A Comparative Study of Cabernet Sauvignon Red Wine Aroma Profiles During Ageing in Medium-Toasted Oak Barrels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemical Reagents

2.1.2. Wooden Barrels

2.1.3. Wine Samples

2.2. Methods

2.2.1. Aroma Analysis

2.2.2. Sensory and Descriptive Analysis

2.2.3. Statistical Evaluation of Experimental Data

3. Results

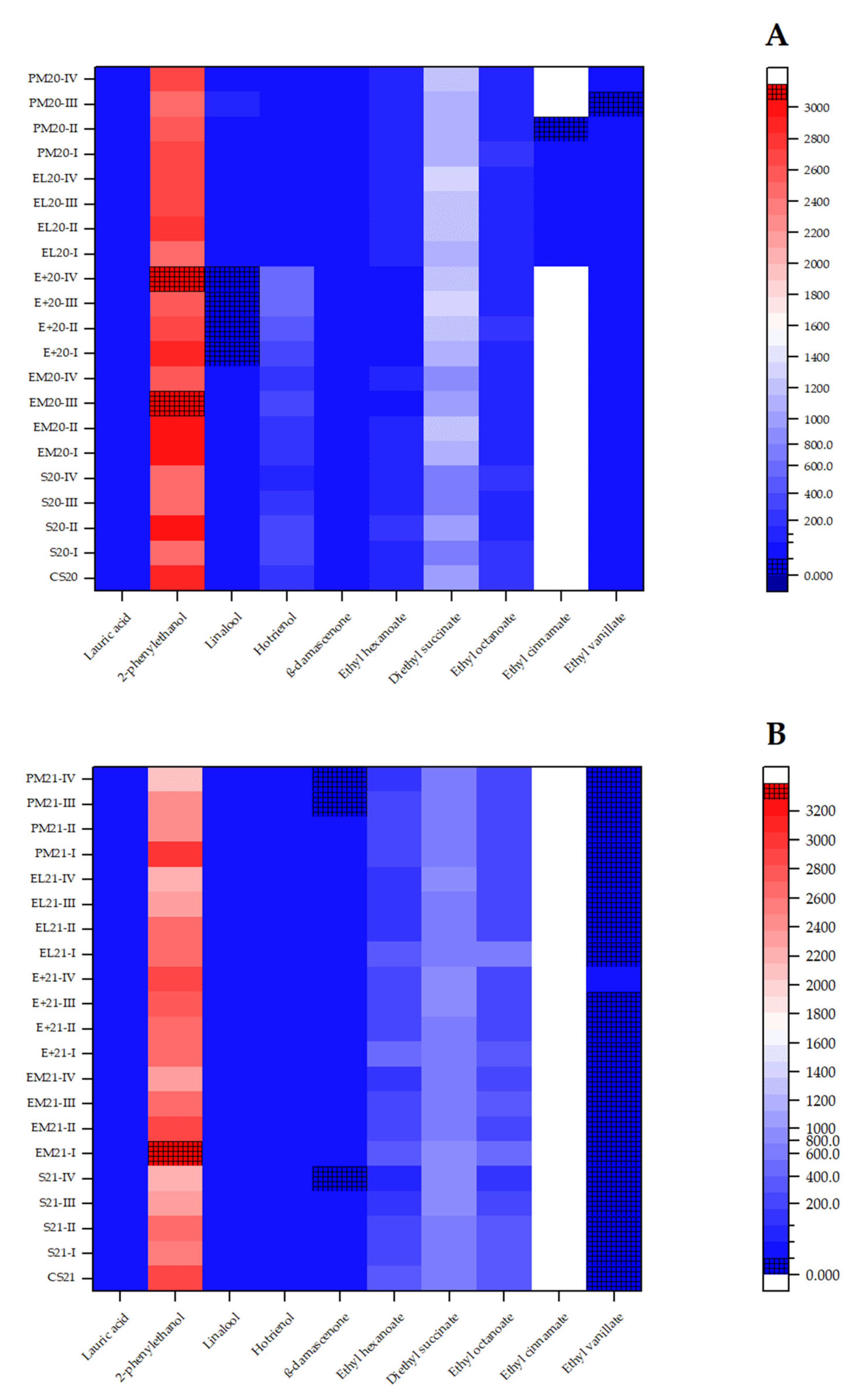

3.1. Individual Aroma Compounds

3.2. Statistical Analysis of Aroma Groups

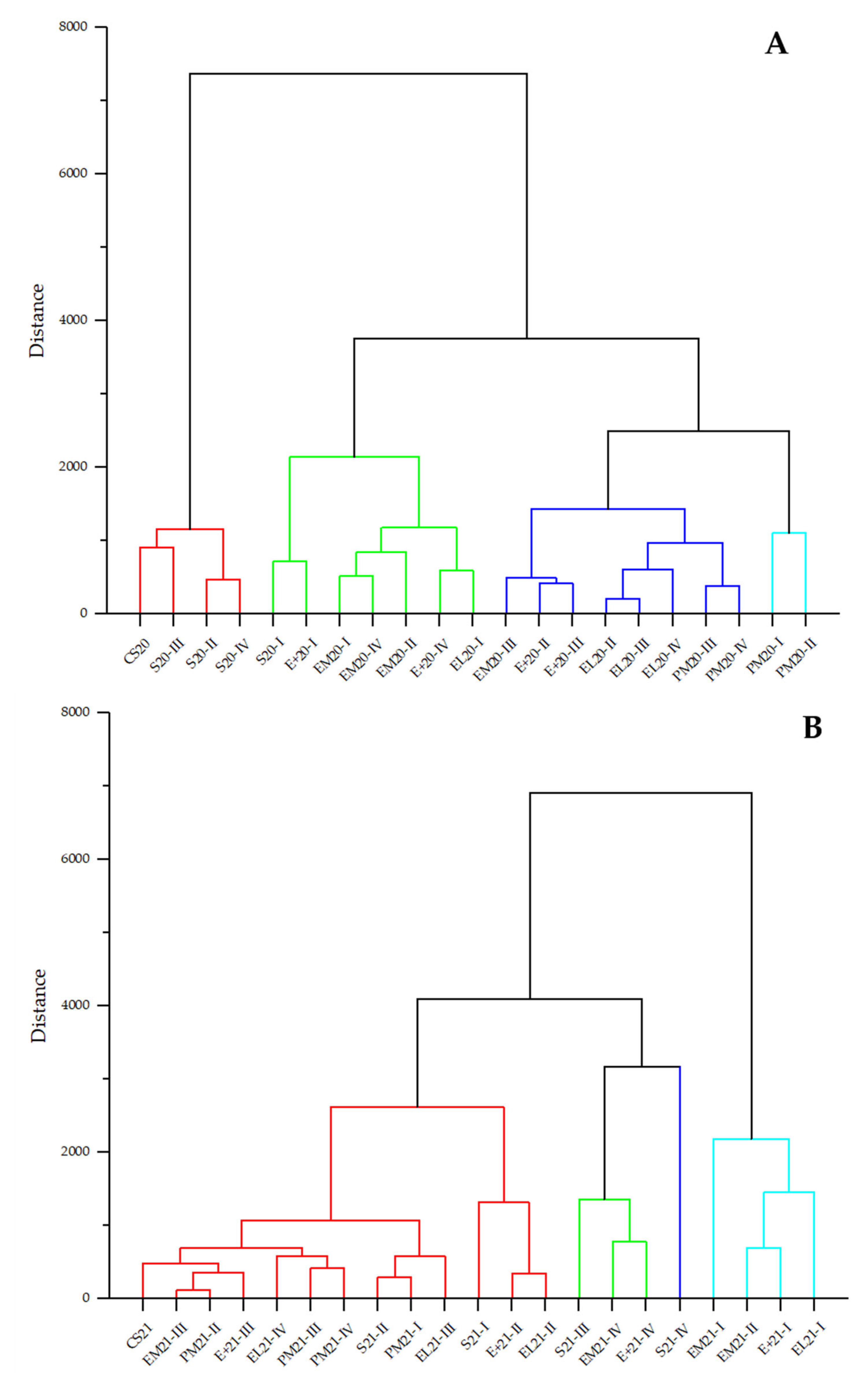

3.2.1. Cluster Analysis of Aroma Groups

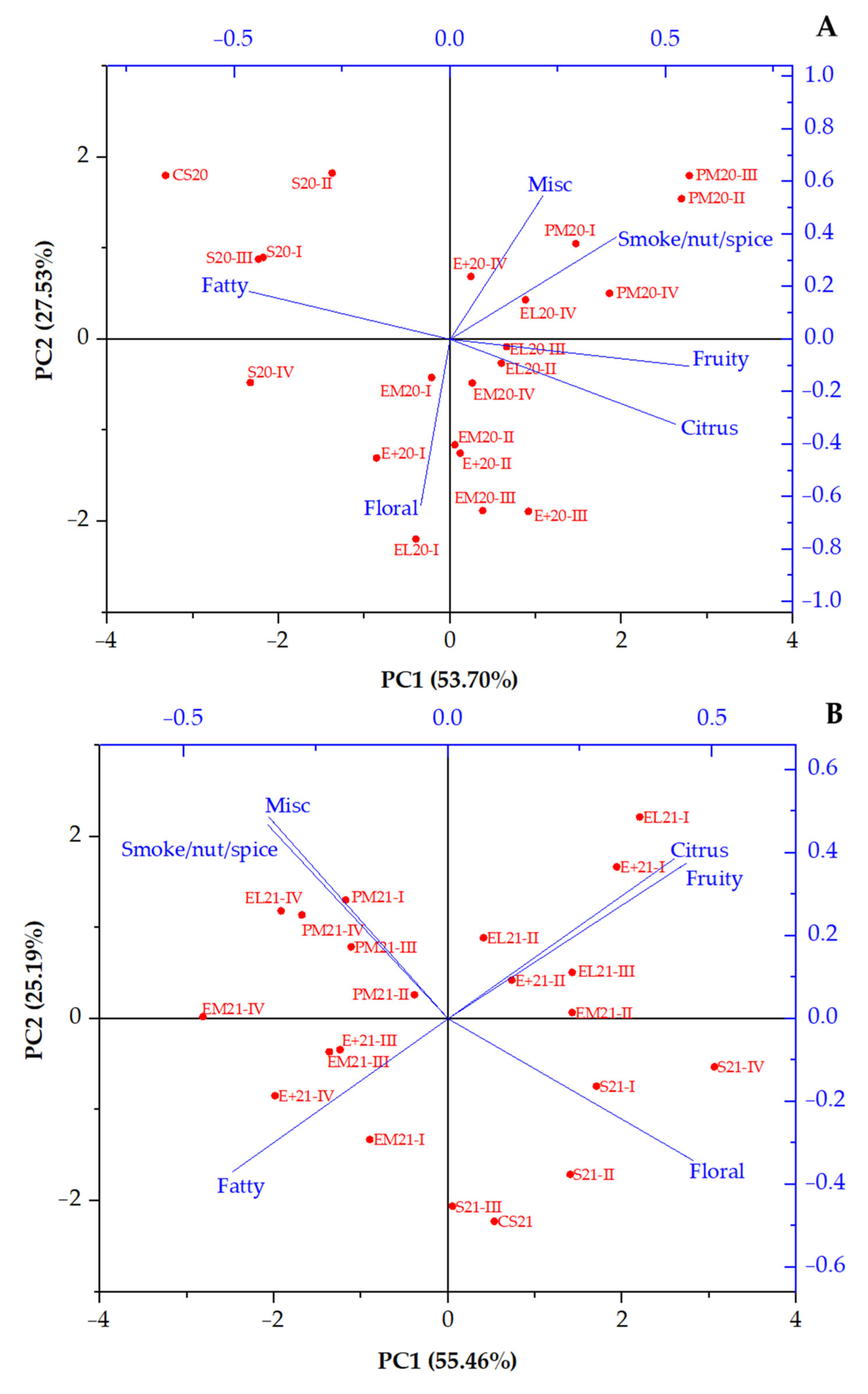

3.2.2. Principal Component Analysis

3.2.3. Key Aroma Compounds

3.2.4. Effect Across Vessel Type

3.2.5. Effect of Ageing Time

3.2.6. Integration with PCA

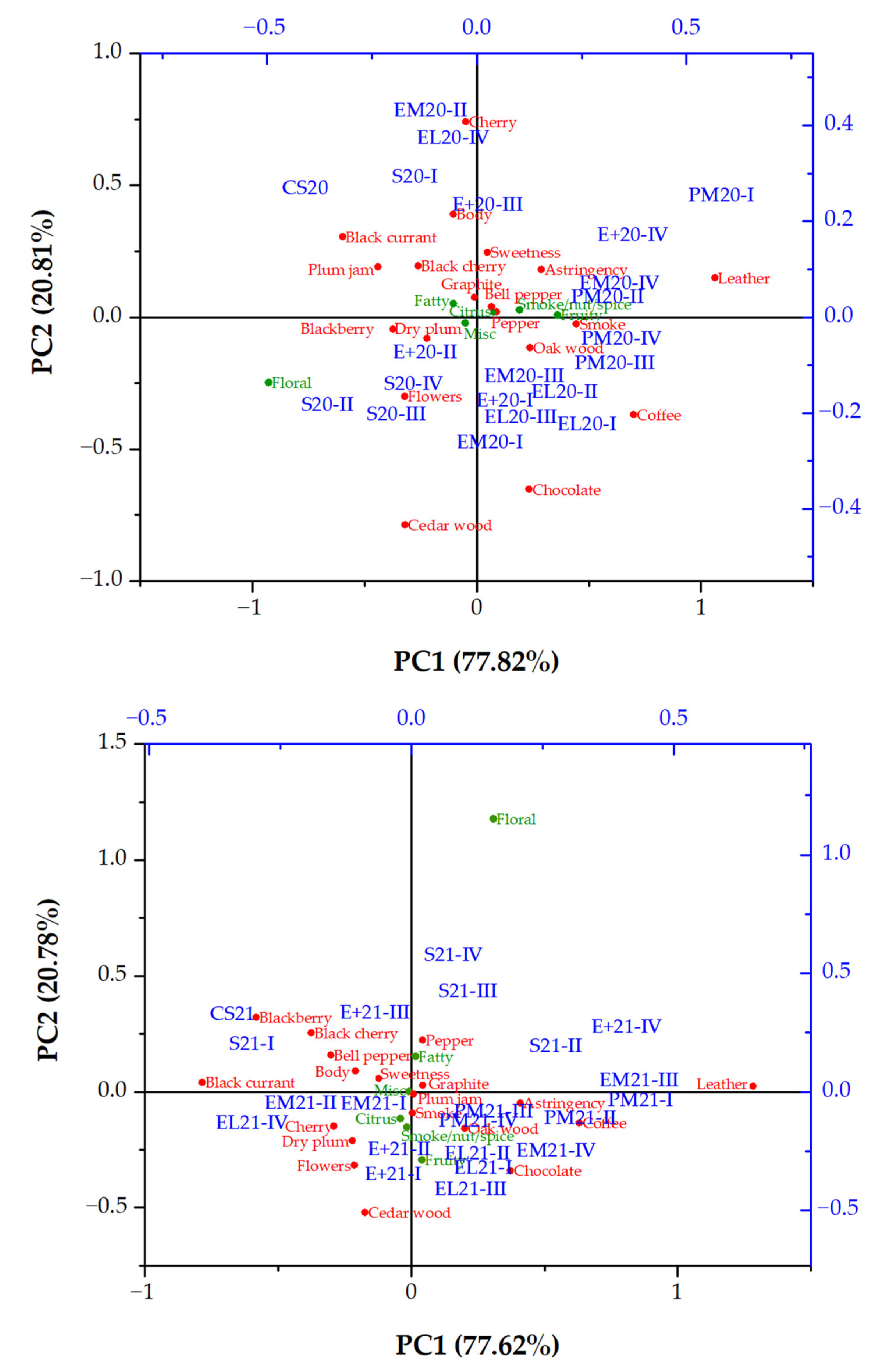

3.2.7. Sensory Evaluation

4. Discussion

5. Conclusions

- Stainless steel tank samples maintained lower total OAVs, preserving fresher, lighter profiles with reduced wood-derived influence.

- Excellence barrels with medium toasting showed moderate ester expression, but a lower tendency to accumulate β-damascenone and linalool.

- Excellence barrels with medium plus toasting exhibited enhanced aromatic enrichment, with moderate impact of β-damascenone and elevated OAVs of ethyl vanillate, and even ethyl cinnamate.

- Excellence barrels with medium long toasting demonstrated distinctive shifts towards spicy and smoky notes, with strong extraction of wood-derived compounds, which also included volatile phenols and lactones.

- Premium barrels with medium toasting resulted in elevated contents of β-damascenone, fruity esters, ethyl vanillate, and volatile phenols and lactones, and this led to a more balanced smoky, woody, and spicy aroma profile.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robinson, J.; Harding, J.; Voulliamouz, J. Wine Grapes—A Complete Guide to 1,368 Vine Varieties, Including Their Origins and Flavours; Allen Lane: London, UK; Ecco: New York, NY, USA, 2012. [Google Scholar]

- Ivić, I.; Kopjar, M.; Jukić, V.; Bošnjak, M.; Maglica, M.; Mesić, J.; Pichler, A. Aroma Profile and Chemical Composition of Reverse Osmosis and Nanofiltration Concentrates of Red Wine Cabernet Sauvignon. Molecules 2021, 26, 874. [Google Scholar] [CrossRef]

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M. Microbial Contribution to Wine Aroma and Its Intended Use for Wine Quality Improvement. Molecules 2017, 22, 189. [Google Scholar] [CrossRef] [PubMed]

- Gamero Lluna, A. Study of the Production and Release of Aromas During Winemaking Carried Out by Different Saccharomyces Species and Hybrids. Ph.D. Thesis, Polytechnic University of Valencia (UPV), Valencia, Spain, 2011; pp. 1–301. [Google Scholar]

- Padilla, B.; Gil, J.V.; Manzanares, P. Past and Future of Non-Saccharomyces Yeasts: From Spoilage Microorganisms to Biotechnological Tools for Improving Wine Aroma Complexity. Front. Microbiol. 2016, 7, 411. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.; Peinado, R. Enological Chemistry, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Jackson, R.S. Wine Science: Principles and Applications, 3rd ed.; Academic Press, Elsevier Inc.: Burlington, MA, USA; London, UK; San Diego, CA, USA, 2008; ISBN 9780123736468. [Google Scholar]

- Pichler, A.; Ivić, I.; Mesić, J.; Drenjančević, M.; Kujundžić, T.; Marković, T.; Kopjar, M. Aroma Profile of Merlot Red Wine Stored in Stainless-Steel Tanks and Wooden Barrels with Different Toasting Methods. Foods 2023, 13, 45. [Google Scholar] [CrossRef]

- Dunlevy, J.D.; Kalua, C.M.; Keyzers, R.A.; Boss, P.K. The production of flavour and aroma compounds in grape berries. In Grapevine Molecular Physiology and Biotechnology; Roubelakis-Angelakis, K.A., Ed.; Springer: Dordrecht, The Netherlands, 2009; pp. 293–340. ISBN 978-90-481-2304-9. [Google Scholar]

- Zhu, F.; Du, B.; Li, J. Aroma compounds in wine. In Grape and Wine Biotechnology; Morata, A., Loira, I., Eds.; Intech: Madrid, Spain, 2016; pp. 273–284. [Google Scholar]

- Montalvo, F.F.; García-Alcaraz, J.L.; Cámara, E.M.; Jiménez-Macías, E.; Blanco-Fernández, J. Environmental Impact of Wine Fermentation in Steel and Concrete Tanks. J. Clean. Prod. 2021, 278, 123602. [Google Scholar] [CrossRef]

- Ortega-Heras, M.; Gonzalez-Huerta, C.; Herrera, P.; Gonzalez-Sanjose, M.L. Changes in Wine Volatile Compounds of Varietal Wines during Ageing in Wood Barrels. Anal. Chim. Acta 2004, 513, 341–350. [Google Scholar] [CrossRef]

- Tao, Y.; García, J.F.; Sun, D.-W. Advances in Wine Aging Technologies for Enhancing Wine Quality and Accelerating Wine Aging Process. Crit. Rev. Food Sci. Nutr. 2014, 54, 817–835. [Google Scholar] [CrossRef] [PubMed]

- de Castro, M.C.; Bortoletto, A.M.; Silvello, G.C.; Alcarde, A.R. Maturation related phenolic compounds in cachaça aged in new oak barrels. J. Inst. Brew. 2021, 127, 70–77. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Tang, K.; Rao, Z.; Chen, J. Effects of Different Aging Methods on the Phenolic Compounds and Antioxidant Activity of Red Wine. Fermentation 2022, 8, 592. [Google Scholar] [CrossRef]

- Lu, H.; Cheng, B.; Lan, Y.; Duan, C.; He, F. Modifications in Aroma Characteristics of ‘Merlot’ Dry Red Wines Aged in American, French and Slovakian Oak Barrels with Different Toasting Degrees. Food Sci. Hum. Wellness 2023, 13, 381–391. [Google Scholar] [CrossRef]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine Aging Technology: Fundamental Role of Wood Barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef] [PubMed]

- Bosso, A.; Petrozziello, M.; Santini, D.; Motta, S.; Guaita, M.; Marulli, C. Effect of Grain Type and Toasting Conditions of Barrels on the Concentration of the Volatile Substances Released by the Wood and on the Sensory Characteristics of Montepulciano d’Abruzzo. J. Food Sci. 2008, 73, S373–S382. [Google Scholar] [CrossRef]

- Chira, K.; Teissedre, P.-L. Extraction of oak volatiles and ellagitannins compounds and sensory profile of wine aged with French winewoods subjected to different toasting methods: Behaviour during storage. Food Chem. 2013, 140, 168–177. [Google Scholar] [CrossRef] [PubMed]

- Collins, T.S.; Miles, J.L.; Boulton, R.B.; Ebeler, S.E. Targeted volatile composition of oak wood samples taken during toasting at a commercial cooperage. Tetrahedron 2015, 71, 2971–2982. [Google Scholar] [CrossRef]

- Chira, K.; Teissedre, P.-L. Chemical and Sensory Evaluation of Wine Matured in Oak Barrel: Effect of Oak Species Involved and Toasting Process. Eur. Food Res. Technol. 2015, 240, 533–547. [Google Scholar] [CrossRef]

- Alañón, M.E.; Schumacher, R.; Castro-Vázquez, L.; Díaz-Maroto, I.J.; Díaz-Maroto, M.C.; Pérez-Coello, M.S. Enological potential of chestnut wood for aging Tempranillo wines part I: Volatile compounds and sensorial properties. Food Res. Int. 2013, 51, 325–334. [Google Scholar] [CrossRef]

- Prida, A.; Chatonnet, P. Impact of Oak-Derived Compounds on the Olfactory Perception of Barrel-Aged Wines. Am. J. Enol. Vitic. 2010, 61, 408–413. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, P.; Gómez-Plaza, E. Effect of Volume and Toast Level of French Oak Barrels (Quercus petraea L.) on Cabernet Sauvignon Wine Characteristics. Am. J. Enol. Vitic. 2011, 62, 359–365. [Google Scholar] [CrossRef]

- Pilet, A.; de Sousa, R.B.; Ricardo-da-Silva, J.M.; Catarino, S. Barrel-to-Barrel Variation of Phenolic and Mineral Composition of Red Wine. BIO Web Conf. 2019, 12, 02011. [Google Scholar] [CrossRef]

- Gómez García-Carpintero, E.; Gómez Gallego, M.A.; Sánchez-Palomo, E.; González Viñas, M.A. Impact of alternative technique to ageing using oak chips in alcoholic or in malolactic fermentation on volatile and sensory composition of red wines. Food Chem. 2012, 134, 851–863. [Google Scholar] [CrossRef]

- Fernández de Simón, B.; Martínez, J.; Sanz, M.; Cadahía, E.; Esteruelas, E.; Muñoz, A.M. Volatile compounds and sensorial characterisation of red wine aged in cherry, chestnut, false acacia, ash and oak wood barrels. Food Chem. 2014, 147, 346–356. [Google Scholar] [CrossRef] [PubMed]

- Spillman, P.J.; Sefton, M.A.; Gawel, R. The effect of oak wood source, location of seasoning and coopering on the composition of volatile compounds in oak-matured wines. Aust. J. Grape Wine Res. 2008, 10, 216–226. [Google Scholar] [CrossRef]

- González-Centeno, M.R.; Chira, K.; Teissedre, P.-L. Ellagitannin Content, Volatile Composition and Sensory Profile of Wines from Different Countries Matured in Oak Barrels Subjected to Different Toasting Methods. Food Chem. 2016, 210, 500–511. [Google Scholar] [CrossRef]

- Spillman, P.J.; Pollnitz, A.P.; Liacopoulos, D.; Pardon, K.H.; Sefton, M.A. Formation and Degradation of Furfuryl Alcohol, 5-Methylfurfuryl Alcohol, Vanillyl Alcohol, and Their Ethyl Ethers in Barrel-Aged Wines. J. Agric. Food Chem. 1998, 46, 657–663. [Google Scholar] [CrossRef]

- Ivić, I.; Kopjar, M.; Obhođaš, J.; Vinković, A.; Pichler, D.; Mesić, J.; Pichler, A. Concentration with Nanofiltration of Red Wine Cabernet Sauvignon Produced from Conventionally and Ecologically Grown Grapes: Effect on Volatile Compounds and Chemical Composition. Membranes 2021, 11, 320. [Google Scholar] [CrossRef]

- Ivić, I.; Kopjar, M.; Obhođaš, J.; Vinković, A.; Babić, J.; Mesić, J.; Pichler, A. Influence of the Processing Parameters on the Aroma Profile and Chemical Composition of Conventional and Ecological Cabernet Sauvignon Red Wines during Concentration by Reverse Osmosis. Membranes 2022, 12, 1008. [Google Scholar] [CrossRef] [PubMed]

- Ailer, Š.; Valšíková, M.; Jedlička, J.; Mankovecký, J.; Baroň, M. Influence of Sugar and Ethanol Content and Color of Wines On the Sensory Evaluation: From Wine Competition “Nemčiňany Wine Days” in Slovak Republic (2013–2016). Erwerbs-Obstbau 2020, 62, 9–16. [Google Scholar] [CrossRef]

- Yu, H.; Xie, T.; Xie, J.; Ai, L.; Tian, H. Characterization of key aroma compounds in Chinese rice wine using gas chromatography-mass spectrometry and gas chromatography-olfactometry. Food Chem. 2019, 293, 8–14. [Google Scholar] [CrossRef]

- de Vries, C.J.; Mokwena, L.M.; Buica, A.; McKay, M. Determination of Volatile Phenol in Cabernet Sauvignon Wines, Made from Smoke-affected Grapes, by using HS-SPME GC-MS. S. Afr. J. Enol. Vitic. 2016, 37, 15–21. [Google Scholar] [CrossRef]

- Arcari, S.G.; Caliari, V.; Sganzerla, M.; Godoy, H.T. Volatile composition of Merlot red wine and its contribution to the aroma: Optimization and validation of analytical method. Talanta 2017, 174, 752–766. [Google Scholar] [CrossRef]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-540-69933-0. [Google Scholar]

- Ouyang, X.; Yuan, G.; Ren, J.; Wang, L.; Wang, M.; Li, Y.; Zhang, B.; Zhu, B. Aromatic compounds and organoleptic features of fermented wolfberry wine: Effects of maceration time. Int. J. Food Prop. 2017, 20, 2234–2248. [Google Scholar] [CrossRef]

- Brown, R.C.; Sefton, M.A.; Taylor, D.K.; Elsey, G.M. An odour detection threshold determination of all four possible stereoisomers of oak lactone in a white and a red wine. Aust. J. Grape Wine Res. 2006, 12, 115–118. [Google Scholar] [CrossRef]

- Chatonnet, P.; Dubourdie, D.; Boidron, J.; Pons, M. The origin of ethylphenols in wines. J. Sci. Food Agric. 1992, 60, 165–178. [Google Scholar] [CrossRef]

- Cao, W.; Shu, N.; Wen, J.; Yang, Y.; Jin, Y.; Lu, W. Characterization of the Key Aroma Volatile Compounds in Nine Different Grape Varieties Wine by Headspace Gas Chromatography–Ion Mobility Spectrometry (HS-GC-IMS), Odor Activity Values (OAV) and Sensory Analysis. Foods 2022, 11, 2767. [Google Scholar] [CrossRef]

- Cordente, A.G.; Solomon, M.; Schulkin, A.; Leigh Francis, I.; Barker, A.; Borneman, A.R.; Curtin, C.D. Novel wine yeast with ARO4 and TYR1 mutations that overproduce ‘floral’ aroma compounds 2-phenylethanol and 2-phenylethyl acetate. Appl. Microbiol. Biotechnol. 2018, 102, 5977–5988. [Google Scholar] [CrossRef]

- Miller, G.C.; Barker, D.; Pilkington, L.I.; Deed, R.C. Synthesis of a novel isotopically labelled standard for quantification of γ-nonalactone in New Zealand Pinot noir via SIDA-SPE-GC–MS. Anal. Bioanal. Chem. 2023, 415, 5035–5047. [Google Scholar] [CrossRef] [PubMed]

- Manolache, M.; Anamaria, C.; Pop, N.; Emese, G.; Pop, T.I. Odor Activity Value in Red Wines Aroma From Three Wine Regions in Romania. Agriculture 2019, 2, 29–38. [Google Scholar]

- Cliff, M.A.; Pickering, G.J. Determination of odour detection thresholds for acetic acid and ethyl acetate in ice wine. J. Wine Res. 2006, 17, 45–52. [Google Scholar] [CrossRef]

- Hernández-Carapia, M.Á.; Verde-Calvo, J.R.; Escalona-Buendía, H.B.; Peña-Álvarez, A. Effect of Maturation with American Oak Chips on the Volatile and Sensory Profile of a Cabernet Sauvignon Rosé Wine and Its Comparison with Commercial Wines. Beverages 2023, 9, 72. [Google Scholar] [CrossRef]

- del Alamo-Sanza, M.; Nevares, I. Oak wine barrel as an active vessel: A critical review of past and current knowledge. Crit. Rev. Food Sci. Nutr. 2018, 58, 2711–2726. [Google Scholar] [CrossRef]

- Dumitriu, G.-D.; Teodosiu, C.; Gabur, I.; Cotea, V.V.; Peinado, R.A.; López de Lerma, N. Evaluation of Aroma Compounds in the Process of Wine Ageing with Oak Chips. Foods 2019, 8, 662. [Google Scholar] [CrossRef]

- Cerdán, T.G.; Goñi, D.T.; Azpilicueta, C.A. Accumulation of volatile compounds during ageing of two red wines with different composition. J. Food Eng. 2004, 65, 349–356. [Google Scholar] [CrossRef]

- Cerdán, T.G.; Rodríguez Mozaz, S.; Ancín Azpilicueta, C. Volatile composition of aged wine in used barrels of French oak and of American oak. Food Res. Int. 2002, 35, 603–610. [Google Scholar] [CrossRef]

- Chira, K.; González-Centeno, M.R.; Teissedre, P.L. Wine Ageing in Oak Barrel: Effect of Toasting Process. Agric. Res. Technol. Open Access J. 2017, 12, 555847. [Google Scholar] [CrossRef]

- Fernández de Simón, B.; Cadahía, E.; del Álamo, M.; Nevares, I. Effect of size, seasoning and toasting in the volatile compounds in toasted oak wood and in a red wine treated with them. Anal. Chim. Acta 2010, 660, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.; Xi, Y.-R.; Ma, Y.; Zhang, H.-N.; Xu, Y. Chemical and Sensory Characterization of Cabernet Sauvignon Wines from the Chinese Loess Plateau Region. Molecules 2019, 24, 1122. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Massonnet, M.; Cantu, D. The genetic basis of grape and wine aroma. Hortic. Res. 2019, 6, 81. [Google Scholar] [CrossRef]

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447. [Google Scholar] [CrossRef]

- du Toit, W.J. The Effect of Oxygen on the Composition and Microbiology of Red Wine. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2006. [Google Scholar]

- Rayne, S.; Eggers, N.J. 4-Ethylphenol and 4-ethylguaiacol in wines: Estimating non-microbial sourced contributions and toxicological considerations. J. Environ. Sci. Health Part B 2007, 42, 887–897. [Google Scholar] [CrossRef]

- Bueno, J.E.; Peinado, R.; Moreno, J.; Medina, M.; Moyano, L.; Zea, L. Selection of Volatile Aroma Compounds by Statistical and Enological Criteria for Analytical Differentiation of Musts and Wines of Two Grape Varieties. J. Food Sci. 2003, 68, 158–163. [Google Scholar] [CrossRef]

- Călugăr, A.; Coldea, T.E.; Pop, C.R.; Pop, T.I.; Babeș, A.C.; Bunea, C.I.; Manolache, M.; Gal, E. Evaluation of Volatile Compounds during Ageing with Oak Chips and Oak Barrel of Muscat Ottonel Wine. Processes 2020, 8, 1000. [Google Scholar] [CrossRef]

- Yue, T.-X.; Chi, M.; Song, C.-Z.; Liu, M.-Y.; Meng, J.-F.; Zhang, Z.-W.; Li, M.-H. Aroma characterization of Cabernet Sauvignon wine from the Plateau of Yunnan (China) with different altitudes using SPME-GC/MS. Int. J. Food Prop. 2014, 18, 1584–1596. [Google Scholar] [CrossRef]

- Pérez-Prieto, L.J.; López-Roca, J.M.; Gómez-Plaza, E. Differences in major volatile compounds of red wines according to storage length and storage conditions. J. Food Compos. Anal. 2003, 16, 697–705. [Google Scholar] [CrossRef]

- Ribereau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology, Volume 2: The Chemistry of Wine Stabilization and Treatments, 2nd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2006; ISBN 9780470010372. [Google Scholar]

- Alpeza, I. Temelji kemijskog sastava vina. Glas. Zaštite Bilja 2008, 31, 143–150. [Google Scholar]

- Lambropoulos, I.; Roussis, I.G. Inhibition of the decrease of volatile esters and terpenes during storage of a white wine and a model wine medium by caffeic acid and gallic acid. Food Res. Int. 2007, 40, 176–181. [Google Scholar] [CrossRef]

- Longo, R.; Blackman, J.W.; Torley, P.J.; Rogiers, S.Y.; Schmidtke, L.M. Changes in Volatile Composition and Sensory Attributes of Wines During Alcohol Content Reduction. J. Sci. Food Agric. 2016, 97, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.M.; De Ropp, J.S.; Ebeler, S.E. Study of interactions between food phenolics and aromatic flavors using one- and two-dimensional 1H NMR spectroscopy. J. Agric. Food Chem. 2000, 48, 407–412. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Sroka, P.; Siuta, M. The Impact of Oxygen at Various Stages of Vinification on the Chemical Composition and the Antioxidant and Sensory Properties of White and Red Wines. Int. J. Food Sci. 2020, 2020, 7902974. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Wei, Z.; Han, Y.; Duan, Y.; Shi, B.; Ma, W. A Review on Wine Flavour Profiles Altered by Bottle Aging. Molecules 2023, 28, 6522. [Google Scholar] [CrossRef] [PubMed]

- Guld, Z.; Nyitrainé Sárdy, D.; Gere, A.; Rácz, A. Comparison of sensory evaluation techniques for Hungarian wines. J. Chemom. 2020, 34, e3219. [Google Scholar] [CrossRef]

| Sample | Lauric Acid (μg/L) | 2-Phenylethanol (mg/L) | Linalool (µg/L) | Hotrienol (µg/L) | Β-Damascenone (µg/L) | Ethyl Hexanoate (µg/L) | Diethyl Succinate (µg/L) | Ethyl Octanoate (µg/L) | Ethyl Cinnamate (mg/L) | Ethyl Vanillate (mg/L) |

|---|---|---|---|---|---|---|---|---|---|---|

| CS20 | 45.6 ± 1.2 k | 2.9 ± 0.1 c | 10.0 ± 0.4 gh | 273.5 ± 3.9 j | 5.2 ± 0.1 a | 117.6 ± 0.1 l | 1026.6 ± 21.8 d | 251.6 ± 5.0 k | - | 12.0 ± 0.5 gh |

| S20-I | 24.9 ± 1.5 i | 2.4 ± 0.1 a | 9.1 ± 0.1 f | 323.4 ± 1.9 l | 10.3 ± 0.1 h | 127.1 ± 2.0 m | 756.7 ± 22.0 b | 178.3 ± 2.9 h | - | 7.8 ± 0.1 c |

| S20-II | 16.9 ± 0.2 ef | 3.0 ± 0.1 cd | 6.7 ± 0.2 e | 359.7 ± 1.1 m | 16.0 ± 0.2 m | 186.7 ± 3.3 o | 1023.3 ± 8.2 d | 147.6 ± 1.7 g | - | 7.9 ± 0.2 c |

| S20-III | 13.2 ± 0.1 c | 2.4 ± 0.1 a | 6.1 ± 0.1 e | 166.6 ± 2.0 h | 13.5 ± 0.1 k | 113.1 ± 1.3 k | 718.4 ± 6.2 ab | 136.3 ± 3.0 ef | - | 17.2 ± 0.1 k |

| S20-IV | 19.5 ± 0.1 g | 2.4 ± 0.1 a | 8.7 ± 0.4 f | 126.1 ± 2.5 g | 14.2 ± 0.1 kl | 149.5 ± 0.8 n | 665.5 ± 2.8 a | 204.1 ± 2.8 i | - | 16.8 ± 0.3 k |

| EM20-I | 24.2 ± 0.5 i | 3.0 ± 0.1 cd | 12.6 ± 0.4 i | 201.2 ± 0.7 i | 12.2 ± 0.3 j | 71.1 ± 1.4 e | 1108.1 ± 34.6 ef | 145.6 ± 3.0 g | - | 12.7 ± 0.3 hi |

| EM20-II | 18.6 ± 0.3 g | 3.0 ± 0.1 cd | 10.6 ± 0.1 h | 291.1 ± 8.3 k | 8.9 ± 0.3 ef | 60.3 ± 0.7 d | 1203.5 ± 11.9 hi | 100.8 ± 0.2 b | - | 13.2 ± 0.1 i |

| EM20-III | 16.5 ± 0.5 e | 3.1 ± 0.1 d | 10.6 ± 0.1 h | 300.9 ± 5.0 k | 5.7 ± 0.1 a | 49.1 ± 0.7 c | 1027.2 ± 22.9 d | 99.9 ± 4.8 b | - | 16.7 ± 0.3 k |

| EM20-IV | 18.4 ± 0.4 fg | 2.6 ± 0.1 ab | 5.2 ± 0.2 d | 203.9 ± 9.2 i | 8.4 ± 0.1 de | 106.2 ± 0.2 j | 847.6 ± 3.0 c | 128.0 ± 6.1 cd | - | 7.5 ± 0.2 bc |

| E+20-I | 9.7 ± 0.5 a | 2.9 ± 0.1 c | 3.9 ± 0.3 bc | 330.8 ± 1.5 l | 7.5 ± 0.1 bc | 14.6 ± 0.5 b | 1068.5 ± 12.5 de | 186.6 ± 1.1 h | - | 15.3 ± 0.1 j |

| E+20-II | 9.2 ± 0.3 a | 2.7 ± 0.1 b | 3.5 ± 0.2 b | 479.3 ± 1.2 n | 7.4 ± 0.2 bc | 10.4 ± 0.2 ab | 1209.8 ± 29.9 hij | 186.1 ± 1.9 h | - | 11.3 ± 0.1 fg |

| E+20-III | 9.6 ± 0.1 a | 2.5 ± 0.1 ab | 4.3 ± 0.1 c | 510.9 ± 5.8 o | 8.7 ± 0.2 e | 9.2 ± 0.1 a | 1358.5 ± 7.6 k | 123.9 ± 1.7 c | - | 10.4 ± 0.1 e |

| E+20-IV | 11.3 ± 0.3 b | 3.1 ± 0.1 d | 2.7 ± 0.2 a | 573.8 ± 5.6 p | 6.8 ± 0.1 b | 10.2 ± 0.1 ab | 1250.7 ± 9.6 ij | 132.4 ± 3.3 de | - | 21.1 ± 0.3 l |

| EL20-I | 14.9 ± 0.3 d | 2.5 ± 0.1 ab | 9.8 ± 0.1 g | 25.7 ± 0.5 bc | 9.5 ± 0.5 fg | 95.2 ± 1.9 i | 1101.1 ± 18.9 ef | 83.6 ± 0.8 a | 6.3 ± 0.1 b | 8.8 ± 0.6 d |

| EL20-II | 15.7 ± 0.1 de | 2.8 ± 0.1 bc | 14.8 ± 0.1 k | 29.5 ± 1.2 cd | 9.7 ± 0.1 gh | 90.1 ± 1.5 h | 1177.5 ± 10.8 gh | 90.5 ± 1.2 a | 6.6 ± 0.1 c | 7.0 ± 0.2 b |

| EL20-III | 14.9 ± 0.2 d | 2.7 ± 0.1 b | 15.2 ± 0.2 k | 14.2 ± 0.1 a | 11.4 ± 0.4 i | 107.5 ± 0.7 j | 1173.3 ± 26.3 gh | 90.2 ± 0.4 a | 6.6 ± 0.1 bc | 7.6 ± 0.1 bc |

| EL20-IV | 16.1 ± 0.1 de | 2.7 ± 0.1 b | 13.6 ± 0.3 j | 18.0 ± 0.2 ab | 14.4 ± 0.2 l | 90.4 ± 1.4 h | 1263.6 ± 14.6 j | 91.3 ± 1.1 a | 7.9 ± 0.1 d | 10.9 ± 0.3 ef |

| PM20-I | 21.1 ± 0.4 h | 2.7 ± 0.1 b | 34.8 ± 0.1 m | 38.4 ± 0.1 de | 13.7 ± 0.3 kl | 96.3 ± 3.7 i | 1130.4 ± 25.4 fg | 217.3 ± 1.3 j | 8.2 ± 0.1 d | 9.2 ± 0.2 d |

| PM20-II | 22.4 ± 0.1 h | 2.5 ± 0.1 ab | 46.0 ± 0.2 n | 50.0 ± 0.5 f | 9.6 ± 0.1 fg | 75.9 ± 2.3 fg | 1103.4 ± 18.2 ef | 142.7 ± 0.2 fg | 2.7 ± 0.1 a | 9.1 ± 0.1 d |

| PM20-III | 18.8 ± 0.3 g | 2.4 ± 0.1 a | 57.7 ± 0.3 o | 42.3 ± 0.8 ef | 7.8 ± 0.3 cd | 80.2 ± 1.3 g | 1131.7 ± 2.7 fg | 132.8 ± 1.0 de | - | 4.6 ± 0.2 a |

| PM20-IV | 39.8 ± 0.6 j | 2.6 ± 0.1 ab | 19.9 ± 0.5 l | 31.2 ± 0.2 cd | 11.7 ± 0.7 ij | 73.1 ± 0.9 ef | 1249.6 ± 29.4 ij | 133.4 ± 2.5 de | - | 10.5 ± 0.6 ef |

| Sample | Lauric Acid (μg/L) | 2-Phenylethanol (mg/L) | Linalool (µg/L) | HOTRIENOL (µg/L) | Β-Damascenone (µg/L) | Ethyl Hexanoate (µg/L) | Diethyl Succinate (µg/L) | Ethyl Octanoate (µg/L) | Ethyl Cinnamate (mg/L) | Ethyl Vanillate (mg/L) |

|---|---|---|---|---|---|---|---|---|---|---|

| CS21 | 31.5 ± 0.3 n | 2.8 ± 0.1 de | 8.5 ± 0.1 cd | 8.4 ± 0.1 fgh | 5.5 ± 0.1 d | 304.7 ± 1.1 k | 579.5 ± 0.9 ab | 396.2 ± 0.5 m | - | 2.0 ± 0.1 fg |

| S21-I | 27.7 ± 0.2 m | 2.6 ± 0.1 cd | 16.0 ± 0.6 l | 10.2 ± 0.3 l | 20.6 ± 0.1 m | 299.9 ± 6.0 k | 557.4 ± 13.1 a | 378.1 ± 1.1 l | - | 1.5 ± 0.1 c |

| S21-II | 19.9 ± 0.9 ij | 2.7± 0.1 d | 10.3 ± 0.2 gh | 6.8 ± 0.1 c | 14.6 ± 0.4 l | 275.8 ± 7.0 j | 608.2 ± 4.6 cd | 377.9 ± 7.5 l | - | 1.4 ± 0.1 c |

| S21-III | 13.4 ± 0.6 d | 2.4 ± 0.1 bc | 10.6 ± 0.4 h | 7.1 ± 0.2 cd | 7.6 ± 0.1 f | 128.8 ± 2.0 bc | 761.6 ± 8.8 i | 158.9 ± 3.8 b | - | 1.6 ± 0.1 cd |

| S21-IV | 9.1 ± 0.1 a | 2.2 ± 0.1 ab | 8.1 ± 0.1 bc | 5.0 ± 0.4 a | 3.8 ± 0.1 b | 95.9 ± 0.1 a | 804.1 ± 1.7 k | 128.4 ± 0.2 a | - | 1.5 ± 0.1 cd |

| EM21-I | 22.0 ± 0.9 l | 3.4 ± 0.1 g | 9.2 ± 0.4 def | 8.2 ± 0.2 efg | 12.5 ± 0.2 j | 345.9 ± 4.5 l | 790.0 ± 5.2 jk | 466.6 ± 4.1 n | - | 2.5 ± 0.1 h |

| EM21-II | 21.8 ± 0.4 l | 3.0 ± 0.1 ef | 9.8 ± 0.5 fg | 8.0 ± 0.2 efg | 8.5 ± 0.1 gh | 174.4 ± 1.0 f | 715.3 ± 18.8 gh | 290.7 ± 4.2 hi | - | 3.0 ± 0.1 i |

| EM21-III | 13.0 ± 0.8 cd | 2.6 ± 0.1 cd | 8.6 ± 0.1 cde | 11.0 ± 0.3 l | 7.6 ± 0.3 f | 192.8 ± 2.9 g | 633.2 ± 6.4 ef | 309.1 ± 3.0 jk | - | 4.1 ± 0.1 j |

| EM21-IV | 11.7 ± 0.1 bc | 2.3 ± 0.1 b | 7.8 ± 0.1 bc | 11.8 ± 0.1 m | 5.5 ± 0.1 cd | 117.6 ± 2.5 b | 786.2 ± 2.7 ij | 232.2 ± 2.1 e | - | 4.8 ± 0.1 k |

| E+21-I | 15.2 ± 0.2 ef | 2.6 ± 0.1 cd | 8.2 ± 0.3 bc | 10.0 ± 0.4 l | 8.1 ± 0.1 fg | 417.5 ± 7.3 n | 573.2 ± 11.3 ab | 317.5 ± 3.4 k | - | 1.4 ± 0.1 c |

| E+21-II | 20.6 ± 0.3 j | 2.7 ± 0.1 d | 9.9 ± 0.1 fgh | 6.9 ± 0.1 c | 12.6 ± 0.7 j | 219.7 ± 0.5 i | 705.3 ± 10.4 gh | 279.3 ± 5.8 g | - | 2.1 ± 0.1 g |

| E+21-III | 17.2 ± 0.4 g | 2.8 ± 0.1 de | 11.5 ± 0.4 i | 9.7 ± 0.5 jl | 10.2 ± 0.1 i | 214.0 ± 3.0 hi | 775.9 ± 4.0 ij | 266.2 ± 1.9 f | - | 4.0 ± 0.1 j |

| E+21-IV | 19.3 ± 0.2 hi | 2.9 ± 0.1 e | 12.7 ± 0.4 j | 11.6 ± 0.1 lm | 12.4 ± 0.3 j | 201.9 ± 1.6 gh | 802.4 ± 1.3 k | 223.9 ± 1.9 e | - | 5.2 ± 0.1 l |

| EL21-I | 16.1 ± 0.1 fg | 2.6 ± 0.1 cd | 9.4 ± 0.2 ef | 9.3 ± 0.2 ij | 16.6 ± 0.3 l | 371.8 ± 0.7 m | 631.6 ± 4.3 ef | 521.8 ± 3.7 o | - | 1.8 ± 0.1 ef |

| EL21-II | 21.0 ± 0.1 jl | 2.6 ± 0.1 cd | 9.3 ± 0.1 def | 5.9 ± 0.2 b | 8.9 ± 0.6 h | 149.2 ± 1.6 e | 697.4 ± 8.4 g | 265.5 ± 0.8 f | - | 1.7 ± 0.1 de |

| EL21-III | 18.5 ± 0.1 h | 2.3 ± 0.1 b | 9.4 ± 0.3 f | 7.6 ± 0.1 de | 9.7 ± 0.1 i | 143.4 ± 0.6 de | 725.4 ± 2.3 h | 204.3 ± 3.2 d | - | 1.5 ± 0.1 c |

| EL21-IV | 19.3 ± 0.1 hi | 2.3 ± 0.1 b | 10.4 ± 0.1 gh | 8.6 ± 0.3 ghi | 6.7 ± 0.2 e | 136.1 ± 2.9 cd | 849.2 ± 0.3 l | 176.7 ± 1.1 c | - | 1.4 ± 0.1 c |

| PM21-I | 25.1 ± 0.3 l | 3.1 ± 0.1 f | 5.6 ± 0.1 a | 8.4 ± 0.1 fgh | 8.6 ± 0.2 gh | 264.4 ± 12.4 j | 612.6 ± 5.3 de | 283.3 ± 4.1 gh | - | 2.7 ± 0.1 h |

| PM21-II | 18.6 ± 0.6 h | 2.4 ± 0.1 bc | 6.2 ± 0.1 a | 5.8 ± 0.2 b | 5.2 ± 0.1 cd | 196.6 ± 5.3 g | 644.0 ± 3.7 f | 298.2 ± 5.6 ij | - | 1.8 ± 0.1 ef |

| PM21-III | 14.8 ± 0.3 e | 2.5 ± 0.1 c | 7.5 ± 0.4 b | 7.9 ± 0.1 ef | 4.8 ± 0.2 c | 166.1 ± 2.4 f | 646.2 ± 12.0 f | 233.6 ± 5.2 e | - | 1.1 ± 0.1 b |

| PM21-IV | 11.4 ± 0.1 b | 2.1 ± 0.1 a | 10.3 ± 0.2 gh | 9.0 ± 0.1 hi | 3.0 ± 0.1 a | 133.8 ± 0.7 cd | 693.9 ± 1.8 g | 229.6 ± 5.3 e | - | 0.7 ± 0.1 a |

| Compound | Odour Threshold (µg/L) | OAV Range | Lowest Concentration (Sample) (µg/L) | Highest Concentration (Sample) (µg/L) | Main Aroma Contribution |

|---|---|---|---|---|---|

| Lauric acid | 5 | 1.8–9.1 | 9.1 (S21-IV) | 45.6 (CS20) | Creamy, fatty aroma balance |

| 2-phenylethanol | 1000 | 2.1–3.4 | 2131.7 (PM21-IV) | 3385.7 (EM21-I) | Rose, floral sweetness |

| Linalool | 6 | 0.4–9.6 | 2.7 (E+20-IV) | 57.7 (PM20-III) | Fresh floral/citrus notes |

| Hotrienol | 110 | 0.1–5.2 | 5.1 (S21-IV) | 573.9 (E+20-IV) | Floral aroma, honey nuance |

| β-damascenone | 0.1 | 30.3–206.3 | 3.3 (PM21-IV) | 20.6 (S21-I) | Fruity/floral complexity |

| Ethyl hexanoate | 100 | 0.1–4.2 | 9.2 (E+20-III) | 417.5 (E+21-I) | Banana, stone fruit notes |

| Diethyl succinate | 1200 | 0.5–1.1 | 557.4 (S21-I) | 1358.5 (E+20-III) | Mild fruity background |

| Ethyl octanoate | 5 | 16.7–104.4 | 83.6 (EL20-I) | 521.8 (EL21-I) | Fresh tropical fruit |

| Ethyl cinnamate | 1.1 | 2.4–7.5 | 2.7 (PM20-II) | 8.22 (PM20-I) | Spicy-fruity enhancement |

| Ethyl vanillate | 3 | 0.2–7.0 | 0.66 (PM21-IV) | 5.20 (E+21-IV) | Sweet vanilla aroma |

| Sample | Visual | Nose | Taste | Harmony | Total | Sample | Visual | Nose | Taste | Harmony | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CS20 | 15.0 | 26.7 | 34.3 | 9.7 | 85.7 | CS21 | 15.0 | 25.0 | 33.7 | 10.3 | 84.0 |

| S20-I | 15.0 | 26.0 | 35.7 | 10.0 | 86.7 | S21-I | 15.0 | 24.3 | 37.7 | 10.0 | 87.0 |

| S20-II | 15.0 | 27.7 | 35.7 | 10.0 | 88.3 | S21-II | 15.0 | 23.3 | 35.0 | 10.0 | 83.3 |

| S20-III | 15.0 | 29.0 | 36.3 | 10.0 | 90.3 | S21-III | 15.0 | 25.3 | 38.0 | 9.7 | 88.0 |

| S20-IV | 15.0 | 29.3 | 37.3 | 10.0 | 91.7 | S21-IV | 15.0 | 23.7 | 38.0 | 9.7 | 86.3 |

| EM20-I | 15.0 | 28.7 | 39.3 | 10.7 | 93.7 | EM21-I | 15.0 | 26.7 | 38.3 | 10.0 | 90.0 |

| EM20-II | 15.0 | 25.7 | 36.7 | 10.0 | 87.3 | EM21-II | 15.0 | 24.3 | 37.3 | 10.0 | 86.7 |

| EM20-III | 15.0 | 27.0 | 35.7 | 10.0 | 87.7 | EM21-III | 15.0 | 22.7 | 32.3 | 9.0 | 79.0 |

| EM20-IV | 15.0 | 25.3 | 35.3 | 10.0 | 85.7 | EM21-IV | 15.0 | 23.0 | 37.3 | 10.0 | 85.3 |

| E+20-I | 15.0 | 27.7 | 37.7 | 10.0 | 90.3 | E+21-I | 15.0 | 26.0 | 38.0 | 9.7 | 88.7 |

| E+20-II | 15.0 | 28.7 | 37.7 | 10.3 | 91.7 | E+21-II | 15.0 | 26.0 | 39.0 | 10.3 | 90.3 |

| E+20-III | 15.0 | 24.7 | 37.7 | 10.3 | 87.7 | E+21-III | 15.0 | 25.3 | 36.3 | 10.0 | 86.7 |

| E+20-IV | 15.0 | 20.0 | 34.3 | 9.3 | 78.7 | E+21-IV | 15.0 | 20.7 | 32.0 | 9.7 | 77.3 |

| EL20-I | 15.0 | 22.3 | 37.3 | 10.0 | 84.7 | EL21-I | 15.0 | 24.7 | 35.0 | 9.7 | 84.3 |

| EL20-II | 15.0 | 26.0 | 37.7 | 9.7 | 88.3 | EL21-II | 15.0 | 27.7 | 37.7 | 10.0 | 90.3 |

| EL20-III | 15.0 | 29.0 | 40.0 | 10.3 | 94.3 | EL21-III | 15.0 | 28.3 | 41.0 | 10.0 | 94.3 |

| EL20-IV | 15.0 | 27.3 | 37.3 | 10.3 | 90.0 | EL21-IV | 15.0 | 24.0 | 37.0 | 10.0 | 86.0 |

| PM20-I | 15.0 | 22.0 | 33.7 | 9.3 | 80.0 | PM21-I | 15.0 | 19.7 | 33.7 | 9.3 | 77.7 |

| PM20-II | 15.0 | 22.0 | 36.7 | 10.0 | 83.7 | PM21-II | 15.0 | 25.3 | 35.7 | 9.3 | 85.3 |

| PM20-III | 15.0 | 25.3 | 38.0 | 10.0 | 88.3 | PM21-III | 15.0 | 24.7 | 37.7 | 10.0 | 87.3 |

| PM20-IV | 15.0 | 26.7 | 39.7 | 10.0 | 91.3 | PM21-IV | 15.0 | 28.0 | 40.7 | 10.3 | 94.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pichler, A.; Ivić, I.; Mesić, J.; Svitlica, B.; Nedić Tiban, N.; Ostrun, I.; Marković, T.; Kopjar, M. A Comparative Study of Cabernet Sauvignon Red Wine Aroma Profiles During Ageing in Medium-Toasted Oak Barrels. Foods 2025, 14, 3178. https://doi.org/10.3390/foods14183178

Pichler A, Ivić I, Mesić J, Svitlica B, Nedić Tiban N, Ostrun I, Marković T, Kopjar M. A Comparative Study of Cabernet Sauvignon Red Wine Aroma Profiles During Ageing in Medium-Toasted Oak Barrels. Foods. 2025; 14(18):3178. https://doi.org/10.3390/foods14183178

Chicago/Turabian StylePichler, Anita, Ivana Ivić, Josip Mesić, Brankica Svitlica, Nela Nedić Tiban, Iva Ostrun, Tanja Marković, and Mirela Kopjar. 2025. "A Comparative Study of Cabernet Sauvignon Red Wine Aroma Profiles During Ageing in Medium-Toasted Oak Barrels" Foods 14, no. 18: 3178. https://doi.org/10.3390/foods14183178

APA StylePichler, A., Ivić, I., Mesić, J., Svitlica, B., Nedić Tiban, N., Ostrun, I., Marković, T., & Kopjar, M. (2025). A Comparative Study of Cabernet Sauvignon Red Wine Aroma Profiles During Ageing in Medium-Toasted Oak Barrels. Foods, 14(18), 3178. https://doi.org/10.3390/foods14183178