 11.31 ± 0.42 | 2.41 ± 0.08 | 9.26 ± 0.07 | 21.42 ± 0.21 |

| 2 | 2.03 ± 0.01 | 0.42 ± 0.01 | 8.40 ± 0.21 | 1.96 ± 0.02 | 10.55 ± 0.03 | 19.73 ± 0.14 | |

| 3 | 1.67 ± 0.03 | 0.38 ± 0.01 | 11.33 ± 0.03 | 1.45 ± 0.01 | 10.63 ± 0.02 | 15.84 ± 0.06 | |

| DCA | 1 | 2.41 ± 0.08 | 0.31 ± 0.03 | 10.68 ± 0.81 | 2.68 ± 0.21 | 7.98 ± 0.32 | 23.11 ± 1.42 |

| 2 | 2.23 ± 0.02 | 0.36 ± 0.01 | 11.09 ± 0.07 | 2.74 ± 0.04 | 8.92 ± 0.06 | 23.11 ± 0.24 | |

| 3 | 2.01 ± 0.04 | 0.34 ± 0.01 | 10.10 ± 0.06 | 1.78 ± 0.04 | 10.69 ± 0.07 | 18.17 ± 0.32 | |

| μ ± σ | 2.07 ± 0.23 | 0.36 ± 0.04 | 10.71 ± 1.23 | 2.08 ± 0.44 | 13.59 ± 6.52 | 19.85 ± 2.46 | |

| Min; Max | 1.64; 2.51 | 0.27; 0.43 | 8.14; 13.55 | 1.44; 2.91 | 7.60; 29.12 | 15.77; 24.83 | |

| Parameter | Mean ± sd | Minimum | Maximum |

|---|---|---|---|

| Peel colour L | 71.93 ± 3.82 | 64.38 | 80.74 |

| Peel colour a* | −6.75 ± 5.51 | −13.57 | 7.33 |

| Peel colour b* | 41.70 ± 2.29 | 37.91 | 47.09 |

| Pulp colour L | 77.70 ± 3.79 | 70.36 | 87.19 |

| Pulp colour a* | −3.45 ± 3.58 | −11.07 | 5.11 |

| Pulp colour b* | 11.19 ± 2.94 | 6.81 | 17.68 |

| Vitamin C (mg/100 mL) | 6.37 ± 2.21 | 1.25 | 11.25 |

| pH | 4.71 ± 0.14 | 4.36 | 4.92 |

| TSS (˚Brix) | 11.69 ± 0.89 | 10.00 | 13.80 |

| Titratable Acidity (g malic acid/100 mL) | 0.16 ± 0.07 | 0.09 | 0.30 |

| Firmness (N) | 12.33 ± 2.33 | 9.10 | 17.96 |

| Total phenols (mg GAE/100 g) | 64.41 ± 13.35 | 39.26 | 93.10 |

| Protein (%) | 2.21 ± 0.52 | 1.54 | 3.51 |

| Lipids (%) | 0.38 ± 0.07 | 0.21 | 0.53 |

| Fibre (%) | 10.93 ± 1.39 | 8.14 | 13.55 |

| Ash (%) | 2.04 ± 0.43 | 1.36 | 2.94 |

| Other including carbohydrates (%) | 12.31 ± 5.63 | 6.23 | 29.12 |

| Energy (Kcal/100 g) | 20.31 ± 3.73 | 11.68 | 28.87 |

| Ripening index | 83.70 ± 27.02 | 37.24 | 141.11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedro, S.I.; Coelho, E.; Peres, F.; Machado, A.; Rodrigues, A.M.; Wessel, D.F.; Coimbra, M.A.; Anjos, O. Physicochemical Fingerprint of “Pera Rocha do Oeste”. A PDO Pear Native from Portugal. Foods 2020, 9, 1209. https://doi.org/10.3390/foods9091209

Pedro SI, Coelho E, Peres F, Machado A, Rodrigues AM, Wessel DF, Coimbra MA, Anjos O. Physicochemical Fingerprint of “Pera Rocha do Oeste”. A PDO Pear Native from Portugal. Foods. 2020; 9(9):1209. https://doi.org/10.3390/foods9091209

Chicago/Turabian StylePedro, Soraia I., Elisabete Coelho, Fátima Peres, Ana Machado, António M. Rodrigues, Dulcineia F. Wessel, Manuel A. Coimbra, and Ofélia Anjos. 2020. "Physicochemical Fingerprint of “Pera Rocha do Oeste”. A PDO Pear Native from Portugal" Foods 9, no. 9: 1209. https://doi.org/10.3390/foods9091209

APA StylePedro, S. I., Coelho, E., Peres, F., Machado, A., Rodrigues, A. M., Wessel, D. F., Coimbra, M. A., & Anjos, O. (2020). Physicochemical Fingerprint of “Pera Rocha do Oeste”. A PDO Pear Native from Portugal. Foods, 9(9), 1209. https://doi.org/10.3390/foods9091209