Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages—A Review

Abstract

1. Introduction

- Q1—What is the biochemical composition of different types of whey, and how do factors such as milk origin, processing technology, and regional or seasonal conditions influence its nutritional profile?

- Q2—Which technological processes are most effective for the valorization of whey into functional and nutritional beverages, and what are their respective advantages and limitations?

- Q3—How can whey-based beverages contribute to sustainable development, and what are the economic, environmental, and health-related benefits of integrating whey into circular food systems?

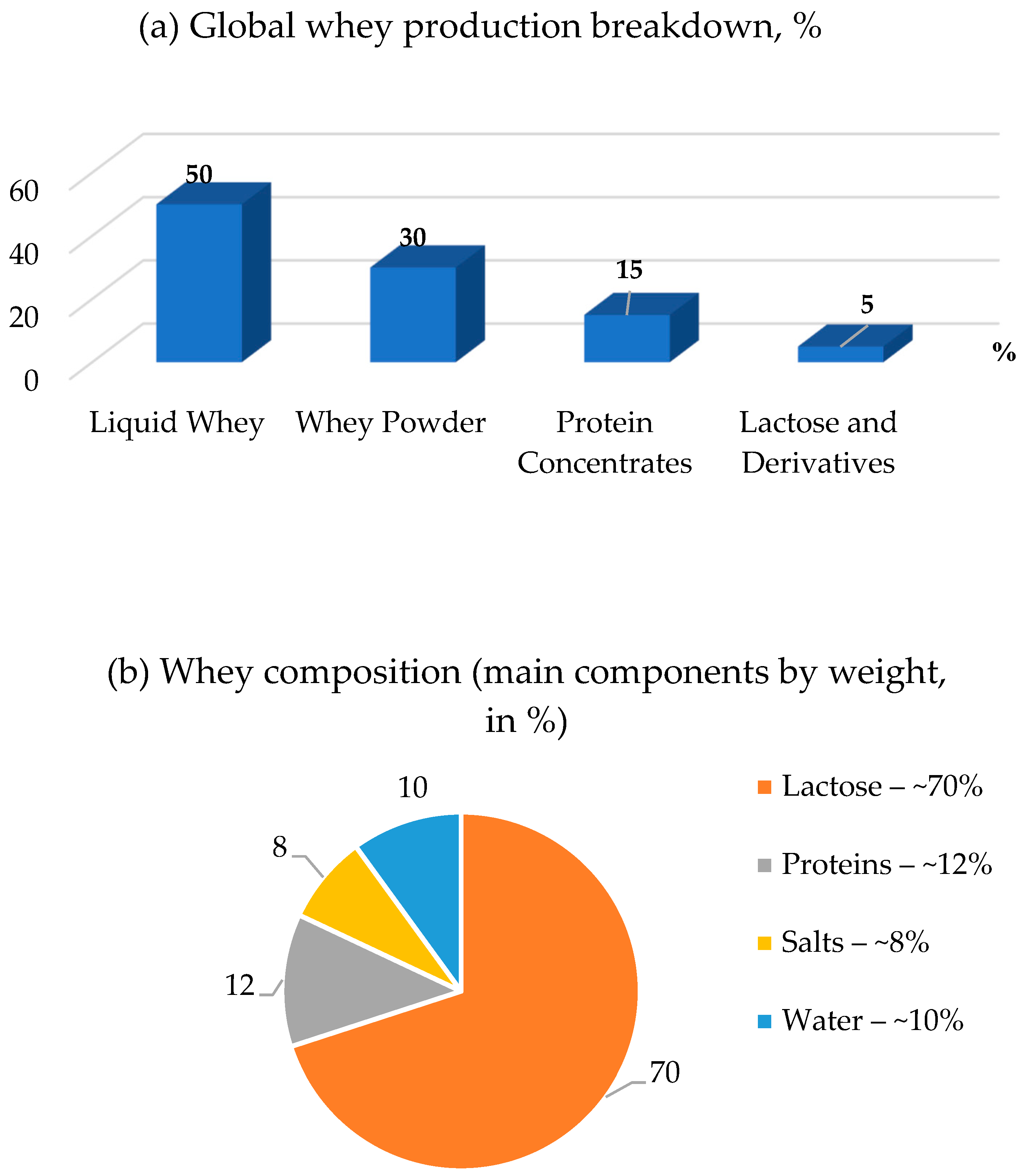

2. The Composition of Whey

| Component | Sweet Whey (Hard Cheese) | Acid Whey (Soft Cheese) | Mediterranean Whey | Notes and Biological Significance | Source |

|---|---|---|---|---|---|

| PROTEINS and AMINO ACIDS | |||||

| Total protein (%) | 0.8–1.0 | 0.5–0.7 | 0.6–0.9 | Higher BCAAs 1 in sweet whey | [42,73] |

| Free amino acids | 4 × milk levels | 10 × milk levels | 6–8 × milk levels | Bioactive peptide precursor | [12] |

| CARBOHYDRATES | |||||

| Lactose (%) | 4.5–5.0 | 5.5–6.0 | 4.0–4.8 | Higher in acid whey | [3,62] |

| Oligosaccharides | Present | Elevated | Variable | Prebiotic effects | [75] |

| FATS | |||||

| Fat content (%) | 0.05–0.3 | 0.1–0.5 | 0.2–0.4 | Impacts creaminess in applications | [76] |

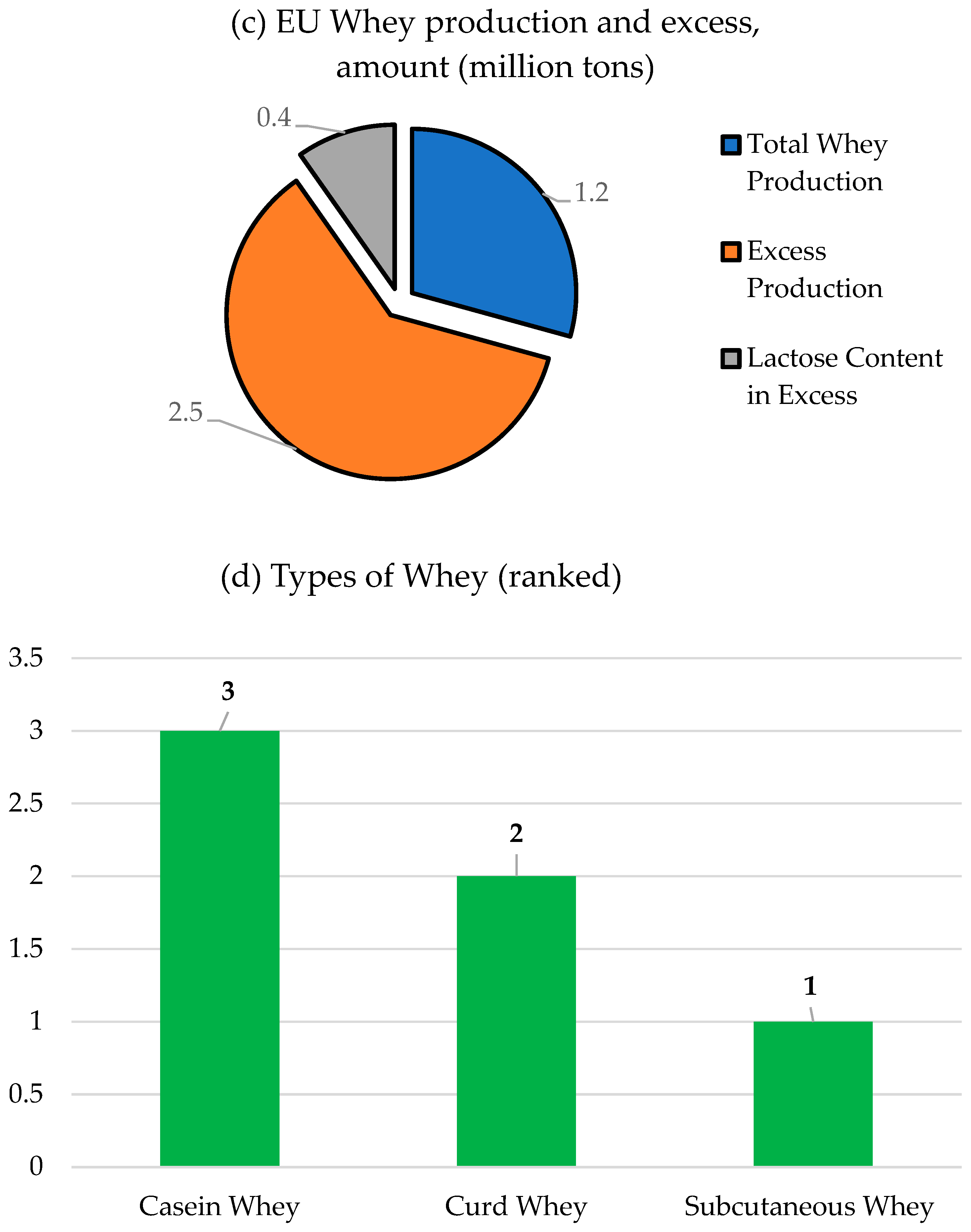

| MINERALS | |||||

| Anions (PO43−, Cl−, citrate, g/L) | 5.831 | 6.120 | 5.450 | Impacts electrolyte balance | [33] |

| Cations (K+, Na+, Ca2+, g/L) | 3.323 | 3.850 | 3.500 | Ca2+ higher in acid whey | [18] |

| Trace elements (mg/100 g) | |||||

| -Zinc | 0.3108 | 0.2800 | 0.2950 | Immune function support | [18] |

| -Iron | 0.0674 | 0.0721 | 0.0690 | Bound to lactoferrin | [18] |

| VITAMINS (% transfer from milk) | |||||

| B vitamins (B1/B2/B12) | 81/91/58 | 75/85/50 | 78/88/55 | Heat-stable in sweet whey | [77] |

| Fat-soluble (A/E) | 11/32 | 8/28 | 10/30 | Lower transfer due to lipid removal | [78] |

3. The Use and Benefits of Milk Whey

4. Technology of Production and Processing of Whey

- -

- -

- Acid whey is made from the manufacturing of cottage cheese and yogurt. Compared to cheese whey, acid whey has a lower protein content but is higher in lactose and minerals, which limits its use in industry [59].

- -

- Casein whey is suitable for certain uses, such as lactose synthesis, as it usually contains less fat and lower levels of calcium and phosphate but higher chloride content than cheese whey [88].

5. Application of Whey in Functional Beverages

Whey Beverages with Fillers and Additives

6. Modern Trends in Enhancing Whey-Based Beverages

7. Discussion on Methods and Standards in Compositional Analysis of Whey

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buchanan, D.; Martindale, W.; Romeih, E.; Hebishy, E. Recent Advances in Whey Processing and Valorisation: Technological and Environmental Perspectives. Int. J. Dairy Technol. 2023, 76, 291–312. [Google Scholar] [CrossRef]

- El-Tanboly, E. Recovery of Cheese Whey, a by-Product from the Dairy Industry for Use as an Animal Feed. J. Nutr. Health Food Eng. 2017, 6, 148. [Google Scholar] [CrossRef][Green Version]

- Zandona, E.; Blažić, M.; Režek Jambrak, A. Whey Utilisation: Sustainable Uses and Environmental Approach. Food Technol. Biotechnol. 2021, 59, 147–161. [Google Scholar] [CrossRef]

- Tsermoula, P.; Khakimov, B.; Nielsen, J.H.; Engelsen, S.B. Whey-The Waste-Stream That Became More Valuable than the Food Product. Trends Food Sci. Technol. 2021, 118, 230–241. [Google Scholar] [CrossRef]

- Sinđić, M.; Pajić, M. Implementation of Good Hygiene Practices in a Milk Processing Plant. In Proceedings of the 3rd International Symposium on Biotechnology, Čačak, Republic of Serbia, 13–14 March 2025; pp. 369–376. [Google Scholar]

- Papademas, P.; Kotsaki, P. Technological Utilization of Whey towards Sustainable Exploitation. Adv. Dairy Res. 2020, 7, 231. [Google Scholar]

- Besediuk, V.; Yatskov, M.; Korchyk, N.; Kucherova, A.; Maletskyi, Z. Whey-From Waste to a Valuable Resource. J. Agric. Food Res. 2024, 18, 101280. [Google Scholar] [CrossRef]

- Biswas, A.C.; Salunke, P.; Metzger, L.E. Effect of Cheese Coagulants on American-Style Natural Cheese Proteolysis and Functional Characteristics of Process Cheese Made Therefrom. Int. Dairy J. 2025, 161, 106135. [Google Scholar] [CrossRef]

- McDonough, F.E.; Hargrove, R.E.; Mattingly, W.A.; Posati, L.P.; Alford, J.A. Composition and Properties of Whey Protein Concentrates from Ultrafiltration. J. Dairy Sci. 1974, 57, 1438–1443. [Google Scholar] [CrossRef] [PubMed]

- Meena, G.S.; Singh, A.K.; Panjagari, N.R.; Arora, S. Milk Protein Concentrates: Opportunities and Challenges. J. Food Sci. Technol. 2017, 54, 3010–3024. [Google Scholar] [CrossRef]

- Arsić, S.; Bulatović, M.; Rakin, M.; Jeločnik, M.; Subić, J. Economic and Ecological Profitability of the Use of Whey in Dairy and Food Industry. Large Anim. Rev. 2018, 24, 99–105. [Google Scholar]

- Borba, K.K.S.; Gadelha, T.S.; Sant’Ana, A.M.S.; Pacheco, M.T.B.; Pinto, L.S.; Madruga, M.S.; Medeiros, A.N.; Bessa, R.J.B.; Alves, S.P.A.; Magnani, M.; et al. Fatty Acids, Essential Amino Acids, Minerals and Proteins Profile in Whey from Goat Cheese: Impacts of Raising System. Small Rumin. Res. 2022, 217, 106842. [Google Scholar] [CrossRef]

- León-López, A.; Pérez-Marroquín, X.A.; Estrada-Fernández, A.G.; Campos-Lozada, G.; Morales-Peñaloza, A.; Campos-Montiel, R.G.; Aguirre-Álvarez, G. Milk Whey Hydrolysates as High Value-Added Natural Polymers: Functional Properties and Applications. Polymers 2022, 14, 1258. [Google Scholar] [CrossRef]

- O’Donoghue, L.T.; Murphy, E.G. Nondairy Food Applications of Whey and Milk Permeates: Direct and Indirect Uses. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2652–2677. [Google Scholar] [CrossRef]

- Saubenova, M.; Oleinikova, Y.; Rapoport, A.; Maksimovich, S.; Yermekbay, Z.; Khamedova, E. Bioactive Peptides Derived from Whey Proteins for Health and Functional Beverages. Fermentation 2024, 10, 359. [Google Scholar] [CrossRef]

- De Wit, J.N. Nutritional and Functional Characteristics of Whey Proteins in Food Products. J. Dairy Sci. 1998, 81, 597–608. [Google Scholar] [CrossRef]

- Abduh, S.B.M.; Rizqiati, H.; Al-Baarri, A.N.; Hintono, A.; Bintoro, V.P.; Putra, H.B.P.; Susetya, A.E.; Setyani, M.; Gilkar, K.R.; Retnowati, A.D. Sensorial Attributes of Fermented Whey Drinks with Either Natural or Artificial Flavoring Agents. IOP Conf. Ser. Earth Environ. Sci. 2024, 1364, 012075. [Google Scholar] [CrossRef]

- Khramtsov, A.G.; Blinov, A.V.; Blinova, A.A.; Serov, A.V. Influence of the Whey Type on Composition and Properties of Its Mineralizates. Foods Raw Mater. 2017, 5, 30–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Truong, T.; Chandrapala, J. Milk Powder Formulations with Varying Casein to Whey Ratios and Calcium Addition: Physico-Chemical and Structural Properties and the Effect of Low-Frequency Ultrasound. Foods 2025, 14, 685. [Google Scholar] [CrossRef] [PubMed]

- Jelen, P.; Currie, R.; Kadis, V.W. Compositional Analysis of Commercial Whey Drinks. J. Dairy Sci. 1987, 70, 892–895. [Google Scholar] [CrossRef]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science; Springer: Boston, MA, USA, 2017; ISBN 978-1-4899-7679-6. [Google Scholar]

- Kashung, P.; Karuthapandian, D. Milk-Derived Bioactive Peptides. Food Prod. Process. Nutr. 2025, 7, 6. [Google Scholar] [CrossRef]

- Barzaghi, S.; Monti, L.; Marinoni, L.; Cattaneo, T.M.P. Chemometrics for the Identification of Nitrogen and Acid Compounds in Milk-Whey as By-Products from Crescenza and Grana Padano Type Cheese-Making. Molecules 2021, 26, 4839. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Bittante, G. From Milk to Cheese: Evolution of Flavor Fingerprint of Milk, Cream, Curd, Whey, Ricotta, Scotta, and Ripened Cheese Obtained during Summer Alpine Pasture. J. Dairy Sci. 2018, 101, 3918–3934. [Google Scholar] [CrossRef]

- Jeewanthi, C.R.K.; Paik, H.-D.; Kim, M.-H.; Lee, N.-K.; Kim, S.-Y.; Yoon, C.Y. Characteristics of Whey Proteinhydrolysates from Cheese Whey, Favors Onvarious Food Applications. Chem. Ind. Chem. Eng. Q. 2014, 20, 503–509. [Google Scholar] [CrossRef]

- Sinha, R.; Radha, C.; Prakash, J.; Kaul, P. Whey Protein Hydrolysate: Functional Properties, Nutritional Quality and Utilization in Beverage Formulation. Food Chem. 2007, 101, 1484–1491. [Google Scholar] [CrossRef]

- Abish, Z.A.; Alibekov, R.S.; Tarapoulouzi, M.; Bakhtybekova, A.R.; Kobzhasarova, Z.I. Review in Deep Processing of Whey. Cogent Food Agric. 2024, 10, 2415380. [Google Scholar] [CrossRef]

- Johansen, A.G.; Vegarud, G.E.; Skeie, S. Seasonal and Regional Variation in the Composition of Whey from Norwegian Cheddar-Type and Dutch-Type Cheeses. Int. Dairy J. 2002, 12, 621–629. [Google Scholar] [CrossRef]

- Lupton, S.J.; Shappell, N.W.; Shelver, W.L.; Hakk, H. Distribution of Spiked Drugs between Milk Fat, Skim Milk, Whey, Curd, and Milk Protein Fractions: Expansion of Partitioning Models. J. Agric. Food Chem. 2018, 66, 306–314. [Google Scholar] [CrossRef]

- Babenyshev, S.P.; Zhidkov, V.E.; Mamay, D.S.; Utkin, V.P.; Shapakov, N.A. Ultrafiltration of Modified Milk Whey. Food Raw Mater. 2016, 4, 101–110. [Google Scholar] [CrossRef]

- Chen, G.Q.; Artemi, A.; Lee, J.; Gras, S.L.; Kentish, S.E. A Pilot Scale Study on the Concentration of Milk and Whey by Forward Osmosis. Sep. Purif. Technol. 2019, 215, 652–659. [Google Scholar] [CrossRef]

- Li, W.; Li, M.; Cao, X.; Han, H.; Kong, F.; Yue, X. Comparative Analysis of Whey Proteins in Donkey Colostrum and Mature Milk Using Quantitative Proteomics. Food Res. Int. 2020, 127, 108741. [Google Scholar] [CrossRef]

- Wong, N.P.; LaCroix, D.E.; McDonough, F.E. Minerals in Whey and Whey Fractions. J. Dairy Sci. 1978, 61, 1700–1703. [Google Scholar] [CrossRef] [PubMed]

- Jelen, P. Whey Processing|Utilization and Products. In Encyclopedia of Dairy Sciences; Elsevier: Amsterdam, The Netherlands, 2011; pp. 731–737. ISBN 978-0-12-374407-4. [Google Scholar]

- Lina, G.; Shaik, N.B.; Naoual, B.; Mustapha, J.; Latifa, E. General Characterization of Whey Protein Extracted through Various Techniques: A Comparative Analysis. Eng. J. 2024, 28, 19–28. [Google Scholar] [CrossRef]

- Costa, F.R.; Maricato, E.; Dias, A.M.N.; Baptista, E.B. Proteínas Do Soro Do Leite: Propriedades Funcionais e Benefícios Para a Saúde Humana. Lect. Educ. Física Deport. 2021, 25, 106–120. [Google Scholar] [CrossRef]

- Anichkina, O.A.; Terekhova, A.A.; Avtsinova, A.A.; Akulina, E.E.; Dotsenko, E.V. Evaluation of the Effectiveness of an Investment Project for the Processing of Whey. IOP Conf. Ser. Earth Environ. Sci. 2021, 677, 022055. [Google Scholar] [CrossRef]

- Božanic, R.; Barukcic, I.; Jakopovic, K.L.; Tratnik, L. Possibilities of Whey Utilisation. Austin J. Nutr. Food Sci. 2014, 2, 1036–1042. [Google Scholar]

- Cortellino, G.; Rizzolo, A. Storage Stability of Novel Functional Drinks Based on Ricotta Cheese Whey and Fruit Juices. Beverages 2018, 4, 67. [Google Scholar] [CrossRef]

- Kaya, B.; Wijayarathna, E.R.K.B.; Yüceer, Y.K.; Agnihotri, S.; Taherzadeh, M.J.; Sar, T. The Use of Cheese Whey Powder in the Cultivation of Protein-Rich Filamentous Fungal Biomass for Sustainable Food Production. Front. Sustain. Food Syst. 2024, 8, 1386519. [Google Scholar] [CrossRef]

- Smithers, G.W. Whey and Whey Proteins—From ‘Gutter-to-Gold’. Int. Dairy J. 2008, 18, 695–704. [Google Scholar] [CrossRef]

- Mollea, C.; Marmo, L.; Bosco, F. Valorisation of Cheese Whey, a By-Product from the Dairy Industry. In Food Industry; IntechOpen: London, UK, 2013; ISBN 978-953-51-0911-2. [Google Scholar]

- Ahmed, T.; Sabuz, A.A.; Mohaldar, A.; Fardows, H.M.S.; Inbaraj, B.S.; Sharma, M.; Rana, M.R.; Sridhar, K. Development of Novel Whey-Mango Based Mixed Beverage: Effect of Storage on Physicochemical, Microbiological, and Sensory Analysis. Foods 2023, 12, 237. [Google Scholar] [CrossRef]

- Rosseto, M.; Rigueto, C.V.T.; Alessandretti, I.; De Oliveira, R.; Raber Wohlmuth, D.A.; Loss, R.A.; Dettmer, A.; Richards, N.S.P.D.S. Whey-based Polymeric Films for Food Packaging Applications: A Review of Recent Trends. J. Sci. Food Agric. 2023, 103, 3217–3229. [Google Scholar] [CrossRef]

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of Whey-Protein-Coated Films and Laminates as Novel Recyclable Food Packaging Materials with Excellent Barrier Properties. Int. J. Polym. Sci. 2012, 2012, 562381. [Google Scholar] [CrossRef]

- Cinelli, P.; Schmid, M.; Bugnicourt, E.; Wildner, J.; Bazzichi, A.; Anguillesi, I.; Lazzeri, A. Whey Protein Layer Applied on Biodegradable Packaging Film to Improve Barrier Properties While Maintaining Biodegradability. Polym. Degrad. Stab. 2014, 108, 151–157. [Google Scholar] [CrossRef]

- Kayadurmus, H.M.; Rezaei, A.; Ilhan, E.; Cesur, S.; Sahin, A.; Gunduz, O.; Kalaskar, D.M.; Ekren, N. Whey Protein-Loaded 3D-Printed Poly (Lactic) Acid Scaffolds for Wound Dressing Applications. Biomed. Mater. 2024, 19, 045045. [Google Scholar] [CrossRef]

- Garavand, F.; Rouhi, M.; Jafarzadeh, S.; Khodaei, D.; Cacciotti, I.; Zargar, M.; Razavi, S.H. Tuning the Physicochemical, Structural, and Antimicrobial Attributes of Whey-Based Poly (L-Lactic Acid) (PLLA) Films by Chitosan Nanoparticles. Front. Nutr. 2022, 9, 880520. [Google Scholar] [CrossRef] [PubMed]

- Phupoksakul, T.; Leuangsukrerk, M.; Numpiboonmarn, P.; Somwangthanaroj, A.; Janjarasskul, T. Properties of Poly(Lactide)–Whey Protein Isolate Laminated Films. J. Sci. Food Agric. 2015, 95, 715–721. [Google Scholar] [CrossRef] [PubMed]

- Maślanka, S.; Juszczyński, J.; Kraszewski, T.; Oleksy, W. Properties of Polylactide, Obtained from Lactic Acid in the Process of Lacticfer mentation of Lactose in Whey Post production (Waste). J. Achiev. Mater. Manuf. Eng. 2018, 2, 58–68. [Google Scholar] [CrossRef]

- Delmoitié, B.; Sakarika, M.; Rabaey, K.; De Wever, H.; Regueira, A. Tailoring Non-Axenic Lactic Acid Fermentation from Cheese Whey Permeate Targeting a Flexible Lactic Acid Platform. J. Environ. Manag. 2025, 373, 123529. [Google Scholar] [CrossRef]

- Goyal, C.; Dhyani, P.; Rai, D.C.; Tyagi, S.; Dhull, S.B.; Sadh, P.K.; Duhan, J.S.; Saharan, B.S. Emerging Trends and Advancements in the Processing of Dairy Whey for Sustainable Biorefining. J. Food Process. Preserv. 2023, 2023, 6626513. [Google Scholar] [CrossRef]

- Iskandaryan, M.; Baghdasaryan, L.; Minasyan, E.; Trchounian, K.; Antranikian, G.; Poladyan, A. A Novel, Cost-Effective Approach for the Production of Hydrogenase Enzymes and Molecular Hydrogen from Recycled Whey-Based by-Products. Int. J. Hydrogen Energy 2025, 140, 1191–1202. [Google Scholar] [CrossRef]

- Wong, S.Y.; Hartel, R.W. Crystallization in Lactose Refining—A Review. J. Food Sci. 2014, 79, R257–R272. [Google Scholar] [CrossRef]

- Kopsahelis, N.; Dimou, C.; Papadaki, A.; Xenopoulos, E.; Kyraleou, M.; Kallithraka, S.; Kotseridis, Y.; Papanikolaou, S.; Koutinas, A.A. Refining of Wine Lees and Cheese Whey for the Production of Microbial Oil, Polyphenol-rich Extracts and Value-added Co-products. J. Chem. Technol. Biotechnol. 2018, 93, 257–268. [Google Scholar] [CrossRef]

- Kilara, A. Whey and Whey Products. In Dairy Processing and Quality Assurance; Chandan, R.C., Kilara, A., Shah, N.P., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 349–366. ISBN 978-1-118-81031-6. [Google Scholar]

- Addai, F.P.; Lin, F.; Wang, T.; Kosiba, A.A.; Sheng, P.; Yu, F.; Gu, J.; Zhou, Y.; Shi, H. Technical Integrative Approaches to Cheese Whey Valorization towards Sustainable Environment. Food Funct. 2020, 11, 8407–8423. [Google Scholar] [CrossRef]

- Lappa, I.; Papadaki, A.; Kachrimanidou, V.; Terpou, A.; Koulougliotis, D.; Eriotou, E.; Kopsahelis, N. Cheese Whey Processing: Integrated Biorefinery Concepts and Emerging Food Applications. Foods 2019, 8, 347. [Google Scholar] [CrossRef]

- Menchik, P.; Zuber, T.; Zuber, A.; Moraru, C.I. Composition of Coproduct Streams from Dairy Processing: Acid Whey and Milk Permeate. J. Dairy Sci. 2019, 102, 3978–3984. [Google Scholar] [CrossRef]

- Morr, C.V. Composition, Physicochemical and Functional Properties of Reference Whey Protein Concentrates. J. Food Sci. 1985, 50, 1406–1411. [Google Scholar] [CrossRef]

- Delaney, R.A.M. Composition, Properties and Uses of Whey Protein Concentrates. Int. J. Dairy Technol. 1976, 29, 91–101. [Google Scholar] [CrossRef]

- Macwan, S.R.; Dabhi, B.K.; Parmar, S.C.; Aparnathi, K.D. Whey and Its Utilization. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 134–155. [Google Scholar] [CrossRef]

- Barone, G.; Moloney, C.; O’Regan, J.; Kelly, A.L.; O’Mahony, J.A. Chemical Composition, Protein Profile and Physicochemical Properties of Whey Protein Concentrate Ingredients Enriched in α-Lactalbumin. J. Food Compos. Anal. 2020, 92, 103546. [Google Scholar] [CrossRef]

- Galdino, I.K.C.P.d.O.; Salles, H.O.; dos Santos, K.M.O.; Veras, G.; Buriti, F.C.A. Proximate Composition Determination in Goat Cheese Whey by near Infrared Spectroscopy (NIRS). PeerJ 2020, 8, e8619. [Google Scholar] [CrossRef]

- Garay, P.A.; Villalva, F.J.; Paz, N.F.; de Oliveira, E.G.; Ibarguren, C.; Alcocer, J.C.; Curti, C.A.; Ramón, A.N. Formulation of a Protein Fortified Drink Based on Goat Milk Whey for Athletes. Small Rumin. Res. 2021, 201, 106418. [Google Scholar] [CrossRef]

- Budiyanto, A.; Usmiati, S.; Ismail, M.R.N.; Batubara, S.C.; Sulistiyani, T.R. The Effect of Types and Concentration of Fillers on the Quality of Whey Protein Products. IOP Conf. Ser. Earth Environ. Sci. 2021, 803, 012042. [Google Scholar] [CrossRef]

- Segundo, R.-F.; Luis, C.-C.; Otiniano, N.M.; De La Cruz-Noriega, M.; Gallozzo-Cardenas, M. Utilization of Cheese Whey for Energy Generation in Microbial Fuel Cells: Performance Evaluation and Metagenomic Analysis. Fermentation 2025, 11, 176. [Google Scholar] [CrossRef]

- Buyanova, I.V.; Lupinskaya, S.M.; Ostroumov, L.A.; Mazeeva, I.A. Innovative Low Temperature Methods of Milk Whey Processing. IOP Conf. Ser. Earth Environ. Sci. 2021, 640, 032007. [Google Scholar] [CrossRef]

- Gupta, C.; Prakash, D. Therapeutic Potential of Milk Whey. Beverages 2017, 3, 31. [Google Scholar] [CrossRef]

- Mavropoulou, I.P.; Kosikowski, F.V. Composition, Solubility, and Stability of Whey Powders. J. Dairy Sci. 1973, 56, 1128–1134. [Google Scholar] [CrossRef]

- Borad, S.G.; Kumar, A.; Singh, A.K. Effect of Processing on Nutritive Values of Milk Protein. Crit. Rev. Food Sci. Nutr. 2017, 57, 3690–3702. [Google Scholar] [CrossRef]

- Fancello, F.; Zara, G.; Hatami, F.; Scano, E.A.; Mannazzu, I. Unlocking the Potential of Second Cheese Whey: A Comprehensive Review on Valorisation Strategies. Rev. Environ. Sci. Biotechnol. 2024, 23, 411–441. [Google Scholar] [CrossRef]

- Minj, S.; Anand, S. Whey Proteins and Its Derivatives: Bioactivity, Functionality, and Current Applications. Dairy 2020, 1, 233–258. [Google Scholar] [CrossRef]

- Jakubowicz, D.; Froy, O. Biochemical and Metabolic Mechanisms by Which Dietary Whey Protein May Combat Obesity and Type 2 Diabetes. J. Nutr. Biochem. 2013, 24, 1–5. [Google Scholar] [CrossRef]

- Sousa, Y.R.F.; Araújo, D.F.S.; Pulido, J.O.; Pintado, M.M.E.; Martínez-Férez, A.; Queiroga, R.C.R.E. Composition and Isolation of Goat Cheese Whey Oligosaccharides by Membrane Technology. Int. J. Biol. Macromol. 2019, 139, 57–62. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Luo, B.; Ni, Y.; Bansal, N.; Zhou, P. Comparison of Milk Fat Globule Membrane and Whey Proteome between Dromedary and Bactrian Camel. Food Chem. 2022, 367, 130658. [Google Scholar] [CrossRef]

- Bakr, A.; Moussa, M.; Amer, D.; Khalil, A. Production of Functional Milk Drink by Using Some Vital Materials from Whey. J. Product. Dev. 2022, 27, 1–13. [Google Scholar] [CrossRef]

- Stout, M.A.; Park, C.W.; Drake, M.A. The Effect of Bleaching Agents on the Degradation of Vitamins and Carotenoids in Spray-Dried Whey Protein Concentrate. J. Dairy Sci. 2017, 100, 7922–7932. [Google Scholar] [CrossRef]

- Pereira, C.; Henriques, M.; Gomes, D.; Gomez-Zavaglia, A.; De Antoni, G. Novel Functional Whey-Based Drinks with Great Potential in the Dairy Industry. Food Technol. Biotechnol. 2015, 53, 307–314. [Google Scholar] [CrossRef]

- Khaire, R.A.; Gogate, P.R. Whey Proteins. In Proteins: Sustainable Source, Processing and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 193–223. ISBN 978-0-12-816695-6. [Google Scholar]

- Deeth, H.; Bansal, N. (Eds.) Whey Proteins: From Milk to Medicine; Academic Press: London, UK, 2019; ISBN 978-0-12-812124-5. [Google Scholar]

- Tugume, M.; Ibrahim, M.G.; Fujii, M.; Nasr, M. Management of Cheese Whey Wastewater and Greywater for Dual Biogas and Biochar Production: A Techno-Economic and Sustainable Approach. Waste Biomass Valorization 2024, 15, 4373–4393. [Google Scholar] [CrossRef]

- Perna, V.; Castelló, E.; Wenzel, J.; Zampol, C.; Fontes Lima, D.M.; Borzacconi, L.; Varesche, M.B.; Zaiat, M.; Etchebehere, C. Hydrogen Production in an Upflow Anaerobic Packed Bed Reactor Used to Treat Cheese Whey. Int. J. Hydrogen Energy 2013, 38, 54–62. [Google Scholar] [CrossRef]

- Tunick, M.H. Whey Protein Production and Utilization: A Brief History. In Whey Processing, Functionality and Health Benefits; Onwulata, C.I., Huth, P.J., Eds.; Wiley: Hoboken, NJ, USA, 2008; pp. 1–13. ISBN 978-0-8138-0903-8. [Google Scholar]

- Bolchini, S.; Nardin, T.; Morozova, K.; Scampicchio, M.; Larcher, R. Antioxidant Maillard Reaction Products from Milk Whey: A Food By-Product Valorisation. Foods 2025, 14, 450. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Wang, M.; Xu, C.; Fan, J.; Du, Q.; Bu, D.; Fan, R.; Jiang, H.; Han, R.; Yang, Y. Physicochemical Properties and Soluble Whey Protein Composition of Local and Imported Commercial Ultra-High-Temperature Milk in China. J. Dairy Sci. 2025, 108, 5558–5569. [Google Scholar] [CrossRef]

- Hamarsland, H.; Johansen, M.K.; Seeberg, F.; Brochmann, M.; Garthe, I.; Benestad, H.B.; Raastad, T. Native Whey Induces Similar Adaptation to Strength Training as Milk, despite Higher Levels of Leucine, in Elderly Individuals. Nutrients 2019, 11, 2094. [Google Scholar] [CrossRef]

- Jeong, E.W.; Park, G.R.; Kim, J.; Baek, Y.; Go, G.; Lee, H.G. Whey Proteins-Fortified Milk with Adjusted Casein to Whey Proteins Ratio Improved Muscle Strength and Endurance Exercise Capacity without Lean Mass Accretion in Rats. Foods 2022, 11, 574. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S. Dairy-Based Functional Beverages. In Milk-Based Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 67–93. ISBN 978-0-12-815504-2. [Google Scholar]

- Sánchez-Moya, T.; López-Nicolás, R.; Planes, D.; González-Bermúdez, C.A.; Ros-Berruezo, G.; Frontela-Saseta, C. In Vitro Modulation of Gut Microbiota by Whey Protein to Preserve Intestinal Health. Food Funct. 2017, 8, 3053–3063. [Google Scholar] [CrossRef]

- Young, K.W.H.; Munro, I.C.; Taylor, S.L.; Veldkamp, P.; Van Dissel, J.T. The Safety of Whey Protein Concentrate Derived from the Milk of Cows Immunized against Clostridium Difficile. Regul. Toxicol. Pharmacol. 2007, 47, 317–326. [Google Scholar] [CrossRef]

- Bosco, F.; Carletto, R.A.; Marmo, L. An Integrated Cheese Whey Valorization Process. Chem. Eng. Trans. 2018, 64, 379–384. [Google Scholar] [CrossRef]

- Chandrapala, J. Whey Wastes and Powders. In Microstructure of Dairy Products; El-Bakry, M.M.A., Sanchez, A., Mehta, B.M., Eds.; Wiley: Hoboken, NJ, USA, 2018; pp. 261–291. ISBN 978-1-118-96422-4. [Google Scholar]

- Rosseto, M.; Rigueto, C.V.T.; Gomes, K.S.; Krein, D.D.C.; Loss, R.A.; Dettmer, A.; Richards, N.S.P.D.S. Whey Filtration: A Review of Products, Application, and Pretreatment with Transglutaminase Enzyme. J. Sci. Food Agric. 2024, 104, 3185–3196. [Google Scholar] [CrossRef]

- Jones, A.; Zhang, S.; Akoh, C.C.; Martini, S. Effect of Anhydrous Milk Fat Fraction Addition to Butter on Water Loss Reduction. Int. Dairy J. 2023, 141, 105618. [Google Scholar] [CrossRef]

- Khurana, S.; Kankarwal, P.; Saini, J.; Panghal, P.; Panghal, A.; Chhikara, N. Potential of Whey for Production of Value-Added Products Using Microbial Fermentations. In Whey Valorization; Poonia, A., Trajkovska Petkoska, A., Eds.; Springer Nature: Singapore, 2023; pp. 115–137. ISBN 978-981-99-5458-2. [Google Scholar]

- Kostenko, K.V.; Blinov, A.V.; Poydun, P.A.; Pirogov, M.A.; Tatov, A.V.; Rekhman, Z.A. Production Technology Optimization for the Functional Milk Drink Enriched with the Essential Nutrient Zinc. Food Ind. 2024, 9, 79–89. [Google Scholar] [CrossRef]

- Poništ, J.; Dubšíková, V.; Schwarz, M.; Samešová, D. Methods of Processing Whey Waste from Dairies. A Review. Environ. Prot. Eng. 2021, 47, 67–84. [Google Scholar] [CrossRef]

- Mc Entee, S.A.; Kelly, A.L.; Lawless, F.N.; McCarthy, N.A.; Murphy, E.G. Effect of Ultrafiltration of Acid Whey at pH 4.6 or 6.5 on Whey Concentrate Composition and Resultant Powder Properties. Int. J. Dairy Technol. 2025, 78, e13116. [Google Scholar] [CrossRef]

- Nishanthi, M.; Chandrapala, J.; Vasiljevic, T. Compositional and Structural Properties of Whey Proteins of Sweet, Acid and Salty Whey Concentrates and Their Respective Spray Dried Powders. Int. Dairy J. 2017, 74, 49–56. [Google Scholar] [CrossRef]

- Blais, H.N.; Schroën, K.; Tobin, J.T. A Review of Multistage Membrane Filtration Approaches for Enhanced Efficiency during Concentration and Fractionation of Milk and Whey. Int. J. Dairy Technol. 2022, 75, 749–760. [Google Scholar] [CrossRef]

- Burmistrov, D.E.; Pavkin, D.Y.; Khakimov, A.R.; Ignatenko, D.N.; Nikitin, E.A.; Lednev, V.N.; Lobachevsky, Y.P.; Gudkov, S.V.; Zvyagin, A.V. Application of Optical Quality Control Technologies in the Dairy Industry: An Overview. Photonics 2021, 8, 551. [Google Scholar] [CrossRef]

- Casino, F.; Kanakaris, V.; Dasaklis, T.K.; Moschuris, S.; Stachtiaris, S.; Pagoni, M.; Rachaniotis, N.P. Blockchain-Based Food Supply Chain Traceability: A Case Study in the Dairy Sector. Int. J. Prod. Res. 2021, 59, 5758–5770. [Google Scholar] [CrossRef]

- Costa, N.C.; Lima, G.F.; Magalhães, C.S.; Arruda, E.J.; Marcuzzo, J.S.; Almeida, G.A.; Luccas, P.O. The Use of Carbon Fiber Restricted Access Material for Cadmium Determination in Milk Whey. Food Anal. Methods 2025, 18, 542–551. [Google Scholar] [CrossRef]

- Vera-Santander, V.E.; Hernández-Figueroa, R.H.; Arrioja-Bretón, D.; Jiménez-Munguía, M.T.; Mani-López, E.; López-Malo, A. Utilization of Whey for Eco-Friendly Bio-Preservation of Mexican-Style Fresh Cheeses: Antimicrobial Activity of Lactobacillus Casei 21/1 Cell-Free Supernatants (CFS). Int. J. Environ. Res. Public Health 2024, 21, 560. [Google Scholar] [CrossRef]

- Graikini, D.; Alvarez-Sabatel, S.; Puértolas, E.; Pérez, M.D.; Sánchez, L. Effect of Ultra-High Pressure Homogenization on the Antirotaviral Activity of Bovine Milk Whey. Innov. Food Sci. Emerg. Technol. 2024, 96, 103745. [Google Scholar] [CrossRef]

- Lima, J.S.; Ribeiro, D.C.S.Z.; Neto, H.A.; Campos, S.V.A.; Leite, M.O.; Fortini, M.E.D.R.; De Carvalho, B.P.M.; Almeida, M.V.O.; Fonseca, L.M. A Machine Learning Proposal Method to Detect Milk Tainted with Cheese Whey. J. Dairy Sci. 2022, 105, 9496–9508. [Google Scholar] [CrossRef]

- Liu, C.; Wang, R.; Wang, T.; Gu, C.; Zhang, L.; Meng, D.; Pan, M.; Yang, R. The Whey–Plant Protein Heteroprotein Systems with Synergistic Properties and Versatile Applications. J. Agric. Food Chem. 2025, 73, 4440–4454. [Google Scholar] [CrossRef]

- Zheng, H.; Meletharayil, H. Constructing Aqueous Foams from Milk Components: Structure and Interfaces. Curr. Opin. Food Sci. 2025, 63, 101290. [Google Scholar] [CrossRef]

- Altuntas, S.; Hapoglu, H. Kefir-Type Drinks from Whey. In Non-Alcoholic Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 185–226. ISBN 978-0-12-815270-6. [Google Scholar]

- Pires, A.F.; Díaz, O.; Cobos, A.; Pereira, C.D. A Review of Recent Developments in Edible Films and Coatings-Focus on Whey-Based Materials. Foods 2024, 13, 2638. [Google Scholar] [CrossRef]

- Bezverkhaya, N.S.; Ogneva, O.A. Development of Whey Milk Drink. New Technol. 2021, 17, 14–20. [Google Scholar] [CrossRef]

- Du, X.; Jing, H.; Wang, L.; Huang, X.; Wang, X.; Wang, H. Characterization of Structure, Physicochemical Properties, and Hypoglycemic Activity of Goat Milk Whey Protein Hydrolysate Processed with Different Proteases. LWT 2022, 159, 113257. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Farahmandi, A.; Hosseinpour, S. Recent Advances in Ultrasound Application as a Novel Technique in Analysis, Processing and Quality Control of Fruits, Juices and Dairy Products Industries: A Review. Ultrason. Sonochem. 2019, 57, 73–88. [Google Scholar] [CrossRef]

- Pant, R.R.; Prakash, G.; Farooquie, J.A. A Framework for Traceability and Transparency in the Dairy Supply Chain Networks. Procedia-Soc. Behav. Sci. 2015, 189, 385–394. [Google Scholar] [CrossRef]

- Foschi, M.; Biancolillo, A.; Reale, S.; Poles, F.; D’Archivio, A.A. Classification of “Ricotta” Whey Cheese from Different Milk and Designation of Origin-Protected Samples through Infrared Spectroscopy and Chemometric Analysis. J. Food Compos. Anal. 2025, 138, 107019. [Google Scholar] [CrossRef]

- Freire, P.; Zambrano, A.; Zamora, A.; Castillo, M. Thermal Denaturation of Milk Whey Proteins: A Comprehensive Review on Rapid Quantification Methods Being Studied, Developed and Implemented. Dairy 2022, 3, 500–512. [Google Scholar] [CrossRef]

- Skryplonek, K. The Use of Acid Whey for the Production of Yogurt-Type Fermented Beverages. Mljekarstvo 2018, 68, 139–149. [Google Scholar] [CrossRef]

- Hassan, T.; Elarnaoutti, M.S. Heavy Metals Transfer from Milk into Milk Products. Turk. J. Agric.-Food Sci. Technol. 2025, 13, 900–906. [Google Scholar] [CrossRef]

- Hyseni, A.; Kalevska, T.; Nikolovska-Nedelkoska, D.; Dimitrovska, G.; Knights, V.; Stamatovska, V.; Hyseni, V. Textural and Sensory Properties of Yogurt Obtained by Bioconversion of Milk-Liquid Whey Mixture and Aronia (Aronia melanocarpa) Supplementation. J. Agric. For. 2024, 70, 115–126. [Google Scholar] [CrossRef]

- Geiselhart, S.; Podzhilkova, A.; Hoffmann-Sommergruber, K. Cow’s Milk Processing—Friend or Foe in Food Allergy? Foods 2021, 10, 572. [Google Scholar] [CrossRef]

- Silva E Alves, A.T.; Spadoti, L.M.; Zacarchenco, P.B.; Trento, F.K.H.S. Probiotic Functional Carbonated Whey Beverages: Development and Quality Evaluation. Beverages 2018, 4, 49. [Google Scholar] [CrossRef]

- Sabokbar, N.; Khodaiyan, F.; Moosavi-Nasab, M. Optimization of Processing Conditions to Improve Antioxidant Activities of Apple Juice and Whey Based Novel Beverage Fermented by Kefir Grains. J. Food Sci. Technol. 2015, 52, 3422–3432. [Google Scholar] [CrossRef]

- Skryplonek, K.; Dmytrów, I.; Mituniewicz-Małek, A. Probiotic Fermented Beverages Based on Acid Whey. J. Dairy Sci. 2019, 102, 7773–7780. [Google Scholar] [CrossRef]

- Turkmen, N.; Akal, C.; Özer, B. Probiotic Dairy-Based Beverages: A Review. J. Funct. Foods 2019, 53, 62–75. [Google Scholar] [CrossRef]

- Igualada, C.; Giraldo, J.; Font, G.; Yusà, V. Validation of a Multi-Residue UHPLC-HRMS Method for Antibiotics Screening in Milk, Fresh Cheese, and Whey. J. Food Compos. Anal. 2022, 106, 104265. [Google Scholar] [CrossRef]

- Jurk, N.A. Marketing Research of Consumer Preferences for Developing Rich Whey Drinks. Econ. Agric. Process. Enterp. 2021, 10, 60–63. [Google Scholar] [CrossRef]

- Matthews, M.E.; Amundson, C.H.; Hill, C.G. Changes in Distribution of Nitrogenous Fractions of Cheddar Cheese Whey During Ultrafiltration. J. Dairy Sci. 1976, 59, 1033–1041. [Google Scholar] [CrossRef]

- Kolotiy, T.B.; Kovalenko, Z.S. Drinks Based on Milk Whey Using Fruit Syrup from Wild Plants. New Technol. 2021, 17, 33–39. [Google Scholar] [CrossRef]

- Utebaeva, A.A.; Alibekov, R.S.; Sysoeva, M.A.; Orymbetova, G.E.; Ablash, A.A.; Abish, Z.A. Functional Whey-Based Drinks with Grape Pomace Extract and Fruit Juice. J. Almaty Technol. Univ. 2024, 145, 26–38. [Google Scholar] [CrossRef]

- Stabnikova, O.; Shevchenko, O.; Stabnikov, V.; Paredes López, O. (Eds.) Bioconversion of Wastes to Value-Added Products. In Food Biotechnology and Engineering, 1st ed.; CRC Press: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2024; ISBN 978-1-003-32967-1. [Google Scholar]

- Sharafi, H.; Moradi, M.; Amiri, S. Application of Cheese Whey Containing Postbiotics of Lactobacillus Acidophilus LA5 and Bifidobacterium Animalis BB12 as a Preserving Liquid in High-Moisture Mozzarella. Foods 2022, 11, 3387. [Google Scholar] [CrossRef] [PubMed]

- León-López, A.; Pérez-Marroquín, X.A.; Campos-Lozada, G.; Campos-Montiel, R.G.; Aguirre-Álvarez, G. Characterization of Whey-Based Fermented Beverages Supplemented with Hydrolyzed Collagen: Antioxidant Activity and Bioavailability. Foods 2020, 9, 1106. [Google Scholar] [CrossRef] [PubMed]

- Zhuravlev, S.S.; Serova, O.P.; Bozhkova, S.E. The Use of Plant Extracts in the Production of Whey Beverage. IOP Conf. Ser. Earth Environ. Sci. 2021, 848, 012034. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, J.; Khan, M.Z.; Alugongo, G.M.; Chen, T.; Liu, S.; Li, S.; Cao, Z. Unlocking the Potential of Milk Whey Protein Components in Colorectal Cancer Prevention and Therapy. Crit. Rev. Food Sci. Nutr. 2024, 64, 12961–12998. [Google Scholar] [CrossRef]

- Elbekjonovich, R.A.; Kholbaevich, R.F. Dry Milk Whey. West. Eur. J. Med. Med. Sci. 2025, 3, 37–39. [Google Scholar]

- Rodionov, I.S.; Evdokimov, I.A. Biotechnological Bases of a Functional Drink Based on Whey. Sovrem. Nauka Innov. 2023, 1, 72–82. [Google Scholar] [CrossRef]

- Skachkov, D.A.; Serova, O.P.; Pilipenko, D.N.; Obrushnikova, L.F.; Surkova, S.A. Innovative Whey Based Tonic Drink with the Plant Components. Agrar.-Food Innov. 2020, 11, 65–75. [Google Scholar] [CrossRef]

- Magalhães, K.T.; Dias, D.R.; de Melo Pereira, G.V.; Oliveira, J.M.; Domingues, L.; Teixeira, J.A.; de Almeida e Silva, J.B.; Schwan, R.F. Chemical Composition and Sensory Analysis of Cheese Whey-Based Beverages Using Kefir Grains as Starter Culture. Int. J. Food Sci. Technol. 2011, 46, 871–878. [Google Scholar] [CrossRef]

- Larionov, G.; Semenov, V.; Lavrentyev, A.; Sherne, V.; Kayukova, O.; Mardaryeva, N.; Ivanova, R. Production of Mint Whey Drink at Private and Collective Farms and Agricultural Holdings. IOP Conf. Ser. Earth Environ. Sci. 2020, 604, 012042. [Google Scholar] [CrossRef]

- Magenis, R.B.; Prudêncio, E.S.; Amboni, R.D.M.C.; Cerqueira Júnior, N.G.; Oliveira, R.V.B.; Soldi, V.; Benedet, H.D. Compositional and Physical Properties of Yogurts Manufactured from Milk and Whey Cheese Concentrated by Ultrafiltration. Int. J. Food Sci. Technol. 2006, 41, 560–568. [Google Scholar] [CrossRef]

- Mahomud, M.S.; Katsuno, N.; Zhang, L.; Nishizu, T. Physical, Rheological, and Microstructural Properties of Whey Protein Enriched Yogurt Influenced by Heating the Milk at Different pH Values. J. Food Process. Preserv. 2017, 41, e13236. [Google Scholar] [CrossRef]

- Barzaghi, S.; Pricca, N.; Cabassi, G.; Marinoni, L. Influence of Milk Fat on Milk Coagulation Process: An Aquaphotomics Approach. In Proceedings of the 21st International Conference on Near Infrared Spectroscopy, Innsbruck, Austria, 20–24 August 2023; Bec, K., Huck, C., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 270–280, ISBN 978-3-031-84793-6. [Google Scholar]

- Yukalo, V.; Datsyshyn, K.; Storozh, L. Improvement of the Method of Comparative Study of Milk Whey Proteins Enzymatic Hydrolysis. EUREKA Life Sci. 2019, 5, 52–57. [Google Scholar] [CrossRef]

- Smith, S.T.; Metzger, L.; Drake, M.A. Evaluation of Whey, Milk, and Delactosed Permeates as Salt Substitutes. J. Dairy Sci. 2016, 99, 8687–8698. [Google Scholar] [CrossRef]

- Saxton, R. Whey Protein Powder Analysis by Kjeldahl and Mid-Infrared Spectroscopy. Master’s Thesis, Boise State University, Boise, ID, USA, 2021. [Google Scholar]

- Saxton, R.; McDougal, O.M. Whey Protein Powder Analysis by Mid-Infrared Spectroscopy. Foods 2021, 10, 1033. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Tan, C.; Tan, C.; Lin, Z. Qualitative and Quantitative Analysis of Whey Protein Adulteration Based on Near-Infrared Spectroscopy and Machine Learning. Microchem. J. 2025, 209, 112844. [Google Scholar] [CrossRef]

- ISO 22662:2024; Milk and Milk Products—Determination of Lactose Content by High-Performance Liquid Chromatography (Reference Method). International Organization for Standardization: Geneva, Switzerland, 2024.

- Naidoo, K.; Naidoo, R.; Bangalee, V. Understanding the Amino Acid Profile of Whey Protein Products. Glob. J. Health Sci. 2018, 10, 45. [Google Scholar] [CrossRef]

- ISO 8968-1:2014; Milk and Milk Products—Determination of Nitrogen Content Part 1: Kjeldahl Principle and Crude Protein Calculation. International Organization for standardization: Geneva, Switzerland, 2014.

- TR CU 033/2013 On Safety of Milk and Dairy Products. Available online: https://www.cu-tr.org/page9?article_id=531 (accessed on 30 June 2025).

- Pappa, I.; Illiopoulos, C.; Massouras, T. On Sustainability of a Dairy Sector in Crisis. Int. J. Food Syst. Dyn. 2019, 10, 130–150. [Google Scholar] [CrossRef]

| Method | Purpose | Advantages | Challenges | Applications | Sources |

|---|---|---|---|---|---|

| Spray Drying | Convert liquid whey to powder | Long shelf life, easy transportation | High energy consumption (~5000 kJ/kg) | Powdered milk, protein supplements | [93,100] |

| Ultrafiltration | Separate proteins and lactose | Produces high-protein concentrates | Requires advanced equipment (membrane fouling risks) | Functional foods, sports nutrition drinks | [30,94,101] |

| Nanofiltration | Extract salts and lactose | Enhances product purity | High initial setup costs | Lactose-free products, infant formulas | [38,94,101] |

| Reverse Osmosis | Reduce water content | Energy-efficient, reduces transportation costs | Limited to pre-filtered whey streams | Pre-concentration for drying | [31] |

| Type of Whey-Based Beverage | Dominant Functional Component | Target Consumer Group | Processing Technology | Sensory Profile |

|---|---|---|---|---|

| Probiotic (e.g., whey kefir) | Probiotics (Lactobacillus, Bifidobacterium) | Individuals supporting gut microbiota | Fermentation with starter cultures | Sour, refreshing, lightly carbonated |

| Amino acid-enriched (for athletes) | BCAAs, leucine, glutamine | Athletes and physically active individuals | Ultrafiltration + amino acid fortification | Neutral, milky, slightly sweet |

| Mineral–vitamin drink (for seniors) | Calcium, magnesium, vitamins B, D, E | Seniors and individuals with deficiencies | Mineral enrichment + spray drying | Delicate, mildly sweet, herbal or mineral-like |

| Herbal whey beverage | Polyphenols, flavonoids, essential oils | Consumers preferring natural, plant-based ingredients | Herbal infusion + pasteurization | Botanical, slightly astringent, aromatic |

| Goat whey drink (for children) | Medium-chain fatty acids, cysteine | Infants, children, people with casein intolerance | Enzymatic hydrolysis + composition standardization | Mild, slightly sweet, smooth |

| Energy drink (with caffeine and BCAAs) | Caffeine, taurine, amino acids | Young adults, students, cognitively active individuals | Protein isolation + concentration + addition of extracts | Intense, stimulating, citrus-like |

| Additives | Benefit of Use | Literature Source |

|---|---|---|

| Fruit juices (e.g., berry, citrus) | Enhance sensory appeal; increase vitamin C content | [38,129,130] |

| Chia seeds, matcha, turmeric | Provide omega-3 fatty acids; add anti-inflammatory and metabolic benefits | [87,131] |

| Probiotic strains (Lactobacillus, Bifidobacterium) | Support digestive health; enhance immune function | [105,124,125,132] |

| Herbal components | Improve gut health; offer anti-inflammatory effects | [129,133,134] |

| Medicinal plant extracts | Address vitamin deficiencies; improve bioavailability of nutrients | [81,135,136] |

| Chamomile, mint, rosehip extracts | Strengthen immune system; provide antioxidant properties | [108,137,138] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirzakulova, A.; Sarsembaeva, T.; Suleimenova, Z.; Kowalski, Ł.; Gajdzik, B.; Wolniak, R.; Bembenek, M. Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages—A Review. Foods 2025, 14, 3245. https://doi.org/10.3390/foods14183245

Mirzakulova A, Sarsembaeva T, Suleimenova Z, Kowalski Ł, Gajdzik B, Wolniak R, Bembenek M. Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages—A Review. Foods. 2025; 14(18):3245. https://doi.org/10.3390/foods14183245

Chicago/Turabian StyleMirzakulova, Assiya, Tolkyn Sarsembaeva, Zhulduz Suleimenova, Łukasz Kowalski, Bożena Gajdzik, Radosław Wolniak, and Michał Bembenek. 2025. "Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages—A Review" Foods 14, no. 18: 3245. https://doi.org/10.3390/foods14183245

APA StyleMirzakulova, A., Sarsembaeva, T., Suleimenova, Z., Kowalski, Ł., Gajdzik, B., Wolniak, R., & Bembenek, M. (2025). Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages—A Review. Foods, 14(18), 3245. https://doi.org/10.3390/foods14183245