Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Packaging, Storage, and Atmosphere Composition

2.3. T. Matsutake Quality Indicators Measurement

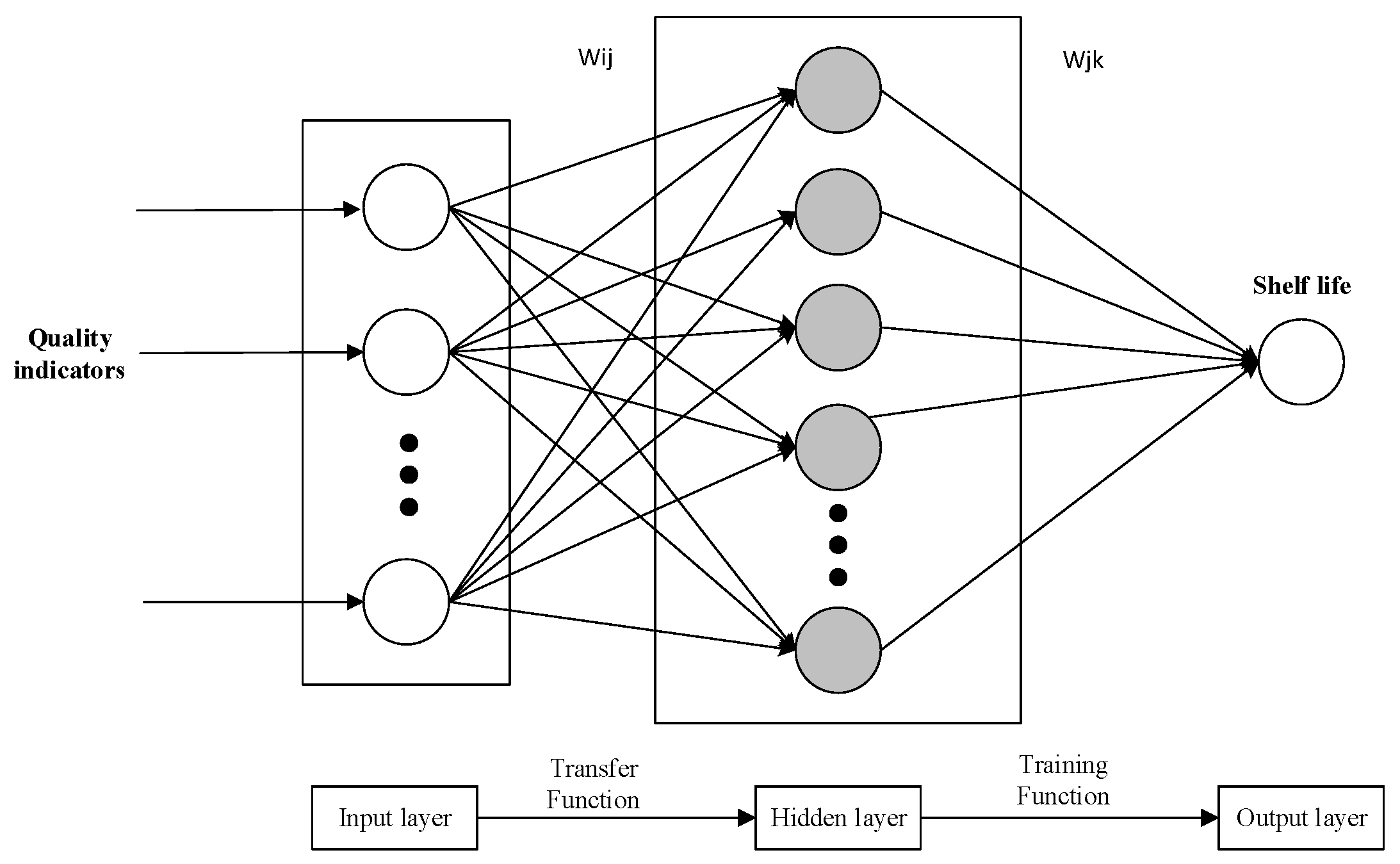

2.4. The Remaining Shelf Life Prediction Method—BP Neural Network

3. Results and Discussion

3.1. Quality Characteristics Analysis of Fresh Tibetan T. matsutake in MAP Conditions

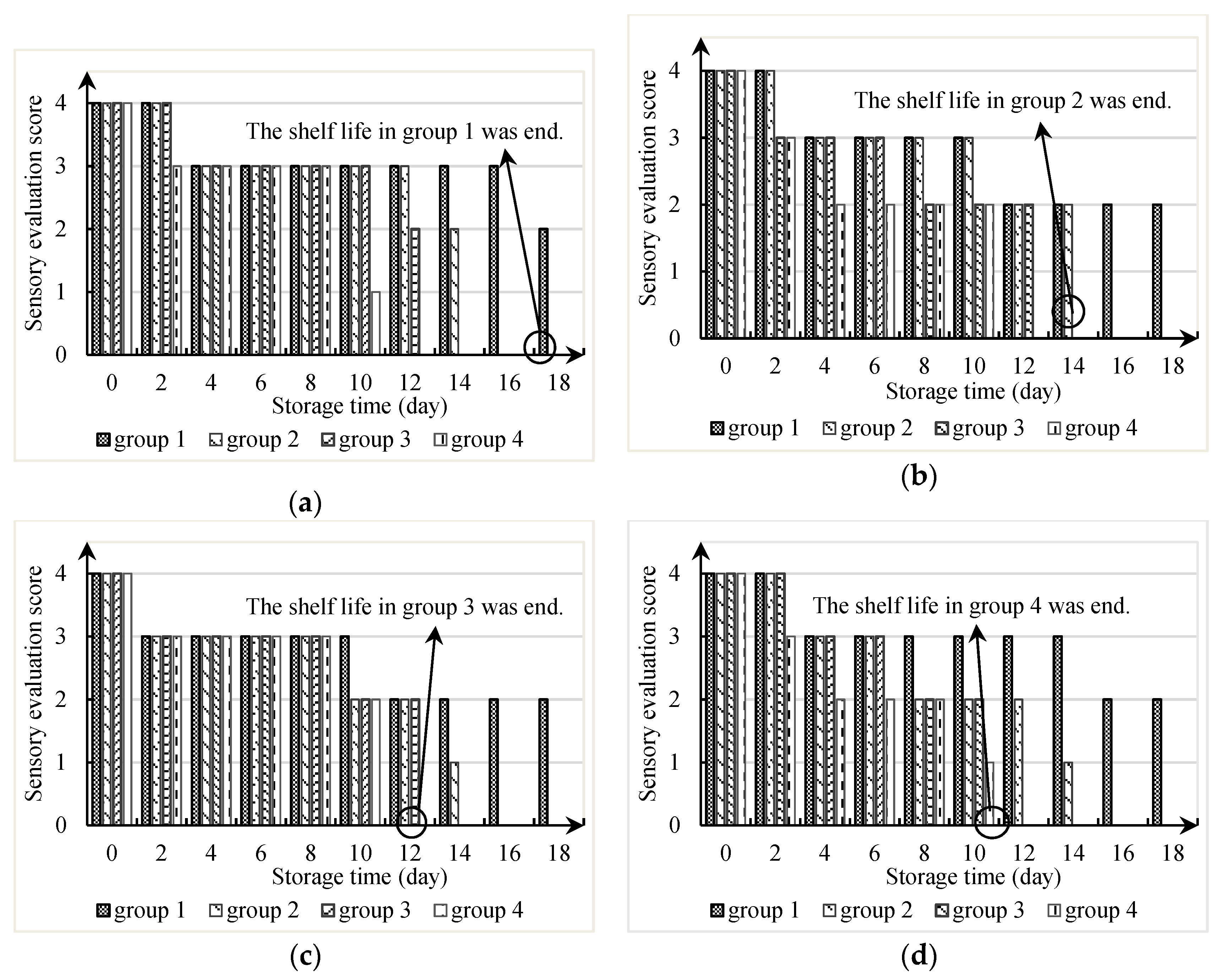

3.1.1. Changes in Sensory Characteristics

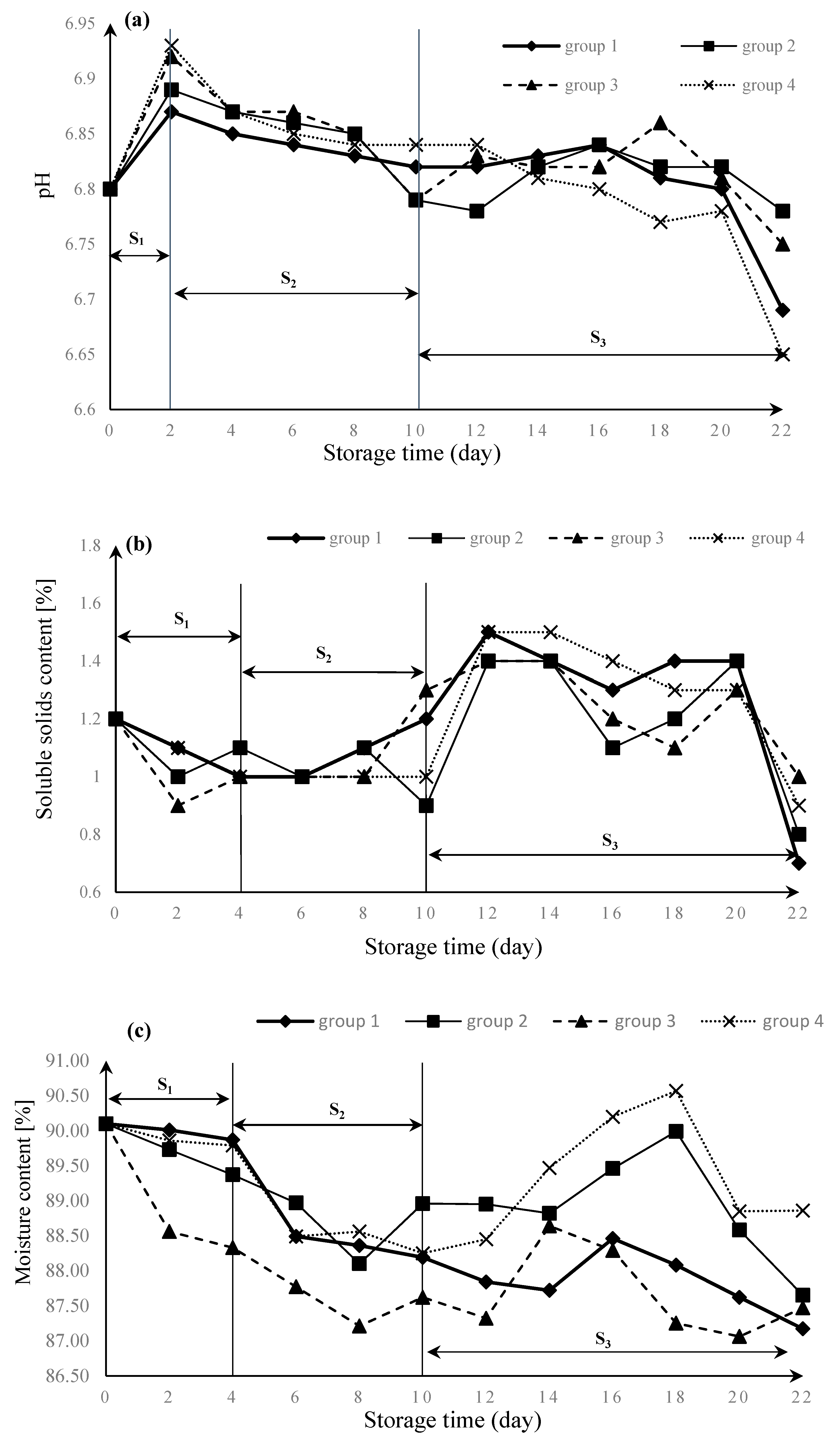

3.1.2. Changes in Physical and Chemical Characteristics

3.2. The Remaining Shelf Life Prediction Modelling by BP Neural Network

3.2.1. Parameter Optimization of Prediction Model

3.2.2. BP Neural Network Construction

3.2.3. Prediction Results of the Remaining Shelf Life Prediction Model

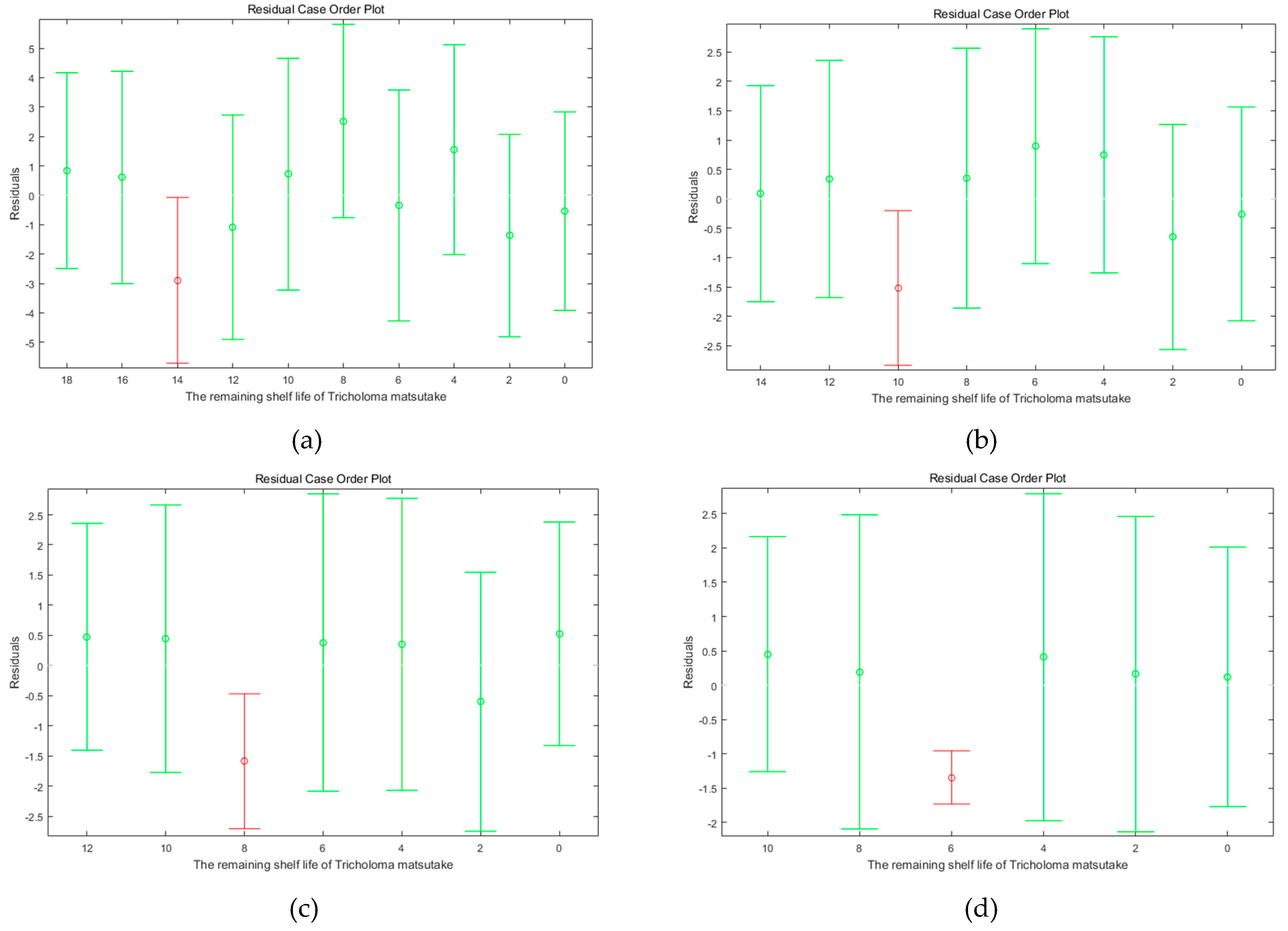

3.2.4. Prediction Models Verification of BP Neural Network

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yu, Z.; Fengzhong, W.; Yanbin, Z.; Ji, D.E.; Yangzhong, Z. The Tricholoma Matsutake Industry Status and Preliminary Study on its Sustainable Development Countermeasure. Farm Prod. Process. 2018, 11, 68–69. [Google Scholar]

- Yang, L.; Yuan, Q.J.; Feng, J.Y.; Zhang, X.S.; Wu, Z.G. Logistics Status of Wild Edible Fungi in Linzhi Area of Tibet. Storage Process. 2017, 17, 104–107. [Google Scholar]

- Shi, F.; Yao, L.I.; Yang, Y.; Tang, Y.; Wu, s.; Ming, J. Effect of Different Drying Methods on the Quality of Tricholoma matsutake. Food Sci. 2018, 38, 141–147. [Google Scholar]

- Chen, Y.; Du, X.-J.; Zhang, Y.; Liu, X.H.; Wang, X.D. Ultrasound extraction optimization, structural features, and antioxidant activity of polysaccharides from Tricholoma matsutake. J. Zhejiang Univ.-Sci. B 2017, 18, 674–684. [Google Scholar] [CrossRef]

- Xue, W.; Wang, Y. Influence of Modified Atmosphere Packaging on Physiological Characteristics of Tricholoma matsutake. Food Sci. 2013, 34, 327–330. [Google Scholar]

- Jun, W.U.; Luo, Y.F.; You, J.; Li, X.Y.; Xiao, G.N.; Zhang, M.; Guo, J. The Effect of MAP of Mushroom on the Shelf Date with Different Water Content Rate. J. Wuxi Univ. Light Ind. 2003, 22, 35–38. [Google Scholar]

- Zhou, C.M.; Wang, X.; Liu, B.L. Study of Different Packaging Films on the Freshness of white Hgpsizygus marmoreus Auto MAP. Food Ferment. Ind. 2010, 36, 205–210. [Google Scholar]

- Zhang, L.; Liu, L.D.; Ding, J.; Huang, Q.R. Screening and Fresh-keeping Effect of Composite Preservatives on Pleurotus ostyeatus. Food Sci. 2011, 32, 314–317. [Google Scholar]

- Luo, X.L.; Deng, Y.Y.; Cao, J.J.; Guo, Y.H. Effect of Controlled Atmosphere Storage on the Quality of Tricholoma matsutake. Edible Fungi China 2013, 32, 47–48. [Google Scholar]

- Wei-Si, Z.; Ming-Ying, G.; Jian-Ying, L.; Yong-Hong, G.; Jing-Jing, C.; Sha-Sha, Z. Effects of Hypobaric Storage on Tricholoma matsutake Fruit Body Parameters. Food Ind. 2017, 38, 16–19. [Google Scholar]

- Wang, Y.; Xue, W. Effect of different temperature and humidity on preservation of Tricholoma matsutake. Sci. Technol. Food Ind. 2012, 33, 365–366. [Google Scholar]

- Yan, Z.; Rui-Guang, L.I.; Yu-Min, L.; Yan, Y.; Yi-Nan, H.U.; Huang, L.; Gang, D.; Li-Fang, Q. Effect of convenience preservation technique (self-regulating gas storage) on preservation quality of Pine mushroom. Food Sci. Technol. 2015, 40, 337–343. [Google Scholar]

- Liu, Y. Research on the Modified Atmosphere Packaging Technology of Lentinus edoes. Food Ferment. Ind. 2007, 33, 155–158. [Google Scholar]

- Zhang, X.; Hua-Li, H.U.; Wang, Y.N.; Li, P.X. Multivariate Analysis of the Effects of Controlled Atmosphere Treatment on Quality of Pleurotus eryngii Mushroom during Shelf-life. Food Sci. 2014, 35, 265–270. [Google Scholar]

- Li, Y.; Ishikawa, Y.; Satake, T.; Kitazawa, H.; Qiu, X.; Rungchang, S. Effect of active modified atmosphere packaging with different initial gas compositions on nutritional compounds of shiitake mushrooms (Lentinus edodes). Postharvest Biol. Technol. 2014, 92, 107–113. [Google Scholar] [CrossRef]

- Matar, C.; Gaucel, S.; Gontard, N.; Guilbert, S.; Guillard, V. Predicting shelf life gain of fresh strawberries ‘Charlotte, cv’ in modified atmosphere packaging. Postharvest Biol. Technol. 2018, 142, 28–38. [Google Scholar] [CrossRef]

- Heydari, A.; Alemzadeh, I.; Vossoughi, M. Study and Mathematical Modeling of Transient Gas Compositions for Modified Atmosphere Packaging. In Analysis and Design of Biological Materials and Structures; Springer: Berlin, Germany, 2012; pp. 163–174. [Google Scholar]

- Mangaraj, S.; Goswami, T.K. Modified atmosphere packaging of fruits and vegetables for extending shelf-life-A review. Fresh produce. 2009, 3, 1–31. [Google Scholar]

- Kader, A.A.; Watkins, C.B. Modified Atmosphere Packaging—Toward 2000 and Beyond. Horttechnology 2000, 10, 483–486. [Google Scholar] [CrossRef]

- Wang, C.T.; Wang, C.T.; Cao, Y.P.; Nout, M.J.R.; Sun, B.G.; Liu, L. Effect of modified atmosphere packaging (MAP) with low and superatmospheric oxygen on the quality and antioxidant enzyme system of golden needle mushrooms (Flammulina velutipes) during postharvest storage. Eur. Food Res. Technol. 2011, 232, 851. [Google Scholar] [CrossRef]

- Selcuk, N.; Erkan, M. The effects of modified and palliflex controlled atmosphere storage on postharvest quality and composition of ‘Istanbul’ medlar fruit. Postharvest Biol. Technol. 2015, 99, 9–19. [Google Scholar] [CrossRef]

- Liamnimitr, N.; Thammawong, M.; Techavuthiporn, C.; Fahmyc, K.; Suzukid, T.; Nakanoa, K. Optimization of bulk modified atmosphere packaging for long-term storage of ‘Fuyu’ persimmon fruit. Postharvest Biol. Technol. 2018, 135, 1–7. [Google Scholar] [CrossRef]

- Charles, F.; Guillaume, C.; Gontard, N. Effect of passive and active modified atmosphere packaging on quality changes of fresh endives. Postharvest Biol. Technol. 2008, 48, 22–29. [Google Scholar] [CrossRef]

- Horev, B.; Sela, S.; Vinokur, Y.; Gorbatsevich, E.; Pinto, R.; Rodov, V. The effects of active and passive modified atmosphere packaging on the survival of Salmonella enterica serotype Typhimurium on washed romaine lettuce leaves. Food Res. Int. 2012, 45, 1129–1132. [Google Scholar] [CrossRef]

- Bhandari, B. Recent Application of Modified Atmosphere Packaging (MAP) in Fresh and Fresh-Cut Foods. Food Rev. Int. 2015, 31, 172–193. [Google Scholar]

- Chen, J.; Liu, X.D.; Deng, B.X.; Xie, J. Research on Kinetics of Quality and Shelf Life of Shiitake under Different Temperatures. J. Anhui Agric. Sci. 2009, 37, 2243–2245. [Google Scholar]

- Shasha, Z.; Yayuan, D.; Xiaoli, L.; Yonghong, G. Effects of Exposure to Hypobaric Conditions on Selected Tricholoma matsutake Fruit Body Parameters. Acta Edulis Fungi 2015, 22, 68–72. [Google Scholar]

- Hong, Z.; Hongmin, L.; Aijun, Z.; Zhonghou, T.; Jian, S.; Fei, X. Changes of respiratory intensity and quality of sweet potato during storage. Chin. Agric. Sci. Bulletin. 2010, 26, 64–67. [Google Scholar]

- Fu, Z.T.; Gao, Q.Z.; Li, X.W.; Zhang, X.; Zhang, X.S. Blueberry Shelf Life Prediction Method Based on the Sensor Information Stored Gas. Trans. Chin. Soc. Agric. Mach. 2018, 49, 308–315. [Google Scholar]

- Wang, P.; Zhang, K.S.; Ren, Y.X. Kinetic model of quality change and prediction of the shelf-life of stored mushroom. Sci. Technol. Food Ind. 2012, 33, 313–316. [Google Scholar]

- Sadeghi, B.H.M. A BP-neural network predictor model for plastic injection molding process. J. Mater. Process. Technol. 2000, 103, 411–416. [Google Scholar] [CrossRef]

- Radfard, M.; Soleimani, H.; Nabavi, S.; Hashemzadeh, B.; Akbari, H.; Akbari, H.; Adibzadeh, A. Data on Estimation for Sodium Absorption Ratio: Using Artificial Neural Network and Multiple Linear Regressions. Data Brief 2018, 20, 1462–1467. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, Y.; Liu, J.; Zhong, M.; Chen, Y.; Li, X. BP Neural Network Based Prediction Model for Fresh Egg’s Shelf Life. Trans. Chin. Soc. Agric. Mach. 2015, 46, 328–334. [Google Scholar]

- Pan, Z.; Huang, Z.; Wang, N.; Zhang, Z.; Xie, X.; Suo, B.; Lu, B.G.; Ai, Z.L. Prediction of shelf life for quick-frozen dumpling based on BP neural network and effective accumulated temperature theory. Trans. Chin. Soc. Agric. Eng. 2012, 28, 276–281. [Google Scholar]

- Wei, Y.; Jin-Liang, S.; Zhi-Gao, Y.; Ling-Mei, I.; Wei, W.; Ming, Y.U. Study on Chitosan Preservation Films Coating Tricholoma matsutake Sing. Edible Fungi China 2006, 1, 46–49. [Google Scholar]

- Xiao, Z.; Ye, S.J.; Zhong, B.; Sun, C.-X. BP neural network with rough set for short term load forecasting. Expert Syst. Appl. 2009, 36, 273–279. [Google Scholar] [CrossRef]

- Li, J.C.; Zhao, D.L.; Ge, B.F.; Yang, K.W.; Chen, Y.W. A link prediction method for heterogeneous networks based on BP neural network. Phys. A Stat. Mech. Its Appl. 2017, 495, 1–17. [Google Scholar] [CrossRef]

- Sun, Y.J.; Shen, Z.; Miao, C.X.; Li, J.M. Improved BP Neural Network for Transformer Fault Diagnosis. J. China Univ. Min. Technol. 2007, 17, 138–142. [Google Scholar] [CrossRef]

- Lv, Z.; Tek, A.; Silva, F.D.; Empereur-mot, C.; Chavent, M.; Baaden, M. Game on, science—How video game technology may help biologists tackle visualization challenges. PLoS ONE 2013, 8, e57990. [Google Scholar] [CrossRef]

- Chen, X.Y.; Zhu, Z.Q.; Zhang, X.S.; Mu, W.S.; Fu, Z.T. Research Progress and Trend of Food Shelf Life Prediction. Trans. Chin. Soc. Agric. Mach. 2015, 46, 192–199. [Google Scholar]

- Gámbaro, A.; Ares, G.; Giménez, A. Shelf-life estimation of apple-baby goods. J. Sens. Stud. 2010, 21, 101–111. [Google Scholar] [CrossRef]

- Lareo, C.; Ares, G.; Ferrando, L.; Lema, P. Influence of temperature on shelf life of butterhead lettuce leaves under passive modified atmosphere packaging. J. Food Qual. 2010, 32, 240–261. [Google Scholar] [CrossRef]

| Group | O2 | CO2 | N2 | Air |

|---|---|---|---|---|

| 1 | 1% | 21% | 78% | - |

| 2 | 5% | 17% | 78% | - |

| 3 | 10% | 12% | 78% | - |

| 4 | - | - | - | 100% |

| Score | Hardness | Color | Odor |

|---|---|---|---|

| 4 | The cap is elastic, and the stipe is hard. | The cap is fresh, and its color is shining chestnut-colored. The stipe is ivory, no browning. | It has strong fragrance. |

| 3 | The cap is less elastic, and the stipe is less hard. | Normal color, slight browning. | Normal, no peculiar smell. |

| 2 | The cap and stipe begin to soften. | Moderate browning. | Slightly peculiar smell. |

| 1 | The cap and stipe begin to severely soften | Severe browning, mildew appearing. | Serious peculiar smell. |

| Groups | Cap Hardness | Stipe Hardness | Color | Odor | pH | Soluble Solids Content | Moisture Content |

|---|---|---|---|---|---|---|---|

| 1 | 0.81 * | 0.93 ** | 0.90 ** | 0.92 ** | 0.26 | −0.71 | 0.84 * |

| 2 | 0.86* | 0.96 ** | 0.91 ** | 0.96 ** | 0.47 | −0.46 | 0.71 |

| 3 | 0.89* | 0.92 ** | 0.89 * | 0.94 ** | 0.33 | −0.58 | 0.88 * |

| 4 | 0.82* | 0.96 ** | 0.92 ** | 0.93 ** | 0.11 | 0.83 * | 0.94 ** |

| Title | Group 1 | Group 2 | Group 3 | Group 4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Actual Data | Prediction Data | Absolut Error | Actual Data | Prediction Data | Absolut Error | Actual Data | Prediction Data | Absolute Error | Actual Data | Prediction Data | Absolute Error | |

| 0 | 18.00 | 18.03 | 0.03 | 14.00 | 13.49 | 0.51 | 12.00 | 12.00 | 0.00 | 10.00 | 9.94 | 0.06 |

| 2 | 16.00 | 15.99 | 0.01 | 12.00 | 11.87 | 0.13 | 10.00 | 10.00 | 0.00 | 8.00 | 7.93 | 0.07 |

| 4 | 14.00 | 10.68 | 3.32 | 10.00 | 8.14 | 1.86 | 8.00 | 6.00 | 2.00 | 6.00 | 4.64 | 1.36 |

| 6 | 12.00 | 10.68 | 1.32 | 8.00 | 8.14 | 0.14 | 6.00 | 6.00 | 0.00 | 4.00 | 4.64 | 0.64 |

| 8 | 10.00 | 10.68 | 0.68 | 6.00 | 6.81 | 0.81 | 4.00 | 4.00 | 0.00 | 2.00 | 2.64 | 0.64 |

| 10 | 8.00 | 10.68 | 2.68 | 4.00 | 4.79 | 0.79 | 2.00 | 1.08 | 0.92 | 0.00 | 0.85 | 0.85 |

| 12 | 6.00 | 6.00 | 0.00 | 2.00 | 1.52 | 0.48 | 0.00 | 0.24 | 0.24 | |||

| 14 | 4.00 | 5.09 | 1.09 | 0.00 | 0.04 | 0.04 | ||||||

| 16 | 2.00 | 1.36 | 0.65 | |||||||||

| 18 | 0.00 | 0.38 | 0.38 | |||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Z.; Zhao, S.; Zhang, X.; Polovka, M.; Wang, X. Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain. Foods 2019, 8, 136. https://doi.org/10.3390/foods8040136

Fu Z, Zhao S, Zhang X, Polovka M, Wang X. Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain. Foods. 2019; 8(4):136. https://doi.org/10.3390/foods8040136

Chicago/Turabian StyleFu, Zetian, Shuang Zhao, Xiaoshuan Zhang, Martin Polovka, and Xiang Wang. 2019. "Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain" Foods 8, no. 4: 136. https://doi.org/10.3390/foods8040136

APA StyleFu, Z., Zhao, S., Zhang, X., Polovka, M., & Wang, X. (2019). Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain. Foods, 8(4), 136. https://doi.org/10.3390/foods8040136