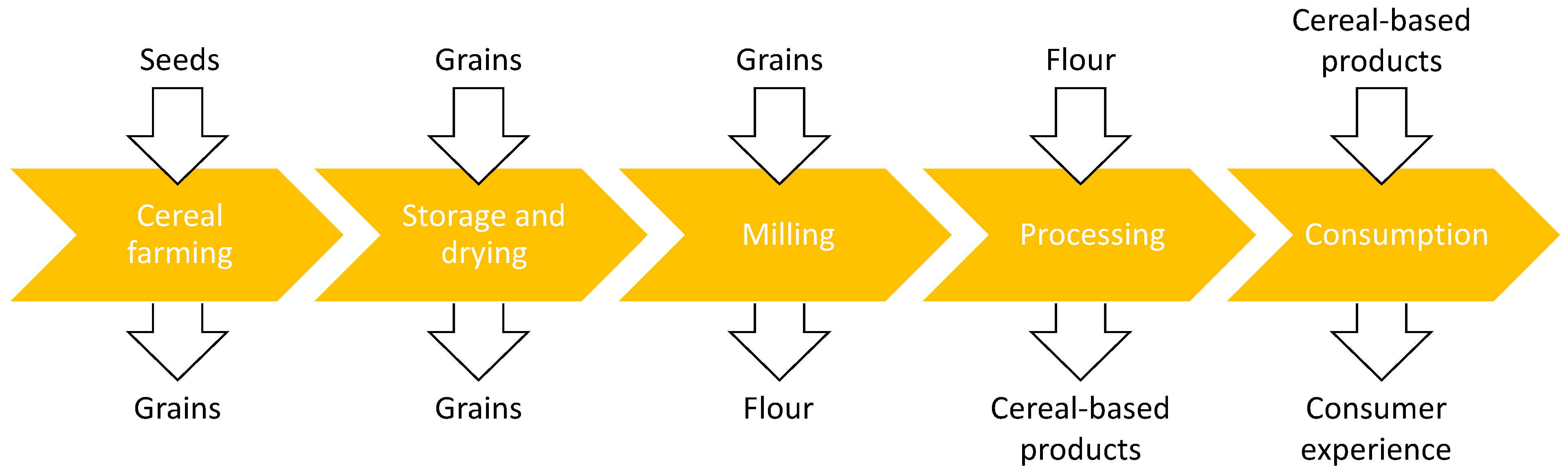

Modelling Processes and Products in the Cereal Chain

Abstract

1. Introduction

2. Modelling Cereal Farming

3. Modelling Storage

4. Modelling Drying

5. Modelling Milling

6. Modelling Processing

6.1. Wheat Flour Mixing

6.2. Forming Processes and Extrusion

6.3. Baking

6.4. Rice Cooking

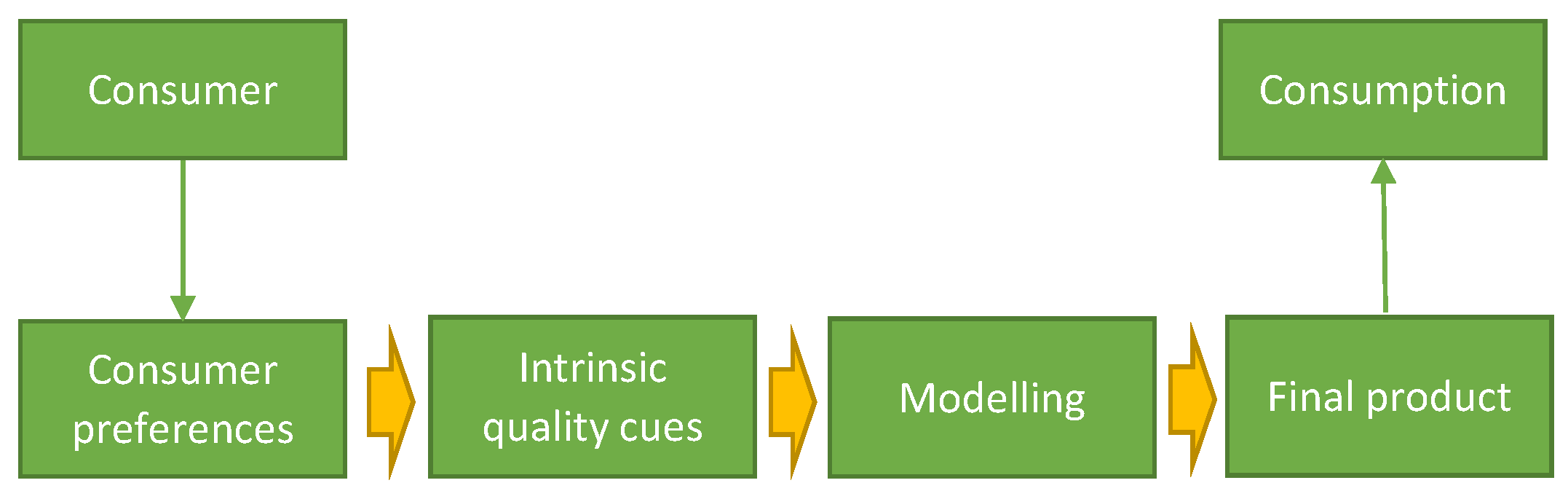

7. Modelling Properties of Cereal Products and Characteristics of Consumption

8. Modelling the Whole Chain

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abecassis, J.; Cuq, B.; Escudier, J.L.; Garric, G.; Kondjoyan, A.; Planchot, V.; Salmon, J.M.; de Vries, H. Food chains; the cradle for scientific ideas and the target for technological innovations. Innov. Food Sci. Emerg. Technol. 2018, 46, 7–17. [Google Scholar] [CrossRef]

- Van Asselt, E.; Meuwissen, M.; Van Asseldonk, M.; Teeuw, J.; Van der Fels-Klerx, H. Selection of critical factors for identifying emerging food safety risks in dynamic food production chains. Food Control 2010, 21, 919–926. [Google Scholar] [CrossRef] [PubMed]

- Lara, C.A.A.; Athès, V.; Buche, P.; Della Valle, G.; Farines, V.; Fonseca, F.; Guillard, V.; Kansou, K.; Kristiawan, M.; Monclus, V.; et al. The virtual food system: Innovative models and experiential feedback in technologies for winemaking, the cereals chain, food packaging and eco-designed starter production. Innov. Food Sci. Emerg. Technol. 2018, 46, 54–64. [Google Scholar] [CrossRef]

- Courtonne, J.Y.; Alapetite, J.; Longaretti, P.Y.; Dupré, D.; Prados, E. Downscaling material flow analysis: The case of the cereal supply chain in France. Ecol. Econ. 2015, 118, 67–80. [Google Scholar] [CrossRef]

- Trystram, G. Modelling of food and food processes. J. Food Eng. 2012, 110, 269–277. [Google Scholar] [CrossRef]

- Djekic, I.; Sanjuán, N.; Clemente, G.; Jambrak, A.R.; Djukić-Vuković, A.; Brodnjak, U.V.; Pop, E.; Thomopoulos, R.; Tonda, A. Review on environmental models in the food chain-Current status and future perspectives. J. Clean. Prod. 2018, 176, 1012–1025. [Google Scholar] [CrossRef]

- Fei, S.; Ni, J.; Santini, G. Local food systems and COVID-19: An insight from China. Resour. Conserv. Recycl. 2020, 162, 105022. [Google Scholar] [CrossRef]

- Djekic, I.; Nikolić, A.; Uzunović, M.; Marijke, A.; Liu, A.; Han, J.; Brnčić, M.; Knežević, N.; Papademas, P.; Lemoniati, K.; et al. Covid-19 pandemic effects on food safety—Multi-country survey study. Food Control 2021, 122, 107800. [Google Scholar] [CrossRef]

- Chlingaryan, A.; Sukkarieh, S.; Whelan, B. Machine learning approaches for crop yield prediction and nitrogen status estimation in precision agriculture: A review. Comput. Electron. Agric. 2018, 151, 61–69. [Google Scholar] [CrossRef]

- Gabrielle, B.; Laville, P.; Hénault, C.; Nicoullaud, B.; Germon, J.C. Simulation of nitrous oxide emissions from wheat-cropped soils using CERES. Nutr. Cycl. Agroecosyst. 2006, 74, 133–146. [Google Scholar] [CrossRef][Green Version]

- Kiniry, J.R.; Williams, J.R.; Major, D.; Izaurralde, R.; Gassman, P.W.; Morrison, M.; Bergentine, R.; Zentner, R. EPIC model parameters for cereal, oilseed, and forage crops in the northern Great Plains region. Can. J. Plant Sci. 1995, 75, 679–688. [Google Scholar] [CrossRef]

- Nendel, C.; Berg, M.; Kersebaum, K.C.; Mirschel, W.; Specka, X.; Wegehenkel, M.; Wenkel, K.; Wieland, R. The MONICA model: Testing predictability for crop growth, soil moisture and nitrogen dynamics. Ecol. Model. 2011, 222, 1614–1625. [Google Scholar] [CrossRef]

- Philips, P.; O’Callaghan, J. Cereal harvesting—A mathematical model. J. Agric. Eng. Res. 1974, 19, 415–433. [Google Scholar] [CrossRef]

- McGechan, M. A parametric study of cereal harvesting models I. Critical assessment of measured data on parameter variability. J. Agric. Eng. Res. 1985, 31, 149–158. [Google Scholar] [CrossRef]

- Niven, B. The stochastic simulation of Tribolium populations. Physiol. Zool. 1967, 40, 67–82. [Google Scholar] [CrossRef]

- Gordon, D.; Gurney, W.; Nisbet, R.; Stewart, R. A model of Cadra cautella larval growth and development. J. Anim. Ecol. 1988, 57, 645–657. [Google Scholar] [CrossRef]

- Campbell, A.; Sinha, R. Analysis and simulation modelling of population dynamics and bioenergetics of Cryptolestes ferrugineus (Coleoptera: Cucujidae) in stored wheat. Res. Popul. Ecol. 1990, 32, 235–254. [Google Scholar] [CrossRef]

- Longstaff, B. The role of modelling in the management of stored-product pests. In Proceedings of the International Working Conference on Stored-Product Protection, Bordeaux, France, 9–14 September 1990; pp. 1995–2007. [Google Scholar]

- Hardman, J. A logistic model simulating environmental changes associated with the growth of populations of rice weevils, Sitophilus oryzae, reared in small cells of wheat. J. Appl. Ecology 1978, 15, 65–87. [Google Scholar] [CrossRef]

- Hagstrum, D.W.; Heid, W.G., Jr. US wheat-marketing system: An insect ecosystem. Bull. ESA 1988, 34, 33–37. [Google Scholar]

- Hagstrum, D.W.; Throne, J.E. Predictability of stored-wheat insect population trends from life history traits. Environ. Entomol. 1989, 18, 660–664. [Google Scholar] [CrossRef]

- Flinn, P.; Hagstrum, D. Simulations comparing the effectiveness of various stored-grain management practices used to control Rhyzopertha dominica (Coleoptera: Bostrichidae). Environ. Entomol. 1990, 19, 725–729. [Google Scholar] [CrossRef]

- Hagstrum, D.W.; Flinn, P.W. Simulations comparing insect species differences in response to wheat storage conditions and management practices. J. Econ. Entomol. 1990, 83, 2469–2475. [Google Scholar] [CrossRef]

- Throne, J.E. Effects of noncatastrophic control technologies that alter life history parameters on insect population growth: A simulation study. Environ. Entomol. 1989, 18, 1050–1055. [Google Scholar] [CrossRef]

- Longstaff, B.C. Decision tools for grain storage pest management. J. Stored Prod. Res. 1997, 33, 99–114. [Google Scholar] [CrossRef]

- Kawamoto, H.; Sinha, R.; Muir, W. Computer simulation modelling for stored-grain pest management. J. Stored Prod. Res. 1992, 28, 139–145. [Google Scholar] [CrossRef]

- White, N. A multidisciplinary approach to stored-grain research. J. Stored Prod. Res. 1992, 28, 127–137. [Google Scholar] [CrossRef]

- Flinn, P.W.; Hagstrum, D.W. Stored Grain Advisor: A knowledge-based system for management of insect pests of stored grain. AI Appl. 1990, 4, 44–52. [Google Scholar]

- Mann, D.D.; Jayas, D.S.; White, N.D.G.; Muir, W.E.; Evans, M.S. Grain storage information system for Canadian farmers and grain storage managers. Can. Agric. Eng. 1997, 39, 49–56. [Google Scholar]

- Ndiaye, A.; Ndiaye, S.; Fleurat-Lessard, F. QualiGrain Expert system for stored grain quality maintenance: Planning optimal storage technical routes. In Advances in Stored Product Protection, Proceedings of the 8th International Working Conference on Stored Product Protection, York, UK, 22–26 July 2002; CABI: Waringford, UK, 2002; pp. 978–988. [Google Scholar]

- Huang, H.; Rajotte, E.G.; Li, Z.; Chen, K.; Zhang, S. Qpais: A Web-Based Expert System for Assisted identification of Quarantine Stored Insect Pests. In Proceedings of the International Conference on Computer and Computing Technologies in Agriculture, Beijing, China, 14–17 October 2008; Springer: Boston, MA, USA, 2008; pp. 701–714. [Google Scholar]

- Flinn, P.; Opit, G.; Throne, J. Predicting stored grain insect population densities using an electronic probe trap. J. Econ. Entomol. 2009, 102, 1696–1704. [Google Scholar] [CrossRef]

- Mrema, G.C.; Gumbe, L.O.; Chepete, H.J.; Agullo, J.O. Rural Structures in the Tropics: Design and Development; Food and Agriculture Organization of the United Nations: Rome, Italy, 2012. [Google Scholar]

- Pabis, S.; Jayas, D.S.; Cenkowski, S. Grain Drying: Theory and Practice; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Banga, J.R.; Singh, R.P. Optimization of air drying of foods. J. Food Eng. 1994, 23, 189–211. [Google Scholar] [CrossRef]

- Srivastava, V.; John, J. Deep bed grain drying modeling. Energy Convers. Manag. 2002, 43, 1689–1708. [Google Scholar] [CrossRef]

- Riadh, M.H.; Ahmad, S.A.B.; Marhaban, M.H.; Soh, A.C. Infrared heating in food drying: An overview. Dry. Technol. 2015, 33, 322–335. [Google Scholar] [CrossRef]

- Pawar, S.B.; Pratape, V. Fundamentals of infrared heating and its application in drying of food materials: A review. J. Food Process Eng. 2017, 40, e12308. [Google Scholar] [CrossRef]

- Bon, J.; Kudra, T. Enthalpy-driven optimization of intermittent drying. Dry. Technol. 2007, 25, 523–532. [Google Scholar] [CrossRef]

- Chou, S.; Chua, K.; Mujumdar, A.; Hawlader, M.N.A.; Ho, J. On the intermittent drying of an agricultural product. Food Bioprod. Process. 2000, 78, 193–203. [Google Scholar] [CrossRef]

- Song, G.; Choudhary, R.; Watson, D.G. Microwave drying kinetics and quality characteristics of corn. Int. J. Agric. Biol. Eng. 2013, 6, 90–99. [Google Scholar]

- Wang, Z.; Sun, J.; Chen, F.; Liao, X.; Hu, X. Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J. Food Eng. 2007, 80, 536–544. [Google Scholar] [CrossRef]

- Shivhare, U.; Raghavan, G.; Bosisio, R. Microwave drying of corn II. Constant power, continuous operation. Trans. ASAE 1992, 35, 951–957. [Google Scholar] [CrossRef]

- Shivhare, U.; Raghavan, G.; Bosisio, R. Modelling the drying kinetics of maize in a microwave environment. J. Agric. Eng. Res. 1994, 57, 199–205. [Google Scholar] [CrossRef]

- García-Pérez, J.; Cárcel, J.; De la Fuente-Blanco, S.; De Sarabia, E.R.F. Ultrasonic drying of foodstuff in a fluidized bed: Parametric study. Ultrasonics 2006, 44, e539–e543. [Google Scholar] [CrossRef]

- García-Pérez, J.V.; Cárcel, J.A.; Riera, E.; Mulet, A. Influence of the Applied Acoustic Energy on the Drying of Carrots and Lemon Peel. Dry. Technol. 2009, 27, 281–287. [Google Scholar] [CrossRef]

- Rodríguez, J.; Mulet, A.; Bon, J. Influence of high-intensity ultrasound on drying kinetics in fixed beds of high porosity. J. Food Eng. 2014, 127, 93–102. [Google Scholar] [CrossRef]

- Goh, S.; Charalambides, M.; Williams, J. On the mechanics of wire cutting of cheese. Eng. Fract. Mech. 2005, 72, 931–946. [Google Scholar] [CrossRef]

- Skamniotis, C.; Charalambides, M. Development of computational design tools for characterising and modelling cutting in ultra soft solids. Extrem. Mech. Lett. 2020, 40, 100964. [Google Scholar] [CrossRef]

- Skamniotis, C.; Edwards, C.H.; Bakalis, S.; Frost, G.; Charalambides, M. Eulerian-Lagrangian finite element modelling of food flow-fracture in the stomach to engineer digestion. Innov. Food Sci. Emerg. Technol. 2020, 66, 102510. [Google Scholar] [CrossRef]

- Karunasena, H.; Brown, R.J.; Gu, Y.; Senadeera, W. Application of meshfree methods to numerically simulate microscale deformations of different plant food materials during drying. J. Food Eng. 2015, 146, 209–226. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Goswami, T. DEM simulation of flow of black pepper seeds in cryogenic grinding system. J. Food Eng. 2017, 196, 36–51. [Google Scholar] [CrossRef]

- Rathnayaka, C.; Karunasena, H.; Senadeera, W.; Gu, Y. Application of a coupled smoothed particle hydrodynamics (SPH) and coarse-grained (CG) numerical modelling approach to study three-dimensional (3-D) deformations of single cells of different food-plant materials during drying. Soft Matter 2018, 14, 2015–2031. [Google Scholar] [CrossRef] [PubMed]

- Sinnott, M.D.; Cleary, P.W.; Harrison, S.M. Peristaltic transport of a particulate suspension in the small intestine. Appl. Math. Model. 2017, 44, 143–159. [Google Scholar] [CrossRef]

- Pojić, M.; Mastilović, J.; Majcen, N. Robustness of the near infrared spectroscopy method determined using univariate and multivariate approach. Food Chem. 2012, 134, 1699–1705. [Google Scholar] [CrossRef] [PubMed]

- Pojić, M.; Rakić, D.; Lazić, Ž. Chemometric optimization of the robustness of the near infrared spectroscopic method in wheat quality control. Talanta 2015, 131, 236–242. [Google Scholar] [CrossRef] [PubMed]

- Affes, R.; Delenne, J.Y.; Monerie, Y.; Radjai, F.; Topin, V. Tensile strength and fracture of cemented granular aggregates. Eur. Phys. J. E 2012, 35, 117. [Google Scholar] [CrossRef] [PubMed]

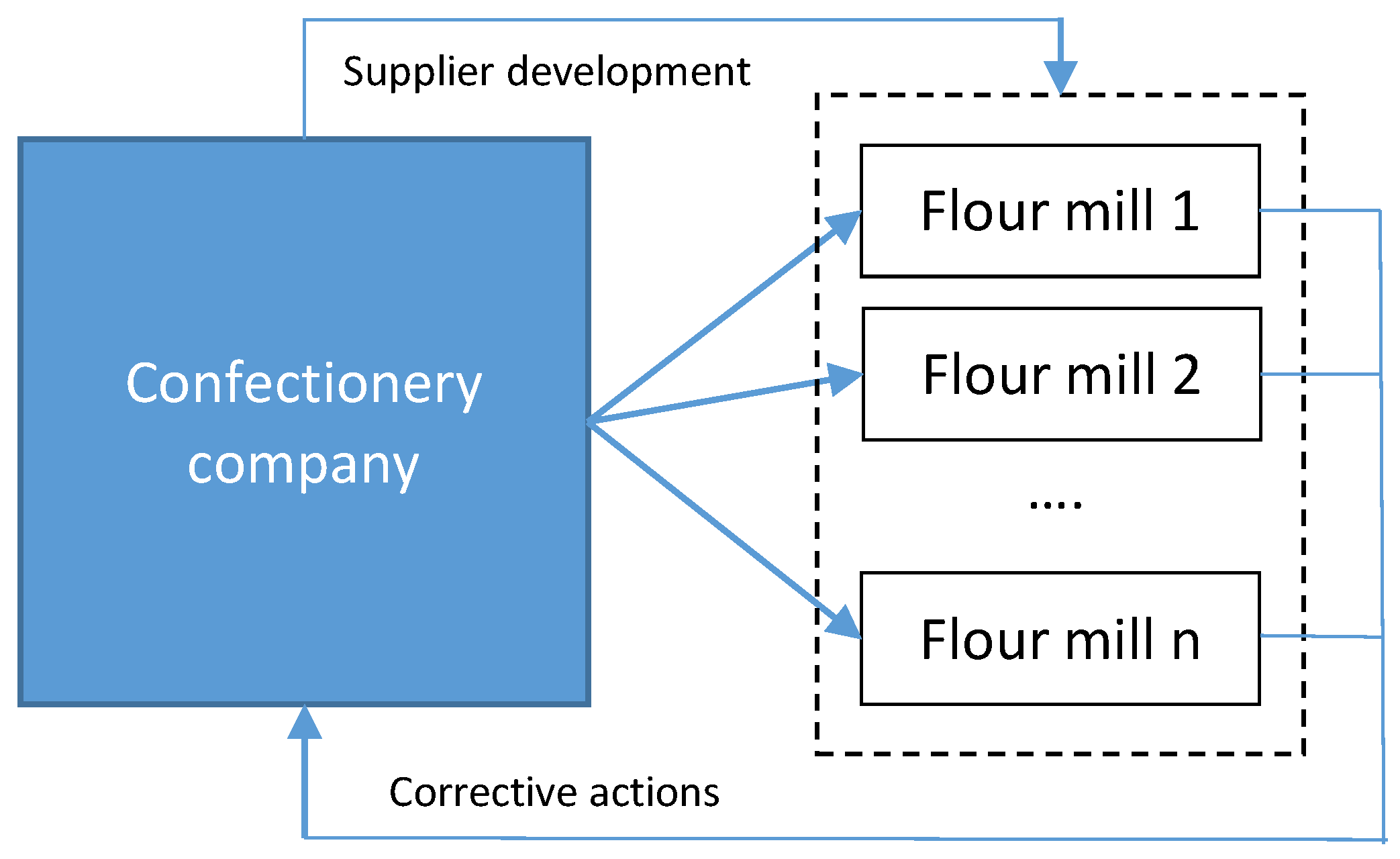

- Djekic, I.; Dragojlovic, S.; Miloradovic, Z.; Miljkovic-Zivanovic, S.; Savic, M.; Kekic, V.; Griffith, C. Improving the confectionery industry supply chain through second party audits. Br. Food J. 2016, 118. [Google Scholar] [CrossRef]

- Djekic, I.; Tomasevic, I.; Zivkovic, N.; Radovanovic, R. Types of food control and application of seven basic quality tools in certified food companies in Serbia. Qual. Assur. Saf. Crop. Foods 2013, 5, 325–332. [Google Scholar] [CrossRef]

- Connelly, R.K.; Kokini, J.L. The effect of shear thinning and differential viscoelasticity on mixing in a model 2D mixer as determined using FEM with particle tracking. J. Non-Newton. Fluid Mech. 2004, 123, 1–17. [Google Scholar] [CrossRef]

- Kansou, K.; Chiron, H.; Della Valle, G.; Ndiaye, A.; Roussel, P. Predicting the quality of wheat flour dough at mixing using an expert system. Food Res. Int. 2014, 64, 772–782. [Google Scholar] [CrossRef]

- Della Valle, G.; Chiron, H.; Cicerelli, L.; Kansou, K.; Katina, K.; Ndiaye, A.; Whitworth, M.; Poutanen, K. Basic knowledge models for the design of bread texture. Trends Food Sci. Technol. 2014, 36, 5–14. [Google Scholar] [CrossRef]

- Mohammed, I.K.; Charalambides, M.; Williams, J.; Rasburn, J. Modelling the deformation of a confectionery wafer as a non-uniform sandwich structure. J. Mater. Sci. 2013, 48, 2462–2478. [Google Scholar] [CrossRef]

- Xiao, W.; Charalambides, M.N.; Gordon Williams, J. Sheeting of wheat flour dough. Int. J. Food Sci. Technol. 2007, 42, 699–707. [Google Scholar] [CrossRef]

- Mohammed, I.; Charalambides, M.; Williams, J.; Rasburn, J. Modelling the microstructural evolution and fracture of a brittle confectionery wafer in compression. Innov. Food Sci. Emerg. Technol. 2014, 24, 48–60. [Google Scholar] [CrossRef]

- Le Roux, D.; Vergnes, B.; Chaurand, M.; Abecassis, J. A thermomechanical approach to pasta extrusion. J. Food Eng. 1995, 26, 351–368. [Google Scholar] [CrossRef]

- Sarghini, F.; Cavella, S.; Torrieri, E.; Masi, P. Experimental analysis of mass transport and mixing in a single screw extruder for semolina dough. J. Food Eng. 2005, 68, 497–503. [Google Scholar] [CrossRef]

- Xu, J.; Bietz, J.A.; Carriere, C.J. Viscoelastic properties of wheat gliadin and glutenin suspensions. Food Chem. 2007, 101, 1025–1030. [Google Scholar] [CrossRef]

- Sarghini, F.; Romano, A.; Masi, P. Experimental analysis and numerical simulation of pasta dough extrusion process. J. Food Eng. 2016, 176, 56–70. [Google Scholar] [CrossRef]

- Ficarella, A.; Milanese, M.; Laforgia, D. Numerical study of the extrusion process in cereals production: Part I. Fluid-dynamic analysis of the extrusion system. J. Food Eng. 2006, 73, 103–111. [Google Scholar] [CrossRef]

- Della Valle, G.; Barres, C.; Plewa, J.; Tayeb, J.; Vergnes, B. Computer simulation of starchy products’ transformation by twin-screw extrusion. J. Food Eng. 1993, 19, 1–31. [Google Scholar] [CrossRef]

- Kristiawan, M.; Della Valle, G.; Kansou, K.; Ndiaye, A.; Vergnes, B. Validation and use for product optimization of a phenomenological model of starch foods expansion by extrusion. J. Food Eng. 2019, 246, 160–178. [Google Scholar] [CrossRef]

- Feyissa, A.H.; Gernaey, K.; Ashokkumar, S.; Adler-Nissen, J. Modelling of coupled heat and mass transfer during a contact baking process. J. Food Eng. 2011, 106, 228–235. [Google Scholar] [CrossRef]

- Nicolas, V.; Vanin, F.; Grenier, D.; Lucas, T.; Doursat, C.; Flick, D. Modeling bread baking with focus on overall deformation and local porosity evolution. AIChE J. 2016, 62, 3847–3863. [Google Scholar] [CrossRef]

- Nicolas, V.; Glouannec, P.; Ploteau, J.P.; Salagnac, P.; Jury, V. Experiment and multiphysic simulation of dough baking by convection, infrared radiation and direct conduction. Int. J. Therm. Sci. 2017, 115, 65–78. [Google Scholar] [CrossRef]

- Demirkol, E.; Erdogdu, F.; Palazoglu, T.K. A numerical approach with variable temperature boundary conditions to determine the effective heat transfer coefficient values during baking of cookies. J. Food Process Eng. 2006, 29, 478–497. [Google Scholar] [CrossRef]

- Demirkol, E.; Erdoğdu, F.; Palazoğlu, T.K. Analysis of mass transfer parameters (changes in mass flux, diffusion coefficient and mass transfer coefficient) during baking of cookies. J. Food Eng. 2006, 72, 364–371. [Google Scholar] [CrossRef]

- Demirkol, E.; Erdogdu, F.; Palazoglu, T.K. Experimental determination of mass transfer coefficient: Moisture content and humidity ratio driving force approaches during baking. J. Food Process Eng. 2006, 29, 188–201. [Google Scholar] [CrossRef]

- Bett-Garber, K.L.; Champagne, E.T.; Ingram, D.A.; McClung, A.M. Influence of water-to-rice ratio on cooked rice flavor and texture. Cereal Chem. 2007, 84, 614–619. [Google Scholar] [CrossRef]

- Billiris, M.; Siebenmorgen, T.; Wang, Y.J. Rice degree of milling effects on hydration, texture, sensory and energy characteristics. Part 2. Cooking using fixed, water-to-rice ratios. J. Food Eng. 2012, 113, 589–597. [Google Scholar] [CrossRef]

- Hanashiro, I.; Ohta, K.; Takeda, C.; Mizukami, H.; Takeda, Y. Leaching of amylose and amylopectin during cooking of rice grains and their effect on adhesiveness of cooked rice. J. Appl. Glycosci. 2004, 51, 349–354. [Google Scholar] [CrossRef]

- Kasai, M.; Lewis, A.R.; Ayabe, S.; Hatae, K.; Fyfe, C.A. Quantitative NMR imaging study of the cooking of Japonica and Indica rice. Food Res. Int. 2007, 40, 1020–1029. [Google Scholar] [CrossRef][Green Version]

- Takeuchi, S.; Maeda, M.; Gomi, Y.i.; Fukuoka, M.; Watanabe, H. The change of moisture distribution in a rice grain during boiling as observed by NMR imaging. J. Food Eng. 1997, 33, 281–297. [Google Scholar] [CrossRef]

- Vasudeva, S.; Vishwanathan, K.; Aswathanarayana, K.; Swamy, Y.I. Hydration behaviour of food grains and modelling their moisture pick up as per Peleg’s equation: Part I. Cereals. J. Food Sci. Technol. 2010, 47, 34–41. [Google Scholar] [CrossRef]

- Dutta, A.; Chanda, A.; Chakraborty, R. A linear driving force (LDF) approximation of moisture diffusion kinetics in white rice. Int. J. Food Eng. 2008, 4. [Google Scholar] [CrossRef]

- Bello, M.; Tolaba, M.P.; Suarez, C. Factors affecting water uptake of rice grain during soaking. LWT-Food Sci. Technol. 2004, 37, 811–816. [Google Scholar] [CrossRef]

- Briffaz, A.; Bohuon, P.; Méot, J.M.; Pons, B.; Matencio, F.; Dornier, M.; Mestres, C. Modelling of brown rice and limited-water cooking modes and its potential use for texture prediction. J. Food Eng. 2014, 141, 99–106. [Google Scholar] [CrossRef]

- Bello, M.; Tolaba, M.P.; Aguerre, R.J.; Suarez, C. Modeling water uptake in a cereal grain during soaking. J. Food Eng. 2010, 97, 95–100. [Google Scholar] [CrossRef]

- Perez, J.H.; Tanaka, F.; Uchino, T. Modeling of mass transfer and initiation of hygroscopically induced cracks in rice grains in a thermally controlled soaking condition: With dependency of diffusion coefficient to moisture content and temperature—A 3D finite element approach. J. Food Eng. 2012, 111, 519–527. [Google Scholar] [CrossRef]

- Sayar, S.; Turhan, M.; Köksel, H. Application of unreacted-core model to in situ gelatinization of chickpea starch. J. Food Eng. 2003, 60, 349–356. [Google Scholar] [CrossRef]

- Bakalis, S.; Kyritsi, A.; Karathanos, V.T.; Yanniotis, S. Modeling of rice hydration using finite elements. J. Food Eng. 2009, 94, 321–325. [Google Scholar] [CrossRef]

- Sağol, S.; Turhan, M.; Sayar, S. A potential method for determining in situ gelatinization temperature of starch using initial water transfer rate in whole cereals. J. Food Eng. 2006, 76, 427–432. [Google Scholar] [CrossRef]

- Briffaz, A.; Mestres, C.; Matencio, F.; Pons, B.; Dornier, M. Modelling starch phase transitions and water uptake of rice kernels during cooking. J. Cereal Sci. 2013, 58, 387–392. [Google Scholar] [CrossRef]

- Watanabe, H.; Yahata, Y.; Fukuoka, M.; Sakiyama, T.; Mihori, T. The thermodynamic basis for the Relative Water Demand Model that describes non-Fickian water diffusion in starchy foods. J. Food Eng. 2007, 83, 130–135. [Google Scholar] [CrossRef]

- Davey, M.J.; Landman, K.A.; McGuinness, M.J.; Jin, H.N. Mathematical modeling of rice cooking and dissolution in beer production. AIChE J. 2002, 48, 1811–1826. [Google Scholar] [CrossRef]

- Chapwanya, M.; Misra, N. A soft condensed matter approach towards mathematical modelling of mass transport and swelling in food grains. J. Food Eng. 2015, 145, 37–44. [Google Scholar] [CrossRef]

- Briffaz, A.; Bohuon, P.; Méot, J.M.; Dornier, M.; Mestres, C. Modelling of water transport and swelling associated with starch gelatinization during rice cooking. J. Food Eng. 2014, 121, 143–151. [Google Scholar] [CrossRef]

- Patindol, J.; Gu, X.; Wang, Y.J. Chemometric analysis of cooked rice texture in relation to starch fine structure and leaching characteristics. Starch-Stärke 2010, 62, 188–197. [Google Scholar] [CrossRef]

- Yadav, B.; Jindal, V. Water uptake and solid loss during cooking of milled rice (Oryza sativa L.) in relation to its physicochemical properties. J. Food Eng. 2007, 80, 46–54. [Google Scholar] [CrossRef]

- Briffaz, A.; Bohuon, P.; Méot, J.M.; Matignon-Pons, B.; Mestres, C. Modelling of water transport with convection effects on amylose transfer in a swelling, eroding and gelatinizing starchy matrix. J. Food Eng. 2018, 221, 132–140. [Google Scholar] [CrossRef]

- Igoumenidis, P.E.; Iosifidis, S.V.; Lopez-Quiroga, E.; Bakalis, S.; Karathanos, V.T. Absorption of phenolic acids in rice kernels after boiling in spearmint aqueous extracts of different concentrations. A diffusion study. J. Food Sci. 2019, 84, 2859–2867. [Google Scholar] [CrossRef]

- Rocca-Poliméni, R.; Flick, D.; Vasseur, J. A model of heat and mass transfer inside a pressure cooker. J. Food Eng. 2011, 107, 393–404. [Google Scholar] [CrossRef]

- Guessasma, S.; Chaunier, L.; Della Valle, G.; Lourdin, D. Mechanical modelling of cereal solid foods. Trends Food Sci. Technol. 2011, 22, 142–153. [Google Scholar] [CrossRef]

- Fradinho, P.; Nunes, M.C.; Raymundo, A. Developing consumer acceptable biscuits enriched with Psyllium fibre. J. Food Sci. Technol. 2015, 52, 4830–4840. [Google Scholar] [CrossRef]

- Gamonpilas, C.; Charalambides, M.; Williams, J.; Dooling, P.; Gibbon, S. Predicting the mechanical behaviour of starch gels through inverse analysis of indentation data. Appl. Rheol. 2010, 20. [Google Scholar] [CrossRef]

- Forte, A.; D’amico, F.; Charalambides, M.; Dini, D.; Williams, J. Modelling and experimental characterisation of the rate dependent fracture properties of gelatine gels. Food Hydrocoll. 2015, 46, 180–190. [Google Scholar] [CrossRef]

- Skamniotis, C.; Patel, Y.; Charalambides, M.; Elliott, M. Fracture investigation in starch-based foods. Interface Focus 2016, 6, 20160005. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Skamniotis, C.; Elliott, M.; Charalambides, M. On modeling the large strain fracture behaviour of soft viscous foods. Phys. Fluids 2017, 29, 121610. [Google Scholar] [CrossRef]

- Skamniotis, C.; Kamaludin, M.; Elliott, M.; Charalambides, M. A novel essential work of fracture experimental methodology for highly dissipative materials. Polymer 2017, 117, 167–182. [Google Scholar] [CrossRef]

- Brečić, R.; Mesić, Ž.; Cerjak, M. Importance of intrinsic and extrinsic quality food characteristics by different consumer segments. Br. Food J. 2017, 119, 845–862. [Google Scholar] [CrossRef]

- Djekic, I.; Ilic, J.; Guiné, R.P.F.; Tomasevic, I. Can we understand food oral processing using Kano model? Case study with confectionery products. J. Texture Stud. 2020, 51, 861–869. [Google Scholar] [CrossRef]

- Djekic, I.; Zivanovic, D.; Dragojlovic, S.; Dragovic, R. Lean manufacturing effects in a Serbian confectionery company—Case Study. Organizacija 2014, 47, 143–152. [Google Scholar] [CrossRef]

- Djekic, I. Lean Manufacturing in Two Serbian Food Companies—Case Studies. Int. J. Qual. Res. 2012, 6. [Google Scholar]

- Foo, D.C.; Elyas, R. Introduction to Process Simulation. Chem. Eng. Process Simul. 2017, 3–21. [Google Scholar] [CrossRef]

- Ramirez, E.C.; Johnston, D.B.; McAloon, A.J.; Yee, W.; Singh, V. Engineering process and cost model for a conventional corn wet milling facility. Ind. Crops Prod. 2008, 27, 91–97. [Google Scholar] [CrossRef]

- Misailidis, N.; Campbell, G.M.; Du, C.; Sadhukhan, J.; Mustafa, M.; Mateos-Salvador, F.; Weightman, R. Evaluating the feasibility of commercial arabinoxylan production in the context of a wheat biorefinery principally producing ethanol: Part 2. Process simulation and economic analysis. Chem. Eng. Res. Des. 2009, 87, 1239–1250. [Google Scholar] [CrossRef]

- Kwiatkowski, J.R.; McAloon, A.J.; Taylor, F.; Johnston, D.B. Modeling the process and costs of fuel ethanol production by the corn dry-grind process. Ind. Crops Prod. 2006, 23, 288–296. [Google Scholar] [CrossRef]

- Kazi, F.K.; Fortman, J.A.; Anex, R.P.; Hsu, D.D.; Aden, A.; Dutta, A.; Kothandaraman, G. Techno-economic comparison of process technologies for biochemical ethanol production from corn stover. Fuel 2010, 89, S20–S28. [Google Scholar] [CrossRef]

- Lam, K.F.; Leung, C.C.J.; Lei, H.M.; Lin, C.S.K. Economic feasibility of a pilot-scale fermentative succinic acid production from bakery wastes. Food Bioprod. Process. 2014, 92, 282–290. [Google Scholar] [CrossRef]

- Dursun, D.; Koulouris, A.; Dalgıç, A.C. Process Simulation and Techno Economic Analysis of Astaxanthin Production from Agro-Industrial Wastes. Waste Biomass Valorization 2020, 11, 943–954. [Google Scholar] [CrossRef]

- Awika, J.M. Major Cereal Grains Production and Use around the World. In Advances in Cereal Science: Implications to Food Processing and Health Promotion; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2011; pp. 1–13. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, O.; Charalambides, M.N.; Djekić, I.; Athanassiou, C.; Bakalis, S.; Benedito, J.; Briffaz, A.; Castañé, C.; Della Valle, G.; de Sousa, I.M.N.; et al. Modelling Processes and Products in the Cereal Chain. Foods 2021, 10, 82. https://doi.org/10.3390/foods10010082

Carvalho O, Charalambides MN, Djekić I, Athanassiou C, Bakalis S, Benedito J, Briffaz A, Castañé C, Della Valle G, de Sousa IMN, et al. Modelling Processes and Products in the Cereal Chain. Foods. 2021; 10(1):82. https://doi.org/10.3390/foods10010082

Chicago/Turabian StyleCarvalho, Otilia, Maria N. Charalambides, Ilija Djekić, Christos Athanassiou, Serafim Bakalis, Jose Benedito, Aurelien Briffaz, Cristina Castañé, Guy Della Valle, Isabel Maria Nunes de Sousa, and et al. 2021. "Modelling Processes and Products in the Cereal Chain" Foods 10, no. 1: 82. https://doi.org/10.3390/foods10010082

APA StyleCarvalho, O., Charalambides, M. N., Djekić, I., Athanassiou, C., Bakalis, S., Benedito, J., Briffaz, A., Castañé, C., Della Valle, G., de Sousa, I. M. N., Erdogdu, F., Feyissa, A. H., Kavallieratos, N. G., Koulouris, A., Pojić, M., Raymundo, A., Riudavets, J., Sarghini, F., Trematerra, P., & Tonda, A. (2021). Modelling Processes and Products in the Cereal Chain. Foods, 10(1), 82. https://doi.org/10.3390/foods10010082