Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread †

Abstract

1. Introduction

2. Materials and Methods

2.1. Flour and Other Ingredients

2.2. Preparation of Sourdough and Bread Making

- In the first stage of sourdough preparation, 10 g of starter culture was mixed with 100 g of flour blend, and 100 mL water (30 ± 1 °C). The dough after mixing was placed in a CL-53 thermostat (Memmert GmbH + Co. KG, Schwabach, Germany) for 24 ± 1 h at 28 ± 1 °C.

- In the second stage, 100 g of flour blend and 100 mL water (30 ± 1 °C) was added to the sourdough made on the previous day. After thorough mixing it was placed in a thermostat for another 24 ± 1 h at 32 ± 1 °C. After the second stage, sourdough was ready for use in the bread preparation. The pH of ready TKS sourdough was 3.67.

2.3. Determination of the Volatile Compounds

2.4. Analysis of Bread Physical-and-Chemical Parameters

2.5. Statistical Analysis

3. Results

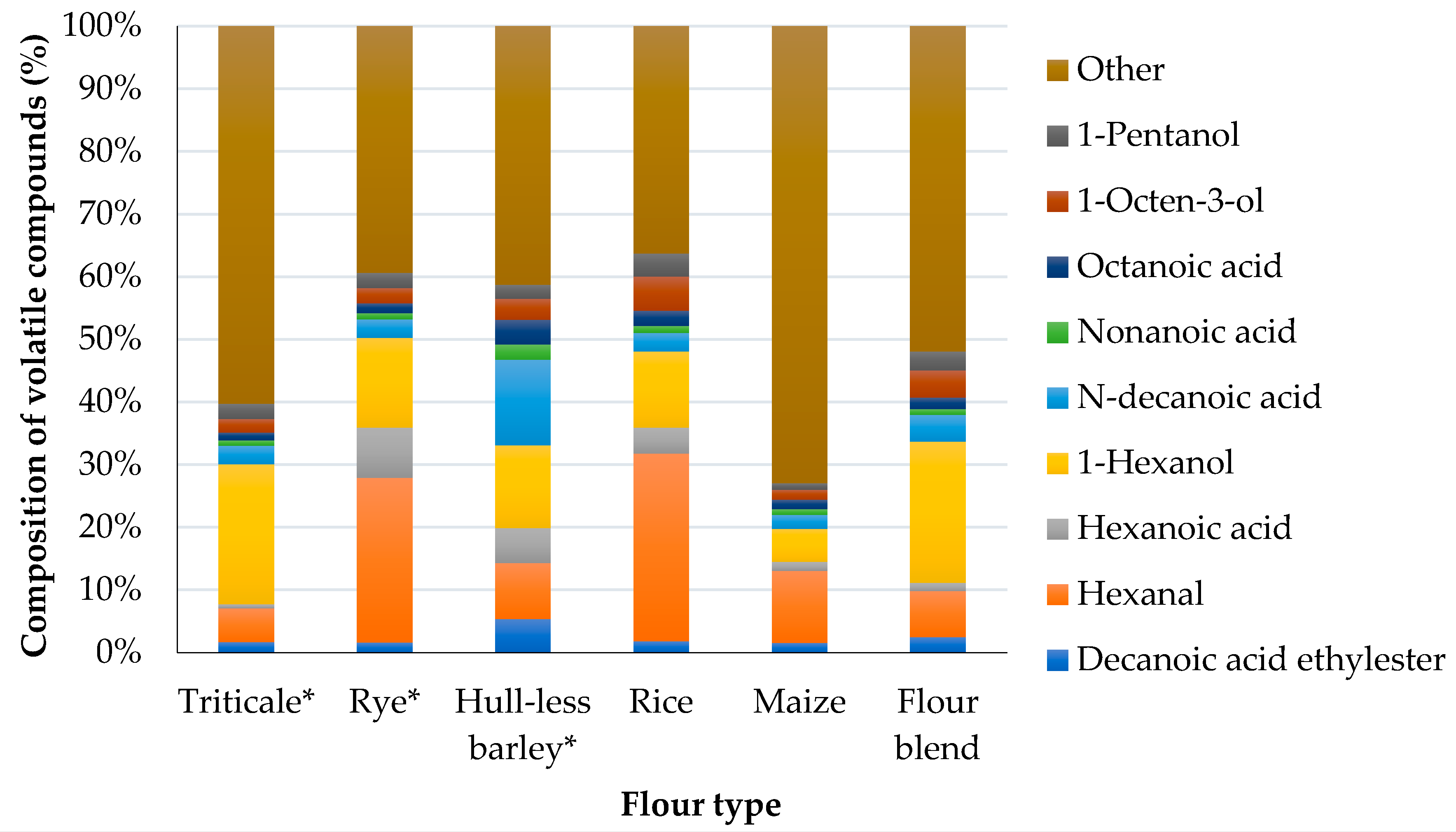

3.1. Composition of Volatile Compounds in Raw Materials

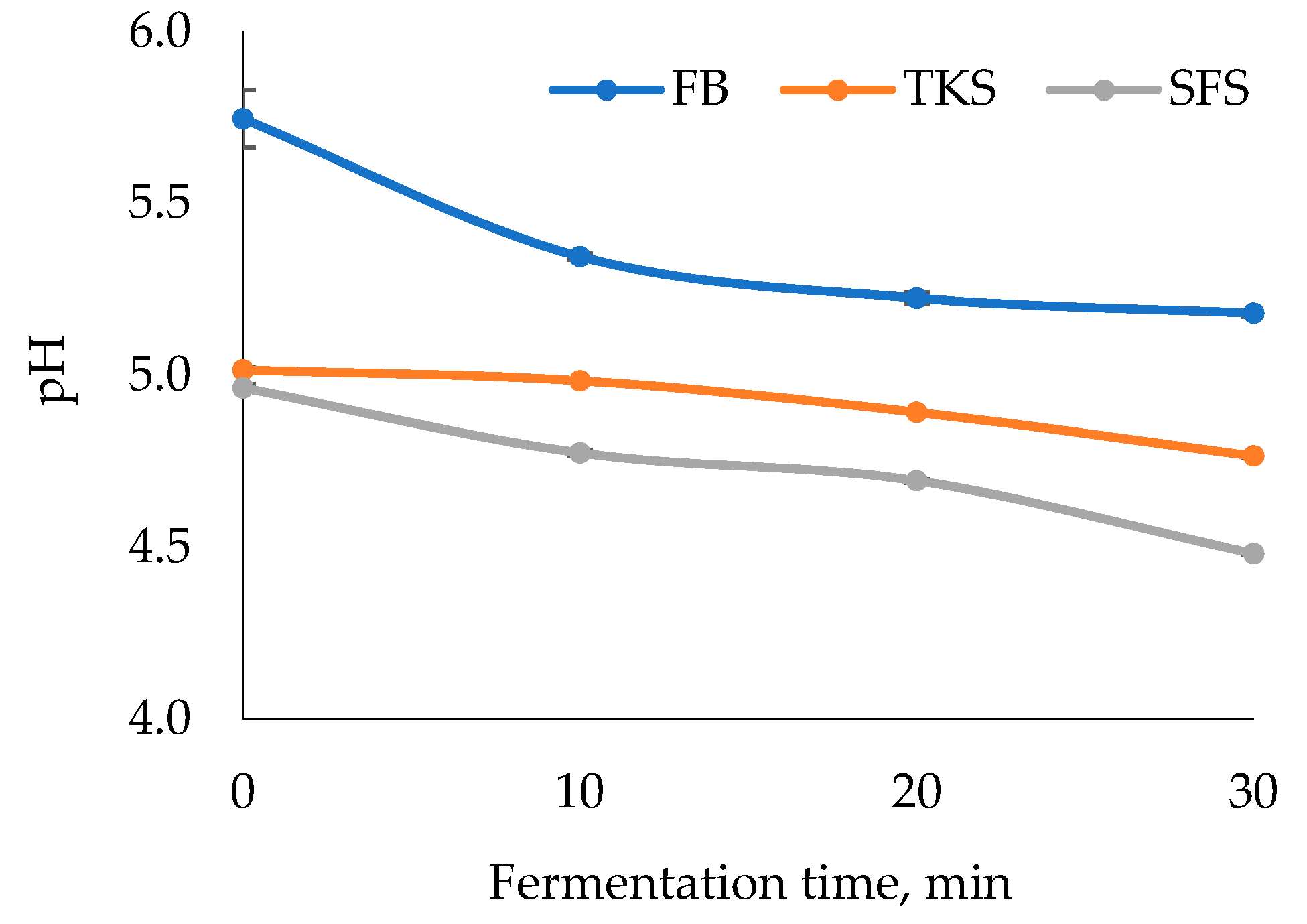

3.2. Volatile Compounds in Mixed and Fermented Dough

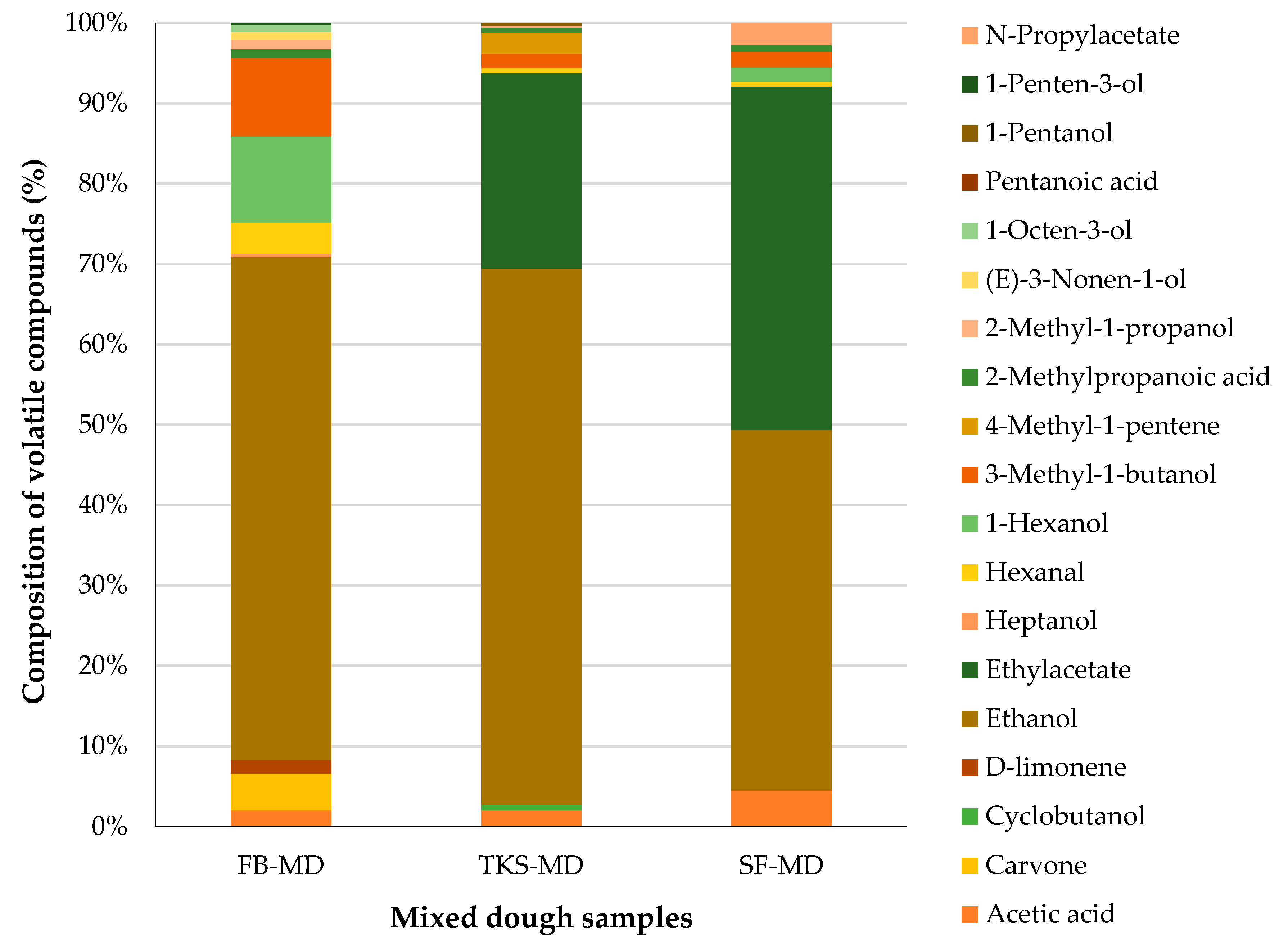

3.2.1. Volatile Compound Profile in Dough after Mixing

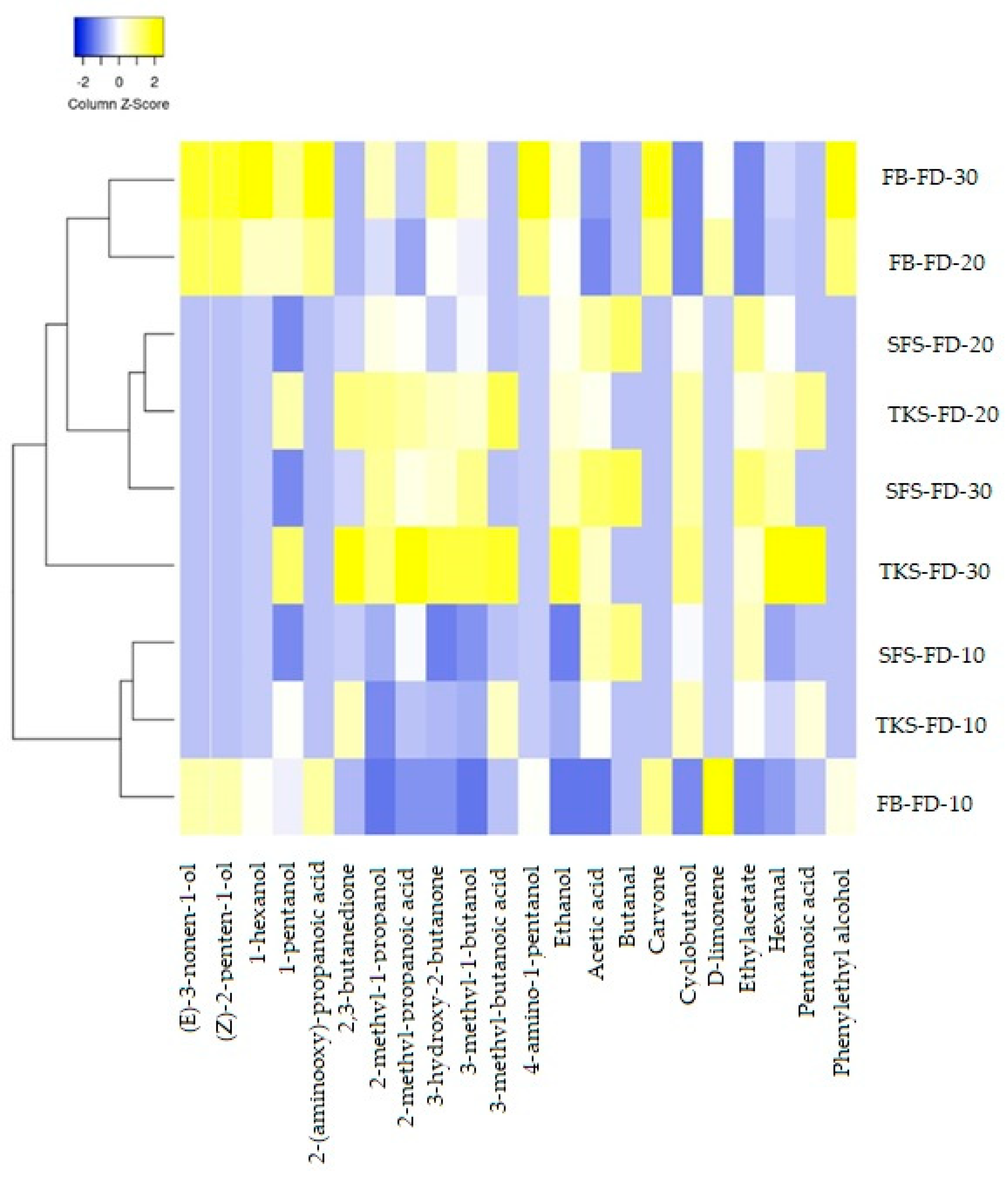

3.2.2. The Effect of Dough Fermentation on Volatile Compound Profile

- All three dough types after 10 min fermentation (FB-F10, TKS-F10, and SFS-F10). The cluster can be characterized by the smallest amount of volatile compounds.

- Dough made with two-stage sourdough after 30 min fermentation (TKS-F30) was grouped separately from other samples. The highest sum of peak areas was detected in this sample. The volatile spectrum was formed by 14 volatile compounds, resulting in substrates for further aroma development in bread.

- Dough made with ready-to-use sourdough after 20 and 30 min fermentation (SFS-F20, SFS-F30) and TKS-F20. The cluster with a medium sum of peak areas and small number of volatile compounds.

- Triticale dough without sourdough after 20 and 30 min fermentation (FB-F20, FB-F30). The cluster with medium sum of peak areas and big number of volatile compounds, with a high intensity of (Z)-2-penten-1-ol, (E)-3-nonen-1-ol.

3.3. Triticale Bread Quality Parameters and Volatile Compounds in Its Crust and Crumb

3.3.1. Physical-and-Chemical Characteristics of the Flour Blend Bread with Sourdough

3.3.2. Volatile Compounds in Crust and Crumb of Triticale Flour Blend Bread with Sourdough

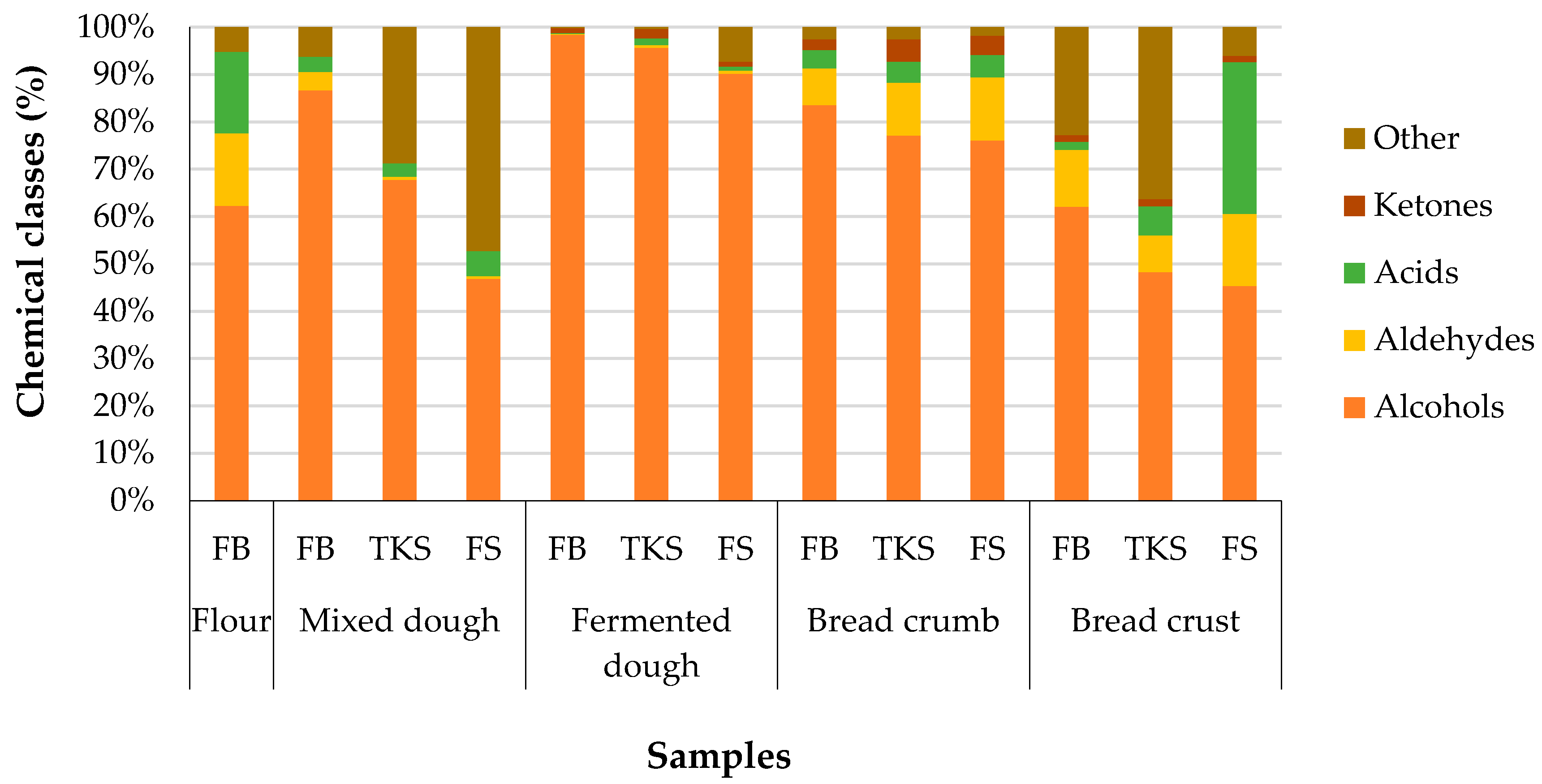

3.4. The Dynamics of Volatile Compound Classes in the Technological Processes of Bread Production

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organisation. FAOSTAT: Statistics Division of Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 14 August 2020).

- Rakha, A.; Åman, P.; Andersson, R. Dietary Fiber in Triticale Grain: Variation in Content, Composition, and Molecular Weight Distribution of Extractable Components. J. Cereal Sci. 2011, 54, 324–331. [Google Scholar] [CrossRef]

- Fraś, A.; Gołębiewska, K.; Gołębiewski, D.; Mańkowski, D.R.; Boros, D.; Szecówka, P. Variability in the Chemical Composition of Triticale Grain, Flour and Bread. J. Cereal Sci. 2016, 71, 66–72. [Google Scholar] [CrossRef]

- Agil, R.; Hosseinian, F. Dual Functionality of Triticale as a Novel Dietary Source of Prebiotics with Antioxidant Activity in Fermented Dairy Products. Plant Foods Hum. Nutr. 2012, 67, 88–93. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F. Triticale: Nutritional Composition and Food Uses. Food Chem. 2018, 241, 468–479. [Google Scholar] [CrossRef]

- Straumite, E.; Galoburda, R.; Tomsone, L.; Kruma, Z.; Gramatiņa, I.; Kronberga, A.; Sturite, I. Nutritional Quality of Triticale (× Triticosecale Wittm.) Grown under Different Cropping Systems. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2017, 71. [Google Scholar] [CrossRef]

- Tohver, M.; Kann, A.; Täht, R.; Mihhalevski, A.; Hakman, J. Quality of Triticale Cultivars Suitable for Growing and Bread-Making in Northern Conditions. Food Chem. 2005, 89, 125–132. [Google Scholar] [CrossRef]

- Fraś, A.; Gołębiewski, D.; Gołębiewska, K.; Mańkowski, D.R.; Gzowska, M.; Boros, D. Triticale-Oat Bread as a New Product Rich in Bioactive and Nutrient Components. J. Cereal Sci. 2018, 82, 146–154. [Google Scholar] [CrossRef]

- Pycia, K.; Jaworska, G.; Telega, J.; Sudoł, I.; Kuźniar, P. Effect of Adding Potato Maltodextrins on Baking Properties of Triticale Flour and Quality of Bread. LWT-Food Sci. Technol. 2018, 96, 199–204. [Google Scholar] [CrossRef]

- Peña, R.J. Food Uses of Triticale. In Triticale Improvement and Production; Mergoum, M., Gómez-Macpherson, H., Eds.; FAO: Rome, Italy, 2004; pp. 37–48. [Google Scholar]

- Martinek, P.; Vinterová, M.; Burešová, I.; Vyhnánek, T. Agronomic and Quality Characteristics of Triticale (x Triticosecale Wittmack) with HMW Glutenin Subunits 5 + 10. J. Cereal Sci. 2008, 47, 68–78. [Google Scholar] [CrossRef]

- Cauvain, S. Other Cereals in Breadmaking. In Technology of Breadmaking; Springer: Cham, Switzerland, 2015; pp. 377–397. [Google Scholar] [CrossRef]

- Torbica, A.; Mocko Blažek, K.; Belović, M.; Janić Hajnal, E. Quality Prediction of Bread Made from Composite Flours Using Different Parameters of Empirical Rheology. J. Cereal Sci. 2019, 89, 102812. [Google Scholar] [CrossRef]

- Poutanen, K.; Flander, L.; Katina, K. Sourdough and Cereal Fermentation in a Nutritional Perspective. Food Microbiol. 2009, 26, 693–699. [Google Scholar] [CrossRef] [PubMed]

- Pacyński, M.; Wojtasiak, R.Z.; Mildner-Szkudlarz, S. Improving the Aroma of Gluten-Free Bread. LWT-Food Sci. Technol. 2015, 63, 706–713. [Google Scholar] [CrossRef]

- Heiniö, R.L.; Noort, M.W.J.; Katina, K.; Alam, S.A.; Sozer, N.; de Kock, H.L.; Hersleth, M.; Poutanen, K. Sensory Characteristics of Wholegrain and Bran-Rich Cereal Foods-A Review. Trends Food Sci. Technol. 2016, 47, 25–38. [Google Scholar] [CrossRef]

- Mohd Roby, B.H.; Muhialdin, B.J.; Abadl, M.M.T.; Mat Nor, N.A.; Marzlan, A.A.; Lim, S.A.H.; Mustapha, N.A.; Meor Hussin, A.S. Physical Properties, Storage Stability, and Consumer Acceptability for Sourdough Bread Produced Using Encapsulated Kombucha Sourdough Starter Culture. J. Food Sci. 2020. [Google Scholar] [CrossRef] [PubMed]

- Debonne, E.; Van Bockstaele, F.; Van Driessche, M.; De Leyn, I.; Eeckhout, M.; Devlieghere, F. Impact of Par-Baking and Packaging on the Microbial Quality of Par-Baked Wheat and Sourdough Bread. Food Control 2018, 91, 12–19. [Google Scholar] [CrossRef]

- Plessas, S.; Fisher, A.; Koureta, K.; Psarianos, C.; Nigam, P.; Koutinas, A.A. Application of Kluyveromyces marxianus, Lactobacillus delbrueckii ssp. bulgaricus and L. helveticus for Sourdough Bread Making. Food Chem. 2008, 106, 985–990. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, H.; Xi, J.; Jin, Y.; Chen, Y.; Guo, L.; Jin, Z.; Xu, X. Improving Bread Aroma Using Low-Temperature Sourdough Fermentation. Food Biosci. 2020, 37, 100704. [Google Scholar] [CrossRef]

- Liukkonen, K.-H.; Katina, K.; Wilhelmsson, A.; Myllymaki, O.; Lampi, A.-M.; Kariluoto, S.; Piironen, V.; Heinonen, S.-M.; Nurmi, T.; Adlercreutz, H.; et al. Process-Induced Changes on Bioactive Compounds in Whole Grain Rye. Proc. Nutr. Soc. 2003, 62, 117–122. [Google Scholar] [CrossRef]

- Gänzle, M.G.; Loponen, J.; Gobbetti, M. Proteolysis in Sourdough Fermentations: Mechanisms and Potential for Improved Bread Quality. Trends Food Sci. Technol. 2008, 19, 513–521. [Google Scholar] [CrossRef]

- Cavallo, N.; De Angelis, M.; Calasso, M.; Quinto, M.; Mentana, A.; Minervini, F.; Cappelle, S.; Gobbetti, M. Microbial Cell-Free Extracts Affect the Biochemical Characteristics and Sensorial Quality of Sourdough Bread. Food Chem. 2017, 237, 159–168. [Google Scholar] [CrossRef]

- Plessas, S.; Alexopoulos, A.; Bekatorou, A.; Mantzourani, I.; Koutinas, A.A.; Bezirtzoglou, E. Examination of Freshness Degradation of Sourdough Bread Made with Kefir through Monitoring the Aroma Volatile Composition during Storage. Food Chem. 2011, 124, 627–633. [Google Scholar] [CrossRef]

- Cayot, N. Sensory Quality of Traditional Foods (doi:10.1016/j.Foodchem.2006.01.012). Food Chem. 2007, 102, 445–453. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat Bread Aroma Compounds in Crumb and Crust: A Review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Pihlava, J.M.; Nordlund, E.; Heiniö, R.L.; Hietaniemi, V.; Lehtinen, P.; Poutanen, K. Phenolic Compounds in Wholegrain Rye and Its Fractions. J. Food Compos. Anal. 2015, 38, 89–97. [Google Scholar] [CrossRef]

- Starr, G.; Petersen, M.A.; Jespersen, B.M.; Hansen, Å.S. Variation of Volatile Compounds among Wheat Varieties and Landraces. Food Chem. 2015, 174, 527–537. [Google Scholar] [CrossRef]

- Belz, M.; Axel, C.; Beauchamp, J.; Zannini, E.; Arendt, E.; Czerny, M. Sodium Chloride and Its Influence on the Aroma Profile of Yeasted Bread. Foods 2017, 6, 66. [Google Scholar] [CrossRef]

- Hansen, A.; Schieberle, P. Generation of Aroma Compounds during Sourdough Fermentation: Applied and Fundamental Aspects. Trends Food Sci. Technol. 2005, 16, 85–94. [Google Scholar] [CrossRef]

- Plessas, S.; Bekatorou, A.; Gallanagh, J.; Nigam, P.; Koutinas, A.A.; Psarianos, C. Evolution of Aroma Volatiles during Storage of Sourdough Breads Made by Mixed Cultures of Kluyveromyces marxianus and Lactobacillus delbrueckii ssp. bulgaricus or Lactobacillus helveticus. Food Chem. 2008, 107, 883–889. [Google Scholar] [CrossRef]

- Campo, E.; del Arco, L.; Urtasun, L.; Oria, R.; Ferrer-Mairal, A. Impact of Sourdough on Sensory Properties and Consumers’ Preference of Gluten-Free Breads Enriched with Teff Flour. J. Cereal Sci. 2016, 67, 75–82. [Google Scholar] [CrossRef]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel Insights on the Functional/Nutritional Features of the Sourdough Fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Arneborg, N.; Hansen, Å.S. Influence of Commercial Baker’s Yeasts on Bread Aroma Profiles. Food Res. Int. 2013, 52, 160–166. [Google Scholar] [CrossRef]

- Ua-Arak, T.; Jakob, F.; Vogel, R.F. Influence of Levan-Producing Acetic Acid Bacteria on Buckwheat-Sourdough Breads. Food Microbiol. 2017, 65, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Gänzle, M.G.; Vermeulen, N.; Vogel, R.F. Carbohydrate, Peptide and Lipid Metabolism of Lactic Acid Bacteria in Sourdough. Food Microbiol. 2007, 24, 128–138. [Google Scholar] [CrossRef] [PubMed]

- Mikael, V.; Katina, K.; Nordlund, E.; Poutanen, K.; Hanhineva, K. Changes in the Phytochemical Profile of Rye Bran Induced by Enzymatic Bioprocessing and Sourdough Fermentation. FRIN 2016, 89, 1106–1115. [Google Scholar] [CrossRef]

- Morris, C.; Morris, G.A. The Effect of Inulin and Fructo-Oligosaccharide Supplementation on the Textural, Rheological and Sensory Properties of Bread and Their Role in Weight Management: A Review. Food Chem. 2012, 133, 237–248. [Google Scholar] [CrossRef]

- Bartkiene, E.; Schleining, G.; Juodeikiene, G.; Vidmantiene, D.; Krungleviciute, V.; Rekstyte, T.; Basinskiene, L.; Stankevicius, M.; Akuneca, I.; Ragazinskiene, O.; et al. The Influence of Lactic Acid Fermentation on Biogenic Amines and Volatile Compounds Formation in Flaxseed and the Effect of Flaxseed Sourdough on the Quality of Wheat Bread. LWT-Food Sci. Technol. 2014, 56, 445–450. [Google Scholar] [CrossRef]

- Bianchi, F.; Careri, M.; Chiavaro, E.; Musci, M.; Vittadini, E. Gas Chromatographic-Mass Spectrometric Characterisation of the Italian Protected Designation of Origin “Altamura” Bread Volatile Profile. Food Chem. 2008, 110, 787–793. [Google Scholar] [CrossRef]

- Purlis, E. Browning Development in Bakery Products-A Review. J. Food Eng. 2010, 99, 239–249. [Google Scholar] [CrossRef]

- Grosch, W.; Schieberle, P. Flavor of Cereal Products. Cereal Chem. 1997, 74, 91–97. [Google Scholar] [CrossRef]

- Sabovics, M.; Straumite, E.; Galoburda, R. The Influence of Baking Temperature on the Quality of Triticale Bread. In Proceedings of the 9th Baltic Conference on Food Science and Technology “Food for Consumer Well-Being”, Jelgava, Latvia, 8–9 May 2014; pp. 228–233. [Google Scholar]

- Sabovics, M.; Straumite, E.; Galoburda, R. Assessment of the Rheological Properties of Flour Using the Mixolab. In Proceedings of the 6th Baltic Conference on Food Science and Technology ‘Innovations for Food Science and Production’ FOODBALT-2011, Jelgava, Latvia, 5–6 May 2011; pp. 33–38. [Google Scholar]

- Sabovics, M. The Evaluation of Triticale Bread Quality and its Volatile Compounds. Ph.D. Thesis, Latvia University of Agriculture, Jelgava, Latvia, 2014. [Google Scholar]

- Sabovics, M.; Straumite, E.; Galoburda, R. Detection of Volatile Compounds in Dough during Mixing. In CEFood 2012—Proceedings of 6th Central European Congress on Food; Levic, J., Ed.; Institute of Food Technology: Novi Sad, Serbia, 2012; pp. 650–655. [Google Scholar]

- Sabovics, M.; Straumite, E.; Galoburda, R. Detection of Volatile Compounds during Wheat Dough Fermentation. In Research for Rural Development; Latvia University of Agriculture: Jelgava, Latvia, 2011; Volume 1, pp. 93–99. [Google Scholar]

- Pétel, C.; Onno, B.; Prost, C. Sourdough Volatile Compounds and Their Contribution to Bread: A Review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Pico, J.; Martínez, M.M.; Bernal, J.; Gómez, M. Evolution of Volatile Compounds in Gluten-Free Bread: From Dough to Crumb. Food Chem. 2017, 227, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhu, X.; Bi, Y.; Zhao, R.; Nie, Y.; Yuan, W. Dynamics of Microbial Community and Changes of Metabolites during Production of Type Ι Sourdough Steamed Bread Made by Retarded Sponge-Dough Method. Food Chem. 2020, 330, 127316. [Google Scholar] [CrossRef] [PubMed]

- Mantzourani, I.; Plessas, S.; Odatzidou, M.; Alexopoulos, A.; Galanis, A.; Bezirtzoglou, E.; Bekatorou, A. Effect of a Novel Lactobacillus Paracasei Starter on Sourdough Bread Quality. Food Chem. 2019, 271, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Karlberg, A.-T.; Magnusson, K.; Nilsson, U. Air Oxidation of d-Limonene (the Citrus Solvent) Creates Potent Allergens. Contact Dermat. 1992, 26, 332–340. [Google Scholar] [CrossRef]

- Schieberle, P. Intense Aroma Compounds: Useful Tools to Monitor the Influence of Processing and Storage on Bread Aroma. Adv. Food Sci. 1996, 18, 237–244. [Google Scholar]

- Nor Qhairul Izzreen, M.N.; Hansen, Å.S.; Petersen, M.A. Volatile Compounds in Whole Meal Bread Crust: The Effects of Yeast Level and Fermentation Temperature. Food Chem. 2016, 210, 566–576. [Google Scholar] [CrossRef]

- Parker, J.K. 1-Introduction to Aroma Compounds in Foods. In Woodhead Publishing Series in Food Science, Technology and Nutrition; Parker, J.K., Elmore, J.S., Methven, L., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 3–30. [Google Scholar] [CrossRef]

- Pozo-Bayón, M.A.; Guichard, E.; Cayot, N. Flavor Control in Baked Cereal Products. Food Rev. Int. 2006, 22, 335–379. [Google Scholar] [CrossRef]

| Volatile Compounds | Sourdough Type | |

|---|---|---|

| TKS | SFS | |

| Acetic acid | 23.36 ± 0.17 b | 48.15 ± 0.95 a |

| Butyl acetate | n.d. | 0.27 ± 0.03 |

| Ethanol | 32.16 ± 0.28 | 13.99 ± 0.61 |

| Ethyl acetate | 34.32 ± 0.42 a | 28.99 ± 0.61 b |

| Ethyl hexonoate | 0.14 ± 0.00 | n.d. |

| Hexanal | n.d. | 0.16 ± 0.00 |

| Hexanoic acid | 0.43 ± 0.03 | n.d. |

| 1-Hexanol | n.d. | 4.91 ± 0.01 |

| Isoamyl acetate | 0.25 ± 0.01 b | 1.85 ± 0.04 a |

| 3-Methyl-1-butanol | 1.60 ± 0.04 a | 1.25 ± 0.09 b |

| 4-Methyl-1-pentene | 6.86 ± 0.05 | n.d. |

| 1-Pentanol | 0.54 ± 0.01 | n.d. |

| 1-Penten-3-ol | 0.11 ± 0.01 | n.d. |

| Phenylethyl alcohol | 0.23 ± 0.00 | n.d. |

| N-Propylacetate | n.d. | 0.43 ± 0.02 |

| TOTAL | 100.0 | 100.0 |

| Parameters | Flour Blend Bread | Triticale Bread with Two-Stage Sourdough | Triticale Bread with Sapore Fidelio Sourdough |

|---|---|---|---|

| Moisture, % | 43.74 ± 0.07 c | 45.13 ± 0.04 a | 44.17 ± 0.03 b |

| Water activity | 0.959 ± 0.001 a | 0.968 ± 0.001 a | 0.957 ± 0.001 a |

| pH | 5.196 ± 0.007 a | 4.642 ± 0.03 b | 4.377 ± 0.008 b |

| Acidity, ° | 3.32 ± 0.04 c | 5.18 ±0.08 b | 6.02 ± 0.05 a |

| Crumb colour | |||

| L* | 52.84 ± 0.57 a | 54.28 ± 0.53 a | 54.94 ± 0.65 a |

| a* | 0.61 ± 0.13 a | 0.59 ± 0.08 a | 0.53 ± 0.06 a |

| b* | 22.81 ± 0.55 a | 22.63 ± 0.68 a | 22.51 ± 0.77 a |

| Crust colour | |||

| L* | 40.54 ± 0.70 a | 39.84 ± 0.77 a | 39.36 ± 0.69 a |

| a* | 4.41 ±0.13 a | 5.32 ± 0.11 a | 5.84 ± 0.47 a |

| b* | 22.72 ± 0.42 a | 20.34 ± 0.60 a | 19.97 ± 0.94 a |

| Crumb hardness, N | 14.53 ± 0.83 a | 12.05 ± 0.25 b | 14.01 ± 0.37 a |

| Crumb stickiness, N | −0.56 ± 0.04 b | −0.96 ± 0.04 a | −0.60 ± 0.03 b |

| Volatile Compounds | RT | LRI | Triticale Bread | TKS-B | SFS-B | Organoleptic Characteristic a,b,c,d,e,f | |||

|---|---|---|---|---|---|---|---|---|---|

| Crumb | Crust | Crumb | Crust | Crumb | Crust | ||||

| Aldehydes | |||||||||

| Heptanal | 15.37 | 1204 | 13.40 ± 0.57 | 15.29 ± 0.40 | 15.14 ± 0.48 | 17.72 ± 0.08 | 13.58 ± 0.77 | 16.08 ± 0.57 | Fresh, aldehydic, fatty, green, burgundy, ozone, grass |

| Hexanal | 12.25 | 1103 | 17.26 ± 0.36 | 13.9 ± 0.17 | 34.98 ± 0.53 | 15.2 ± 0.38 | 25.6 ± 0.52 | 13.11 ± 0.10 | Fresh, green, grass, fatty, aldehydic, leafy, fruity, flowery |

| 3-Methylbutanal | 7.01 | 926 | 5.7 ± 0.02 | 17.36 ± 0.11 | 13.8 ± 0.07 | 14.57 ± 0.62 | 29.07 ± 0.72 | 64.79 ± 0.90 | Malty, roasty, cucumber-like |

| 2-Methylpropanal | 5.07 | 805 | 1.01 ± 0.01 | 6.25 ± 0.06 | 3.52 ± 0.24 | 11.23 ± 0.84 | 2.08 ± 0.10 | 8.64 ± 1.03 | Wet cereal or straw |

| Alcohols | |||||||||

| Cyclobutanol | 3.77 | 667 | 1.68 ± 0.05 | 3.54 ± 0.03 | 4.46 ± 0.07 | 5.91 ± 0.05 | 2.48 ± 0.05 | 4.01 ± 0.01 | Roasted |

| Ethanol | 7.29 | 942 | 214.97 ± 2.80 | 171.68 ± 2.37 | 286.71 ± 3.08 | 254.84 ± 0.09 | 259.16 ± 7.95 | 204.63 ± 5.98 | Strong, alcohol, medicinal |

| 1-Hexanol | 19.99 | 1382 | 51.78 ± 054 | 17.76 ± 0.70 | n.d. | n.d. | n.d. | 11.79 ± 0.12 | Ethereal, oil, alcohol, green, grass, fruity sweet, woody, floral |

| 3-Methyl-1-butanol | 16.22 | 1247 | 103.47 ± 0.75 | 43.72 ± 1.17 | 121.62 ± 2.83 | 58.58 ± 0.40 | 105.13 ± 2.80 | 49.38 ± 0.23 | Oil, alcohol, fruity, banana, malty, almond, sweet, balsamic |

| 2-Methyl-1-propanol (Isobutyl alcohol) | 12.79 | 1209 | 12.4 ± 0.23 | 7.52 ± 0.11 | 12.65 ± 0.34 | 8.28 ± 0.27 | 11.76 ± 0.66 | 8.27 ± 0.20 | Ethereal, winey, alcohol, malty |

| 1-Pentanol | 17.02 | 1306 | n.d. | n.d. | 14.83 ± 0.22 | 1.76 ± 0.12 | 2.07 ± 0.05 | 0.24 ± 0.01 | Oil, sweet, balsamic, fruity |

| 2-Phenylethyl alcohol | 31.20 | 1738 | 13.03 ± 0.03 | 9.25 ± 0.40 | 28.56 ± 1.67 | 16.61 ± 0.72 | 14.86 ± 0.50 | 11.97 ± 0.98 | Sweet, floral, fresh and bready with a honey nuance |

| Ketones | |||||||||

| 3-Hydroxy-2-butanone (Acetoin) | 18.71 | 1314 | 10.79 ± 0.08 | 6.36 ± 0.39 | 12.04 ± 1.01 | 7.01 ± 0.22 | 10.92 ± 096 | 7.01 ± 0.62 | Sweet, butter, creamy, dairy product, caramel, fatty |

| 3-Methyl-2-butanone | 9.07 | 1001 | n.d. | n.d. | 16.46 ± 0.71 | 4.21 ± 0.22 | 10.74 ± 0.06 | 2.06 ± 0.04 | Camphor |

| Acids | |||||||||

| Acetic acid | 22.50 | 1454 | 7.7 ± 0.43 | 14.12 ± 1.04 | 7.13 ± 0.62 | 14.72 ± 0.504 | 9.41 ± 0.17 | 40.83 ± 1.67 | Sharp, acrid, vinegar, sour |

| Butanoic acid (Butyric acid) | 26.27 | 1573 | n.d. | n.d. | 0.76 ± 0.09 | 0.74 ± 0.01 | 1.31 ± 0.57 | 141.64 ± 3.06 | Sharp, acetic, cheesy, butter, fruity, sweet, sour, sweat, Parmesan, rancid |

| Hexanoic acid (Caproic acid) | 30.01 | 1698 | 3.1 ± 0.07 | 5.17 ± 0.07 | 7.93 ± 0.09 | 21.36 ± 0.13 | 5.07 ± 0.29 | 18.13 ± 1.09 | Sour, fatty, sweat, cheesy, goat like |

| 2-Methyl-propanoic acid (Isobutyric acid) | 25.03 | 1532 | 3.06 ± 0.02 | 1.04 ± 0.08 | 2.13 ± 0.31 | 7.21 ± 0.18 | 2.97 ± 0.11 | 7.21 ± 0.05 | Acidic, sour |

| 3-Methyl-butanoic acid (Isovaleric acid) | 27.07 | 1600 | 4.83 ± 0.16 | n.d. | 5.01 ± 0.08 | 1.13 ± 0.05 | 5.96 ± 0.09 | 7.22 ± 0.20 | Parmesan cheese, sweaty, butter, fatty, sour, rancid |

| Pentanoic acid | 29.29 | 1674 | n.d. | n.d. | 4.29 ± 0.35 | 1.6 ± 0.02 | n.d. | n.d. | Stinky, putrid, acidic, sweat, rancid, acrid |

| Heterocyclic Compounds | |||||||||

| 2-Furan methanol | 27.05 | 1599 | n.d. | 71.4 ± 0.59 | n.d. | 141.43 ± 1.77 | n.d. | 1.3 ± 0.05 | Alcohol, chemical, bread, coffee, musty, sweet, caramel, brunt, oil, earthy |

| Furfural (2-Furaldehyde) | 23.01 | 1469 | 7.37 ± 0.09 | 13.32 ± 0.04 | 8.42 ± 1.99 | 46.73 ± 0.65 | 9.25 ± 0.02 | 6.57 ± 0.13 | Sweet, woody, almond, bread, rancid, roasted, toasted |

| 2-Methylfuran | 17.87 | 1328 | n.d. | n.d. | n.d. | 33.13 ± 0.55 | n.d. | 22.77 ± 0.09 | Ethereal, acetone, chocolate |

| 5-Methyl-2-furfural | 25.43 | 1546 | n.d. | n.d. | n.d. | 7.53 ± 0.18 | n.d. | 0.91 ± 0.10 | Spicy, caramel, maple, almond |

| Maltol (3-Hydroxy-2-methyl-4-pyrone) | 32.13 | 1768 | 4.56 ± 0.09 | 6.23 ± 0.13 | 8.84 ± 0.63 | 19.65 ± 1.75 | 5.3 ± 0.14 | 13.87 ± 1.37 | Caramel, warmy-fruity |

| Pyrrole | 28.15 | 1636 | n.d. | n.d. | n.d. | 10.96 ± 0.72 | n.d. | 12.09 ± 0.87 | Nut |

| Others | |||||||||

| Carvone | 28.62 | 1652 | 4.9 ± 0.05 | 6.13 ± 0.11 | n.d. | n.d. | n.d. | n.d. | Mint, licorice |

| Tridecane | 18.26 | 1338 | n.d. | 9.11 ± 0.09 | n.d. | 2.18 ± 0.04 | n.d. | 2.28 ± 0.24 | Alkane |

| n.i. | 23.94 | 1496 | n.d. | n.d. | n.d. | 12.74 ± 0.51 | n.d. | 6.51 ± 0.38 | - |

| n.i. | 35.16 | 1868 | n.d. | n.d. | 7.09 ± 0.13 | 20.46 ± 0.76 | n.d. | n.d. | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galoburda, R.; Straumite, E.; Sabovics, M.; Kruma, Z. Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread. Foods 2020, 9, 1837. https://doi.org/10.3390/foods9121837

Galoburda R, Straumite E, Sabovics M, Kruma Z. Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread. Foods. 2020; 9(12):1837. https://doi.org/10.3390/foods9121837

Chicago/Turabian StyleGaloburda, Ruta, Evita Straumite, Martins Sabovics, and Zanda Kruma. 2020. "Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread" Foods 9, no. 12: 1837. https://doi.org/10.3390/foods9121837

APA StyleGaloburda, R., Straumite, E., Sabovics, M., & Kruma, Z. (2020). Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread. Foods, 9(12), 1837. https://doi.org/10.3390/foods9121837