Effects of Pregelatinization on the Physicochemical Properties of Corn Grits and the Quality of Cooked Waxy Corn Wrapped in Plant Leaves

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pregelatinization Process

2.3. Determination of the Pasting Properties of Corn Grits

2.4. Determination of Thermodynamic Properties of Corn Grits

2.5. Determination of Solubility, Swelling Power, and Water-Holding Capacity of Corn Grits

2.6. Determination of Corn Grit Regeneration Degree

2.7. Crystallinity Analysis of Corn Grits

2.8. Determination of Short-Range Orderliness of Corn Grits

2.9. Morphological Analysis of Corn Grits

2.10. Preparation of Cooked Waxy Corn Wrapped in Plant Leaves

2.11. Establishment of Sensory Evaluation Panel

2.12. Sensory Evaluation Methods

2.13. Determination of the Weights of Sensory Evaluation Indicators

2.14. Determination of Gelatinization Degree of Cooked Waxy Corn Wrapped in Plant Leaves

2.15. Determination of Moisture Distribution in Cooked Waxy Corn Wrapped in Plant Leaves

2.16. Pregelatinization Procedure of Cooked Waxy Corn Wrapped in Plant Leaves During Storage

2.17. Data Statistics and Analysis

3. Results and Discussion

3.1. Effect of Pregelatinization Treatment on Physicochemical Properties of Corn Grits

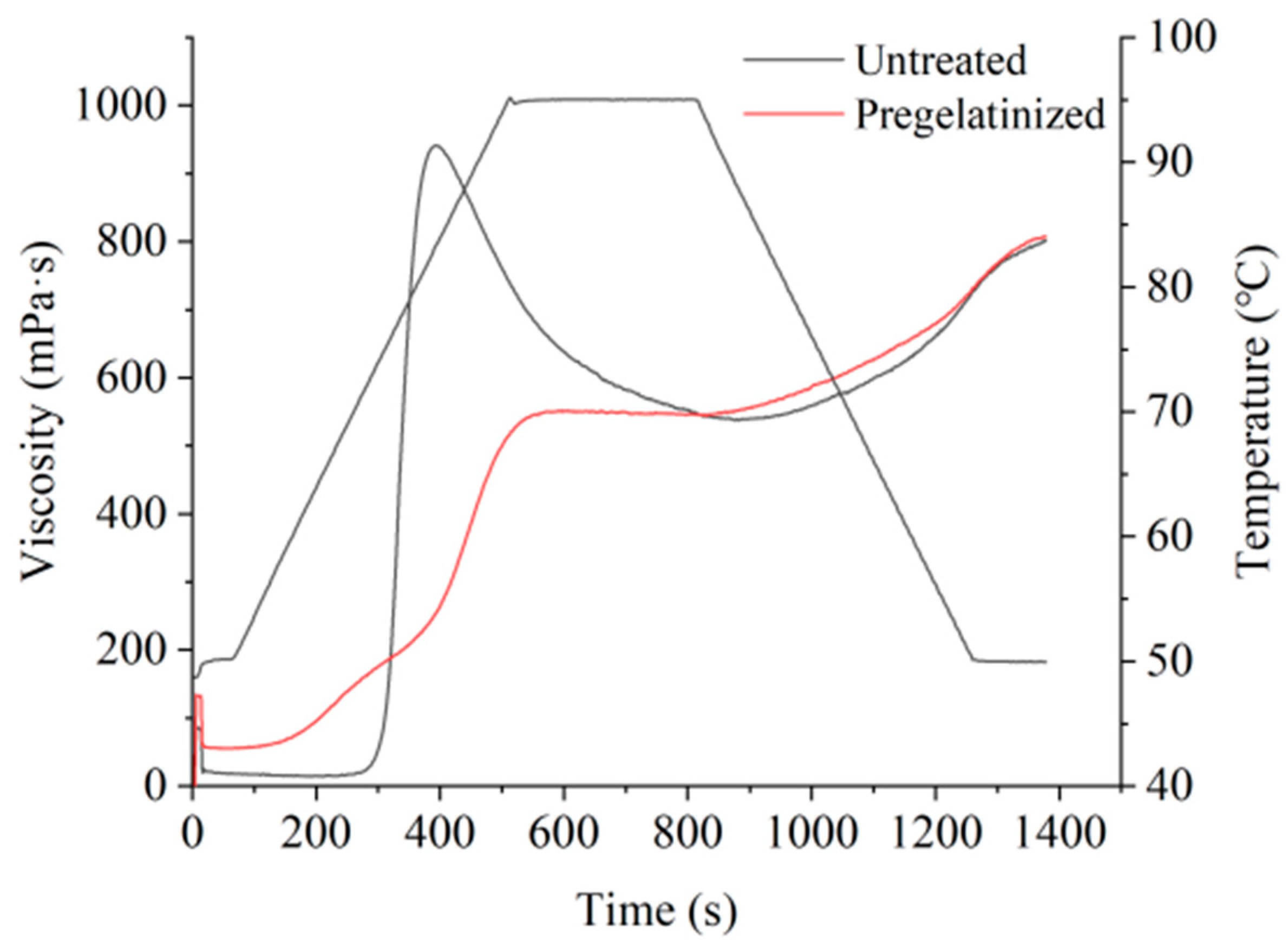

3.1.1. Effect of Pregelatinization Treatment on the Pasting Properties of Corn Grits

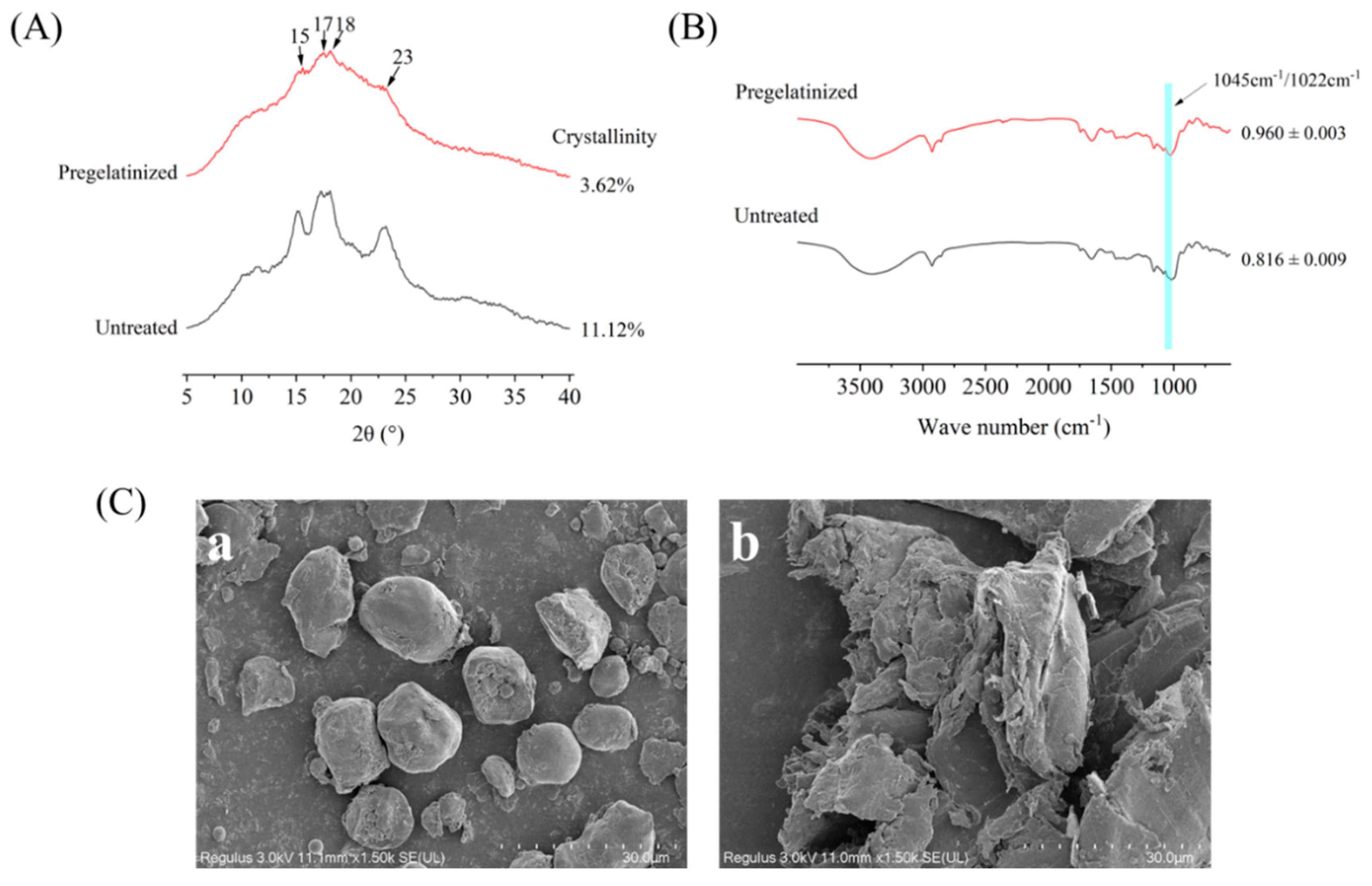

3.1.2. Effect of Pregelatinization Treatment on the Application Properties of Corn Grits

3.1.3. Effect of Pregelatinization Treatment on the Microstructure of Corn Grits

3.2. Effect of Pregelatinization Treatment on the Quality of Cooked Waxy Corn Wrapped in Plant Leaves

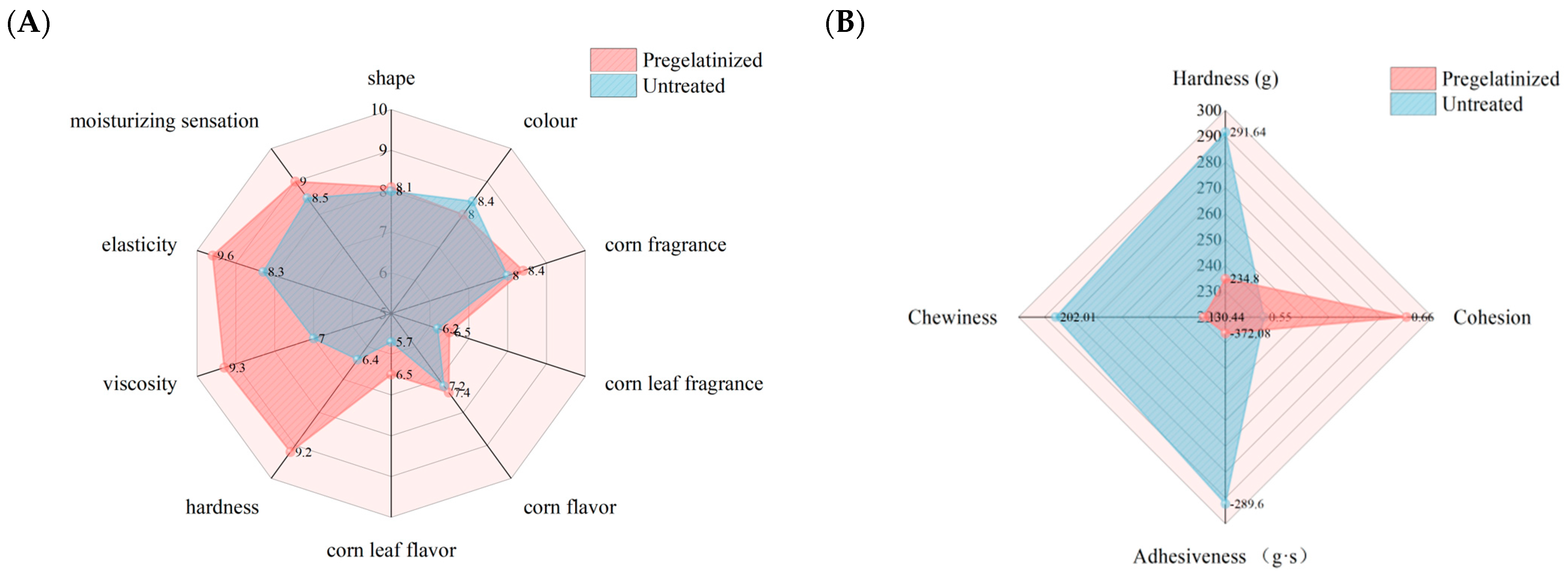

3.2.1. Effect of Pregelatinization Treatment on the Eating Quality of Cooked Waxy Corn Wrapped in Plant Leaves

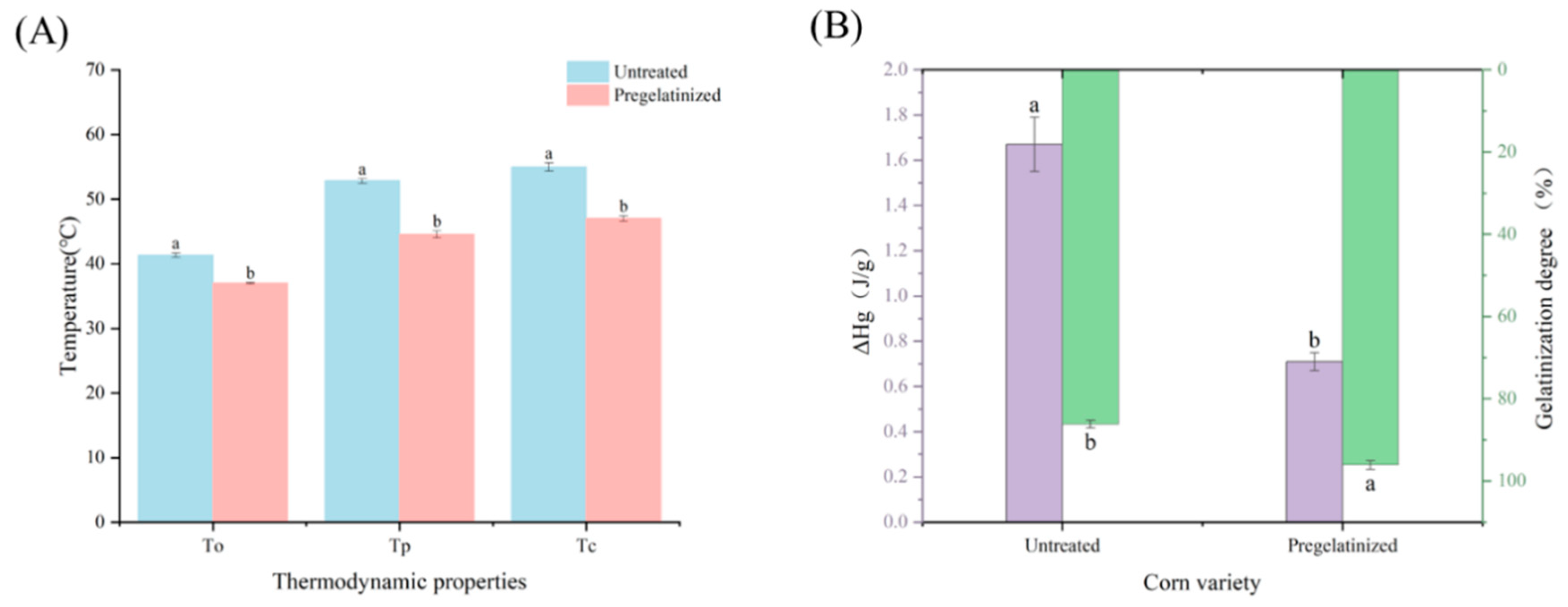

3.2.2. Effect of Pregelatinization Treatment on the Pasting Characteristics of Cooked Waxy Corn Wrapped in Plant Leaves

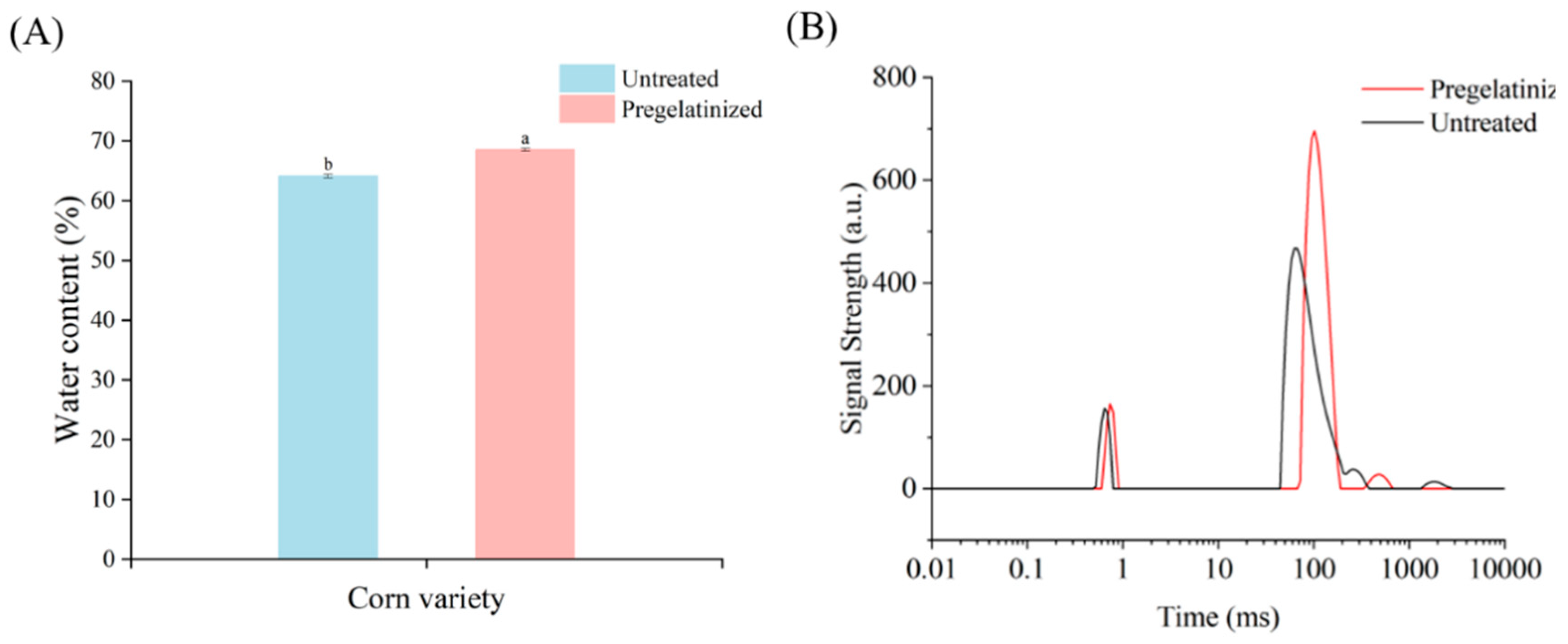

3.2.3. Effect of Pregelatinization Treatment on Moisture Content and Moisture Distribution of Cooked Waxy Corn Wrapped in Plant Leaves

3.3. Effect of Pregelatinization Treatment on the Quality of Cooked Waxy Corn Wrapped in Plant Leaves During Storage

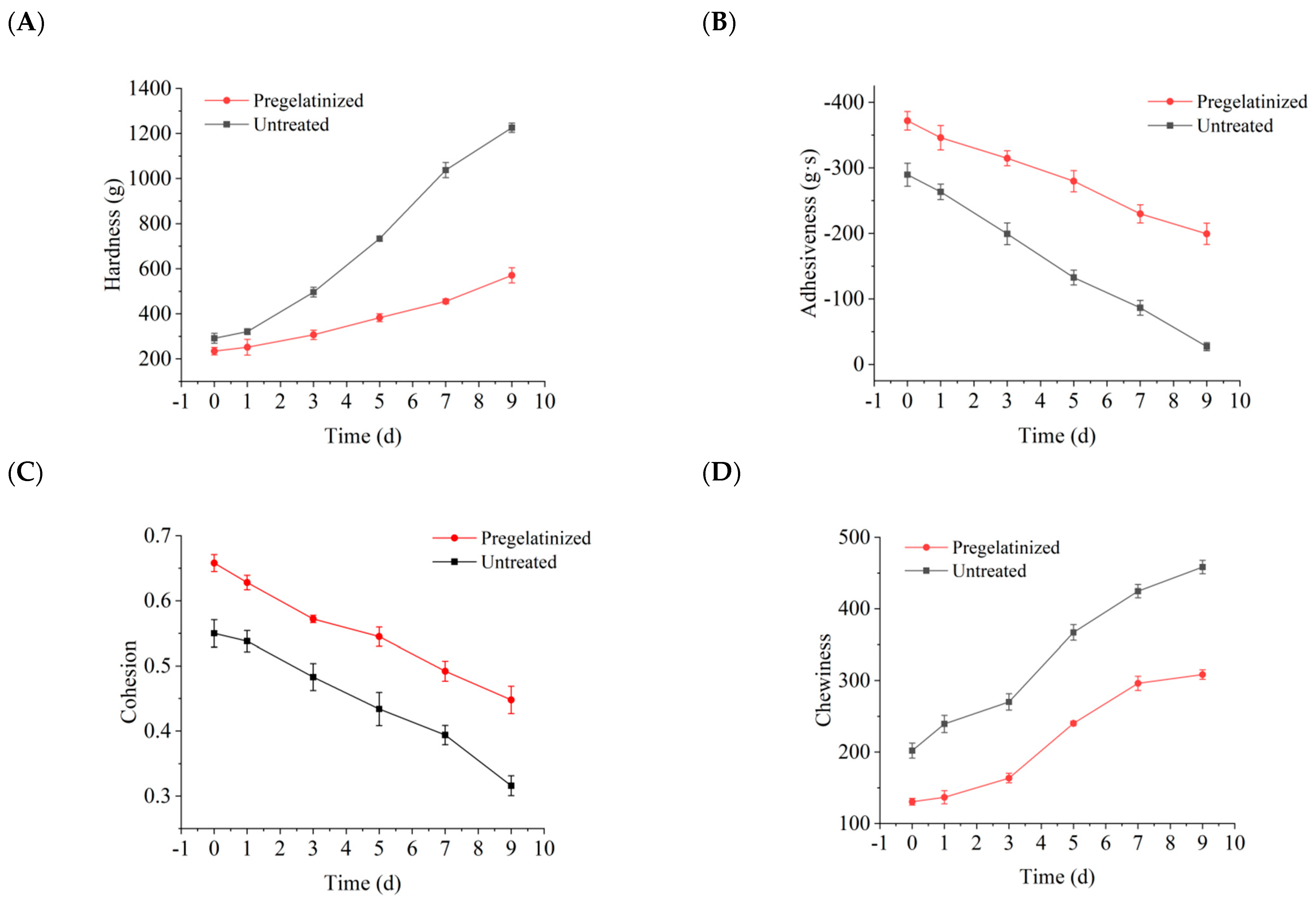

3.3.1. Effect of Pregelatinization on the Textural Characteristics of Cooked Waxy Corn Wrapped in Plant Leaves During Storage

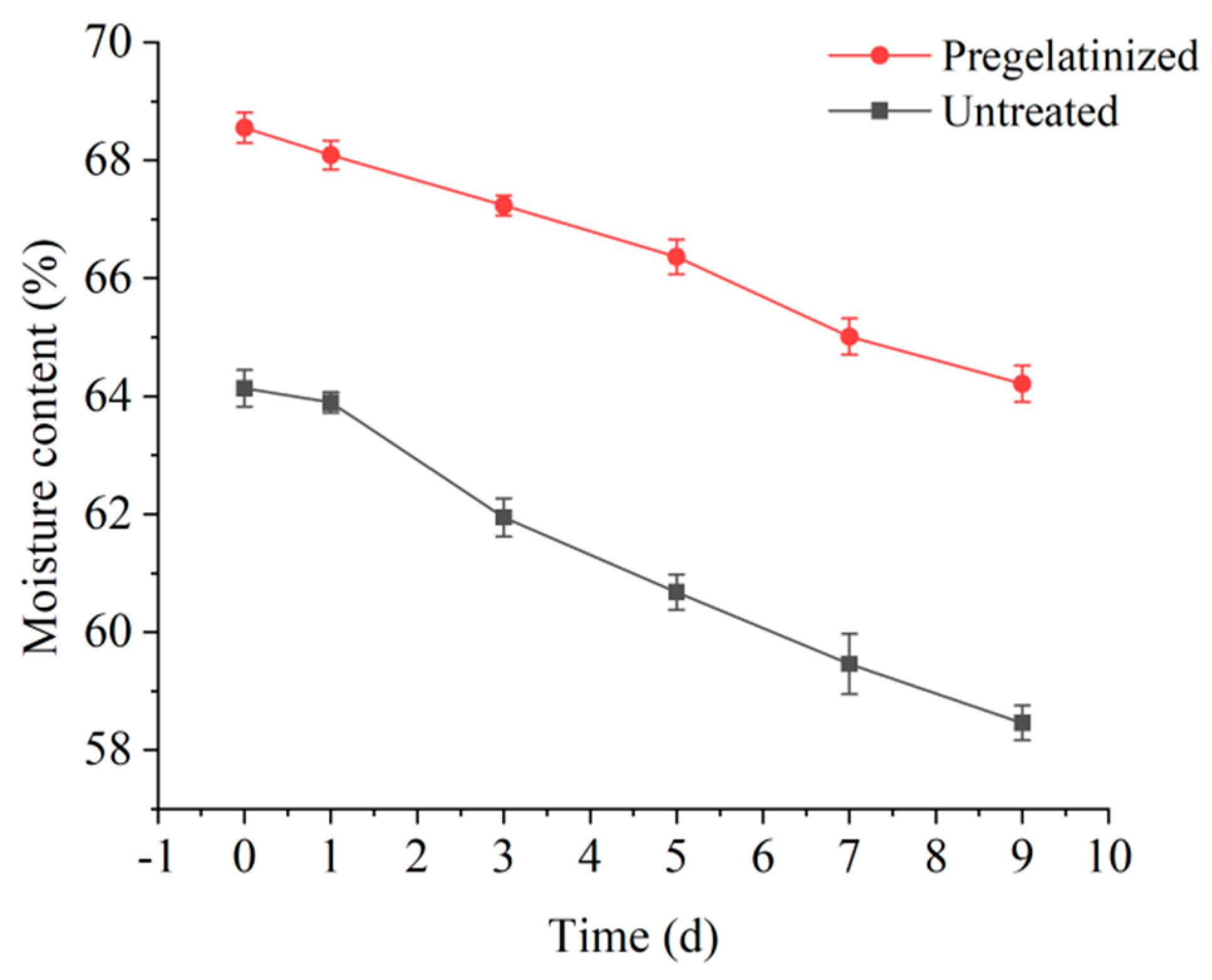

3.3.2. Effect of Pregelatinization Treatment on the Moisture Content of Cooked Waxy Corn Wrapped in Plant Leaves During Storage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. FAOSTAT: Crops and Livestock Products; Food and Agriculture Organization of the United Nations: Rome, Italy, 2023. [Google Scholar]

- Sheng, S.; Tong, L.; Liu, R. Corn Phytochemicals and Their Health Benefits. Food Sci. Hum. Wellness 2018, 7, 185–195. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook; China Statistics Press: Beijing, China, 2023.

- Huang, B.; Zhao, G.; Zou, X.; Cheng, X.; Li, S.; Yang, L. Feasibility of Replacing Waxy Rice with Waxy or Sweet-Waxy Corn Viewed from the Structure and Physicochemical Properties of Starches. Food Res. Int. 2024, 182, 114178. [Google Scholar] [CrossRef]

- Pineda-Gomez, P.; Acosta-Osorio, A.A.; Coral, D.F.; Rosales-Rivera, A.; Sanchez-Echeverri, L.A.; Rojas-Molina, I.; Rodriguez-Garcia, M.E. Physicochemical Characterization of Traditional and Commercial Instant Corn Flours Prepared with Threshed White Corn. CYTA-J. Food 2012, 10, 287–295. [Google Scholar] [CrossRef]

- Lee, D.J.; Choi, S.M.; Lim, S.T. Effect of Hydrothermal and Enzymatic Treatments on the Physicochemical Properties of Waxy Maize Flour. Korean J. Food Sci. Technol. 2016, 48, 165–171. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Carrillo-Navas, H.; Vernon-Carter, E.J.; Alvarez-Ramirez, J. Rheological and Thermal Properties of Dough and Textural and Microstructural Features of Bread Obtained from Nixtamalized Corn/Wheat Flour Blends. J. Cereal Sci. 2016, 69, 158–165. [Google Scholar] [CrossRef]

- Vanessa Calderon-Peralta, C.; Jimenez-Hernandez, J.; Ixchel Maldonado-Astudillo, Y.; Flores-Casamayor, V.; Arambula-Villa, G.; Salazar, R. Influence of Hymenaea Courbaril Gum as a New Additive on Nixtamalized Flour Properties and Quality of Tortilla. J. Food Process Eng. 2017, 40, e12525. [Google Scholar] [CrossRef]

- Sophia, L.; Angel, L.G.; Malissa, K.; Assad, A.-A.; Dipak, R.; Vic, R. Performance Evaluation of Maltogenic Amylases on Nixtamalized Corn Flour Tortilla. Cereal Chem. 2024, 101, 554–562. [Google Scholar] [CrossRef]

- Lu, S.; Li, J.; Xu, M.; Mu, Y.; Wen, Y.; Li, H.; Wang, J.; Sun, B. The Textural Properties of Cooked Convenience Rice upon Repeated Freeze–Thaw Treatments Are Largely Affected by Water Mobility at Grain Level. Food Res. Int. 2023, 163, 112254. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Chen, X.; Zhang, X.; Dai, Q.; Wei, H. Comparisons of Rice Taste and Starch Physicochemical Properties in Superior and Inferior Grains of Rice with Different Taste Value. Food Res. Int. 2023, 169, 112886. [Google Scholar] [CrossRef]

- Liu, H.-M.; Liu, C.; Yang, H.-S.; Ma, S. Influence of Cellular Structure, and Non-Starch Components, on the Functional Properties of Starch in Plant-Derived Foods: Editorial. Int. J. Food Sci. Technol. 2023, 58, 4860–4861. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, L.; Li, D.; Adhikari, B. Effects of Partial Gelatinization on Structure and Thermal Properties of Corn Starch after Spray Drying. Carbohydr. Polym. 2012, 88, 1319–1325. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, X.; Gu, Z.; Hong, Y.; Li, Z.; Li, C.; Ban, X. Effects of Different Gelatinization Degrees of Starch in Potato Flour on the Quality of Steamed Bread. Int. J. Biol. Macromol. 2022, 209, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Sun, B.; Gu, Y.; Ma, S.; Wang, X. Enhancing the Quality of Steamed Oat Cake by Partially Gelatinized Starch in Oat Flour and Its Molecular Mechanism. Int. J. Biol. Macromol. 2023, 238, 124139. [Google Scholar] [CrossRef]

- Zhu, D.; Fang, C.; Qian, Z.; Guo, B.; Huo, Z. Differences in Starch Structure, Physicochemical Properties and Texture Characteristics in Superior and Inferior Grains of Rice Varieties with Different Amylose Contents. Food Hydrocoll. 2021, 110, 106170. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Tarzi, B.G.; Asghari, M. Effect of Pre-Gelatinized Wheat Starch on Physical and Rheological Properties of Shortened Cake Batter and Cake Texture. Eng. Technol. Appl. Sci. Res. 2016, 6, 1162–1166. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, H.; Chen, F.; Tong, P.; Cao, W.; Jiang, Y. Study on Structural Changes of Starches with Different Amylose Content during Gelatinization Process. Starch/Staerke 2022, 74, 2100269. [Google Scholar] [CrossRef]

- Wu, J.; Xu, S.; Huang, Y.; Zhang, X.; Liu, Y.; Wang, H.; Zhong, Y.; Bai, L.; Liu, C. Prevents Kudzu Starch from Agglomeration during Rapid Pasting with Hot Water by a Non-Destructive Superheated Steam Treatment. Food Chem. 2022, 386, 132819. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Liu, X.; Ke, Z.; Yang, J.; Li, Y.; Xie, X.; Li, L. Insight into the Improvement in Pasting and Gel Properties of Waxy Corn Starch by Critical Melting Treatments. Int. J. Biol. Macromol. 2023, 253, 127285. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, R.; Hou, X.; Zhuang, X.; Wu, H.; Yin, D.; Yang, Y. Structural and Physicochemical Properties of Microwave-Processing Pregelatinized Maize Starch, and Its Influence on Drug Release from Tablets. J. Drug Deliv. Sci. Technol. 2023, 84, 104452. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Zhu, F. Physicochemical Properties of Quinoa Starch. Carbohydr. Polym. 2016, 137, 328–338. [Google Scholar] [CrossRef]

- Temsiripong, T.; Pongsawatmanit, R.; Ikeda, S.; Nishinari, K. Influence of Xyloglucan on Gelatinization and Retrogradation of Tapioca Starch. Food Hydrocoll. 2005, 19, 1054–1063. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Ban, X.; Gu, Z. A Study on the Correlation between the Edible Quality and Starch Properties of Fresh Glutinous Corn. J. Food Biotechnol. 2023, 42, 43–52. [Google Scholar]

- Bie, P.; Li, X.; Xie, F.; Chen, L.; Zhang, B.; Li, L. Supramolecular Structure and Thermal Behavior of Cassava Starch Treated by Oxygen and Helium Glow-Plasmas. Innov. Food Sci. Emerg. Technol. 2016, 34, 336–343. [Google Scholar] [CrossRef]

- Dai, D.; Sun, S.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Structural and Functional Characteristics of Butyrylated Maize Starch. LWT–Food Sci. Technol. 2019, 112, 108254. [Google Scholar] [CrossRef]

- GB/T 16291.1-2012; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, & Standardization Administration of China. Sensory Analysis—General Guidance for the Selection, Training and Monitoring of Assessors—Part 1: Selected Assessors. China Standards Press: Beijing, China, 2012.

- Kreutzmann, S.; Thybo, A.K.; Bredie, W.L.P. Training of a Sensory Panel and Profiling of Winter Hardy and Coloured Carrot Genotypes. Food Qual. Prefer. 2006, 18, 482–489. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Zhang, B.; Dhital, S.; Haque, E.; Gidley, M.J. Preparation and Characterization of Gelatinized Granular Starches from Aqueous Ethanol Treatments. Carbohydr. Polym. 2012, 90, 1587–1594. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Sharma, S.; Sharma, R.; Gupta, A.; Kumar, R. Influence of Pre-Gelatinization in Conjunction with Guar Gum Addition on Texture Functionality, Bioactive Profile, In Vitro Nutrient Digestibility, Morphology and Secondary Structure of Protein of Quality Protein Maize Pasta. Int. J. Food Sci. Technol. 2023, 58, 3448–3457. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Obadi, M.; Jiang, Y.; Chen, Z.; Jiang, S.; Xu, B. Effect of Steaming and Defatting Treatments of Oats on the Processing and Eating Quality of Noodles with a High Oat Flour Content. J. Cereal Sci. 2019, 89, 102794. [Google Scholar] [CrossRef]

- Shang, J.; Li, L.; Zhao, B.; Liu, M.; Zheng, X. Comparative Studies on Physicochemical Properties of Total, A- and B-Type Starch from Soft and Hard Wheat Varieties. Int. J. Biol. Macromol. 2020, 154, 714–723. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, W.; Pan, Y.; Ali, B.; Xu, D.; Xu, X. Physicochemical, Crystalline Characterization and Digestibility of Wheat Starch under Superheated Steam Treatment. Food Hydrocoll. 2021, 118, 106720. [Google Scholar] [CrossRef]

- Lang, S.; Gao, F.; Li, X.; Liu, Y.; Zhang, H.; Wang, L. Effect of Different Pre-Gelatinization Treatments on the Properties of Acidified Mung Bean Starch. Starch/Staerke 2023, 75, 2200211. [Google Scholar] [CrossRef]

- Zhang, C.-W.; Li, F.-Y.; Li, J.-F.; Li, Y.-L.; Xu, J.; Xie, Q.; Chen, S.; Guo, A.-F. Novel Treatments for Compatibility of Plant Fiber and Starch by Forming New Hydrogen Bonds. J. Clean. Prod. 2018, 185, 357–365. [Google Scholar] [CrossRef]

- Sun, X.; Li, W.; Hu, Y.; Zhou, X.; Ji, M.; Yu, D.; Fujita, K.; Tatsumi, E.; Luan, G. Comparison of Pregelatinization Methods on Physicochemical, Functional and Structural Properties of Tartary Buckwheat Flour and Noodle Quality. J. Cereal Sci. 2018, 80, 63–71. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, X.; Zhang, L.; Hong, Y.; Zhang, G.; Lyu, F. Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean. Foods 2022, 11, 171. [Google Scholar] [CrossRef]

| Corn Grits Sample | Gelatinization Temp (°C) | Peak Viscosity (mPa·s) | Trough Viscosity (mPa·s) | Final Viscosity (mPa·s) | Breakdown (mPa·s) | Setback (mPa·s) |

|---|---|---|---|---|---|---|

| Untreated | 72.90 ± 0.53 a | 941.60 ± 10.08 a | 538.42 ± 6.13 a | 801.40 ± 7.38 a | 403.83 ± 17.85 d | 274.83 ± 5.22 a |

| Pregelatinized | 66.30 ± 0.24 b | 552.71 ± 11.81 a | 544.70 ± 8.54 a | 807.60 ± 8.47 a | 8.20 ± 2.47 b | 154.52 ± 3.04 b |

| Corn Grits Sample | To (°C) | Tp (°C) | Tc (°C) | ΔHg (J/g) |

|---|---|---|---|---|

| Untreated | 69.29 ± 0.47 a | 77.86 ± 1.33 a | 85.72 ± 3.74 a | 9.66 ± 0.14 a |

| Pregelatinized | 45.35 ± 0.33 b | 55.74 ± 0.30 b | 56.30 ± 0.18 b | 2.27 ± 0.09 b |

| Corn Grits Sample | 95 °C | ||

|---|---|---|---|

| Solubility (%) | Swelling Power (g/g) | Water-Holding Capacity (g/g) | |

| Untreated | 20.10 ± 0.71 b | 21.91 ± 0.76 b | 19.17 ± 0.45 b |

| Pregelatinized | 28.80 ± 0.28 a | 31.15 ± 0.50 a | 23.18 ± 1.15 a |

| Corn Grits Sample | To (°C) | Tp (°C) | Tc (°C) | ΔHr (J/g) | RD (%) |

|---|---|---|---|---|---|

| Untreated | 41.33 ± 0.43 b | 55.70 ± 0.72 a | 65.56 ± 1.55 a | 5.42 ± 0.16 a | 56.06 |

| Pregelatinized | 43.58 ± 0.63 a | 56.33 ± 0.19 a | 63.76 ± 0.34 a | 1.03 ± 0.07 b | 45.26 |

| Corn Grits Sample | T21 (ms) | M21 (%) | T22 (ms) | M22 (%) | T23 (ms) | M23 (%) |

|---|---|---|---|---|---|---|

| Untreated | 0.474 ± 0.030 b | 7.10 ± 0.62 b | 46.342 ± 0.405 b | 82.34 ± 0.51 b | 225.624 ± 6.485 b | 4.87 ± 0.04 b |

| Pregelatinized | 0.602 ± 0.012 a | 9.45 ± 0.50 a | 68.020 ± 0.413 b | 91.94 ± 0.57 a | 315.325 ± 8.413 b | 1.69 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, R.; Yan, Y.; Niu, W.; Wang, Y.; Shen, M.; Wang, R.; Cheng, L. Effects of Pregelatinization on the Physicochemical Properties of Corn Grits and the Quality of Cooked Waxy Corn Wrapped in Plant Leaves. Foods 2025, 14, 2287. https://doi.org/10.3390/foods14132287

Wang Y, Li R, Yan Y, Niu W, Wang Y, Shen M, Wang R, Cheng L. Effects of Pregelatinization on the Physicochemical Properties of Corn Grits and the Quality of Cooked Waxy Corn Wrapped in Plant Leaves. Foods. 2025; 14(13):2287. https://doi.org/10.3390/foods14132287

Chicago/Turabian StyleWang, Yi, Ruixuan Li, Yijiao Yan, Wanyi Niu, Yue Wang, Mingyi Shen, Ruifang Wang, and Li Cheng. 2025. "Effects of Pregelatinization on the Physicochemical Properties of Corn Grits and the Quality of Cooked Waxy Corn Wrapped in Plant Leaves" Foods 14, no. 13: 2287. https://doi.org/10.3390/foods14132287

APA StyleWang, Y., Li, R., Yan, Y., Niu, W., Wang, Y., Shen, M., Wang, R., & Cheng, L. (2025). Effects of Pregelatinization on the Physicochemical Properties of Corn Grits and the Quality of Cooked Waxy Corn Wrapped in Plant Leaves. Foods, 14(13), 2287. https://doi.org/10.3390/foods14132287