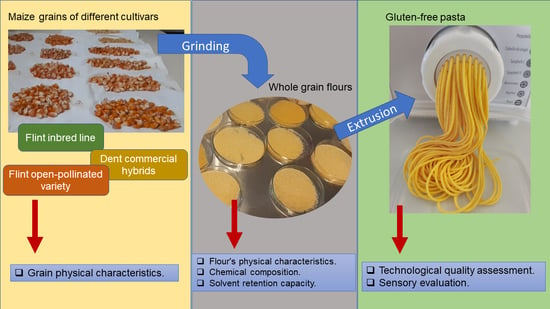

Technological and Sensory Quality of Gluten-Free Pasta Made from Flint Maize Cultivars

Abstract

1. Introduction

2. Materials and Methods

2.1. Genetic Material

2.2. Physical Determinations

2.3. Flour Physical and Chemical Characterization

2.4. Solvent Retention Capacity

2.5. Pasta Making

2.6. Pasta Quality Parameters

2.7. Sensory Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Grain and Flour Physical Traits

3.2. Solvent Retention Capacity and Flour Chemical Composition

3.3. Pasta Quality Traits

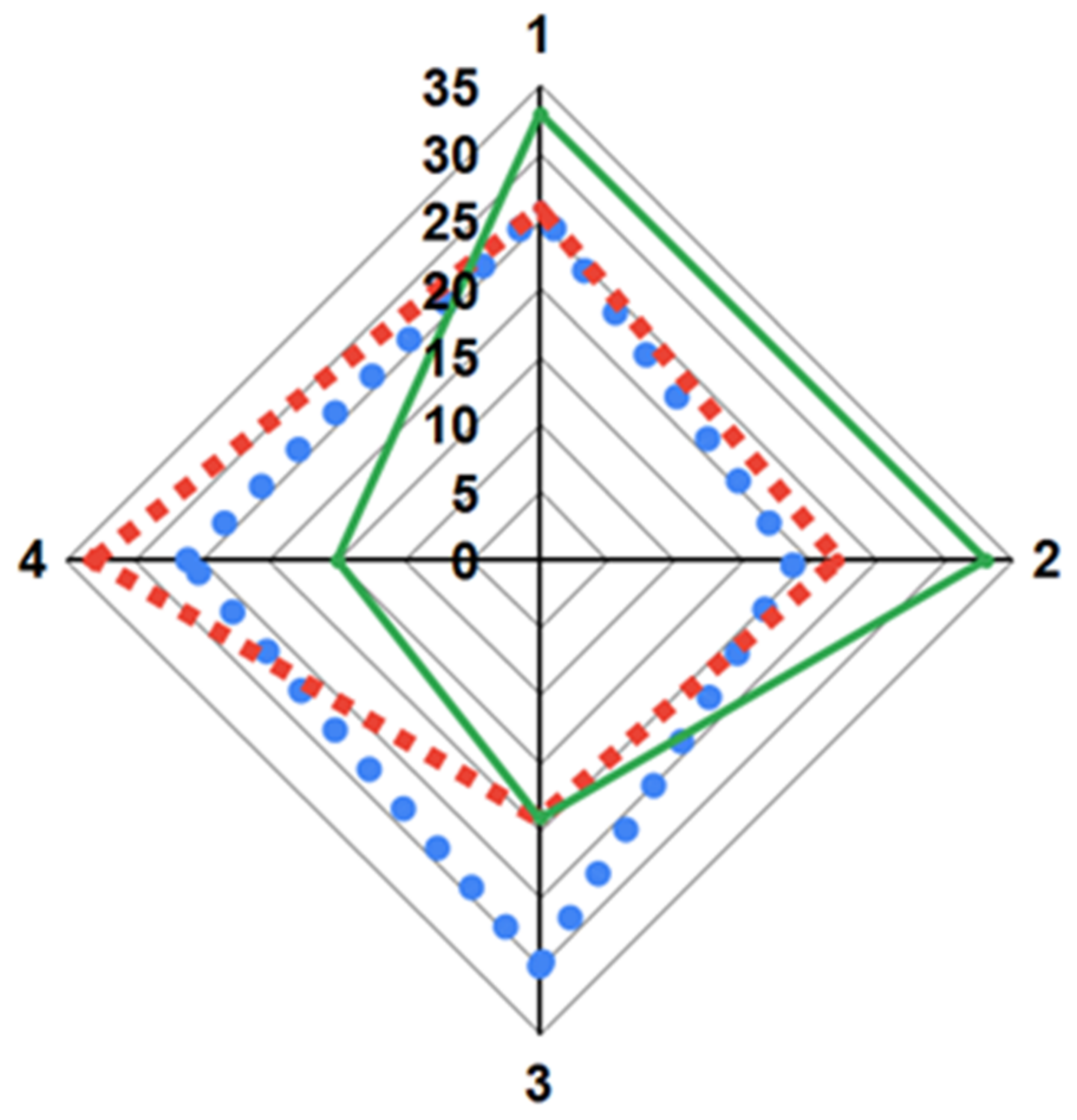

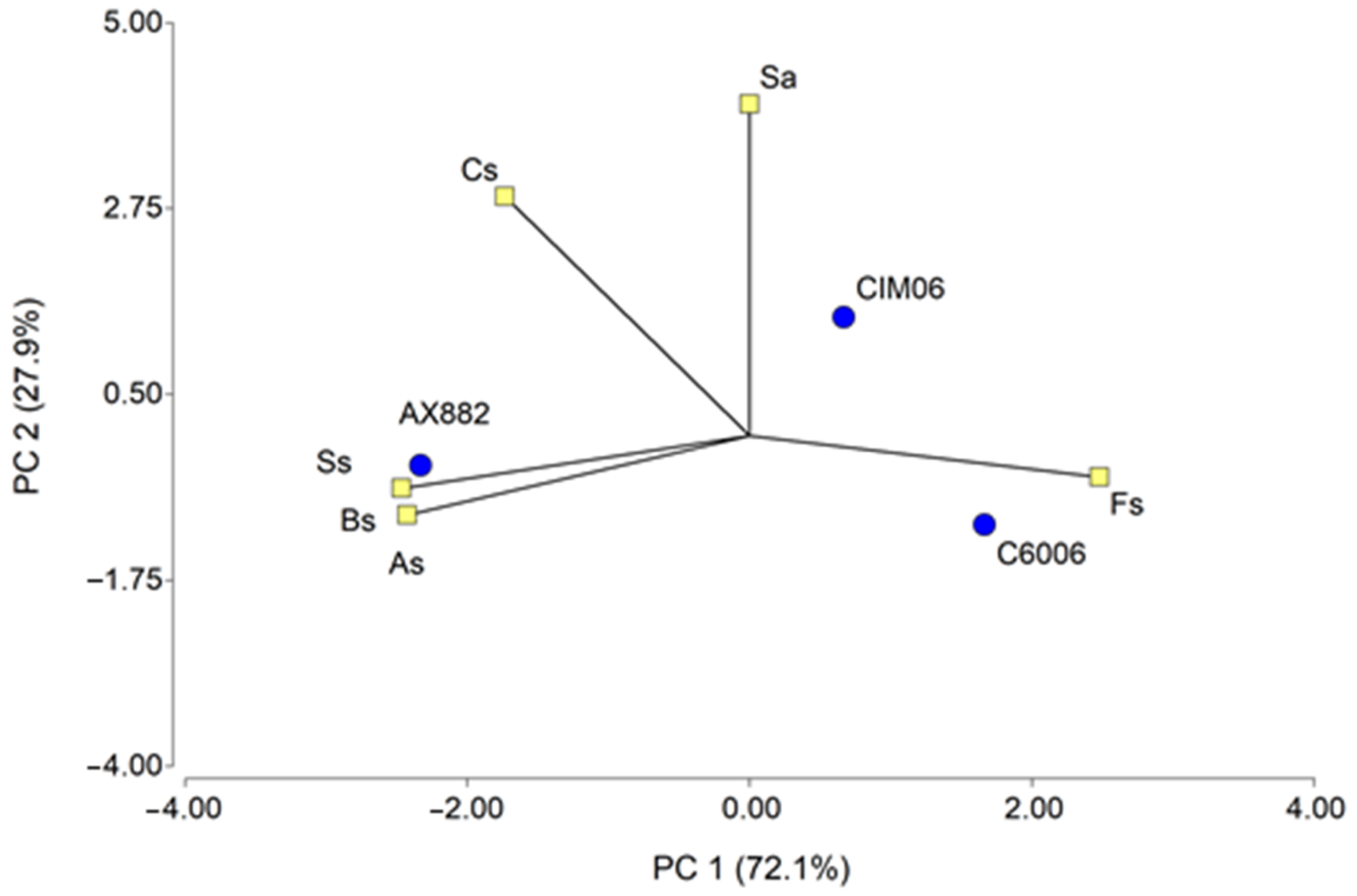

3.4. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moreno Amador, M.D.L.; Comino Montilla, I.M.; Sousa Martín, C. Alternative grains as potential raw material for gluten–free food development in the diet of celiac and gluten–sensitive patients. Austin J. Nutri. Food Sci. 2014, 2, 1–9. [Google Scholar]

- Marti, A.; Pagani, M.A. What can play the role of gluten in gluten free pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Cubadda, R.E.; Carcea, M.; Marconi, E.; Trivisonno, M.C. Influence of gluten proteins and drying temperature on the cooking quality of durum wheat pasta. Cereal Chem. 2007, 84, 48–55. [Google Scholar] [CrossRef]

- Marti, A.; D’Egidio, M.A.; Pagani, M.A. Pasta: Quality testing methods. In Encyclopedia of Food Grains; Wrigley, C.W., Cork, H., Seetharaman, K., Faubion, J., Eds.; Academic Press: Waltham, MA, USA, 2015; pp. 161–165. [Google Scholar]

- do Nascimento, K.D.O.; Paes, S.D.N.D.; de Oliveira, I.R.; Reis, I.P.; Augusta, I.M. Teff: Suitability for different food applications and as a raw material of gluten-free, a literature review. J. Food Nutr. Res. 2018, 6, 74–81. [Google Scholar] [CrossRef]

- Gkountenoudi-Eskitzi, I.; Kotsiou, K.; Irakli, M.N.; Lazaridis, A.; Biliaderis, C.G.; Lazaridou, A. In vitro and in vivo glycemic responses and antioxidant potency of acorn and chickpea fortified gluten-free breads. Food Res. Int. 2023, 166, 112579. [Google Scholar] [CrossRef] [PubMed]

- Bongianino, N.F.; Steffolani, M.E.; Biasutti, C.A.; León, A.E. Suitability of Argentinian maize hybrids for polenta production. Int. J. Food Sci. Technol. 2022, 57, 4859–4867. [Google Scholar] [CrossRef]

- Widelska, G.; Wójtowicz, A.; Kasprzak, K.; Dib, A.; Oniszczuk, T.; Olech, M.; Wojtunik-Kulesza, K.; Nowak, R.; Sujak, A.; Dobrzański, B.; et al. Impact of xanthan gum addition on phenolic acids composition and selected properties of new gluten-free maize-field bean pasta. Open Chem. 2019, 17, 587–598. [Google Scholar] [CrossRef]

- Padalino, L.; Mastromatteo, M.; Sepielli, G.; Nobile, M.A.D. Formulation optimization of gluten-free functional spaghetti based on maize flour and oat bran enriched in b-glucans. Materials 2011, 4, 2119–2135. [Google Scholar] [CrossRef]

- Yalcin, S.; Basman, A. Quality characteristics of corn noodles containing gelatinized starch, transglutaminase and gum. J. Food Qual. 2008, 31, 465–479. [Google Scholar] [CrossRef]

- Scarton, M.; Clerici, M.T.P.S. Gluten-free pastas: Ingredients and processing for technological and nutritional quality improvement. Food Sci. Technol. 2022, 42, e65622. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A.; Seetharaman, K. Textural attri-butes of wheat and gluten free pasta. In Food Texture Design Andoptimization; Dar, Y.L., Light, J.M., Eds.; John Wiley & Sons: New York, NY, USA, 2014; pp. 222–224. [Google Scholar]

- Gao, Y.; Janes, M.E.; Chaiya, B.; Brennan, M.A.; Brennan, C.S.; Prinyawiwatkul, W. Gluten-free bakery and pasta products: Prevalence and quality improvement. Int. J. Food Sci. Technol. 2018, 53, 19–32. [Google Scholar] [CrossRef]

- Tamagno, S.; Greco, I.A.; Almeida, H.; Borras, L. Physiological differences in yield related traits between flint and dent Argentinean commercial maize genotypes. Eur. J. Agron. 2015, 68, 50–56. [Google Scholar] [CrossRef]

- Abdala, L.J.; Gambin, B.L.; Borrás, L. Sowing date and maize grain quality for dry milling. Eur. J. Agron. 2018, 92, 1–8. [Google Scholar] [CrossRef]

- Borrás, L.; Caballero-Rothar, N.N.; Saenz, E.; Segui, M.; Gerde, J.A. Challenges and opportunities of hard endosperm food grade maize sourced from South America to Europe. Eur. J. Agron. 2022, 140, 126596. [Google Scholar] [CrossRef]

- Ortiz-Monasterio, J.I.; Palacios-Rojas, N.; Meng, E.; Pixley, K.; Trethowan, R.; Pena, R.J. Enhancing the mineral and vitamin content of wheat and maize through plant breeding. J. Cereal Sci. 2007, 46, 293–307. [Google Scholar] [CrossRef]

- Palacios-Rojas, N. Calidad Nutricional e Industrial de maíz: Laboratorio de Calidad Nutricional de Maíz “Evangelina Villegas”; International Maize and Wheat Improvement Center (CIMMYT), CDMX: Mexico City, México, 2018; pp. 37–40. [Google Scholar]

- Cappa, C.; Lucisano, M.; Barbosa-Cánovas, G.V.; Mariotti, M. Physical and structural changes induced by high pressure on corn starch, rice flour and waxy rice flour. Food Res. Int. 2016, 85, 95–103. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Cooking effect on the bioactive compounds, texture, and color properties of cold-extruded rice/bean-based pasta supplemented with whole carob fruit. Foods 2020, 9, 415. [Google Scholar] [CrossRef]

- Kamble, D.B.; Singh, R.; Rani, S.; Pratap, D. Physicochemical properties, in vitro digestibility and structural attributes of okara-enriched functional pasta. J. Food Process. Preserv. 2019, 43, 14232. [Google Scholar] [CrossRef]

- Bustos, M.C.; Paesani, C.; Quiroga, F.; León, A.E. Technological and sensorial quality of berry-enriched pasta. Cereal Chem. 2019, 96, 967–976. [Google Scholar] [CrossRef]

- Martínez, M.L.; Marín, M.A.; Gili, R.D.; Penci, M.C.; Ribotta, P.D. Effect of defatted almond flour on cooking, chemical and sensorial properties of gluten-free fresh pasta. Int. J. Food Sci. Technol. 2017, 52, 2148–2155. [Google Scholar] [CrossRef]

- Salvador-Reyes, R.; Sampaio, U.M.; de Menezes Alves Moro, T.; Brito, A.D.C.D.; Behrens, J.; Campelo, P.H.; Pedrosa Silva Clerici, M.T. Andean purple maize to produce extruded breakfast cereals: Impact on techno-functional properties and sensory acceptance. J. Sci. Food Agric. 2023, 103, 548–559. [Google Scholar] [CrossRef]

- Anderson, B.; Almeida, H. Corn Dry Milling: Processes, Products, and Applications; Corn AACC International Press: St. Louis, MO, USA, 2019; pp. 405–433. [Google Scholar]

- Shi, L.; Li, W.; Sun, J.; Qiu, Y.; Wei, X.; Luan, G.; Hu, Y.; Tatsumi, E. Grinding of maize: The effects of fine grinding on compositional, functional and physicochemical properties of maize flour. J. Cereal Sci. 2016, 68, 25–30. [Google Scholar] [CrossRef]

- León, A.E.; Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; Rosell, C.M. Effect of damaged starch levels on flour-thermal behaviour and bread staling. Eur. Food Res. Technol. 2006, 224, 187–192. [Google Scholar] [CrossRef]

- Saad, M.M.; Gaiani, C.; Scher, J.; Cuq, B.; Ehrhardt, J.J.; Desobry, S. Impact of re-grinding on hydration properties and surface composition of wheat flour. J. Cereal Sci. 2009, 49, 134–140. [Google Scholar] [CrossRef]

- Gerde, J.A.; Spinozzi, J.I.; Borrás, L. Maize kernel hardness, endosperm zein profiles, and ethanol production. BioEnergy Res. 2017, 10, 760–771. [Google Scholar] [CrossRef]

- Robutti, J.; Borrás, F.; Gonzalez, R.; Torres, R.; De Greef, D. Endosperm properties and extrusion cooking behavior of maize cultivars. LWT-Food Sci. Technol. 2002, 35, 663–669. [Google Scholar] [CrossRef]

- Flores-Silva, P.C.; Berrios, J.D.J.; Pan, J.; Agama-Acevedo, E.; Monsalve-González, A.; Bello-Pérez, L.A. Gluten-free spaghetti with unripe plantain, chickpea and maize: Physicochemical, texture and sensory properties. CyTA-J. Food. 2015, 13, 159–166. [Google Scholar] [CrossRef]

- Camelo-Méndez, G.A.; Tovar, J.; Bello-Pérez, L.A. Influence of blue maize flour on gluten-free pasta quality and antioxidant retention characteristics. J. Food Sci. Technol. 2018, 55, 2739–2748. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Drausinger, J.; Ottenschlaeger, V.; Jurackova, K.; Berghofer, E. Functional properties of gluten-free pasta produced from amaranth, quinoa and buckwheat. Plant Foods Hum. Nutr. 2010, 65, 339–349. [Google Scholar] [CrossRef]

- Baah, R.O.; Duodu, K.G.; Emmambux, M.N. Cooking quality, nutritional and antioxidant properties of gluten-free maize–Orange-fleshed sweet potato pasta produced by extrusion. LWT-Food Sci. Technol. 2022, 162, 113415. [Google Scholar] [CrossRef]

- Sissons, M. Role of durum wheat composition on the quality of pasta and bread. Food 2008, 2, 75–90. [Google Scholar]

- Susanna, S.; Prabhasankar, P. A study on development of Gluten free pasta and its biochemical and immunological validation. LWT-Food Sci. Technol. 2013, 50, 613–621. [Google Scholar] [CrossRef]

- Deepa, C.; Sarabhai, S.; Prabhasankar, P.; Hebbar, H.U. Effect of micronization of maize on quality characteristics of pasta. Cereal Chem. 2017, 94, 840–846. [Google Scholar] [CrossRef]

- Bresciani, A.; Giordano, D.; Vanara, F.; Blandino, M.; Marti, A. High-amylose corn in gluten-free pasta: Strategies to deliver nutritional benefits ensuring the overall quality. Food Chem. 2021, 353, 129489. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Li, L.; Zheng, X. A review of milling damaged starch: Generation, measurement, functionality and its effect on starch-based food systems. Food Chem. 2020, 315, 126267. [Google Scholar] [CrossRef] [PubMed]

- Batterman-Azcona, S.J.; Hamaker, B.R. Changes occurring in protein body structure and α-zein during cornflake processing. Cereal Chem. 1998, 75, 217–221. [Google Scholar] [CrossRef]

- Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; León, A.E. Influence of damaged starch on cookie and bread-making quality. Eur. Food Res. Technol. 2007, 225, 1–7. [Google Scholar] [CrossRef]

- Milde, L.B.; Chigal, P.S.; Olivera, J.E.; González, K.G. Incorporation of xanthan gum to gluten-free pasta with cassava starch. Physical, textural and sensory attributes. LWT—Food Sci. Technol. 2020, 131, 109674. [Google Scholar] [CrossRef]

| Attribute | Instructions |

|---|---|

| Brightness | Take a strand of pasta and place it in line with your view, turn it slightly so that the light falls on it, and see how much it reflects. |

| Surface appearance | Take a strand of pasta and place it on the plate. Observe and count how many points you can observe. |

| Firmness | Take one strand of pasta at a time, place it between the incisors, and bite evenly, assessing the force required to compress and cut evenly. |

| Chewiness | Take a strand of pasta, place it between the molars, and chew it at a steady, speed. Count the number of times you chew to reduce it to a swallowable state. |

| Springiness | Take a strand of pasta from one of its ends and roll it out. Assess the degree to which the pasta reaches its original length/stretch resistance without breaking. |

| Adhesiveness | Place the pasta in the mouth, pressing it against the roof of the mouth, and determine the force required to remove it with the tongue. |

| Genotype | AX882 | P1815 | P2089 | C6006 | CIM06 |

|---|---|---|---|---|---|

| P100 (g) | 35.27 ± 3.94 bc | 31.25 ± 4.53 a | 37.98 ± 0.38 c | 32.95 ± 1.17 ab | 33.40 ± 1.16 ab |

| TW (Kg/HL) | 85.00 ± 1.92 b | 88.80 ± 1.17 c | 81.60 ± 1.03 a | 92.00 ± 0.73 d | 92.50 ± 1.10 d |

| FI (%) | 90.50 ± 3.42 d | 74.00 ± 6.32 c | 94.00 ± 1.63 d | 21.50 ± 5.51 b | 10.50 ± 4.12 a |

| WRC (%) | 237.44 ± 2.06 a | 234.46 ± 6.07 a | 234.33 ± 8.94 a | 256.31 ± 9.39 b | 255.77 ± 10.15 b |

| ScRC (%) | 213.19 ± 29.9 a | 233.21 ± 2.27 ab | 224.19 ± 12.97 a | 263.10 ± 6.29 c | 245.97 ± 2.41 bc |

| D901 (µm) | 78.35 ± 3.56 abc | 70.75 ± 12.10 a | 72.94 ± 14.79 ab | 91.47 ± 13.77 bc | 92.69 ± 13.61 c |

| D902 (µm) | 631.86 ± 100.05 ab | 693.93 ± 187.04 abc | 524.39 ± 143.21 a | 722.87 ± 77.71 bc | 823.42 ± 53.96 c |

| Ash (%) | 1.54 ± 0.04 ab | 1.66 ± 0.10 c | 1.52 ± 0.04 a | 1.73 ± 0.13 c | 1.65 ± 0.06 bc |

| Protein (%) | 8.46 ± 0.53 b | 7.95 ± 0.25 b | 7.39 ± 0.27 a | 10.33 ± 0.58 c | 10.47 ± 0.21 c |

| Oil (%) | 5.15 ± 0.33 a | 6.05 ± 1.65 b | 6.11 ± 1.67 b | 4.67 ± 0.16 a | 6.77 ± 0.12 b |

| Starch (%) | 74.00 ± 4.74 d | 72.96 ± 1.86 cd | 65.93 ± 2.99 ab | 68.98 ± 2.59 bc | 63.96 ± 2.07 a |

| Amylose (%) | 22.08 ± 1.29 b | 18.27 ± 3.94 a | 21.33 ± 0.61 b | 22.04 ± 1.15 b | 21.83 ± 0.57 b |

| Amylose/Starch (%) | 0.30 ± 0.03 ab | 0.25 ± 0.06 a | 0.32 ± 0.01 b | 0.32 ± 0.02 b | 0.34 ± 0.02 b |

| Dam.S (%) | 14.29 ± 1.97 a | 20.83 ± 0.70 b | 13.61 ± 0.75 a | 22.92 ± 3.05 c | 26.1 ± 0.71 d |

| Genotype | SS | GS (N) | FS (N) | AS (J) | SI | WA (%) | CL (%) |

|---|---|---|---|---|---|---|---|

| AX882 | 0.89 ± 0.03 b | 5.53 ± 1.37 a | 13.95 ± 2.31 a | 0.00021 ± 0.000054 a | 2.28 ± 0.18 c | 296.10 ± 54.55 c | 7.63 ± 0.76 a |

| P1815 | 0.82 ± 0.07 a | 8.03 ± 2.87 c | 17.56 ± 2.57 b | 0.00026 ± 0.000042 ab | 2.06 ± 0.08 b | 216.50 ± 42.90 b | 7.30 ± 0.64 a |

| P2089 | 0.83 ± 0.07 a | 7.44 ± 0.93 bc | 17.09 ± 1.01 b | 0.00031 ± 0.000027 b | 2.22 ± 0.12 bc | 278.86 ± 51.22 c | 6.78 ± 0.75 a |

| C6006 | 0.83 ± 0.05 ab | 6.66 ± 0.79 abc | 19.68 ± 1.83 c | 0.00023 ± 0.000046 a | 1.77 ± 0.14 a | 124.30 ± 44.98 a | 6.98 ± 0.89 a |

| CIM06 | 0.82 ± 0.08 a | 6.56 ± 0.96 ab | 21.65 ± 1.31 c | 0.00022 ± 0.00001 a | 1.77 ± 0.10 a | 134.58 ± 24.27 a | 7.10 ± 1.25 a |

| Variable | PC1 | PC2 |

|---|---|---|

| Value | 4.32 | 1.68 |

| Proportion | 0.72 | 0.28 |

| Cumulative proportion | 0.72 | 1 |

| Sensory parameters | ||

| Bs | −0.47 | −0.19 |

| Sa | 1.20 × 10−4 | 0.77 |

| Fs | 0.48 | −0.1 |

| Cs | −0.33 | 0.56 |

| As | −0.47 | −0.19 |

| Ss | −0.47 | −0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bongianino, N.F.; Steffolani, M.E.; Morales, C.D.; Biasutti, C.A.; León, A.E. Technological and Sensory Quality of Gluten-Free Pasta Made from Flint Maize Cultivars. Foods 2023, 12, 2780. https://doi.org/10.3390/foods12142780

Bongianino NF, Steffolani ME, Morales CD, Biasutti CA, León AE. Technological and Sensory Quality of Gluten-Free Pasta Made from Flint Maize Cultivars. Foods. 2023; 12(14):2780. https://doi.org/10.3390/foods12142780

Chicago/Turabian StyleBongianino, Nicolás Francisco, María Eugenia Steffolani, Claudio David Morales, Carlos Alberto Biasutti, and Alberto Edel León. 2023. "Technological and Sensory Quality of Gluten-Free Pasta Made from Flint Maize Cultivars" Foods 12, no. 14: 2780. https://doi.org/10.3390/foods12142780

APA StyleBongianino, N. F., Steffolani, M. E., Morales, C. D., Biasutti, C. A., & León, A. E. (2023). Technological and Sensory Quality of Gluten-Free Pasta Made from Flint Maize Cultivars. Foods, 12(14), 2780. https://doi.org/10.3390/foods12142780