Exploring the Impacts of Sorghum (Sorghum bicolor L. Moench) Germination on the Flour’s Nutritional, Chemical, Bioactive, and Technological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples and Flour Preparation

2.2. Thermo-Mechanical Properties of the Flours

2.2.1. Granulometry

2.2.2. Color Parameters

2.2.3. Flour Granules Microscopy

2.2.4. Flour Gel Hydration Properties

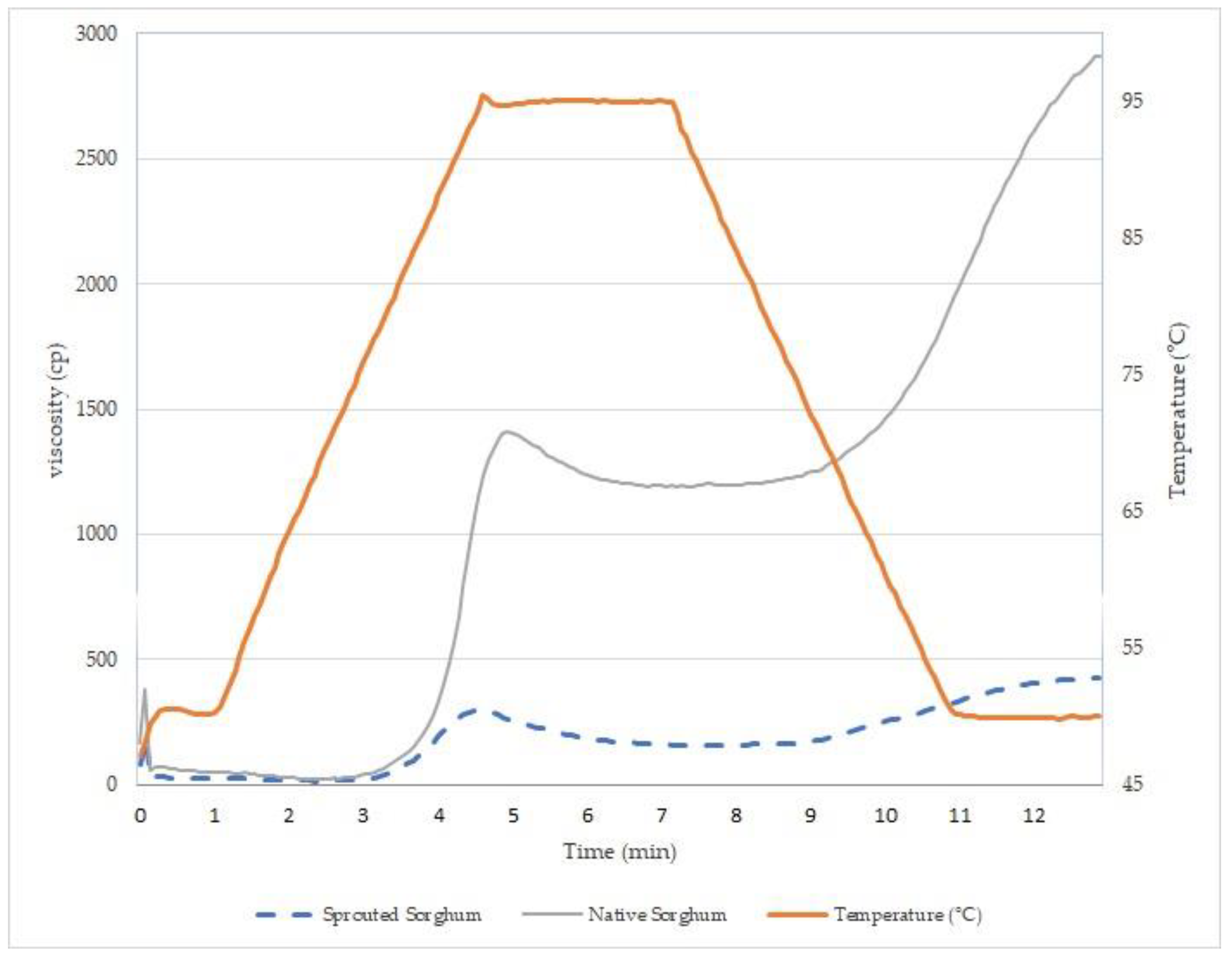

2.2.5. Pasting Properties

2.2.6. Firmness

2.3. Nutritional Profile and Chemical Composition

2.3.1. Moisture and Nutritional Characterization

2.3.2. Free Sugars

2.3.3. Organic Acids

2.3.4. Fatty Acids

2.3.5. Tocopherols

2.4. Bioactivities and Phenolic Profile

2.4.1. Extract Preparation

2.4.2. In Vitro Antioxidant Activity

2.4.3. In Vitro Antiproliferative Activity

2.4.4. In Vitro Anti-Inflammatory Activity

2.4.5. Phenolic Profile

2.5. Statistical Analysis

3. Results and Discussion

3.1. Thermo-Mechanical Properties of the Flours

3.2. Nutritional Profiles and Chemical Compositions of the Flours

3.3. Chemical Compositions of the Flours

3.4. Bioactivities Profiles of Hydroethanolic Extracts from Native and Sprouted Sorghum Flours

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stutts, L.R.; Vermerris, W. Elucidating Anthracnose Resistance Mechanisms in Sorghum—A Review. Phytopathology 2020, 110, 1863–1876. [Google Scholar] [CrossRef] [PubMed]

- Tolentino, D.C.; Rodrigues, J.A.S.; Pires, D.A.d.A.; Veriato, F.T.; Lima, L.O.B.; Moura, M.M.A. The quality of silage of different sorghum genotypes. Acta Sci. 2016, 38, 143. [Google Scholar] [CrossRef][Green Version]

- Weerasooriya, D.K.; Bean, S.R.; Nugusu, Y.; Ioerger, B.P.; Tesso, T.T. The effect of genotype and traditional food processing methods on in-vitro protein digestibility and micronutrient profile of sorghum cooked products. PLoS ONE 2018, 13, e0203005. [Google Scholar] [CrossRef] [PubMed]

- Marchini, M.; Marti, A.; Folli, C.; Prandi, B.; Ganino, T.; Conte, P.; Fadda, C.; Mattarozzi, M.; Carini, E. Sprouting of Sorghum (Sorghum bicolor [L.] Moench): Effect of Drying Treatment on Protein and Starch Features. Foods 2021, 10, 407. [Google Scholar] [CrossRef]

- Ratnavathi, C.V. Grain Structure, Quality, and Nutrition. In Breeding Sorghum for Diverse End Uses; Elsevier: Amsterdam, The Netherlands, 2019; pp. 193–207. [Google Scholar] [CrossRef]

- Crozier, D.; Riera-Lizarazu, O.; Rooney, W.L. Application of X-ray computed tomography to analyze the structure of sorghum grain. Plant Methods 2022, 18, 3. [Google Scholar] [CrossRef] [PubMed]

- Queiroz, V.A.V.; Silva, C.S.; Menezes, C.B.; Schaffert, R.E.; Guimaraes, F.F.M.; Guimaraes, L.J.M.; Guimaraes, P.E.O.; Tardin, F.D. Nutritional composition of sorghum [Sorghum bicolor (L.) Moench] genotypes cultivated without and with water stress. J. Cereal Sci. 2015, 65, 103–111. [Google Scholar] [CrossRef]

- Espitia-Hernández, P.; Chávez González, M.L.; Ascacio-Valdés, J.A.; Dávila-Medina, D.; Flores-Naveda, A.; Silva, T.; Ruelas Chacón, X.; Sepúlveda, L. Sorghum (Sorghum bicolor L.) as a potential source of bioactive substances and their biological properties. Crit. Rev. Food Sci. Nutr. 2022, 62, 2269–2280. [Google Scholar] [CrossRef]

- Kang, J.; Price, W.E.; Ashton, J.; Tapsell, L.C.; Johnson, S. Identification and characterization of phenolic compounds in hydromethanolic extracts of sorghum wholegrains by LC-ESI-MSn. Food Chem. 2016, 211, 215–226. [Google Scholar] [CrossRef]

- Palacios, C.E.; Nagai, A.; Torres, P.; Rodrigues, J.A.; Salatino, A. Contents of tannins of cultivars of sorghum cultivated in Brazil, as determined by four quantification methods. Food Chem. 2021, 337, 127970. [Google Scholar] [CrossRef]

- Wu, Y.; Li, X.; Xiang, W.; Zhu, C.; Lin, Z.; Wu, Y.; Li, J.; Pandravada, S.; Ridder, D.D.; Bai, G.; et al. Presence of tannins in sorghum grains is conditioned by different natural alleles of Tannin1. Proc. Natl. Acad. Sci. USA 2012, 109, 10281–10286. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Zhao, Y. Phenolic Compounds in Whole Grain Sorghum and Their Health Benefits. Foods 2021, 10, 1921. [Google Scholar] [CrossRef]

- Saithalavi, K.M.; Bhasin, A.; Yaqoob, M. Impact of sprouting on physicochemical and nutritional properties of sorghum: A review. J. Food Meas. Charact. 2021, 15, 4190–4204. [Google Scholar] [CrossRef]

- Xu, M.; Jin, Z.; Simsek, S.; Hall, C.; Rao, J.; Chen, B. Effect of germination on the chemical composition, thermal, pasting, and moisture sorption properties of flours from chickpea, lentil, and yellow pea. Food Chem. 2019, 295, 579–587. [Google Scholar] [CrossRef]

- Ocheme, B.O.; Adedeji, E.O.; Lawal, G.; Zakari, M.U. Effect of Germination on Functional Properties and Degree of Starch Gelatinization of Sorghum Flour. J. Food Res. 2015, 4, 159. [Google Scholar] [CrossRef]

- Liu, S.; Wang, W.; Lu, H.; Shu, Q.; Zhang, Y.; Chen, Q. New perspectives on physiological, biochemical and bioactive components during germination of edible seeds: A review. Trends Food Sci. Technol. 2022, 123, 187–197. [Google Scholar] [CrossRef]

- Singh, A.; Sharma, S.; Singh, B. Effect of germination time and temperature on the functionality and protein solubility of sorghum flour. J. Cereal Sci. 2017, 76, 131–139. [Google Scholar] [CrossRef]

- Leite, D.D.F.; Cavalcanti, M.T.; Silva, A.S.; Gonçalves, M.C.; Almeida, M.C.B.M. Propriedades funcionais da semente do sorgo (Sorghum bicolor (L.) Moench) in natura e germinado. Rev. Verde Agroecol. Desenvolv. Sustent. 2016, 11, 7. [Google Scholar] [CrossRef][Green Version]

- Contreras-Jiménez, B.; Del Real, A.; Millan-Malo, B.M.; Gaytán-Martínez, M.; Morales-Sánchez, E.; Rodríguez-García, M.E. Physicochemical changes in barley starch during malting. J. Inst. Brew. 2019, 125, 10–17. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Guerra-Oliveira, P.; Belorio, M.; Gómez, M. Wasted bread flour as a novel ingredient in cake making. Int. J. Food Sci. Technol. 2022, 57, 4754–4762. [Google Scholar] [CrossRef]

- Beuchat, L.R. Functional and electrophoretic characteristics of succinylated peanut flour protein. J. Agric. Food Chem. 1977, 25, 258–261. [Google Scholar] [CrossRef]

- Köhn, C.R.; Fontoura, A.M.; Kempka, A.; Demiate, I.; Kubota, E.H.; Prestes Dornelles, R. Assessment of different methods for determining the capacity of water absorption of ingredients and additives used in the meat industry. Int. Food Res. J. 2015, 22, 356–362. [Google Scholar]

- Lin, M.J.Y.; Humbert, E.S.; Sosulski, F.W. Certain Functional Properties of Sunflower Meal Products. J. Food Sci. 1974, 39, 368–370. [Google Scholar] [CrossRef]

- Spier, F.; Zavareze, E.d.R.; Marques e Silva, R.; Elias, M.C.; Dias, A.R.G. Effect of alkali and oxidative treatments on the physicochemical, pasting, thermal and morphological properties of corn starch. J. Sci. Food Agric. 2013, 93, 2331–2337. [Google Scholar] [CrossRef] [PubMed]

- Curti, M.I.; Belorio, M.; Palavecino, P.M.; Camiña, J.M.; Ribotta, P.D.; Gómez, M. Effect of sorghum flour properties on gluten-free sponge cake. J. Food Sci. Technol. 2022, 59, 1407–1418. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis of AOAC International, 16th ed.; AOAC (Association of Official Analytical Chemists) International: Arlington, TX, USA, 1999; Volume 2. [Google Scholar]

- UNIÃO EUROPEIA. Regulamento (UE) No. 1169/2011 do Parlamento Europeu e do Conselho de 25 de Outubro de 2011 Relativo à Prestação de Informação aos Consumidores Sobre os Qéneros Alimentícios. 2011. Available online: https://www.proquest.com/openview/9e7994d22db38bb29f9a5ebc50704420/1?pq-origsite=gscholar&cbl=2026366&diss=y (accessed on 7 January 2024).

- Barros, L.; Pereira, E.; Calhelha, R.C.; Duẽnas, M.; Carvalho, A.M.; Santos-Buelga, C.; Ferreira, I.C.F.R. Bioactivity and chemical characterization in hydrophilic and lipophilic compounds of Chenopodium ambrosioides L. J. Funct. Foods 2013, 5, 1732–1740. [Google Scholar] [CrossRef]

- Souilem, F.; Fernandes, Â.; Calhelha, R.C.; Barreira, J.C.M.; Barros, L.; Skhiri, F.; Martins, A.; Ferreira, I.C.F.R. Wild mushrooms and their mycelia as sources of bioactive compounds: Antioxidant, anti-inflammatory and cytotoxic properties. Food Chem. 2017, 230, 40–48. [Google Scholar] [CrossRef]

- Lockowandt, L.; Pinela, J.; Roriz, C.L.; Pereira, C.; Abreu, R.M.V.; Calhelha, R.C.; Alves, M.J.; Barros, L.; Bredol, M.; Ferreira, I.C.F.R. Chemical features and bioactivities of cornflower (Centaurea cyanus L.) capitula: The blue flowers and the unexplored non-edible part. Ind. Crops Prod. 2019, 128, 496–503. [Google Scholar] [CrossRef]

- Mandim, F.; Petropoulos, S.A.; Dias, M.I.; Pinela, J.; Kostic, M.; Soković, M.; Santos-Buelga, C.; Ferreira, I.C.F.R.; Barros, L. Seasonal variation in bioactive properties and phenolic composition of cardoon (Cynara cardunculus var. altilis) bracts. Food Chem. 2021, 336, 127744. [Google Scholar] [CrossRef]

- Bessada, S.M.F.; Barreira, J.C.M.; Barros, L.; Ferreira, I.C.F.R.; Oliveira, M.B.P.P. Phenolic profile and antioxidant activity of Coleostephus myconis (L.) Rchb.f.: An underexploited and highly disseminated species. Ind. Crops Prod. 2016, 89, 45–51. [Google Scholar] [CrossRef]

- Sajdakowska, M.; Gębski, J.; Żakowska-Biemans, S.; Jeżewska-Zychowicz, M. Willingness to eat bread with health benefits: Habits, taste and health in bread choice. Public. Health 2019, 167, 78–87. [Google Scholar] [CrossRef]

- Dong, Y.; Karboune, S. A review of bread qualities and current strategies for bread bioprotection: Flavor, sensory, rheological, and textural attributes. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1937–1981. [Google Scholar] [CrossRef]

- Garvey, E.C.; O’Sullivan, M.G.; Kerry, J.P.; Kilcawley, K.N. Factors influencing the sensory perception of reformulated baked confectionary products. Crit. Rev. Food Sci. Nutr. 2020, 60, 1160–1188. [Google Scholar] [CrossRef]

- Guiné, R.P.F. Textural Properties of Bakery Products: A Review of Instrumental and Sensory Evaluation Studies. Appl. Sci. 2022, 12, 8628. [Google Scholar] [CrossRef]

- Liu, T.; Hou, G.G.; Cardin, M.; Marquart, L.; Dubat, A. Quality attributes of whole-wheat flour tortillas with sprouted whole-wheat flour substitution. LWT 2017, 77, 1–7. [Google Scholar] [CrossRef]

- Olamiti, G.; Takalani, T.K.; Beswa, D.; Jideani, A.I.O. Effect of malting and fermentation on colour, thermal properties, functional groups and crystallinity level of flours from pearl millet (Pennisetum glaucum) and sorghum (Sorghum bicolor). Heliyon 2020, 6, e05467. [Google Scholar] [CrossRef] [PubMed]

- Martino, H.; Tomaz, P.; Moraes, É.; Conceição, L.; Oliveira, D.; Queiroz, V.; Rodrigues, J.; Pirozi, M.; Pinheiro-Sant'Ana, H.; Ribeiro, S. Chemical characterization and size distribution of sorghum genotypes for human consumption. Rev. Inst. Adolfo Lutz 2012, 71, 337–344. [Google Scholar]

- Jribi, S.; Sahagùn, M.; Debbabi, H.; Gomez, M. Evolution of functional, thermal and pasting properties of sprouted whole durum wheat flour with sprouting time. Int. J. Food Sci. Technol. 2019, 54, 2718–2724. [Google Scholar] [CrossRef]

- Rothschild, J.; Rosentrater, K.; Onwulata, C.; Singh, M.; Menutti, L.; Jambazian, P.; Omary, M. Influence of quinoa roasting on sensory and physicochemical properties of allergen-free, gluten-free cakes. Int. J. Food Sci. Technol. 2015, 50, 1873–1881. [Google Scholar] [CrossRef]

- Lin, S.; Gao, J.; Jin, X.; Wang, Y.; Dong, Z.; Ying, J.; Zhou, W. Whole-wheat flour particle size influences dough properties, bread structure and in vitro starch digestibility. Food Funct. 2020, 11, 3610–3620. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Marsolais, F.; Bernards, M.A.; Sumarah, M.W.; Bykova, N.V.; Igamberdiev, A.U. Glyoxylate cycle and metabolism of organic acids in the scutellum of barley seeds during germination. Plant Sci. 2016, 248, 37–44. [Google Scholar] [CrossRef]

- Li, C.; Oh, S.-G.; Lee, D.-H.; Baik, H.-W.; Chung, H.-J. Effect of germination on the structures and physicochemical properties of starches from brown rice, oat, sorghum, and millet. Int. J. Biol. Macromol. 2017, 105, 931–939. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Song, S.; Li, C.; Zhang, X.; Liu, H. Effect of germination on the main chemical compounds and 5-methyltetrahydrofolate metabolism of different quinoa varieties. Food Res. Int. 2022, 159, 111601. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Xu, Z.; Gao, Y.; Huang, X.; Zou, Y.; Yang, T. Effects of Germination on the Nutritional Properties, Phenolic Profiles, and Antioxidant Activities of Buckwheat. J. Food Sci. 2015, 80, H1111–H1119. [Google Scholar] [CrossRef] [PubMed]

- Igamberdiev, A.U.; Eprintsev, A.T. Organic Acids: The Pools of Fixed Carbon Involved in Redox Regulation and Energy Balance in Higher Plants. Front. Plant Sci. 2016, 7. [Google Scholar] [CrossRef]

- Beltrão, N.E.d.M.; de Oliveira, M.I.P. Biossíntese e Degradação de Lipídios, Carboidratos e Proteínas em Oleaginosas. Embrapa Algodão-Documentos (INFOTECA-E). 2007. Available online: https://www.infoteca.cnptia.embrapa.br/bitstream/doc/275924/1/DOC178.pdf (accessed on 7 January 2024).

- Zhang, Q.; Peng, S.; Li, Y.; Zhang, H.; Qin, X.; Liu, G. Malic acid enhances proanthocyanidin stability and their combined effects on dough rheological properties and bread quality. LWT 2023, 184, 115066. [Google Scholar] [CrossRef]

- Su, X.; Wu, F.; Zhang, Y.; Yang, N.; Chen, F.; Jin, Z.; Xu, X. Effect of organic acids on bread quality improvement. Food Chem. 2019, 278, 267–275. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Dong, S.; Li, Y.; Wei, L.; Zhao, C.; Li, J.; Liu, X.; Wang, Y. Effects of germination on tocopherol, secoisolarlciresinol diglucoside, cyanogenic glycosides and antioxidant activities in flaxseed (Linum usitatissimum L.). Int. J. Food Sci. Technol. 2019, 54, 2346–2354. [Google Scholar] [CrossRef]

- Sruthi, N.U.; Rao, P.S. Effect of processing on storage stability of millet flour: A review. Trends Food Sci. Technol. 2021, 112, 58–74. [Google Scholar] [CrossRef]

- Barden, L.; Decker, E.A. Lipid Oxidation in Low-moisture Food: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 2467–2482. [Google Scholar] [CrossRef]

- Rios, R.V.; Pessanha, M.D.F.; de Almeida, P.F.; Viana, C.L.; Lannes, S.C. da S. Application of fats in some food products. Food Sci. Technol. 2014, 34, 3–15. [Google Scholar] [CrossRef]

- Pinheiro, S.S.; Anunciação, P.C.; de Morais-Cardoso, L.; Della Lucia, C.M.; de Carvalho, C.W.P.; Queiroz, V.A.V.; Sant'Ana, H.M.P. Stability of B vitamins, vitamin E, xanthophylls and flavonoids during germination and maceration of sorghum (Sorghum bicolor L.). Food Chem. 2021, 345, 128775. [Google Scholar] [CrossRef] [PubMed]

- Irondi, E.A.; Adegoke, B.M.; Effion, E.S.; Oyewo, S.O.; Alamu, E.O.; Boligon, A.A. Enzymes inhibitory property, antioxidant activity and phenolics profile of raw and roasted red sorghum grains in vitro. Food Sci. Hum. Wellness 2019, 8, 142–148. [Google Scholar] [CrossRef]

- Pontieri, P.; Pepe, G.; Campiglia, P.; Merciai, F.; Basilicata, M.G.; Smolensky, D.; Calcagnile, M.; Troisi, J.; Romano, R.; Giudice, F.; et al. Comparison of Content in Phenolic Compounds and Antioxidant Capacity in Grains of White, Red, and Black Sorghum Varieties Grown in the Mediterranean Area. ACS Food Sci. Technol. 2021, 1, 1109–1119. [Google Scholar] [CrossRef]

- Wu, G.; Johnson, S.K.; Bornman, J.S.; Bennett, S.J.; Fang, Z. Changes in whole grain polyphenols and antioxidant activity of six sorghum genotypes under different irrigation treatments. Food Chem. 2017, 214, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Bennett, S.J.; Bornman, J.F.; Clarke, M.W.; Fang, Z.; Johnson, S.K. Phenolic profile and content of sorghum grains under different irrigation managements. Food Res. Int. 2017, 97, 347–355. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, P.; Warner, R.D.; Fang, Z. Sorghum Grain: From Genotype, Nutrition, and Phenolic Profile to Its Health Benefits and Food Applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 2025–2046. [Google Scholar] [CrossRef]

- Xiong, Y.; Damasceno Teixeira, T.V.; Zhang, P.; Warner, R.D.; Shen, S.; Fang, Z. Cellular antioxidant activities of phenolic extracts from five sorghum grain genotypes. Food Biosci. 2021, 41, 101068. [Google Scholar] [CrossRef]

- Cáceres, P.J.; Martínez-Villaluenga, C.; Amigo, L.; Frias, J. Maximising the phytochemical content and antioxidant activity of Ecuadorian brown rice sprouts through optimal germination conditions. Food Chem. 2014, 152, 407–414. [Google Scholar] [CrossRef]

| Sprouted Sorghum | Native Sorghum | p-Value 1 | |

|---|---|---|---|

| Color parameters | |||

| L* | 73.5 ± 0.3 | 76.7 ± 0.5 | <0.001 |

| a* | 0.92 ± 0.07 | 0.24 ± 0.01 | <0.001 |

| b* | 20.4 ± 0.4 | 21.4 ± 0.7 | 0.001 |

| Granulometry | |||

| Sieves/Opening (µm) | Retained Sample (%) | ||

| 16/1.18 | 0.16 ± 0.05 | 0.42 ± 0.02 | <0.001 |

| 20/85 | 7.9 ± 0.9 | 7.1 ± 0.2 | 0.002 |

| 35/5 | 57 ± 2 | 78.6 ± 0.8 | <0.001 |

| 60/250 | 17 ± 3 | 10.2 ± 0.9 | <0.001 |

| Base/<150 | 17.5 ± 0.3 | 3.7 ± 0.4 | <0.001 |

| WAC (g/g) | 2.349 ± 0.001 | 2.35 ± 0.03 | 0.793 |

| OAC (g/g) | 1.91 ± 0.02 | 1.77 ± 0.01 | <0.001 |

| SP (g/g) | 6.59 ± 0.05 | 7.64 ± 0.05 | 0.004 |

| WSI (%) | 0.89 ± 0.02 | 0.53 ± 0.02 | <0.001 |

| Firmness (g/cm2) | |||

| 24 h | 23.7 ± 0.8 | 220 ± 11 | <0.001 |

| 48 h | 40 ± 6 | 229.024 ± 0.008 | <0.001 |

| 72 h | 52.6 ± 0.1 | 307 ± 24 | <0.001 |

| Sprouted Sorghum | Native Sorghum | p-Value 1 | |

|---|---|---|---|

| Moisture (g/100 g fw) | 10.79 ± 0.01 | 9.505 ± 0.005 | <0.001 |

| Nutritional profile (g/100 g dw) | |||

| Ash | 1.03 ± 0.02 | 0.89 ± 0.02 | <0.001 |

| Fat | 3.018 ± 0.004 | 4.21 ± 0.09 | <0.001 |

| Protein | 9.0 ± 0.4 | 5.9 ± 0.1 | <0.001 |

| Total dietary fiber | 13.6 ± 0.6 | 14.9 ± 0.2 | <0.001 |

| Carbohydrate | 73 ± 1 | 74.1 ± 0.5 | 0.005 |

| Energy contribution (kcal/100 g dw) | 384 ± 1 | 417.5 ± 0.4 | <0.001 |

| Sprouted Sorghum | Native Sorghum | p-Value 1 | |

|---|---|---|---|

| Soluble sugars (g/100 g dw) | |||

| Glucose | 0.64 ± 0.01 a | nd | <0.001 |

| Sucrose | 0.84 ± 0.03 a | 0.82 ± 0.04 b | 0.094 |

| Sum | 1.49 ± 0.04 a | 0.82 ± 0.04 b | <0.001 |

| Organic acids (g/100 g dw) | |||

| Oxalic acid | tr | tr | <0.001 |

| Malic acid | 1.49 ± 0.01 | 0.11 ± 0.01 | <0.001 |

| Citric acid | 0.26 ± 0.01 | 0.23 ± 0.01 | <0.001 |

| Succinic acid | nd | tr | <0.001 |

| Fumaric acid | tr | 0.67 ± 0.01 | <0.001 |

| Sum | 1.75 ± 0.01 | 0.99 ± 0.01 | <0.001 |

| Fatty Acids (Relative Percentage, %) | Sprouted Sorghum | Native Sorghum | p-Value 1 |

|---|---|---|---|

| Palmitic acid (C16:0) | 14.4 ± 0.1 | 28.019 ± 0.008 | <0.001 |

| Caprylic Acid (C8:0) | 0.082 ± 0.001 | 0.47 ± 0.02 | <0.001 |

| Capric Acid (C10:0) | 0.033 ± 0.001 | nd | <0.001 |

| Undecanoic Acid (C11:0) | 0.066 ± 0.001 | 0.66 ± 0.03 | <0.001 |

| Lauric Acid (C12:0) | 0.063 ± 0.001 | 0.208 ± 0.005 | <0.001 |

| Tridecanoic Acid (C13:0) | 0.084 ± 0.004 | nd | <0.001 |

| Myristic Acid (C14:0) | 0.101 ± 0.002 | 0.158 ± 0.002 | <0.001 |

| Pentadecanoic Acid (C15:0) | 0.061 ± 0.001 | nd | <0.001 |

| cis-10-Pentadecenoic Acid (C15:1) | 0.054 ± 0.001 | 1.21 ± 0.01 | <0.001 |

| Palmitic Acid (C16:0) | 14.35 ± 0.11 | 28.019 ± 0.008 | <0.001 |

| Palmitoleic Acid (C16:1) | 0.397 ± 0.007 | 0.431 ± 0.006 | <0.001 |

| Heptadecanoic Acid (C17:0) | 0.206 ± 0.008 | 5.627 ± 0.005 | <0.001 |

| Stearic Acid (C18:0) | 1.533 ± 0.002 | 3.742 ± 0.008 | <0.001 |

| Oleic Acid (C18:1n9c) | 36.99 ± 0.05 | 50.38 ± 0.01 | <0.001 |

| Linolelaidic Acid (C18:2n6t) | 0.041 ± 0.001 | nd | <0.001 |

| Linoleic Acid (C18:2n6c) | 41.907 ± 0.037 | 5.159 ± 0.002 | <0.001 |

| Alpha-Linolenic Acid (C18:3n3) | 1.709 ± 0.006 | 0.145 ± 0.001 | <0.001 |

| Arachidic Acid (C20:0) | 0.222 ± 0.006 | 1.034 ± 0.005 | <0.001 |

| cis-11-Eicosenoic Acid (C20:1) | 0.441 ± 0.003 | 0.282 ± 0.001 | <0.001 |

| cis-11,14-Eicosadienoic Acid (C20:2) | 0.765 ± 0.007 | nd | <0.001 |

| Heneicosanoic Acid (C21:0) | nd | 0.282 ± 0.001 | <0.001 |

| Arachidonic Acid (C20:4n6) | 0.091 ± 0.001 | 0.78 ± 0.01 | <0.001 |

| Behenic Acid (C22:0) | 0.228 ± 0.004 | 0.32 ± 0.01 | <0.001 |

| cis-11,14,17-Eicosatrienoic Acid (C20:3n3) | nd | 0.211 ± 0.005 | <0.001 |

| cis-13,16-Docosadienoic Acid (C22:2) | 0.117 ± 0.004 | 0.356 ± 0.002 | <0.001 |

| Tricosanoic Acid (C23:0) | 0.219 ± 0.001 | 0.271 ± 0.002 | <0.001 |

| Lignoceric Acid (C24:0) | 0.249 ± 0.001 | nd | <0.001 |

| SFA | 17.5 ± 0.1 | 40.518 ± 0.008 | <0.001 |

| MUFA | 37.89 ± 0.06 | 52.83 ± 0.01 | <0.001 |

| PUFA | 44.62 ± 0.05 | 6.65 ± 0.01 | <0.001 |

| Tocopherols (g/100 g dw) | |||

| α-Tocopherol | 0.142 ± 0.005 | 0.127 ± 0.001 | <0.001 |

| γ-Tocopherol | 0.234 ± 0.003 | 0.72 ± 0.01 | <0.001 |

| Sum | 0.376 ± 0.003 | 0.85 ± 0.01 | <0.001 |

| Quantification (mg/g Extract) | |||||||

|---|---|---|---|---|---|---|---|

| Peak | Rt (min) | λmax (nm) | [M-H]- (m/z) | MS2 (m/z) | Tentative Identification | Sprouted Sorghum | Native Sorghum |

| 1 | 5.36 | 253 | 153 | 109(100) | Protocatechuic acid | 0.35 ± 0.01 | nd |

| 2 | 7.42 | 324 | 415 | 253(100), 179(34), 161(46), 135(5) | 1-O-Caffeoyl-2-O-glucosylglycerol | 0.314 ± 0.001 | 0.782 ± 0.003 |

| 3 | 7.83 | 319 | 253 | 179(12), 161(5), 135(100) | O-Caffeoylglycerol | 0.234 ± 0.002 | 0.64 ± 0.02 |

| 4 | 9.92 | 325 | 253 | 179(39), 161(42), 135(100) | O-Caffeoylglycerol | 0.846 ± 0.005 | 2.21 ± 0.02 |

| 5 | 10.47 | 323 | 179 | 135(100) | Caffeic acid | 0.047 ± 0.004 | 0.29 ± 0.02 |

| 6 | 11.38 | 320 | 449 | 287(100), 269(5) | Dihydrokaempferol hexoside | 0.3984 ± 0.0005 | 0.417 ± 0.0001 |

| 7 | 12.8 | 321 | 449 | 287(100), 269(5) | Dihydrokaempferol hexoside | 0.3794 ± 0.004 | 0.513 ± 0.002 |

| 8 | 13.46 | 327 | 563 | 545(66), 503(86), 473(100), 443(69), 383(88), 353(40) | Apigenin-C-pentosyl-C-hexoside | 0.0138 ± 0.003 | 0.169 ± 0.002 |

| 9 | 13.72 | 323 | 563 | 545(50), 503(76), 473(79), 443(100), 383(12), 353(50) | Apigenin-C-pentosyl-C-hexoside | 0.29 ± 0.01 | 1.62 ± 0.001 |

| 10 | 13.96 | 334 | 563 | 545(12), 503(14), 473(67), 443(100), 383(37), 353(32) | Apigenin-C-pentosyl-C-hexoside | 0.27 ± 0.01 | 1.44 ± 0.01 |

| 11 | 14.27 | 285 | 883 | 721(34), 595(100), 567(13), 433(52), 405(10), 287(10) | Pyrano-3′,4′,5′,5,7-pentahydroxyflavanone-(3 → 4)-catechin-7-O-glucoside. | 0.18 ± 0.003 | 0.68 ± 0.01 |

| 12 | 15.26 | 274/331 | 563 | 545(17), 503(11), 473(100), 443(47), 413(11) 383(33), 353(25), 311(4) | Apigenin-C-pentosyl-C-hexoside | tr | 0.0706 ± 0.0001 |

| 13 | 15.97 | 284 | 433 | 271(100) | Naringenin-O-hexoside | 0.024 ± 0.003 | 1.686 ± 0.003 |

| 14 | 16.53 | 284 | 851 | 689(28),563(100),551(55),401(89),389(5) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside I | 0.063 ± 0.001 | 0.16 ± 0.01 |

| 15 | 16.83 | 286 | 867 | 705(100), 579(52), 449(12), 417(34), 287(10) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside I | 0.067 ± 0.002 | 0.78 ± 0.02 |

| 16 | 17.06 | 283 | 433 | 271(100) | Naringenine-O-hexoside | tr | 2.8122 ± 0.0003 |

| 17 | 17.75 | 285 | 867 | 705(100), 579(32), 525(5), 449(32), 417(62), 287(26) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside II | 0.055 ± 0.0003 | 0.15 ± 0.002 |

| 18 | 18.18 | 287 | 867 | 705(100), 579(43), 525(5), 449(29), 417(49), 287(5) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside II | 0.102 ± 0.003 | 0.267 ± 0.004 |

| 19 | 18.43 | 284 | 579 | 417(50), 271(100) | Naringenin O-hexosyl-deoxyhexoside | tr | 0.213 ± 0.002 |

| 20 | 20.78 | 285 | 851 | 689(28), 563(100), 551(55), 401(89), 389(5) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside II | 0.052 ± 0.001 | 0.64 ± 0.02 |

| 21 | 21.27 | 285 | 851 | 689(34), 563(100), 551(46), 401(92), 389(6) | Pyrano-naringenin-(3 → 4)-catechin-7-O-glucoside III | 0.0373 ± 0.0004 | 0.146 ± 0.003 |

| Phenolic Acids | 1.79 ± 0.01 | 3.93 ± 0.02 | |||||

| Flavanols | 0.7777 ± 0.0004 | 0.93 ± 0.002 | |||||

| C-glycosylated Flavones | 0.5744 ± 0.0002 | 3.14 ± 0.01 | |||||

| Flavanones | 0.024 ± 0.003 | 4.711 ± 0.001 | |||||

| Pyrano-flavanone-flavanol Dimers | 0.557 ± 0.004 | 2.82 ± 0.02 | |||||

| Total Phenolic Compounds | 3.72 ± 0.02 | 15.53 ± 0.01 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvati, D.; Paschoalinotto, B.H.; Mandim, F.; Ferreira, I.C.F.R.; Steinmacher, N.C.; Pereira, C.; Dias, M.I. Exploring the Impacts of Sorghum (Sorghum bicolor L. Moench) Germination on the Flour’s Nutritional, Chemical, Bioactive, and Technological Properties. Foods 2024, 13, 491. https://doi.org/10.3390/foods13030491

Salvati D, Paschoalinotto BH, Mandim F, Ferreira ICFR, Steinmacher NC, Pereira C, Dias MI. Exploring the Impacts of Sorghum (Sorghum bicolor L. Moench) Germination on the Flour’s Nutritional, Chemical, Bioactive, and Technological Properties. Foods. 2024; 13(3):491. https://doi.org/10.3390/foods13030491

Chicago/Turabian StyleSalvati, Diogo, Beatriz Helena Paschoalinotto, Filipa Mandim, Isabel C. F. R. Ferreira, Nádia Cristiane Steinmacher, Carla Pereira, and Maria Inês Dias. 2024. "Exploring the Impacts of Sorghum (Sorghum bicolor L. Moench) Germination on the Flour’s Nutritional, Chemical, Bioactive, and Technological Properties" Foods 13, no. 3: 491. https://doi.org/10.3390/foods13030491

APA StyleSalvati, D., Paschoalinotto, B. H., Mandim, F., Ferreira, I. C. F. R., Steinmacher, N. C., Pereira, C., & Dias, M. I. (2024). Exploring the Impacts of Sorghum (Sorghum bicolor L. Moench) Germination on the Flour’s Nutritional, Chemical, Bioactive, and Technological Properties. Foods, 13(3), 491. https://doi.org/10.3390/foods13030491