Cereal- and Fruit-Based Ethiopian Traditional Fermented Alcoholic Beverages

Abstract

:1. Introduction

2. Cereal-Based Traditional Alcoholic Beverages

2.1. Tella

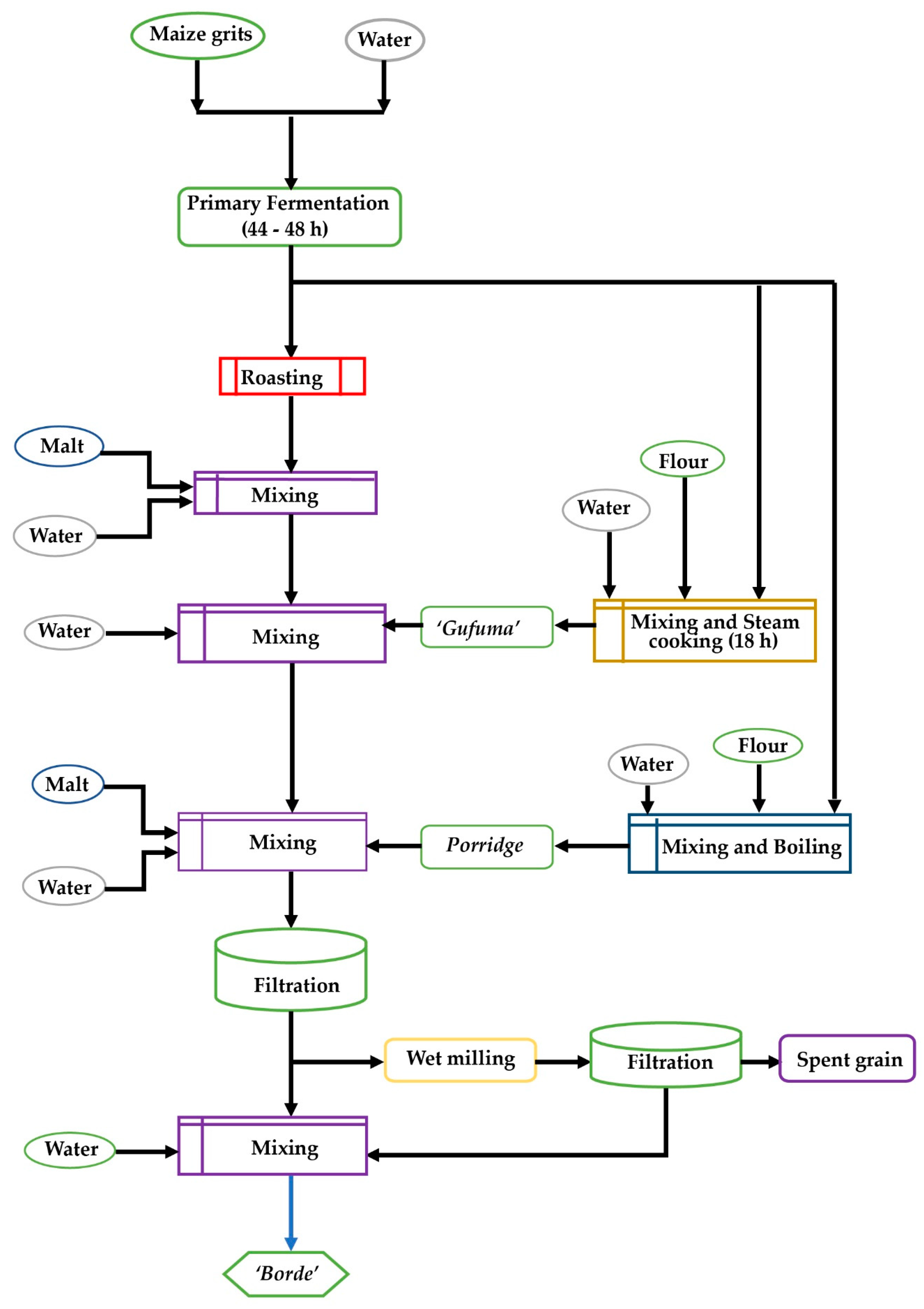

2.2. Borde

2.3. Shamita

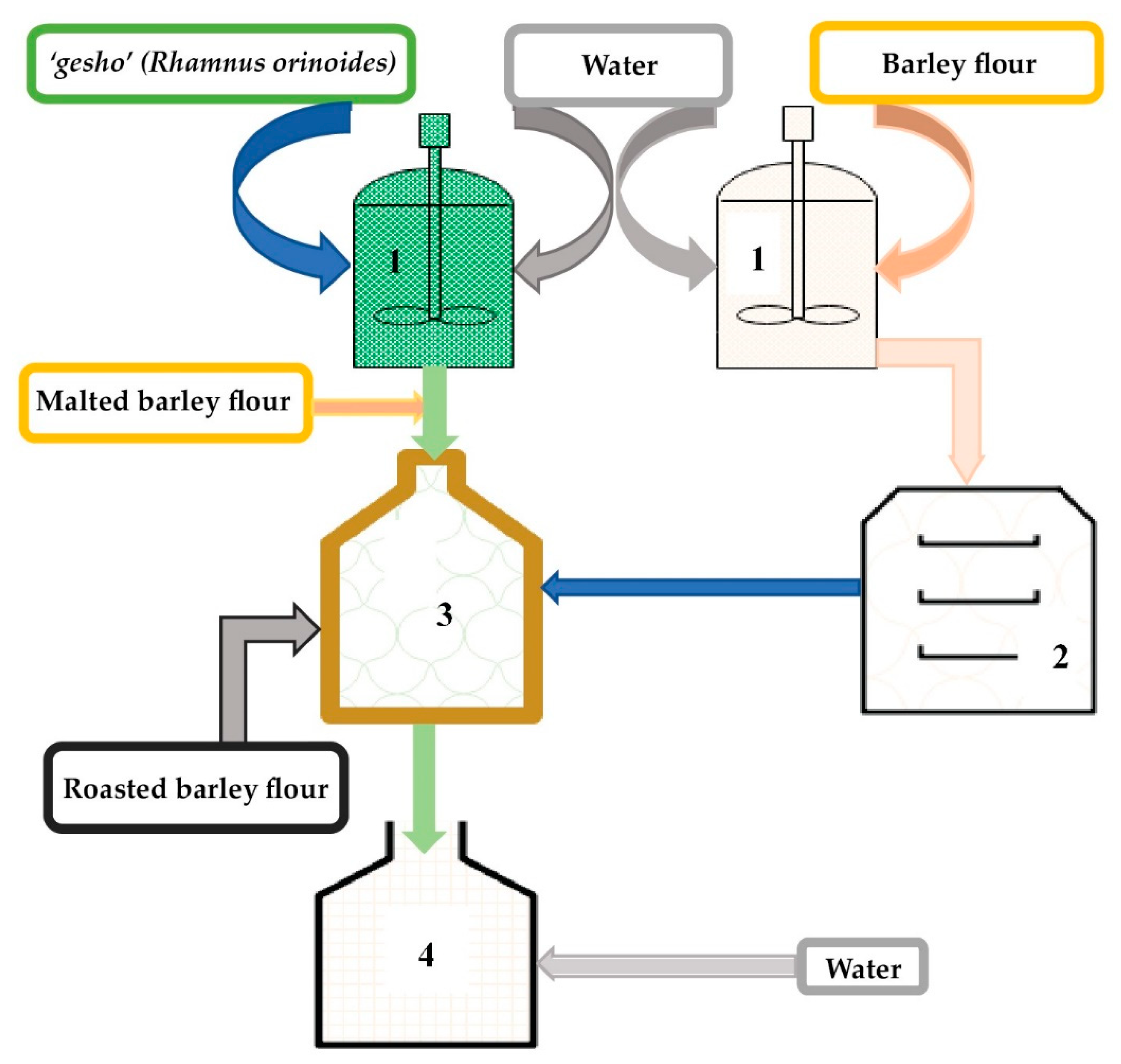

2.4. Korefe

2.5. Cheka

2.6. Keribo

3. Fruit-Based Traditional Alcoholic Beverages

3.1. Tej

3.2. Ogol

3.3. Booka

4. Nutritional Value, Function Properties and Safety Issues of Ethiopian Alcoholic Beverages

5. Conclusions and Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tekle, B.; Jabasingh, S.; Fantaw, D.; Gebreslassie, T.; Rao, S.; Baraki, H.; Gebregziabher, K. An insight into the Ethiopian traditional alcoholic beverage: Tella processing, fermentation kinetics, microbial profiling and nutrient analysis. LWT Food Sci. Technol. 2019, 107, 9–15. [Google Scholar] [CrossRef]

- Tamang, J. Diversity of fermented beverages and alcoholic drinks. In Fermented Foods and Beverages of the World; Tamang, J., Kailasapathy, K., Eds.; Taylor and Francis Group: New York, NY, USA, 2010; pp. 86–117. [Google Scholar]

- Marshall, E.; Mejia, A. Traditional Fermented Food and Beverages for Improved Livelihoods; FAO: Rome, Italy, 2011. [Google Scholar]

- CSA. Agricultural Sample Survey 2015/2016 (2009 E.C.). Volume I. Report on Area and Production of Major Crops (Private Peasant Holdings, Meher Season); Addis: Ababa, Ethiopia, 2016. [Google Scholar]

- WHO. Global Status Report on Alcohol and Health 2018; World Health Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Tamang, J.P.; Thapa, N.; Bhalla, T.C. Ethnic Fermented Foods and Beverages of India. In Ethnic Fermented Foods and Alcoholic Beverages of Asia, 1st ed.; Tamang, J., Ed.; Springer India: New Delhi, India, 2016; pp. 17–72. [Google Scholar]

- Lyumugabe, F.; Kamaliza, G.; Bajyana, E.; Thonart, P. Microbiological and physico-chemical characteristic of Rwandese traditional beer Ikigage. Afr. J. Biotechnol. 2010, 9, 4241–4246. [Google Scholar]

- Ogunbanwo, S.; Ogunsanya, B. Quality assessment of oti-oka like beverage produced from pearl millet. J. Appl. Biosci. 2012, 51, 3608–3617. [Google Scholar]

- Namugumya, B.; Muyanja, C. Traditional processing, microbiological, physiochemical and sensory characteristics of kwete, a Ugandan fermented maize based beverage. Afr. J. Food Agric. Nutr. Dev. 2009, 9, 1046–1059. [Google Scholar]

- Kirui, M.; Alakonya, A.; Talam, K.; Tohru, G.; Bii, C. Total aflatoxin, fumonisin and deoxynivalenol contamination of busaa in Bomet county, Kenya. Afr. J. Biotechnol. 2014, 13, 2675–2678. [Google Scholar]

- Kim, E.; Chang, Y.; Ko, J.; Jeong, J. Physicochemical and microbial properties of the Korean traditional rice wine, Makgeolli, supplemented with banana during fermentation. Prev. Nutr. Food Sci. 2013, 18, 203–209. [Google Scholar] [CrossRef] [Green Version]

- Valadez-Blanco, R.; Bravo-Villa, G.; Santos-Sánchez, N.; Velasco-Almendarez, S.; Montville, T. The Artisanal Production of Pulque, a Traditional Beverage of the Mexican Highlands. Probiotics Antimicrob. Proteins 2012, 4, 140–144. [Google Scholar] [CrossRef]

- Abegaz, K. Isolation, characterization and identification of lactic acid bacteria involved in traditional fermentation of Borde, an Ethiopian cereal beverage. Afr. J. Biotechnol. 2007, 6, 1469–1478. [Google Scholar]

- Bacha, K.; Mehari, T.; Ashenafi, M. Microbiology of the fermentation of ‘shamita’, a traditional Ethiopian fermented beverage. Ethiop. J. Sci. 1999, 22, 113–126. [Google Scholar] [CrossRef] [Green Version]

- Getnet, B.; Berhanu, A. Microbial dynamics, roles and physico-chemical properties of ‘Korefe’, a traditional fermented Ethiopian beverage. Biotechnol. Int. 2016, 9, 56–175. [Google Scholar]

- Abawari, R. Microbiology of keribo fermentation; an Ethiopian tradtional fermented beverage. Pak. J. Biol. Sci. 2013, 16, 1113–1121. [Google Scholar] [PubMed] [Green Version]

- Worku, B.; Gemede, H.; Woldegiorgis, A. Nutritional and alcoholic contents of cheka: A traditional fermented beverage in Southwestern Ethiopia. Food Sci. Nutr. 2018, 6, 2466–2472. [Google Scholar] [CrossRef] [PubMed]

- Bahiru, B.; Mehari, T.; Ashenafi, M. Chemical and nutritional properties of ‘tej’, an indigenous Ethiopian honey wine: Variations within and between production units. J. Food Technol. Afr. 2001, 6, 104–108. [Google Scholar]

- Teramoto, Y.; Sato, R.; Ueda, S. Characteristics of fermentation yeast isolated from traditional Ethiopian honey wine, ogol. Afr. J. Biotechnol. 2005, 4, 160–163. [Google Scholar]

- Elema, T.; Olana, B.; Elema, A.; Gemeda, H. Processing methods, physical properties and proximate analysis of fermented beverage of honey wine Booka in Gujii, Ethiopia. J. Nutr. Food Sci. 2018, 8, 2. [Google Scholar] [CrossRef]

- Nemo, R.; Bacha, K. Microbial, physicochemical and proximate analysis of selected Ethiopian traditional fermented beverages. LWT—Food Sci. Technol. 2020, 131, 109713. [Google Scholar] [CrossRef]

- Herman, J.; Maynard, A. Wine. In Microbial Technology: Fermentation Technology; Peppler, H., Perlman, D., Eds.; Academic Press Inc.: London, UK, 1979; Volume 2, p. 132. [Google Scholar]

- Pederson, S. Microbiology of Food Fermentation; AVI Publishing Co. Inc.: Westport, CT, USA, 1979. [Google Scholar]

- Steinkraus, K. Indigenous Fermented Foods in Which Ethanol Is a Major Product, 2nd ed.; Taylor & Francis: New York, NY, USA, 1996; pp. 365–402. [Google Scholar]

- Amabye, T. Evaluation of phytochemical, chemical composition, antioxidant and antimicrobial screening parameters of rhamnus prinoides (Gesho) available in the market of mekelle, tigray, Ethiopia. Nat. Prod. Chem. Res. 2015, 3, 6. [Google Scholar] [CrossRef]

- Abegaz, B.; Kebede, T. Geshoidin: A bitter principle of Rhamus Prinoides and other constituents of the leaves. Bull. Chem. Soc. Ethiop. 1995, 9, 107–114. [Google Scholar]

- Alemu, H.; Abegaz, B.; Bezabih, M. Electrochemical behaviour and voltammetric determination of geshoidin and its spectrophotometric and antioxidant properties in aqueous buffer solutions. Bull. Chem. Soc. Ethiop. 2007, 21, 89–204. [Google Scholar]

- FAO. Traditional Fermented Food and Beverage for Improved Livelihoods; A Global Perspective; FAO: Rome, Italy, 2012. [Google Scholar]

- Abegaz, K.; Beyene, F.; Langsrud, T.; Narvhus, J. Indigenous processing methods and raw materials of ‘Borde’, an Ethiopian traditional fermented beverage. J. Food Technol. Afr. 2002, 7, 59–64. [Google Scholar] [CrossRef] [Green Version]

- Andualem, B.; Shiferaw, M.; Berhane, N. Isolation and characterization of saccaromyces cervisiae yeasts isolates from ‘Tella’ for beer production. Annu. Res. Rev. Biol. 2017, 15, 1–12. [Google Scholar] [CrossRef]

- Tekluu, B.; Gebremariam, G.; Aregai, T.; Harikrishna, R. Determination of alcoholic content and other parameters of local alcoholic beverage (Tella) at different stages in Gondar, Ethiopia. Int. J. IT Eng. Appl. Sci. Res. 2015, 4, 37–40. [Google Scholar]

- Bacha, K.; Mehari, T.; Ashenafi, M. The microbial dynamics of ‘Borde’ fermentation, a traditional Ethiopian fermented beverage. Ethiop. J. Sci. 1998, 21, 195–205. [Google Scholar] [CrossRef] [Green Version]

- Ashenafi, M.; Mehari, T. Some microbiological and nutritional properties of ‘Borde’ and ‘Shamita’, traditional Ethiopian fermented beverages. Ethiop. J. Health Dev. 1995, 9, 105–110. [Google Scholar]

- Abawari, R. Indigenous Processing Methodsand Raw Materials of Keribo: An Ethiopian Traditional Fermented Beverage. J. Food Resour. Sci. 2013, 2, 13–20. [Google Scholar]

- Worku, B.; Woldegiorgis, A.; Gemeda, H. Indigenous processing methods of Cheka: A traditional fermented beverage in southwestern Ethiopia. J. Food Process. Technol. 2015, 7, 1. [Google Scholar]

- Desta, B.; Melese, G. Determination of protein value and alcoholic content in locally prepared different types of Cheka at different stages using CHNS elemental analyzer and specific gravity methods. Am. J. Appl. Chem. 2019, 7, 168–174. [Google Scholar] [CrossRef]

- Lee, M.; Regu, M.; Seleshe, S. Uniqueness of Ethiopian traditional alcoholic beverage of plant origin, Tella. J. Ethn. Foods. 2015, 2, 110–114. [Google Scholar] [CrossRef] [Green Version]

- Debebe, A.; Chandravanshi, B.; Redi-Abshiro, M. Total contents of phenolics, flavonoids, tannins and antioxidant capacity of selected traditional ethiopian alcoholic beverages. Bull. Chem. Soc. Ethiop. 2016, 30, 27–37. [Google Scholar] [CrossRef] [Green Version]

- Tafere, G. A review on Traditional Fermented Beverages of Ethiopian. J. Nat. Sci. Res. 2015, 5, 94–103. [Google Scholar]

- Bahiru, B.; Mehari, T.; Ashenafi, M. Yeast and lactic acid flora of tej, an indigenous Ethiopian honey wine: Variations within and between production units. Food Microbiol. 2006, 23, 277–282. [Google Scholar] [CrossRef] [PubMed]

- Berza, B.; Wolde, A. Fermenter Technology Modification Changes Microbiological and Physicochemical Parameters, Improves Sensory Characteristics in the Fermentation of Tella: An Ethiopian Traditional Fermented Alcoholic Beverage. J. Food Process. Technol. 2014, 5, 1–8. [Google Scholar]

- Berhanu, A. Microbial profile of Tella and the role of gesho (Rhamnus prinoides) as bittering and antimicrobial agent in traditional Tella (Beer) production. Int. Food Res. J. 2014, 21, 357–365. [Google Scholar]

- Yohannes, T.; Melak, F.; Siraj, K. Preparation and physicochemical analysis of some Ethiopian traditional alcoholic beverages. Afr. J. Food Sci. 2013, 7, 399–403. [Google Scholar] [CrossRef] [Green Version]

- Tadesse, S.; Chandravanshi, B.; Ele, E.; Zewge, F. Ethanol, methanol, acid content and other quality parameters of Ethiopian traditional fermented, distilled and factory produced Ethiopian traditional fermented, distilled and factory produced. SINET Ethiop. J. Sci. 2017, 40, 16–35. [Google Scholar]

- Fite, A.; Tadesse, A.; Urga, K.; Seyoum, E. Methanol, fusel oil and ethanol contents of some Ethiopian traditional alcoholic beverages. SINET Ethiop. J. Sci. 1991, 14, 19–27. [Google Scholar]

- Getaye, A.; Tesfaye, D.; Zerihun, A.; Melese, F. Production, optimization and characterization of Ethiopian traditional fermented beverage ‘Tella’ From Barley. J. Emerg. Technol. Innov. Res. 2018, 5, 797–799. [Google Scholar]

- Abegaz, K.; Langsrud, T.; Beyene, F.; Narvhus, J. The effect of technological modifications on the fermentation of ‘Borde’, an Ethiopian tradtional fermented cereal beverage. J. Food Technol. Afr. 2004, 9, 3–12. [Google Scholar]

- Tadesse, G.; Ashenafi, M.; Ephraim, E. Survival of E. coli O157: H7 Staphylococcus aureus, Shigella flexneri and Salmonella spp. in fermenting ‘Borde’, a traditional Ethiopian beverage. Food Control 2005, 16, 189–196. [Google Scholar] [CrossRef]

- Tadesse, G.; Ephraim, E.; Ashenafi, M. Assessment of the antimicrobial activity of lactic acid bacteria isolated from Borde and Shamita, traditional Ethiopian fermented beverages, on some food-borne pathogens and effect of growth medium on the inhibitory activity. Internet J. Food Saf. 2005, 4, 13–20. [Google Scholar]

- Gebreyohannes, G.; Welegergs, B. Determination of alcoholic content and other parameters of locally preparedalcoholic beverages (korefe and tej) at different stages in Gondar town. Int. J. Integr. Sci. Technol. 2015, 4, 1–4. [Google Scholar]

- Dibaba, K.; Tilahun, L.; Satheesh, N.; Geremu, M. Acrylamide occurrence in Keribo: Ethiopian traditional fermented beverage. Food Control 2018, 86, 77–82. [Google Scholar] [CrossRef]

- Vogel; Gobezie. Indigenous fermented foods in which ethanol is a major product. In Handbook of Indigenous Fermented Foods, 2nd ed.; Steinkraus, K., Ed.; Marcel Dekker Inc.: New York, NY, USA, 1996; pp. 367–369. [Google Scholar]

- Gebretsadik, T.; Negash, D. Honeybee production system, challenges and opportunities in selected districts of gedeo zone, southern nation, nationalities and peoples regional state, Ethiopia. Int. J. Res. 2016, 4, 49–63. [Google Scholar]

- Gebremedhin, G.; Tadesse, G.; Kebede, E. Physiochemical characteristics of honey obtained from traditional and modern hive production systems in Tigray region, northern Ethiopia. Momona Ethiop. J. Sci. 2013, 5, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Lemi, B. Microbiology of Ethiopian Traditionally Fermented Beverages and Condiments. Int. J. Food Microbiol. 2020, 2020, 1478536. [Google Scholar]

- Lucke, F. Indigenous lactic acid bacteria of various food commodities and factor affecting their growth. In Lactic Acid Bacteria: Current Advances in Metabolism, Gentics and Application, 1st ed.; Bozoglu, T., Ray, B., Eds.; Springer: Berlin, Germany, 2015. [Google Scholar]

- Djeni, T.; Karen, H.; Ake, K.; Laurent, S. Microbial diversity and metabolite profiles of palm wine produced from three different palm tree species in Côte d’Ivoire. Sci. Rep. 2020, 10, 1715. [Google Scholar] [CrossRef]

- Cason, E.; Mahlomaholo, B.; Taole, M.; Abong, G.; Vermeulen, J.; Smidt, O.; Vermeulen, M.; Steyn, L. Bacterial and fungal dynamics during the fermentation process of sesotho, a traditional beer of Southern Africa. Front. Microbiol. 2020, 11, 1451. [Google Scholar] [CrossRef]

- Cory, H.; Passarelli, S.; Szeto, J.; Tamez, M.; Mattei, J. The Role of polyphenols in human health and food systems: A mini-review. Front. Nutr. 2018, 5, 87. [Google Scholar] [CrossRef] [Green Version]

- Ganesan, K.; Xu, B. A critical review on polyphenols and health benefits of black soybeans. Nutrients 2017, 9, 455. [Google Scholar] [CrossRef] [Green Version]

- Shewakena, S.; Chandravanshi, B.; Debeb, A. Levels of total polyphenol, flavonoid, tannin and antioxidant activity of selected Ethiopian fermented traditional beverages. Int. Food Res. J. 2017, 24, 2033–2040. [Google Scholar]

- Lachenmeier, D.; Haupt, S.; Schulz, K. Defining maximum levels of higher alcohols in alcoholic beverages and surrogate alcohol products. Regul. Toxicol. Pharmacol. 2008, 50, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Shin, J.; Lee, K. Determination of fusel oil content in various types of liquor distributed in Korea Pre-treatment of samples GC analysis of fusel oil. Korean Soc. Food Preserv. 2017, 24, 510–516. [Google Scholar] [CrossRef]

- Fawell, J.; Bailey, K.; Chilton, J.; Dahi, E.; Fewtrell, L.; Magara, Y. Fluoride in Drinking Water; World Health Organization and IWA Publishing, Inc.: London, UK, 2006. [Google Scholar]

- Belete, Y.; Chandravanshi, B.S.; Zewgea, F. Levels of the fluoride ion in six traditional alcoholic fermented beverages commonly consumed in Ethiopia. Fluoride 2017, 50, 79. [Google Scholar]

| Category of Beverages | Beverages | Raw Materials | Prominent Production and Consumption Regions | References |

|---|---|---|---|---|

| Beers | Tella | Barley (Hordeum vulgare L.), wheat (Triticum aestivum L.), maize (Zea mays L.), finger millet (Eleusine coracana L.), sorghum (Sorghum bicolor L.), “teff” (Eragrostis tef L.), “gesho” (R. prinoides) | Amhara, Oromia, Tigray, SNNP, Addis Ababa | [30,31] |

| Borde | Maize (Z. mays), barley (H. vulgare), wheat (T. aestivum), finger millet (E. coracana), sorghum (S. bicolor) | SNNP | [13,32] | |

| Shamita | Roasted barley (H. vulgare) flour, salt, linseed (Linum usitatissimum L.) flour, chili pepper (Capsicum annuum) | SNNP, Addis Ababa | [13,33] | |

| Korefe | Malted and non-malted barley (H. vulgare), “gesho” (R. prinoides) | Amhara | [15] | |

| Keribo | Barley (H. vulgare), sugar, bakery yeast (Saccharomyces cerevisiae) | Oromia, Amhara, Addis Ababa | [16,34] | |

| Cheka | Sorghum (S. bicolor), maize (Z. mays), finger millet (E. coracana), vegetables, root of taro (Colocasia esculenta L.) | SNNP | [17,35,36] | |

| Areke | Barley (H. vulgare), “gesho” (R. prinoides), sorghum | Amhara, Oromia, Tigray, SNNP, Addis Ababa | [37,38,39] | |

| Wine | Tej | Honey, “gesho” (R. prinoides) | Oromia, Amhara, Tigray, Addis Ababa | [18,39,40] |

| Ogol | honey, barks of native tree (Blighia unijungata L.) | Gambella (Majangir) | [19] | |

| Booka | Honey, bladder of cow | Oromia (Gujii) | [20] |

| Area of Investigation | Shelf Stability, Microbial and Physicochemical Properties | Concluding Remarks | References |

|---|---|---|---|

| Storage stability, and microbial dynamics for vacuum filtered (VF), pasteurized (P) and control Tella |

| Pasteurization is an efficient method to extend the shelf life compared to vacuum filtration | [1] |

| Optimization of Tella production |

| The optimum fermentation process parameters:

| [46] |

| Isolation and characterization of S. cerevisiae from Tella |

| Isolated strains have a good fermentative potential, especially for beer production | [30] |

| Physicochemical properties of fresh and matured Tella |

|

| [31] |

| Area of Investigation | Microbial Load, Microbial Dynamics, and Processing Methods | Concluding Remarks | References |

|---|---|---|---|

| Isolation and characterization of lactic acid bacteria (LAB) involved in Borde fermentation |

| Dominant microorganisms have a potential to be used as a starter culture | [13] |

| Antagonist effect of lactic acid bacteria over pathogenic microorganisms |

| Secondary metabolites of LAB have a significant antimicrobial effect | [48] |

| Modified process technology for Borde production |

| Borde making process can be simplified without compromising quality | [47] |

| Survey on local methods of processing and sensory analysis of Borde |

|

| [29] |

| Microbial dynamics of Borde fermentation |

|

| [32] |

| Area of Investigation | Microbial and Physicochemical Properties | Concluding Remarks | References |

|---|---|---|---|

| Flora of yeast and lactic acid bacteria of Tej |

| Yeasts and LAB are among the dominant microbes in Tej fermentation | [40] |

| Physicochemical properties of Tej |

| Natural and spontaneous fermentation is a major source of physicochemical variation in collected Tej samples | [18,44] |

| Isolating fermentative yeast from Ogol |

| Isolated yeast from Ogol has the potential to be used for ethanol fermentation | [19] |

| Physicochemical properties of Booka |

| Booka can be used as a meal replacement | [20] |

| Beverages | Nutritional Value | Functional Properties (Average Values) | Higher Alcohol and Fluoride Ion (Average Values) | References |

|---|---|---|---|---|

| Tella | Total protein—0.4% Carbohydrate—1.98% | TP (µg mL−1)—232.40 AA (µg mL−1)—296.00 Folate (mgcg−1)—0.093 | Fusel oil (ppm)—51 Methanol (ppm)—41.5 Fluoride ion (mg/L)—4.26 | [1,46,61,65] |

| Borde | Total protein—9.55%, Crude fat—6.88%, Total ash—3.66% | TP (µg mL−1)—9.50 AA (µg mL−1)—198.5 | Fluoride ion (mg/L)—4.95 | [29,33,39,65] |

| Shamita | Total protein—10.37% Crude fat—6.85% Total ash—3.46% | – | Fluoride ion (mg/L)—5.21 | [33,34,65] |

| Korefe | – | TP (µg mL−1)—167.60 AA (µg mL−1)—278.13 | Fluoride ion (mg/L)—1.39 | [63,65] |

| Cheka | Total protein—3.83% Crude fat—1.49% Carbohydrate—16.59% Total ash—0.79% | – | Methanol(ppm)—271.55 | [17] |

| Keribo | – | TP (µg mL−1)—12.65 AA (µg mL−1)—64.66 | – | [38] |

| Tej | Total protein—0.35% Crude fat—0.35% Carbohydrate—3.58% Total ash—0.04% | TP (µg mL−1)—197.00 AA (µg mL−1)—240.37 | Fusel oil (ppm)—205.08 Fluoride ion (mg/L)—6.68 | [18,21,38,61,65] |

| Bokaa | Moisture content—82.18% Ash content—0.82% Crude fat content—1.43% Total Nitrogen—7.01% | – | – | [20] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fentie, E.G.; Emire, S.A.; Demsash, H.D.; Dadi, D.W.; Shin, J.-H. Cereal- and Fruit-Based Ethiopian Traditional Fermented Alcoholic Beverages. Foods 2020, 9, 1781. https://doi.org/10.3390/foods9121781

Fentie EG, Emire SA, Demsash HD, Dadi DW, Shin J-H. Cereal- and Fruit-Based Ethiopian Traditional Fermented Alcoholic Beverages. Foods. 2020; 9(12):1781. https://doi.org/10.3390/foods9121781

Chicago/Turabian StyleFentie, Eskindir Getachew, Shimelis Admassu Emire, Hundessa Dessalegn Demsash, Debebe Worku Dadi, and Jae-Ho Shin. 2020. "Cereal- and Fruit-Based Ethiopian Traditional Fermented Alcoholic Beverages" Foods 9, no. 12: 1781. https://doi.org/10.3390/foods9121781

APA StyleFentie, E. G., Emire, S. A., Demsash, H. D., Dadi, D. W., & Shin, J.-H. (2020). Cereal- and Fruit-Based Ethiopian Traditional Fermented Alcoholic Beverages. Foods, 9(12), 1781. https://doi.org/10.3390/foods9121781