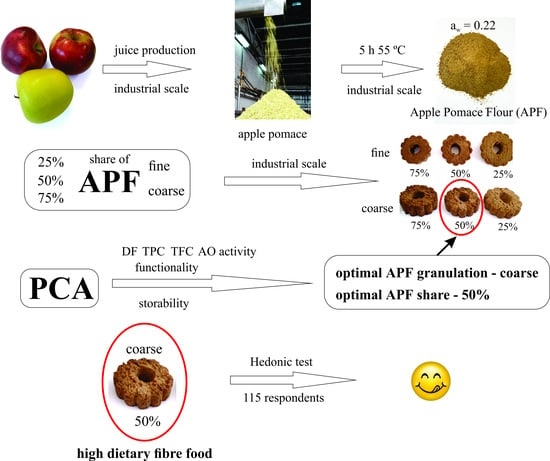

Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemicals

2.1.2. Apple Pomace Flour Production and Analysis

2.2. Determination of Technological Properties of APF

2.3. Production of Fortified Cookies with 25%, 50% and 75% of APF

2.4. Determination of Fortified Cookies Functionality

2.4.1. Determination of Dietary Fiber Content

2.4.2. Determination of Total Polyphenolics (TPCs) and Flavonoids Content (TFCs)

2.4.3. Determination of Antioxidant Activity

2.5. Sensory Analysis of Fortified Cookies using a Scoring Method

2.6. Estimation of Fortified Cookies Storability

2.7. Estimation of Optimal Share and Particle Size of APF

2.8. Estimation of Consumer Acceptance of Fortified Cookies with Optimal APF Share

2.9. Statistical Analysis

3. Results and Discussion

3.1. Production and Analysis of APF

3.2. Technological Properties of Industrially Produced APF

3.3. Production of Fortified Cookies with 25%, 50% and 75% of APF

3.4. Functionality of Fortified Cookies

3.4.1. Content of Dietary Fibers

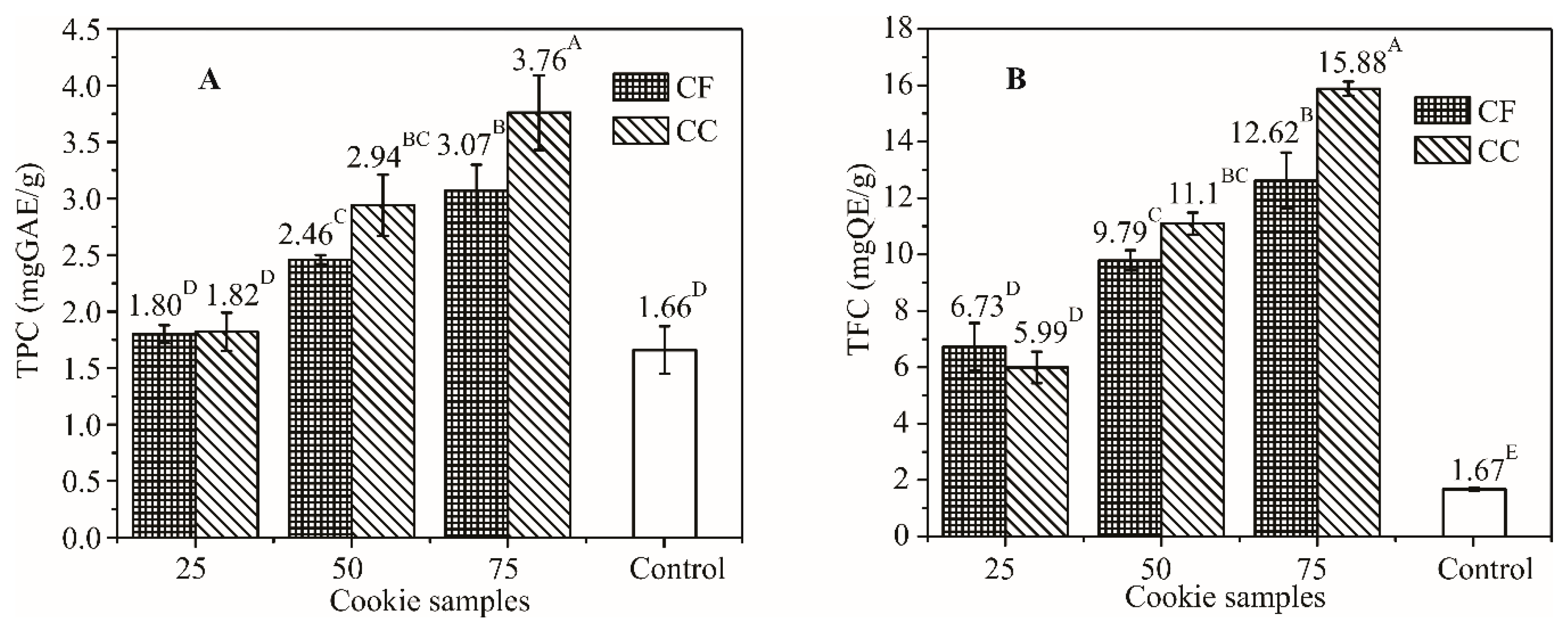

3.4.2. Content of Dietary Polyphenolics (TPCs) and Flavonoids (TFCs)

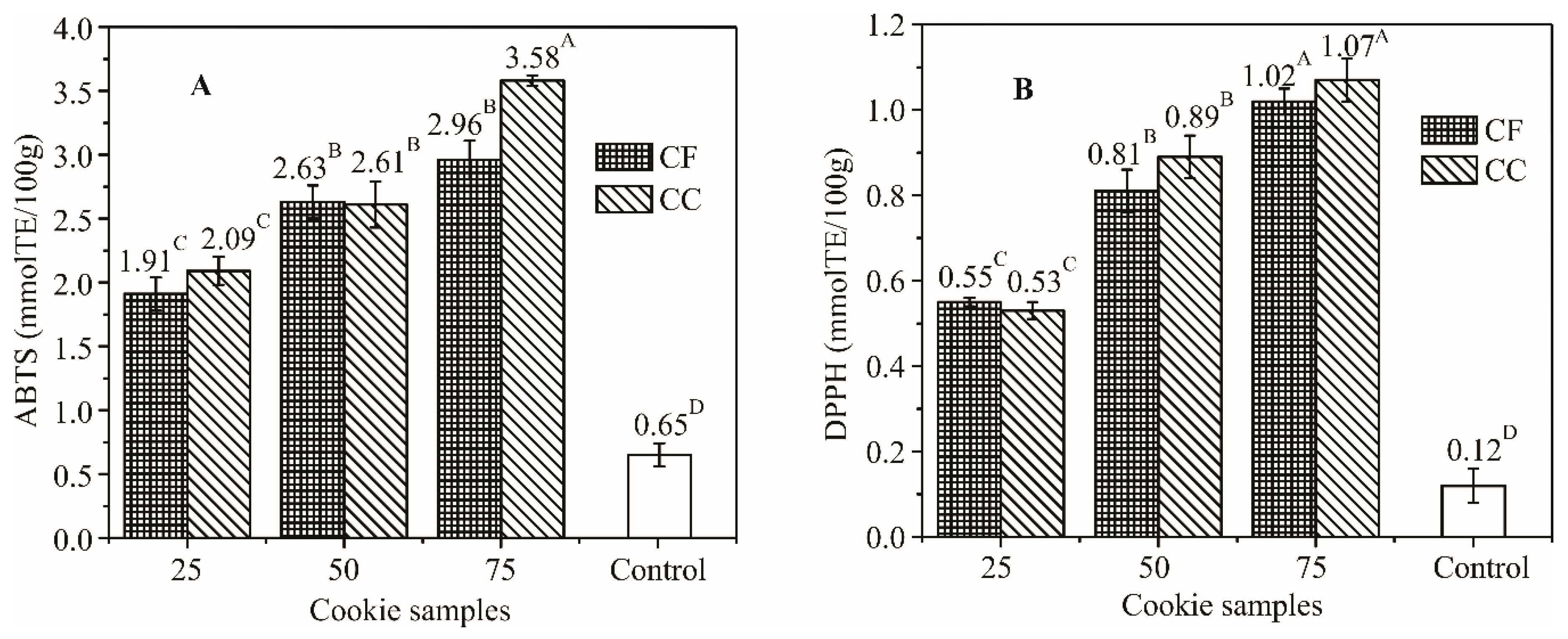

3.4.3. Antioxidant Activity

3.5. Sensorial Properties of Fortified Cookies

3.6. Storability of Fortified Cookies

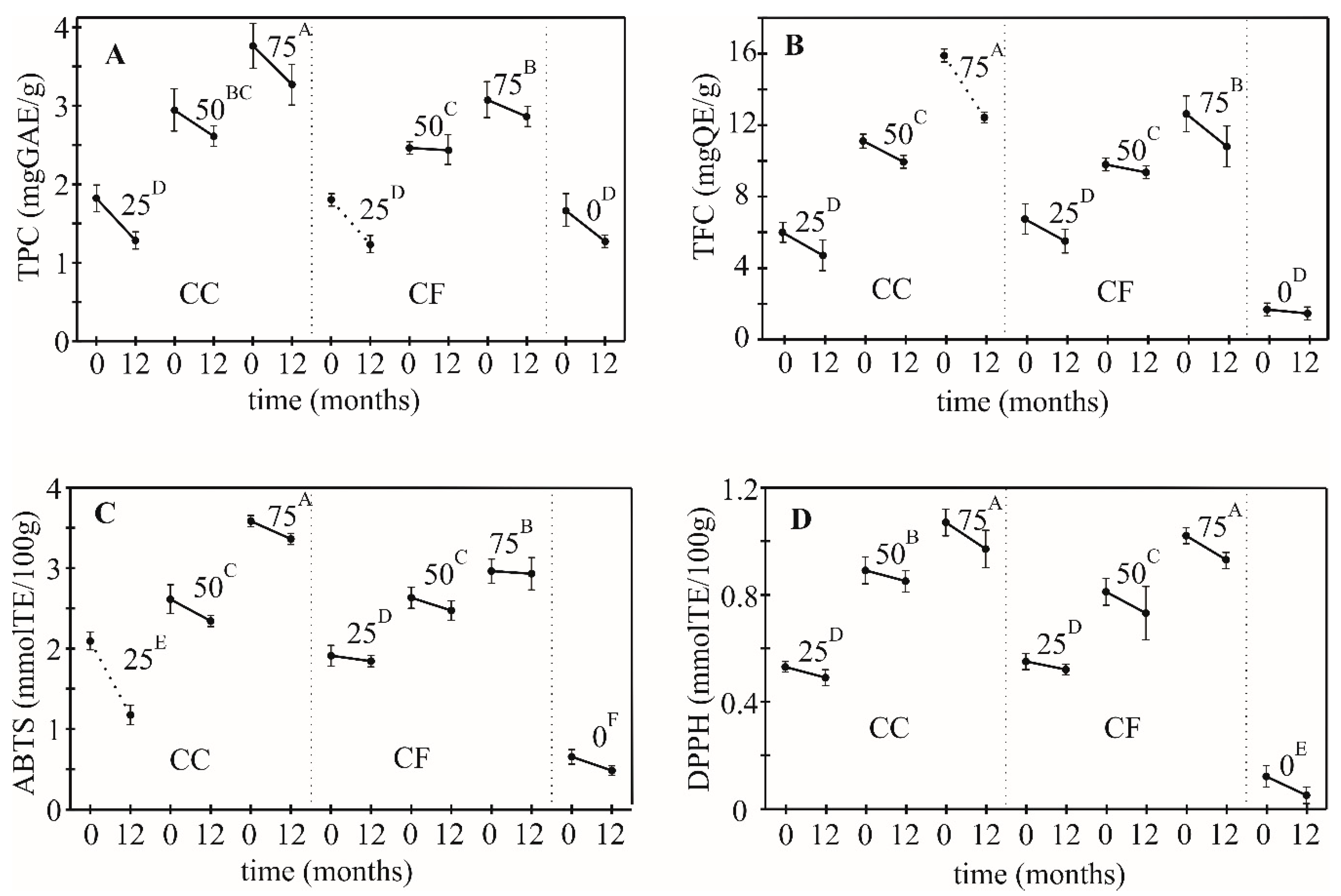

3.6.1. The Effect of Storage on the Functional Properties of Fortified Cookies

3.6.2. The Effect of Storage on the Sensorial Properties of Fortified Cookies

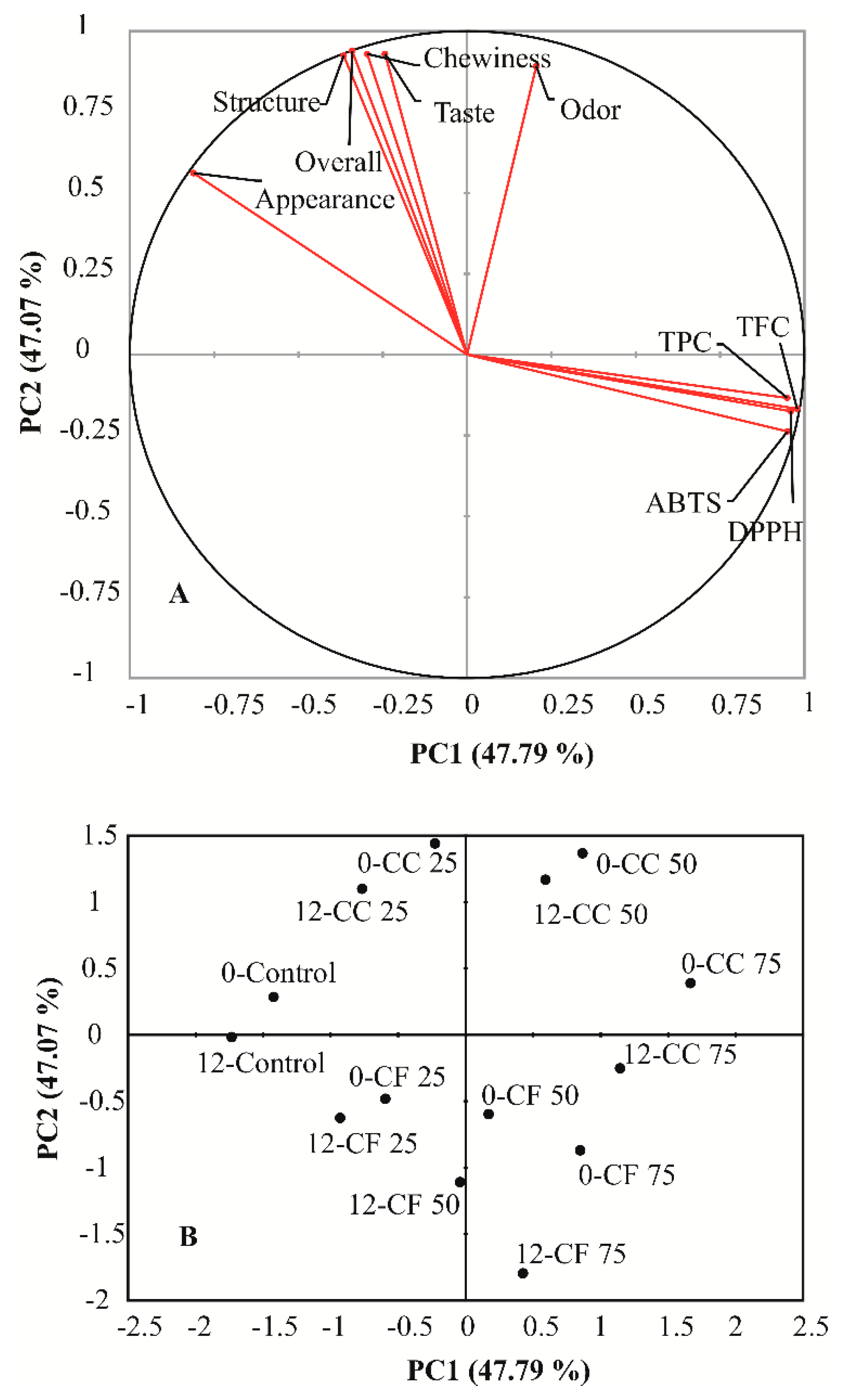

3.7. Estimation of the Optimal Share and Particle Size of APF

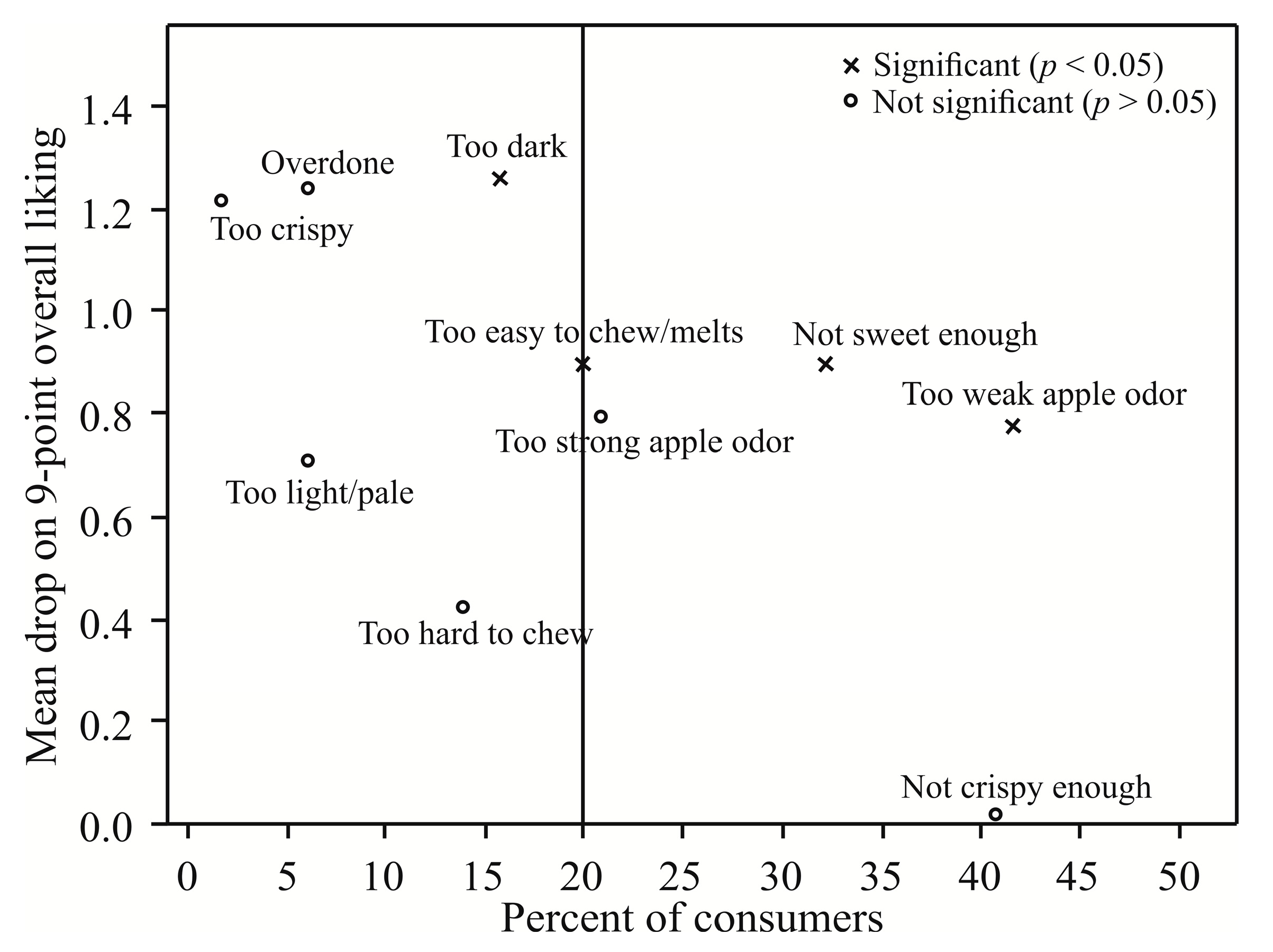

3.8. Consumer Acceptability of Cookies with 50% of Coarse APF

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Skinner, R.C.; Gigliotti, J.C.; Ku, K.-M.M.; Tou, J.C. A comprehensive analysis of the composition, health benefits, and safety of apple pomace. Nutr. Rev. 2018, 76, 893–909. [Google Scholar] [CrossRef]

- Masoodi, F.A.; Sharma, B.; Chauhan, G.S. Use of apple pomace as a source of dietary fiber in cakes. Plant Foods Hum. Nutr. 2002, 57, 121–128. [Google Scholar] [CrossRef]

- Wolfe, K.L.; Liu, R.H. Apple Peels as a Value-Added Food Ingredient. J. Agric. Food Chem. 2003, 51, 1676–1683. [Google Scholar] [CrossRef]

- Sun, L.; Sun, J.; Meng, Y.; Yang, X.; Guo, Y. Purification, Characterization, Antioxidant and Antitumour Activities of Polysaccharides from Apple Peel Pomace Obtained by Pre-pressing Separation. Int. J. Food Eng. 2017, 13, 14. [Google Scholar] [CrossRef]

- Yang, X.; Yang, S.; Guo, Y.; Jiao, Y.; Zhao, Y. Compositional characterisation of soluble apple polysaccharides, and their antioxidant and hepatoprotective effects on acute CCl4-caused liver damage in mice. Food Chem. 2013, 138, 1256–1264. [Google Scholar] [CrossRef]

- Cao, X.; Wang, C.; Pei, H.; Sun, B. Separation and identification of polyphenols in apple pomace by high-speed counter-current chromatography and high-performance liquid chromatography coupled with mass spectrometry. J. Chromatogr. A 2009, 1216, 4268–4274. [Google Scholar] [CrossRef]

- Ćetković, G.; Čanadanović-Brunet, J.; Djilas, S.; Savatović, S.; Mandić, A.; Tumbas, V. Assessment of polyphenolic content and in vitro antiradical characteristics of apple pomace. Food Chem. 2008, 109, 340–347. [Google Scholar] [CrossRef]

- Rana, S.; Rana, A.; Gulati, A.; Bhushan, S. RP-HPLC-DAD Determination of Phenolics in Industrial Apple Pomace. Food Anal. Methods 2014, 7, 1424–1432. [Google Scholar] [CrossRef]

- Sánchez-Rabaneda, F.; Jáuregui, O.; Lamuela-Raventós, R.M.; Viladomat, F.; Bastida, J.; Codina, C. Qualitative analysis of phenolic compounds in apple pomace using liquid chromatography coupled to mass spectrometry in tandem mode. Rapid Commun. Mass Spectrom. 2004, 18, 553–563. [Google Scholar] [CrossRef]

- Reis, S.F.; Rai, D.K.; Abu-Ghannam, N. Apple pomace as a potential ingredient for the development of new functional foods. Int. J. Food Sci. Technol. 2014, 49, 1743–1750. [Google Scholar] [CrossRef]

- Rana, S.; Bhushan, S. Apple phenolics as nutraceuticals: Assessment, analysis and application. J. Food Sci. Technol. 2016, 53, 1727–1738. [Google Scholar] [CrossRef] [PubMed]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Tambunan, A.H.; Yudistira; Kisdiyani; Hernani. Freeze drying characteristics of medicinal herbs. Dry. Technol. 2001, 19, 325–331. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Effect of Different Drying Methods and Storage Time on the Retention of Bioactive Compounds and Antibacterial Activity of Wine Grape Pomace (Pinot Noir and Merlot). J. Food Sci. 2012, 77, H192–H201. [Google Scholar] [CrossRef]

- Veselinović, N.; Veselinović, M. Solar and Electric Energy Dryers. U.S. 2010/0223807 A1 9 September 2010. [Google Scholar]

- Zlatanović, S.; Gorjanović, S.; Ostojić, S.; Micić, D.; Pastor, F.; Kalušević, A.; Laličić-Petronijević, J. Method for Producing Gluten-Free Flour Made of Apple Pomace. RS P20180918 PCT/RS2019/000019 3 August 2019. International Patent Application 2019. [Google Scholar]

- Zlatanović, S.; Ostojić, S.; Micić, D.; Rankov, S.; Dodevska, M.; Vukosavljević, P.; Gorjanović, S. Thermal behaviour and degradation kinetics of apple pomace flours. Thermochim. Acta 2019, 673, 17–25. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Wang, L.; Huber, G.M.; Pitts, N.L. Effect of baking on dietary fibre and phenolics of muffins incorporated with apple skin powder. Food Chem. 2008, 107, 1217–1224. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Masoodi, F.A.; Chauhan, G.S. Use of apple pomace as a source of dietary fiber in wheat bread. J. Food Process. Preserv. 1998, 22, 255–263. [Google Scholar] [CrossRef]

- Jung, J.; Cavender, G.; Zhao, Y. Impingement drying for preparing dried apple pomace flour and its fortification in bakery and meat products. J. Food Sci. Technol. 2015, 52, 5568–5578. [Google Scholar] [CrossRef]

- Mir, S.A.; Bosco, S.J.D.; Shah, M.A.; Santhalakshmy, S.; Mir, M.M. Effect of apple pomace on quality characteristics of brown rice based cracker. J. Saudi Soc. Agric. Sci. 2017, 16, 25–32. [Google Scholar] [CrossRef]

- Kaushal, N.; Joshi, V. Preparation and evaluation of apple pomace based cookies. Indian Food Pack 1995, 49, 17–24. [Google Scholar]

- Saeed, M.; Inam-Ur-Raheem, M.; Shakeel, A.; Wasim Aslam, H.K.; Siddique Raza, M.; Razzaq, Z.; Muhammad, R.S.; Shoaib, M. Effect of water chest nut and apple pomace powder on the quality parameters of cookies. J. Glob. Innov. Agric. Soc. Sci. 2015, 3, 142–145. [Google Scholar]

- Carson, K.J.; Collins, J.L.; Penfield, M.P. Unrefined, Dried Apple Pomace as a Potential Food Ingredient. J. Food Sci. 1994, 59, 1213–1215. [Google Scholar] [CrossRef]

- Jacobs, P.J.; Hemdane, S.; Dornez, E.; Delcour, J.A.; Courtin, C.M. Study of hydration properties of wheat bran as a function of particle size. Food Chem. 2015, 179, 296–304. [Google Scholar] [CrossRef]

- Elkhalifa, A.E.O.; Schiffler, B.; Bernhardt, R. Effect of fermentation on the functional properties of sorghum flour. Food Chem. 2005, 92, 1–5. [Google Scholar] [CrossRef]

- Rana, S.; Gupta, S.; Rana, A.; Bhushan, S. Functional properties, phenolic constituents and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 2015, 4, 180–187. [Google Scholar] [CrossRef]

- Robertson, J.A.; de Monredon, F.D.; Dysseler, P.; Guillon, F.; Amado, R.; Thibault, J.-F. Hydration Properties of Dietary Fibre and Resistant Starch: A European Collaborative Study. LWT Food Sci. Technol. 2000, 33, 72–79. [Google Scholar] [CrossRef]

- AOAC. Total dietary fiber in foods: Enzymatic-gravimetric method. In Official Methods of Analysis, Method 985.29; AOAC International: Arlington, VA, USA, 1990. [Google Scholar]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- Kaneda, H.; Kobayashi, N.; Furusho, S.; Sahara, H.; Koshino, S. Reducing activity and flavor stability of beer. Tech. Q. Master Brew. Assoc. Am. 1995, 32, 90–94. [Google Scholar]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Schraidt, M. Appendix L: Penalty analysis or mean drop analysis. In ASTM Manual Series: MNL 63—Just-About-Right (JAR) Scales: Design, Usage, Benefits and Risks; Rothman, L., Parker, M.J., Eds.; ASTM International—American Society for Testing and Materials: Bridgeport, NJ, USA, 2009; pp. 50–53. [Google Scholar]

- Sahni, P.; Shere, D. Effect of Different Packaging Materials on Sensory Attributes of Fibre Rich Cookies during Storage. Int. J. Pure Appl. Biosci. 2017, 5, 265–272. [Google Scholar] [CrossRef]

- Jakubczyka, E.; Gondeka, E.; Tamborb, K. Characteristics of selected functional properties of apple powders obtained by the foam-mat drying method. In Proceedings of the Food Process Engineering in a Changing World, Athens, Greece, 22–26 May 2011; Taoukis, P.S., Stoforos, N.G., Karathanos, V.T., Saravacos, G.D., Eds.; Cosmosware: Athens, Greece, 2011; pp. 1385–1386. [Google Scholar]

- Oyeyinka, S.A.; Oyeyinka, A.T.; Opaleke, D.O.; Karim, O.R.; Kolawole, F.L.; Ogunlakin, G.O.; Olayiwola, O.H. Cake production from wheat (triticum aestivum) and cowpea (vigna unguiculata) flours using date fruit as a sweetener. Ann. Food Sci. Technol. 2014, 15, 20–28. [Google Scholar]

- Joshi, A.U.; Liu, C.; Sathe, S.K. Functional properties of select seed flours. LWT Food Sci. Technol. 2015, 60, 325–331. [Google Scholar] [CrossRef]

- Kang, H.-M.; Lee, J.-H.; Kim, R.-H.; Yun, J.-H.; Chun, B.-S. Characterization of Wheat Flour Treated by Supercritical Carbon Dioxide. APCBEE Procedia 2012, 2, 12–16. [Google Scholar] [CrossRef][Green Version]

- Rosniyana, A.; Hazila, K.K.; Norin, S.; Abdullah, S. Characteristics of local rice flour (MR 220) produced by wet and dry milling methods. J. Trop. Agric. Fd. Sc 2016, 44, 147–155. [Google Scholar]

- Charrondiere, U.R.; Haytowitz, D.; Stadlmayr, B. INFOODS: FAO/INFOODS Density Database—Version 2.0; FAO: Rome, Italy, 2012. [Google Scholar]

- Oladapo, A.; Adepeju, A.; Akinyele, A.; Adepeju, D. The Proximate, Functional and Anti-Nutritional Properties of Three Selected Varieties of Maize (Yellow, White and Pop Corn) Flour. Int. J. Sci. Sci. 2017, 1, 23–26. [Google Scholar]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; O’Shea, N.; Gallagher, E. Rheological properties of wheat dough supplemented with functional by-products of food processing: Brewer’s spent grain and apple pomace. J. Food Eng. 2013, 116, 362–368. [Google Scholar] [CrossRef]

- Alongi, M.; Melchior, S.; Anese, M. Reducing the glycemic index of short dough biscuits by using apple pomace as a functional ingredient. LWT 2019, 100, 300–305. [Google Scholar] [CrossRef]

- Cerda-Tapia, A.; Pérez-Chabela, M.L.; Pérez-Álvarez, J.Á.; Fernández-López, J.; Viuda-Martos, M. Valorization of Pomace Powder Obtained from Native Mexican Apple (Malus domestica var. rayada): Chemical, Techno-functional and Antioxidant Properties. Plant Foods Hum. Nutr. 2015, 70, 310–316. [Google Scholar] [CrossRef] [PubMed]

- Bushuk, W.; Békés, F. Contribution of protein to flour quality. In Novel Raw Materials, Technologies and Products-New Challenge for the Quality Control; Salgo, A., Tomoskozi, S., Lasztity, R., Eds.; International Association for Cereal Science and Technology (ICC): Budapest, Hungary, 2002; pp. 14–19. [Google Scholar]

- Kohajdová, Z.; Karovičová, J.; Jurasová, M.; Kukurová, K. Effect of the addition of commercial apple fibre powder on the baking and sensory properties of cookies. Acta Chim. Slovaca 2011, 4, 88–97. [Google Scholar]

- Belorio, M.; Sahagún, M.; Gómez, M. Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies. Foods 2019, 8, 83. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Rubenthaler, G.L.; Leung, H.K.; Baranowski, J.D. Chemical, Physical, and Baking Properties of Apple Fiber Compared with Wheat and Oat Bran. Cereal Chem. 1988, 65, 244–247. [Google Scholar]

- Wang, X.; Kristo, E.; LaPointe, G. The effect of apple pomace on the texture, rheology and microstructure of set type yogurt. Food Hydrocoll. 2019, 91, 83–91. [Google Scholar] [CrossRef]

- Dhingra, D.; Michael, M.; Rajput, H.; Patil, R.T. Dietary fibre in foods: A review. J. Food Sci. Technol. 2012, 49, 255–266. [Google Scholar] [CrossRef]

- Sahni, P.; Shere, D. Comparative Evaluation of Physico-chemical and Functional Properties of Apple, Carrot and Beetroot Pomace Powders. Int. J. Food Ferment. Technol. 2017, 7, 317–323. [Google Scholar]

- Rabetafika, H.N.; Bchir, B.; Aguedo, M.; Paquot, M.; Blecker, C. Effects of Processing on the Compositions and Physicochemical Properties of Fibre Concentrate from Cooked Fruit Pomaces. Food Bioprocess Technol. 2014, 7, 749–760. [Google Scholar] [CrossRef]

- Garau, M.C.; Simal, S.; Rosselló, C.; Femenia, A. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem. 2007, 104, 1014–1024. [Google Scholar] [CrossRef]

- Grover, S.S.; Chauhan, G.S.; Masoodi, F.A. Effect of Particle Size on Surface Properties of Apple Pomace. Int. J. Food Prop. 2003, 6, 1–7. [Google Scholar] [CrossRef]

- Sangnark, A.; Noomhorm, A. Effect of particle sizes on functional properties of dietary fibre prepared from sugarcane bagasse. Food Chem. 2003, 80, 221–229. [Google Scholar] [CrossRef]

- Agostoni, C.; Bresson, J.-L.; Fairweather-Tait, S.; Flynn, A.; Golly, I.; Korhonen, H.; Lagiou, P.; Løvik, M.; Marchelli, R.; Martin, A.; et al. Scientific Opinion on Dietary Reference Values for carbohydrates and dietary fibre. EFSA J. 2010, 8, 1462. [Google Scholar]

- Ajila, C.M.; Leelavathi, K.; Prasada Rao, U.J.S. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Tańska, M.; Roszkowska, B.; Czaplicki, S.; Borowska, E.J.; Bojarska, J.; Dąbrowska, A. Effect of Fruit Pomace Addition on Shortbread Cookies to Improve Their Physical and Nutritional Values. Plant Foods Hum. Nutr. 2016, 71, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Sudha, M.L. Apple Pomace (By-Product of Fruit Juice Industry) as a Flour Fortification Strategy. Flour Breads Their Fortif. Heal. Dis. Prev. 2011, 395–405. [Google Scholar]

- Lawless, H.T.; Heymann, H. Introduction. In Sensory Evaluation of Food; Springer: New York, NY, USA, 2010; pp. 1–18. [Google Scholar]

- Espino-Díaz, M.; Sepúlveda, D.R.; González-Aguilar, G.; Olivas, G.I. Biochemistry of apple aroma: A review. Food Technol. Biotechnol. 2016, 54, 375–397. [Google Scholar] [CrossRef]

- Bangerth, F.K.; Song, J.; Streif, J. Physiological Impacts of Fruit Ripening and Storage Conditions on Aroma Volatile Formation in Apple and Strawberry Fruit: A Review. HortScience 2012, 47, 4–10. [Google Scholar] [CrossRef]

| Technological Properties | APF (Fine) | APF (Coarse) |

|---|---|---|

| Bulked density (g/L) | 435 ± 16 | 459 ± 20 |

| Packed density(g/L) | 632 ± 25 | 591 ± 24 |

| Water holding capacity (g/g) | 4.69 ± 0.19 | 4.79 ± 0.18 |

| Solubility (%) | 27.9 ± 0.9 | 29.1 ± 0.7 |

| Hydrated density (g/mL) | 0.50 ± 0.02 | 0.63 ± 0.03 |

| Swelling capacity (mL/g) | 5.5 ± 0.2 | 7.0 ± 0.3 |

| Oil holding capacity (g/g) | 1.27 ± 0.04 | 1.4 ± 0.05 |

| Appearance | Structure, Snap, Doneness | Chewiness | Odor | Taste | Overall | |

|---|---|---|---|---|---|---|

| Control | 4.81 ± 0.12 a | 4.44 ± 0.12 ab | 4.16 ± 0.23 bcd | 4.66 ± 0.44 abc | 4.34 ± 0.13 abc | 4.46 ± 0.10 b |

| 0-CF25 | 4.06 ± 0.12 cd | 3.94 ± 0.18 cde | 4.06 ± 0.12 cd | 4.12 ± 0.23 cd | 4.25 ± 0.19 bc | 4.10 ± 0.08 cd |

| 0-CF50 | 3.84 ± 0.13 cde | 3.81 ± 0.26 de | 3.75 ± 0.33 def | 4.19 ± 0.22 cd | 4.06 ± 0.12 cd | 3.94 ± 0.10 de |

| 0-CF75 | 3.59 ± 0.13 ef | 3.50 ± 0.23 ef | 3.34 ± 0.13 ef | 4.44 ± 0.32 abcd | 3.63 ± 0.44 de | 3.70 ± 0.21 ef |

| 0-CC25 | 4.59 ± 0.33 ab | 4.75 ± 0.00 a | 4.75 ± 0.35 a | 4.84 ± 0.13 a | 4.84 ± 0.19 a | 4.77 ± 0.11 a |

| 0-CC50 | 4.06 ± 0.18 cd | 4.66 ± 0.13 a | 4.50 ± 0.33 abc | 4.81 ± 0.12 a | 4.75 ± 0.19 ab | 4.59 ± 0.11 ab |

| 0-CC75 | 3.66 ± 0.30 def | 3.94 ± 0.18 cde | 3.84 ± 0.19 de | 4.75 ± 0.19 ab | 4.13 ± 0.40 cd | 4.09 ± 0.14 d |

| Appearance | Structure, Snap, Doneness | Chewiness | Odor | Taste | Overall | |

|---|---|---|---|---|---|---|

| 12-control | 4.81 ± 0.12 a | 4.41 ± 0.30 abc | 4.13 ± 0.23 bcd | 4.50 ± 0.40 abcd | 4.25 ± 0.30 bc | 4.39 ± 0.18 bc |

| 12-CF25 | 4.22 ± 0.21 bc | 4.03 ± 0.36 bcd | 3.94 ± 0.12 cd | 4.13 ± 0.27 cd | 4.13 ± 0.13 cd | 4.08 ± 0.12 d |

| 12-CF50 | 3.91 ± 0.19 cde | 3.72 ± 0.41 de | 3.34 ± 0.27 ef | 4.22 ± 0.21 bcd | 3.63 ± 0.30 de | 3.75 ± 0.18 e |

| 12-CF75 | 3.34 ± 0.30 f | 3.22 ± 0.39 f | 3.19 ± 0.32 f | 4.06 ± 0.44 d | 3.25 ± 0.52 e | 3.41 ± 0.26 f |

| 12-CC25 | 4.66 ± 0.30 a | 4.75 ± 0.19 a | 4.66 ± 0.44 ab | 4.81 ± 0.22 a | 4.59 ± 0.30 abc | 4.69 ± 0.10 ab |

| 12-CC50 | 4.09 ± 0.13 c | 4.50 ± 0.19 ab | 4.44 ± 0.55 abc | 4.81 ± 0.22 a | 4.72 ± 0.25 ab | 4.54 ± 0.17 ab |

| 12-CC75 | 3.50 ± 0.19 ef | 3.81 ± 0.26 de | 3.72 ± 0.21 def | 4.66 ± 0.13 abc | 3.69 ± 0.12 de | 3.88 ± 0.13 de |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zlatanović, S.; Kalušević, A.; Micić, D.; Laličić-Petronijević, J.; Tomić, N.; Ostojić, S.; Gorjanović, S. Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration. Foods 2019, 8, 561. https://doi.org/10.3390/foods8110561

Zlatanović S, Kalušević A, Micić D, Laličić-Petronijević J, Tomić N, Ostojić S, Gorjanović S. Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration. Foods. 2019; 8(11):561. https://doi.org/10.3390/foods8110561

Chicago/Turabian StyleZlatanović, Snežana, Ana Kalušević, Darko Micić, Jovanka Laličić-Petronijević, Nikola Tomić, Sanja Ostojić, and Stanislava Gorjanović. 2019. "Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration" Foods 8, no. 11: 561. https://doi.org/10.3390/foods8110561

APA StyleZlatanović, S., Kalušević, A., Micić, D., Laličić-Petronijević, J., Tomić, N., Ostojić, S., & Gorjanović, S. (2019). Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration. Foods, 8(11), 561. https://doi.org/10.3390/foods8110561