1. Introduction

Greenhouse gas emissions resulting from anthropogenic activities have accelerated global warming, posing a critical threat to global food production and food security [

1]. Among the major contributors to greenhouse gas emissions is the livestock sector, necessitating the development of alternative strategies to reduce meat consumption and alleviate reliance on conventional animal agriculture [

2]. In this context, increasing attention has been directed toward sustainable alternative protein sources. Among these, edible insects, which have long been consumed in various cultural contexts, have recently gained significant global recognition as a viable and environmentally friendly protein option [

3]. Edible insects are characterized by high reproductive efficiency, rapid growth rates, excellent feed conversion, and minimal environmental impact [

4]. They also require significantly less space and fewer resources than traditional livestock, further enhancing their economic viability and underscoring their potential as a sustainable protein source [

3].

Among various insect species,

Gryllus bimaculatus (GB) is one of the most widely consumed edible insects globally, owing to its high nutritional value [

4]. According to a compositional analysis of five commercially available edible insect species conducted in the Republic of Korea, GB contains approximately 58.3% crude protein, 11.9% fat, 9.5% crude fiber, 9.7% ash, and 10.6% nitrogen-free extract on a dry matter basis [

5]. It is also rich in essential amino acids such as methionine, lysine, histidine, valine, and leucine. In particular, the fat content of GB includes health-beneficial fatty acids such as linoleic acid and stearic acid. Notably, stearic acid, despite being a saturated fatty acid, has been reported to have a neutral or even favorable effect on blood cholesterol levels [

6]. Additionally, chitin, a primary insoluble fiber found in crickets, has been reported to support digestive health and function as a prebiotic by stimulating the growth of beneficial gut microbiota [

4]. However, despite the nutritional and environmental advantages of edible insects, consumers often exhibit disgust and fear toward their consumption, leading to general avoidance [

7]. To address these negative perceptions, strategies such as processing insects into unrecognizable forms or incorporating them into familiar food products have been actively proposed [

7].

Concurrently, the prevalence of gluten-related disorders, including celiac disease, non-celiac gluten sensitivity, wheat allergy, and irritable bowel syndrome, has led to increased consumer demand for gluten-free (GF) products [

8]. Strict adherence to a GF diet is essential for managing these conditions, and in recent years, GF foods have also gained popularity among health-conscious consumers regardless of medical necessity [

9]. Despite the growing GF market, most commercial GF products rely heavily on carbohydrate-based ingredients such as corn, rice, and starch, resulting in low levels of protein, dietary fiber, and minerals and thereby presenting nutritional limitations [

10]. To address these imbalances, the incorporation of functional ingredients with enhanced nutritional profiles has become imperative. Edible insects, with their high protein and fat content, offer promising potential to enhance the nutritional value of GF foods and serve as alternative protein sources [

9].

Three-dimensional (3D) printing is an advanced manufacturing technology that fabricates complex structures by depositing successive layers of material based on a digital 3D model [

11]. Owing to its versatility and precision, 3D printing has found applications across various industries including military, automotive, and textiles and is increasingly being explored in the food sector [

12]. In particular, 3D food printing enables the modification of ingredient shape and texture, thus facilitating the development of novel sensory experiences and promoting the consumption of alternative protein sources such as edible insects [

13]. Furthermore, additive manufacturing enables the production of customized food products tailored to individual nutritional needs and preferences, thereby contributing to health-oriented dietary solutions [

14,

15].

The use of food ink allows for precise control over ingredient composition, making it a viable method for formulating functional foods for individuals with dietary restrictions such as lactose intolerance or gluten sensitivity. However, the production of such foods requires not only optimized 3D printing processes but also appropriate post-processing techniques [

16,

17]. Post-processing methods are generally categorized into conventional cooking (e.g., baking, steaming, frying, etc.), advanced thermal techniques (e.g., laser cooking, infrared cooking, etc.), and dehydration methods [

18]. Ensuring compatibility between 3D printing and traditional cooking methods is crucial for the scalability and industrial implementation of 3D food printing [

18]. Thus, it is necessary to investigate the compatibility of printed food with conventional cooking processes and to assess how post-processing affects the final product quality.

One of the key challenges in the food industry is improving the consumer acceptability of insect-based foods [

19]. Edible insects exhibit diverse sensory attributes, including appearance, aroma, flavor, texture, and even sound during mastication, with over 2000 species reported globally as potential food sources [

20]. However, not all sensory attributes are perceived positively by consumers, particularly those unfamiliar with entomophagy, who may exhibit food neophobia and feelings of disgust, ultimately reducing their willingness to consume insect-based products [

21]. Although altering the physical appearance of insect-based foods may partially mitigate consumer aversion, visual transformation alone is insufficient to overcome negative perceptions [

19]. In addition, Ghosh et al. [

22] emphasized that, beyond sensory attributes, various factors such as cultural background, prior experience with insect consumption, individual attitudes, and the visibility of insect components significantly influence consumer acceptance. Therefore, a comprehensive understanding of how consumers perceive and evaluate the sensory attributes of insect-based foods is essential for enhancing their acceptability. Consumer-based sensory evaluations play a significant role in improving familiarity and preference, enabling the development of products that align with consumer expectations [

23].

Several studies have investigated the application of 3D printing using edible insects. These include evaluations of the printability of commercial insect gels and the role of protein and chitin in printability [

2], studies on the 4D printing of edible insect-based materials with shape transformation upon thermal dehydration [

13], the development of health snacks using

Tenebrio molitor and

Alphitobius diaperinus powders with 3D printing applications [

24], and the use of insect protein as emulsifiers to produce high internal phase emulsions as fat substitutes for 3D printing [

25].

Product quality is a critical determinant of consumer purchasing behavior. With the growing demand for fresh, safe, and high-quality food products, the food industry is increasingly required to define acceptable sensory defect thresholds and to accurately predict sensory shelf life using scientific methods [

26]. In food science, survival analysis has traditionally been employed to estimate shelf life, treating storage time as the event-related variable. Subsequently, some studies have applied survival models using the concentration of specific components instead of time [

27]. More recently, multivariate techniques like principal component analysis (PCA) have been used to derive quality deterioration indices, which are then modeled in relation to consumer rejection data using survival analysis to estimate sensory rejection thresholds or sensory shelf life [

28]. This consumer-centric approach enables the establishment of failure criteria grounded in sensory perception, rather than relying on arbitrary or producer-defined limits, thereby improving the relevance and accuracy of product acceptability evaluations.

Although research on 3D printing applications for edible insects is progressing, there remains a lack of studies exploring the use of GB as a food ink component and its effects on the quality and consumer acceptance of 3D-printed cookies. Therefore, this study aims to provide valuable insights to support the edible insect industry, develop cookie dough formulations incorporating insect powder, and assess the physicochemical properties and consumer acceptability of 3D-printed cookies using survival analysis.

2. Materials and Methods

2.1. Materials

The following ingredients were used in this study: gluten-free wheat starch (Wecanfood, Seoul, Republic of Korea), refined sugar (CJ CheilJedang, Seoul, Republic of Korea), unsalted butter (WestGold, Emart, Seoul, Republic of Korea), cocoa powder (Mix & Bake, Samyang, Seongnam, Republic of Korea), vanilla extract (Low&Oil, Venta, Seoul, Republic of Korea), and refined salt (Daesang, Seoul, Republic of Korea). The wheat starch used in this study was labeled as gluten-free according to the distribution information provided by the manufacturer and is considered suitable for consumers sensitive to gluten. All ingredients, except eggs, were purchased through an online retailer (Emart-mall), while fresh eggs were obtained from a local supermarket in Cheonan, Korea. GB specimens were purchased in a mid-infrared dried form from Cricket Farm (Hwaseong, Republic of Korea) via an online order. The dried crickets were first coarsely ground using a mortar and pestle (Samhwa, Seoul, Republic of Korea), followed by fine grinding using a commercial blender (HR2096, Philips, Amsterdam, The Netherlands). The resulting powder was passed through a 60-mesh sieve (203–250 μm, Chunggye, Seoul, Republic of Korea) to ensure uniform particle size. The processed cricket powder was portioned into 100 g units, vacuum-sealed, and stored at −25 °C. All samples were used within two months of preparation for experimental consistency.

2.2. Cookie Dough Preparation

Chocolate cookie doughs were prepared according to the formulation presented in

Table 1. A preliminary experiment showed that when GB powder was added at concentrations below 3%, the sensory differences between samples were minimal due to the dominant chocolate flavor, which likely masked the perceptible characteristics of the insect powder. Therefore, the experimental groups consisted of doughs in which 3, 6, 9, 12, and 15% (

w/

w) of wheat starch was replaced with GB powder (designated as CP3, CP6, CP9, CP12, and CP15, respectively), while the control group contained no insect powder. Initially, unsalted butter was softened at room temperature (25 °C) for 1 h and manually creamed for 5 min. Granulated sugar was then added in three portions and thoroughly mixed to achieve homogeneity. Subsequently, room-temperature eggs, salt, and vanilla extract were incorporated and blended for an additional 3 min. The wheat starch and GB powder were pre-sifted and added to the mixture, followed by 5 min of kneading to form the dough. The completed dough was rested under refrigeration at 4 °C for 30 min prior to further processing.

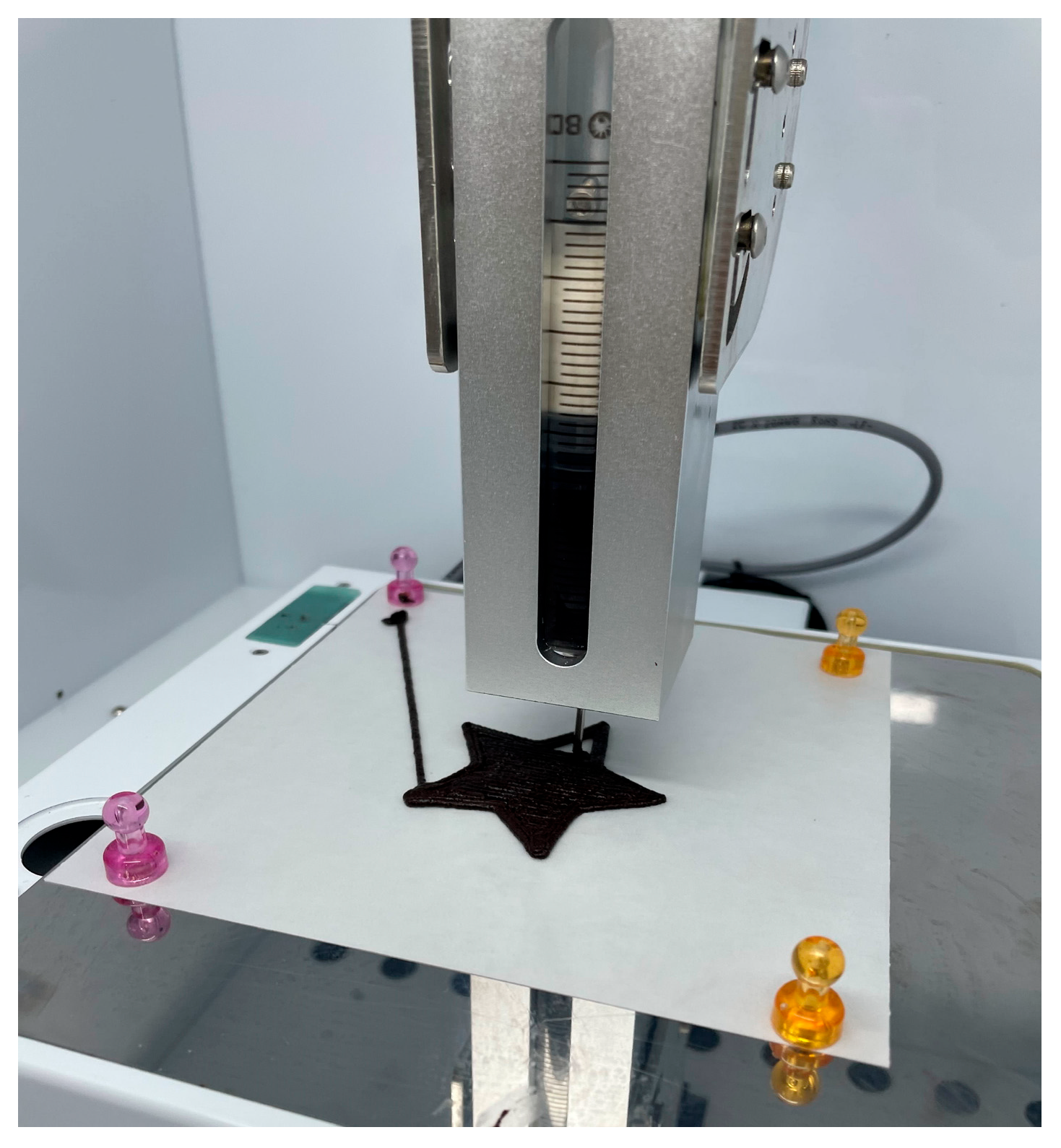

2.3. Three-Dimensional Printing and Post-Processing

The cookie dough was stabilized at room temperature (25 °C) for approximately 30 min prior to loading into 60 mL cartridges (Becton-Dickinson Inc., Franklin Lakes, NJ, USA). The filled cartridges were then installed in a 3D food printer (YOLI LAB 1.0, YOLILO Co., Seoul, Republic of Korea) for printing (

Figure 1). Before printing, slicing parameters were set using Cura software (version 2.4, Ultimaker BV, Federales, The Netherlands) with an infill density of 80%, a reticular infill pattern, and a printing angle of 90°. Preliminary trials involving various shapes revealed that a star-shaped design with a height of 2 mm exhibited superior structural stability during printing, with minimal layer separation or collapse. Additionally, this geometry effectively distributed mechanical stress through multidirectional protrusions and facilitated uniform heat transfer during baking due to its large surface area, thereby contributing to consistent moisture evaporation and product quality. These observations were consistent with previous findings indicating that shape and internal architecture significantly influence printability and post-processing stability in 3D-printed foods [

15].

The printing conditions were set as follows: a nozzle diameter of 1.5 mm, first layer height of 1.8 mm, subsequent layer height of 1.7 mm, printing speed of 30 mm/s, and infill speed of 20 mm/s. These parameters fall within the effective range reported by Barrios-Rodríguez et al. [

29] for semi-solid food materials using rice protein-based inks. Each cookie was printed in approximately 1 min and 43 s. Following printing, the cookies were baked in a convection oven (SK Magic EON-B420M, SK Magic Co., Seoul, Republic of Korea) at 120 °C for 30 min. After baking, the samples were cooled at room temperature and stored under refrigeration (4 °C) for three days prior to analysis.

2.4. Proximate Composition of Cookies

The proximate composition of chocolate cookies containing GB powder was analyzed in accordance with the standard methods of the Association of Official Analytical Chemists [

30]. Moisture content was determined using the 105 °C hot air oven drying method; crude protein content was measured by the semi-micro-Kjeldahl method; crude fat content was determined using Soxhlet extraction; and ash content was assessed via the dry ashing method. All analyses were performed in triplicate, and the results are presented as the mean ± standard deviation.

2.5. pH and Density of Cookie Dough

The pH of chocolate cookie doughs formulated with varying levels of GB powder was measured by homogenizing 3 g of dough with 20 mL of distilled water using a magnetic stirrer (MS-H280-Pro, DLAB, Seoul, Republic of Korea) for 20 min. The mixture was then filtered, and the supernatant was analyzed using a calibrated pH meter (HI98163, Hanna Instruments, Seoul, Republic of Korea), following the method of Koh et al. [

31].

Dough density was determined by adding 5 g of dough to a 50 mL graduated cylinder containing 40 mL of distilled water and recording the change in volume. The density was calculated as the weight-to-volume ratio (g/mL), in accordance with the method described by Koh et al. [

31]. All measurements were conducted in quintuplicate, and mean values were used for analysis.

2.6. pH and Color Analysis of Cookies

The pH of chocolate cookies containing GB powder was determined by homogenizing 3 g of cookie samples with 27 mL of distilled water through stirring for 30 min. The homogenate was filtered, and the supernatant was analyzed using a calibrated pH meter (HI98163, Hanna Instruments, Seoul, Republic of Korea). Measurements were performed five times per sample, and mean values were used for the analysis [

31].

Color measurements were conducted using a colorimeter (RM200QC, Lovibond, UK) after calibration with a standard white plate (L* = 97.4; a* = 0.5; b* = 1.3). The color parameters were recorded according to the CIE (Commission Internationale de l’Éclairage) color space, specifically lightness (L*), redness (a*), and yellowness (b*). Each sample was measured in triplicate, and the average values were reported.

2.7. Physical Properties of Cookies

The cookie spread ratio was determined according to the AACC standard method 10-50D [

32]. The diameter was measured by aligning six cookies horizontally, recording the total length, rotating them 90°, and re-measuring. The average of the two measurements was used. The height was determined by stacking six cookies vertically, measuring the total height, and then repeating the measurement after rearranging the stacking order. The spread ratio was calculated as the ratio of diameter to thickness (D/H) using Equation (1). All measurements were performed in triplicate, and the mean values were used for analysis [

33].

The loss rate was calculated based on the weight of cookies before and after baking, comparing the changes between the control and experimental groups. This was computed using Equation (2) [

31]. Cookie weights were measured precisely using an analytical balance (EPG214DC, Ohaus Corp., Parsippany, NJ, USA). All measurements were conducted five times per sample, and mean values were reported.

2.8. Textural Analysis of Cookies

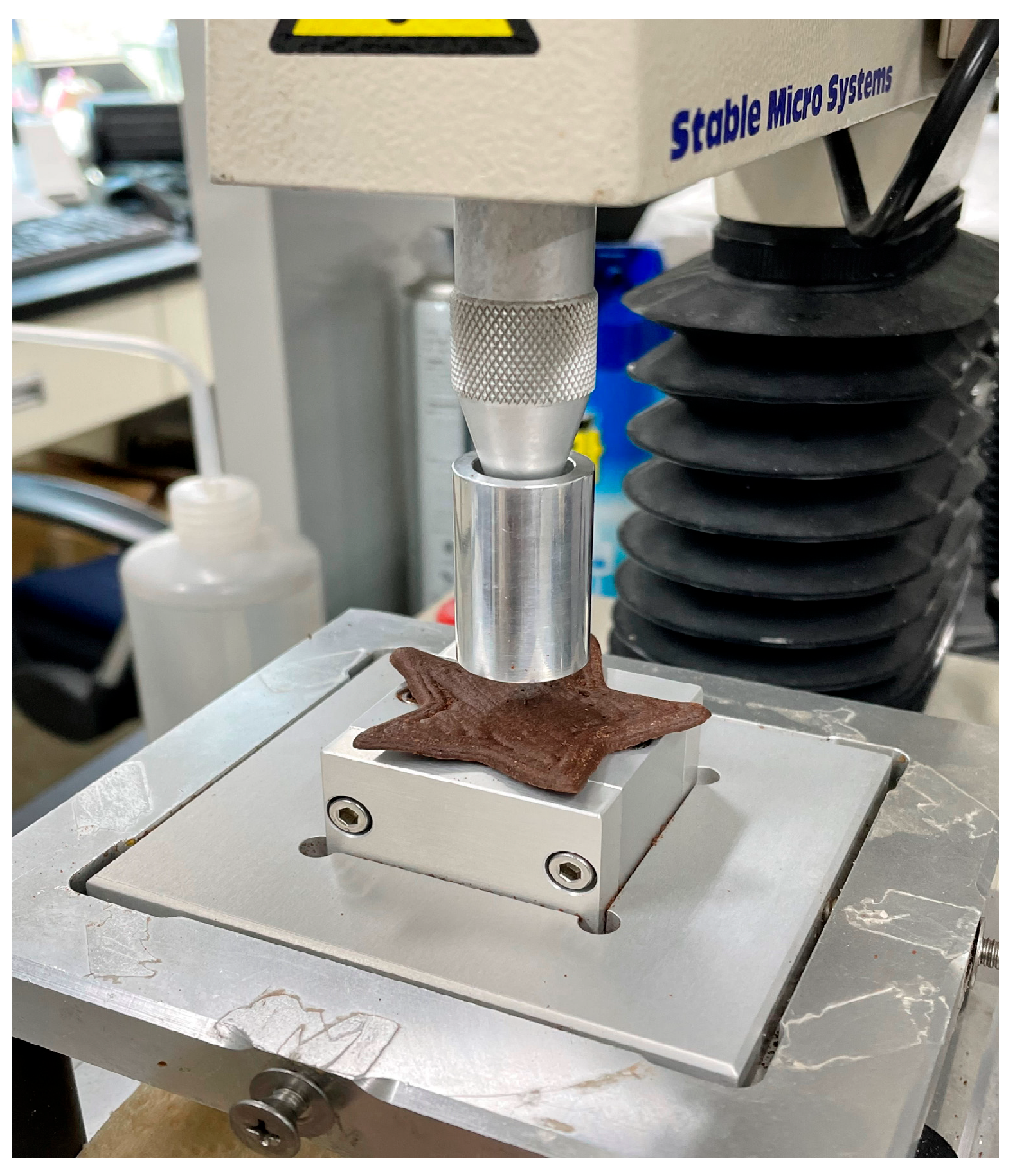

The mechanical properties of chocolate cookies formulated with GB powder were evaluated using a texture analyzer (TA.XTplus, Stable Micro Systems, Godalming, UK) as shown in

Figure 2. A cylindrical probe (P/20, diameter 20 mm) was employed under the following test conditions: trigger force 0.049 N, distance 5 mm, pre-test speed 1 mm/s, test speed 1 mm/s, and post-test speed 3 mm/s. All measurements were conducted at room temperature (25 °C). Hardness was assessed based on the maximum compression force (peak force, N) and the total area under the force–time curve. The peak force represents the maximum force required to fracture the cookie, while the total area reflects the overall distribution of force exerted during compression [

34]. Each sample was measured 15 times, and mean values were used for analysis.

Figure 2.

Single compression test of baked gluten-free chocolate cookies to evaluate mechanical force and energy.

Figure 2.

Single compression test of baked gluten-free chocolate cookies to evaluate mechanical force and energy.

2.9. Consumer Test of Cookies

The consumer acceptance test was conducted following approval from the Institutional Review Board of Dankook University (Approval No.: DKU 2022-02-001), with participation from 100 subjects (81 females and 19 males). Prior to evaluation, cookie samples were equilibrated at room temperature (25 °C) for 1 h and individually presented to each panelist. Each sample was labeled with a random three-digit code, and the order of presentation was randomized using a Williams Latin Square design to minimize order bias. Participants were instructed to rinse their mouths with water between samples to avoid carryover effects.

Consumers were asked to assess their overall liking using a 9-point verbal category scale (1 = dislike extremely to 9 = like extremely). Consumers were asked to check all the terms that they considered to be appropriate to describe the samples and then rated the intensity of the relevant terms using a 5-point intensity scale (1 = “low intensity”; 3 = “medium”; and 5 =“high intensity”), which was referred to rate-all-that-apply (RATA) [

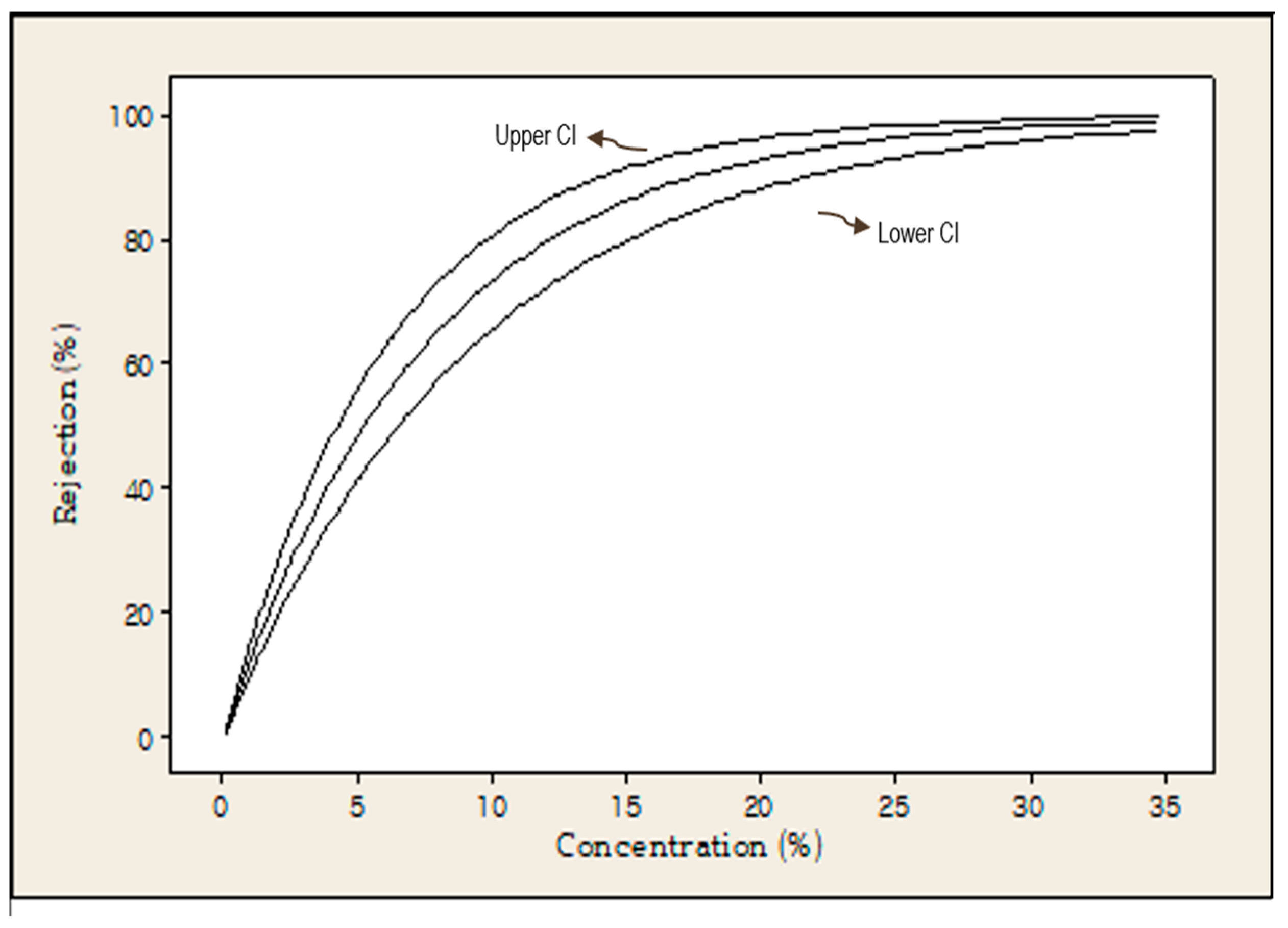

35]. The presentation of the samples in the questionnaire was balanced within and across subjects using a Williams design to avoid presentation bias. Consumers were then asked the following question: “Would you normally consume this product? Yes or No?” This question aimed to determine whether the consumers would accept the product if the product was purchased or served. A survival analysis was performed to estimate the maximum acceptable concentration of GB powder that would not elicit consumer rejection, following the method described by Meneses et al. [

36].

In addition, sensory attributes were categorized into four descriptors: appearance (brownness, fissureness, and density), aroma (butter aroma, vanilla aroma, caramel aroma, and chocolate aroma), taste (sweetness, saltiness, bitter taste, savory taste, chocolate taste, vanilla taste, oily taste, nutty taste, and ripe barley taste), and texture or mouthfeel (hardness, fracturability, cohesiveness, crispiness, moisture release, residual characteristic, cotton mouth, and loose particles).

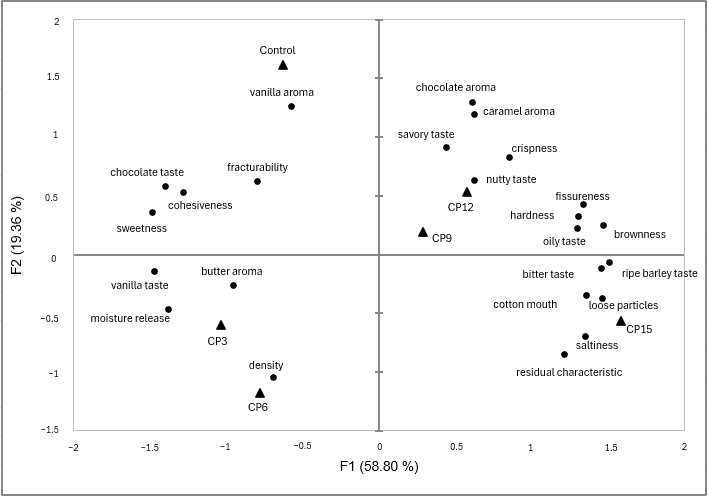

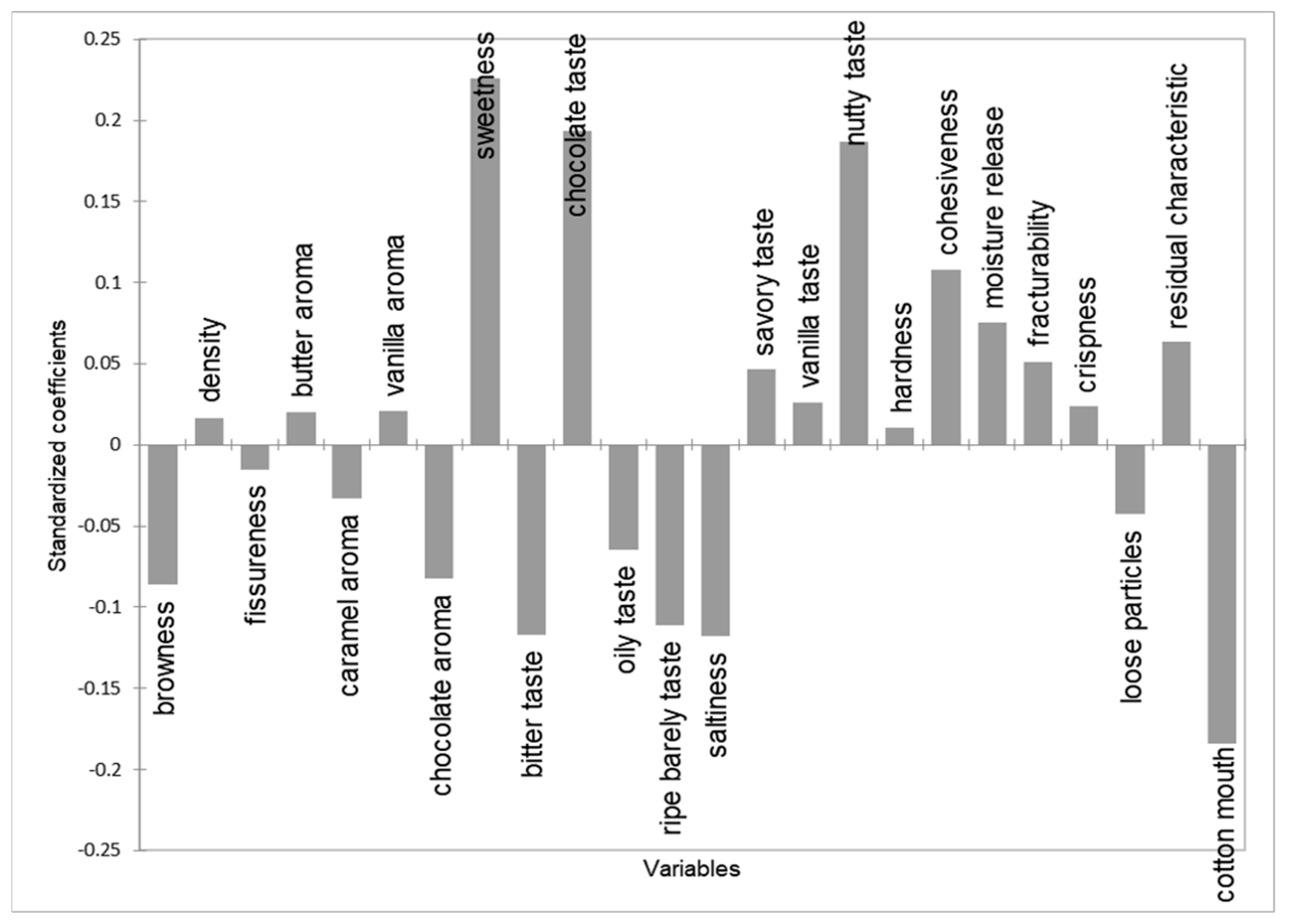

2.10. Statistical Analysis

All statistical analyses were performed using XLSTAT software (version 2016 for Windows; Addinsoft, Inc., Paris, France). A one-way analysis of variance (ANOVA) was conducted to examine the statistical significance of differences among samples. When significant differences were detected (p < 0.05), Tukey’s post hoc test was applied to determine specific pairwise differences among sample means.

To investigate sensory attribute differences among samples based on consumer test data, PCA was conducted. Furthermore, partial least squares regression (PLSR) was employed to identify key sensory drivers influencing consumer liking by correlating overall acceptability scores with RATA attribute intensities. To predict consumer acceptance thresholds for the samples, survival analysis was conducted using MINITAB® 16 (Minitab Inc., San Diego, CA, USA). Since consumers were exposed to predetermined concentration levels, the exact rejection concentration could not be directly observed in all cases, and thus, censoring was considered in the analysis. Specifically, consumers who rejected the lowest concentration level were classified as left-censored, while those who accepted lower concentrations but rejected higher concentrations were considered interval-censored. Participants who accepted all concentrations, including the maximum level provided, were classified as right-censored. Since the distribution of consumer rejection thresholds was not normally distributed, the exponential distribution was selected for survival data modeling.