Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Quality Determination in Sausages

2.2.1. Proximal Analysis

2.2.2. Energy Value

2.2.3. Color

2.2.4. Microbiological Analysis

2.2.5. Sensory Quality

2.2.6. Chlorides Determination

2.2.7. Nitrite Determination

2.3. Lipid Content Quantification

2.3.1. Fat Extraction

2.3.2. Methyl Esterification of Fatty Acids

2.3.3. Chromatographic Determination

2.3.4. Identification and Quantification of Fatty Acids

2.4. Statistical Analysis

3. Results

3.1. Proximal Composition and Nutritional Estimations

3.2. Acidity and pH

3.3. Water Activity, Chlorides, and Nitrites

3.4. Color Properties

3.5. Microbiological Analysis

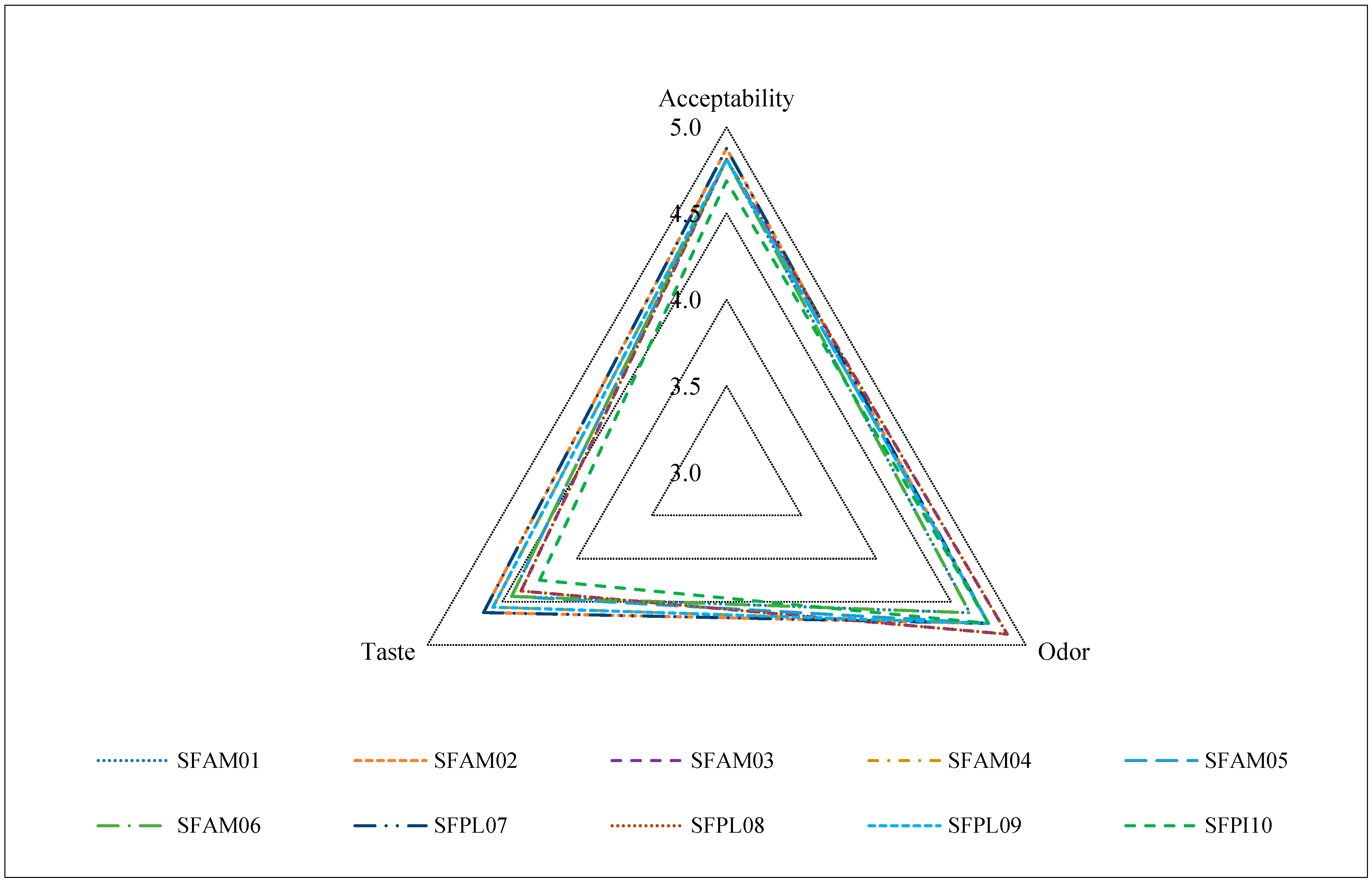

3.6. Sensory Analysis

3.7. Lipidic Content of Sausages

4. Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salazar, D.; Arancibia, M.; Calderón, L.; López-Caballero, M.E.; Montero, M.P. Underutilized Green Banana (Musa acuminata AAA) flours to develop fiber enriched frankfurter-type sausages. Foods 2021, 10, 1142. [Google Scholar] [CrossRef]

- Elias, M.; Laranjo, M.; Agulheiro-Santos, A.C.; Potes, M.E. The role of salt on food and human health. In Salt in the Earth; IntechOpen: London, UK, 2020; Volume 19. [Google Scholar]

- FAO. Global Emergence of Infectious Diseases: Links with Wild Meat Consumption, Ecosystem Disruption, Habitat Degradation and Biodiversity Loss; FAO: Rome, Italy, 2020; p. 6. [Google Scholar]

- Méndez-Zamora, G.; García-Macías, J.A.; Santellano-Estrada, E.; Chávez-Martínez, A.; Durán-Meléndez, L.A.; Silva-Vázquez, R.; Quintero-Ramos, A. Fat reduction in the formulation of frankfurter sausages using inulin and pectin. Food Sci. Technol. 2015, 35, 25–31. [Google Scholar] [CrossRef]

- San-Cristobal, R.; Navas-Carretero, S.; Martínez-González, M.Á.; Ordovas, J.M.; Martínez, J.A. Contribution of macronutrients to obesity: Implications for precision nutrition. Nat. Rev. Endocrinol. 2020, 16, 305–320. [Google Scholar] [CrossRef] [PubMed]

- Malik, V.S.; Hu, F.B. The role of sugar-sweetened beverages in the global epidemics of obesity and chronic diseases. Nat. Rev. Endocrinol. 2022, 18, 205–218. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, I.M.C.; Paglarini, C.d.S.; Vidal, V.A.S.; Pollonio, M.A.R. Bamboo fiber improves the functional properties of reduced salt and phosphate-free Bologna sausage. J. Offood Process. Preserv. 2020, 44, e14929. [Google Scholar]

- Salejda, A.M.; Olender, K.; Zielińska-Dawidziak, M.; Mazur, M.; Szperlik, J.; Miedzianka, J.; Zawiślak, I.; Kolniak-Ostek, J.; Szmaja, A. Frankfurter-type sausage enriched with buckwheat by-product as a source of bioactive compounds. Foods 2022, 11, 674. [Google Scholar] [CrossRef]

- Araya-Quesada, Y.; Araya-Morice, A.; Araya-Vargas, S.; Redondo-Solano, M.; Madrigal-Arias, E.; Cubero-Castillo, E. Reduction of sodium additives in cooked sausages: Effect on physicochemical, sensory and microbiological characteristics. J. Food Sci. Technol. 2020, 57, 3051–3059. [Google Scholar] [CrossRef]

- Rees, J. Food Adulteration and Food Fraud; Reaktion Books: London, UK, 2020. [Google Scholar]

- Kim, T.-K.; Yong, H.-I.; Jung, S.; Kim, H.-W.; Choi, Y.-S. Technologies for the production of meat products with a low sodium chloride content and improved quality characteristics—A review. Foods 2021, 10, 957. [Google Scholar] [CrossRef]

- Rodrigues, I.; Gonçalves, L.A.; Carvalho, F.A.; Pires, M.; JP Rocha, Y.; Barros, J.C.; Carvalho, L.T.; Trindade, M.A. Understanding salt reduction in fat-reduced hot dog sausages: Network structure, emulsion stability and consumer acceptance. Food Sci. Technol. Int. 2020, 26, 123–131. [Google Scholar] [CrossRef]

- Morrow, L.; Greenwald, B. Healthy Food choices, physical activity, and Screening Reduce the Risk of colorectal cancer. Gastroenterol. Nurs. 2022, 45, 113–119. [Google Scholar] [CrossRef]

- Nasonova, V.V.; Tunieva, E.K. A comparative study of fat replacers in cooked sausages. IOP Conf. Ser. Earth. Environ. Sci. 2019, 333, 012085. [Google Scholar] [CrossRef]

- Patel, A.R.; Nicholson, R.A.; Marangoni, A.G. Applications of fat mimetics for the replacement of saturated and hydrogenated fat in food products. Curr. Opin. Food Sci. 2020, 33, 61–68. [Google Scholar] [CrossRef]

- Karwowska, M.; Kononiuk, A.D.; Borrajo, P.; Lorenzo, J.M. Comparative studies on the fatty acid profile and volatile compounds of fallow deer and beef fermented sausages without nitrite produced with the addition of acid whey. Appl. Sci. 2021, 11, 1320. [Google Scholar] [CrossRef]

- de Carvalho, F.A.L.; Munekata, P.E.S.; Pateiro, M.; Campagnol, P.C.B.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT 2020, 122, 109052. [Google Scholar] [CrossRef]

- Islam, M.A.; Amin, M.N.; Siddiqui, S.A.; Hossain, M.P.; Sultana, F.; Kabir, M.R. Trans fatty acids and lipid profile: A serious risk factor to cardiovascular disease, cancer and diabetes. Diabetes Metab. Syndr. 2019, 13, 1643–1647. [Google Scholar] [CrossRef]

- Moreira, M.J.; García-Díez, J.; de Almeida, J.M.M.M.; Saraiva, C. Consumer knowledge about food labeling and fraud. Foods 2021, 10, 1095. [Google Scholar] [CrossRef]

- Pleadin, J.; Lešić, T.; Vujačić, V.; Milićević, D.; Buneta, A.; Šušnić, S.; Lukanić, I.; Krešić, G. Comparison of Chemical Composition and Fatty Acid Profile of Traditional Meat Products from Croatia and Montenegro. J. Food Qual. 2021, 2021, 5586436. [Google Scholar] [CrossRef]

- López-Pedrouso, M.; Lorenzo, J.M.; Gullón, B.; Campagnol, P.C.B.; Franco, D. Novel strategy for developing healthy meat products replacing saturated fat with oleogels. Curr. Opin. Food Sci. 2021, 40, 40–45. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; AOAC: Rockville, MD, USA, 2005. [Google Scholar]

- Canadian Food Inspection Agency (CFIA). Food Labelling for Industry. Available online: https://www.inspection.gc.ca/food-label-requirements/labelling/industry/nutrition-labelling/elements-within-the-nutrition-facts-table/eng/1389206763218/1389206811747?chap=1 (accessed on 10 September 2023).

- Food Drug Administration (FDA). Nutrition Labeling of Food. 21 CFR 101.9. Available online: https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-101/subpart-A/section-101.9 (accessed on 10 September 2023).

- Bennett, R.W.; Monday, S.R. Staphylococcus aureus. In International Handbook of Foodborne Pathogens; CRC Press: Boca Raton, FL, USA, 2003; pp. 61–80. [Google Scholar]

- Korkmaz, D. Precipitation titration: “Determination of chloride by the Mohr method”. Methods 2001, 2, 1–6. [Google Scholar]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Ichihara, K.i.; Fukubayashi, Y. Preparation of fatty acid methyl esters for gas-liquid chromatography. J. Lipid Res. 2010, 51, 635–640. [Google Scholar] [CrossRef]

- Orata, F. Derivatization Reactions and Reagents for Gas Chromatography Analysis; Intech: Penang, Malaysia, 2012; Volume 91. [Google Scholar]

- Antolín, E.M.; Delange, D.M.; Canavaciolo, V.G. Evaluation of five methods for derivatization and GC determination of a mixture of very long chain fatty acids (C24:0–C36:0). J. Pharm. Biomed. Anal. 2008, 46, 194–199. [Google Scholar] [CrossRef]

- Chin, K.B.; Lee, H.L.; Chun, S.S. Product characteristics of comminuted sausages as affected by various fat and moisture combinations. Asian-Australas. J. Anim. Sci. 2004, 17, 538–542. [Google Scholar] [CrossRef]

- Rosero-Chasoy, G.; Serna-Cock, L. Effect of plantain (Musa paradisiaca L. cv. Dominico Harton) peel flour as binder in frankfurter-type sausage. Acta Agron. 2017, 66, 305–310. [Google Scholar] [CrossRef]

- dos Santos Alves, L.A.A.; Lorenzo, J.M.; Gonçalves, C.A.A.; dos Santos, B.A.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Choe, J.; Kim, H.-Y. Quality characteristics of reduced fat emulsion-type chicken sausages using chicken skin and wheat fiber mixture as fat replacer. Poult. Sci. 2019, 98, 2662–2669. [Google Scholar] [CrossRef] [PubMed]

- Alvarado-Ramírez, M.; Santana-Gálvez, J.; Santacruz, A.; Carranza-Montealvo, L.D.; Ortega-Hernández, E.; Tirado-Escobosa, J.; Cisneros-Zevallos, L.; Jacobo-Velázquez, D.A. Using a functional carrot powder ingredient to produce sausages with high levels of nutraceuticals. J. Food Sci. 2018, 83, 2351–2361. [Google Scholar] [CrossRef] [PubMed]

- Ecuadorian Institue of Normalization. Carne y Productos Cárnicos. In Productos Cárnicos Crudos, Productos Cárnicos Curados-Madurados y Productos Cárnicos Precocidos-Cocidos; Ecuadorian Institue of Normalization: Quito, Ecuador, 2012. [Google Scholar]

- de los Angeles Vivar-Vera, M.; Pérez-Silva, A.; Ruiz-López, I.I.; Hernández-Cázares, A.S.; Solano-Barrera, S.; Ruiz-Espinosa, H.; Bernardino-Nicanor, A.; González-Cruz, L. Chemical, physical and sensory properties of Vienna sausages formulated with a starfruit dietary fiber concentrate. J. Food Sci. Technol. 2018, 55, 3303–3313. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Choi, J.-H.; Lee, M.-A.; Chung, H.-J.; Kim, C.-J. Physicochemical properties and sensory characteristics of reduced-fat frankfurters with pork back fat replaced by dietary fiber extracted from makgeolli lees. Meat Sci. 2014, 96, 892–900. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Ruiz-Capillas Pérez, C.; Solas, M.T.; Jiménez-Colmenero, F. Healthier oils stabilized in konjac matrix as fat replacers in n−3 PUFA enriched frankfurters. Meat Sci. 2013, 93, 757–766. [Google Scholar] [CrossRef]

- WHO. Diet, Nutrition and the Prevention of Chronic Diseases; Technical Report Series 916; WHO: Geneva, Switzerland, 2003. [Google Scholar]

- Wang, Y.; Han, J.; Wang, D.; Gao, F.; Zhang, K.; Tian, J.; Jin, Y. Research update on the impact of lactic acid bacteria on the substance metabolism, flavor, and quality characteristics of fermented meat products. Foods 2022, 11, 2090. [Google Scholar] [CrossRef]

- Sallan, S.; Yılmaz Oral, Z.F.; Kaya, M. A review on the role of lactic acid bacteria in the formation and reduction of volatile nitrosamines in fermented sausages. Foods 2023, 12, 702. [Google Scholar] [CrossRef]

- Paudel, N.; Subedi, D.; Khanal, S.; Acharya, D.R.; Bhattarai, S. Estimation of nitrite level and effect of processing on residual nitrite level in sausages marketed in Dharan, Nepal. Afr. J. Food Sci. 2021, 15, 67–71. [Google Scholar]

- González-Tenorio, R.; Totosaus, A.; Caro, I.; Mateo, J. Caracterización de Propiedades Químicas y Fisicoquímicas de Chorizos Comercializados en la Zona Centro de México. Inf. Tecnol. 2013, 24, 3–14. [Google Scholar] [CrossRef]

- Perez-Baez, A.J.; Camou, J.P.; Valenzuela-Melendres, M.; Lucas-Gonzalez, R.; Viuda-Martos, M. Assessment of chemical, physico-chemical and sensorial properties of frankfurter-type sausages added with roselle (Hibiscus sabdariffa L.), extracts. Proceedings 2021, 70, 73. [Google Scholar]

- Castro Bolanos, M.; Herrera Ramirez, C.H.; Lutz Cruz, G. Composition, characterization and atherogenic potential of oils, fats and other by products produced or marketed in Costa Rica. Acta Med. Costarric 2005, 47, 36–42. [Google Scholar]

- International Commission on Microbiological Specifications for Foods. Microorganisms in Foods 5: Characteristics of Microbial Pathogens; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996; Volume 5. [Google Scholar]

- Kamboj, S.; Gupta, N.; Bandral, J.D.; Gandotra, G.; Anjum, N. Food safety and hygiene: A review. Int. J. Chem. Stud. 2020, 8, 358–368. [Google Scholar] [CrossRef]

- FDA. Food Additives Permitted for Direct Addition to Food for Human Consumption; FDA: Silver Spring, MD, USA, 2023; Volume 3.

- Stoica, M.; Antohi, V.M.; Alexe, P.; Ivan, A.S.; Stanciu, S.; Stoica, D.; Zlati, M.L.; Stuparu-Cretu, M. New strategies for the total/partial replacement of conventional sodium nitrite in meat products: A review. Food. Bioproc. Tech. 2022, 15, 514–538. [Google Scholar] [CrossRef]

- Yang, X.; Sebranek, J.G.; Luo, X.; Zhang, W.; Zhang, M.; Xu, B.; Zhang, Y.; Liang, R. Effects of calcium salts on the physicochemical quality of cured beef sausages during manufacturing and storage: A potential calcium application for sausages with alginate casings. Foods 2021, 10, 2783. [Google Scholar] [CrossRef]

- Pérez-Alvarez, J.A.; Fernández-López, J. Color Characteristics of Meat and Poultry Processing; CRC Press: Boca Raton, FL, USA, 2009; pp. 355–373. [Google Scholar]

- Üren, A.; Babayiğit, D. Colour parameters of Turkish-type fermented sausage during fermentation and ripening. Meat Sci. 1997, 45, 539–549. [Google Scholar] [CrossRef]

- Fadda, S.; Vignolo, G. Central and South American Products; Wiley: Medford, MA, USA, 2014; pp. 355–360. [Google Scholar]

- Aykın-Dinçer, E.; Güngör, K.K.; Çağlar, E.; Erbaş, M. The use of beetroot extract and extract powder in sausages as natural food colorant. Int. J. Food Eng. 2020, 17, 75–82. [Google Scholar] [CrossRef]

- Jin, S.-k.; Kim, S.-H.; Choi, J.-S.; Yim, D.-G. Effect of diverse binder materials and their addition levels on physico-chemical characteristics of sausages. J. Food Meas. Charact. 2019, 13, 1558–1565. [Google Scholar] [CrossRef]

- Khatkar, A.B.; Kaur, A. Effect of protein incorporation on functional, thermal, textural and overall quality characteristics of instant noodles. J. Food Meas. Charact. 2018, 12, 2218–2229. [Google Scholar] [CrossRef]

- Noguerol, A.T.; Larrea, V.; Pagán, M.J. The effect of psyllium (Plantago ovata Forsk) fibres on the mechanical and physicochemical characteristics of plant-based sausages. Eur. Food Res. Technol. 2022, 248, 2483–2496. [Google Scholar] [CrossRef]

- Ranucci, D.; Roila, R.; Andoni, E.; Braconi, P.; Branciari, R. Punica granatum and Citrus spp. extract mix affects spoilage microorganisms growth rate in vacuum-packaged cooked sausages made from pork meat, emmer wheat (Triticum dicoccum Schübler), almond (Prunus dulcis Mill.) and hazelnut (Corylus avellana L.). Foods 2019, 8, 664. [Google Scholar] [CrossRef]

- Fudali, A.; Chełmecka, I.; Salejda, A.M.; Krasnowska, G. Microbiological safety and organoleptic quality of homogenized sausages manufactured with commercial functional additives. Appl. Sci. 2021, 11, 11662. [Google Scholar] [CrossRef]

- Varga-Visi, É.; Toxanbayeva, B.; Andrássyné Baka, G.; Romváari, R. Shelf life and quality of Bologna-type fat reduced turkey sausage. Acta Aliment. 2020, 49, 60–68. [Google Scholar] [CrossRef]

- Cerón-Guevara, M.I.; Rangel-Vargas, E.; Lorenzo, J.M.; Bermúdez, R.; Pateiro, M.; Rodríguez, J.A.; Sánchez-Ortega, I.; Santos, E.M. Reduction of salt and fat in Frankfurter sausages by addition of Agaricus bisporus and Pleurotus ostreatus flour. Foods 2020, 9, 760. [Google Scholar] [CrossRef]

- Sachindra, N.; Sakhare, P.; Yashoda, K.; Rao, D.N. Microbial profile of buffalo sausage during processing and storage. Food Control 2005, 16, 31–35. [Google Scholar] [CrossRef]

- Macedo, R.C.B.D.S.; Rebouças, C.K.D.O.; Melo, E.C.C.D.; Freire, B.C.F.; Mendonça, L.P.D.; Santana, F.E.D.O.; Bezerra, A.C.D.S.; Soares, K.M.D.P. Evaluation of the physicochemical and microbiological quality of hot dog sausages in the city of Mossoró, Rio Grande do Norte, Brazil. Res. Soc. Dev. 2021, 10, e118101119195. [Google Scholar] [CrossRef]

- de Marco, I.; Vogel, C.; Morandin, G.C.; Beilke, L.; Valduga, N.Z.; Zambiazi, E.T.; Martinhago, J.V.; Schittler, L. Salsichas tipo hot dog: Perfil microbiológico, isolamento e caracterização de bactérias ácido láticas (BAL) com potencial antagonista. In Proceedings of the Revista do Congresso Sul Brasileiro de Engenharia de Alimentos, Guarapuava, Brazil, 5–9 November 2018. [Google Scholar]

- Nkekesi, B.; Amenya, P.; Aboagye, G.; Kortei, N.K. Street-vended grilled beef sausages as potential vehicles of bacterial and fungal pathogens: An exploratory survey in Ho, the capital city of the Volta Region of Ghana. Food Sci. Nutr. 2023, 11, 7013–7025. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Hu, J.Y.; Wu, Y.; Chen, M.; Ou, J.; Yan, W.L. Assessment of the inhibitory effects of sodium nitrite, nisin, potassium sorbate, and sodium lactate on Staphylococcus aureus growth and staphylococcal enterotoxin A production in cooked pork sausage using a predictive growth model. Food Sci. Hum. Wellness. 2018, 7, 83–90. [Google Scholar] [CrossRef]

- Muchekeza, J.T.; Jombo, T.Z.; Magogo, C.; Mugari, A.; Manjeru, P.; Manhokwe, S. Proximate, physico-chemical, functional and sensory properties of quinoa and amaranth flour AS potential binders in beef sausages. Food. Chem. 2021, 365, 130619. [Google Scholar] [CrossRef]

- Sam, F.E.; Ma, T.-Z.; Atuna, R.A.; Salifu, R.; Nubalanaan, B.-A.; Amagloh, F.K.; Han, S.-Y. Physicochemical, oxidative stability and sensory properties of frankfurter-type sausage as influenced by the addition of carrot (Daucus carota) paste. Foods 2021, 10, 3032. [Google Scholar] [CrossRef] [PubMed]

- Zaini, H.B.M.; Sintang, M.D.B.; Pindi, W. The roles of banana peel powders to alter technological functionality, sensory and nutritional quality of chicken sausage. Food Sci. Nutr. 2020, 8, 5497–5507. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.S.; Choi, J.H.; Han, D.J.; Kim, H.Y.; Kim, H.W.; Lee, M.A.; Chung, H.J.; Kim, C.J. Effects of Laminaria japonica on the physico-chemical and sensory characteristics of reduced-fat pork patties. Meat Sci 2012, 91, 1–7. [Google Scholar] [CrossRef]

- Van Elswyk, M.E.; McNeill, S.H. Impact of grass/forage feeding versus grain finishing on beef nutrients and sensory quality: The U.S. experience. Meat Sci. 2014, 96, 535–540. [Google Scholar] [CrossRef]

- Valenzuela, C.A.; Baker, E.J.; De Souza, C.O.; Miles, E.A.; Calder, P.C. Differential effects of ruminant and industrial 18-carbon trans-monounsaturated fatty acids (trans vaccenic and elaidic) on the inflammatory responses of an endothelial cell line. Molecules 2021, 26, 5834. [Google Scholar] [CrossRef] [PubMed]

- Belichovska, D.; Pejkovski, Z.; Nikolova, A.S.; Belichovska, K.; Nastova, R.; Gjorgovska, N. Chemical and fatty acid composition of poultry meat and pork fatback as a raw material for the production of frankfurters. Maced. J. Anim. Sci. 2020, 10, 23–28. [Google Scholar] [CrossRef]

- Franco, I.; Iglesias, S.; Prieto, B.; Carballo, J.; de los Alimentos, Á.d.T. Perfiles de ácidos grasos totales y libres en embutidos crudo-curados tradicionales de Galicia. Grasas Aceites 2004, 55, 273–281. [Google Scholar]

- García, M.; García, A.; Gil Hernández, A. Importancia de los lípidos en el tratamiento nutricional de las patologías de base inflamatoria. Nutr. Hosp. 2006, 21, 30–43. [Google Scholar]

- Pipoyan, D.; Stepanyan, S.; Stepanyan, S.; Beglaryan, M.; Costantini, L.; Molinari, R.; Merendino, N. The effect of trans fatty acids on human health: Regulation and consumption patterns. Foods 2021, 10, 2452. [Google Scholar] [CrossRef] [PubMed]

- Tvrzicka, E.; Kremmyda, L.S.; Stankova, B.; Zak, A. Fatty Acids as Biocompounds: Their Role in Human Metabolism, Health and Disease—A Review. Part 1: Classification, Dietary Sources and Biological Functions; Biomedical Papers of the Medical Faculty of Palacky University in Olomouc; Palacky University in Olomouc: Olomouc, Czech Republic, 2011; Volume 155, pp. 117–130. [Google Scholar] [CrossRef]

- Chan, D.S.; Lau, R.; Aune, D.; Vieira, R.; Greenwood, D.C.; Kampman, E.; Norat, T. Red and processed meat and colorectal cancer incidence: Meta-analysis of prospective studies. PLoS ONE 2011, 6, e20456. [Google Scholar] [CrossRef]

- Aronson, W.J.; Glaspy, J.A.; Reddy, S.T.; Reese, D.; Heber, D.; Bagga, D. Modulation of omega-3/omega-6 polyunsaturated ratios with dietary fish oils in men with prostate cancer. Urology 2001, 58, 283–288. [Google Scholar] [CrossRef] [PubMed]

- Slama, A.; Cherif, A.; Sakouhi, F.; Boukhchina, S.; Radhouane, L. Fatty acids, phytochemical composition and antioxidant potential of pearl millet oil. J. Cons. Protect. Food Saf. 2020, 15, 145–151. [Google Scholar] [CrossRef]

- Simopoulos, A.P. Omega-6 and omega-3 fatty acids: Endocannabinoids, genetics and obesity. Ocl 2020, 27, 7. [Google Scholar] [CrossRef]

- Baylin, A.; Siles, X.; Donovan-Palmer, A.; Fernandez, X.; Campos, H. Fatty acid composition of Costa Rican foods including trans fatty acid content. J. Food Compos. Anal. 2007, 20, 182–192. [Google Scholar] [CrossRef]

| Parameters | Samples | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SFAM01 | SFAM02 | SFAM03 | SFAM04 | SFAM05 | SFAM06 | SFPL07 | SFPL08 | SFPL09 | SFPI10 | |

| Moisture | 66.72 ± 0.01 c | 66.28 ± 0.01 cd | 66.70 ± 0.32 c | 70.00 ± 0.17 a | 63.21 ± 0.09 f | 67.27 ± 0.01 b | 62.50 ± 0.21 g | 64.27 ± 0.01 e | 65.84 ± 0.14 d | 64.13 ± 0.21 e |

| Protein | 9.54 ± 0.05 h | 12.97 ± 0.05 c | 10.85 ± 0.01 e | 10.67 ± 0.02 f | 15.70 ± 0.02 a | 13.64 ± 0.01 b | 10.95 ± 0.09 e | 9.66 ± 0.05 g | 12.17 ± 0.02 d | 12.19 ± 0.02 d |

| Fat | 8.69 ± 0.30 ef | 8.01 ± 0.30 f | 8.31 ± 0.32 f | 6.61 ± 0.28 g | 10.18 ± 0.56 c | 9.91 ± 0.21 cd | 12.33 ± 0.01 a | 9.27 ± 0.03 de | 9.41 ± 0.16 cde | 11.09 ± 0.06 b |

| Ash | 2.68 ± 0.01 de | 3.25 ± 0.01 c | 3.50 ± 0.10 b | 3.45 ± 0.01 b | 4.31 ± 0.01 a | 2.71 ± 0.05 d | 2.73 ± 0.09 d | 2.80 ± 0.05 d | 2.54 ± 0.04 e | 3.37 ± 0.06 bc |

| Carbohydrates | 12.39 ± 0.03 b | 9.51 ± 0.03 f | 11.10 ± 0.03 d | 9.56 ± 0.02 f | 6.99 ± 0.02 g | 6.65 ± 0.02 h | 11.76 ± 0.29 c | 14.16 ± 0.13 a | 10.26 ± 0.04 e | 9.34 ± 0.05 f |

| Calories | 165.93 ± 1.20 g | 162.01 ± 0.82 h | 162.59 ± 0.35 h | 140.42 ± 0.65 i | 182.42 ± 0.21 c | 170.37 ± 0.38 f | 201.84 ± 0.57 a | 178.67 ± 0.99 d | 174.47 ± 0.71 e | 185.89 ± 0.82 b |

| pH | 7.16 ± 0.01 a | 7.14 ± 0.01 a | 7.10 ± 0.07 ab | 6.64 ± 0.47 cde | 6.24 ± 0.01 e | 6.48 ± 0.01 de | 6.65 ± 0.03 cde | 6.47 ± 0.01 de | 6.97 ± 0.01 abc | 6.70 ± 0.01 bcd |

| Acidity | 0.39 ± 0.02 e | 0.48 ± 0.01 b | 0.42 ± 0.01 c | 0.36 ± 0.01 e | 0.70 ± 0.01 a | 0.42 ± 0.01 c | 0.31 ± 0.01 f | 0.31 ± 0.01 f | 0.47 ± 0.01 b | 0.42 ± 0.01 c |

| Sample | Water Activity (aw) | Nitrites (ppm) | Chlorides (%) |

|---|---|---|---|

| SFAM01 | 0.98 ± 0.01 a | 100 ± 5.00 d | 1.81 ± 0.09 d |

| SFAM02 | 0.98 ± 0.01 a | 100 ± 8.00 d | 2.60 ± 0.12 b |

| SFAM03 | 0.98 ± 0.01 a | 140 ± 6.00 a | 2.62 ± 0.17 b |

| SFAM04 | 0.97 ± 0.01 a | 130 ± 4.00 ab | 2.87 ± 0.20 b |

| SFAM05 | 0.96 ± 0.01 a | 140 ± 7.00 a | 3.41 ± 0.01 a |

| SFAM06 | 0.98 ± 0.01 a | 110 ± 5.00 cd | 1.98 ± 0.09 cd |

| SFPL07 | 0.98 ± 0.01 a | 122 ± 7.00 bc | 2.16 ± 0.02 d |

| SFPL08 | 0.98 ± 0.01 a | 122 ± 6.00 bc | 2.10 ± 0.02 cd |

| SFPL09 | 0.98 ± 0.01 a | 116 ± 5.00 bcd | 1.81 ± 0.06 d |

| SFPI10 | 0.98 ± 0.01 a | 121 ± 4.00 bc | 2.14 ± 0.01 c |

| Sample | L* | a* | b* | C* | h* |

|---|---|---|---|---|---|

| SFAM01 | 50.09 ± 0.52 de | 21.45 ± 0.16 c | 16.97 ± 0.16 bc | 27.35 ± 0.53 bc | 38.35 ± 0.17 de |

| SFAM02 | 46.45 ± 0.33 g | 23.08 ± 0.08 b | 16.52 ± 0.18 c | 28.38 ± 0.34 b | 35.59 ± 0.09 f |

| SFAM03 | 52.20 ± 0.48 bc | 16.15 ± 0.27 e | 14.82 ± 0.27 d | 21.92 ± 0.49 e | 42.54 ± 0.28 b |

| SFAM04 | 53.98 ± 0.84 a | 14.65 ± 0.79 f | 13.23 ± 0.77 f | 19.74 ± 0.85 f | 42.08 ± 0.80 b |

| SFAM05 | 49.45 ± 0.51 e | 25.91 ± 0.38 a | 17.98 ± 0.17 b | 31.54 ± 0.52 a | 34.76 ± 0.39 fg |

| SFAM06 | 47.56 ± 0.44 fg | 20.48 ± 0.13 cd | 16.27 ± 0.33 c | 26.16 ± 0.45 cd | 38.46 ± 0.14 cd |

| SFPL07 | 51.64 ± 0.14 bc | 12.01 ± 0.17 g | 22.92 ± 0.48 a | 25.88 ± 0.15 d | 62.35 ± 0.18 a |

| SFPL08 | 51.28 ± 0.47 cd | 20.32 ± 0.48 d | 16.73 ± 0.37 bc | 26.32 ± 0.48 cd | 39.47 ± 0.49 c |

| SFPL09 | 48.85 ± 0.56 ef | 25.54 ± 0.21 a | 17.05 ± 0.97 bc | 30.71 ± 0.57 a | 33.73 ± 0.22 g |

| SFPI10 | 52.70 ± 0.29 ab | 21.51 ± 0.46 c | 16.41 ± 0.42 c | 27.05 ± 0.30 bcd | 37.34 ± 0.47 e |

| Fatty Acids | Artisan Sausages | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (g/100 g) | SFAM01 | SFAM02 | SFAM03 | SFAM04 | SFAM05 | SFAM06 | SFPL07 | SFPL08 | SFPL09 | SFPI10 |

| Lauric | 0.21 ± 0.04 b | 0.15 ± 0.04 b | 0.22 ± 0.09 b | 0.12 ± 0.02 b | 0.12 ± 0.06 b | 0.14 ± 0.00 b | 0.11 ± 0.02 b | 0.30 ± 0.15 a | 0.16 ± 0.05 b | 0.10 ± 0.05 b |

| Myristic | 1.34 ± 0.07 bcd | 1.69 ± 0.07 b | 1.05 ± 0.32 | 1.25 ± 0.16 cd | 2.13 ± 0.01 a | 1.68 ± 0.05 b | 0.74 ± 0.05 e | 1.37 ± 0.24 bc | 1.54 ± 0.04 bc | 1.30 ± 0.18 bc |

| Myristoleic | 0.31 ± 0.03 b | 0.42 ± 0.01 a | - | 0.43 ± 0.00 a | 0.41 ± 0.03 a | 0.21 ± 0.02 cd | 0.16 ± 0.01 d | 0.21 ± 0.10 bc | 0.40 ± 0.08 a | 0.15 ± 0.04 d |

| Pentadecyl | 0.36 ± 0.04 a | 0.34 ± 0.01 abc | - | 0.37 ± 0.05 ab | 0.31 ± 0.01 abcd | 0.21 ± 0.04 d | 0.12 ± 0.02 e | 0.19 ± 0.11 cd | 0.25 ± 0.05 bcd | 0.12 ± 0.00 e |

| Palmitic | 23.21 ± 0.95 a | 25.08 ± 0.06 a | 22.04 ± 2.40 a | 22.74 ± 2.55 a | 23.65 ± 0.08 a | 24.28 ± 0.75 a | 25.22 ± 0.60 a | 22.85 ± 2.98 a | 18.60 ± 5.59 a | 24.46 ± 1.79 a |

| Palmitoleic | 3.65 ± 0.01 cd | 4.65 ± 0.21 ab | 4.26 ± 0.55 bc | 4.93 ± 0.07 a | 3.16 ± 0.03 de | 3.04 ± 0.16 de | 4.91 ± 0.09 a | 2.91 ± 0.54 de | 2.90 ± 0.28 de | 2.36 ± 0.39 e |

| Margaric | 0.72 ± 0.01 a | 0.73 ± 0.01 a | - | 0.76 ± 0.11 a | 0.76 ± 0.00 a | 0.58 ± 0.11 ab | 0.25 ± 0.02 c | 0.32 ± 0.00 c | 0.65 ± 0.20 a | 0.45 ± 0.06 b |

| Cis-10-heptadecenoic | 0.28 ± 0.03 de | 0.35 ± 0.01 cd | - | 0.28 ± 0.07 de | 0.38 ± 0.03 ab | 0.28 ± 0.03 de | - | 0.18 ± 0.04 e | 0.43 ± 0.04 a | 0.32 ± 0.08 abc |

| Stearic | 12.83 ± 0.39 bc | 13.17 ± 0.10 b | 6.06 ± 1.19 d | 13.92 ± 1.35 b | 16.07 ± 0.13 b | 13.87 ± 0.14 b | 7.13 ± 0.86 d | 7.84 ± 2.47 cd | 12.43 ± 3.33 b | 17.60 ± 3.94 a |

| Oleic | 2.22 ± 0.06 a | 1.30 ± 0.10 c | 0.11 ± 0.16 f | 1.44 ± 0.03 c | 1.66 ± 0.08 b | 0.87 ± 0.16 d | 0.30 ± 0.14 e | 0.55 ± 0.02 e | 2.37 ± 0.01 a | 0.32 ± 0.07 e |

| Elaidic | 35.81 ± 1.32 c | 38.96 ± 0.061 bc | 44.26 ± 3.84 ab | 39.18 ± 2.46 bc | 39.52 ± 0.36 bc | 40.13 ± 1.60 bc | 43.87 ± 0.78 ab | 43.06 ± 1.11 b | 45.15 ± 6.95 a | 38.54 ± 3.13 bc |

| Linolelaidic | 17.50 ± 2.00 bc | 11.27 ± 0.39 fg | 21.06 ± 0.22 a | 13.37 ± 1.52 ef | 9.97 ± 0.26 g | 12.36 ± 0.03 efg | 16.37 ± 1.13 cd | 18.70 ± 3.00 ab | 13.74 ± 1.66 de | 12.47 ± 2.02 ef |

| Arachidic | 0.30 ± 0.10 b | - | - | 0.14 ± 0.01 b | 0.22 ± 0.08 b | 0.39 ± 0.36 a | 0.10 ± 0.03 b | 0.13 ± 0.00 b | - | 0.27 ± 0.05 b |

| Linolenic | 0.88 ± 0.28 b | 1.56 ± 0.13 a | 0.92 ± 0.17 bc | 0.67 ± 0.04 cde | 0.63 ± 0.17 bcde | 0.63 ± 0.30 bcd | 0.46 ± 0.01 e | 0.80 ± 0.04 bcd | 0.67 ± 0.06 bcde | 0.52 ± 0.07 de |

| Cis-11-eicosenoic | 0.32 ± 0.05 cd | 0.32 ± 0.06 cd | - | 0.37 ± 0.07 bcd | 0.49 ± 0.10 b | 0.68 ± 0.29 a | 0.24 ± 0.02 d | 0.31 ± 0.02 d | 0.39 ± 0.020 bcd | 0.50 ± 0.03 bc |

| Eicosadiene | - | - | - | - | 0.49 ± 0.24 ab | 0.65 ± 0.64 a | - | 0.27 ± 0.07 b | 0.36 ± 0.05 b | 0.50 ± 0.02 b |

| Samples | Saturated Fatty Acids (%) | Unsaturated Fatty Acids (%) | Trans-fatty Acids (%) | Saturated/ Unsaturated | ω-6/ω-3 | Atherogenicity Index (I.A.) |

|---|---|---|---|---|---|---|

| SFAM01 | 39.01 ± 0.04 e | 7.67 ± 0.04 c | 53.32 ± 0.05 e | 5.08 ± 0.01 de | 0.00 | 3.76 ± 0.03 f |

| SFAM02 | 41.17 ± 0.04 c | 8.61 ± 0.01 a | 50.23 ± 0.06 fg | 4.78 ± 0.21 de | 0.00 | 3.72 ± 0.01 f |

| SFAM03 | 33.64 ± 0.09 f | 7.47 ± 0.05 d | 58.89 ± 0.02 d | 4.50 ± 0.55 e | 0.55 ± 0.02 c | 3.34 ± 0.02 g |

| SFAM04 | 29.38 ± 0.02 h | 5.30 ± 0.05 h | 65.32 ± 0.04 a | 5.55 ± 0.07 cd | 0.00 | 5.00 ± 0.07 c |

| SFAM05 | 39.30 ± 0.06 d | 8.14 ± 0.01 b | 52.56 ± 0.08 e | 4.83 ± 0.03 de | 0.00 | 3.42 ± 0.03 g |

| SFAM06 | 43.29 ± 0.05 b | 7.23 ± 0.04 e | 49.49 ± 0.05 g | 5.99 ± 0.16 bc | 0.78 ± 0.11 b | 4.47 ± 0.03 e |

| SFPL07 | 41.15 ± 0.02 c | 6.36 ± 0.02 g | 52.49 ± 0.06 e | 6.47 ± 0.09 b | 1.02 ± 0.02 a | 4.89 ± 0.02 cd |

| SFPL08 | 44.30 ± 0.01 a | 4.68 ± 0.11 i | 51.02 ± 0.03 f | 9.47 ± 0.54 a | 0.97 ± 0.02 a | 6.36 ± 0.04 a |

| SFPL09 | 33.68 ± 0.05 f | 6.70 ± 0.05 f | 60.25 ± 0.02 c | 5.55 ± 0.28 cd | 0.00 | 4.67 ± 0.04 de |

| SFPI10 | 33.01 ± 0.05 g | 5.22 ± 0.01 h | 61.77 ± 0.01 b | 6.32 ± 0.39 bc | 0.33 ± 0.06 d | 5.49 ± 0.08 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, L.; Pincay, R.; Salazar, D.; Flores, N.; Escolastico, C. Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador. Foods 2023, 12, 4288. https://doi.org/10.3390/foods12234288

Pérez L, Pincay R, Salazar D, Flores N, Escolastico C. Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador. Foods. 2023; 12(23):4288. https://doi.org/10.3390/foods12234288

Chicago/Turabian StylePérez, Lander, Rosa Pincay, Diego Salazar, Nelly Flores, and Consuelo Escolastico. 2023. "Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador" Foods 12, no. 23: 4288. https://doi.org/10.3390/foods12234288

APA StylePérez, L., Pincay, R., Salazar, D., Flores, N., & Escolastico, C. (2023). Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador. Foods, 12(23), 4288. https://doi.org/10.3390/foods12234288