Optimizing 3D Food Printing of Surimi via Regression Analysis: Physical Properties and Additive Formulations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Surimi Paste

2.3. Screw-Based 3D Food Printer and 3D Model

2.4. Printability

2.5. Physical Properties of Surimi

2.5.1. Rheological Properties

Oscillation Amplitude Tests

Oscillation Frequency Tests

2.5.2. Texture Profile Analysis

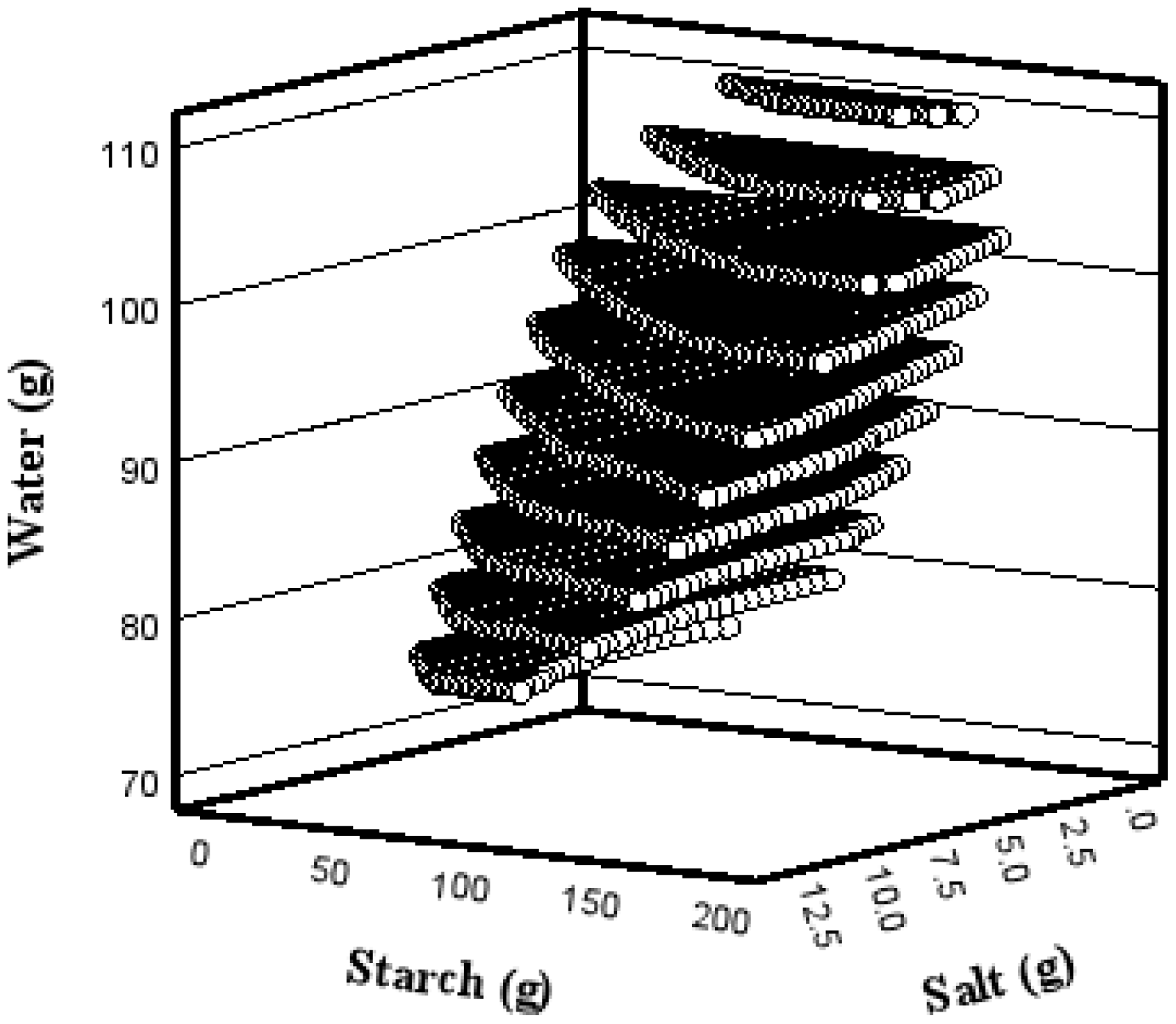

2.6. Central Composite Design for Regression Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Printability

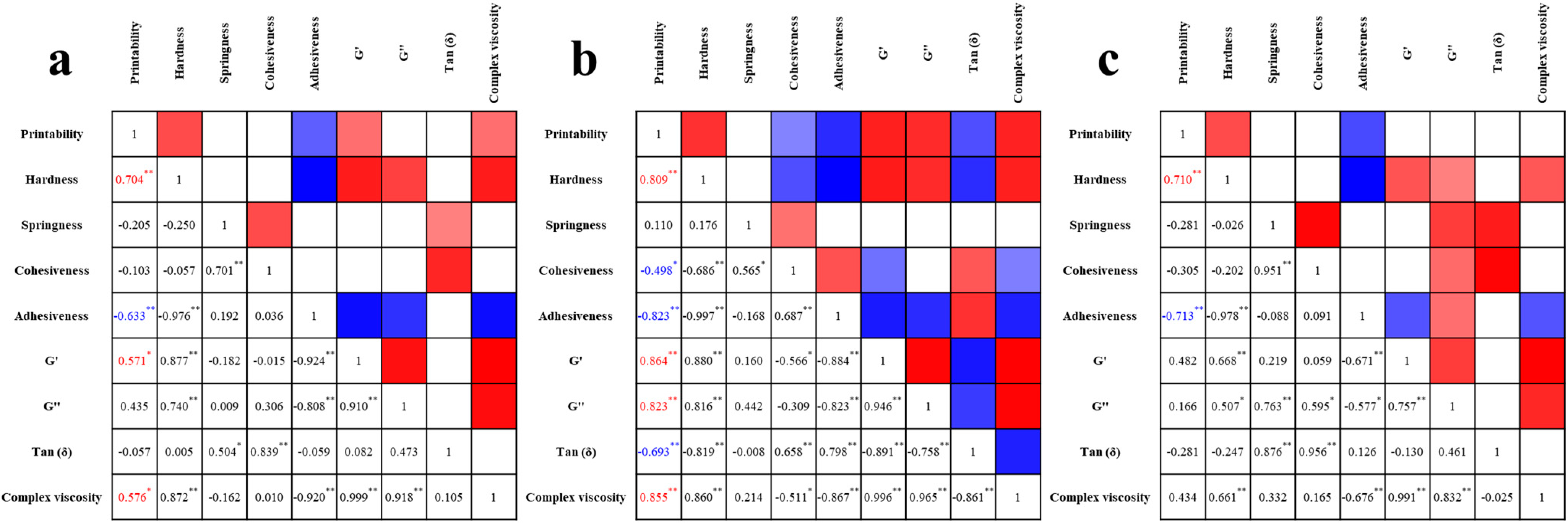

3.2. Correlation Between Physical Properties

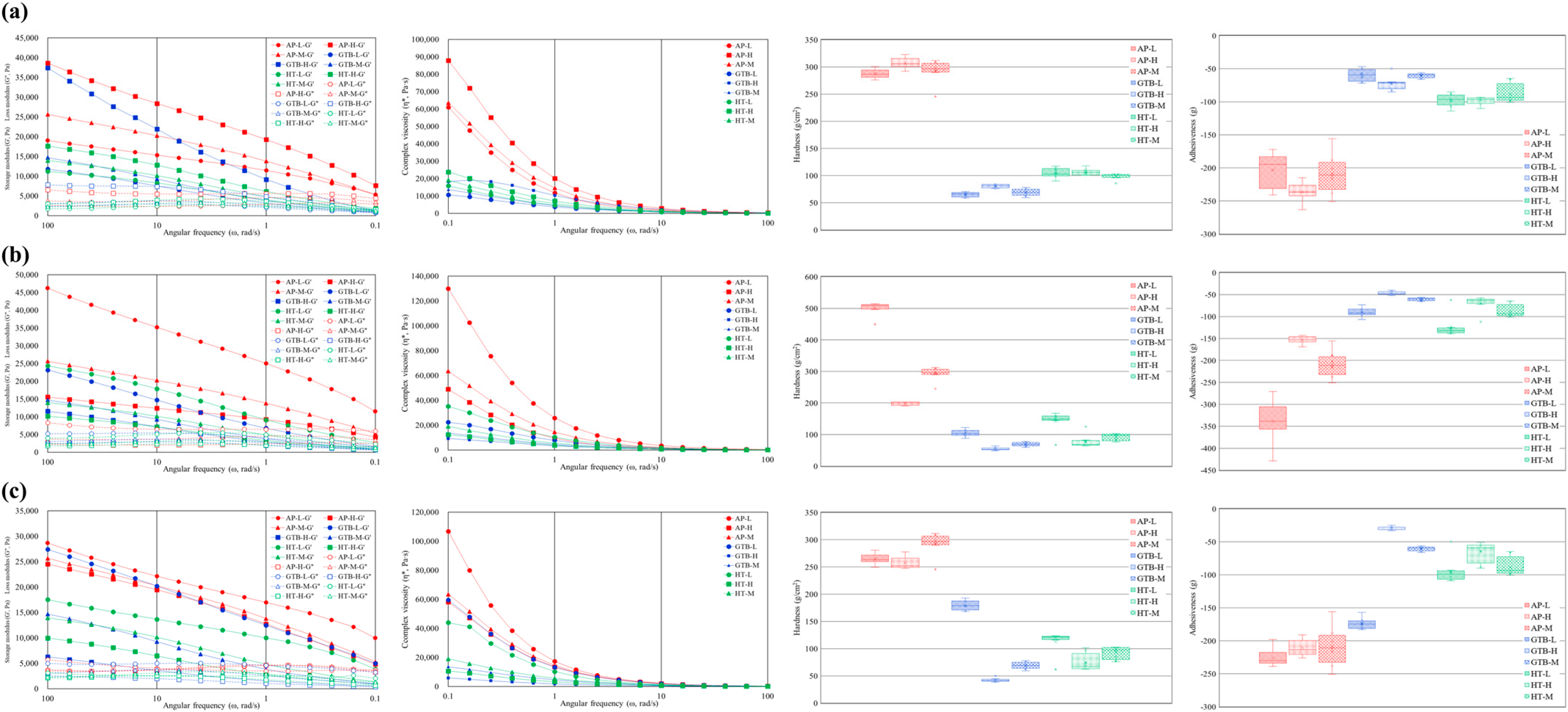

3.3. Rheology and Texture Profile

3.4. Regression Model of Physical Properties

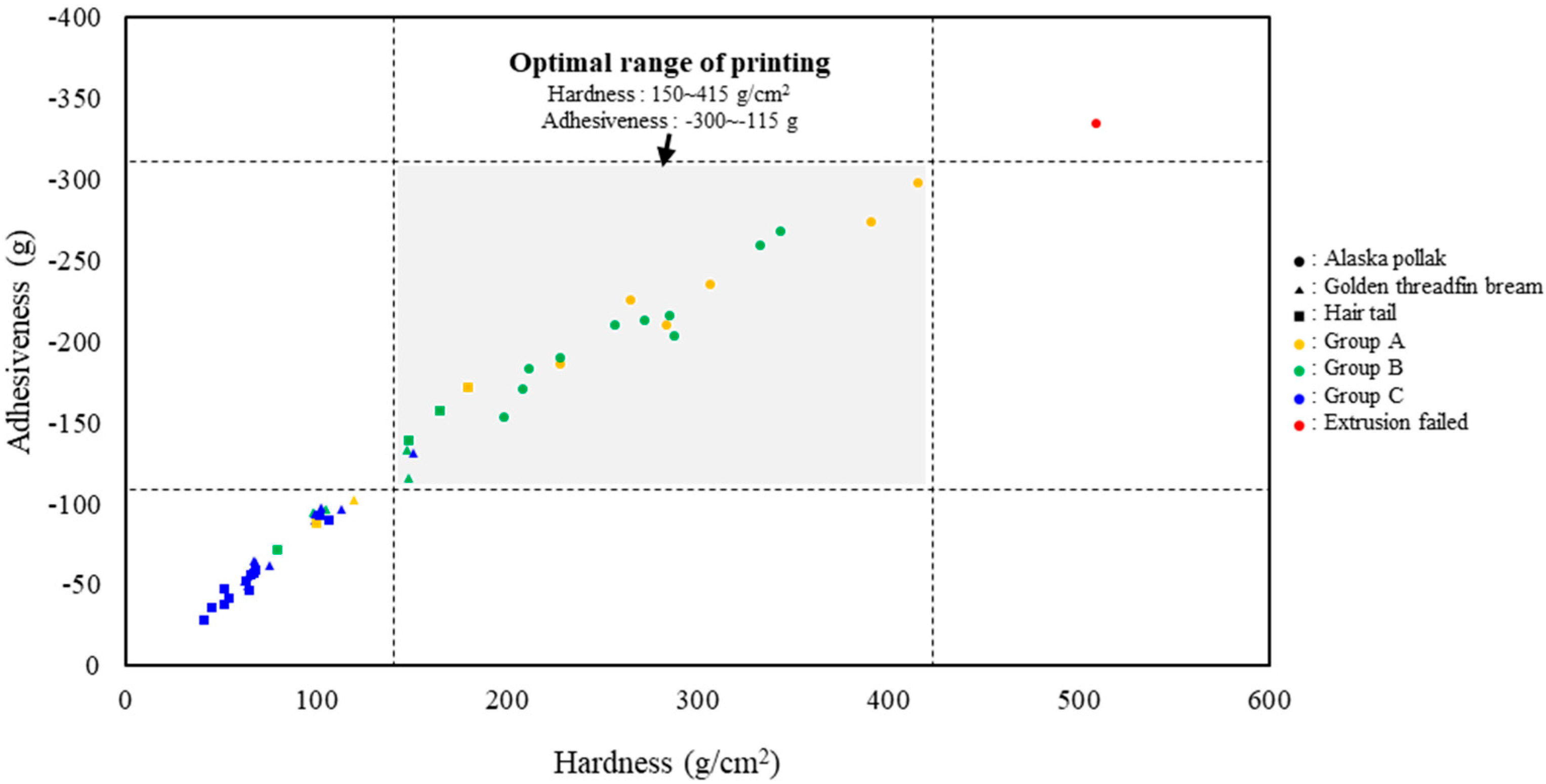

3.5. Optimal Additive Range

3.6. Deviations in Physical Properties Within Optimal Additive Range

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCD | Central composite design |

| R2 | Coefficient of Determination |

| G′ | Storage modulus |

| G” | Loss modulus |

| Tan(δ) | Loss tangent |

| TPA | Texture profile analysis |

| LVR | Linear viscoelastic region |

| ANOVA | Analysis of variance |

References

- Miller, O.; Scarlett, C.J.; Akanbi, T.O. Plant-based meat analogues and consumer interest in 3d-printed products: A mini-review. Foods 2024, 13, 2314. [Google Scholar] [CrossRef] [PubMed]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of macronutrients printability and 3d-printer parameters on 3d-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef]

- Pant, A.; Lee, A.Y.; Karyappa, R.; Lee, C.P.; An, J.; Hashimoto, M.; Tan, U.-X.; Wong, G.; Chua, C.K.; Zhang, Y. 3d food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Gholamipour-Shirazi, A.; Norton, I.T.; Mills, T. Designing hydrocolloid based food-ink formulations for extrusion 3d printing. Food Hydrocoll. 2019, 95, 161–167. [Google Scholar] [CrossRef]

- Dong, H.; Wang, P.; Yang, Z.; Xu, X. 3d printing based on meat materials: Challenges and opportunities. Curr. Res. Food Sci. 2023, 6, 100423. [Google Scholar] [CrossRef] [PubMed]

- Voon, S.L.; An, J.; Wong, G.; Zhang, Y.; Chua, C.K. 3d food printing: A categorised review of inks and their development. Virtual Phys. Prototyp. 2019, 14, 203–218. [Google Scholar] [CrossRef]

- Escalante-Aburto, A.; Santiago, G.T.; Álvarez, M.M.; Chuck-Hernández, C. Advances and prospective applications of 3d food printing for health improvement and personalized nutrition. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5722–5741. [Google Scholar] [CrossRef]

- Sharma, R.; Nath, P.C.; Hazarika, T.K.; Ojha, A.; Nayak, P.K.; Sridhar, K. Recent advances in 3d printing properties of natural food gels: Application of innovative food additives. Food Chem. 2024, 432, 137196. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Li, G.; Zhan, J.; Hu, Z.; Huang, J.; Yuan, C.; Takaki, K.; Hu, Y.; Yao, Q. Effects of heating process on 3d printing properties of pennahia argentata surimi: Water distribution, gel formation, rheology, chemical bonds. J. Food Process Eng. 2023, 46, e14262. [Google Scholar] [CrossRef]

- Hussain, S.; Malakar, S.; Arora, V.K. Extrusion-based 3d food printing: Technological approaches, material characteristics, printing stability, and post-processing. Food Eng. Rev. 2022, 14, 100–119. [Google Scholar] [CrossRef]

- Reche, C.; Umaña, M.; Dalmau, E.; Carcel, J.A.; Eim, V. Improving 3d printed food characteristics by using mushroom by-products and olive oil in the formulation. LWT 2024, 202, 116238. [Google Scholar] [CrossRef]

- Kadival, A.; Mitra, J.; Kaushal, M.; Machavaram, R. Prediction of viscoelastic properties of peanut-based 3d printable food ink. J. Texture Stud. 2024, 55, e12817. [Google Scholar] [CrossRef] [PubMed]

- Umeda, T.; Kozu, H.; Kobayashi, I. Analysis of pumpkin paste printability for screw-based 3d food printer. Food Bioprocess Technol. 2024, 17, 188–204. [Google Scholar] [CrossRef]

- Neamah, H.A.; Tandio, J. Towards the development of foods 3d printer: Trends and technologies for foods printing. Heliyon 2024, 10, e33882. [Google Scholar] [CrossRef] [PubMed]

- Oyinloye, T.M.; Yoon, W.B. Investigation of flow field, die swelling, and residual stress in 3d printing of surimi paste using the finite element method. Innov. Food Sci. Emerg. Technol. 2022, 78, 103008. [Google Scholar] [CrossRef]

- Gao, Y.; Fukushima, H.; Deng, S.; Jia, R.; Osako, K.; Okazaki, E. Effect of emulsifying stability of myofibrillar protein on the gel properties of emulsified surimi gel. Food Sci. Nutr. 2018, 6, 1229–1237. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, Q.; Liu, Y.; Wei, S.; Han, Z.; Zheng, O.; Ji, H.; Zhang, B.; Liu, S. Optimization of 3d printing formulation of shrimp surimi based on response surface method. LWT 2024, 199, 116126. [Google Scholar] [CrossRef]

- Walayat, N.; Xiong, H.; Xiong, Z.; Moreno, H.M.; Nawaz, A.; Niaz, N.; Randhawa, M.A. Role of cryoprotectants in surimi and factors affecting surimi gel properties: A review. Food Rev. Int. 2022, 38, 1103–1122. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, K.; Zhao, Y.; Shi, X.; Mao, W.; Zheng, B.; Xu, Y.; Gao, P.; Zhou, R. Effects of different heat-induced setting methods on the structural stability and properties of 3d-printed surimi gels. LWT 2024, 198, 115957. [Google Scholar] [CrossRef]

- Yingchutrakul, M.; Wasinnitiwong, N.; Benjakul, S.; Singh, A.; Zheng, Y.; Mubango, E.; Luo, Y.; Tan, Y.; Hong, H. Asian carp, an alternative material for surimi production: Progress and future. Foods 2022, 11, 1318. [Google Scholar] [CrossRef]

- Xie, D.; Tang, Y.; Dong, G. Various factors affecting the gel properties of surimi: A review. J. Texture Stud. 2024, 55, e12847. [Google Scholar] [CrossRef] [PubMed]

- Monto, A.R.; Li, M.; Wang, X.; Wijaya, G.Y.A.; Shi, T.; Xiong, Z.; Yuan, L.; Jin, W.; Li, J.; Gao, R. Recent developments in maintaining gel properties of surimi products under reduced salt conditions and use of additives. Crit. Rev. Food Sci. Nutr. 2022, 62, 8518–8533. [Google Scholar] [CrossRef]

- Yang, G.; Tao, Y.; Wang, P.; Xu, X.; Zhu, X. Optimizing 3d printing of chicken meat by response surface methodology and genetic algorithm: Feasibility study of 3d printed chicken product. LWT 2022, 154, 112693. [Google Scholar] [CrossRef]

- Han, N.; Baek, S.; Alauddin, A.A.D.; Jo, H.; Ma, Y.; Lee, S.; Bae, J.-E. Optimizing tilapia-based surimi ink for 3d printing: Enhancing physicochemical properties and printability with ulva powder. Food Chem. 2025, 464, 141759. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhao, Z.; Zhang, N.; Zhu, Z.; Liu, Y.; Zhang, H.; Chen, W.; Fan, D. A novel method for high-temperature microwave 3d printing of golden thread surimi: Combination of thermally reversible gelatin and κ-carrageenan. Food Hydrocoll. 2025, 161, 110856. [Google Scholar] [CrossRef]

- Szpisják-Gulyás, N.; Al-Tayawi, A.N.; Horváth, Z.H.; László, Z.; Kertész, S.; Hodúr, C. Methods for experimental design, central composite design and the box–behnken design, to optimise operational parameters: A review. Acta Aliment. 2023, 52, 521–537. [Google Scholar] [CrossRef]

- Poowakanjana, S.; Mayer, S.G.; Park, J.W. Optimum chopping conditions for alaska pollock, pacific whiting, and threadfin bream surimi paste and gel based on rheological and raman spectroscopic analysis. J. Food Sci. 2012, 77, E88–E97. [Google Scholar] [CrossRef]

- Reynolds, C.D.; Slater, P.R.; Hare, S.D.; Simmons, M.J.; Kendrick, E. A review of metrology in lithium-ion electrode coating processes. Mater. Des. 2021, 209, 109971. [Google Scholar] [CrossRef]

- Rodríguez-Herrera, V.V.; Umeda, T.; Kozu, H.; Sasaki, T.; Kobayashi, I. Printability of nixtamalized corn dough during screw-based three-dimensional food printing. Foods 2024, 13, 293. [Google Scholar] [CrossRef]

- Park, J.W. Surimi seafood: Products, market, and manufacturing. In Surimi and Surimi Seafood; CRC Press: Boca Raton, FL, USA, 2000; pp. 201–236. [Google Scholar]

- Li, G.; Zhan, J.; Hu, Z.; Huang, J.; Luo, X.; Chen, J.; Yuan, C.; Takaki, K.; Hu, Y. 3d printing properties and printability definition of pennahiaargentata surimi and rice starch. Food Biosci. 2022, 48, 101748. [Google Scholar] [CrossRef]

- He, D.; Yi, X.; Xia, G.; Liu, Z.; Zhang, X.; Li, C.; Shen, X. Effects of fish oil on the gel properties and emulsifying stability of myofibrillar proteins: A comparative study of tilapia, hairtail and squid. LWT 2022, 161, 113373. [Google Scholar] [CrossRef]

- Núñez-Flores, R.; Cando, D.; Borderías, A.J.; Moreno, H.M. Importance of salt and temperature in myosin polymerization during surimi gelation. Food Chem. 2018, 239, 1226–1234. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 2019, 87, 413–424. [Google Scholar] [CrossRef]

- Shi, Y.; Tu, L.; Yuan, C.; Wu, J.; Li, X.; Wang, S.; Chen, H.; Chen, X. Regulatory mechanisms governing collagen peptides and their 3d printing application for frozen surimi. J. Food Sci. 2022, 87, 2692–2706. [Google Scholar] [CrossRef] [PubMed]

- Kong, C.; Ogawa, H.; Iso, N. Compression properties of fish-meat gel as affected by gelatinization of added starch. J. Food Sci. 1999, 64, 283–286. [Google Scholar] [CrossRef]

- Li, Q.; Chen, S.; You, J.; Hu, Y.; Yin, T.; Liu, R. A comprehensive unraveling of the mystery of reduced-salt surimi gels: From molecular mechanism to future prospects. Trends Food Sci. Technol. 2024, 154, 104783. [Google Scholar] [CrossRef]

- Chen, H.-Z.; Zhang, M.; Yang, C.-H. Comparative analysis of 3d printability and rheological properties of surimi gels via lf-nmr and dielectric characteristics. J. Food Eng. 2021, 292, 110278. [Google Scholar] [CrossRef]

- Park, B.-R.; No, J.; Oh, H.; Park, C.S.; You, K.-M.; Chewaka, L.S. Exploring puffed rice as a novel ink for 3d food printing: Rheological characterization and printability analysis. J. Food Eng. 2024, 387, 112313. [Google Scholar] [CrossRef]

- Mi, H.; Li, Y.; Wang, C.; Yi, S.; Li, X.; Li, J. The interaction of starch-gums and their effect on gel properties and protein conformation of silver carp surimi. Food Hydrocoll. 2021, 112, 106290. [Google Scholar] [CrossRef]

- Moore, D.S.; Kirkland, S. The Basic Practice of Statistics; WH Freeman: New York, NY, USA, 2007. [Google Scholar]

- Wang, Z.; Yu, X.; Song, L.; Jiao, J.; Prakash, S.; Dong, X. Encapsulation of β-carotene in gelatin-gum arabic-sodium carboxymethylcellulose complex coacervates: Enhancing surimi gel properties and exploring 3d printing potential. Int. J. Biol. Macromol. 2024, 278, 134129. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Wang, Z.; Pan, Y.; Jiang, P.; Pan, J.; Yu, C.; Dong, X. Effect of κ-carrageenan on quality improvement of 3d printed hypophthalmichthys molitrix-sea cucumber compound surimi product. LWT 2022, 154, 112279. [Google Scholar] [CrossRef]

| Parameter | Condition |

|---|---|

| Print speed (stage movement speed) (mm/s) | 15 |

| Flow rate (%) | 0.3 |

| Nozzle inner diameter (mm) | 1.94 |

| Initial nozzle height (mm) | 1.20 |

| Infill pattern | Concentric |

| Infill density (%) | 80 |

| Number of outer shells | 0 |

| Temperature (°C) | 25 |

| Parameter | Condition | Score |

|---|---|---|

| Angle of slope | Within 10% deviation | +1 |

| Over 10% deviation | 0 | |

| Peak intensity threshold | Within 50% dark area | +1 |

| Over 50% dark area | 0 |

| Independent Variables | Code | −α | −1 | 0 | +1 | +α |

|---|---|---|---|---|---|---|

| Starch (g) | x1 | 10 | 45 | 100 | 155 | 190 |

| Water (g) | x2 | 10 | 85 | 200 | 315 | 390 |

| Salt (g) | x3 | 1 | 10 | 25 | 40 | 50 |

| Run No. | Alaska Pollock | Golden Threadfin Bream | Hairtail | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Slope Angle | Dark Area | Group | Slope Angle | Dark Area | Group | Slope Angle | Dark Area | Group | |

| 1 | 47.70 ± 3.01 | 41.58 ± 0.65 | A | 54.39 ± 0.41 | 35.57 ± 0.06 | B | 52.51 ± 7.81 | 39.45 ± 0.41 | B |

| 2 | 43.42 ± 4.17 | 44.82 ± 2.02 | A | 56.89 ± 6.92 | 48.92 ± 8.33 | B | 56.37 ± 1.63 | 39.78 ± 1.26 | B |

| 3 | 51.96 ± 0.68 | 38.06 ± 3.18 | B | 75.42 ± 10.74 | 55.48 ± 4.52 | C | 60.96 ± 2.48 | 55.22 ± 6.15 | C |

| 4 | 51.94 ± 4.02 | 38.43 ± 8.09 | B | 55.68 ± 6.58 | 44.88 ± 3.95 | C | 65.32 ± 8.29 | 61.11 ± 1.31 | C |

| 5 | 54.94 ± 2.73 | 35.68 ± 6.20 | B | 79.76 ± 1.99 | 65.62 ± 0.51 | C | 60.76 ± 3.59 | 45.81 ± 0.63 | C |

| 6 | 52.99 ± 3.45 | 29.97 ± 0.07 | B | 69.34 ± 1.77 | 63.07 ± 7.69 | C | 63.91 ± 1.35 | 44.08 ± 2.70 | C |

| 7 | 66.94 ± 2.91 | 46.15 ± 1.29 | B | 80.88 ± 4.53 | 61.39 ± 4.95 | C | 68.74 ± 3.48 | 57.41 ± 3.86 | C |

| 8 | 49.92 ± 3.61 | 32.05 ± 1.07 | A | 75.83 ± 3.21 | 56.58 ± 7.80 | C | 68.08 ± 5.56 | 65.99 ± 0.08 | C |

| 9 | 50.26 ± 6.20 | 39.86 ± 1.71 | B | 75.46 ± 2.50 | 56.89 ± 1.70 | C | 65.15 ± 2.62 | 54.98 ± 0.53 | C |

| 10 | 47.55 ± 2.89 | 31.89 ± 6.62 | A | 64.20 ± 0.96 | 46.52 ± 4.98 | B | 64.30 ± 0.23 | 36.28 ± 2.09 | B |

| 11 | Extrusion failed | C | 35.67 ± 27.59 | 45.95 ± 3.44 | B | 68.77 ± 2.05 | 50.78 ± 2.71 | B | |

| 12 | 57.16 ± 1.96 | 49.94 ± 1.59 | B | 80.98 ± 2.59 | 73.52 ± 3.16 | A | 73.07 ± 1.51 | 52.74 ± 2.32 | C |

| 13 | 46.62 ± 4.24 | 48.54 ± 2.58 | A | 45.38 ± 0.09 | 36.41 ± 5.94 | C | 49.52 ± 2.25 | 44.50 ± 1.38 | A |

| 14 | 51.81 ± 1.16 | 31.62 ± 3.74 | B | 77.76 ± 8.25 | 54.05 ± 0.05 | A | 61.64 ± 4.11 | 51.90 ± 3.33 | C |

| 15 | 55.82 ± 2.69 | 35.73 ± 1.04 | B | 67.02 ± 8.53 | 53.75 ± 1.86 | C | 64.11 ± 5.16 | 49.80 ± 4.79 | B |

| 16 | 48.76 ± 7.39 | 32.73 ± 3.64 | A | 65.78 ± 1.86 | 54.93 ± 1.57 | C | 63.13 ± 0.51 | 51.01 ± 0.36 | C |

| 17 | 50.64 ± 0.70 | 31.18 ± 5.41 | B | 65.53 ± 2.59 | 56.47 ± 0.16 | C | 64.53 ± 2.33 | 51.62 ± 1.15 | C |

| Run No. | Independent Variables 1 | Alaska Pollock 2 | Golden Threadfin Bream 2 | Hairtail 2 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | y1 | y2 | y3 | y4 | y1 | y2 | y3 | y4 | y1 | y2 | y3 | y4 | |

| g/cm2 | g | Pa | Pa·s | g/cm2 | g | Pa | Pa·s | g/cm2 | g | Pa | Pa·s | ||||

| 1 | 45 | 85 | 10 | 391.2 | −273.4 | 19,096.8 | 20,184.7 | 148.5 | −139.3 | 7401.1 | 8458.1 | 147.4 | −132.8 | 3245.9 | 3546.4 |

| 2 | 155 | 85 | 10 | 415.5 | −297.8 | 25,157.0 | 25,802.3 | 165.1 | −157.3 | 9066.5 | 10,630.8 | 148.4 | −115.8 | 4961.1 | 5365.1 |

| 3 | 45 | 315 | 10 | 211.9 | −183.3 | 10,636.4 | 11,067.3 | 106.9 | −90.0 | 4242.8 | 4829.6 | 62.4 | −52.3 | 1701.9 | 1778.2 |

| 4 | 155 | 315 | 10 | 227.9 | −190.0 | 12,855.5 | 13,328.3 | 102.1 | −93.0 | 5273.1 | 6291.3 | 63.8 | −49.6 | 1889.3 | 2068.0 |

| 5 | 45 | 85 | 40 | 332.6 | −259.7 | 15,008.8 | 15,647.1 | 54.6 | −41.3 | 2041.2 | 2562.8 | 75.3 | −62.3 | 3237.5 | 4001.3 |

| 6 | 155 | 85 | 40 | 343.1 | −268.1 | 23,972.5 | 25,489.0 | 65.0 | −46.2 | 5166.3 | 5704.4 | 113.5 | −97.0 | 6226.6 | 7220.4 |

| 7 | 45 | 315 | 40 | 208.3 | −171.0 | 8839.9 | 9266.0 | 45.3 | −35.4 | 1390.4 | 1741.9 | 68.2 | −63.6 | 2784.4 | 3330.3 |

| 8 | 155 | 315 | 40 | 228.0 | −186.4 | 13,764.7 | 14,660.7 | 51.5 | −38.0 | 2005.0 | 2526.6 | 67.4 | −64.3 | 3232.8 | 4042.5 |

| 9 | 10 | 200 | 25 | 287.5 | −203.3 | 11,306.9 | 11,711.5 | 63.1 | −52.5 | 3131.1 | 3769.5 | 99.7 | −93.3 | 3845.6 | 4520.2 |

| 10 | 190 | 200 | 25 | 306.8 | −235.7 | 18,504.1 | 20,035.5 | 79.6 | −71.5 | 8378.2 | 10,371.9 | 105.0 | −97.0 | 6045.2 | 7115.3 |

| 11 | 100 | 10 | 25 | 509.2 | −334.8 | 24,868.1 | 26,186.8 | 100.3 | −88.0 | 6691.0 | 7844.8 | 150.9 | −131.5 | 8570.0 | 10,389.5 |

| 12 | 100 | 390 | 25 | 198.8 | −153.4 | 9122.1 | 9530.2 | 51.7 | −47.5 | 2611.5 | 3487.2 | 68.5 | −62.3 | 3289.6 | 3873.4 |

| 13 | 100 | 200 | 1 | 264.6 | −225.8 | 16,766.7 | 17,330.0 | 179.2 | −171.6 | 12,323.5 | 13,300.1 | 120.0 | −102.5 | 9884.9 | 10,310.2 |

| 14 | 100 | 200 | 50 | 257.0 | −210.6 | 12,572.6 | 13,557.7 | 40.8 | −28.6 | 1496.1 | 1821.0 | 64.3 | −55.3 | 2813.7 | 3292.8 |

| 15 | 100 | 200 | 25 | 271.8 | −213.3 | 13,500.0 | 14,178.1 | 67.8 | −59.2 | 3783.6 | 4601.5 | 98.2 | −94.3 | 4784.0 | 5668.1 |

| 16 | 100 | 200 | 25 | 283.5 | −210.0 | 14,045.3 | 14,688.8 | 65.5 | −56.5 | 4752.3 | 5834.1 | 99.4 | −90.1 | 4772.4 | 5636.2 |

| 17 | 100 | 200 | 25 | 285.6 | −215.9 | 14,068.0 | 14,433.4 | 67.4 | −57.0 | 4731.4 | 5604.5 | 102.6 | −97.3 | 5151.9 | 6062.0 |

| Sample | Starch (x1) | Water (x2) | Salt (x3) | Run | Hardness | Adhesiveness |

|---|---|---|---|---|---|---|

| g/cm2 | g | |||||

| Alaska pollock | 153.6 | 79.1 | 28.7 | Predicted value | 398.4 | −286.7 |

| Actual value | 385.3 | −294.8 | ||||

| p-value | 0.425 | 0.284 | ||||

| 91.8 | 182.7 | 10.8 | Predicted value | 296.7 | −227.7 | |

| Actual value | 313.7 | −220.6 | ||||

| p-value | 1.000 | 0.997 | ||||

| Golden threadfin bream | 190 | 10 | 14 | Predicted value | 176.7 | −166.7 |

| Actual value | 134.1 | −121.3 | ||||

| p-value | 0.605 | 0.267 | ||||

| 190 | 340.5 | 1.57 | Predicted value | 146.2 | −139.7 | |

| Actual value | 143.3 | −123.3 | ||||

| p-value | 0.111 | 0.158 | ||||

| Hairtail | 164.5 | 60 | 16.8 | Predicted value | 158.2 | −130.4 |

| Actual value | 173.1 | −140.8 | ||||

| p-value | 0.814 | 0.274 | ||||

| 149.9 | 82.7 | 13.8 | Predicted value | 152.2 | −127.3 | |

| Actual value | 160.2 | −135.0 | ||||

| p-value | 0.990 | 0.487 |

| Physical Properties | Model 1 | Alaska Pollock | Golden Threadfin Bream | Hairtail | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coefficient | t-Value | p-Value | Coefficient | t-Value | p-Value | Coefficient | t-Value | p-Value | ||

| Hardness (y1) | R2 | 96.48% | 99.37% | 96.48% | ||||||

| Intercept | 530.30 | 11.33 | 0.00 | 244.50 | 18.85 | 0.00 | 190.90 | 8.56 | 0.00 | |

| x1 | −0.0560 | −0.12 | 0.91 | −0.0130 | −0.09 | 0.93 | 0.1690 | 0.74 | 0.48 | |

| x2 | −1.6900 | −7.54 | 0.00 | −0.3597 | −5.79 | 0.00 | −0.4110 | −3.85 | 0.01 | |

| x3 | −0.2400 | −0.14 | 0.89 | −7.8410 | −16.47 | 0.00 | −2.0430 | −2.50 | 0.04 | |

| x12 | 0.0012 | 0.61 | 0.56 | 0.0009 | 1.64 | 0.15 | −0.0004 | −0.47 | 0.66 | |

| x22 | 0.0018 | 4.33 | 0.00 | 0.0003 | 2.72 | 0.03 | 0.0001 | 0.56 | 0.59 | |

| x32 | −0.0434 | −1.71 | 0.13 | 0.0778 | 11.07 | 0.00 | −0.0222 | −1.83 | 0.11 | |

| x1x2 | 0.0000 | 0.02 | 0.99 | −0.0005 | −1.77 | 0.12 | −0.0008 | −1.56 | 0.16 | |

| x1x3 | −0.0015 | −0.19 | 0.85 | 0.0007 | 0.34 | 0.75 | 0.0053 | 1.41 | 0.20 | |

| x2x3 | 0.0092 | 2.44 | 0.05 | 0.0059 | 5.65 | 0.00 | 0.0084 | 4.68 | 0.00 | |

| Adhesiveness (y2) | R2 | 98.90% | 99.45% | 93.40% | ||||||

| Intercept | −346.00 | −18.05 | 0.00 | −232.00 | −18.74 | 0.00 | −168.10 | −6.39 | 0.00 | |

| x1 | −0.0600 | −0.31 | 0.77 | −0.0820 | −0.65 | 0.54 | −0.0390 | −0.14 | 0.89 | |

| x2 | 0.8038 | 8.75 | 0.00 | 0.3887 | 6.55 | 0.00 | 0.3170 | 2.51 | 0.04 | |

| x3 | 1.1610 | 1.65 | 0.14 | 7.7020 | 16.93 | 0.00 | 1.3760 | 1.42 | 0.20 | |

| x12 | −0.0008 | −1.02 | 0.34 | −0.0006 | −1.19 | 0.27 | 0.0007 | 0.66 | 0.53 | |

| x22 | −0.0009 | −4.94 | 0.00 | −0.0003 | −2.60 | 0.04 | 0.0001 | 0.44 | 0.67 | |

| x32 | −0.0090 | −0.86 | 0.42 | −0.0734 | −10.93 | 0.00 | 0.0364 | 2.55 | 0.04 | |

| x1x2 | 0.0002 | 0.50 | 0.63 | 0.0003 | 1.26 | 0.25 | 0.0004 | 0.67 | 0.53 | |

| x1x3 | 0.0011 | 0.34 | 0.74 | 0.0020 | 0.97 | 0.36 | −0.0084 | −1.88 | 0.10 | |

| x2x3 | −0.0020 | −1.29 | 0.24 | −0.0072 | −7.21 | 0.00 | −0.0084 | −3.93 | 0.01 | |

| G′ (y3) | R2 | 99.33% | 89.31% | 48.08% | ||||||

| Intercept | 26,522.00 | 16.16 | 0.00 | 10,711.00 | 2.81 | 0.03 | 3598.00 | 0.58 | 0.58 | |

| x1 | 23.6000 | 1.40 | 0.21 | 19.8000 | 0.50 | 0.63 | 63.3000 | 0.99 | 0.36 | |

| x2 | −71.9000 | −9.15 | 0.00 | −3.0000 | −0.16 | 0.88 | 1.9000 | 0.06 | 0.95 | |

| x3 | −310.3000 | −5.15 | 0.00 | −362.0000 | −2.58 | 0.04 | −54.0000 | −0.24 | 0.82 | |

| x12 | 0.1662 | 2.52 | 0.04 | 0.0470 | 0.31 | 0.77 | −0.2030 | −0.81 | 0.44 | |

| x22 | 0.0958 | 6.44 | 0.00 | −0.0199 | −0.58 | 0.58 | −0.0172 | −0.31 | 0.77 | |

| x32 | 1.8650 | 2.10 | 0.07 | 2.6300 | 1.27 | 0.25 | −0.5200 | −0.15 | 0.88 | |

| x1x2 | −0.1577 | −4.36 | 0.00 | −0.0629 | −0.75 | 0.48 | −0.0810 | −0.59 | 0.57 | |

| x1x3 | 0.8610 | 3.10 | 0.02 | 0.1600 | 0.25 | 0.81 | 0.2400 | 0.22 | 0.83 | |

| x2x3 | 0.3220 | 2.43 | 0.05 | 0.2300 | 0.75 | 0.48 | 0.0860 | 0.17 | 0.87 | |

| Complex viscosity (y4) | R2 | 99.59% | 89.53% | 47.83% | ||||||

| Intercept | 28,043.00 | 20.98 | 0.00 | 11,533.00 | 2.79 | 0.03 | 3645.00 | 0.53 | 0.61 | |

| x1 | 12.40 | 0.90 | 0.40 | 20.80 | 0.49 | 0.64 | 68.90 | 0.97 | 0.36 | |

| x2 | −75.53 | −11.80 | 0.00 | −5.00 | −0.25 | 0.81 | −1.30 | −0.04 | 0.97 | |

| x3 | −335.00 | −6.83 | 0.00 | −339.00 | −2.24 | 0.06 | 9.00 | 0.04 | 0.97 | |

| x12 | 0.20 | 3.77 | 0.01 | 0.08 | 0.46 | 0.66 | −0.23 | −0.83 | 0.43 | |

| x22 | 0.10 | 8.29 | 0.00 | −0.02 | −0.57 | 0.59 | −0.01 | −0.23 | 0.83 | |

| x32 | 2.04 | 2.81 | 0.03 | 1.90 | 0.85 | 0.42 | −1.63 | −0.44 | 0.68 | |

| x1x2 | −0.15 | −5.24 | 0.00 | −0.06 | −0.67 | 0.53 | −0.08 | −0.53 | 0.61 | |

| x1x3 | 1.12 | 4.94 | 0.00 | 0.04 | 0.06 | 0.95 | 0.28 | 0.24 | 0.82 | |

| x2x3 | 0.32 | 2.94 | 0.02 | 0.29 | 0.86 | 0.42 | 0.09 | 0.16 | 0.88 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.B.; Yoon, N.Y.; Bae, Y.J.; Kwon, G.Y.; Sohn, S.K.; Lee, H.R.; Kim, H.J.; Kim, M.J.; Park, H.E.; Shim, K.B. Optimizing 3D Food Printing of Surimi via Regression Analysis: Physical Properties and Additive Formulations. Foods 2025, 14, 889. https://doi.org/10.3390/foods14050889

Lee JB, Yoon NY, Bae YJ, Kwon GY, Sohn SK, Lee HR, Kim HJ, Kim MJ, Park HE, Shim KB. Optimizing 3D Food Printing of Surimi via Regression Analysis: Physical Properties and Additive Formulations. Foods. 2025; 14(5):889. https://doi.org/10.3390/foods14050889

Chicago/Turabian StyleLee, Jong Bong, Na Young Yoon, Yeon Joo Bae, Ga Yeon Kwon, Suk Kyung Sohn, Hyo Rim Lee, Hyeong Jun Kim, Min Jae Kim, Ha Eun Park, and Kil Bo Shim. 2025. "Optimizing 3D Food Printing of Surimi via Regression Analysis: Physical Properties and Additive Formulations" Foods 14, no. 5: 889. https://doi.org/10.3390/foods14050889

APA StyleLee, J. B., Yoon, N. Y., Bae, Y. J., Kwon, G. Y., Sohn, S. K., Lee, H. R., Kim, H. J., Kim, M. J., Park, H. E., & Shim, K. B. (2025). Optimizing 3D Food Printing of Surimi via Regression Analysis: Physical Properties and Additive Formulations. Foods, 14(5), 889. https://doi.org/10.3390/foods14050889