The Use of Whey Powder to Improve Bread Quality: A Sustainable Solution for Utilizing Dairy By-Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Obtainment of Whey Powder

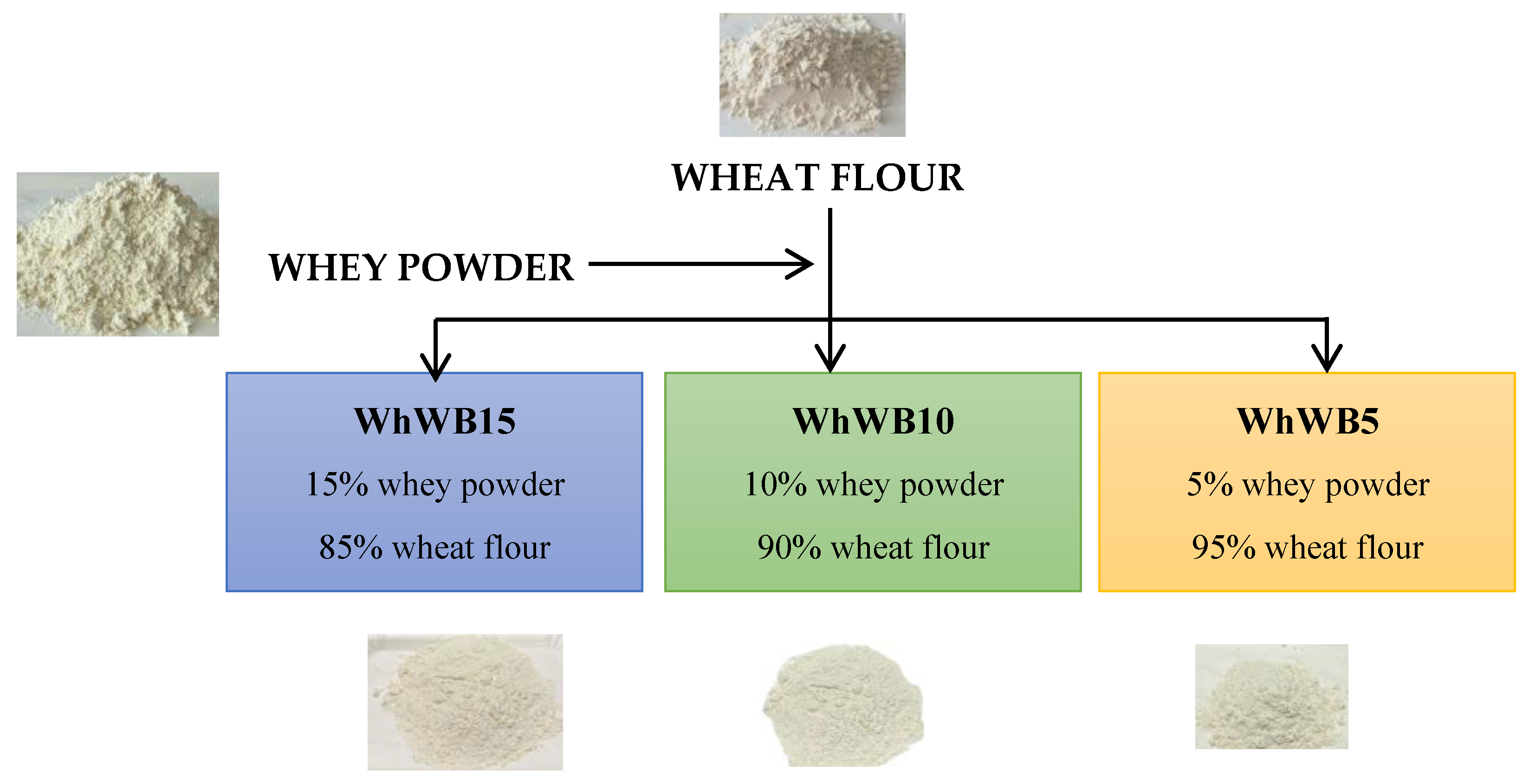

2.3. Composite Flours Preparation

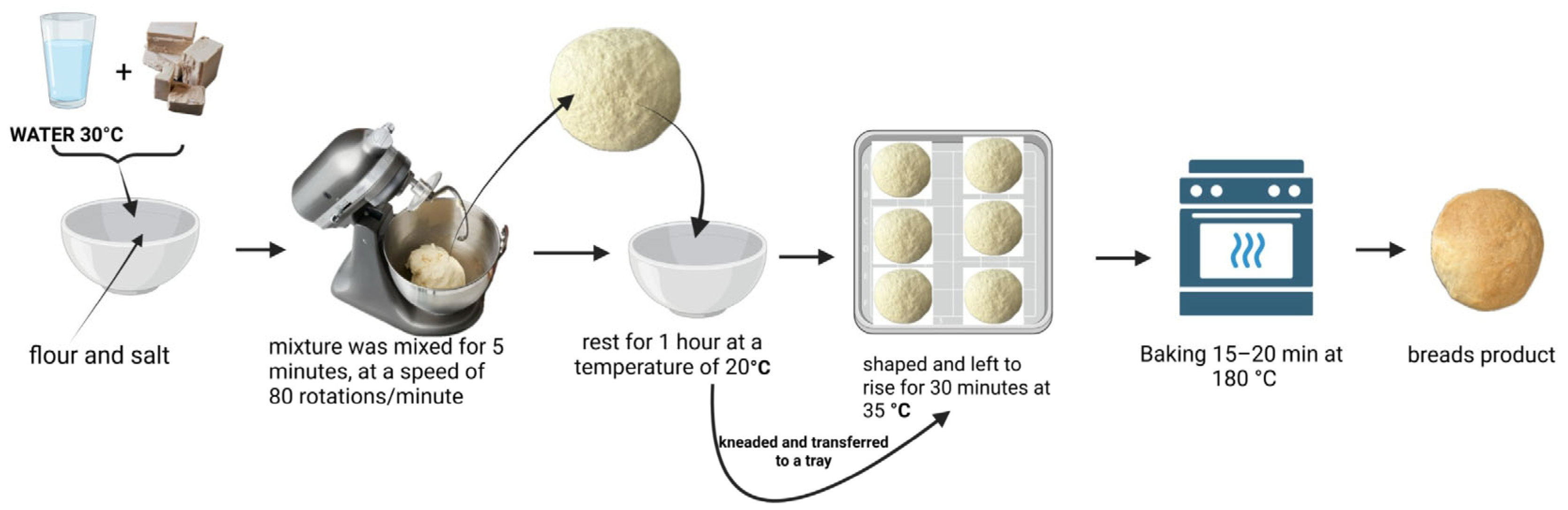

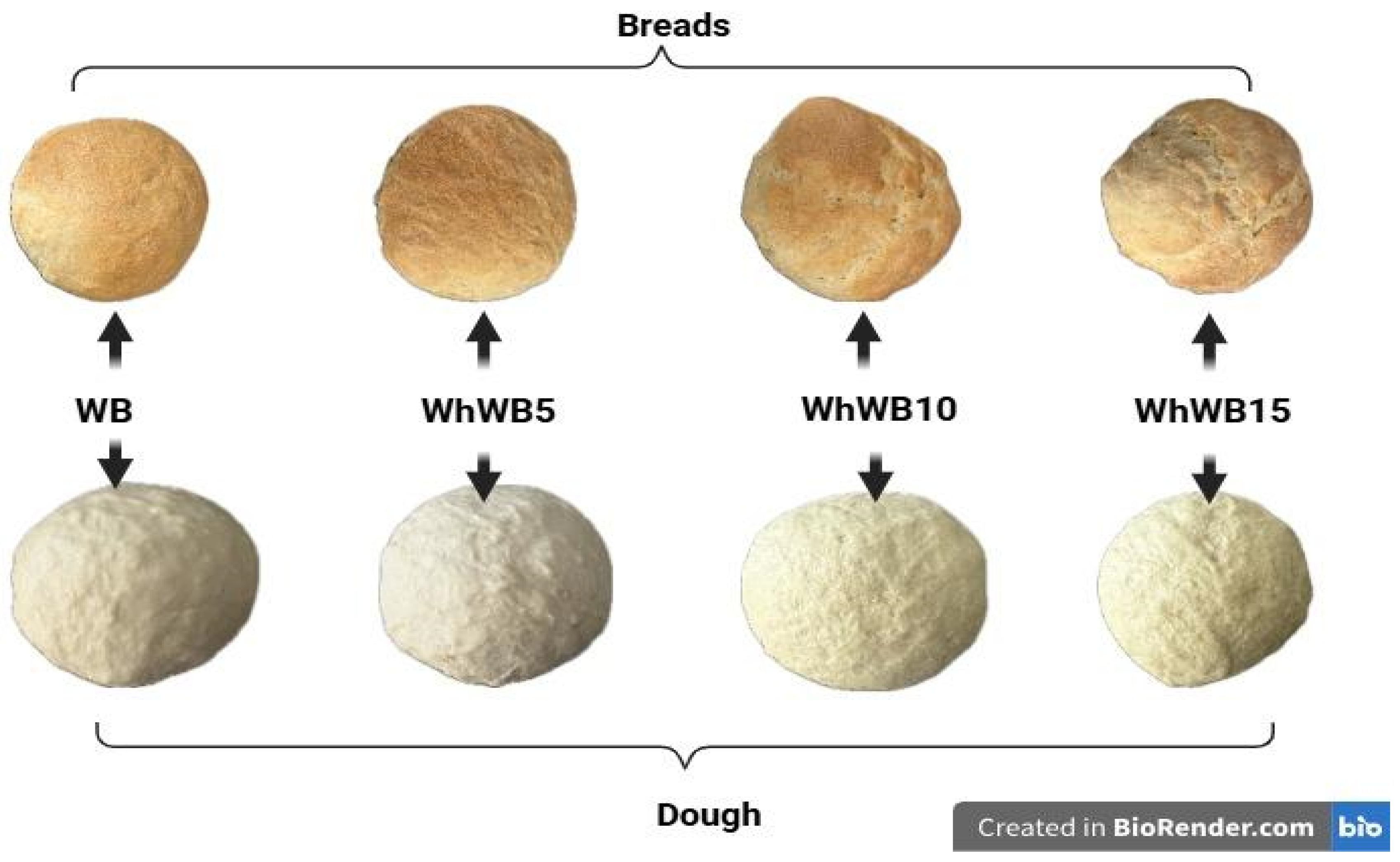

2.4. Fortified Bread Preparation

2.5. Determination of the Proximate Composition of Composite Flours and Breads

2.6. Determination of Macro and Microelements

2.7. Determination of Physical–Chemical Properties of Bread

2.7.1. Determination of Bread Volume

- V1—volume of displaced rapeseeds, in cm3;

- m—mass of the bread sample, in g.

2.7.2. Determination of Bread Elasticity

- A—height of the core cylinder before pressing, in cm;

- B—height of the core cylinder after pressing and its return to the initial position, in cm.

2.7.3. Determination of Bread Porosity

- V—the volume of the core cylinder, in cm3;

- m—the mass of the core cylinder, in g;

- ρ—the density of the compact core, in g/cm3.

2.7.4. Determination of the H/D Ratio

- H—height of the product, in cm;

- D—arithmetic mean of two perpendicular diameters, in cm.

2.8. Determination of the Phytochemical Profile

2.8.1. Preparation of Alcoholic Extracts

2.8.2. Evaluation of the Total Phenolic Content (TPC)

2.8.3. Antioxidant Activity

- Acontrol—Absorbance of control sample denotes the control absorbance values, and Asamples—Absorbance of samples.

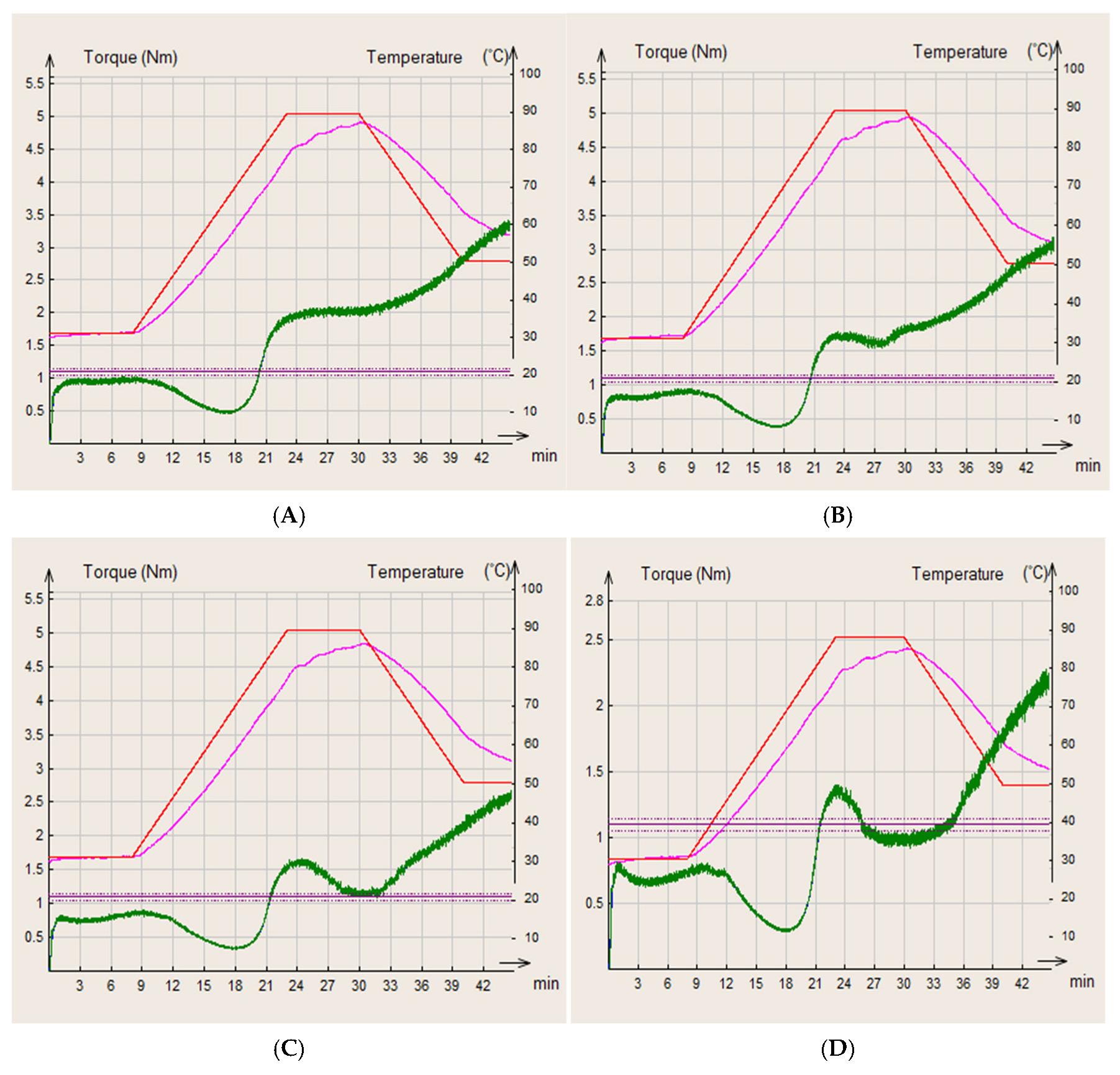

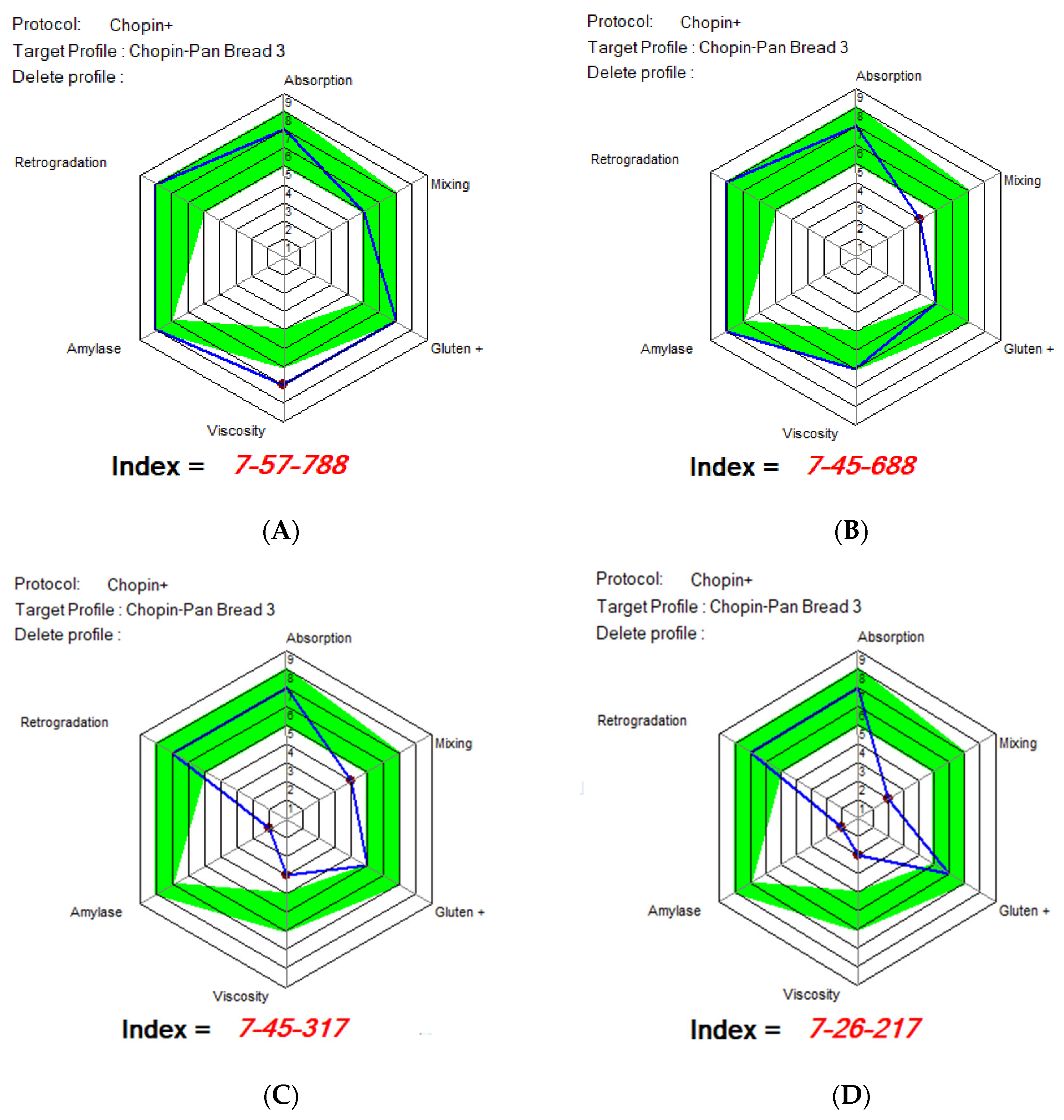

2.9. Rheological Analysis

2.10. Sensory Evaluation

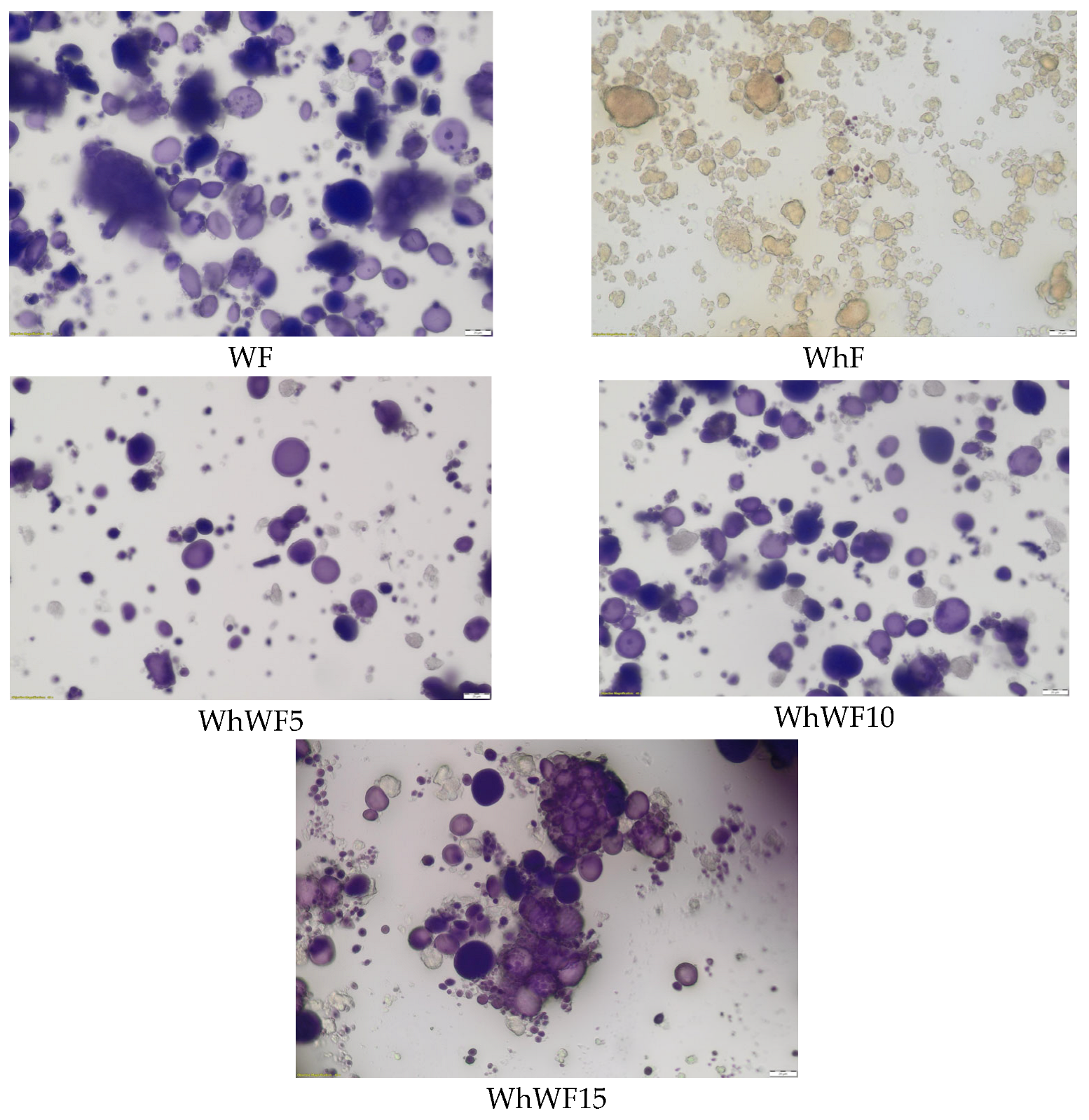

2.11. The Microscopic Analysis of Composite Flours

2.12. Fourier Transform Infrared Spectroscopy (FTIR) of Composite Flours

2.13. Small-Wide Angle X-Ray Scattering (SAXS/WAXS) of Composite Flours

- I(q)—scattered intensity;

- q—scattering variable;

- Rg—radius of gyration.

2.14. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition of Composite Flours and Fortified Breads with Whey Powder

3.2. Macro and Microelements Content of Composite Flours and Breads Fortified with Whey Powder

3.3. Physical–Chemical Properties of Fortified Breads with Whey Powder

3.4. Phytochemical Profile of Fortified Flours and Breads with Whey Powder

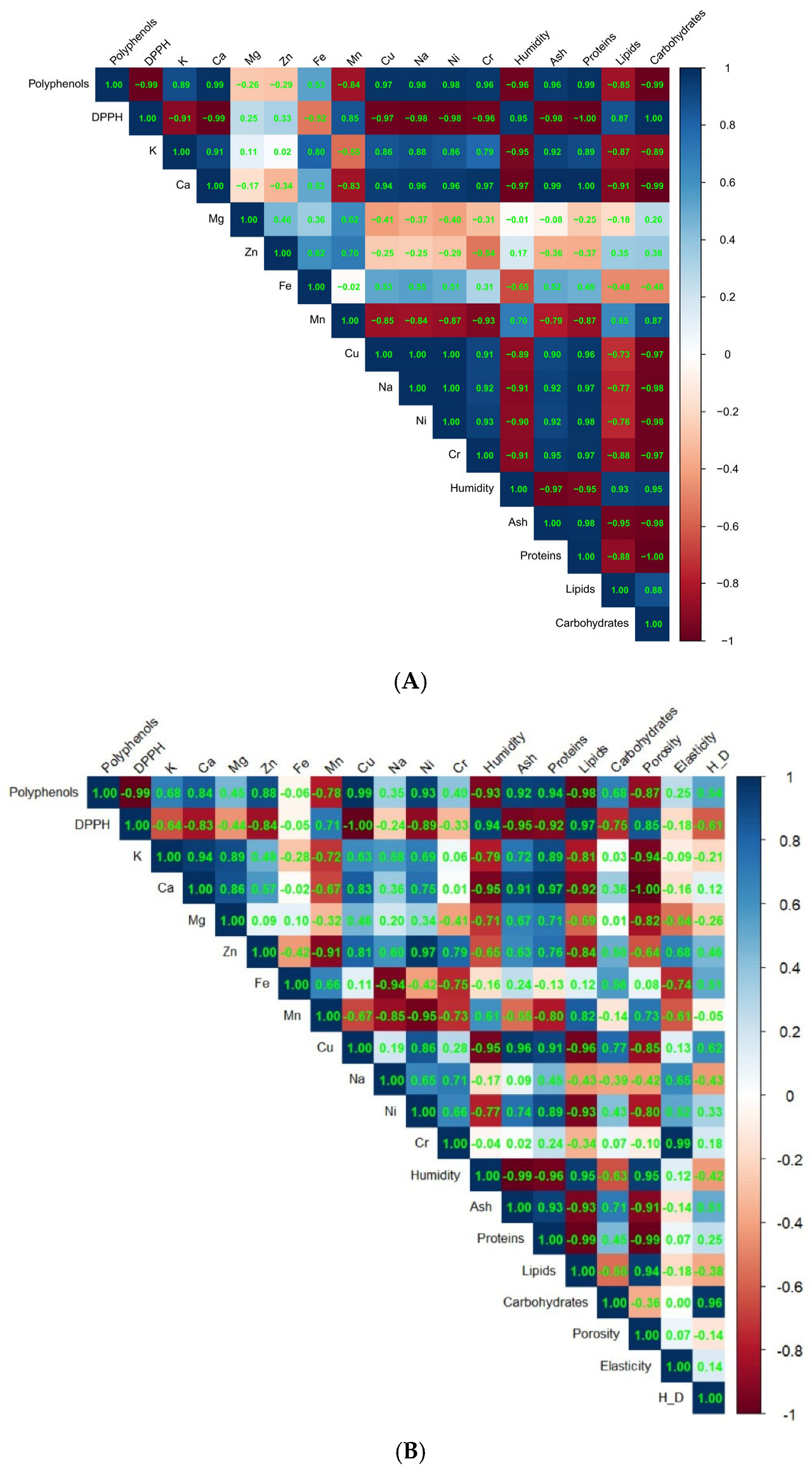

3.5. Analysis of Correlation Between Physical–Chemical, Macro and Microelements, and Phytochemical Parameters in Composite Flours with Whey Powder and in Fortified Bread

3.6. Rheological Analysis of Fortified Bread with Whey Powder

3.7. Sensory Evaluation of Fortified Bread with Whey Powder

3.8. Spectroscopy Analysis (FTIR) of Fortified Flours with Whey Powder

3.9. Microscopic Evaluation of Composite Flours with Whey Powder

3.10. Small—Wide Angle X-Ray Scattering (SAXS/WAXS) of Fortified Flours with Whey Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verma, D.K.; Patel, A.R.; Tripathy, S.; Gupta, A.K.; Singh, S.; Shah, N.; Utama, G.L.; Chávez-González, M.L.; Zongo, K.; Banwo, K.; et al. Processing and Formulation Technology of Nutritional and Functional Food Products by Utilizing Cheese and/or Paneer Whey: A Critical Review. J. King Saud Univ. Sci. 2024, 36, 103508. [Google Scholar] [CrossRef]

- Buchanan, D.; Martindale, W.; Romeih, E.; Hebishy, E. Recent Advances in Whey Processing and Valorisation: Technological and Environmental Perspectives. Int. J. Dairy Technol. 2023, 76, 291–312. [Google Scholar] [CrossRef]

- Minj, S.; Anand, S. Whey Proteins and Its Derivatives: Bioactivity, Functionality, and Current Applications. Dairy 2020, 1, 233–258. [Google Scholar] [CrossRef]

- Mazorra-Manzano, M.A.; Martínez-García, A.; Torres-Llanez, M.J.; Ramírez-Suárez, J.C.; López-Franco, Y.L.; Brown-Bojórquez, F.; Teutle-Paredes, J.G.; Lugo-Sánchez, M.E. Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition. Dairy 2025, 6, 32. [Google Scholar] [CrossRef]

- Luparelli, A.; Trisciuzzi, D.; Schirinzi, W.M.; Caputo, L.; Smiriglia, L.; Quintieri, L.; Nicolotti, O.; Monaci, L. Whey Proteins and Bioactive Peptides: Advances in Production, Selection and Bioactivity Profiling. Biomedicines 2025, 13, 1311. [Google Scholar] [CrossRef]

- Srikanlaya, C.; Therdthai, N.; Ritthiruangdej, P.; Zhou, W. Effect of Hydroxypropyl Methylcellulose, Whey Protein Concentrate and Soy Protein Isolate Enrichment on Characteristics of Gluten-Free Rice Dough and Bread. Int. J. Food Sci. Technol. 2018, 53, 1760–1770. [Google Scholar] [CrossRef]

- Dopazo, V.; Illueca, F.; Luz, C.; Musto, L.; Moreno, A.; Calpe, J.; Meca, G. Evaluation of Shelf Life and Technological Properties of Bread Elaborated with Lactic Acid Bacteria Fermented Whey as a Bio-Preservation Ingredient. LWT 2023, 174, 114427. [Google Scholar] [CrossRef]

- Iosca, G.; Turetta, M.; De Vero, L.; Bang-Berthelsen, C.H.; Gullo, M.; Pulvirenti, A. Valorization of Wheat Bread Waste and Cheese Whey Through Cultivation of Lactic Acid Bacteria for Bio-Preservation of Bakery Products. LWT 2023, 176, 114524. [Google Scholar] [CrossRef]

- El-Azab, H.M.; Abd El-Latif, B.M.; Bahlol, H.E.M.; Ghazal, G.A.I.; Mahmoud, M.H.M. Getting the Dried Whey Protein Concentrate and Its Effect on Pan Bread Evaluation. Ann. Agric. Sci. Moshtohor. 2019, 57, 383–394. [Google Scholar] [CrossRef]

- Komeroski, M.R.; Oliveira, V.R.d. Influence of the Amount and Type of Whey Protein on the Chemical, Technological, and Sensory Quality of Pasta and Bakery Products. Foods 2023, 12, 2801. [Google Scholar] [CrossRef]

- Komeroski, M.R.; Homem, R.V.; Schmidt, H.O.; Rockett, F.C.; de Lira, L.; da Farias, D.V.; Kist, T.L.; Doneda, D.; Rios, A.D.O.; de Oliveira, V.R. Effect of Whey Protein and Mixed Flours on the Quality Parameters of Gluten-Free Breads. Int. J. Gastron. Food Sci. 2021, 24, 100361. [Google Scholar] [CrossRef]

- Izzo, L.; Luz, C.; Ritieni, A.; Mañes, J.; Meca, G. Whey Fermented by Using Lactobacillus plantarum Strains: A Promising Approach to Increase the Shelf Life of Pita Bread. J. Dairy Sci. 2020, 103, 5906–5915. [Google Scholar] [CrossRef] [PubMed]

- Dobhal, A.; Awasthi, P.; Shahi, N.C.; Kumar, A.; Bisht, B.; Joshi, S.; Kumar, S. Process optimization of nutritious whey incorporated wheat-barley buns and assessment of their physical, nutritional, and antioxidant profiles. J. Food Meas. Charact. 2024, 18, 1759–1775. [Google Scholar] [CrossRef]

- Kakan, A.V.; Changade, S.P.; Shaikh, A.; Suvartan, R. Effect of different levels of paneer whey on physico-chemical and microbial characteristics of milk bread. Int. J. Chem. Stud. 2018, 6, 545–555. [Google Scholar]

- Paul, S.; Kulkarni, S.; Rao, K.J. Utilisation of concentrated whey in the production of multigrain bread: Optimisation of solid levels in concentrated whey and temperatures of baking. Int. Food Res. J. 2019, 26, 599–606. [Google Scholar]

- Pico, J.; Reguilón, M.P.; Bernal, J.; Gómez, M. Effect of Rice, Pea, Egg White and Whey Proteins on Crust Quality of Rice Flour-Corn Starch Based Gluten-Free Breads. J. Cereal Sci. 2019, 86, 92–101. [Google Scholar] [CrossRef]

- Achalu, B.I.; Tessema, H.A.; Ayele, A.T. Development and Characterization of Gluten-Free Bread Enriched with Whey Protein from Sorghum-Rice Composite Flours. Appl. Food Res. 2025, 5, 101133. [Google Scholar] [CrossRef]

- ISO 2171:2007; Cereals, Pulses and By-Products—Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- ICC. Determination of Moisture and Protein in Cereals and Cereal Products; ICC Standard Methods; International Association for Cereal Science and Technology: Vienna, Austria, 2003. [Google Scholar]

- AOAC. Official Methods of Analysis, 17th ed.; Method 920.39 (Fat Content); Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Dossa, S.; Negrea, M.; Cocan, I.; Berbecea, A.; Obistioiu, D.; Dragomir, C.; Alexa, E.; Rivis, A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods 2023, 12, 2697. [Google Scholar] [CrossRef]

- Ruja, A.; Cozma, A.; Cozma, B.; Horablaga, N.M.; Dinulescu, C.; Alexa, E.; Buzna, C.; Cocan, I.; Berbecea, A.; Dossa, S.; et al. Nutritional, Phytochemical, and Rheological Profiles of Different Oat Varieties and Their Potential in the Flour Industry. Agronomy 2024, 14, 1438. [Google Scholar] [CrossRef]

- AACC International. Method 10-05.01: Guidelines for Measurement of Volume; AACC International: St. Paul, MN, USA, 2000. [Google Scholar]

- Salameh, D.; Bouazizi, L.; Attia, H. Effect of Ingredients and Processing on Bread Porosity and Texture. Foods 2022, 11, 3667. [Google Scholar] [CrossRef]

- Lalanne, V.; Keramat, J.; Jury, V.; Prost, C.; Le-Bail, A. Influence of Baking Conditions on Bread Characteristics and Acrylamide Concentration. J. Food Sci. Nutr. Res. 2020, 3, 291–310. [Google Scholar] [CrossRef]

- Plustea, L.; Dossa, S.; Dragomir, C.; Cocan, I.; Negrea, M.; Obistioiu, D.; Poiana, M.-A.; Voica, D.; Berbecea, A.; Alexa, E. Comparative Study of the Nutritional, Phytochemical, Sensory Characteristics and Glycemic Response of Cookies Enriched with Lupin Sprout Flour and Lupin Green Sprout. Foods 2024, 13, 656. [Google Scholar] [CrossRef]

- Handbook of heological and Enzymatic Analysis; Chopin Applications Laboratory: Villeneuve-la-Garenne, France, 2009.

- O’Sullivan, M.G. Sensory Affective (Hedonic) Testing. In A Handbook for Sensory and Consumer-Driven New Product Development; O’Sullivan, M.G., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 39–57. ISBN 978-0081003527. [Google Scholar]

- Zielińska, E.; Baraniak, B.; Karaś, M.; Rybczyńska, K.; Jakubczyk, A. Selected species of edible insects as a source of nutrient composition. Food Res. Int. 2018, 105, 58–68. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanović, V.; Cardinali, F.; Osimani, A.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Pasquini, M.; Mozzon, M. Edible insects and insect-based foods: From farm to fork. Curr. Opin. Food Sci. 2019, 30, 33–39. [Google Scholar] [CrossRef]

- Smriga, M.; Walter, J.; Prakash, S. Sustainable sources of protein in the future diet. Trends Food Sci. Technol. 2020, 100, 285–295. [Google Scholar] [CrossRef]

- FAO. Edible Insects: Future Prospects for Food and Feed Security; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Caparros Megido, R.; Sablon, L.; Geuens, M.; Brostaux, Y.; Alabi, T.; Blecker, C.; Drugmand, D.; Haubruge, E.; Francis, F. Edible insects acceptance by Belgian consumers: Promising attitude for entomophagy development. Appetite 2016, 106, 133–144. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Ekonomou, S.I.; Stratakos, A.C.; Pintado, T. Protein-based ingredients as alternative fat replacers in meat products. Food Hydrocoll. 2019, 96, 469–482. [Google Scholar] [CrossRef]

- Stone, A.K.; Karalash, A.; Tyler, R.T.; Warkentin, T.D.; Nickerson, M.T. Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res. Int. 2015, 76, 31–38. [Google Scholar] [CrossRef]

- Sienkiewicz, S.; Czerwonka, M.; Drywień, M.E.; Wierzbicka, A. Whey and Whey Preparations—Characteristics, Nutritional Value and Health-Promoting Properties. Foods 2021, 10, 1517. [Google Scholar] [CrossRef]

- Amalfitano, N.; Patel, N.; Haddi, M.-L.; Benabid, H.; Pazzola, M.; Vacca, G.M.; Tagliapietra, F.; Schiavon, S.; Bittante, G. Detailed Mineral Profile of Milk, Whey, and Cheese from Cows, Buffaloes, Goats, Ewes, and Dromedary Camels, and Efficiency of Recovery of Minerals in Their Cheese. J. Dairy Sci. 2024, 107, 8887–8907. [Google Scholar] [CrossRef]

- Mehra, R.; Kumar, H.; Kumar, N.; Ranvir, S.G.; Jana, A.; Buttar, H.; Telessy, I.; Awuchi, C.; Okpala, C.; Korzeniowska, M.; et al. Whey Proteins Processing and Emergent Derivatives: An Insight Perspective from Constituents, Bioactivities, Functionalities to Therapeutic Applications. J. Funct. Foods 2021, 87, 104760. [Google Scholar] [CrossRef]

- Renzetti, S.; van den Hoek, I.A.F.; Hamer, R.J. Optimisation of the basic ingredients for gluten-free bread: A response surface methodology study. Food Chem. 2008, 107, 1225–1233. [Google Scholar]

- Amina, D.; Meziane, M.; Dilmi Bouras, A.; Megateli, S. Fortifying Wheat Bread with Whey Proteins: Impact on Nutritional Value and Technological Properties. South Asian J. Exp. Biol. 2021, 11, 700–709. [Google Scholar] [CrossRef]

- Yildiz, M.; Tufekci, F. The effect of whey powder addition on the quality of bread. GIDA J. Food 2013, 38, 271–277. [Google Scholar]

- Ktenioudaki, A.; Chaurin, V.; Reis, S.F.; Gallagher, E. Brewer’s spent grain as a functional ingredient for breadsticks. Int. J. Food Sci. Technol. 2012, 47, 1765–1771. [Google Scholar] [CrossRef]

- Sulieman, A.M.E.; El-Hassan, A.M.; El-Obeid, T.K. Use of whey protein concentrate in the production of bread. Pak. J. Nutr. 2006, 5, 182–184. [Google Scholar]

- Gallagher, E.; Gormley, T.R.; Arendt, E.K. Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci. Technol. 2004, 15, 143–152. [Google Scholar] [CrossRef]

- Smetana, S.; Schmitt, E.; Mathys, A. Sustainable use of Hermetia illucens insect biomass for feed and food: Attributional and consequential life cycle assessment. Resour. Conserv. Recycl. 2019, 144, 285–296. [Google Scholar] [CrossRef]

- Zielińska, E.; Pankiewicz, U. Nutritional, physiochemical, and antioxidative properties of powdered honey bee drone larvae (Apis mellifera) as a novel food ingredient. Nutrients 2020, 12, 1472. [Google Scholar] [CrossRef]

- Mugisha, M.K.; Oduor, C.O.; Nyangweso, P.M.; Waweru, B.; Wangari, P. Effect of baking on antioxidant activity of wheat flour enriched with African leafy vegetables. Food Sci. Nutr. 2020, 8, 4753–4762. [Google Scholar] [CrossRef]

- Durazzo, A. Study Approach of Antioxidant Properties in Foods: Update and Considerations. Foods 2017, 6, 17. [Google Scholar] [CrossRef]

- Mishra, S.; Monro, J.; Hedderley, D.; Rich, L.; Hall, R. Influence of processing on the antioxidant activity and glycemic impact of polyphenol-rich foods: A review. J. Funct. Foods 2019, 52, 629–640. [Google Scholar] [CrossRef]

- Kučerová, J.; Mikušová, L.; Kohajdová, Z.; Karovičová, J. The Impact of Insect-Based Ingredients on the Rheological Properties of Wheat Dough and Bread Quality. Appl. Sci. 2021, 11, 4427. [Google Scholar] [CrossRef]

- Delcour, J.A.; Hoseney, R.C. Principles of Cereal Science and Technology, 3rd ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Pořízka, J.; Slavíková, Z.; Bidmonová, K.; Vymětalová, M.; Diviš, P. Physiochemical and Sensory Properties of Bread Fortified with Wheat Bran and Whey Protein Isolates. Foods 2023, 12, 2635. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of dietary fibre on dough rheology and bread quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

- Liu, Y.; Ran, C.; Zhang, H.; Cheng, Y.; Huanbieke, M.; Liu, Y.; Yang, J.; Mei, Y.; Qu, Y. Effects of the Maillard Reaction on the Structural and Functional Properties of Camel Whey Protein. Foods 2025, 14, 2201. [Google Scholar] [CrossRef]

- Yue, Y.; Jiang, Y.; Shi, J. The Effects of Ultrasonic Pretreatment and Enzymatic Modification on the Structure, Functional Properties, and In Vitro Digestion of Whey Protein Isolate. Foods 2025, 14, 1445. [Google Scholar] [CrossRef]

- Barth, A. The Infrared Absorption of Amino Acid Side Chains. Prog. Biophys. Mol. Biol. 2000, 74, 141–173. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Gai, G. FTIR Spectroscopic Characterization of Protein–Polysaccharide Interactions in Food Systems. Food Chem. 2020, 317, 126429. [Google Scholar] [CrossRef]

- De Marchi, M.; Fagan, C.C.; O’Donnell, C.P.; Cecchinato, A.; Dal Zotto, R.; Cassandro, M.; Penasa, M.; Bittante, G. Prediction of coagulation properties, titratable acidity, and pH of bovine milk using mid-infrared spectroscopy. J. Dairy Sci. 2009, 92, 423–432. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013, 4, 1564–1580. [Google Scholar] [CrossRef]

- Madenci, A.B.; Bilgiçli, N. Effect of whey protein concentrate addition on the rheological properties of gluten-free bread dough based on rice and corn flour. Food Hydrocoll. 2014, 35, 168–174. [Google Scholar] [CrossRef]

- Li, W.; Zhang, C.; Wang, X.; Zhang, H. Effects of whey protein concentrate addition on dough rheological characteristics and bread making quality. J. Food Sci. 2020, 85, 1207–1214. [Google Scholar] [CrossRef]

- Day, L.; Augustin, M.A.; Batey, I.L.; Wrigley, C.W. Wheat-gluten uses and industry needs. Trends Food Sci. Technol. 2006, 17, 82–90. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, M.; Du, X.; Chen, Z.; Liu, C.; Zhao, H. Morphological and physicochemical properties of rice starch dry heated with whey protein isolate. Food Hydrocoll. 2020, 109, 106091. [Google Scholar] [CrossRef]

- Madhav, A.N.; Sreekantaiah, H.M. Influence of High Protein on the Rheological Properties, Microstructure and X-Ray Diffraction of Crackers Formulations. Curr. Res. Nutr. Food Sci. 2025, 13, 132–144. [Google Scholar] [CrossRef]

- Hoover, R. Composition, molecular structure, and physicochemical properties of tuber and root starches: A review. Carbohydr. Polym. 2001, 45, 253–267. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Zhao, C.; Liu, Y. The Effect of Protein–Starch Interaction on the Structure and Physicochemical Properties of Oat Starch: XRD and FTIR. Foods 2023, 14, 778. [Google Scholar] [CrossRef]

| Whey Powder (g) | Wheat Flour Type 550 (g) | Yeast (g) | Salt (g) | Sugar (g) | Water (mL) | |

|---|---|---|---|---|---|---|

| WB | - | 100 | 3 | 2 | 1 | 50 |

| WhWB5 | 5 | 95 | 3 | 2 | 1 | 50 |

| WhWB10 | 10 | 90 | 3 | 2 | 1 | 50 |

| WhWB15 | 15 | 85 | 3 | 2 | 1 | 50 |

| Samples | Nutritional Characteristics | ||||

|---|---|---|---|---|---|

| Humidity | Ash | Proteins | Lipids | Carbohydrates | |

| (%) | (%) | (%) | (%) | (g/100 g) | |

| Composite flours | |||||

| WF | 12.70 ± 0.15 a | 0.59 ± 0.04 e | 11.26 ± 0.02 a | 1.35 ± 0.02 a | 74.11 ± 0.11 a |

| WhF | 9.41 ± 0.14 d | 3.01 ± 0.02 a | 85.85 ± 0.03 a | 0.53 ± 0.02 e | 1.21 ± 0.11 e |

| WhWF5 | 12.11 ± 0.21 b | 1.25 ± 0.04 d | 25.24 ± 0.06 d | 0.97 ± 0.02 b | 60.44 ± 0.28 b |

| WhWF10 | 11.59 ± 0.01 c | 1.64 ± 0.03 c | 31.77 ± 0.02 c | 0.84 ± 0.01 c | 54.17 ± 0.02 c |

| WhWF15 | 10.60 ± 0.26 d | 1.77 ± 0.02 b | 37.77 ± 0.10 b | 0.76 ± 0.01 d | 49.10 ± 0.18 d |

| Breads | |||||

| WB | 29.37 ± 0.10 a | 1.33 ± 0.02 b | 14.12 ± 0.04 d | 6.68 ± 0.02 a | 48.49 ± 0.08 a |

| WhWB5 | 28.32 ± 0.24 b | 1.48 ± 0.26 a,b | 16.64 ± 0.03 c | 5.46 ± 0.04 b | 47.96 ± 0.29 b |

| WhWB10 | 27.43 ± 0.03 c | 1.88 ± 0.18 a | 17.01 ± 0.03 b | 4.96 ± 0.03 c | 47.83 ± 0.19 b |

| WhWB15 | 27.03 ± 0.06 d | 2.40 ± 0.16 a | 18.89 ± 0.03 a | 3.47 ± 0.01 d | 48.21 ± 0.15 a |

| Samples | Macro and Microelements Content (mg/kg) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K | Ca | Mg | Zn | Fe | Mn | Cu | Na | Ni | Cr | |

| Composite flours | ||||||||||

| WF | 1388.26 ± 70 d | 337.58 ± 0.50 e | 532.5 ± 1.00 d | 11.18 ± 0.80 b | 11.34 ± 0.90 c | 8.83 ± 0.56 a | 2.64 ± 0.45 c | 40.85 ± 0.37 d | 0.88 ± 0.08 d | 0.60 ± 0.15 a |

| WhF | 2264.54 ± 20 a | 802.69 ± 0.50 a | 510.74 ± 0.40 e | 7.82 ± 0.60 d | 13.46 ± 0.60 a,b | 0.76 ± 0.19 c | 19.33 ± 0.60 a | 111.1 ± 0.67 a | 10.9 ± 0.38 a | 0.84 ± 0.11 a |

| WhWF5 | 1320.78 ± 0.70 e | 438.98 ± 0.40 d | 563.88 ± 0.10 c | 6.52 ± 0.30 e | 7.65 ± 0.20 d | 5.50 ± 0.17 b | 1.55 ± 0.38 d | 38.03 ± 0.38 e | 0.83 ± 0.09 d | 0.69 ± 0.07 a |

| WhWF10 | 1809.25 ± 10 c | 480.10 ± 0.63 c | 671.47 ± 0.80 b | 9.56 ± 0.50 c | 12.26 ± 0.60 b,c | 8.38 ± 0.44 a | 3.45 ± 0.30 c | 48.66 ± 0.57 c | 1.71 ± 0.08 c | 0.66 ± 0.09 a |

| WhWF15 | 1906.19 ± 0.70 ab | 544.78 ± 0.45 b | 702.84 ± 0.70 a | 11.31 ± 0.60 a | 14.23 ± 0.60 a | 8.55 ± 0.30 a | 5.41 ± 0.60 b | 55.56 ± 0.36 b | 2.83 ± 0.33 b | 0.69 ± 0.17 a |

| Fortified Breads | ||||||||||

| WB | 1207.06 ± 0.90 d | 360.28 ± 0.60 d | 530.84 ± 0.40 d | 10.87 ± 0.70 a | 8.49 ± 0.20 b | 5.75 ± 0.65 a | 1.52 ± 0.32 c | 209.18 ± 0.57 c | 0.55 ± 0.28 b | 0.71 ± 0.26 a |

| WhWB5 | 1531.09 ± 50 b | 464.07 ± 0.30 c | 581.75 ± 0.30 a | 9.91 ± 0.10 b | 7.78 ± 0.30 c | 5.32 ± 0.36 a,b | 1.74 ± 0.17 b,c | 221.08 ± 0.34 b | 0.85 ± 0.10 b | 0.68 ± 0.18 a |

| WhWB10 | 1431.19 ± 0.50 c | 475.18 ± 0.60 b | 578.27 ± 0.60 b | 11.45 ± 0.50 a | 10.09 ± 0.20 a | 5.74 ± 0.30 a | 2.38 ± 0.55 a,b | 201.19 ± 0.61 d | 0.78 ± 0.20 b | 0.64 ± 0.14 a |

| WhWB15 | 1542.59 ± 0.70 a | 505.13 ± 0.50 a | 568.08 ± 0.70 c | 16.68 ± 0.40 c | 7.87 ± 0.40 b,c | 4.73 ± 0.50 b | 2.87 ± 0.19 a | 222.85 ± 0.88 a | 1.72 ± 0.15 a | 0.75 ± 0.16 a |

| Indices | M.U. | WB | WhWB5 | WhWB10 | WhWB15 |

|---|---|---|---|---|---|

| Porosity | % | 77.87 ± 0.01 a | 73.22 ± 0.02 b | 72.89 ± 0.04 c | 70.91 ± 0.01 d |

| Elasticity | % | 90.00 ± 6.01 a | 86.53 ± 2.45 a,b | 82.96 ± 0.50 b | 80.95 ± 3.80 b |

| H/D | - | 0.945 ± 0.003 b | 0.885 ± 0.002 c | 0.965 ± 0.04 a | 0.966 ± 0.002 a |

| Samples | Total Polyphenols Content (mg/100 g) | Antioxidant Activity, DPPH (%) |

|---|---|---|

| Composite flours | ||

| WF | 184.98 ± 1.14 e | 28.26 ± 0.44 a |

| WhF | 532.56 ± 2.02 a | 20.54 ± 0.21 e |

| WhWF5 | 230.46 ± 2.87 d | 27.19 ± 0.11 b |

| WhWF10 | 237.37 ± 2.63 c | 26.27 ± 0.15 c |

| WhWF15 | 323.38 ± 2.89 b | 25.57 ± 0.15 d |

| Fortified Breads | ||

| WB | 229.29 ± 1.72 d | 27.25 ± 0.04 a |

| WhWB5 | 254.13 ± 1.15 c | 26.75 ± 0.01 b |

| WhWB10 | 289.13 ± 0.64 b | 25.47 ± 0.01 c |

| WhWB15 | 348.53 ± 0.97 a | 24.18 ± 0.01 d |

| Sample | Median of the Distribution, nm | Surface Equivalent Mean Size, nm | Goodness of Fit |

|---|---|---|---|

| WF | 904 | 88 | 1.00 |

| WhF | 878 | 57 | 1.02 |

| WhWF5 | 897 | 78 | 1.02 |

| WhWF10 | 891 | 70 | 1.00 |

| WhWF15 | 895 | 74 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fluerasu, D.; Neagu, C.; Dossa, S.; Negrea, M.; Jianu, C.; Berbecea, A.; Stoin, D.; Lalescu, D.; Brezovan, D.; Cseh, L.; et al. The Use of Whey Powder to Improve Bread Quality: A Sustainable Solution for Utilizing Dairy By-Products. Foods 2025, 14, 2911. https://doi.org/10.3390/foods14162911

Fluerasu D, Neagu C, Dossa S, Negrea M, Jianu C, Berbecea A, Stoin D, Lalescu D, Brezovan D, Cseh L, et al. The Use of Whey Powder to Improve Bread Quality: A Sustainable Solution for Utilizing Dairy By-Products. Foods. 2025; 14(16):2911. https://doi.org/10.3390/foods14162911

Chicago/Turabian StyleFluerasu (Bălțatu), Diana, Christine Neagu, Sylvestre Dossa, Monica Negrea, Călin Jianu, Adina Berbecea, Daniela Stoin, Dacian Lalescu, Diana Brezovan, Liliana Cseh, and et al. 2025. "The Use of Whey Powder to Improve Bread Quality: A Sustainable Solution for Utilizing Dairy By-Products" Foods 14, no. 16: 2911. https://doi.org/10.3390/foods14162911

APA StyleFluerasu, D., Neagu, C., Dossa, S., Negrea, M., Jianu, C., Berbecea, A., Stoin, D., Lalescu, D., Brezovan, D., Cseh, L., Suba, M., Ianasi, C., & Alexa, E. (2025). The Use of Whey Powder to Improve Bread Quality: A Sustainable Solution for Utilizing Dairy By-Products. Foods, 14(16), 2911. https://doi.org/10.3390/foods14162911