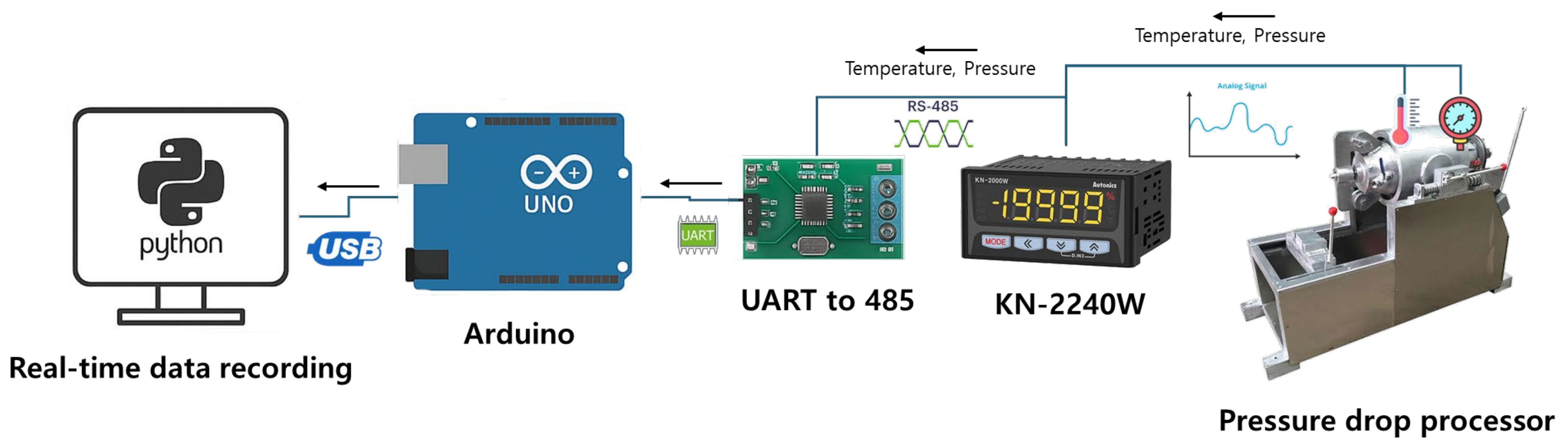

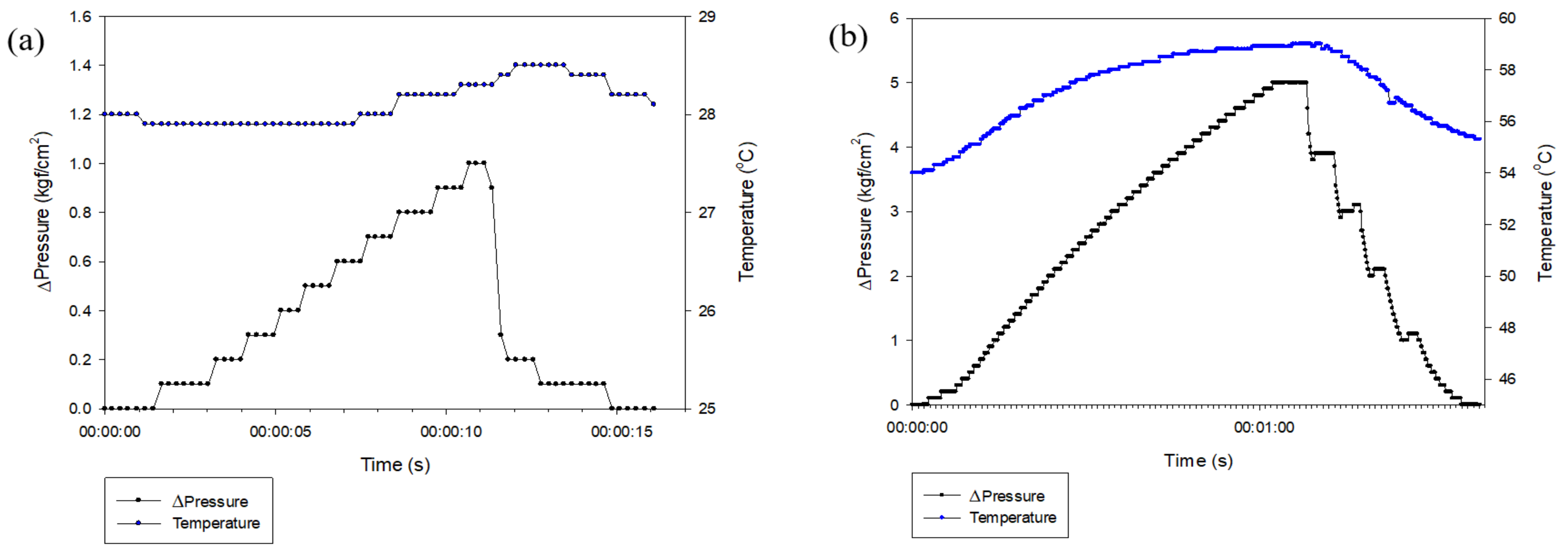

3.1. Pressure Drop Process

A record of the pressure drop over time is shown in

Figure 4. The PDA is forced to drop the pressure through the entrance, so it decreases very rapidly at the beginning and decreases relatively slowly from 0.3 kgf/cm

2 to reach atmospheric pressure. The temperature increases as pressure is applied and decreases as it drops, and the temperature difference during the drop is within 0.6–0.8 °C. The PDB used a locking valve to reduce the pressure. Therefore, the rate of pressure reduction was adjustable. When the pressure was high, the rate of decrease was rapid, and as the pressure difference decreased, the rate of decrease slowed. We also found that immediately after stopping the pressure drop, the decreasing pressure increased by 0.1–0.2 kgf/cm

2. This suggests that the pressure inside the pressure chamber after a rapid pressure drop was not constant but fluctuated. Such internal pressure fluctuations may induce cavitation, particularly in the PDB process, where repeated pressure changes occur, unlike the single pressure drop in the PDA. In addition, because PDB starts from a higher initial pressure than PDA, it is presumed that greater structural modifications may occur during the treatment.

Although PDB showed a greater temperature change compared to PDA, with a difference of 4–5 °C at a maximum pressure of 5 kgf/cm2, its thermal stability was lower than that of PDA, which may be disadvantageous in thermal processes. However, when used in nonthermal applications, this difference is expected to have minimal impact.

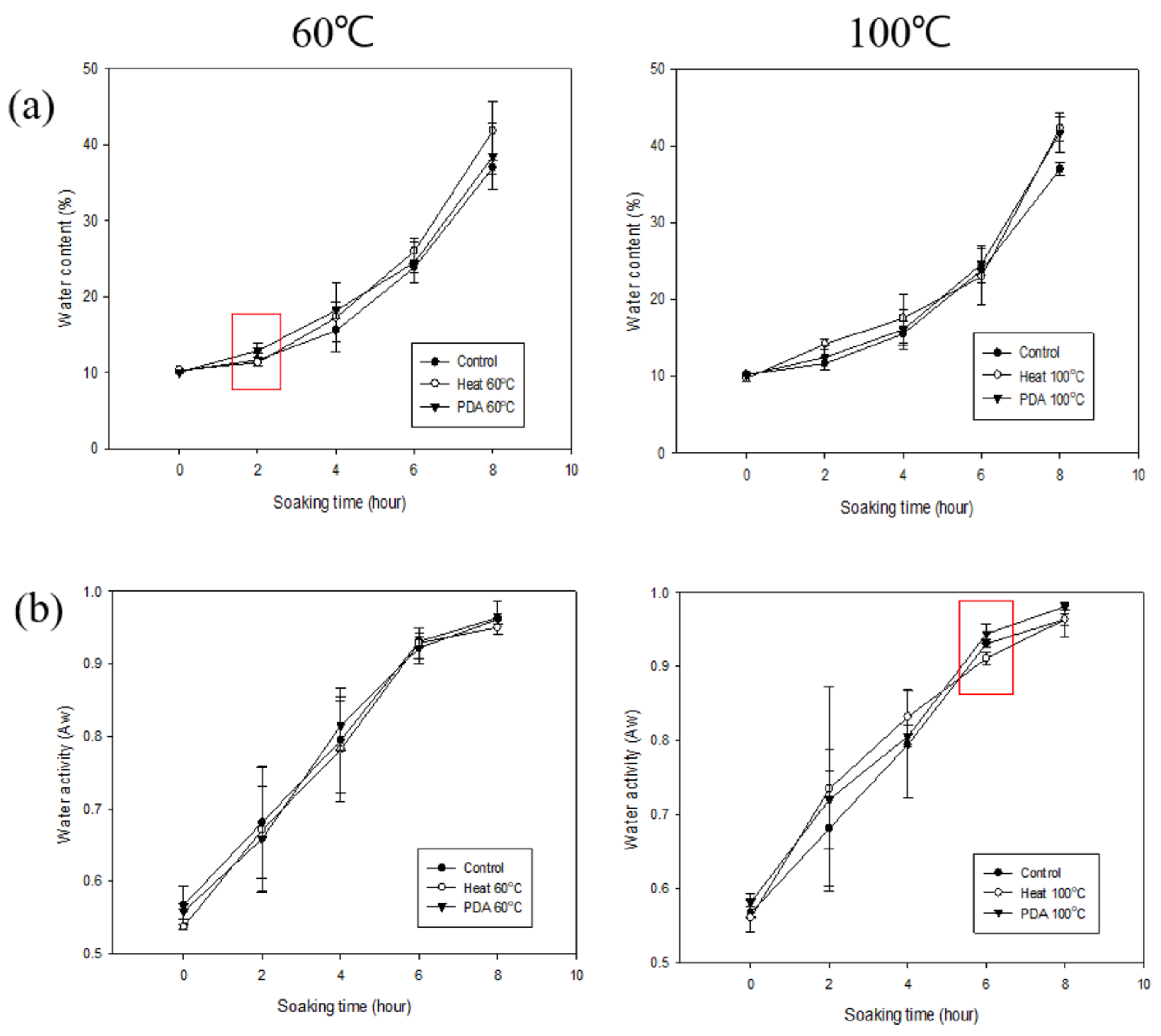

3.5. Moisture Content and Water Activity of PDA-Treated Adzuki Beans Under Different Conditions

Since the hilum damage to the PDA-treated adzuki beans at 100 °C increased, we performed an experiment to determine whether soaking was effective. The PDA treatment conditions were repeated 20 times at 25, 60, and 100 °C for 20 min each. For comparison, the heat treatment was performed at 60 and 100 °C for 20 min each. The water content and activity of adzuki beans soaked for 0–8 h after pretreatment were investigated (

Figure 8). The moisture content of the control group was 10.21 ± 0.27%, 11.58 ± 0.80%, 15.55 ± 1.56%, 24.12 ± 0.82%, and 37.20 ± 0.94% at 0, 2, 4, 6, and 8 h of soaking, respectively (

Table 3). In the 100 °C heat-treated group, the moisture content was 14.19 ± 3.17% at 2 h, which was significantly higher than that of the control. In the 60 °C PDA-treated group, the moisture content was 12.91 ± 0.91% at 2 h, which was significantly higher than that of the 60 °C heat-treated group. The water activity of the control group increased gradually over time, reaching 0.9637 ± 0.0233 at 8 h (

Table 4). In the 100 °C PDA-treated group, the water activity at 6 h (0.9443 ± 0.0131) was significantly higher than that of the 100 °C heat-treated group at the same time point. Although most of the results were not significantly different from those of the control group, the PDA-treated adzuki beans exhibited a slightly faster soaking rate than the heat-treated beans at the same temperature. However, PDA treatment at 100 °C did not lead to a clear improvement in hydration, despite increasing hilum damage. This aligns with our earlier observation that excessive hilum damage may reduce water absorption efficiency. Therefore, the structural alterations caused by the high-intensity PDA treatment may have compromised the internal matrix of the adzuki bean, hindering, rather than enhancing, water uptake.

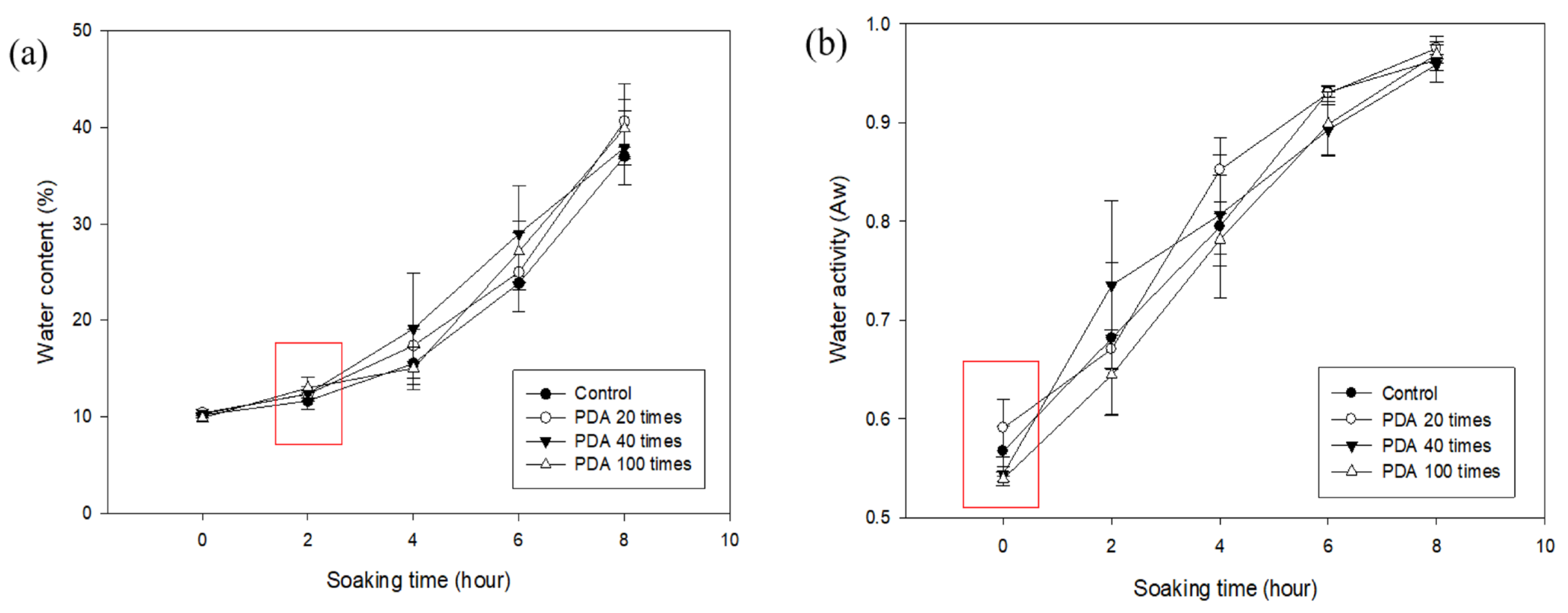

The moisture content and water activity of the adzuki beans treated with PDA (25 °C, 20, 40, 100 times) and the control group are shown in

Figure 9,

Table 5 and

Table 6. The beans treated with PDA 100 times had a moisture content of 13.02 ± 1.08% at 2 h soaking, which was significantly higher than the control. The water activity for this PDA treatment ranged from 0.5390 ± 0.0071 (0 h) to 0.9693 ± 0.0092 (8 h) and was not significantly different from the control, but it was significantly lower than the value following the treatment conducted 20 times. The PDA 100-time treatment enhanced the initial moisture absorption at 2 h but showed no sustained effect over longer soaking times (4–8 h), suggesting that structural changes caused by the PDA may limit prolonged moisture uptake. The lower water activity in the PDA 100-time treatment compared to the 20-time treatment indicates increased moisture evaporation due to the repeated pressure drops, which enhances drying. However, it did not significantly affect the soaking efficiency compared to the control. The PDA 100-time treatment slightly improved the early moisture absorption, but excessive treatments (more than 40 times) increased the drying without enhancing the long-term soaking efficiency. Optimizing the PDA for 40 or fewer cycles may be more effective.

Table 6.

Water activity of untreated and PDA-treated (20, 40, and 100 times) adzuki beans.

Table 6.

Water activity of untreated and PDA-treated (20, 40, and 100 times) adzuki beans.

| Soaking Time (h) | Water Activity (Aw) |

|---|

| Control | PDA 20 Times | PDA 40 Times | PDA 100 Times |

|---|

| 0 | 0.5671 ± 0.0258 ab | 0.5906 ± 0.0294 b | 0.5438 ± 0.0079 a | 0.5390 ± 0.0071 a |

| 2 | 0.6812 ± 0.0773 a | 0.6704 ± 0.0197 a | 0.7352 ± 0.0858 a | 0.6442 ± 0.0407 a |

| 4 | 0.7945 ± 0.0727 a | 0.8522 ± 0.0329 a | 0.8067 ± 0.0403 a | 0.7815 ± 0.0268 a |

| 6 | 0.9310 ± 0.0054 a | 0.9298 ± 0.0083 a | 0.8927 ± 0.0249 a | 0.8984 ± 0.0324 a |

| 8 | 0.9637 ± 0.0233 a | 0.9752 ± 0.0062 a | 0.9588 ± 0.0055 a | 0.9693 ± 0.0092 a |

3.6. Moisture Content and Water Activity of PDB-Treated Adzuki Beans Under Different Conditions

The results of the experiment that was performed to investigate the difference in the moisture content of PDB-treated adzuki beans at maximum pressures of 3, 5, and 7 kgf/cm

2 are shown in

Figure 10,

Table 7 and

Table 8.

The maximum pressure of the PDB, which was pressurized to the maximum pressure and then lowered by 1 kgf/cm2 to stop at atmospheric pressure, was 3, 5 and 7 kgf/cm2. The moisture contents of the adzuki beans treated with PDB at 3 kgf/cm2 were 9.77 ± 0.27% (0 h), 11.96 ± 1.59% (2 h), 14.23 ± 1.53% (4 h), 24.73 ± 1.91% (6 h), and 40.96 ± 3.61% (8 h). All the values were significantly lower than the control at 0 h. The respective values at 0, 2, 4, 6, and 8 h for the beans treated with PDB 7 kgf/cm2 were 10.00 ± 0.07%, 10.26 ± 0.68%, 14.41 ± 2.55%, 23.94 ± 2.07%, and 37.80 ± 3.48%. These values were similar to the control values but significantly lower than PDB 3 kgf/cm2 at 2 h.

The water activity values for the adzuki beans treated with PDB 3 kgf/cm2 at 0, 2, 4, 6, and 8 h were 0.5335 ± 0.0122, 0.7076 ± 0.1036, 0.8414 ± 0.0560, 0.9371 ± 0.0175, and 0.9704 ± 0.0042. These values were significantly lower than the control at 0 h. For the beans treated with PDB 7 kgf/cm2, the water activity values at the same respective times were 0.5154 ± 0.0048, 0.7144 ± 0.0264, 0.7933 ± 0.0330, 0.8762 ± 0.0356, and 0.9682 ± 0.0144. These values were significantly lower than the control at 0 and 6 h. Both the moisture content and water activity values were generally lower than the control in the beans treated with PDB 7 kgf/cm2. The findings suggest the absence of a soaking effect. Treatment with PDB 3 kgf/cm2 was lower than that of the control at 0 h of soaking because it was not possible to form a structure that could better absorb moisture. Therefore, only moisture near the surface was allowed to evaporate. The lack of enhanced moisture absorption in the adzuki beans treated with 7 kgf/cm2 PDB may be attributed to excessive structural damage or compaction of the seed coat and hilum. The higher pressure could have caused overcompression or collapse of the porous network within the bean, limiting water penetration. Based on these results, 5 kgf/cm2 is considered an appropriate level for PDB implementation, and treatment with PDB 10 times at 25 °C did not have a significant effect on soaking.

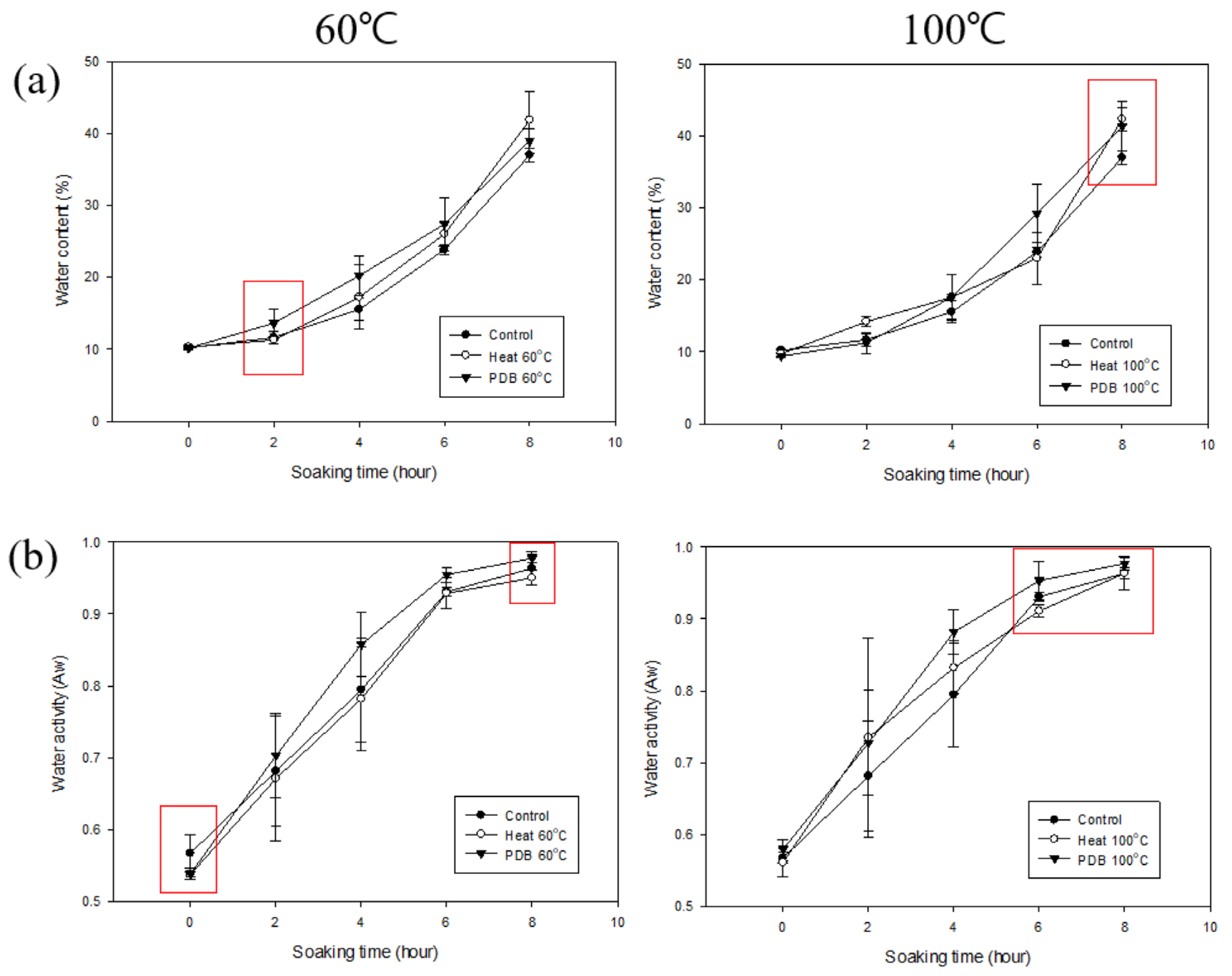

Since PDB at 25 °C was ineffective for soaking, experiments were performed to determine the effect of PDB treatment at different temperatures. The PDB treatment conditions were 25, 60, and 100 °C for 20 min each, with 10 repetitions. Heat treatment at 60 and 100 °C for 20 min was carried out for comparison (

Figure 11).

The moisture content of the adzuki beans heat-treated at 60 °C was 10.33 ± 0.26% (0 h), 11.31 ± 0.08% (2 h), 17.25 ± 4.50% (4 h), 26.00 ± 1.64% (6 h), and 41.84 ± 3.94% (8 h). All the values were significantly higher than the control at 8 h (

Table 9). The values for the 100 °C heat treatment were 9.75 ± 0.43% (0 h), 14.19 ± 3.17% (2 h), 17.58 ± 3.17% (4 h), 23.01 ± 3.61% (6 h), and 42.31 ± 1.59% (8 h). These values were significantly higher than the control at 2 and 8 h. The values for the PDB treatment at 60 °C were 10.18 ± 0.16% (0 h), 13.64 ± 1.89% (2 h), 20.22 ± 2.75% (4 h), 27.40 ± 3.65% (6 h), and 38.95 ± 1.71% (8 h). These values were significantly different from the control at 2 h. Finally, the values for the PDB treatment at 100 °C were 9.40 ± 0.26% (0 h), 11.24 ± 1.50% (2 h), 17.58 ± 3.07% (4 h), 29.21 ± 4.04% (6 h), and 41.33 ± 3.43% (8 h). These values were significantly lower than the control at 0 h, higher at 8 h, and higher than the 100 °C heat-treated beans at 6 h.

The water activity of the adzuki beans heat-treated at 60 °C was 0.5374 ± 0.0040 (0 h), 0.6709 ± 0.0865 (2 h), 0.7821 ± 0.0720 (4 h), 0.9288 ± 0.0213 (6 h), and 0.9502 ± 0.0100 (8 h). All the values were significantly lower than the control at 0 h (

Table 10). The values following the heat treatment with PDB at 60 °C were 0.5385 ± 0.0074 (0 h), 0.7027 ± 0.0586 (2 h), 0.8578 ± 0.0452 (4 h), 0.9548 ± 0.0106 (6 h), and 0.9775 ± 0.0058 (8 h). The values were lower than the control at 0 h but higher at 8 h, and higher than those of the 60 °C heat treatment. The values following the treatment with PDB at 100 °C were 0.5792 ± 0.0043 (0 h), 0.7275 ± 0.0730 (2 h), 0.8819 ± 0.0309 (4 h), 0.9534 ± 0.0270 (6 h), and 0.9773 ± 0.0085 (8 h). These values were significantly higher than the control at 8 h and higher than 100 °C heat treatment at 6 h.

Based on the moisture content and water activity findings, PDB treatment appears more effective for soaking than treatments at 60 and 100 °C.

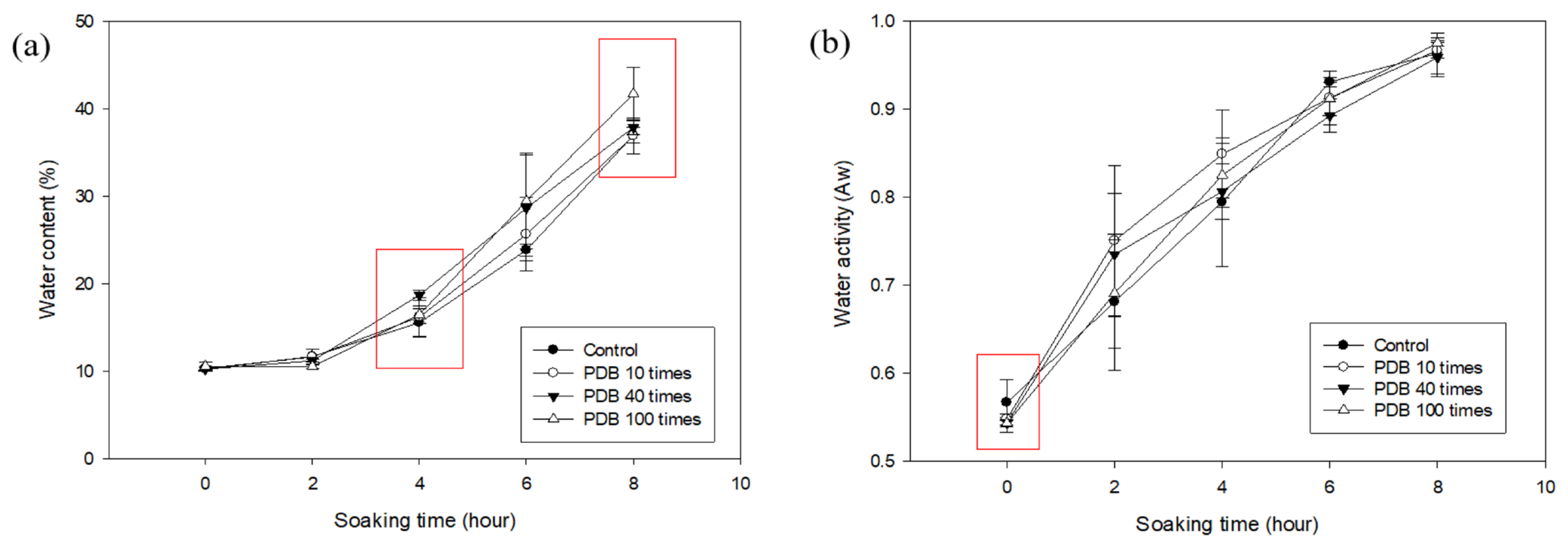

The moisture content and water activity for the PDB treatment at 25 °C with 10, 40, and 100 repetitions are shown in

Figure 12,

Table 11 and

Table 12.

The moisture content values for 40 cycles were 10.22 ± 0.23% (0 h), 11.17 ± 0.20% (2 h), 18.71 ± 0.60% (4 h), 28.66 ± 6.07% (6 h), and 37.90 ± 0.77% (8 h). All the values were higher than the control at 4 h. The values for 100 cycles were 10.54 ± 0.46% (0 h), 10.53 ± 0.24% (2 h), 16.48 ± 0.98% (4 h), 29.47 ± 5.49% (6 h), and 41.76 ± 3.04% (8 h). The values were significantly different from the control at 8 h. The water activity values for 40 cycles were 0.5355 ± 0.0043 (0 h), 0.6988 ± 0.0693 (2 h), 0.8317 ± 0.0316 (4 h), 0.8904 ± 0.0187 (6 h), and 0.9716 ± 0.0223 (8 h). All the values were lower than the control at 0 h. Correlation analysis between the number of cycles and moisture content at 8 h showed a positive relationship, indicating that increased PDB cycles generally enhanced moisture uptake. However, the difference in moisture gain between 40 and 100 cycles was relatively small, suggesting a potential saturation point in the efficacy of the repeated pressure drop treatment. This may be due to the limited capacity of the seed structure to accommodate additional water, or a plateau in the disruption of the seed surface. Moreover, it is possible that excessive PDB cycles compromise structural integrity or promote the leaching of internal solutes, which could reduce the net effectiveness of soaking enhancement. Further microstructural or compositional analyses would be helpful in confirming these effects. A similar trend was observed in the PDA-treated samples, where the soaking performance did not markedly improve beyond 40 cycles, suggesting consistent results across both treatment types. These findings indicate that although repeated PDB and PDA treatments can enhance soaking performance, more than 40 cycles may yield diminishing returns.

3.7. SEM Surface Analysis of Adzuki Beans Pretreated Using the Pressure Drop Process

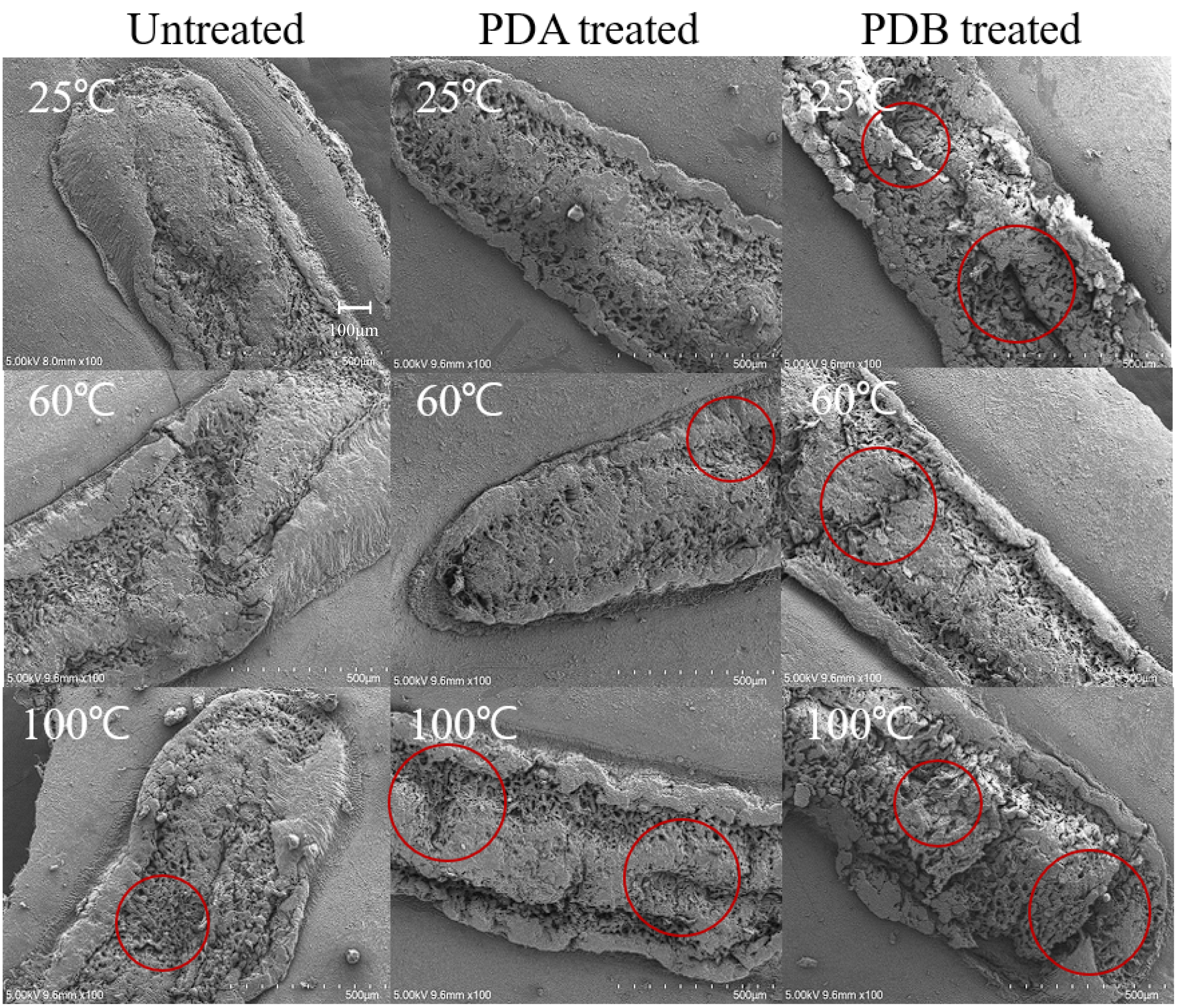

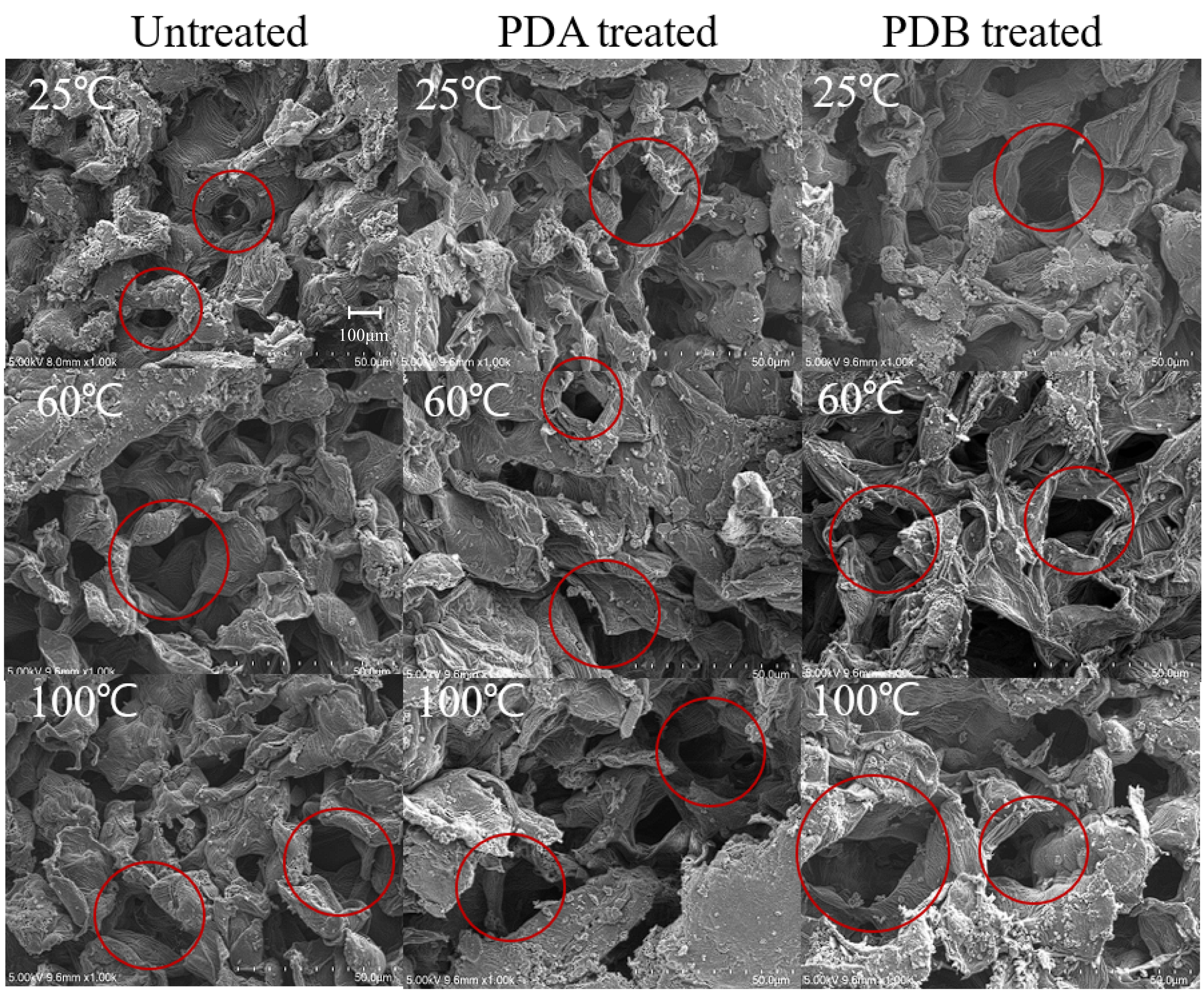

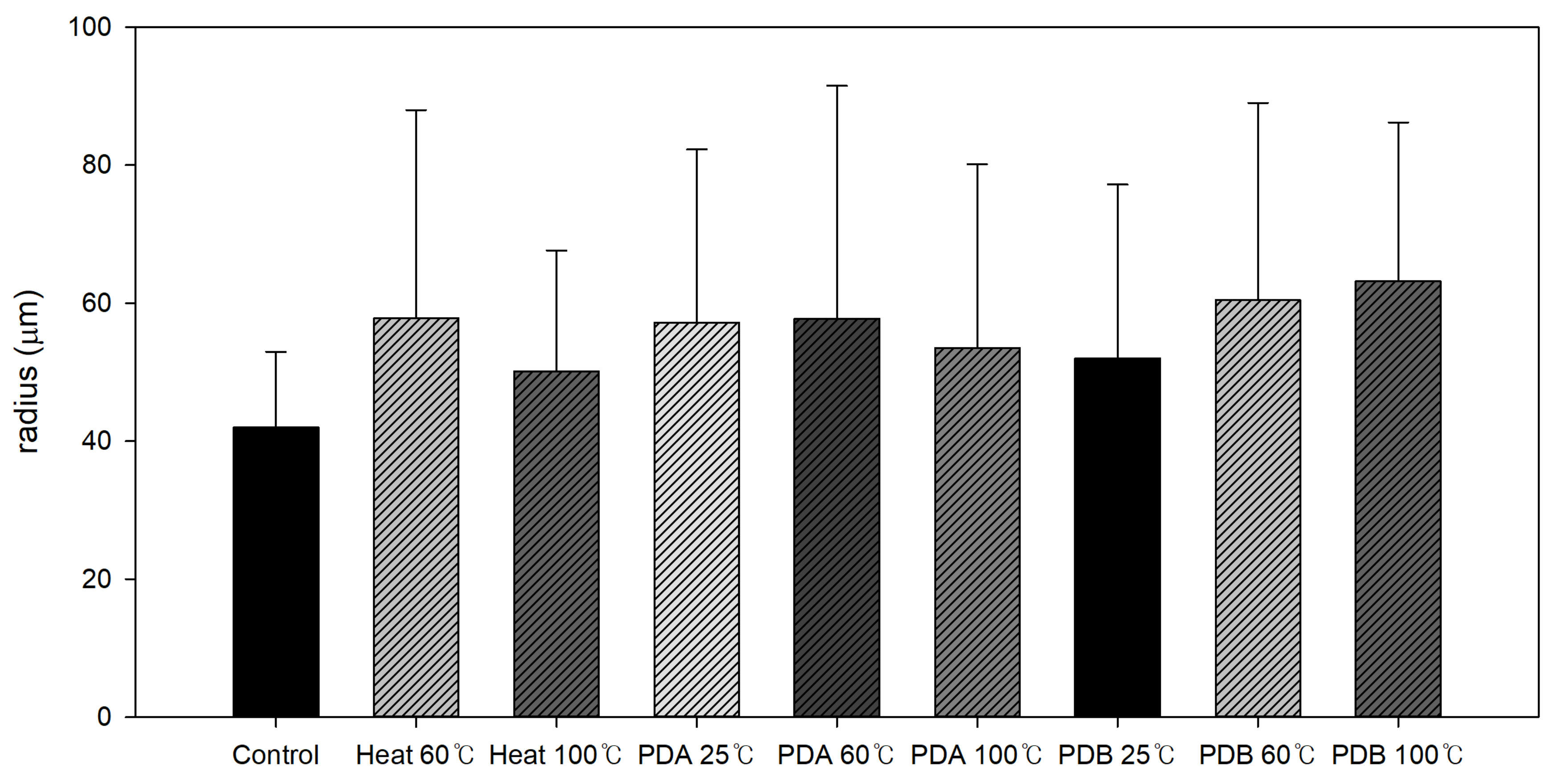

SEM was used to examine the surface differences among control and heat-, PDA-, and PDB-treated adzuki beans. At 100× magnification, the control hilum showed a membrane-like substance in some areas and a net-like mesh structure in uncovered areas (

Figure 13). The heat-, PDA-, and PDB-treated hila were cracked with increased mesh structure. Notably, the hilum treated with PDA at 100 °C and PDB at 25, 60, and 100 °C appeared swollen or collapsed, likely due to the escape of water or volatiles during the pressure drop process, as indicated by the areas marked with red circles. At 1000× magnification, the control sample’s mesh structure had pores of 80–100 μm, while treated samples (heat, PDA, and PDB) showed larger pores (100–200 μm), indicating that these treatments not only damaged the hilum but also enlarged the mesh structure (The area marked by red circles in

Figure 14 and

Figure 15). This increase has been reported to positively affect hydration, as supported by structural change studies using DIC [

23,

24,

25,

26]. The SEM images confirmed that PDA, PDB, and DIC led to an enlarged mesh structure and increased pore sizes (100–200 μm in this study vs. 100–300 μm in a previous study [

23]). These microstructural changes are known to enhance water uptake by increasing the surface area and forming capillary-like channels that facilitate faster water diffusion into core tissues, as reported for DIC-treated plant materials. Consistent with this, the moisture content after soaking (e.g., 41.76% at 8 h for PDB 100 times) aligns with the 30–50% rehydration range reported elsewhere [

23,

25], and the water activity values (e.g., 0.9716 for PDB 40 times) fall within the 0.9–0.98 range previously reported [

26]. These findings indicate effective hydration and water retention. However, hydration limitations have also been observed. Despite the structural expansion, the adzuki beans showed a slower initial moisture uptake than DIC-treated fruits or mushrooms, likely because of their dense, starch-rich cellular matrix. Additionally, while DIC at higher temperatures (80–120 °C) significantly improved rehydration in previous studies, PDB at 25 °C was less effective, underscoring the role of thermal input alongside structural changes in enhancing water absorption.

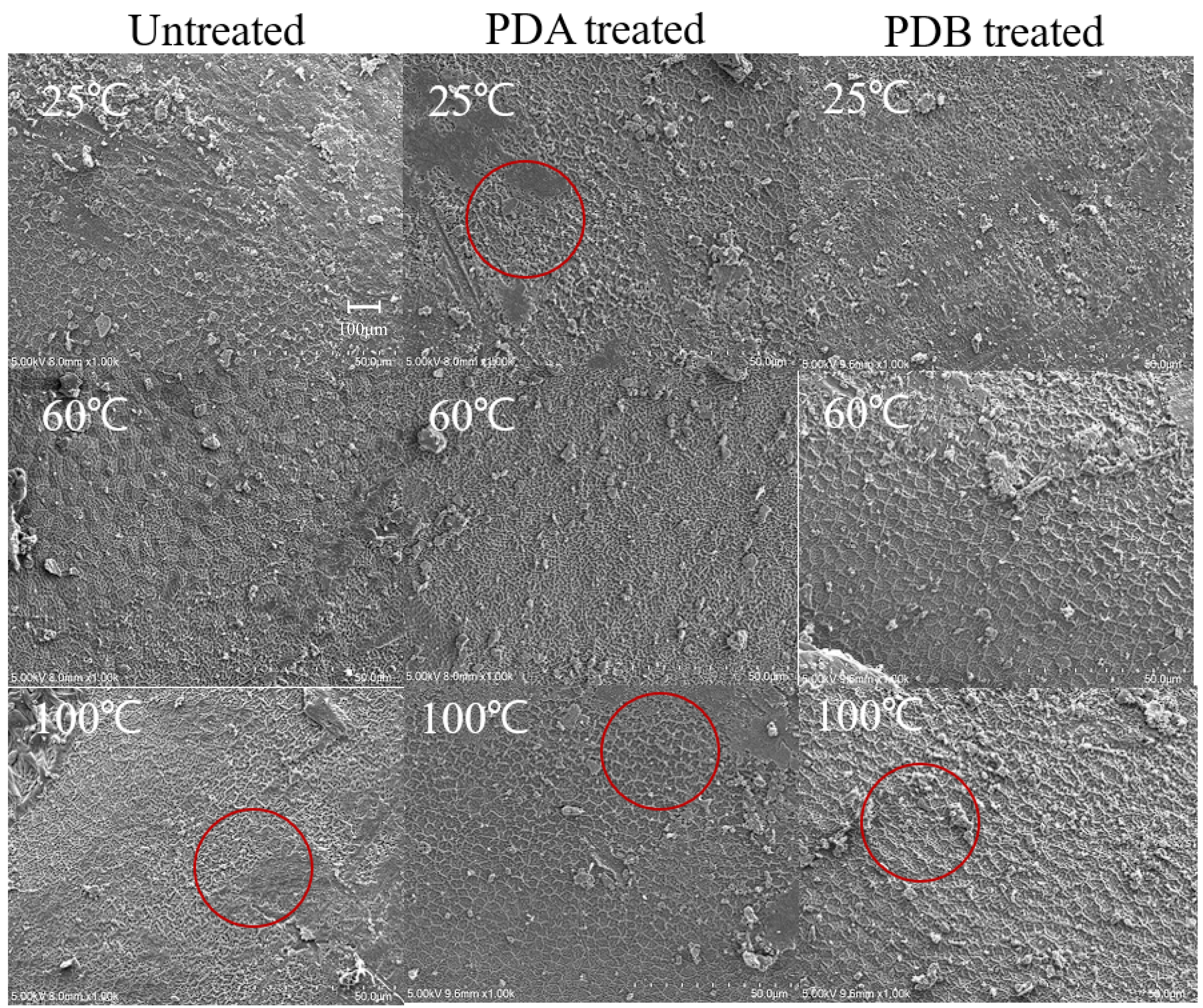

Representative views of the surfaces of the adzuki beans evident at 1000× magnification are shown in

Figure 16. When observing the control group, we noticed wrinkles on the surface around the hilum. This phenomenon was also observed when other samples were observed over a larger area than the untreated samples, as indicated by the red circles. It was assumed that the wrinkles were caused by damage to the adzuki bean surface layer. Because the wrinkles increased after the treatment, it can be presumed that some force was applied to the surface layer, causing some of the surface to peel off and reveal wrinkles.