Effect of Agave Fructans as Carrier on the Encapsulation of Blue Corn Anthocyanins by Spray Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Extraction of Blue Corn Anthocyanins

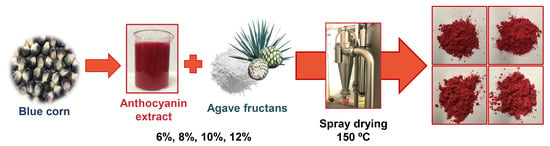

2.3. Encapsulation of Blue Corn Anthocyanin Extract

2.4. Characterization of the Encapsulated Powders

2.4.1. Moisture and Water Activity (aw)

2.4.2. Hygroscopicity

2.4.3. Bulk Density

2.4.4. pH

2.4.5. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.4.6. Glass Transition Temperature (Tg)

2.4.7. Scanning Electron Microscopy (SEM)

2.4.8. Color

2.4.9. Preparation of the Extracts from Blue Corn Encapsulated Powders

2.4.10. Total Anthocyanin Content

2.4.11. Total Polyphenols

2.4.12. Antioxidant Activity

2.4.13. High-Pressure Liquid Chromatography (HPLC) Determination of Individual Anthocyanins

2.5. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Blue Corn Extract

3.2. Characterization of the Encapsulated Powders

3.2.1. Moisture Content

3.2.2. Water Activity (aw)

3.2.3. Hygroscopicity

3.2.4. Bulk Density

3.2.5. pH

3.2.6. Water Absorption Index (WAI) and Water Solubility Index (WSI)

3.2.7. Glass Transition Temperature (Tg)

3.2.8. Color

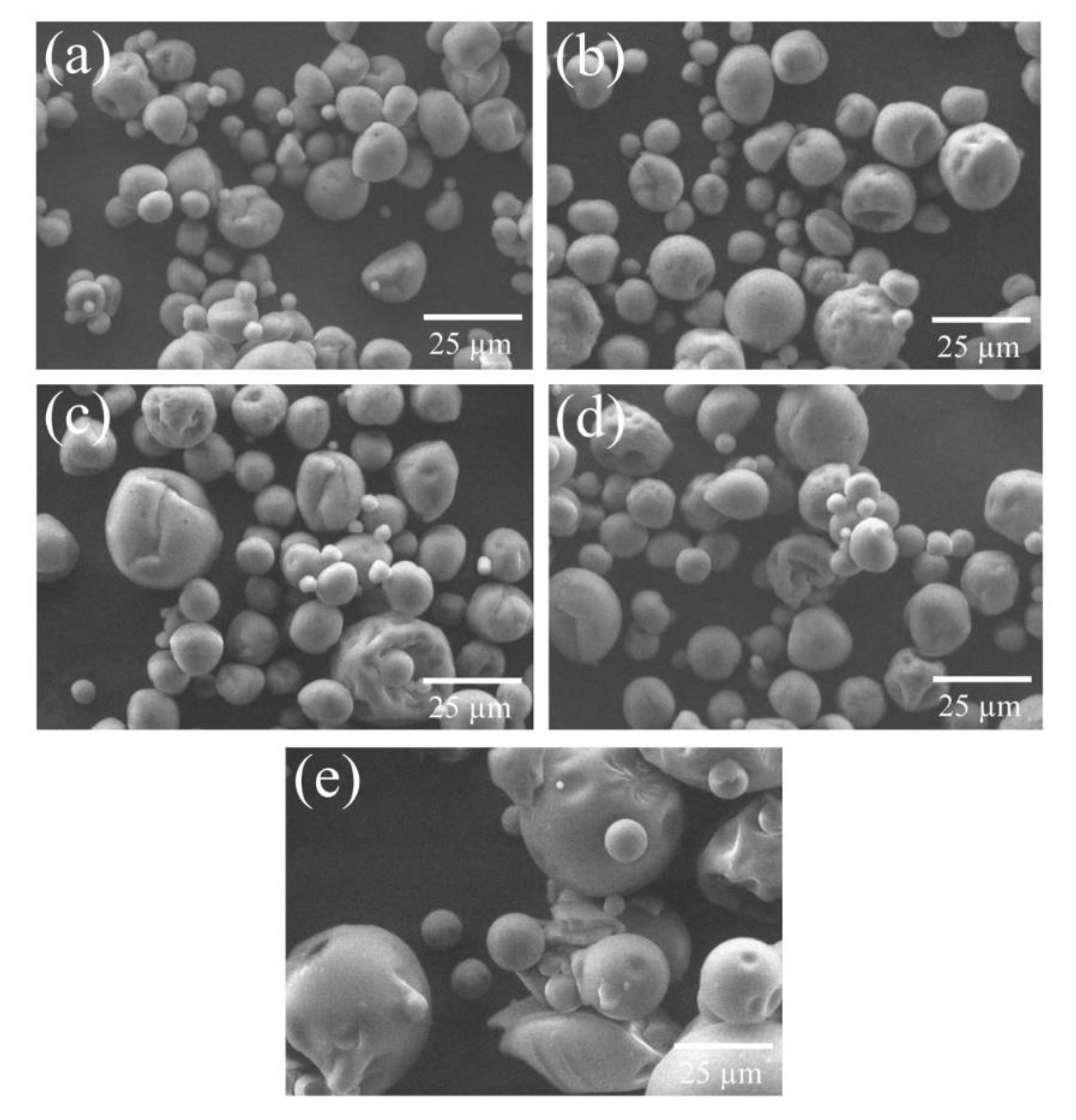

3.2.9. Scanning Electron Microscopy (SEM)

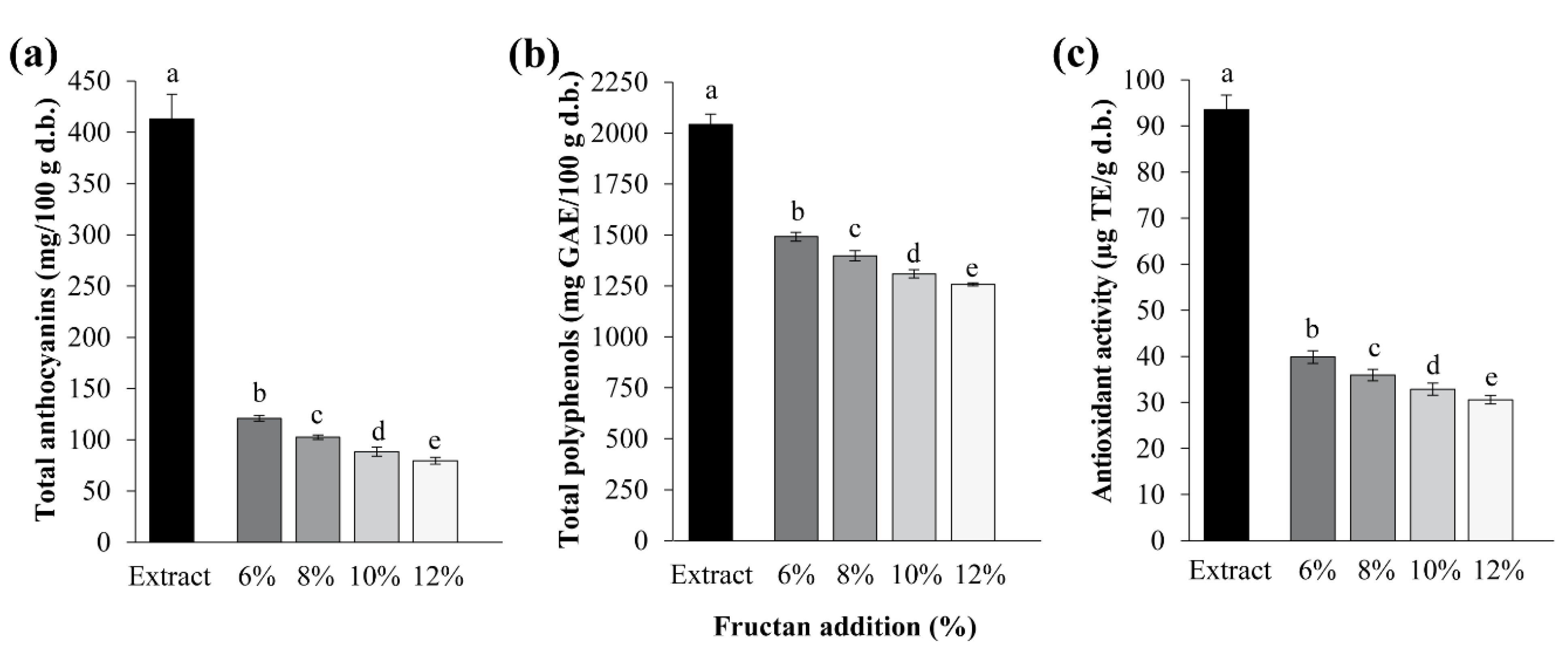

3.2.10. Total Anthocyanin Content

3.2.11. Total Polyphenols

3.2.12. Antioxidant Activity

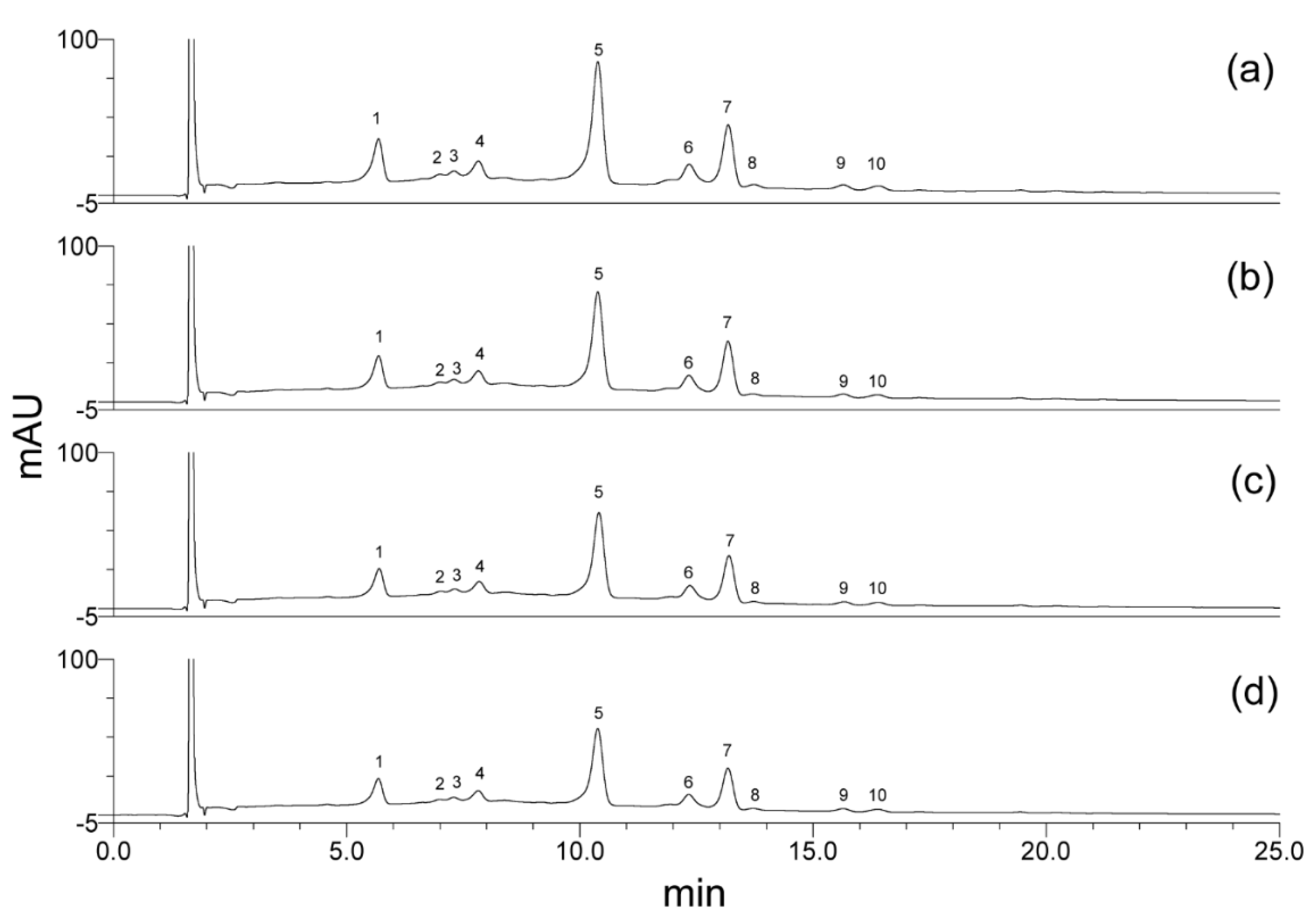

3.2.13. Individual Anthocyanins

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Urias-Peraldí, M.; Gutiérrez-Uribe, J.A.; Preciado-Ortiz, R.E.; Cruz-Morales, A.S.; Serna-Saldívar, S.O.; García-Lara, S. Nutraceutical profiles of improved blue maize (Zea mays) hybrids for subtropical regions. Field Crops Res. 2013, 141, 69–76. [Google Scholar] [CrossRef]

- Mora-Rochín, S.; Gaxiola-Cuevas, N.; Gutiérrez-Uribe, J.A.; Milán-Carrillo, J.; Milán-Noris, E.M.; Reyes-Moreno, C.; Serna-Saldívar, S.O.; Cuevas-Rodríguez, E.O. Effect of traditional nixtamalization on anthocyanin content and profile in Mexican blue maize (Zea mays L.) landraces. LWT Food Sci. Technol. 2016, 68, 563–569. [Google Scholar] [CrossRef]

- He, J.; Giusti, M.M. Anthocyanins: Natural colorants with health-promoting properties. Annu. Rev. Food Sci. Technol. 2010, 1, 163–187. [Google Scholar] [CrossRef] [PubMed]

- Tsuda, T. Dietary anthocyanin-rich plants: Biochemical basis and recent progress in health benefits studies. Mol. Nutr. Food Res. 2012, 56, 159–170. [Google Scholar] [CrossRef]

- Cavalcanti, R.N.; Santos, D.T.; Meireles, M.A.A. Non-thermal stabilization mechanisms of anthocyanins in model and food systems—An overview. Food Res. Int. 2011, 44, 499–509. [Google Scholar] [CrossRef]

- Saénz, C.; Tapia, S.; Chávez, J.; Robert, P. Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chem. 2009, 114, 616–622. [Google Scholar] [CrossRef]

- Bakowska-Barczak, A.M.; Kolodziejczyk, P.P. Black currant polyphenols: Their storage stability and microencapsulation. Ind. Crops Prod. 2011, 34, 1301–1309. [Google Scholar] [CrossRef]

- Cai, Y.Z.; Corke, H. Production and properties of spray-dried amaranthus betacyanin pigments. J. Food Sci. 2000, 65, 1248–1252. [Google Scholar] [CrossRef]

- Bustos-Garza, C.; Yáñez-Fernández, J.; Barragán-Huerta, B.E. Thermal and pH stability of spray-dried encapsulated astaxanthin oleoresin from Haematococcus pluvialis using several encapsulation wall materials. Food Res. Int. 2013, 54, 641–649. [Google Scholar] [CrossRef]

- Ahmed, M.; Akter, M.S.; Lee, J.C.; Eun, J.B. Encapsulation by spray drying of bioactive components, physicochemical and morphological properties from purple sweet potato. LWT Food Sci. Technol. 2010, 43, 1307–1312. [Google Scholar] [CrossRef]

- Tonon, R.V.; Baroni, A.F.; Brabet, C.; Gibert, O.; Pallet, D.; Hubinger, M.D. Water sorption and glass transition temperature of spray dried açai (Euterpe oleracea Mart.) juice. J. Food Eng. 2009, 94, 215–221. [Google Scholar] [CrossRef]

- Saikia, S.; Mahnot, N.K.; Mahanta, C.L. Optimisation of phenolic extraction from Averrhoa carambola pomace by response surface methodology and its microencapsulation by spray and freeze drying. Food Chem. 2015, 171, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Mancilla-Margalli, N.A.; López, M.G. Water-soluble carbohydrates and fructan structure patterns from Agave and Dasylirion species. J. Agric. Food Chem. 2006, 54, 7832–7839. [Google Scholar] [CrossRef] [PubMed]

- López, M.G.; Urías-Silvas, J.E. Agave fructans as prebiotics. In Recent Advances in Fructooligosaccharides Research; Shiomi, N., Benkeblia, N., Onodera, S., Eds.; Research Signpoint: Kerala, India, 2007; Volume 37, pp. 297–310. [Google Scholar]

- Rajam, R.; Anandharamakrishnan, C. Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wall material by spray drying. LWT Food Sci. Technol. 2015, 60, 773–780. [Google Scholar] [CrossRef]

- Sánchez-Madrigal, M.Á.; Quintero-Ramos, A.; Martínez-Bustos, F.; Meléndez-Pizarro, C.O.; Ruiz-Gutiérrez, M.G. Effect of different calcium sources on the antioxidant stability of tortilla chips from extruded and nixtamalized blue corn (Zea mays L.) flours. Food Sci. Technol. 2014, 34, 143–149. [Google Scholar] [CrossRef]

- García-Tejeda, Y.V.; Salinas-Moreno, Y.; Martínez-Bustos, F. Acetylation of normal and waxy maize starches as encapsulating agents for maize anthocyanins microencapsulation. Food Bioprod. Process. 2015, 94, 717–726. [Google Scholar] [CrossRef]

- Li, C.Y.; Kim, H.W.; Won, S.R.; Min, H.K.; Park, K.J.; Park, J.Y.; Ahn, M.S.; Rhee, H.I. Corn husk as a potential source of anthocyanins. J. Agric. Food Chem. 2008, 56, 11413–11416. [Google Scholar] [CrossRef] [PubMed]

- Mutlu, C.; Arslan-Tontul, S.; Candal, C.; Kilic, O.; Erbas, M. Physicochemical, thermal, and sensory properties of blue corn (Zea mays L.). J. Food Sci. 2018, 83, 53–59. [Google Scholar] [CrossRef]

- Cuevas Montilla, E.; Hillebrand, S.; Antezana, A.; Winterhalter, P. Soluble and bound phenolic compounds in different Bolivian purple corn (Zea mays L.) cultivars. J. Agric. Food Chem. 2011, 59, 7068–7074. [Google Scholar] [CrossRef]

- Harakotr, B.; Suriharn, B.; Tangwongchai, R.; Scott, M.P.; Lertrat, K. Anthocyanin, phenolics and antioxidant activity changes in purple waxy corn as affected by traditional cooking. Food Chem. 2014, 164, 510–517. [Google Scholar] [CrossRef]

- Salinas Moreno, Y.; Sánchez, G.S.; Hernández, D.R.; Lobato, N.R. Characterization of anthocyanin extracts from maize kernels. J. Chromatogr. Sci. 2005, 43, 483–487. [Google Scholar] [CrossRef]

- Kuck, L.S.; Noreña, C.P.Z. Microencapsulation of grape (Vitis labrusca var. Bordo) skin phenolic extract using gum Arabic, polydextrose, and partially hydrolyzed guar gum as encapsulating agents. Food Chem. 2016, 194, 569–576. [Google Scholar] [CrossRef]

- Ruiz-Gutiérrez, M.G.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; de Jesús Ruiz-Anchondo, T.; Gutiérrez-Uribe, J.A.; Baez-González, J.G.; Lardizabal-Gutiérrez, D.; Campos-Venegas, K. Effect of soluble fiber on the physicochemical properties of cactus pear (Opuntia ficus indica) encapsulated using spray drying. Food Sci. Biotechnol. 2014, 23, 755–763. [Google Scholar] [CrossRef]

- de Barros Fernandes, R.V.; Borges, S.V.; Botrel, D.A.; Oliveira, C.R.D. Physical and chemical properties of encapsulated rosemary essential oil by spray drying using whey protein–inulin blends as carriers. Int. J. Food Sci. Technol. 2014, 49, 1522–1529. [Google Scholar] [CrossRef]

- de Barros Fernandes, R.V.; Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532. [Google Scholar] [CrossRef]

- Pitalua, E.; Jimenez, M.; Vernon-Carter, E.J.; Beristain, C.I. Antioxidative activity of microcapsules with beetroot juice using gum Arabic as wall material. Food Bioprod. Process. 2010, 88, 253–258. [Google Scholar] [CrossRef]

- Kha, T.C.; Nguyen, M.H.; Roach, P.D. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 2010, 98, 385–392. [Google Scholar] [CrossRef]

- Otálora, M.C.; Carriazo, J.G.; Iturriaga, L.; Nazareno, M.A.; Osorio, C. Microencapsulation of betalains obtained from cactus fruit (Opuntia ficus-indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents. Food Chem. 2015, 187, 174–181. [Google Scholar] [CrossRef]

- Ersus, S.; Yurdagel, U. Microencapsulation of anthocyanin pigments of black carrot (Daucus carota L.) by spray drier. J. Food Eng. 2007, 80, 805–812. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Chegini, G.R.; Ghobadian, B. Effect of spray-drying conditions on physical properties of orange juice powder. Dry. Technol. 2005, 23, 657–668. [Google Scholar] [CrossRef]

- Glibowski, P.; Bukowska, A. The effect of pH, temperature and heating time on inulin chemical stability. Acta Sci. Pol. Technol. Aliment. 2011, 10, 189–196. [Google Scholar]

- Ahmed, M.; Akter, M.S.; Eun, J.B. Impact of α-amylase and maltodextrin on physicochemical, functional and antioxidant capacity of spray-dried purple sweet potato flour. J. Sci. Food Agric. 2010, 90, 494–502. [Google Scholar] [CrossRef]

- Syamaladevi, R.M.; Insan, S.K.; Dhawan, S.; Andrews, P.; Sablani, S.S. Physicochemical properties of encapsulated red raspberry (Rubus idaeus) powder: Influence of high-pressure homogenization. Dry. Technol. 2012, 30, 484–493. [Google Scholar] [CrossRef]

- Alamilla-Beltran, L.; Chanona-Perez, J.J.; Jimenez-Aparicio, A.R.; Gutierrez-Lopez, G.F. Description of morphological changes of particles along spray drying. J. Food Eng. 2005, 67, 179–184. [Google Scholar] [CrossRef]

- Osorio, C.; Acevedo, B.; Hillebrand, S.; Carriazo, J.; Winterhalter, P.; Morales, A.L. Microencapsulation by spray-drying of anthocyanin pigments from corozo (Bactris guineensis) fruit. J. Agric. Food Chem. 2010, 58, 6977–6985. [Google Scholar] [CrossRef]

- Brouillard, R.; Delaporte, B. Chemistry of anthocyanin pigments. 2. Kinetic and thermodynamic study of proton transfer, hydration, and tautomeric reactions of malvidin 3-glucoside. J. Am. Chem. Soc. 1977, 99, 8461–8468. [Google Scholar] [CrossRef]

- Laleh, G.H.; Frydoonfar, H.; Heidary, R.; Jameei, R.; Zare, S. The effect of light, temperature, pH and species on stability of anthocyanin pigments in four Berberis species. Pak. J. Nutr. 2006, 5, 90–92. [Google Scholar]

- Robert, P.; Gorena, T.; Romero, N.; Sepulveda, E.; Chavez, J.; Saenz, C. Encapsulation of polyphenols and anthocyanins from pomegranate (Punica granatum) by spray drying. Int. J. Food Sci. Technol. 2010, 45, 1386–1394. [Google Scholar] [CrossRef]

- Suda, I.; Oki, T.; Masuda, M.; Nishiba, Y.; Furuta, S.; Matsugano, K.; Sugita, K.; Terahara, N. Direct absorption of acylated anthocyanin in purple-fleshed sweet potato into rats. J. Agric. Food Chem. 2002, 50, 1672–1676. [Google Scholar] [CrossRef]

- Lao, F.; Giusti, M.M. The effect of pigment matrix, temperature and amount of carrier on the yield and final color properties of spray dried purple corn (Zea mays L.) cob anthocyanin powders. Food Chem. 2017, 227, 376–382. [Google Scholar] [CrossRef]

| Determination | Extract |

|---|---|

| °Brix | 5.73 ± 0.11 |

| Moisture (%) | 95.97 ± 0.02 |

| Water activity (aw) | 0.99 ± 0.03 |

| pH | 1.79 ± 0.02 |

| Total anthocyanins (mg/100 g d.b.) | 412.97 ± 24.13 |

| Total polyphenols (mg GAE/100 g d.b.) | 2042.42 ± 51.28 |

| Antioxidant activity (μmol TE/g d.b.) | 93.57 ± 3.10 |

| Color parameters | |

| L* | 34.30 ± 0.03 |

| a* | 37.44 ± 0.07 |

| b* | 9.75 ± 0.04 |

| Chroma* | 38.69 ± 0.08 |

| Hue° | 0.254 ± 0.001 |

| Agave Fructans (% w/v) | Moisture (%) | Water Activity (aw) | Higroscopicity (%) | Bulk Density (g/cm3) | pH | WAI | WSI | Tg (°C) |

|---|---|---|---|---|---|---|---|---|

| 6% | 9.47 ± 0.39 b | 0.123 ± 0.005 c | 49.68 ± 0.92 a | 0.625 ± 0.008 b | 2.15 ± 0.005 c,d | 0.944 ± 0.02 a | 1.34 ± 0.02 d | 50.71 ± 0.48 a |

| 8% | 10.03 ± 0.07 b | 0.141 ± 0.021 b,c | 46.34 ± 1.02 b | 0.640 ± 0.012 a | 2.16 ± 0.005 d | 0.765 ± 0.04 b | 1.38 ± 0.02 c | 53.55 ± 2.62 a |

| 10% | 10.49 ± 0.27 a,b | 0.143 ± 0.016 b,c | 41.07 ± 1.07 c | 0.642 ± 0.004 a | 2.20 ± 0.032 b,c | 0.619 ± 0.01 c | 1.45 ± 0.02 b | 50.01 ± 1.08 a |

| 12% | 11.07 ± 0.86 a | 0.156 ± 0.005 b | 38.17 ± 0.27 c,d | 0.647 ± 0.012 a | 2.23 ± 0.032 b | 0.554 ± 0.02 d | 1.48 ± 0.01 b | 52.15 ± 2.39 a |

| Agave fructans | 4.44 ± 0.39 c | 0.189 ± 0.010 a | 36.45 ± 0.53 d | 0.580 ± 0.007 c | 5.12 ± 0.017 a | 0.148 ± 0.01 e | 1.57 ± 0.01 a | 50.13 ± 0.51 a |

| Agave Fructans (% w/v) | L* | a* | b* | Chroma* | Hue° | ΔE |

|---|---|---|---|---|---|---|

| 6% | 36.79 ± 0.32 d | 36.25 ± 1.34 a | 13.62 ± 0.26 a | 38.73 ± 1.18 a | 0.359 ± 0.018 a | 5.04 ± 0.35 c |

| 8% | 37.77 ± 0.94 c | 36.29 ± 0.64 a | 13.46 ± 0.25 a | 38.90 ± 0.48 a | 0.355 ± 0.006 a | 5.29 ± 0.64 c |

| 10% | 40.09 ± 0.50 b | 36.26 ± 0.21 a | 13.79 ± 0.39 a | 38.80 ± 0.33 a | 0.363 ± 0.007 a | 7.11 ± 0.61 b |

| 12% | 42.32 ± 0.46 a | 36.33 ± 0.30 a | 13.65 ± 0.24 a | 38.81 ± 0.21 a | 0.359 ± 0.008 a | 8.57 ± 0.47 a |

| Determinations | Total Anthocyanins | Total Polyphenols |

|---|---|---|

| Total polyphenols | 0.951 * | |

| Antioxidant activity | 0.933 * | 0.938 * |

| Agave Fructans (% w/v) | Cy-3-glu (mg/100 g d.b.) | RP (%) | Pe-3-glu (mg/100 g d.b.) | RP (%) |

|---|---|---|---|---|

| 6% | 50.09 ± 4.60 b | 23.24 | 6.32 ± 0.46 b | 19.95 |

| 8% | 38.70 ± 0.14 bc | 17.96 | 5.30 ± 0.04 b | 16.72 |

| 10% | 30.69 ± 0.27 cd | 14.24 | 3.95 ± 0.04 c | 12.47 |

| 12% | 21.19 ± 0.23 d | 9.83 | 3.75 ± 0.11 c | 11.85 |

| Extract | 215.50 ± 3.57 a | 100.0 | 31.70 ± 0.35 a | 100.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Madrigal, M.Á.; Quintero-Ramos, A.; Amaya-Guerra, C.A.; Meléndez-Pizarro, C.O.; Castillo-Hernández, S.L.; Aguilera-González, C.J. Effect of Agave Fructans as Carrier on the Encapsulation of Blue Corn Anthocyanins by Spray Drying. Foods 2019, 8, 268. https://doi.org/10.3390/foods8070268

Sánchez-Madrigal MÁ, Quintero-Ramos A, Amaya-Guerra CA, Meléndez-Pizarro CO, Castillo-Hernández SL, Aguilera-González CJ. Effect of Agave Fructans as Carrier on the Encapsulation of Blue Corn Anthocyanins by Spray Drying. Foods. 2019; 8(7):268. https://doi.org/10.3390/foods8070268

Chicago/Turabian StyleSánchez-Madrigal, Miguel Á., Armando Quintero-Ramos, Carlos A. Amaya-Guerra, Carmen O. Meléndez-Pizarro, Sandra L. Castillo-Hernández, and Carlos J. Aguilera-González. 2019. "Effect of Agave Fructans as Carrier on the Encapsulation of Blue Corn Anthocyanins by Spray Drying" Foods 8, no. 7: 268. https://doi.org/10.3390/foods8070268

APA StyleSánchez-Madrigal, M. Á., Quintero-Ramos, A., Amaya-Guerra, C. A., Meléndez-Pizarro, C. O., Castillo-Hernández, S. L., & Aguilera-González, C. J. (2019). Effect of Agave Fructans as Carrier on the Encapsulation of Blue Corn Anthocyanins by Spray Drying. Foods, 8(7), 268. https://doi.org/10.3390/foods8070268