Optimizing Red Vinasse-Blue Round Scad Processing Using Integrated Dimensionality Reduction and RSM: Effects on Lipid Storage Stability

Abstract

1. Introduction

2. Materials and Methods

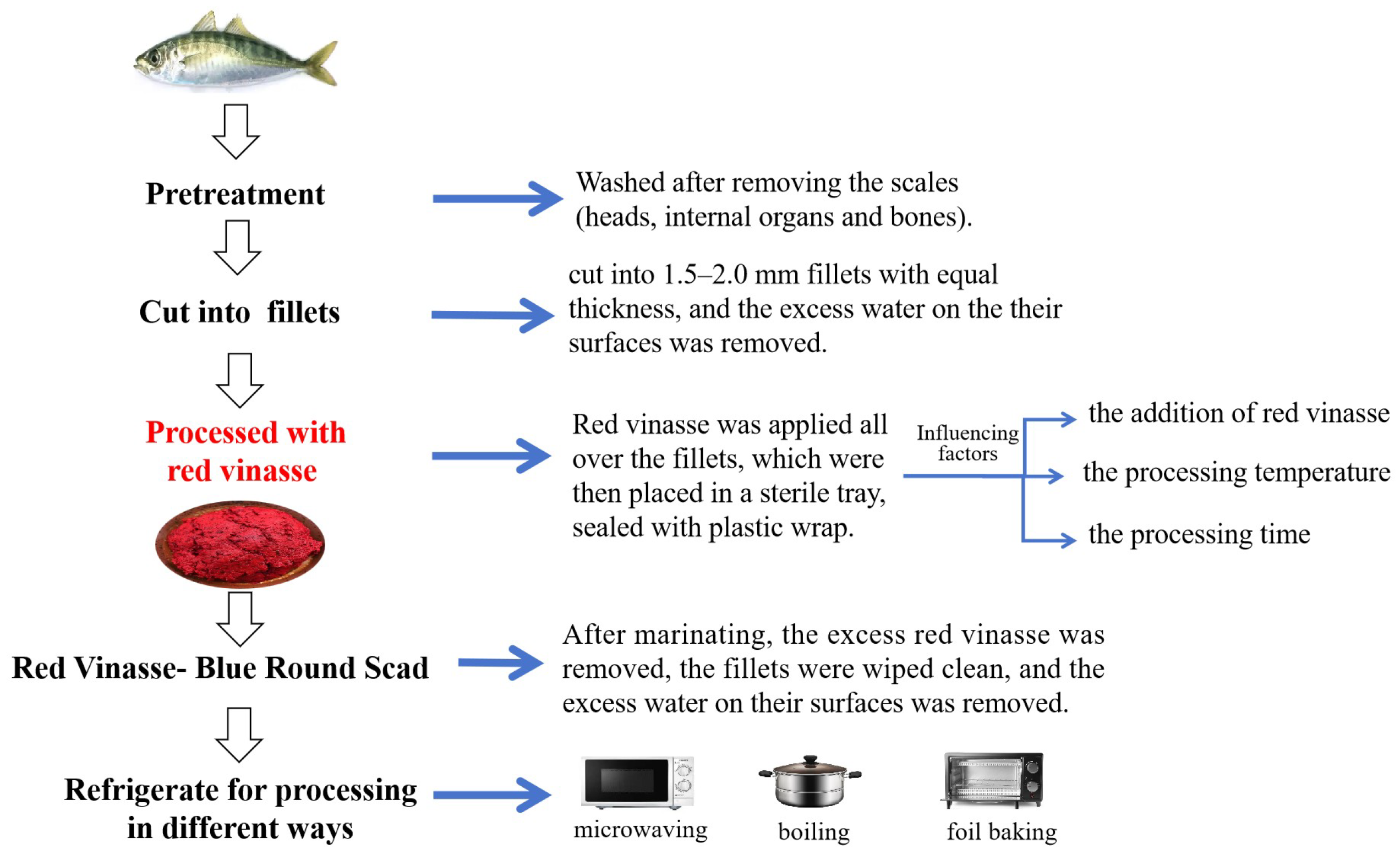

2.1. Preparation of Blue Round Scad Processed with Red Vinasse

2.2. Single Factor Experiment on Processing Technological Parameter of Red Vinasse-Blue Round Scad

2.3. Determination of Texture Composite Score and Sensory Scores

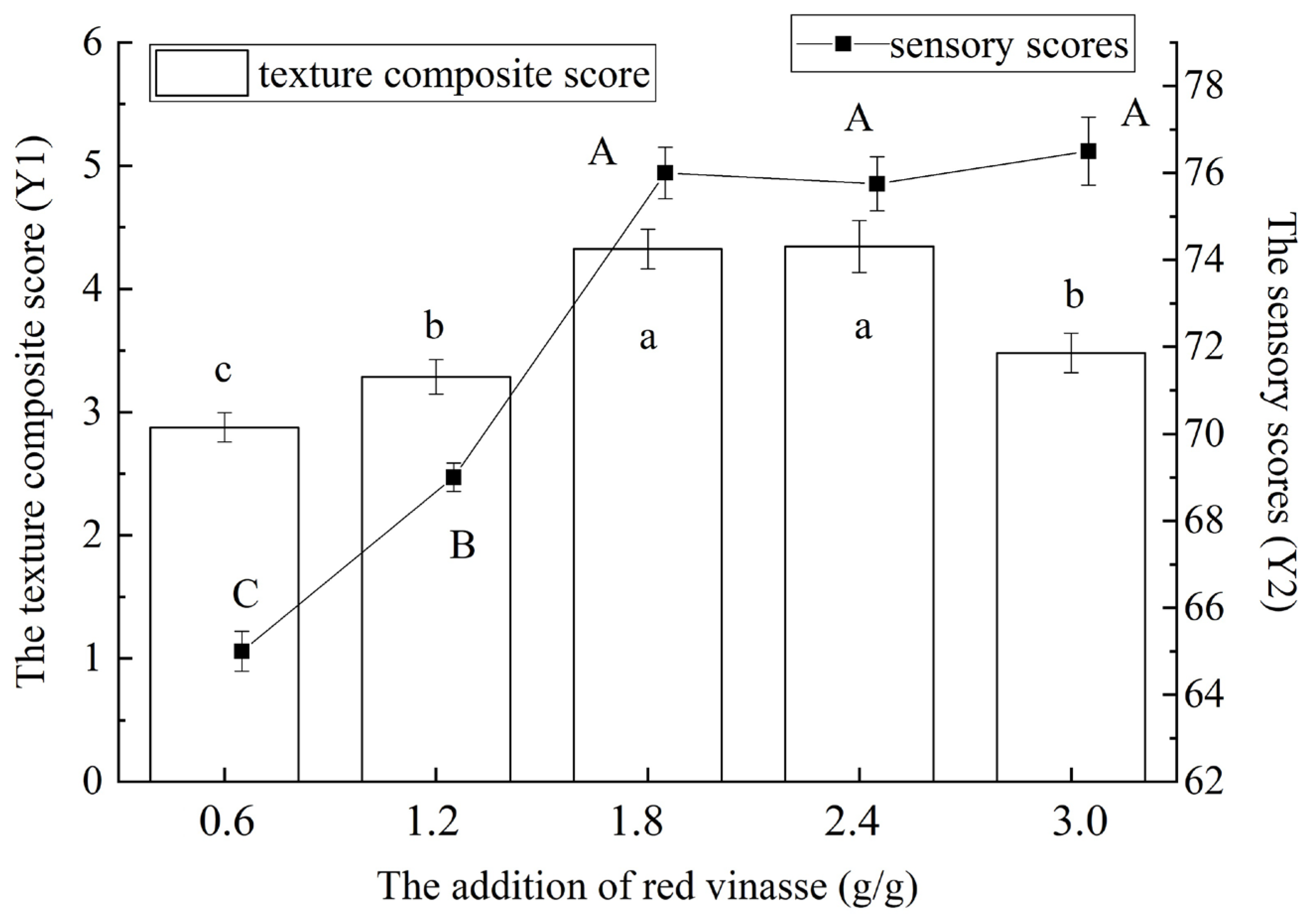

2.3.1. Determination of Texture Composite Score (Y1)

2.3.2. Determination of Sensory Scores (Y2)

2.4. The Response Surface Design Combined with MATLAB Analysis

2.5. The Influence of Different Processing on the Lipids Stability of Red Vinasse-Blue Round Scad During Storage

2.5.1. The Different Processing Methods

2.5.2. Extraction and Determination of Total Fat

2.5.3. Determination of Thiobarbituric Acid Reactive Substances (TBARS)

2.5.4. Determination of Fatty Acid Composition

2.6. Statistical Analysis

3. Results and Discussion

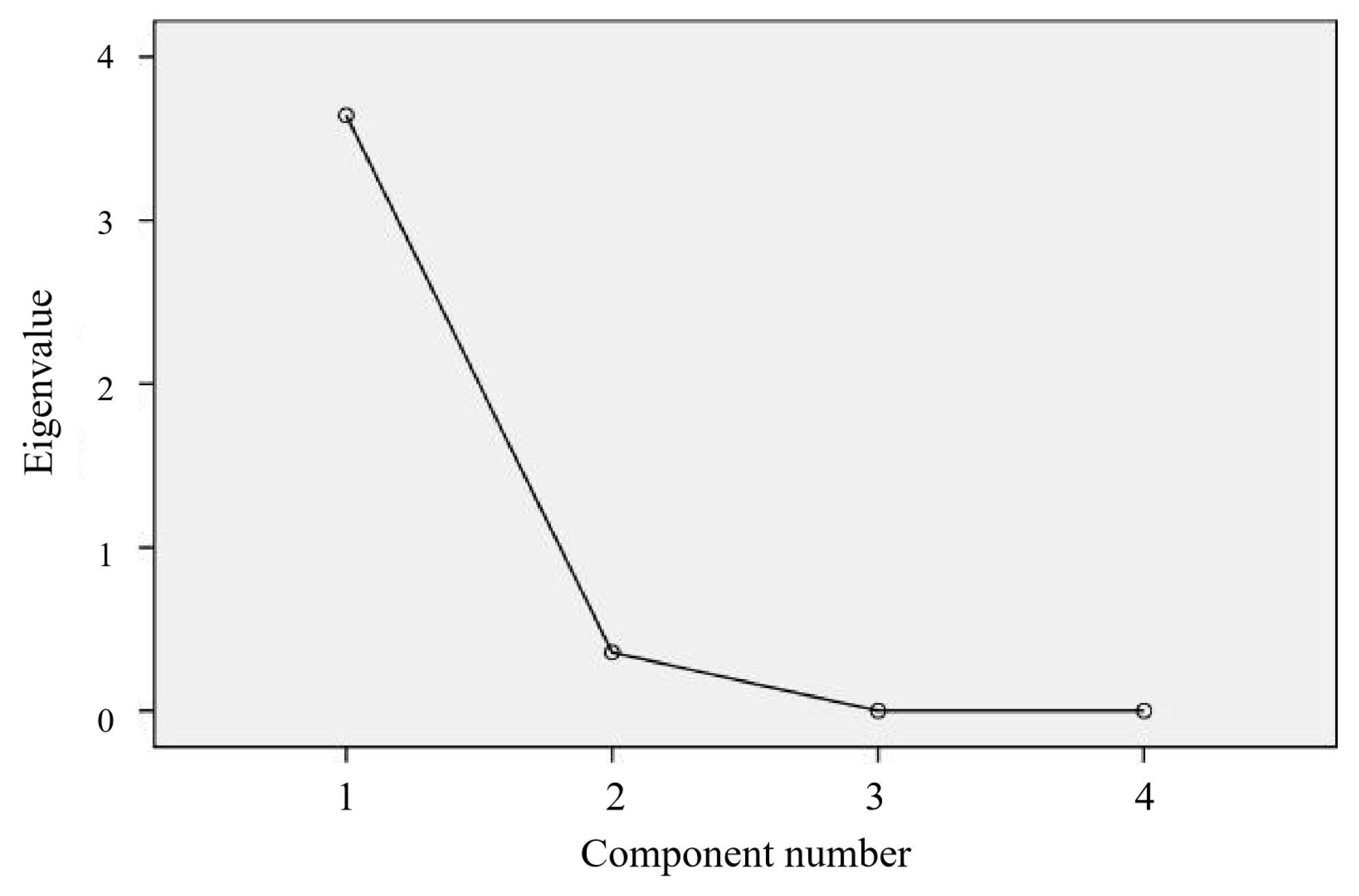

3.1. Establishment of Evaluation Model of Texture Composite Score of Red Vinasse-Blue Round Scad

3.1.1. The Suitability Test

3.1.2. Total Variance of Interpretation

3.1.3. Extraction of Common Factors to Establish Comprehensive Index Calculation

3.2. The Influence of Different Factors on Texture Composite Score of Red Vinasse-Blue Round Scad

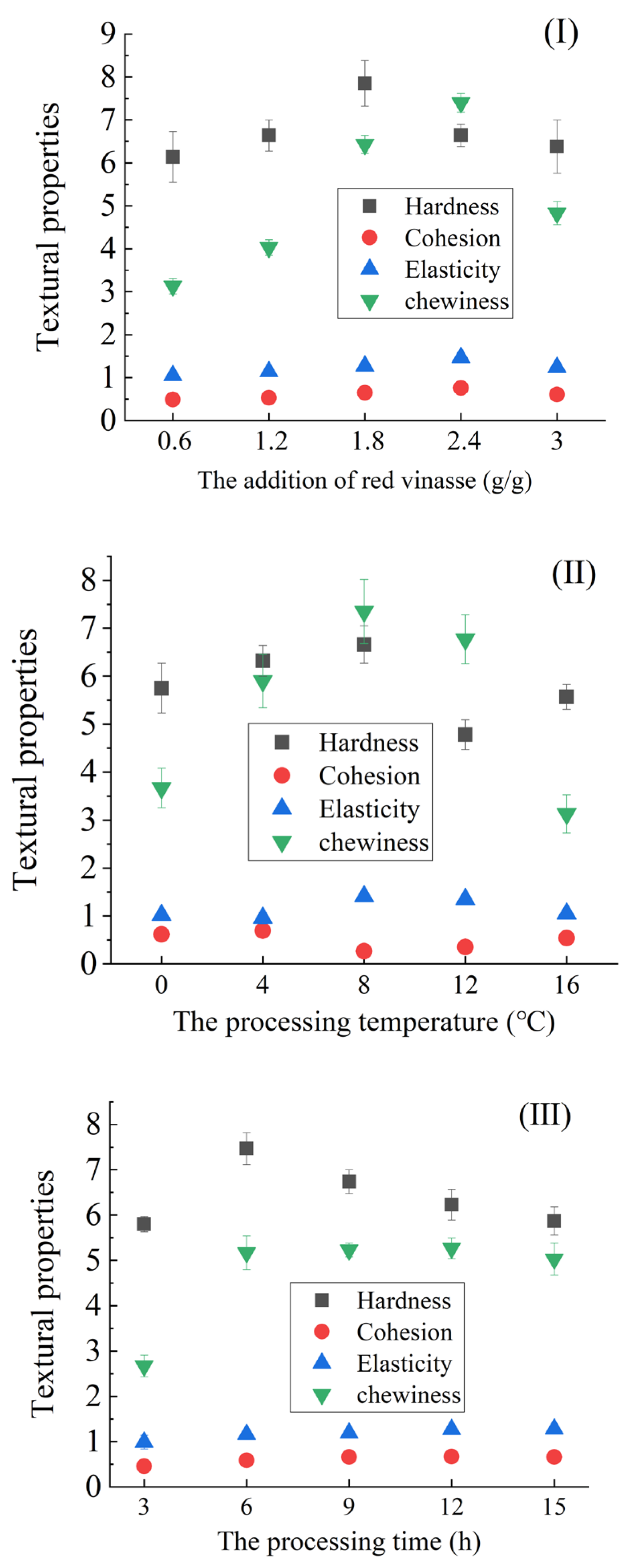

3.2.1. The Influence of the Addition of Red Vinasse on Texture Composite Score

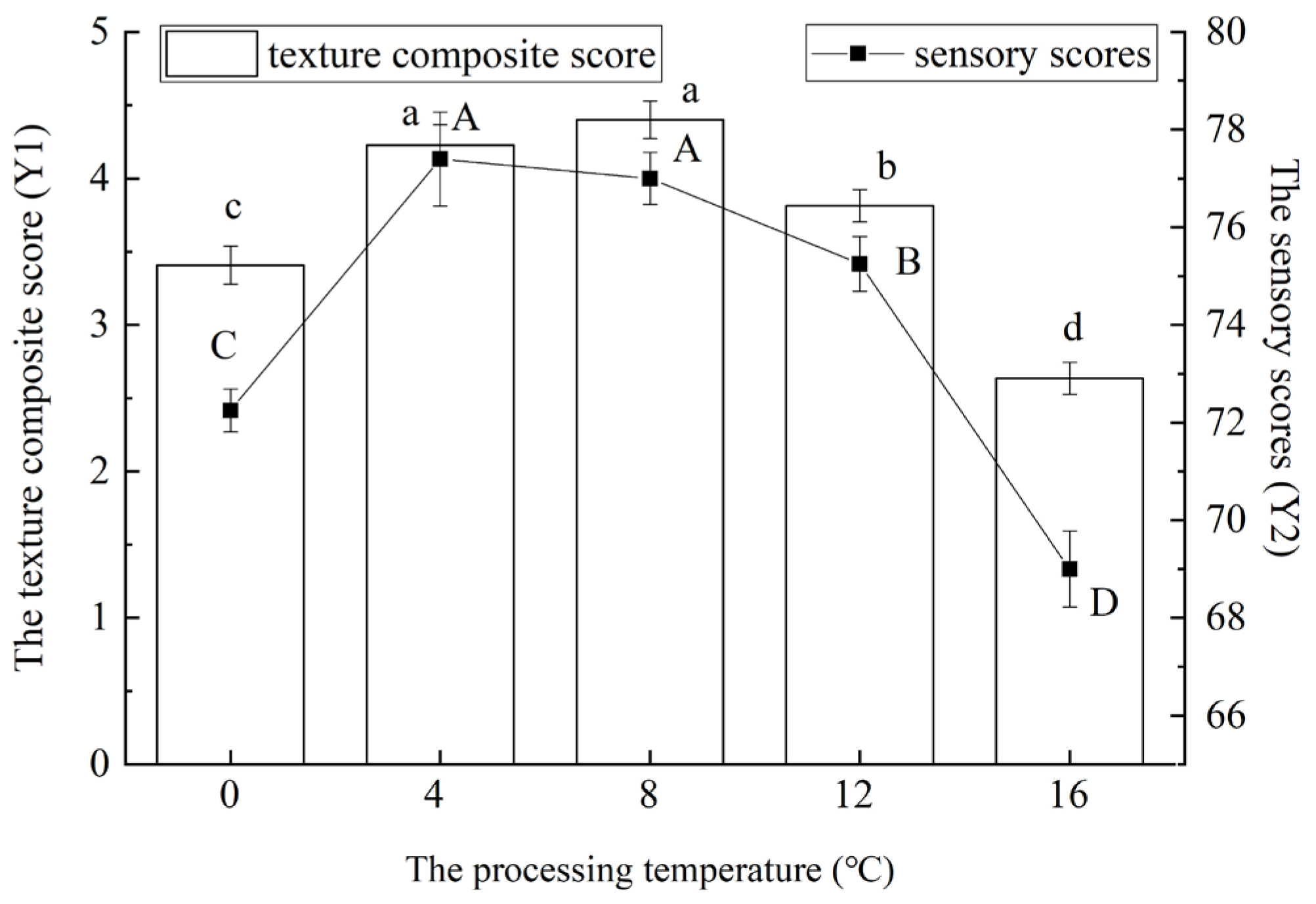

3.2.2. The Influence of Processing Temperature on Texture Composite Score

3.2.3. The Influence of Processing Time on Texture Composite Score

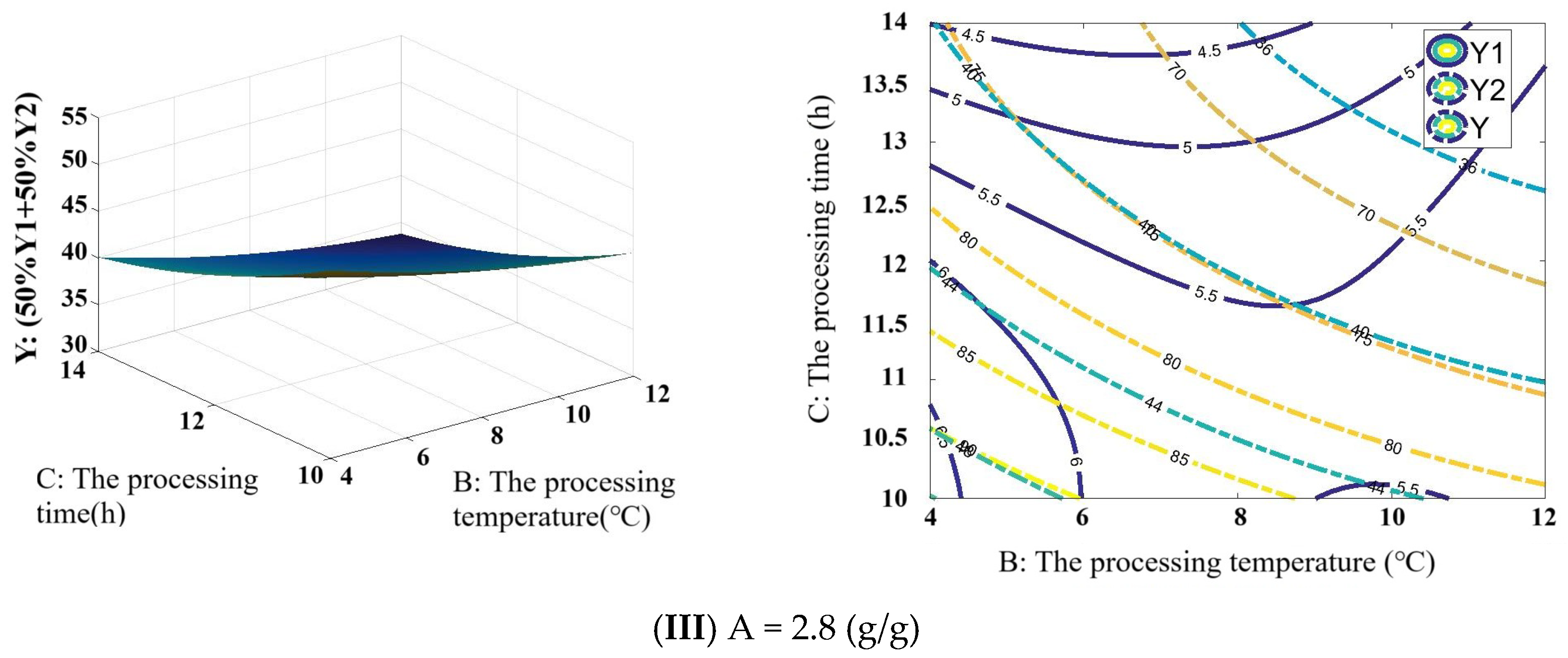

3.3. Results of Box–Behnken Design Combined with MATLAB Analysis

3.3.1. Establishment of Response Surface Model of Box–Behnken Design

3.3.2. Significance Test of Response Surface Model of Box–Behnken Design

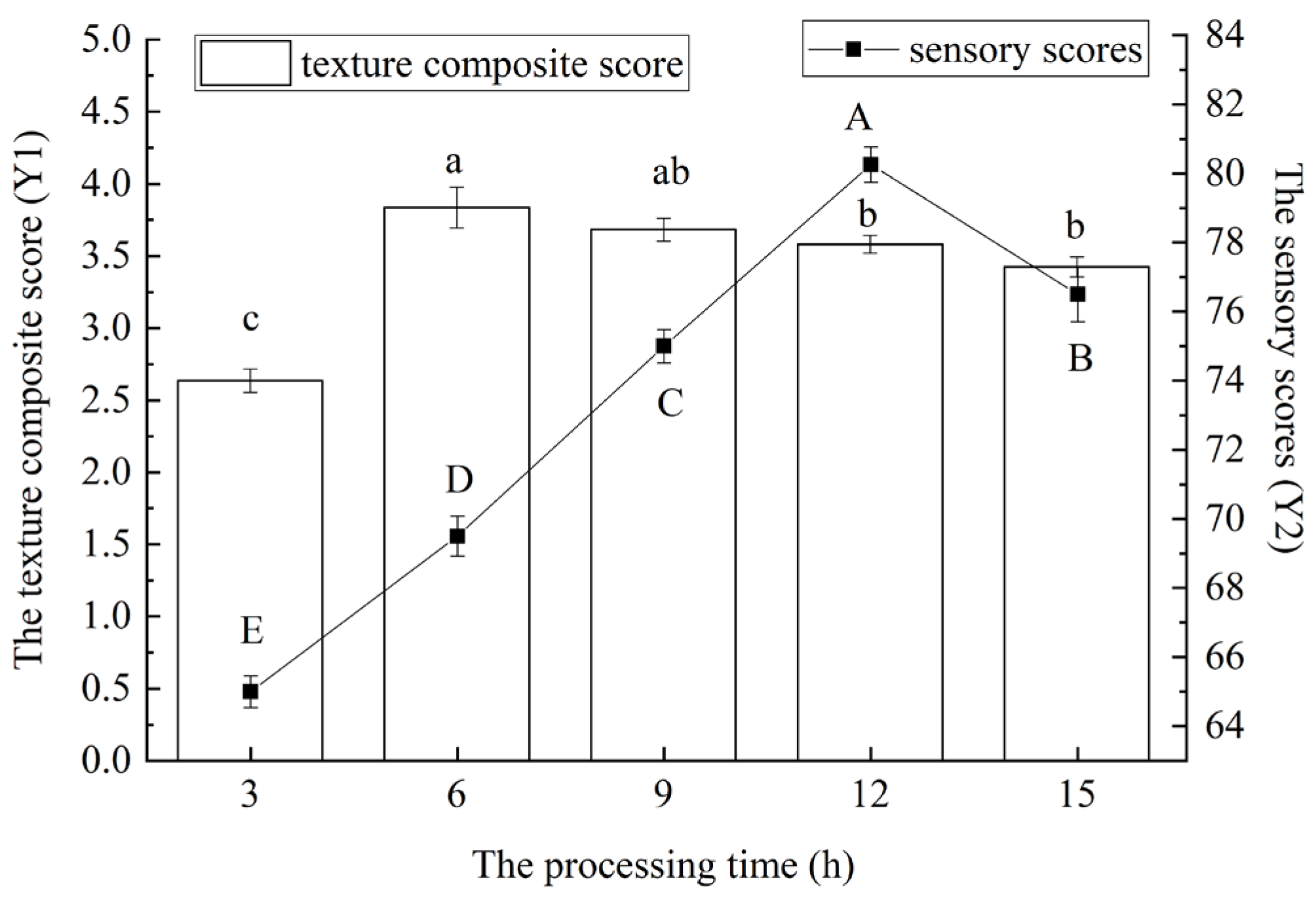

3.3.3. Analysis of the Result of Box–Behnken Design

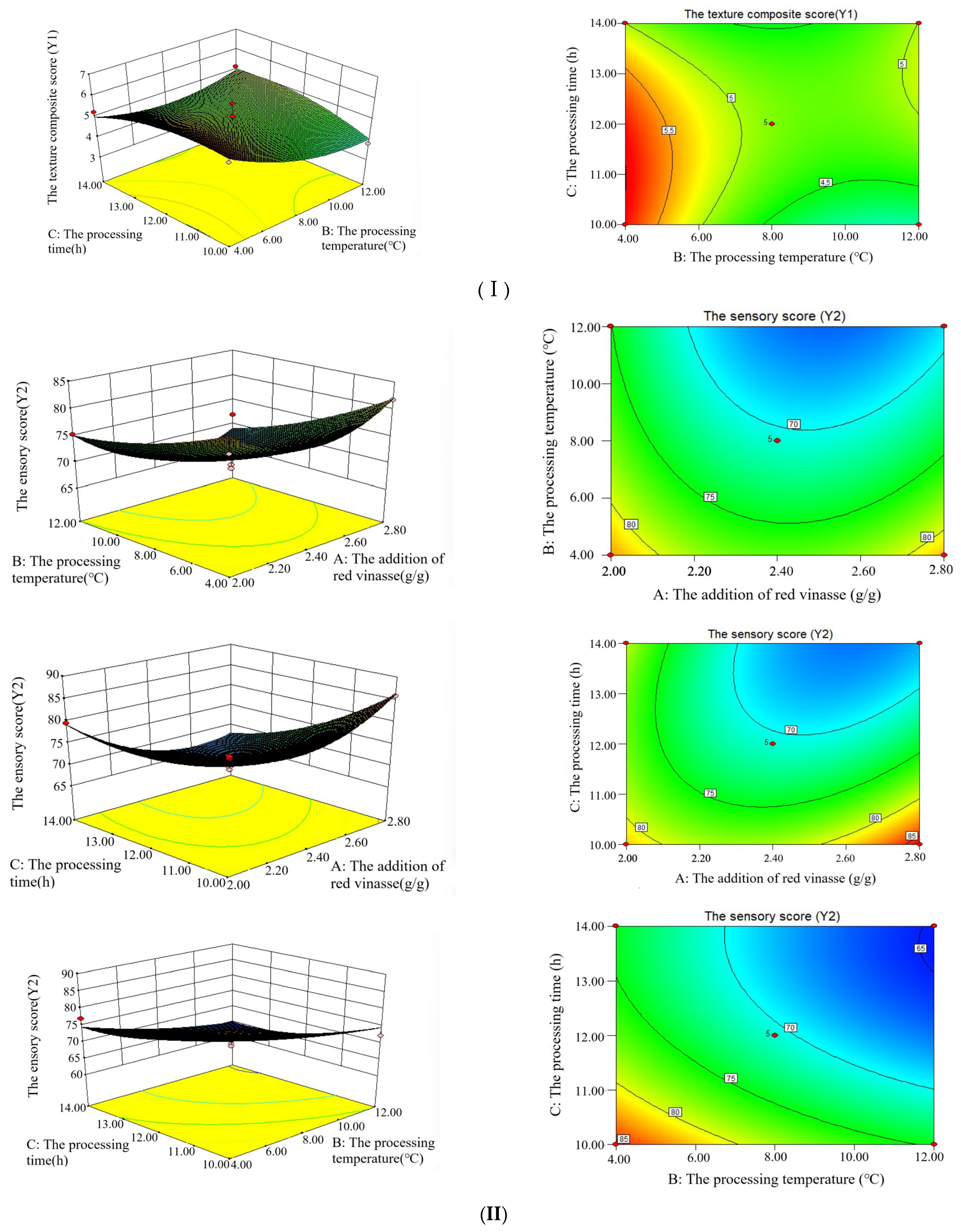

3.3.4. Matlab Analysis of Four-Dimensional Interaction

3.3.5. Verification Test

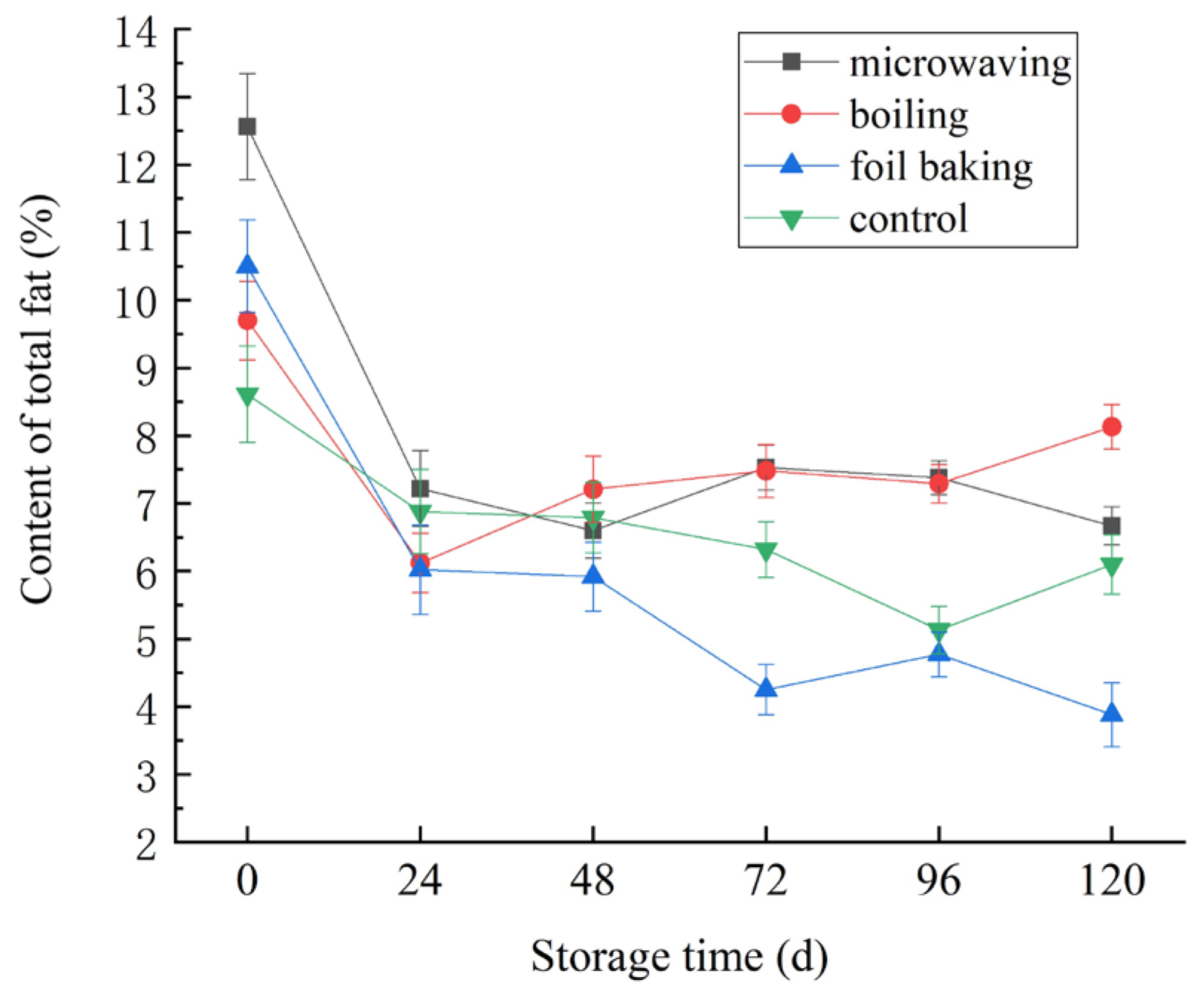

3.4. Effects of Different Processing Methods on Total Fat Content of Red Vinasse-Blue Round Scad

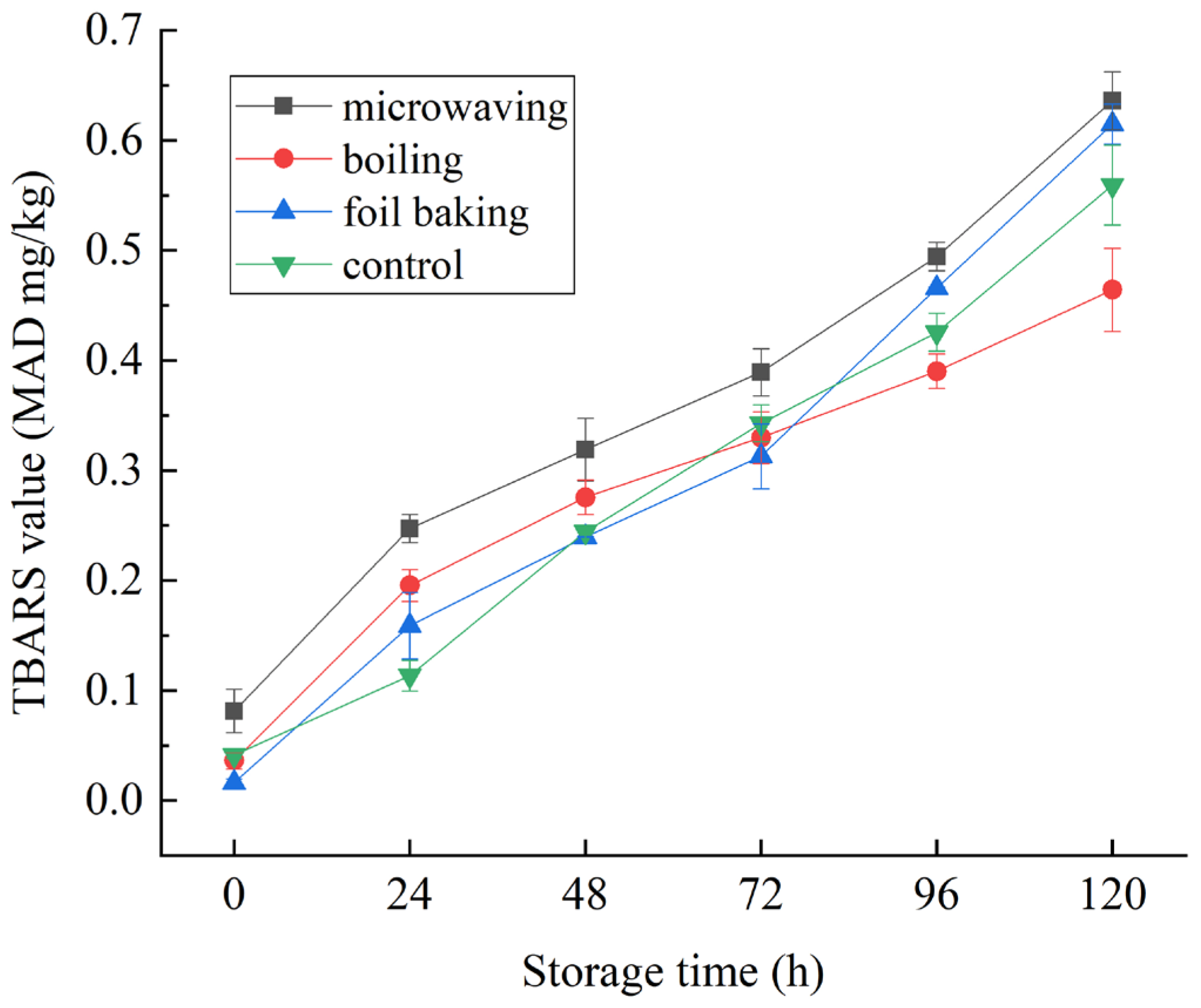

3.5. Effects of Different Processing Methods on TBARS of Red Vinasse-Blue Round Scad

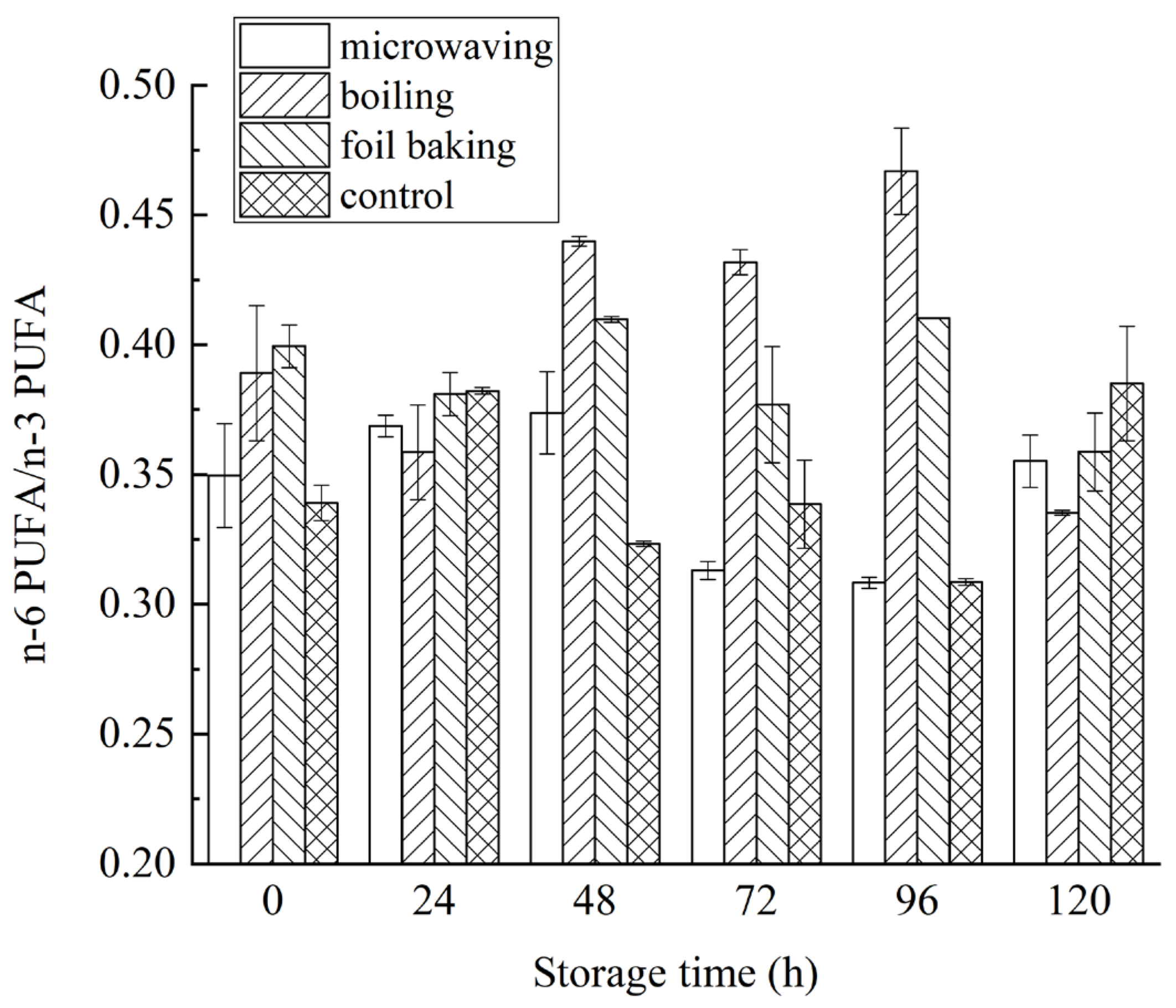

3.6. Effects of Different Processing Methods on Fatty Acid Composition of Red Vinasse-Blue Round Scad

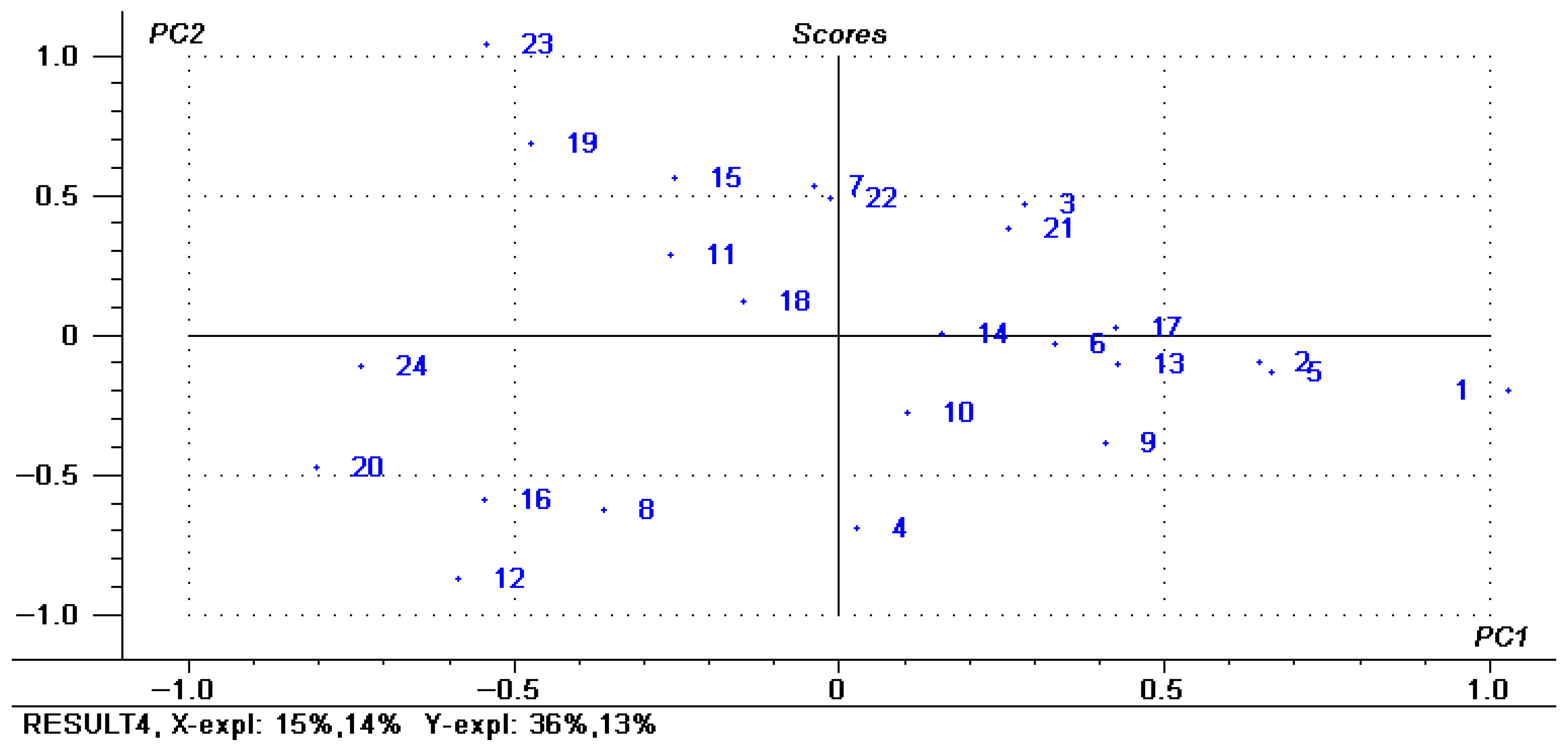

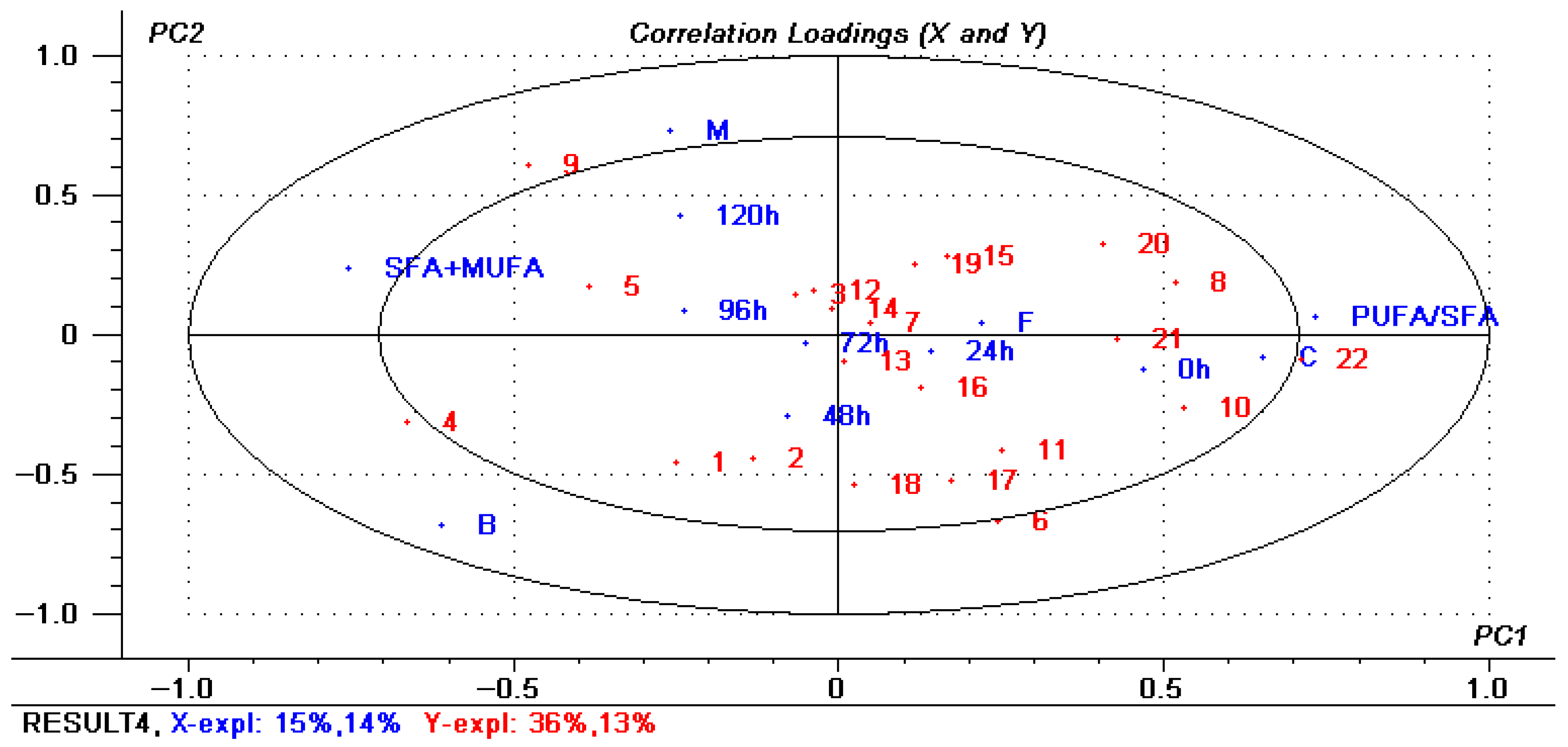

3.7. PLSR Analysis of Fatty Acid Composition of Red Vinasse-Blue Round Scad by Different Processing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, H.Y.; Luo, L.X.; Li, S.S.; Mao, R.F. Effects of adding red kojic rice on the quality and volatile flavor of fermented radish. Food Ind. Sci. Technol. 2024, 46, 14–24. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, H.L.; Li, G.L.; Su, G.C.; Liu, J.W.; Li, J. Separation and Purification of the Antioxidant Compounds from Gutian Red Yeast Rice. Mod. Food Sci. Technol. 2018, 34, 136–142. (In Chinese) [Google Scholar]

- Hou, Y.Q.; Liu, J.; Zhao, M.M.; Shao, Y.C.; Chen, F.S.; Peng, L.J.; Zhou, Y.X. Analysis of the related standards about monascus products. China Brew. 2020, 39, 1–6. (In Chinese) [Google Scholar]

- Yuan, Y.J.; Yang, Z.Y.; Liang, Z.H.; Wu, Q.; Yan, Y.Y.; Chen, S.Y.; Li, X.Y.; Ai, L.Z.; Ni, L.; Lv, X.C. The regulatory effects of microbial community on the formation of higher alcohols and volatile flavor components in Hongqu rice wine brewing. Food Biosci. 2023, 56, 103142. [Google Scholar] [CrossRef]

- Chen, W.P.; He, Y.; Zhou, Y.X.; Shao, Y.C.; Feng, Y.L.; Li, M.; Chen, F.S. Edible filamentous fungi from the species monascus: Early traditional fermentations, modern molecularbiology, and futuregenomics. Compr. Rev. Food Sci. Food Saf. 2015, 14, 555–567. [Google Scholar] [CrossRef]

- Agboyibor, C.; Kong, W.B.; Chen, D.; Zhang, A.M.; Niu, S.Q. Monascus pigments production, composition, bioactivity and its application: A review. Biocatal. Agric. Biotechnol. 2018, 16, 433–447. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Dong, Y.J.; Zhou, F.J.; Chen, J.P.; Zhou, T.Y.; Tian, C.W.; Chen, C.Q. Research progress on chemical constituents, pharmacological action and clinical application of Fermentum rubrum. Chin. Tradit. Herb. Drugs 2021, 52, 7379–7388. [Google Scholar]

- Xue, S. Current Situation and Trend Expectation of High Value Utilization of Round Scad. Storage Process 2020, 20, 226–232. (In Chinese) [Google Scholar]

- Sun, L.C.; Lin, Y.C.; Liu, W.F.; Qiu, X.J.; Cao, K.Y.; Liu, G.M.; Cao, M.J. Effect of pH shifting on conformation and gelation properties of myosin from skeletal muscle of blue round scads (Decapterus maruadsi). Food Hydrocoll. 2019, 93, 137–145. [Google Scholar] [CrossRef]

- Yao, W.Z.; Zhang, Y.F.; Zhang, G.P. Marine peptides as potential anti-aging agents: Preparation, characterization, mechanisms of action, and future perspectives. Food Chem. 2024, 460, 140413. [Google Scholar] [CrossRef]

- Jiang, H.P.; Tong, T.Z.; Sun, J.H.; Xu, Y.J.; Zhao, Z.X.; Liao, D.K. Purification and characterization of antioxidative peptides from round scad (Decapterus maruadsi) muscle protein hydrolysate. Food Chem. 2014, 154, 158–163. [Google Scholar] [CrossRef]

- Li, R.; Sun, Z.L.; Li, L.H.; Yang, X.Q.; Wei, Y.; Cen, J.W.; Xiang, Y.; Zhao, Y.Q. Effects of different thermal processing methods on edible quality of tilapia fillets. Food Ferment. Ind. 2020, 46, 127–135. (In Chinese) [Google Scholar]

- Chen, H.; Liu, Y.; Li, Z.P.; Huang, L.H. The influence of thermal treatment on grass carp quality and volatile flavor compounds. Food Mach. 2017, 33, 53–58+68. (In Chinese) [Google Scholar]

- Hu, L.L.; Ren, S.J.; Shen, Q.; Chen, J.C.; Ye, X.Q. Effect of Different Cooking Treatments and in Vitro Digestion on Protein Oxidation and Digestibility of Sturgeon Fillets. Food Sci. 2018, 39, 63–70. (In Chinese) [Google Scholar]

- Yuan, K.Y.; Zhao, T.T.; Jiao, W.J.; Liu, J.; Zhou, F.; Liu, W.F.; Zhang, Y.H.; Peng, L.Q.; Nan, H.J.; Chen, X.Y. Impact of different cooking methods on the quality of golden pompano fish fillets. Sci. Technol. Food Ind. 2024, 46, 81–90. (In Chinese) [Google Scholar] [CrossRef]

- Mi, X.X.; Zheng, X.; Tang, M.; Dai, H.J.; Ma, L.; Zhang, Y.H. Impact of superheated steam technology on ‘crispy outside and tender inside’ quality characteristics and flavor of roasted fish. Food Ferment. Ind. 2025, 51, 61–71. (In Chinese) [Google Scholar]

- Ruan, S.Y.; Jiang, J.H.; Zhou, Z.; Xiong, G.Q.; Ke, L.; Wang, L.; Shi, L. Optimization of Processing Technology and Shelf-Life Prediction of Ready-to-Eat Dried Orange Peel and Eel. Food Ind. Sci. Technol. 2025. (In Chinese) [Google Scholar] [CrossRef]

- Chen, L.L.; Zhang, S.F.; Yuan, M.L.; Zhao, L.; Jiang, Y. Effects of Different Cooking Methods on the Nutritional Quality of Ctenopharyngodon idellus. China Condiment 2019, 44, 40–45. [Google Scholar]

- Xue, S.; Chen, S.; Liu, B.; Liu, J. Effects of red vinasse on physicochemical qualities of blue round scad (Decapterus maruadsi) during storage, and shelf life prediction. Foods 2024, 13, 3654. [Google Scholar] [CrossRef]

- Xue, S.; Zhao, X.; Hu, P. Plackett-Burman test combined with Box-Behnken response surface method to optimize the formulation of pork meatball added with soluble antioxidant dietary fiber from sponge layer of Guanxi pomelo. Sci. Technol. Food Ind. 2024, 45, 176–186. (In Chinese) [Google Scholar]

- Xue, S.; Zhao, J.; Xiong, Z.; Huang, J. Preparation of ovalbumin/xanthan gum/chitosan pickering emulsion oleogel added with amomum villosum lour. Extract and its application in cookies. Gels 2024, 10, 683. [Google Scholar] [CrossRef]

- Xue, S.; Xiao, X.; He, Z.F.; Li, H.J. Effect of different cooking methods on the composition and nutritional value of intramuscular fatty acids of Hyla rabbit. Korean J. Food Sci. Anim. Resour. 2016, 36, 178–185. [Google Scholar] [CrossRef]

- Xue, S.; Xiao, X.; Huang, Y. Optimization of extraction process of pumpkin seed oil characterized with high PUFA content via double response surface in combination with matlab methodology. Ital. J. Food Sci. 2020, 32, 428–444. [Google Scholar]

- Xue, S.; Huang, Y.T.; Li, D.D. Optimization of extraction process of pumpkin seed oil with high linoleic acid content based on box-behnken-matlab analysis. J. Chin. Cereals Oils Assoc. 2022, 37, 102–109. (In Chinese) [Google Scholar]

- Li, T.; Zhang, Y.; Gu, M.Q.; Hu, Y.; Zhang, S.S.; Tu, C.H.; Li, C.; Zhang, B. Comprehensive analysis of flavor compounds and metabolites of vinasse hairtail fermentation based on GC-IMS and untargeted-based metabolomics. Food Biosci. 2024, 61, 104883. [Google Scholar] [CrossRef]

- Nirmal, N.; Santivarangkna, C.; Bekhit, A.A.; Barba, F.J. Chapter Four-Production of Fish Protein Hydrolysate by Microbial Fermentation. Fish Protein Hydrolysates; Academic Press: Cambridge, MA, USA, 2025; pp. 69–92. [Google Scholar]

- Yin, H.; Hong, Q.; Yu, X.; Wang, H.; Shi, X.D.; Liu, W.; Yuan, T.; Tu, Z.C. Dynamic changes in volatile profiles and bacterial communities during natural fermentation of Mei yu, traditional Chinese fermented fish pieces. Food Res. Int. 2024, 194, 114882. [Google Scholar] [CrossRef]

- Xue, S.; He, L. Optimization of adding polysaccharides from chicory root based on fuzzy mathematics to improve physicochemical properties of silver carp surimi balls during storage. J. Food Process. Pres. 2021, 45, e15307. [Google Scholar] [CrossRef]

- Xue, S.; Xiao, X.; Xie, J.S. Process optimization of soluble antioxidant dietary fiber extracted from spongy layer of Guanxi honey-pomelo peels by ultrasonic assisted enzymatic method. Sci. Technol. Food Ind. 2021, 42, 197–203+210. [Google Scholar]

- Wang, N.; Jia, G.; Wang, C.; Chen, M.; Xie, F.; Nepovinnykh, N.V.; Goff, H.D.; Guo, Q. Structural characterisation and immunomodulatory activity of exopolysaccharides from liquid fermentation of Monascus purpureus (Hong Qu). Food Hydrocoll. 2020, 103, e105636. [Google Scholar] [CrossRef]

- Wang, Z.; Bian, D.; He, L.; Ni, L.; Zhang, W.; Liu, Z. Studies on the fungal community of the traditional fermentation starter of Hong Qu glutinous rice wine. J. Chin. Inst. Food Sci. Technol. 2019, 19, 200–206. [Google Scholar]

- Wu, B.S.; Sun, Y.H.; Liu, S.Y.; Wang, G.Y.; Pu, Y.H.; Cheng, Z.B.; Gu, D.H.; Xu, Z.Q.; Liao, G.Z. Relationship between hydrolysis and oxidation of fat and protein with microorganisms in fermented meat products. J. Food Saf. Qual. 2017, 8, 832–837. [Google Scholar]

- Zhang, Z.H.; Chen, J.L.; Huang, X.; Aadil, R.M.; Li, B.; Gao, X.L. Natural pigments in the food industry: Enhancing stability, nutritional benefits, and gut microbiome health. Food Chem. 2024, 460, 140514. [Google Scholar] [CrossRef] [PubMed]

- Pignoli, G.; Bou, R.; Rodriguez-Estrada, M.T.; Decker, E.A. Suitability of saturated aldehydes as lipid oxidation markers in washed turkey meat. Meat Sci. 2009, 83, 412–416. [Google Scholar] [CrossRef]

- Liu, J.X.; Chen, J.L.; Wang, S.; Xie, J.J.; Wang, Y.X.; Chai, T.T.; Ong, M.K.; Wu, J.Z.; Tian, L.M.; Bai, W.B. Effects of monascus application on in vitro digestion and fermentation characteristics of fish protein. Food Chem. 2022, 377, 132000. [Google Scholar] [CrossRef]

- Benito, M.J.; Rodríguez, M.; Córdoba, M.G.; Andrade, M.J.; Córdoba, J.J. Effect of the fungal protease EPg222 on proteolysis and texture in the dry fermented sausage ‘salchichón’. J. Sci. Food Agric. 2005, 85, 273–280. [Google Scholar] [CrossRef]

- Gong, Z.H.; Jiao, P.F.; Huang, F.; Zhang, S.; Zhou, B.; Lin, Q.L.; Liu, J.; Liang, Y. Separation and antioxidant activity of the water-soluble yellow monascus pigment and its application in the preparation of functional rice noodles. LWT 2023, 185, 115172. [Google Scholar] [CrossRef]

- Wei, S.; He, Y.F.; Yang, J.; Li, Y.; Liu, Z.J.; Wang, W.P. Effects of exogenous ascorbic acid on yields of citrinin and pigments, antioxidant capacities, and fatty acid composition of monascus ruber. LWT 2022, 154, 112800. [Google Scholar] [CrossRef]

- Simopoulos, A.P. Omega-3 fatty acids and antioxidants in edible wild plants. Biol. Res. 2004, 37, 263–277. [Google Scholar] [CrossRef]

- Williams, C.M. Dietary fatty acids and human health. Ann. Zootech. 2000, 49, 165–180. [Google Scholar] [CrossRef]

- Simopoulos, A.P. The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomed. Pharmacother. 2002, 56, 365–379. [Google Scholar] [CrossRef]

- Xue, S.; He, Z.F.; Lu, J.Z.; Tao, X.Q.; Zheng, L.; Xie, Y.J.; Xiao, X.; Peng, R.; Li, H.J. Effect of growth on fatty acid composition of total intramuscular lipid and phospholipids in Ira rabbits. Korean J. Food Sci. Anim. Resour. 2015, 35, 10–18. [Google Scholar] [CrossRef][Green Version]

- Marini, F. Classification methods in chemometrics. Curr. Anal. Chem. 2010, 6, 72–79. [Google Scholar] [CrossRef]

- Xue, S. Composition of intramuscular phospholipid fatty acids of Inra rabbit at different ages. Ital. J. Food Sci. 2016, 28, 683–696. [Google Scholar]

- Cruz, A.G.; Cadena, R.S.; Alvaro, M.B.; Sant’Ana, A.S.; Oliveira, C.A.F.; Faria, J.A.F.; Bolini, H.M.A.; Ferreira, M.M.C. Assessing the use of different chemometric techniques to discriminate low-fat and full-fat yogurts. LWT-Food Sci. Technol. 2013, 50, 210–214. [Google Scholar] [CrossRef]

- Matera, J.A.; Cruz, A.G.; Raices, R.S.L.; Silva, M.C.; Nogueira, L.C.; Quitério, S.L.; Cavalcanti, R.N.; Freiras, M.Q.; Conte Júnior, C.A. Discrimination of Brazilian artisanal and inspected pork sausages: Application of unsupervised, linear and non-linear supervised chemometric methods. Food Res. Int. 2014, 64, 380–386. [Google Scholar] [CrossRef]

- Huang, Y.C.; Li, H.J.; Wu, Z.M.; Li, F. Comparison of muscle lipid content and fatty acid composition among different positions of Rongchang pork carcass. Food Sci. 2011, 32, 216–220. (In Chinese) [Google Scholar]

- Xue, S. Cooking ways on composition of intramuscular phospholipid fatty acids of inra rabbit. Ciência Rural 2019, 49, e20190007. [Google Scholar] [CrossRef]

| Index | Scoring Standard | Scores |

|---|---|---|

| Appearance | The surface of the fillet looks clean, fresh, and non-shrinking. | 16~20 |

| The surface cleanliness of the fillet was good, and the meat had a slight shrinkage phenomenon. | 11~15 | |

| The surface of the fillet had a sticky phenomenon, and the meat was slightly contracted and slimy. | 6~10 | |

| The surface of the fillet was seriously sticky, and the meat had obvious slippage. | 0~5 | |

| Color | The fillets had a natural reddish color and were uniform. | 26~30 |

| The color of the fillet was slightly red, and the color was more uniform. | 20~25 | |

| The fillets had uneven shades. | 10~19 | |

| The fillets were dark and uneven. | 0~9 | |

| The aroma of red vinasse | The fillets had a slight wine aroma and a strong red vinasse aroma | 12~15 |

| The fillets had a slight wine aroma and a general red vinasse aroma. | 8~11 | |

| The fillets had a slight wine aroma and a general red vinasse aroma. | 4~7 | |

| No obvious wine aroma and red vinasse aroma. | 0~3 | |

| Unpleasant odor | No odor or fat oxidation. | 12~15 |

| Light fishy smell or a small amount of fat oxidation. | 8~11 | |

| The fillets had a light fishy taste, and the fat oxidation taste was heavy. | 4~7 | |

| The fillets had a more pronounced fishy smell and fat oxidation smell. | 0~3 | |

| Tissue | The fillets were firm, well textured, and elastic. | 16~20 |

| The fillets were firmer, and the texture was clearer and more elastic. | 11~15 | |

| The fillets were not tight, locally looser, with poor elasticity. | 6~10 | |

| The fillets were soft and rotten, the loose phenomenon was heavier, and the fish had no elasticity. | 0~5 |

| Factors | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A: addition of red vinasse (g/g) | 1:2.0 | 1:2.4 | 1:2.8 |

| B: processing temperature (°C) | 4 | 8 | 12 |

| C: processing time (h) | 10 | 12 | 14 |

| KMO Measure of Sampling Adequacy | 0.596 | |

|---|---|---|

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 15.179 |

| df | 6 | |

| Sig. | 0.19 | |

| Component | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 3.663 | 91.557 | 91.557 | 3.663 | 91.577 | 91.577 |

| 2 | 0.264 | 6.604 | 98.182 | |||

| 3 | 0.069 | 1.723 | 99.905 | |||

| 4 | 0.004 | 0.095 | 100.000 | |||

| No. | The Addition of Red Vinasse (g/g) | The Processing Temperature (°C) | The Processing Time (h) | Y1 | Y2 | Y |

|---|---|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 5.64 | 79.87 | 42.71 |

| 2 | 1 | −1 | 0 | 5.82 | 81.79 | 43.69 |

| 3 | −1 | 1 | 0 | 3.95 | 75.30 | 39.64 |

| 4 | 1 | 1 | 0 | 5.80 | 71.93 | 38.47 |

| 5 | −1 | 0 | −1 | 3.10 | 83.99 | 43.20 |

| 6 | 1 | 0 | −1 | 5.94 | 85.84 | 45.72 |

| 7 | −1 | 0 | 1 | 3.96 | 79.59 | 41.86 |

| 8 | 1 | 0 | 1 | 4.31 | 65.65 | 35.02 |

| 9 | 0 | −1 | −1 | 5.76 | 86.00 | 45.58 |

| 10 | 0 | 1 | −1 | 3.82 | 72.20 | 38.41 |

| 11 | 0 | −1 | 1 | 5.24 | 77.04 | 41.22 |

| 12 | 0 | 1 | 1 | 5.17 | 64.30 | 34.66 |

| 13 | 0 | 0 | 0 | 5.71 | 71.02 | 38.81 |

| 14 | 0 | 0 | 0 | 5.10 | 71.63 | 38.32 |

| 15 | 0 | 0 | 0 | 4.65 | 69.60 | 36.93 |

| 16 | 0 | 0 | 0 | 4.84 | 68.88 | 36.63 |

| 17 | 0 | 0 | 0 | 4.08 | 72.00 | 38.41 |

| Sours | Sum of Squares | df | Mean Square | F Value | Prob > F | Significant |

|---|---|---|---|---|---|---|

| Model | 174.2501 | 9 | 19.36112 | 11.75373 | 0.0019 | ** |

| A | 2.548153 | 1 | 2.548153 | 1.54693 | 0.2536 | |

| B | 60.61005 | 1 | 60.61005 | 36.79509 | 0.0005 | ** |

| C | 50.72763 | 1 | 50.72763 | 30.79568 | 0.0009 | ** |

| AB | 1.161006 | 1 | 1.161006 | 0.704823 | 0.4289 | |

| AC | 21.85563 | 1 | 21.85563 | 13.26809 | 0.0083 | ** |

| BC | 0.094556 | 1 | 0.094556 | 0.057403 | 0.8175 | |

| A2 | 24.18195 | 1 | 24.18195 | 14.68035 | 0.0064 | ** |

| B2 | 3.507842 | 1 | 3.507842 | 2.129538 | 0.1879 | |

| C2 | 6.411604 | 1 | 6.411604 | 3.892351 | 0.0891 | |

| Residual | 11.53062 | 7 | 1.647232 | |||

| Lack of Fit | 7.748094 | 3 | 2.582698 | 2.731186 | 0.1781 | Not |

| Pure Error | 3.78253 | 4 | 0.945633 | |||

| Cor Total | 185.7807 | 16 |

| Fatty Acids | Microwave | Boiling | Foil Baking | Control | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 h | 24 h | 48 h | 72 h | 96 h | 120 h | 0 h | 24 h | 48 h | 72 h | 96 h | 120 h | 0 h | 24 h | 48 h | 72 h | 96 h | 120 h | 0 h | 24 h | 48 h | 72 h | 96 h | 120 h | |

| C14:0 | 0.74 ± 0.01 b | 0.61 ± 0.06 b | 0.60 ± 0.13 bc | 0.34 ± 0.04 b | 0.46 ± 0.05 b | 0.71 ± 0.04 b | 0.74 ± 0.01 b | 0.66 ± 0.15 ab | 1.35 ± 0.05 a | 1.16 ± 0.21 a | 1.13 ± 0.17 a | 0.79 ± 0.09 ab | 0.63 ± 0.02 c | 0.85 ± 0.06 ab | 0.52 ± 0.04 c | 0.70 ± 0.00 b | 1.15 ± 0.14 a | 0.76 ± 0.03 ab | 0.65 ± 0.02 c | 0.89 ± 0.00 a | 0.79 ± 0.04 b | 0.67 ± 0.15 b | 0.72 ± 0.21 ab | 0.90 ± 0.06 a |

| C15:0 | 0.25 ± 0.01 a | 0.15 ± 0.00 c | 0.14 ± 0.07 a | 0.20 ± 0.04 b | 0.12 ± 0.01 b | 0.10 ± 0.05 b | 0.25 ± 0.01 a | 0.25 ± 0.00 a | 0.25 ± 0.03 a | 0.34 ± 0.00 a | 0.31 ± 0.05 a | 0.13 ± 0.02 b | 0.20 ± 0.04 a | 0.22 ± 0.04 ab | 0.13 ± 0.04 a | 0.18 ± 0.06 b | 0.27 ± 0.05 a | 0.41 ± 0.17 a | 0.24 ± 0.02 a | 0.18 ± 0.00 bc | 0.22 ± 0.01 a | 0.13 ± 0.08 b | 0.15 ± 0.01 b | 0.15 ± 0.01 b |

| C15:1 | 1.12 ± 0.09 ab | 1.16 ± 0.03 a | 1.33 ± 0.09 a | 1.46 ± 0.03 a | 1.08 ± 0.06 a | 1.20 ± 0.00 b | 1.12 ± 0.09 ab | 1.21 ± 0.02 a | 1.26 ± 0.08 a | 1.34 ± 0.01 bc | 1.02 ± 0.11 a | 1.15 ± 0.05 b | 1.26 ± 0.03 a | 1.05 ± 0.06 b | 1.34 ± 0.05 a | 1.40 ± 0.03 ab | 1.19 ± 0.03 a | 2.54 ± 0.33 a | 1.19 ± 0.03 ab | 1.00 ± 0.02 b | 1.30 ± 0.03 a | 1.28 ± 0.06 c | 1.01 ± 0.04 a | 0.90 ± 0.00 b |

| C16:0 | 18.98 ± 0.68 a | 19.09 ± 0.29 b | 21.46 ± 0.30 c | 20.74 ± 0.49 b | 20.14 ± 0.02 b | 23.87 ± 0.09 a | 18.98 ± 0.68 a | 22.58 ± 0.15 a | 24.05 ± 0.10 a | 25.06 ± 0.13 a | 25.78 ± 1.01 a | 23.12 ± 0.38 a | 19.55 ± 0.41 a | 19.17 ± 0.20 b | 20.22 ± 0.02 d | 18.76 ± 0.73 c | 24.84 ± 1.33 a | 14.65 ± 0.42 c | 17.69 ± 0.08 b | 19.65 ± 0.28 b | 22.04 ± 0.25 b | 20.71 ± 0.47 b | 17.30 ± 0.41 c | 19.67 ± 0.77 b |

| C16:1 n-7 | 1.35 ± 0.73 a | 1.50 ± 0.00 ab | 1.59 ± 0.21 bc | 1.30 ± 0.11 ab | 1.85 ± 0.10 ab | 2.67 ± 0.07 b | 1.35 ± 0.73 a | 1.28 ± 0.00 b | 2.21 ± 0.07 a | 2.01 ± 0.01 a | 3.35 ± 0.13 a | 2.36 ± 0.24 bc | 1.66 ± 0.31 a | 1.39 ± 0.11 ab | 1.80 ± 0.00 b | 0.60 ± 0.55 b | 2.07 ± 1.59 ab | 6.19 ± 0.05 a | 0.79 ± 0.01 a | 1.78 ± 0.29 a | 1.28 ± 0.13 c | 1.42 ± 0.05 a | 0.36 ± 0.01 b | 2.15 ± 0.05 c |

| C17:0 | 1.41 ± 0.08 a | 0.88 ± 0.00 d | 1.09 ± 0.00 b | 1.02 ± 0.14 b | 0.85 ± 0.02 b | 0.76 ± 0.04 a | 1.41 ± 0.08 a | 1.37 ± 0.01 a | 1.12 ± 0.01 c | 1.11 ± 0.03 b | 1.06 ± 0.11 a | 1.00 ± 0.13 a | 1.28 ± 0.01 a | 1.17 ± 0.00 b | 1.04 ± 0.02 d | 1.36 ± 0.01 a | 1.04 ± 0.01 a | 0.77 ± 0.15 a | 1.29 ± 0.03 a | 1.09 ± 0.01 c | 1.18 ± 0.00 a | 0.79 ± 0.04 c | 0.99 ± 0.06 ab | 0.95 ± 0.07 a |

| C17:1 | 0.61 ± 0.06 b | 0.60 ± 0.06 b | 0.82 ± 0.01 a | 0.84 ± 0.03 a | 0.58 ± 0.04 ab | 0.60 ± 0.00 b | 0.61 ± 0.06 b | 0.78 ± 0.04 a | 0.61 ± 0.01 b | 0.79 ± 0.12 a | 0.45 ± 0.02 c | 0.60 ± 0.07 b | 0.78 ± 0.03 a | 0.64 ± 0.00 b | 0.64 ± 0.04 b | 0.59 ± 0.03 b | 0.60 ± 0.02 a | 1.07 ± 0.05 a | 0.66 ± 0.01 b | 0.60 ± 0.03 b | 0.82 ± 0.00 a | 0.67 ± 0.04 ab | 0.51 ± 0.03 bc | 0.45 ± 0.00 c |

| C18:0 | 14.27 ± 0.11 a | 12.96 ± 0.10 b | 12.76 ± 0.21 b | 12.69 ± 0.05 a | 14.26 ± 0.00 a | 12.20 ± 0.05 b | 14.27 ± 0.11 a | 13.82 ± 0.11 a | 10.79 ± 0.07 c | 9.16 ± 0.67 b | 10.38 ± 0.97 c | 12.02 ± 0.03 b | 13.11 ± 0.50 b | 13.61 ± 0.03 a | 13.14 ± 0.22 ab | 12.86 ± 0.26 a | 9.57 ± 0.69 c | 11.91 ± 0.02 b | 14.55 ± 0.24 a | 13.10 ± 0.09 b | 13.36 ± 0.04 a | 12.28 ± 0.08 a | 12.12 ± 0.14 b | 13.17 ± 0.27 a |

| C18:1 n-9 c | 8.35 ± 0.24 b | 14.52 ± 0.31 a | 10.25 ± 0.06 b | 12.40 ± 0.00 b | 14.80 ± 0.03 a | 15.64 ± 0.09 a | 8.35 ± 0.24 b | 9.09 ± 0.05 c | 12.35 ± 0.05 a | 10.51 ± 0.05 c | 13.74 ± 1.68 a | 11.19 ± 1.07 b | 8.34 ± 1.21 b | 8.65 ± 0.27 c | 10.37 ± 0.43 b | 10.27 ± 1.14 c | 13.30 ± 0.20 a | 14.90 ± 0.12 a | 7.30 ± 0.12 b | 10.34 ± 0.06 b | 8.78 ± 0.15 c | 14.26 ± 0.08 a | 10.06 ± 0.16 b | 12.71 ± 0.36 b |

| C18:2 n-6 c | 3.01 ± 0.82 ab | 2.02 ± 0.04 a | 2.57 ± 0.08 b | 2.03 ± 0.06 b | 1.97 ± 0.19 b | 1.52 ± 0.09 b | 3.01 ± 0.82 ab | 2.74 ± 0.53 a | 1.57 ± 0.03 d | 1.92 ± 0.01 b | 1.78 ± 0.11 b | 1.81 ± 0.15 b | 3.67 ± 0.09 a | 2.68 ± 0.23 a | 3.12 ± 0.04 a | 2.62 ± 0.01 a | 1.69 ± 0.24 b | 1.68 ± 0.27 b | 2.43 ± 0.17 ab | 2.69 ± 0.04 a | 2.40 ± 0.04 c | 1.61 ± 0.10 c | 3.38 ± 0.17 a | 2.65 ± 0.04 a |

| C18:3 n-6 | 0.75 ± 0.03 b | 0.37 ± 0.00 b | 0.28 ± 0.15 a | 0.27 ± 0.03 c | 0.19 ± 0.06 b | 0.33 ± 0.07 b | 0.75 ± 0.03 b | 0.29 ± 0.12 b | 0.46 ± 0.08 a | 0.72 ± 0.02 a | 0.44 ± 0.06 a | 0.31 ± 0.01 b | 0.64 ± 0.00 c | 0.59 ± 0.01 a | 0.28 ± 0.13 a | 0.40 ± 0.04 b | 0.44 ± 0.03 a | 0.47 ± 0.01 a | 0.86 ± 0.03 a | 0.40 ± 0.03 b | 0.20 ± 0.00 a | 0.30 ± 0.01 c | 0.31 ± 0.12 ab | 0.37 ± 0.04 ab |

| C18:3 n-3 | 0.32 ± 0.04 b | 0.29 ± 0.02 b | 0.24 ± 0.01 b | 0.36 ± 0.04 b | 0.43 ± 0.00 a | 0.22 ± 0.01 a | 0.32 ± 0.04 b | 0.27 ± 0.01 c | 0.38 ± 0.02 a | 0.52 ± 0.07 a | 0.30 ± 0.10 ab | 0.27 ± 0.02 a | 0.48 ± 0.01 b | 0.45 ± 0.02 ab | 0.27 ± 0.02 b | 0.34 ± 0.02 bc | 0.39 ± 0.06 a | 0.50 ± 0.22 a | 0.22 ± 0.03 b | 0.23 ± 0.02 c | 0.24 ± 0.00 b | 0.24 ± 0.02 c | 0.20 ± 0.01 b | 0.40 ± 0.00 a |

| C20:1 n-9 | 0.12 ± 0.00 a | 0.08 ± 0.02 a | 0.07 ± 0.00 b | 0.10 ± 0.02 a | 0.06 ± 0.01 c | 0.08 ± 0.02 a | 0.12 ± 0.00 a | 0.09 ± 0.03 a | 0.16 ± 0.01 a | 0.20 ± 0.07 a | 0.13 ± 0.04 ab | 0.07 ± 0.01 a | 0.10 ± 0.00 ab | 0.48 ± 0.57 a | 0.08 ± 0.00 b | 0.14 ± 0.07 a | 0.18 ± 0.00 a | 0.31 ± 0.22 a | 0.10 ± 0.03 ab | 0.09 ± 0.01 a | 0.05 ± 0.00 c | 0.07 ± 0.01 a | 0.08 ± 0.00 bc | 0.06 ± 0.00 a |

| C20:2 n-6 | 0.46 ± 0.03 b | 0.20 ± 0.01 c | 0.33 ± 0.03 a | 0.70 ± 0.00 a | 0.64 ± 0.00 a | 0.21 ± 0.01 b | 0.46 ± 0.03 b | 0.29 ± 0.03 b | 0.24 ± 0.01 b | 0.50 ± 0.00 b | 0.39 ± 0.16 ab | 0.30 ± 0.05 b | 0.34 ± 0.01 bc | 0.40 ± 0.01 a | 0.22 ± 0.00 b | 0.36 ± 0.02 c | 0.23 ± 0.08 b | 0.55 ± 0.04 a | 0.68 ± 0.12 a | 0.25 ± 0.01 b | 0.25 ± 0.03 b | 0.21 ± 0.04 d | 0.28 ± 0.02 b | 0.27 ± 0.04 b |

| C22:0 | 0.13 ± 0.00 b | 0.16 ± 0.01 a | 0.12 ± 0.00 ab | 0.11 ± 0.01 ab | 0.13 ± 0.00 a | 0.10 ± 0.02 b | 0.13 ± 0.00 b | 0.08 ± 0.01 c | 0.10 ± 0.01 ab | 0.09 ± 0.00 bc | 0.13 ± 0.06 a | 0.09 ± 0.02 b | 0.13 ± 0.00 b | 0.13 ± 0.00 b | 0.13 ± 0.02 a | 0.08 ± 0.00 c | 0.10 ± 0.01 a | 0.38 ± 0.11 a | 0.16 ± 0.02 b | 0.13 ± 0.01 b | 0.09 ± 0.01 b | 0.12 ± 0.01 a | 0.12 ± 0.00 a | 0.08 ± 0.00 b |

| C20:3 n-6 | 4.00 ± 0.15 b | 4.39 ± 0.01 a | 3.50 ± 0.02 c | 3.68 ± 0.03 b | 3.62 ± 0.00 b | 3.54 ± 0.10 b | 4.00 ± 0.15 b | 3.97 ± 0.00 c | 4.26 ± 0.03 a | 4.02 ± 0.18 a | 3.89 ± 0.10 a | 3.57 ± 0.15 b | 4.11 ± 0.20 b | 4.28 ± 0.03 b | 3.63 ± 0.18 c | 4.02 ± 0.08 a | 3.72 ± 0.05 ab | 3.95 ± 0.09 a | 3.80 ± 0.07 b | 3.65 ± 0.04 d | 3.96 ± 0.01 b | 4.11 ± 0.06 a | 3.19 ± 0.08 c | 3.99 ± 0.09 a |

| C20:3 n-3 | 0.26 ± 0.02 a | 0.24 ± 0.00 a | 0.20 ± 0.01 b | 0.15 ± 0.01 c | 0.14 ± 0.02 b | 0.14 ± 0.01 a | 0.26 ± 0.02 a | 0.23 ± 0.01 a | 0.31 ± 0.01 a | 0.33 ± 0.02 a | 0.18 ± 0.03 ab | 0.18 ± 0.06 a | 0.23 ± 0.03 a | 0.24 ± 0.00 a | 0.22 ± 0.04 b | 0.17 ± 0.04 bc | 0.26 ± 0.06 a | 0.26 ± 0.13 a | 0.27 ± 0.04 a | 0.25 ± 0.01 a | 0.21 ± 0.01 b | 0.23 ± 0.00 b | 0.16 ± 0.03 b | 0.22 ± 0.00 a |

| C20:4 n-6 | 6.07 ± 0.12 a | 5.56 ± 0.03 c | 6.59 ± 0.13 b | 4.13 ± 0.20 d | 3.77 ± 0.07 c | 5.11 ± 0.04 a | 6.07 ± 0.12 a | 5.03 ± 0.03 d | 7.00 ± 0.06 a | 7.00 ± 0.04 a | 6.67 ± 0.45 ab | 5.68 ± 0.01 a | 5.85 ± 0.02 ab | 6.05 ± 0.08 b | 7.14 ± 0.01 a | 6.70 ± 0.04 b | 6.89 ± 0.42 a | 4.75 ± 0.95 a | 5.78 ± 0.10 bc | 6.68 ± 0.07 a | 5.03 ± 0.00 c | 5.42 ± 0.05 c | 5.92 ± 0.03 b | 5.96 ± 0.15 a |

| C22:2 n-6 | 0.45 ± 0.07 b | 0.47 ± 0.19 a | 0.27 ± 0.03 b | 0.82 ± 0.08 a | 0.58 ± 0.01 a | 0.31 ± 0.01 b | 0.45 ± 0.07 b | 0.55 ± 0.04 a | 0.44 ± 0.07 a | 0.37 ± 0.00 b | 0.37 ± 0.02 b | 0.26 ± 0.02 b | 0.51 ± 0.05 b | 0.52 ± 0.07 a | 0.31 ± 0.07 ab | 0.41 ± 0.13 b | 0.31 ± 0.05 bc | 0.75 ± 0.17 a | 0.48 ± 0.03 b | 0.48 ± 0.00 a | 0.39 ± 0.01 ab | 0.38 ± 0.03 b | 0.26 ± 0.04 c | 0.32 ± 0.01 b |

| C20:5 n-3 | 2.41 ± 0.07 b | 2.29 ± 0.07 a | 1.91 ± 0.07 a | 2.91 ± 0.02 a | 2.73 ± 0.06 a | 1.65 ± 0.08 b | 2.41 ± 0.07 b | 2.00 ± 0.11 b | 1.61 ± 0.08 b | 1.51 ± 0.01 c | 1.42 ± 0.02 c | 1.62 ± 0.11 b | 2.12 ± 0.04 c | 2.13 ± 0.08 ab | 1.95 ± 0.01 a | 1.89 ± 0.11 b | 1.33 ± 0.02 c | 2.54 ± 0.30 a | 2.61 ± 0.08 a | 2.11 ± 0.11 ab | 1.99 ± 0.03 a | 2.02 ± 0.02 b | 2.34 ± 0.12 b | 1.58 ± 0.09 b |

| C22:5 n-3 | 1.93 ± 0.08 c | 2.12 ± 0.00 a | 2.00 ± 0.10 ab | 1.59 ± 0.09 c | 1.64 ± 0.02 a | 1.74 ± 0.12 a | 1.93 ± 0.08 c | 1.91 ± 0.01 d | 1.90 ± 0.11 b | 1.75 ± 0.01 bc | 1.54 ± 0.11 a | 2.08 ± 0.24 a | 2.11 ± 0.02 b | 2.06 ± 0.02 b | 2.12 ± 0.03 a | 2.38 ± 0.25 a | 1.53 ± 0.01 a | 1.84 ± 0.10 a | 1.97 ± 0.02 c | 2.01 ± 0.03 c | 1.80 ± 0.01 b | 2.04 ± 0.15 ab | 1.78 ± 0.14 a | 2.00 ± 0.21 a |

| C22:6 n-3 | 33.01 ± 1.18 b | 30.34 ± 0.26 d | 31.88 ± 0.20 b | 32.16 ± 0.23 ab | 29.97 ± 0.10 b | 27.30 ± 0.22 b | 33.01 ± 1.18 b | 31.50 ± 0.08 c | 27.57 ± 0.13 d | 29.55 ± 0.15 b | 25.54 ± 0.56 c | 31.41 ± 0.76 a | 32.90 ± 0.99 b | 33.22 ± 0.12 a | 31.32 ± 0.17 c | 33.78 ± 2.16 a | 28.89 ± 1.72 b | 28.81 ± 0.26 b | 36.29 ± 0.28 a | 32.41 ± 0.28 b | 33.59 ± 0.07 a | 31.04 ± 1.14 ab | 38.76 ± 0.18 a | 31.06 ± 1.25 a |

| SFA | 35.79 ± 0.89 a | 33.84 ± 0.46 c | 36.17 ± 0.72 b | 35.09 ± 0.78 b | 35.95 ± 0.10 b | 37.74 ± 0.30 a | 35.79 ± 0.89 a | 38.77 ± 0.44 a | 37.67 ± 0.27 a | 36.93 ± 1.04 a | 38.78 ± 2.37 a | 37.14 ± 0.66 a | 34.91 ± 0.99 b | 35.15 ± 0.33 b | 35.18 ± 0.35 c | 33.94 ± 1.06 b | 36.95 ± 2.23 b | 28.88 ± 0.89 c | 34.57 ± 0.41 bc | 35.04 ± 0.40 b | 37.69 ± 0.35 a | 34.70 ± 0.83 b | 31.39 ± 0.83 c | 34.92 ± 1.18 b |

| MUFA | 11.55 ± 1.13 b | 17.86 ± 0.43 a | 14.06 ± 0.37 b | 16.10 ± 0.19 ab | 18.38 ± 0.23 a | 20.18 ± 0.19 b | 11.55 ± 1.13 b | 12.45 ± 0.14 c | 16.59 ± 0.22 a | 14.86 ± 0.27 bc | 18.70 ± 1.97 a | 15.38 ± 1.44 c | 12.14 ± 1.59 b | 12.22 ± 1.01 c | 14.23 ± 0.52 b | 12.99 ± 1.82 c | 17.34 ± 1.84 a | 25.01 ± 0.77 a | 10.04 ± 0.19 c | 13.81 ± 0.41 b | 12.24 ± 0.31 c | 17.70 ± 0.24 a | 12.03 ± 0.24 b | 16.26 ± 0.42 c |

| PUFA | 52.66 ± 2.60 b | 48.29 ± 0.65 c | 49.77 ± 0.84 a | 48.81 ± 0.79 b | 45.67 ± 0.53 b | 42.08 ± 0.75 c | 52.66 ± 2.60 b | 48.79 ± 0.97 c | 45.75 ± 0.63 b | 48.20 ± 0.51 b | 42.52 ± 1.72 b | 47.48 ± 1.57 ab | 52.95 ± 1.46 b | 52.63 ± 0.65 a | 50.58 ± 0.71 a | 53.06 ± 2.88 a | 45.71 ± 2.74 b | 46.11 ± 2.53 b | 55.39 ± 0.97 a | 51.15 ± 0.63 b | 50.07 ± 0.22 a | 47.59 ± 1.64 b | 56.58 ± 0.93 a | 48.82 ± 1.93 a |

| n-6 PUFA | 14.74 ± 1.22 a | 13.01 ± 0.29 b | 13.54 ± 0.45 b | 11.64 ± 0.40 b | 10.76 ± 0.34 b | 11.03 ± 0.31 b | 14.74 ± 1.22 a | 12.87 ± 0.75 b | 13.98 ± 0.29 b | 14.54 ± 0.25 a | 13.54 ± 0.90 a | 11.92 ± 0.38 ab | 15.11 ± 0.37 a | 14.52 ± 0.42 a | 14.70 ± 0.43 a | 14.51 ± 0.32 a | 13.29 ± 0.87 a | 12.16 ± 1.53 ab | 14.03 ± 0.53 ab | 14.15 ± 0.19 a | 12.23 ± 0.10 c | 12.03 ± 0.29 b | 13.34 ± 0.46 a | 13.56 ± 0.37 a |

| n-3 PUFA | 37.92 ± 1.38 b | 35.28 ± 0.36 d | 36.23 ± 0.39 b | 37.17 ± 0.39 ab | 34.91 ± 0.20 b | 31.06 ± 0.43 b | 37.92 ± 1.38 b | 35.91 ± 0.22 c | 31.77 ± 0.34 c | 33.66 ± 0.26 b | 28.98 ± 0.82 d | 35.56 ± 1.19 a | 37.84 ± 1.08 b | 38.11 ± 0.23 a | 35.88 ± 0.28 b | 38.56 ± 2.57 a | 32.41 ± 1.87 c | 33.95 ± 1.01 a | 41.37 ± 0.44 a | 37.01 ± 0.44 b | 37.84 ± 0.12 a | 35.56 ± 1.34 ab | 43.24 ± 0.48 a | 35.26 ± 1.56 a |

| PUFA/SFA | 1.47 ± 2.91 b | 1.43 ± 1.41 b | 1.38 ± 1.17 b | 1.39 ± 1.01 b | 1.27 ± 5.12 b | 1.12 ± 2.48 c | 1.47 ± 2.91 b | 1.26 ± 2.19 c | 1.21 ± 2.32 d | 1.31 ± 0.49 b | 1.10 ± 0.72 c | 1.28 ± 2.37 b | 1.52 ± 1.47 ab | 1.50 ± 1.96 a | 1.44 ± 2.04 a | 1.56 ± 2.71 a | 1.24 ± 1.23 b | 1.60 ± 2.84 a | 1.60 ± 2.34 a | 1.46 ± 1.60 ab | 1.33 ± 0.63 c | 1.37 ± 1.96 b | 1.80 ± 1.13 a | 1.40 ± 1.64 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, S.; Liu, B.; Lan, G.; Liu, J. Optimizing Red Vinasse-Blue Round Scad Processing Using Integrated Dimensionality Reduction and RSM: Effects on Lipid Storage Stability. Foods 2025, 14, 3215. https://doi.org/10.3390/foods14183215

Xue S, Liu B, Lan G, Liu J. Optimizing Red Vinasse-Blue Round Scad Processing Using Integrated Dimensionality Reduction and RSM: Effects on Lipid Storage Stability. Foods. 2025; 14(18):3215. https://doi.org/10.3390/foods14183215

Chicago/Turabian StyleXue, Shan, Bohu Liu, Guojin Lan, and Jia Liu. 2025. "Optimizing Red Vinasse-Blue Round Scad Processing Using Integrated Dimensionality Reduction and RSM: Effects on Lipid Storage Stability" Foods 14, no. 18: 3215. https://doi.org/10.3390/foods14183215

APA StyleXue, S., Liu, B., Lan, G., & Liu, J. (2025). Optimizing Red Vinasse-Blue Round Scad Processing Using Integrated Dimensionality Reduction and RSM: Effects on Lipid Storage Stability. Foods, 14(18), 3215. https://doi.org/10.3390/foods14183215